Low temperature sintering temperature-stable microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic, temperature-stable technology, applied in the field of electronic ceramics and its preparation, can solve the problems of high sintering temperature and inability to apply multi-layer microwave devices, and achieves low sintering temperature, excellent microwave dielectric properties, and reduced dielectric The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

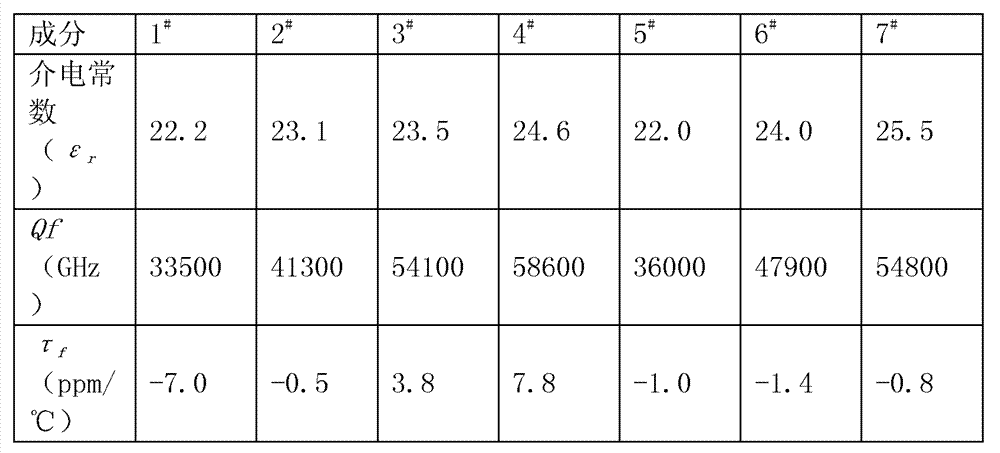

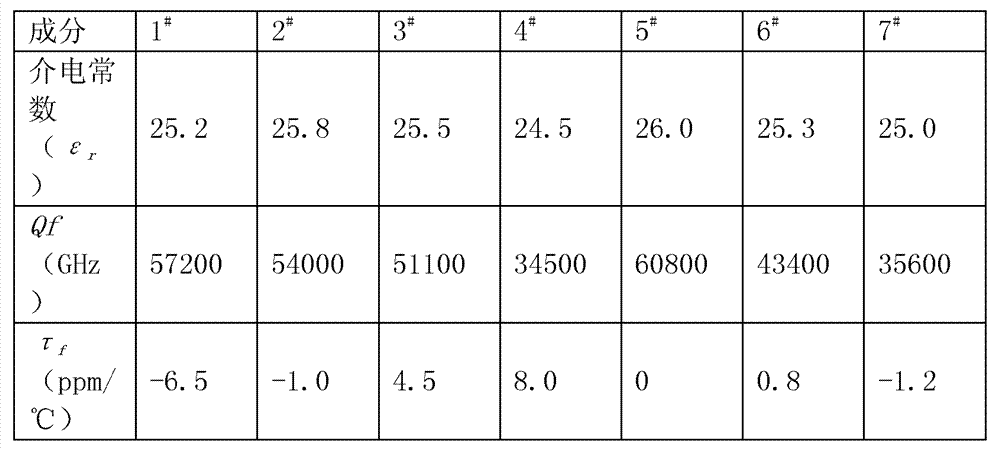

Examples

Embodiment 1

[0029] Embodiment 1: the first step: with Li 2 CO 3 , ZnO and TiO 2 Raw material according to Li 2 ZnTi 3 o 8 The stoichiometric ratio ingredients were wet ball milled for 24 hours, dried and placed in an alumina crucible, and then the alumina crucible was placed in a high-temperature box-type electric furnace at 900 ° C for 4 hours to obtain Li 2 ZnTi 3 o 8 Powder;

[0030] The second step: the Li 2 CO 3 and TiO 2 Raw material according to Li 2 TiO 3 The stoichiometric ratio ingredients were wet ball milled for 12 hours, dried and placed in an alumina crucible, and then the alumina crucible was placed in a high-temperature box-type electric furnace at 920 ° C for 2 hours to obtain Li 2 TiO 3 Powder;

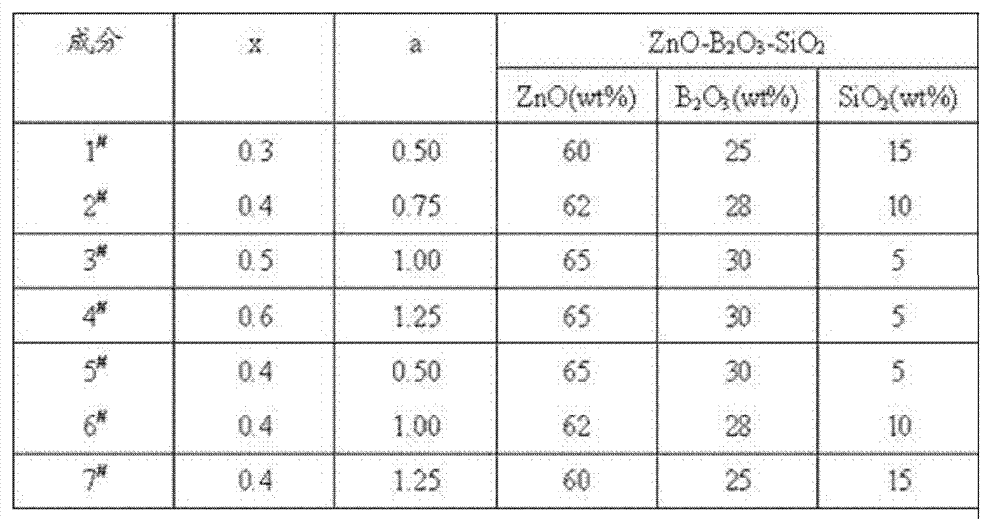

[0031] The third step: the ZnO, B 2 o 3 and SiO 2 The raw materials are dosed according to the composition requirements described in Table 1, and then dry milled in a planetary ball mill for 6 hours. The speed of the planetary ball mill is 350 rpm to obtain a mi...

Embodiment 2

[0039] Embodiment 2: the first step: with Li 2 CO 3 , ZnO and TiO 2 Raw material according to Li 2 ZnTi 3 o 8 The stoichiometric ratio ingredients were wet ball milled for 24 hours, dried and placed in an alumina crucible, and then the alumina crucible was placed in a high-temperature box-type electric furnace at 900 ° C for 4 hours to obtain Li 2 ZnTi 3 o 8 Powder;

[0040] The second step: the Li 2 CO 3 and TiO 2 Raw material according to Li 2 TiO 3 The stoichiometric ratio ingredients were wet ball milled for 12 hours, dried and placed in an alumina crucible, and then the alumina crucible was placed in a high-temperature box-type electric furnace at 920 ° C for 2 hours to obtain Li 2 TiO 3 Powder;

[0041] The third step: the ZnO, B 2 o 3 and SiO 2 The raw materials are dosed according to the composition requirements described in Table 1, and then dry milled in a planetary ball mill for 6 hours. The speed of the planetary ball mill is 350 rpm to obtain a mi...

Embodiment 3

[0049] Embodiment 3: the first step: with Li 2 CO 3 , ZnO and TiO 2 Raw material according to Li 2 ZnTi 3 o 8 The stoichiometric ratio ingredients were wet ball milled for 24 hours, dried and placed in an alumina crucible, and then the alumina crucible was placed in a high-temperature box-type electric furnace at 900 ° C for 4 hours to obtain Li 2 ZnTi 3 o 8 Powder;

[0050] The second step: the Li 2 CO 3 and TiO 2 Raw material according to Li 2 TiO 3 The stoichiometric ratio ingredients were wet ball milled for 12 hours, dried and placed in an alumina crucible, and then the alumina crucible was placed in a high-temperature box-type electric furnace at 920 ° C for 2 hours to obtain Li 2 TiO 3 Powder;

[0051] The third step: the ZnO, B 2 o 3 and SiO 2 The raw materials are dosed according to the composition requirements described in Table 1, and then dry milled in a planetary ball mill for 6 hours. The speed of the planetary ball mill is 350 rpm to obtain a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com