Temperature-stable type low-loss microwave dielectric ceramic and preparing method thereof

A microwave dielectric ceramic and temperature-stable technology, which is applied in the field of temperature-stable low-loss microwave dielectric ceramics and its preparation, can solve the problems of high energy consumption in the preparation process, non-compliance with low-carbon environmental protection, and high sintering temperature. Excellent electrical performance, saving energy costs, and reducing the effect of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

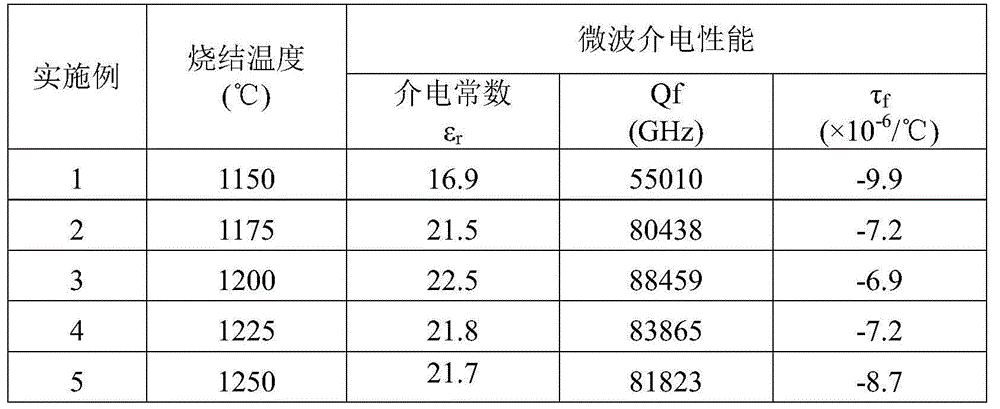

Examples

Embodiment Construction

[0022] The present invention uses MgO and TiO with a purity greater than 99% 2 , CaCO 3 、Al 2 o 3 , ZnO and La with a purity greater than 99.5% 2 o 3 As the starting material, microwave dielectric ceramics were prepared by a simple solid-state method. The specific implementation plan is as follows:

[0023] (1) MgO, TiO 2 and CaCO 3 According to the stoichiometric formula 0.95(Mg 0.97 Zn 0.03 )TiO 3 -0.05CaTiO 3 For batching, the ratio of raw materials is: 3.04025g MgO, 0.18985g ZnO, 6.54037g TiO 2 , 0.40966g CaCO 3 . Put about 10g of mixed powder into a polyester tank, add 200ml of deionized water, add 150g of zirconium balls, and mill on a planetary ball mill for 12 hours at a speed of 400 rpm;

[0024] (2) Put the ball-milled raw materials in step (1) into a drying oven, dry them at 100-120° C., and pass through a 40-mesh sieve;

[0025] (3) Put the powder sieved in step (2) into a medium-temperature furnace, pre-fire at 1100°C, and keep warm for 4 hours;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com