Microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and mass ratio, which is applied in the field of electronic materials and components, can solve the problems of high raw material prices, harsh manufacturing process conditions, and high prices, and achieve the effects of reducing prices, reducing costs, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Application of the microwave dielectric ceramics prepared by the above method for preparing microwave dielectric ceramics in passive microwave devices or microwave electronic components.

[0028] The passive microwave device can be a microwave communication device such as a microwave dielectric resonator, a dielectric filter, or a microwave antenna.

[0029] Microwave electronic components can be microwave substrates or temperature compensation capacitors.

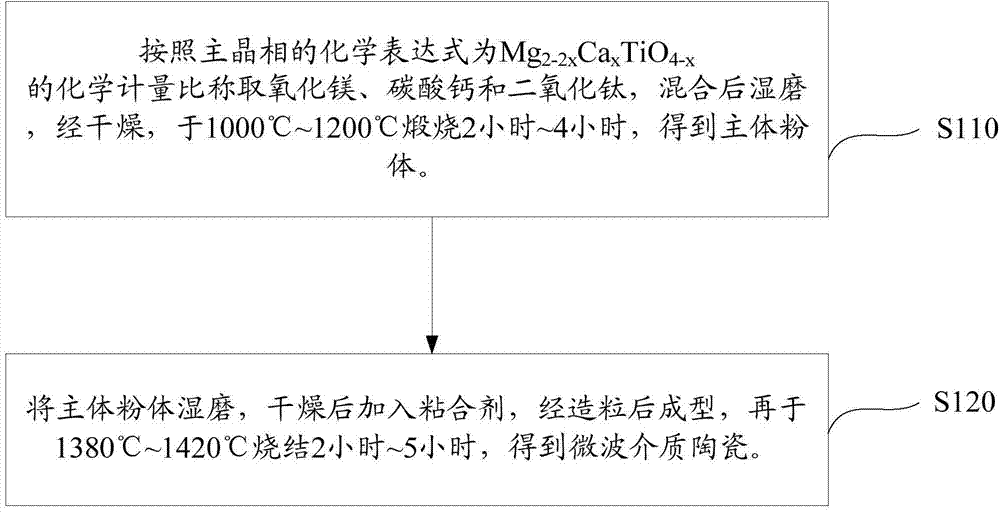

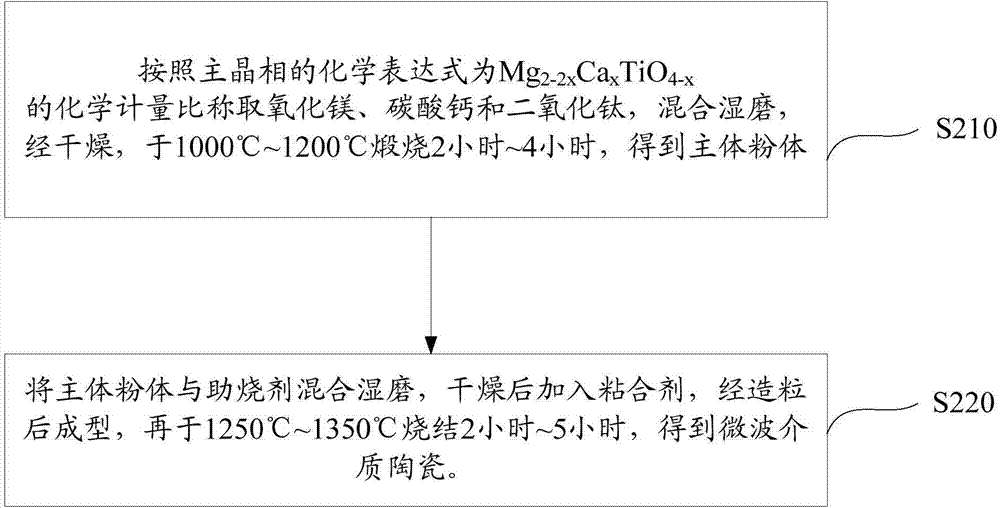

[0030] Such as figure 1 Shown, the preparation method of the microwave dielectric ceramic of one embodiment, comprises the following steps:

[0031] Step S110: according to the chemical expression of the main crystal phase is Mg 2-2x Ca x TiO 4-x The stoichiometric ratio of magnesium oxide (MgO), calcium carbonate (CaCO 3 ) and titanium dioxide (TiO 2 ), wet grinding after mixing, drying, and calcining at 1000°C to 1200°C for 2 hours to 4 hours to obtain the main body powder. Among them, 0.05≤x≤0.2.

[0032]...

Embodiment 1

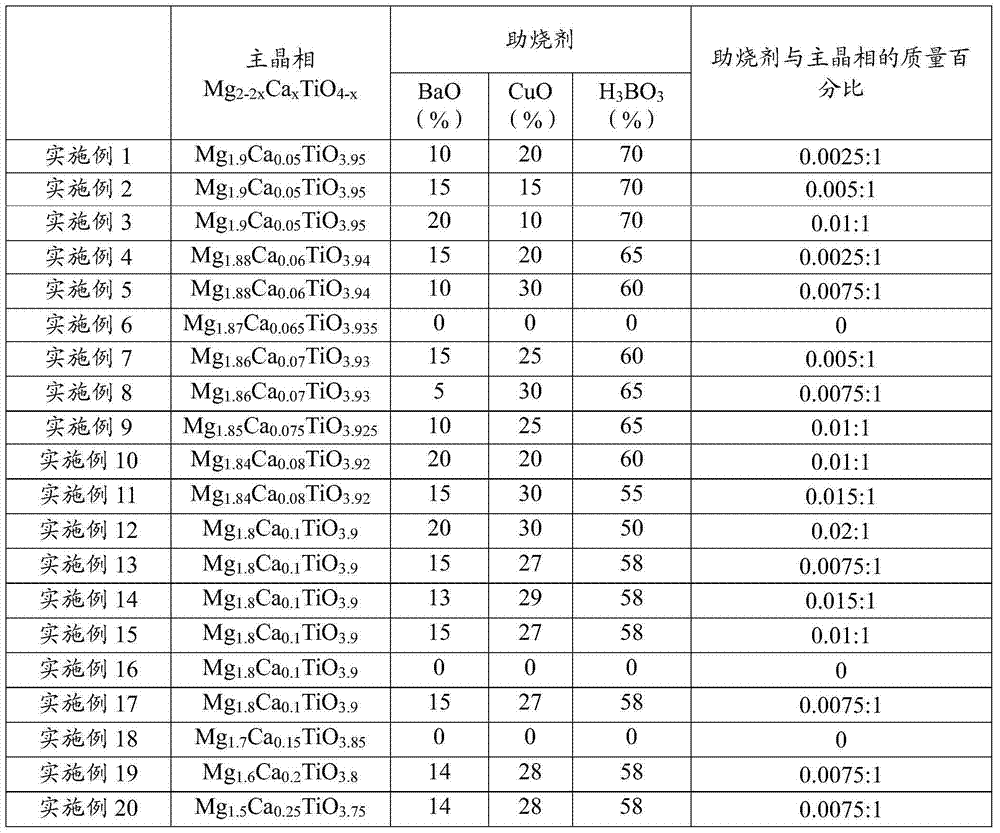

[0062] (1) According to the stoichiometric ratio of the chemical expression of the main crystal phase in Table 1, weigh magnesium oxide (MgO), calcium carbonate (CaCO 3 ) and titanium dioxide (TiO 2 ), wet ball milling for 4 hours, and then placed in a microwave dryer to dry at 120°C, then pulverized, and calcined at 1000°C for 4 hours in an air atmosphere to obtain the main powder.

[0063] (2) According to Table 1, barium oxide (BaO), copper oxide (CuO) and boric acid (H 3 BO 3 ) Wet ball milling for 24 hours, dried at 120°C with a microwave dryer, crushed, passed through a 300-mesh sieve, and then put into a high-temperature crucible and melted at 1300°C for 20 minutes. The melted product was extracted with deionized water, and again After crushing, ball mill for 24 hours and dry to obtain the sintering aid BaO-CuO-H 3 BO 3 .

[0064] (3) According to Table 1, the sintering aid BaO-CuO-H 3 BO 3 Pass through a 40-mesh sieve and a 200-mesh sieve in turn, take the inter...

Embodiment 2

[0067] (1) According to the stoichiometric ratio of the chemical expression of the main crystal phase in Table 1, weigh magnesium oxide (MgO), calcium carbonate (CaCO 3 ) and titanium dioxide (TiO 2 ), wet ball milling for 12 hours, and then dried in a microwave dryer at 120°C, pulverized, and calcined at 1200°C for 2 hours in an air atmosphere to obtain the main powder.

[0068] (2) According to Table 1, barium oxide (BaO), copper oxide (CuO) and boric acid (H 3 BO 3 ) Ball milled for 24 hours, dried at 120°C with a microwave dryer, crushed, passed through a 300-mesh sieve, and then put into a high-temperature crucible and melted at 1250°C for 30 minutes. The melted product was extracted with deionized water, and crushed again Ball milled for 24 hours and dried to obtain the sintering aid BaO-CuO-H 3 BO 3 .

[0069] (3) According to Table 1, the sintering aid BaO-CuO-H 3 BO 3 Pass through a 40-mesh sieve and a 200-mesh sieve in turn, take the intermediate powder and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com