Temperature stable type magnesium antimonite lithium base medium microwave composite ceramic and its preparation method

A lithium magnesium antimonate-based, temperature-stable technology, which is applied in the field of electronic ceramics and its manufacturing, can solve the problems of ceramic sintering cracking, large temperature coefficient of resonant frequency, etc., and achieves the effects of low cost, abundant sources, and improved temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of Li 3 Mg 2 SbO 6 Burnt powder

[0023] Press Li 3 Mg 2 SbO 6 The stoichiometric ratio of the raw material MgO 2.391g, Li 2 CO 3 3.354g, Sb 2 o 3 4.366g, put into a nylon ball mill jar, add 20g of agate balls and 20g of absolute ethanol, mix and mill with a planetary ball mill for 8 hours at a speed of 360 rpm, and dry in an oven at 80-100°C for 4 hours after ball milling , and then placed in a corundum crucible and pre-fired at 950°C for 4 hours to prepare Li 3 Mg 2 SbO 6 Burnt powder.

[0024] 2. Preparation of Ba 3 (VO 4 ) 2 Burnt powder

[0025] Press Ba 3 (VO 4 ) 2 The stoichiometric ratio of the raw material BaCO was weighed 3 7.650g, V 2 o 5 2. 350g, put it into a nylon ball mill jar, add 20g of agate balls and 20g of absolute ethanol, mix and mill with a planetary ball mill for 8 hours at a speed of 360 rpm, and dry in an oven at 80-100°C for 4 hours after ball milling , and then placed in a corundum crucible and pre-fir...

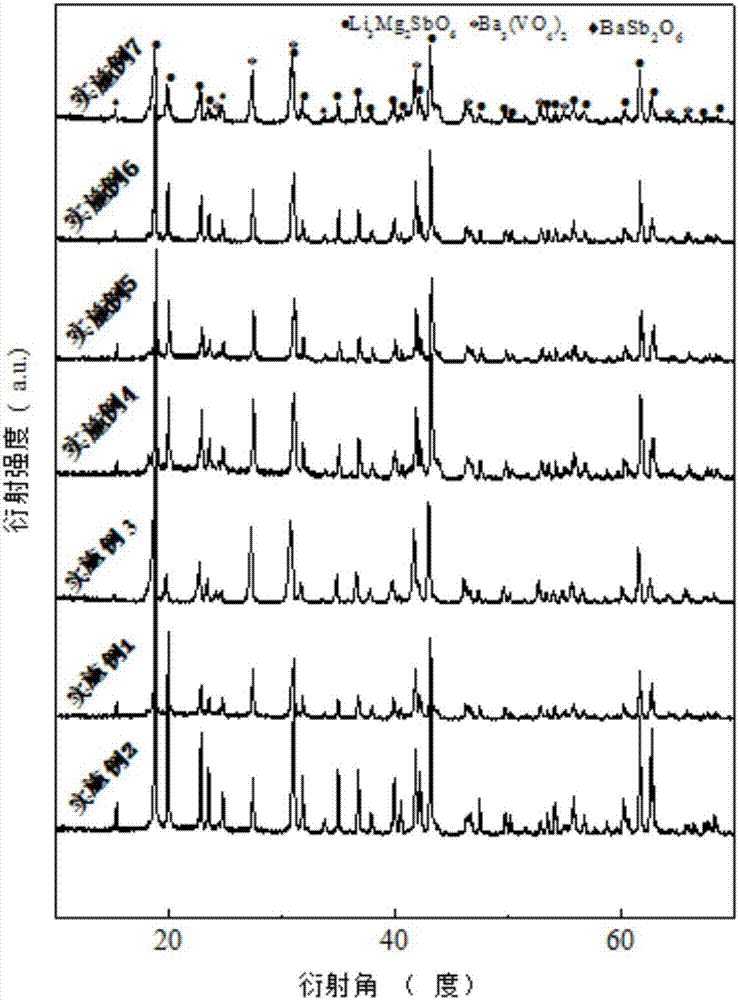

Embodiment 2

[0029] In step 3 of the present embodiment, press 0.95Li 3 Mg 2 SbO 6 -0.05Ba 3 (VO 4 ) 2 The stoichiometric ratio of Li 3 Mg 2 SbO 6 Calcined powder 8.948g, Ba 3 (VO 4 ) 2 Calcined powder 1.052g, and other steps are the same as in Example 1, to prepare a temperature-stable magnesium antimonate lithium-based microwave dielectric composite ceramic.

Embodiment 3

[0031] In step 3 of the present embodiment, press 0.85Li 3 Mg 2 SbO 6 -0.15Ba 3 (VO 4 ) 2 The stoichiometric ratio of Li 3 Mg 2 SbO 6 Calcined powder 7.171g, Ba 3 (VO 4 ) 2 Put 2.829g of pre-burnt powder into a nylon ball mill jar, add 20g of agate balls and 20g of absolute ethanol, mix and mill with a planetary ball mill for 8 hours at a speed of 360 rpm, and place in an oven at 80-100°C after ball milling Dry for 4 hours, then add 0.5g of polyvinyl alcohol aqueous solution with a mass fraction of 5% for granulation, pass through a 120 mesh sieve, and press it into a cylindrical green body with a diameter of 10mm and a thickness of 5mm with a powder tablet press under a pressure of 4MPa , the cylindrical green body was sintered at 1100 °C for 5 hours. The other steps are the same as in Example 1, and a temperature-stable magnesium-lithium antimonate-based microwave dielectric composite ceramic is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com