Warmly-mixed TOR (trans-polyoctenamer rubber reactive modifier) rubber asphalt mixture and preparation method thereof

A rubber asphalt and mixture technology, which is applied in the field of warm-mix TOR rubber asphalt mixture and its preparation, can solve the problem of no relevant reports on warm-mix TOR rubber asphalt mixture, and achieve the goals of reducing energy consumption, simplifying production procedures, and reducing emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] like Figure 4 As shown, the preparation method of the warm-mix TOR rubber-asphalt mixture comprises the following steps:

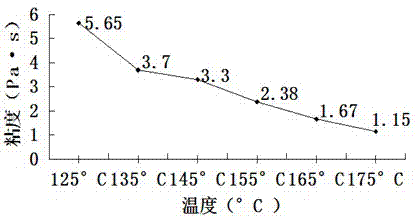

[0028] (1) Preparation of TOR rubber asphalt: TOR, rubber powder and asphalt are proportioned by weight, rubber powder: asphalt = 18:100, TOR: rubber powder = 4.5:100, put the asphalt in a mixer and heat it to 140 ° C and then add TOR and rubber powder, the mixer continues to heat to 167 ° C and continue to stir for 60 minutes, and then stand at 170 ° C to swell for 60 minutes to obtain TOR rubber asphalt; the asphalt is 70# road petroleum asphalt;

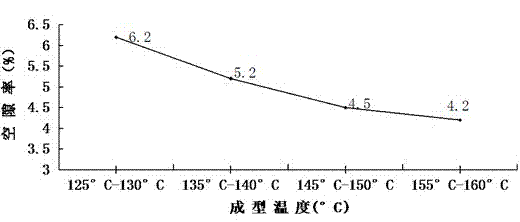

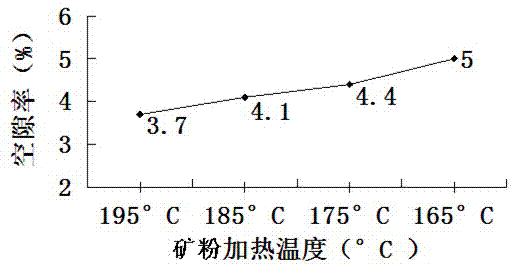

[0029] (2) Aggregate pretreatment: the aggregate and the TOR rubber asphalt obtained in step (1) are proportioned by weight, aggregate: TOR rubber asphalt=6:88, and the aggregate is heated in a 175°C oven for 6.5 hours Then add it to the mixing pot at 160°C;

[0030] (3) Add TOR rubber asphalt and warm mix agent: add the TOR rubber asphalt obtained in step (1) into the mixing pot, and at the same tim...

Embodiment 2

[0034] like Figure 4 As shown, the preparation method of the warm-mix TOR rubber-asphalt mixture comprises the following steps:

[0035] (1) Preparation of TOR rubber asphalt: TOR, rubber powder and asphalt are proportioned by weight, rubber powder: asphalt = 18:100, TOR: rubber powder = 4.5:100, put the asphalt in a mixer and heat it to 140 ° C and then add TOR and rubber powder, the mixer continues to heat to 173 ° C and continue to stir for 60 minutes, and then stand at 170 ° C to swell for 60 minutes to obtain TOR rubber asphalt; the asphalt is 70# road petroleum asphalt;

[0036] (2) Aggregate pretreatment: the aggregate and the TOR rubber asphalt obtained in step (1) are proportioned by weight, aggregate: TOR rubber asphalt=6:88, and the aggregate is heated in an oven at 175°C for 7 hours Then add it to the mixing pot at 160°C;

[0037] (3) Add TOR rubber asphalt and warm mix agent: add the TOR rubber asphalt obtained in step (1) into the mixing pot, and at the same t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com