Patents

Literature

332results about How to "Reduce spawn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

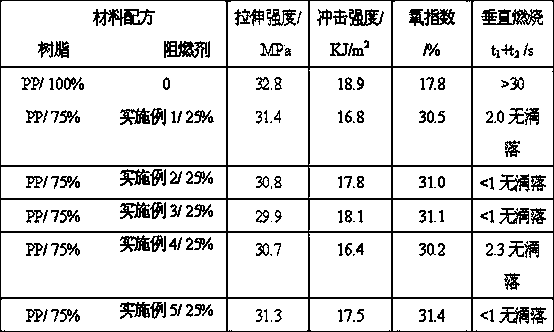

Composite flame retardant containing microcapsule-coated intumescent flame retardant and preparation method

InactiveCN103724666AHigh flame retardant efficiencyOvercome moisture absorptionPolymer scienceHindered amine light stabilizers

The invention belongs to the field of flame retardant materials, and particularly relates to a composite flame retardant containing a microcapsule-coated intumescent flame retardant and a preparation method. The composite flame retardant containing the microcapsule-coated intumescent flame retardant consists of the following components in percentage by mass: 60-94 percent of microcapsule intumescent flame retardant, 5-25 percent of flame-retardant synergist, 0.9-10 percent of smoke suppressant and 0.1-5 percent of hindered amine light stabilizer. The preparation method comprises the following steps: preparing the microcapsule-coated intumescent flame retardant; placing the microcapsule-coated intumescent flame retardant, the flame-retardant synergist, the smoke suppressant and the hindered amine light stabilizer into a high-speed mixer for mixing uniformly, and discharging to obtain the composite flame retardant containing the microcapsule-coated intumescent flame retardant. Multiple components in the composite flame retardant can play roles in retarding flame in a synergetic way, so that the flame retardance of a high polymer material is improved remarkably, the production of toxic and harmful smog in a burning process can be suppressed, and the flame retarding efficiency is increased greatly.

Owner:LIAONING TECHNICAL UNIVERSITY

Nano ZSM-5 molecular sieve based catalyst and preparation and use methods

ActiveCN104941695AShorten the diffusion pathEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsStrong acidsZSM-5

The invention discloses a nano ZSM-5 molecular sieve based catalyst and preparation and use methods. The molecular sieve catalyst consists of molecular sieves and metal components, wherein the molecular sieves are nano ZSM-5 molecular sieves with a short b-axis, a medium high silica-alumina ratio, less strong acid, high Lewis acid content, and resistance to hydrothermal deactivation. The preparation method is as follows: mixing a silicon source, an aluminum source, a template agent, a structure promoter, an additive and alkali with water, and stirring to prepare a precursor solution, then crystallizing, separating solid from liquid, and calcinating to obtain molecular sieve raw powder; mixing the molecular sieve raw powder with an ammonium salt solution, stirring, filtering, mixing with the ammonium salt solution for several times, stirring, filtering, and calcinating to obtain hydrogen-type ZSM-5 molecular sieves; mixing with the metal precursor solution, drying and calcinating to obtain the aromatization catalyst. The use method is as follows: transforming oxy-compound raw materials to aromatic hydrocarbon through the catalyst under the reaction conditions. The nano ZSM-5 molecular sieve based catalyst has the characteristics of being high in aromatics yield (reaching up to 99%) and long in service life (the catalyst is alive after 300 hours, and the aromatics selectivity reaches up to 70% after the catalyst is subjected to hydrothermal aging at 760 DEG C for 4 hours).

Owner:TSINGHUA UNIV

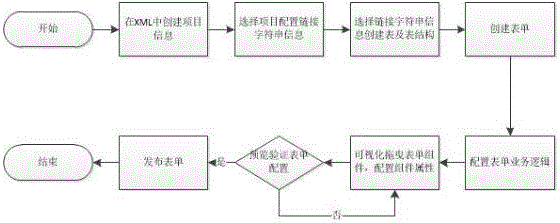

Intelligent form system and generation method thereof

InactiveCN106021211AImplement configurationLow costText processingSpecial data processing applicationsInformatizationIntelligent Network

The invention relates to the field of computers, and discloses an intelligent form system capable of self-defining business logic generation and form layout generation on the basis of Portal, and specifically discloses an intelligent form system and a generation method thereof. The invention provides a Web form intelligent configuration application system suitable for all walks of life, and the system can be used for realizing the conversion from system architecture and code development to data informatization, solving the problem of architecture selection before system construction, solving the problem of largely writing codes by programmers, solving the project safety problem, solving the log system problem and solving the project layout change problem. The system has the advantages as follows: the system is entirely oriented to all levels of users; code-free configuration can be realized; operation can be carried out on business logic data by directly utilizing Web applications without knowing Sql; configuration work can be directly carried out on business logics without knowing the C# language or other languages; log operations aiming at all levels of operations exist in the system so that log services do not need to be written; form page display can be completed without knowing Html, Css and Jquery; and the bug generation rate can be decreased so as to improve the work efficiency and reduce the project cost.

Owner:山东达创网络科技股份有限公司

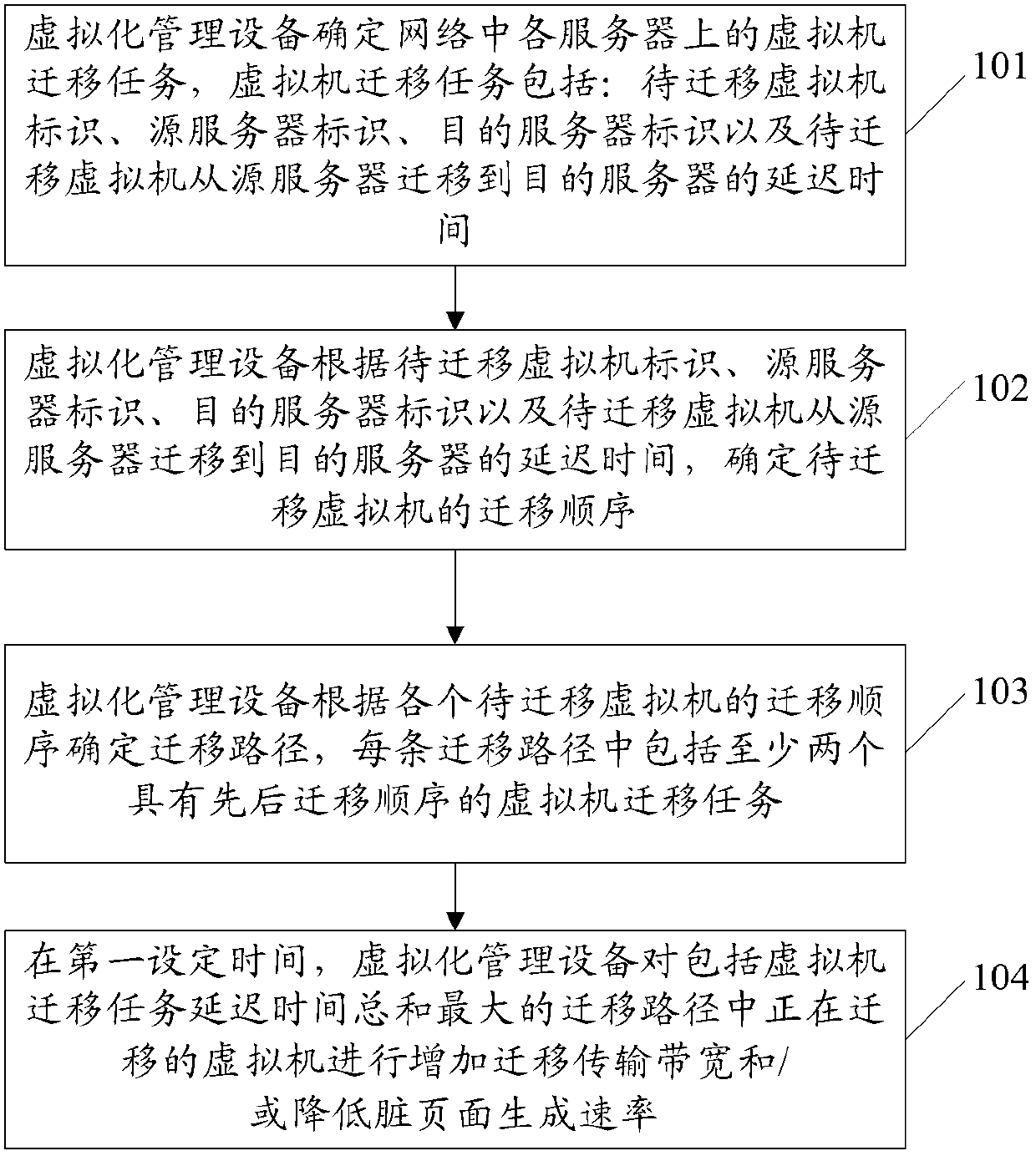

Virtual machine migration method and device

InactiveCN103218260AReduce latencyReduce dispatch timeProgram initiation/switchingSoftware simulation/interpretation/emulationDirty pageSpeed reduction

The invention provides a virtual machine migration method and a virtual machine migration device, wherein the method comprises the following steps that a virtual machine migration task on each server in a network is determined, the virtual machine migration task comprises a mark of a virtual machine to be migrated, a mark of a source server, a mark of a target server and the delay time for migrating the virtual machine to be migrated from the source server to the target server, the migration sequence of the virtual machine to be migrated is determined according to the mark of the virtual machine to be migrated, the mark of the source server, the mark of the target server and the delay time for migrating the virtual machine to be migrated from the source server to the target server, the migration path is determined according to the migration sequence of each virtual machine to be migrated, each migration path comprises at least two virtual machine migration tasks with the successive migration sequences, and at the first set time, the migration transmission bandwidth increase and / or dirty page generation speed reduction is carried out on the migrating virtual machines in the migration path with the maximum virtual machine migration task delay time sum.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

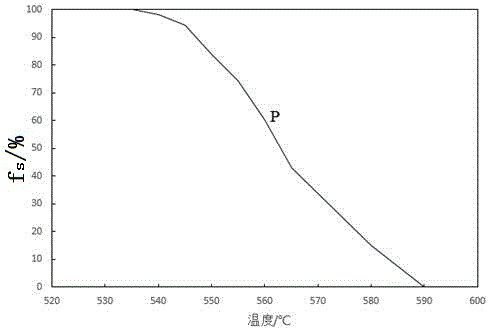

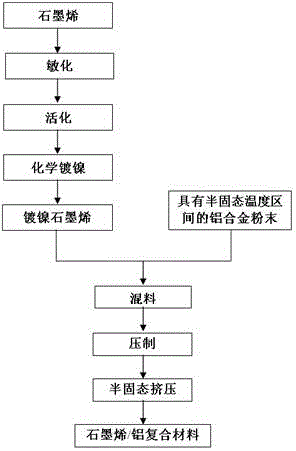

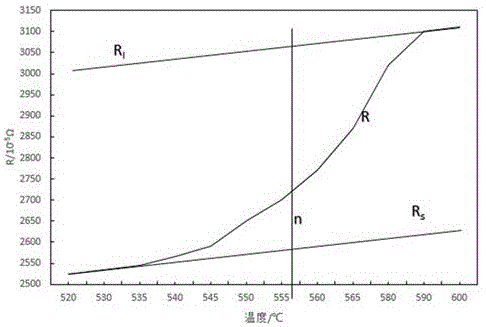

Production method of graphene-aluminum composite

ActiveCN106513621AOvercome the disadvantage of being easy to pull out from the aluminum alloy matrixTake full advantage of enhanced capabilitiesLiquid/solution decomposition chemical coatingElectricityMetal matrix composite

The invention discloses a production method of a graphene-aluminum composite, and belongs to the field of metal-matrix composites. Aluminum alloy powder with the semisolid temperature interval and graphene are adopted as raw materials. The method mainly includes the steps of 1, chemical nickel plating of the graphene; 2, mixing; 3, pressing; and 4, semisolid extruding. According to the graphene-aluminum composite produced through the method, the wettability and the metallurgical bonding strength of the nickel-plated graphene and aluminum alloy are high, the nickel-plated graphene is uniformly distributed in the matrix aluminum alloy, the microstructure is compact, the specific strength and the specific stiffness are high, and the thermal conductivity and the electrical conductivity are good. Thus, the graphene-aluminum composite has wide application prospects in the fields of the national defense and military industry, aerospace, electricity and heat exchange.

Owner:KUNMING UNIV OF SCI & TECH

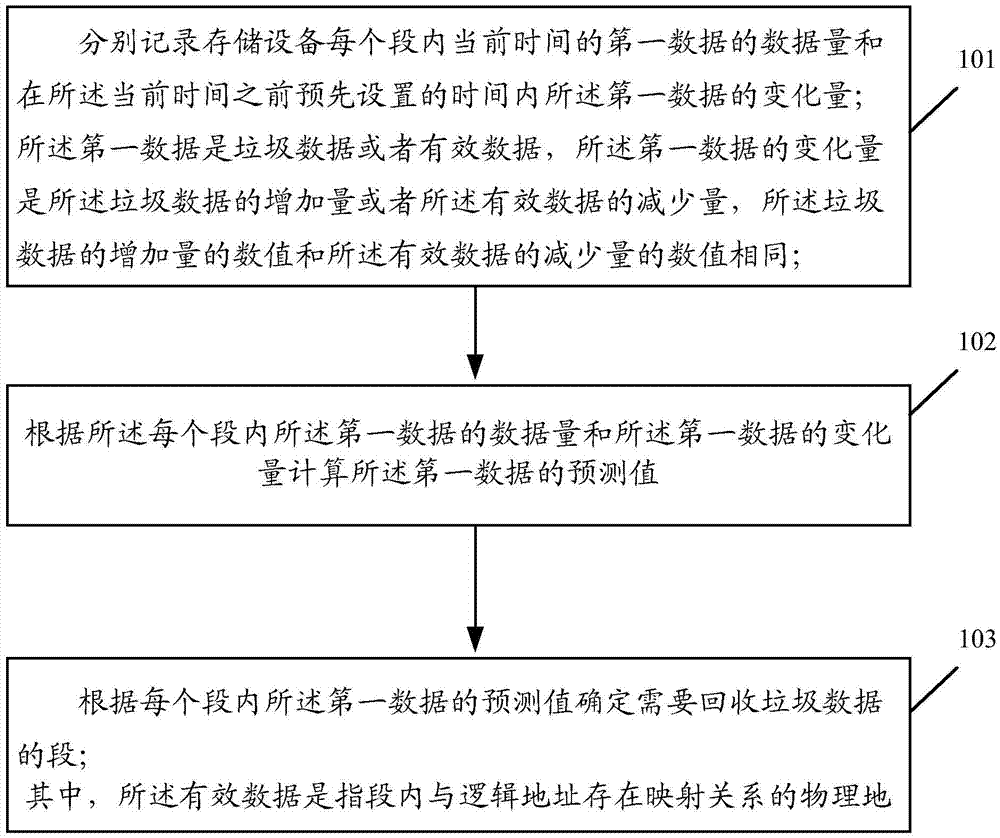

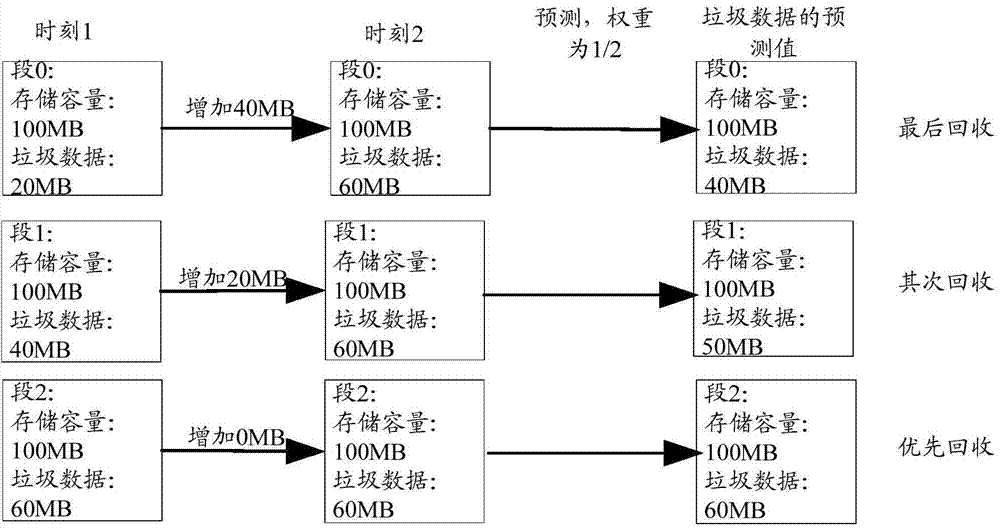

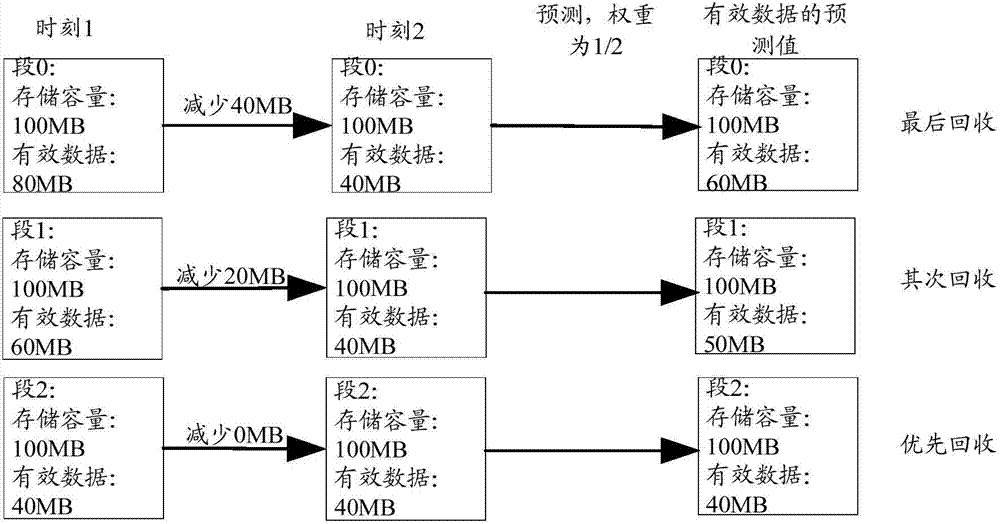

Junk data recycling method and storage device

ActiveCN103577338AReduce spawn rateMemory architecture accessing/allocationInput/output to record carriersData needsCurrent time

The embodiment of the invention provides a junk data recycling method and a storage device. A data volume of first data at current time and variable quantity of the first data within a preset period before the current time in each segment of the storage device are recorded respectively; according to the data volume of the first data and the variable quantity of the first data in each segment, a predicted value of the first data is calculated; according to the predicted value of the first data in each segment, segments in which junk data need recycling are determined, junk data in the segments with more junk data needing recycling and a lower junk generating speed are recycled preferentially, and therefore efficiency of recycling junk data is improved.

Owner:XFUSION DIGITAL TECH CO LTD

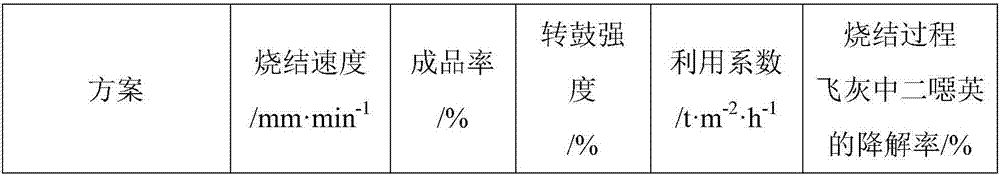

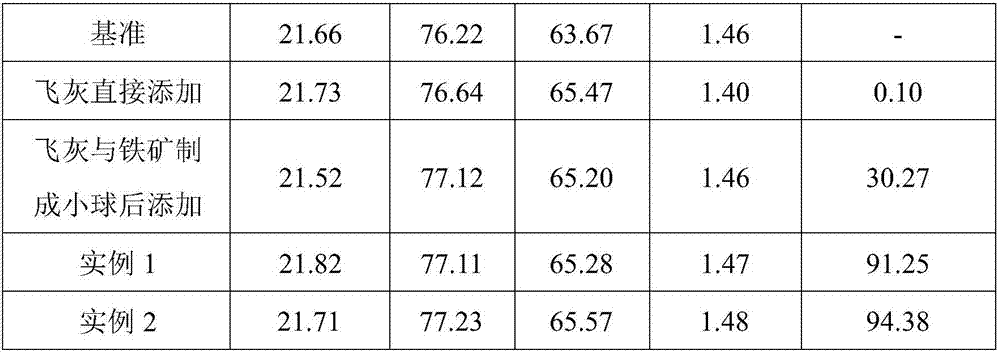

Dioxin control method for iron ore sintering garbage fly ash coprocessing process

ActiveCN107159678ARealize normal sinteringEffectively fixedTransportation and packagingSolid waste disposalSludgeLitter

The invention discloses a dioxin control method for the iron ore sintering garbage fly ash coprocessing process. According to the method, garbage fly ash, lime milk, flammable solid fuel and sludge are subject to mixed granulation and drying, and small balls containing garbage fly ash are obtained; iron core sintering raw materials are granulated and then are mixed with the small balls of the garbage fly ash, and after distribution, ignition and sintering are carried out. According to the method, on the premise that the iron ore sintering is not affected, efficient decomposing of dioxin contained in the fly ash can be achieved, dioxin secondarily formed in the garbage fly ash sintering process is prevented, according to the method, the decomposing rate of the garbage fly ash dioxin reaches 90% or above, meanwhile, effective solidifying of the garbage fly ash can be ensured, and in the sintering process, the aim of cleaning the garbage fly ash is achieved.

Owner:CENT SOUTH UNIV +1

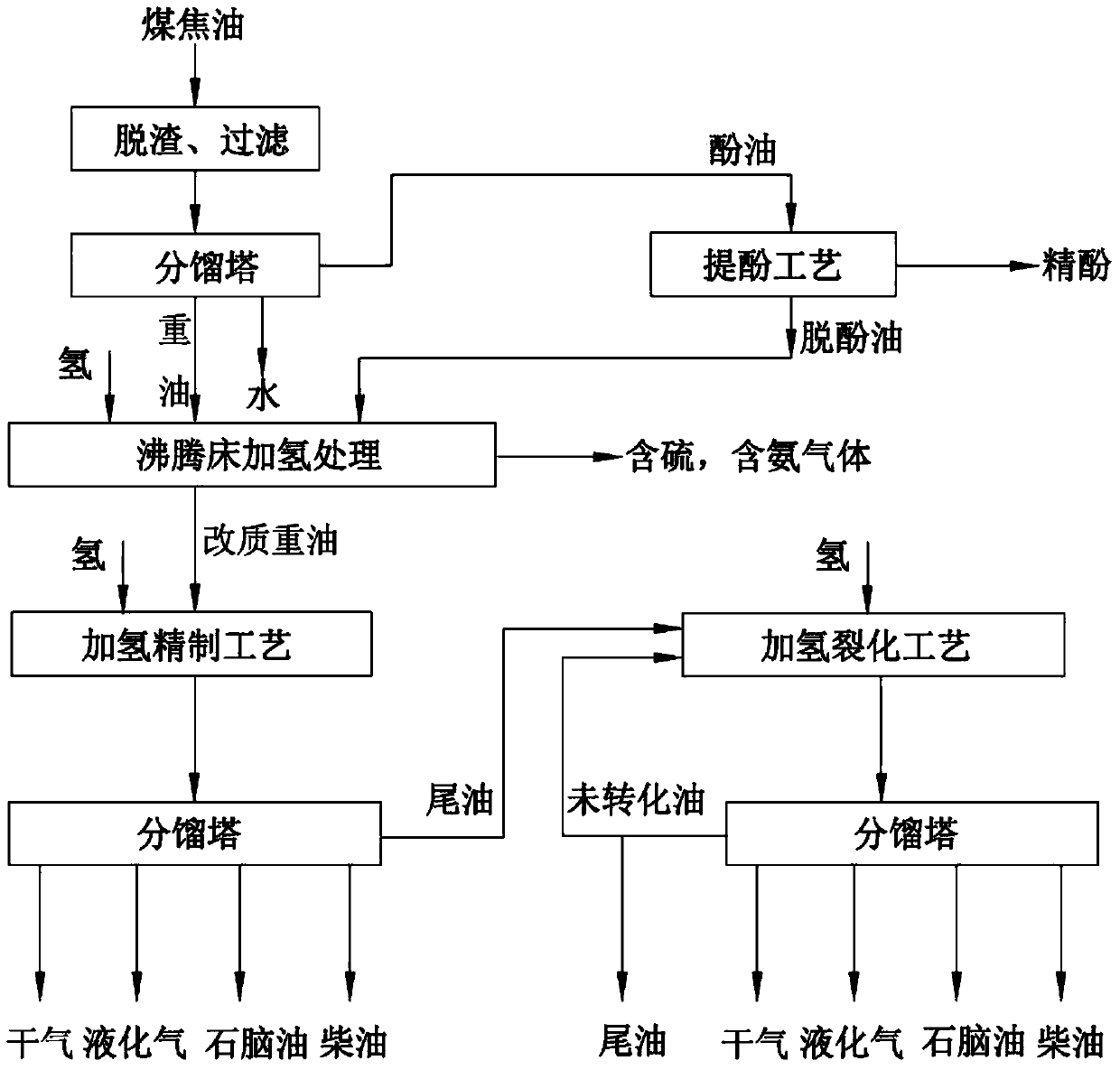

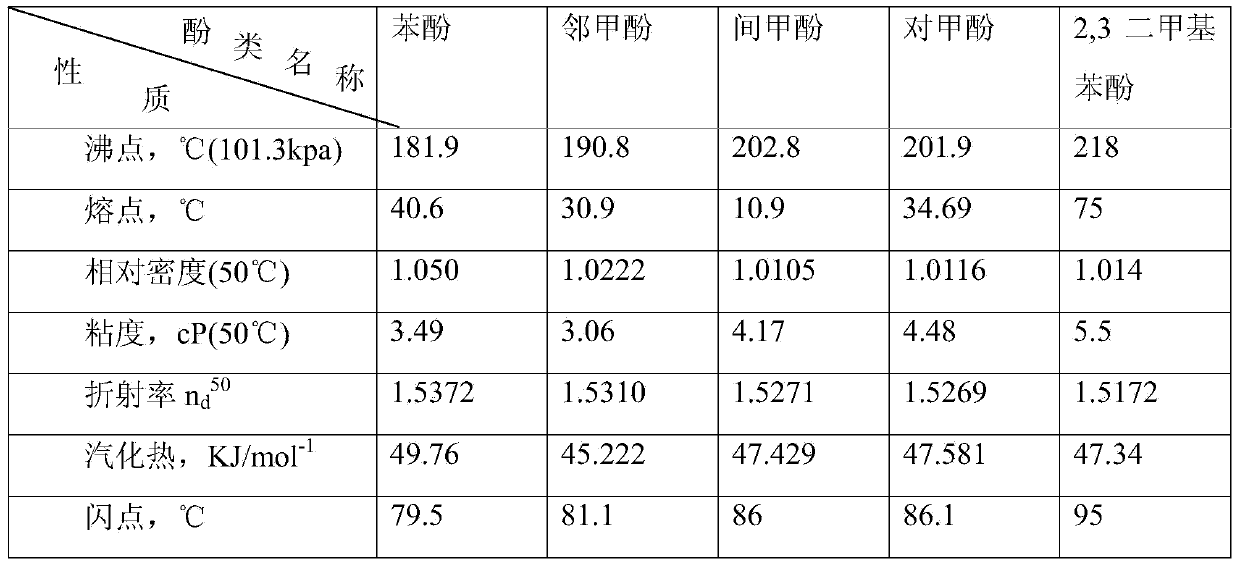

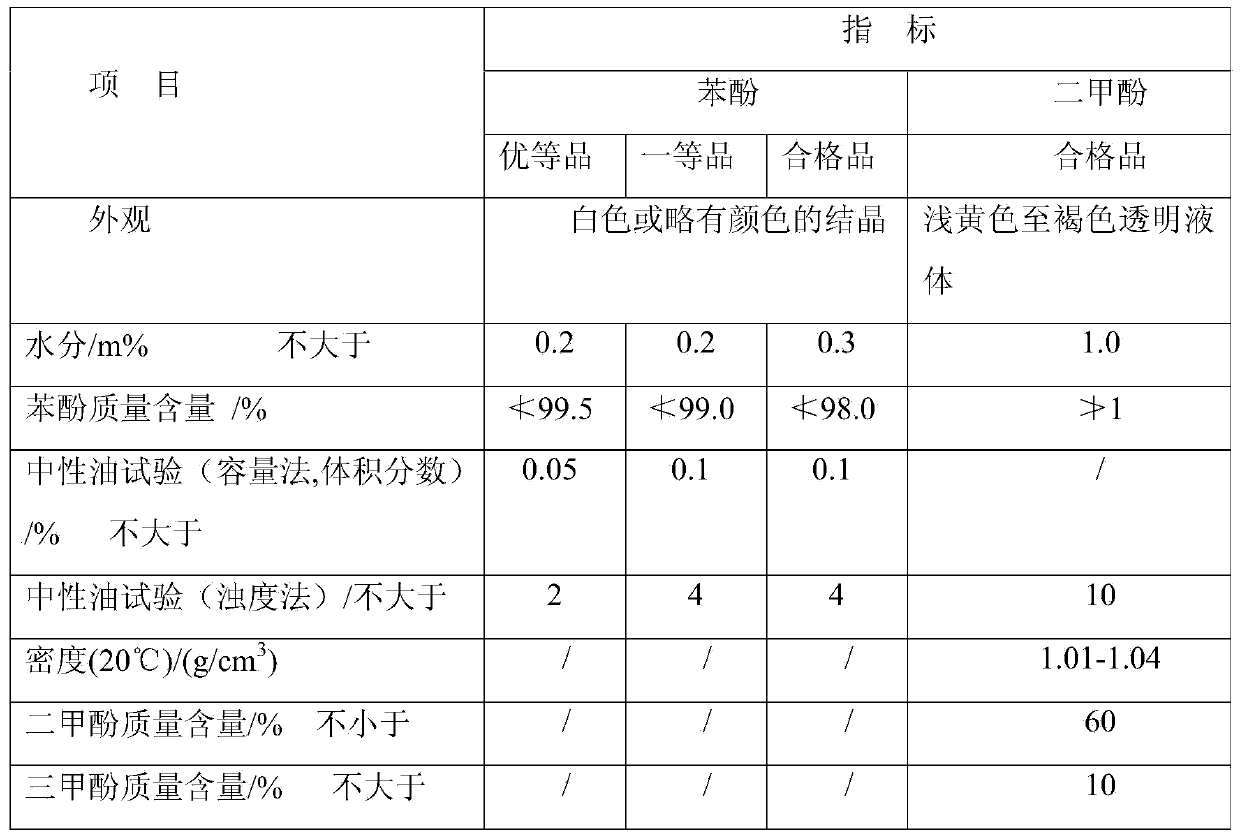

Medium and low temperature coal tar processing method

ActiveCN103695036AHigh yieldSolve the deactivation fastTreatment with hydrotreatment processesWorking-up tarSide productCoal chemical industry

The invention belongs to the field of the coal chemical industry, and in particular relates to a medium and low temperature coal tar processing method. The method comprises the following steps: removing solid residues from the medium and low temperature coal tar, preprocessing the coal tar to obtain carbolic oil, water and heavy oil; performing phenol extraction on the obtained carbolic oil to obtain a pure phenol product and dephenolized oil; mixing the obtained heavy oil and the obtained dephenolized oil and introducing the mixture in a fluidized bed reactor to perform a hydrogenation reaction, and obtaining modified heavy oil, sulfur-containing and ammonia-containing gas side products; performing hydrorefining and hydrocracking reactions on the modified heavy oil to obtain dry gas, liquefied gas, naphtha, a diesel oil product and a tail oil product. The naphtha and the diesel oil are clean and stable in performance. In addition, a plurality of high value added products are obtained. After hydrotreatment of the fluidized bed, the catalyst service life of the fixed bed reactor is prolonged; furthermore, the heavy component processing problem in the coal tar can be solved. The modified heavy oil after hydrotreatment of the fluidized bed can be subjected to hydrorefining and hydrocracking to improve the oil property.

Owner:上海竣铭化工工程设计有限公司

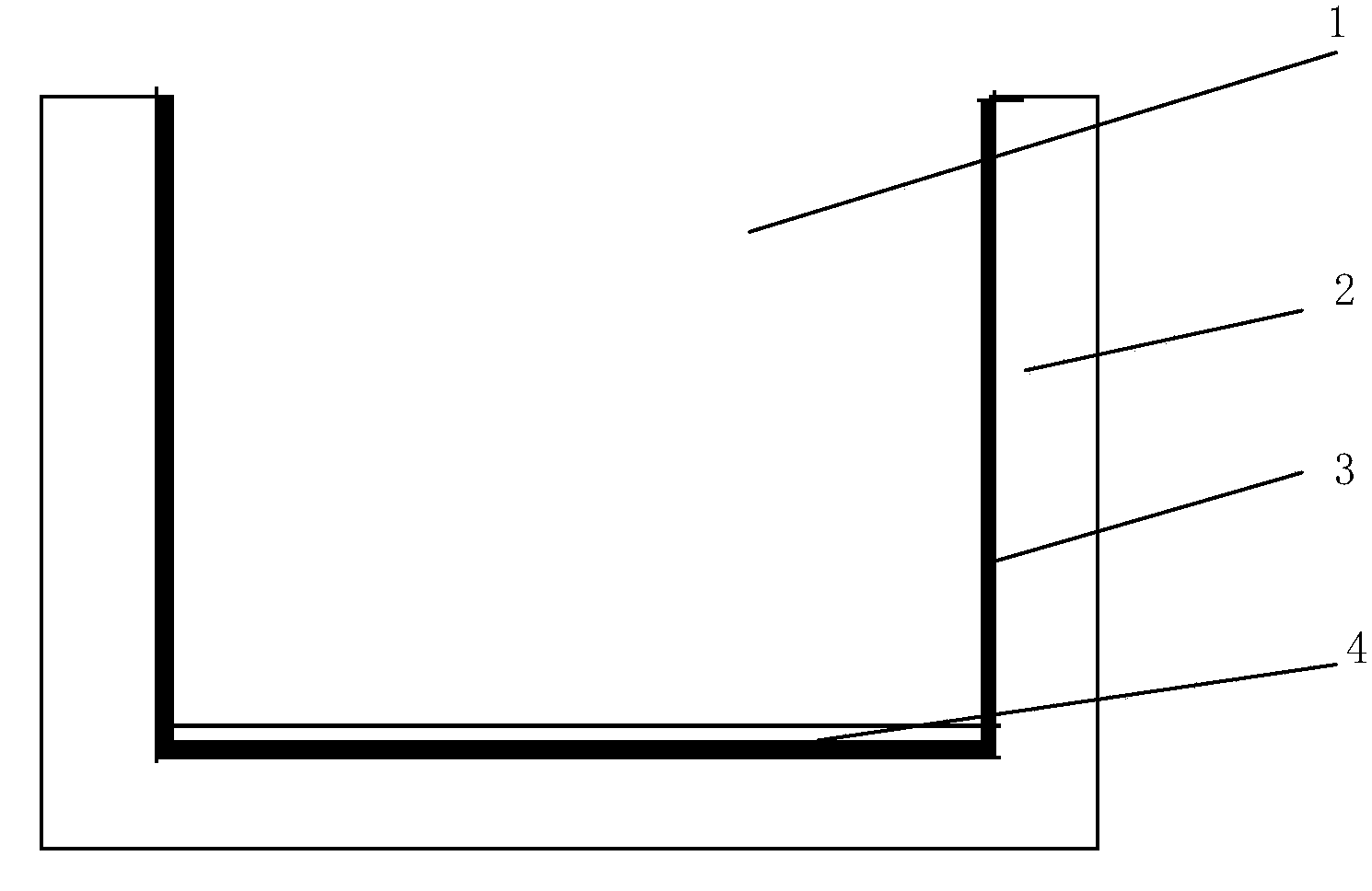

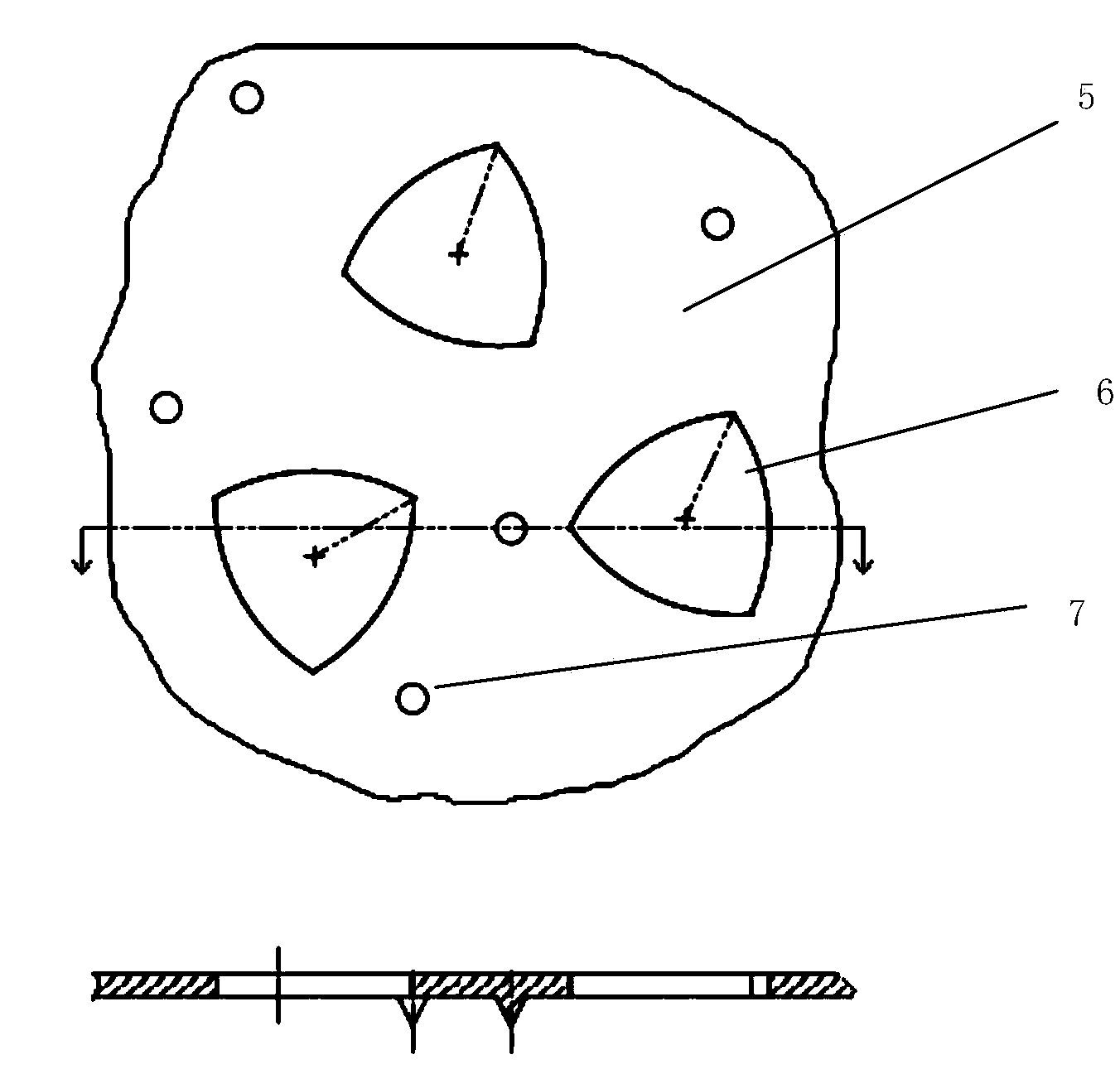

Novel ingot casting crucible and manufacturing method thereof

InactiveCN104047048AHigh yieldLow impurity contentPolycrystalline material growthFrom frozen solutionsIngot castingCrucible

The invention discloses a novel ingot casting crucible which is a high-efficiency ingot casting crucible, wherein the ingot casting crucible is obtained through secondary coating of inductive nucleation substances such as silicon dioxide slurry and the like based on a condition that a general silicon nitride coating is sprayed on the surface of the inner wall of an existing ingot casting crucible, and has the advantage of improving the yield of ingot casting; The inductive nucleation substances at the bottom of the crucible can be sprayed in a geometric figure including tetragon, hexagon and the like and the figure can also be provided with a concave-convex structure so as to facilitate the aggregation and subsequent processing and removal of impurities at the bottom of a silicon ingot. The high-efficiency ingot casting crucible is used for inducing the nucleation of crystal silicon by using silicon dioxide powder and the like during a crystal growth process, so that the defects including dislocation, crystal boundary and the like of the crystal in the preliminary stage of crystal growth can be reduced, the quality of the crystal growth and the overall quality of silicon crystal can be improved, thus the yield of the silicon ingot can be further increased and the overall economic efficiency can be improved.

Owner:XUZHOU COLLEGE OF INDAL TECH

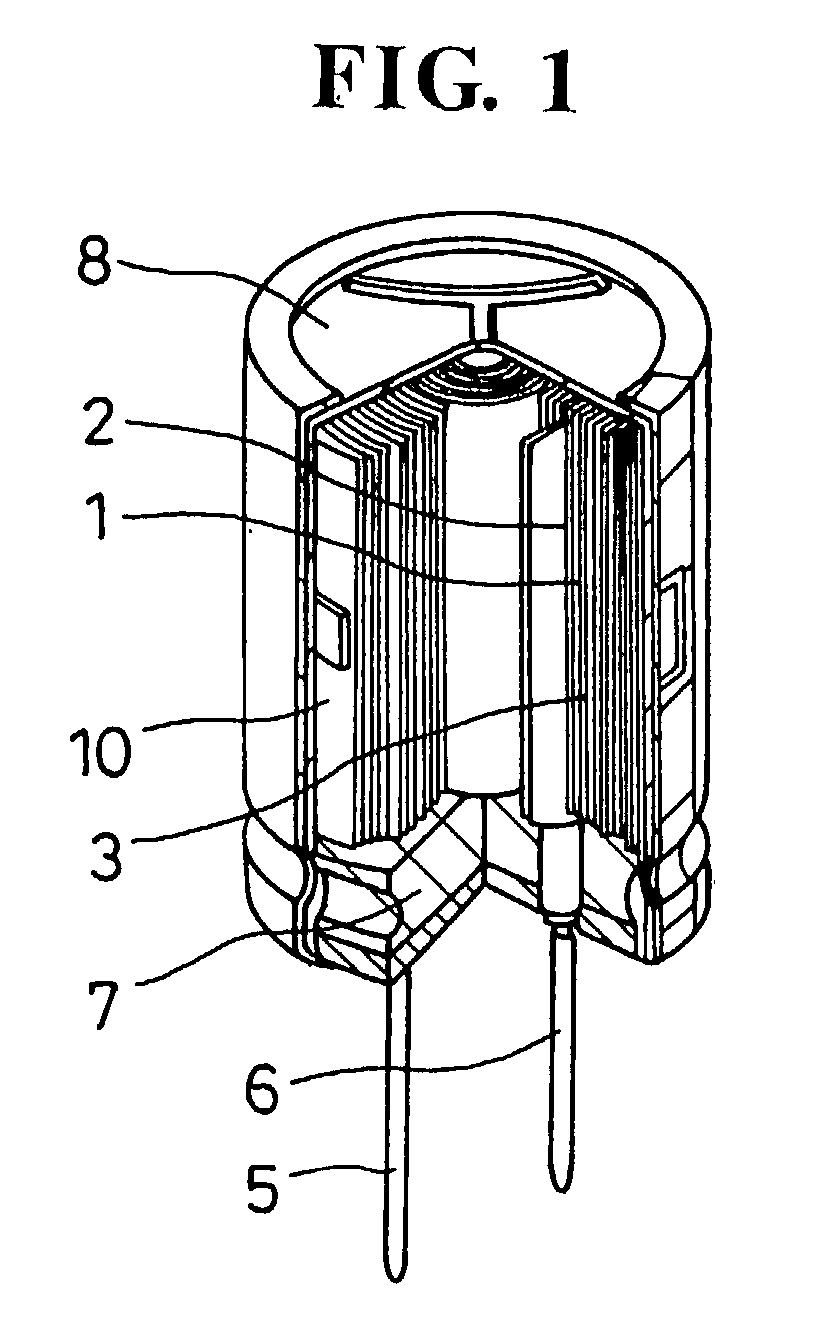

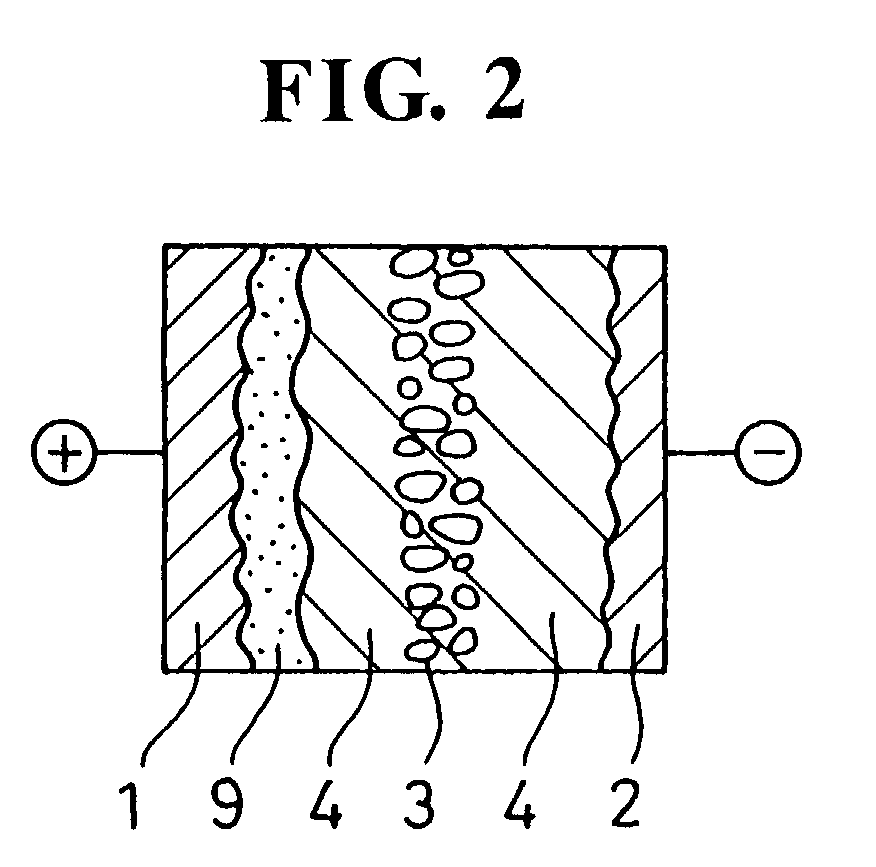

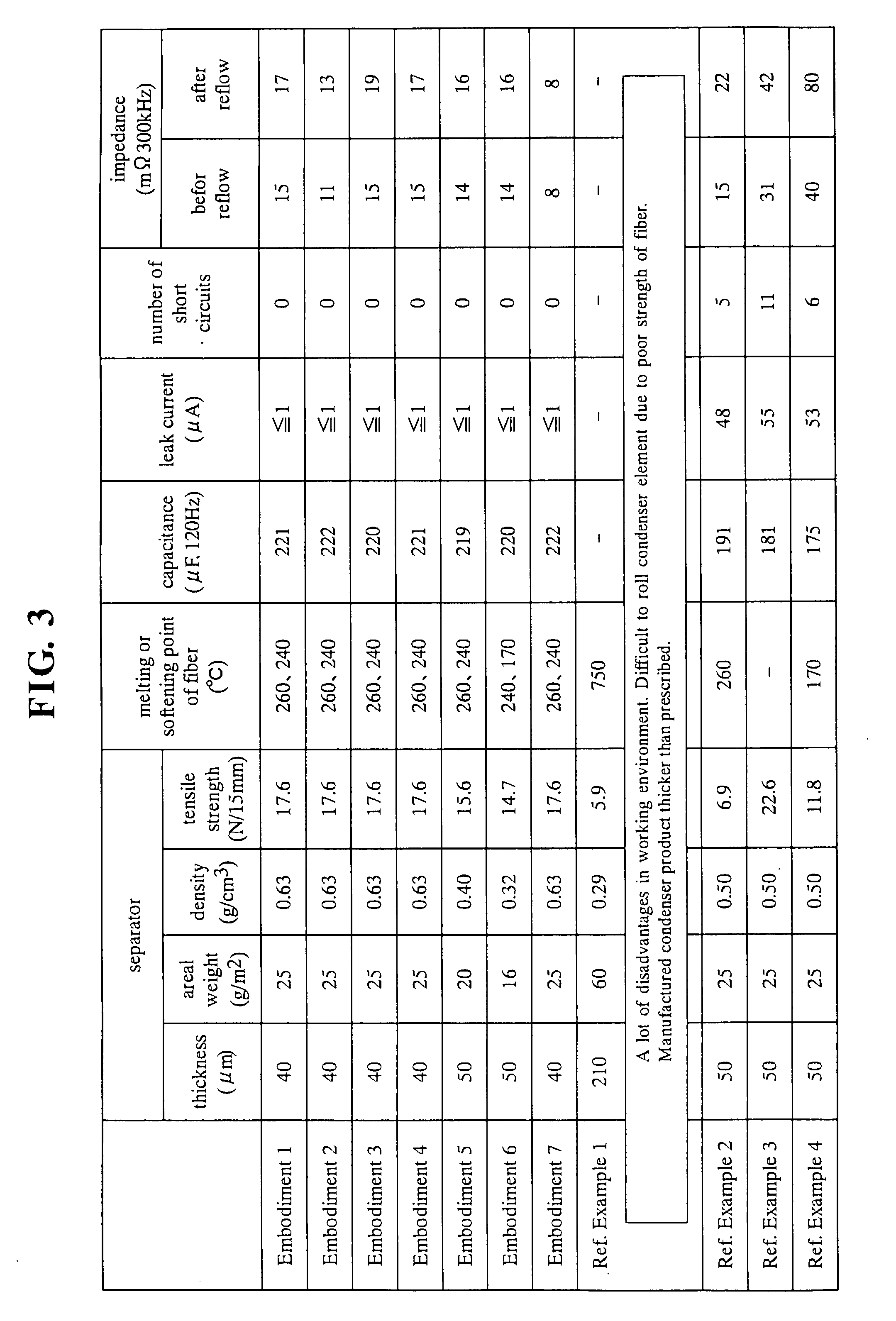

Separator for solid electrolyte condenser and solid electrolyte condenser using the same

ActiveUS20020117394A1High frequencyReduce resistanceHybrid capacitor separatorsHybrid capacitor electrolytesChemistryElectrolyte

An object of the present invention is to provide a separator which is excellent in sticking and adhesion capability with the solid electrolyte, physically strong and highly heat-resistive and to provide a solid electrolyte condenser which is excellent in the impedance characteristic and leak current characteristic. In a solid electrolyte condenser comprising an anode foil, a cathode foil, a separator, the separator is made of a nonwoven fabric containing polyester resin or its derivative manufactured by the wet method. The condenser element is formed by rolling the anode foil and the cathode foil together with the separator between them. The solid electrolyte is provided between the anode foil and the cathode foil of the condenser element.

Owner:NIPPON KODOSHI +1

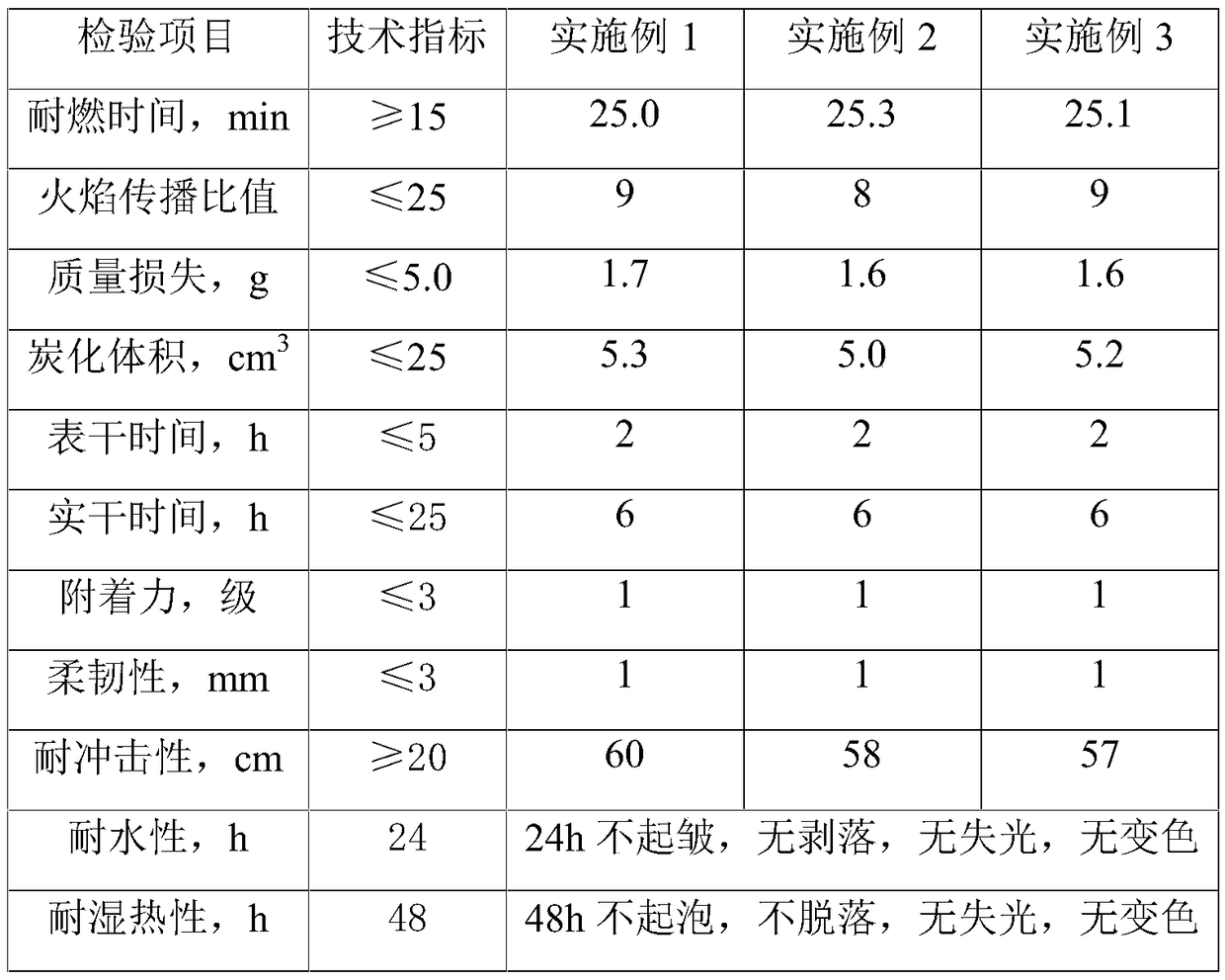

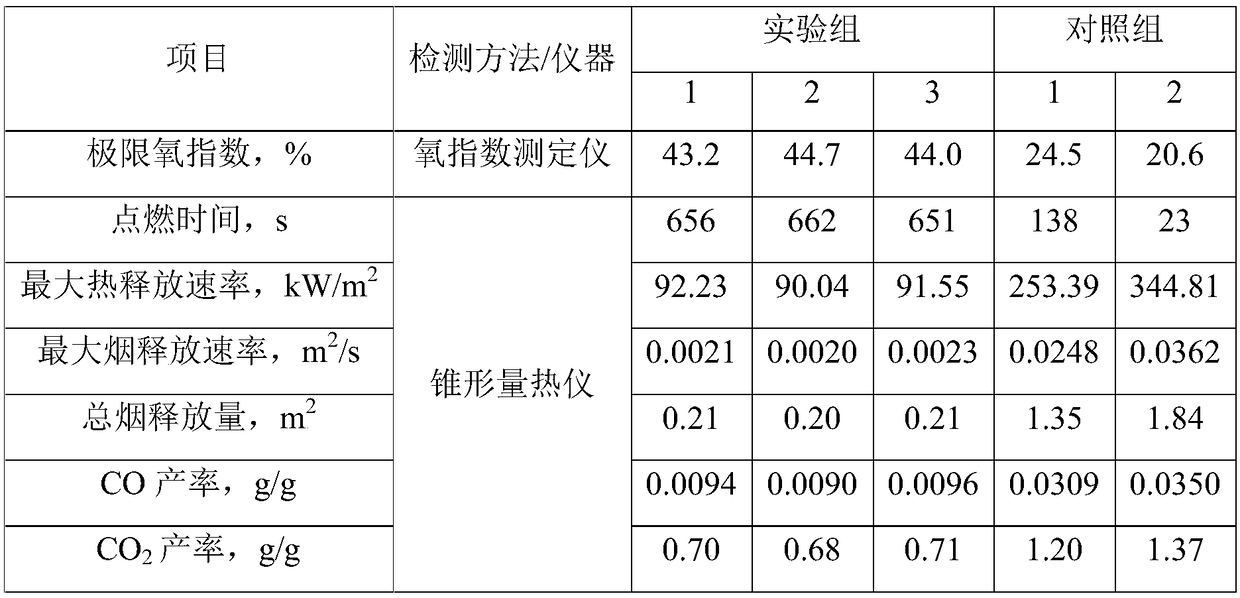

Expansive waterborne fireproof and flame-retardant coating for wood material and preparation method of expansive waterborne fireproof and flame-retardant coating

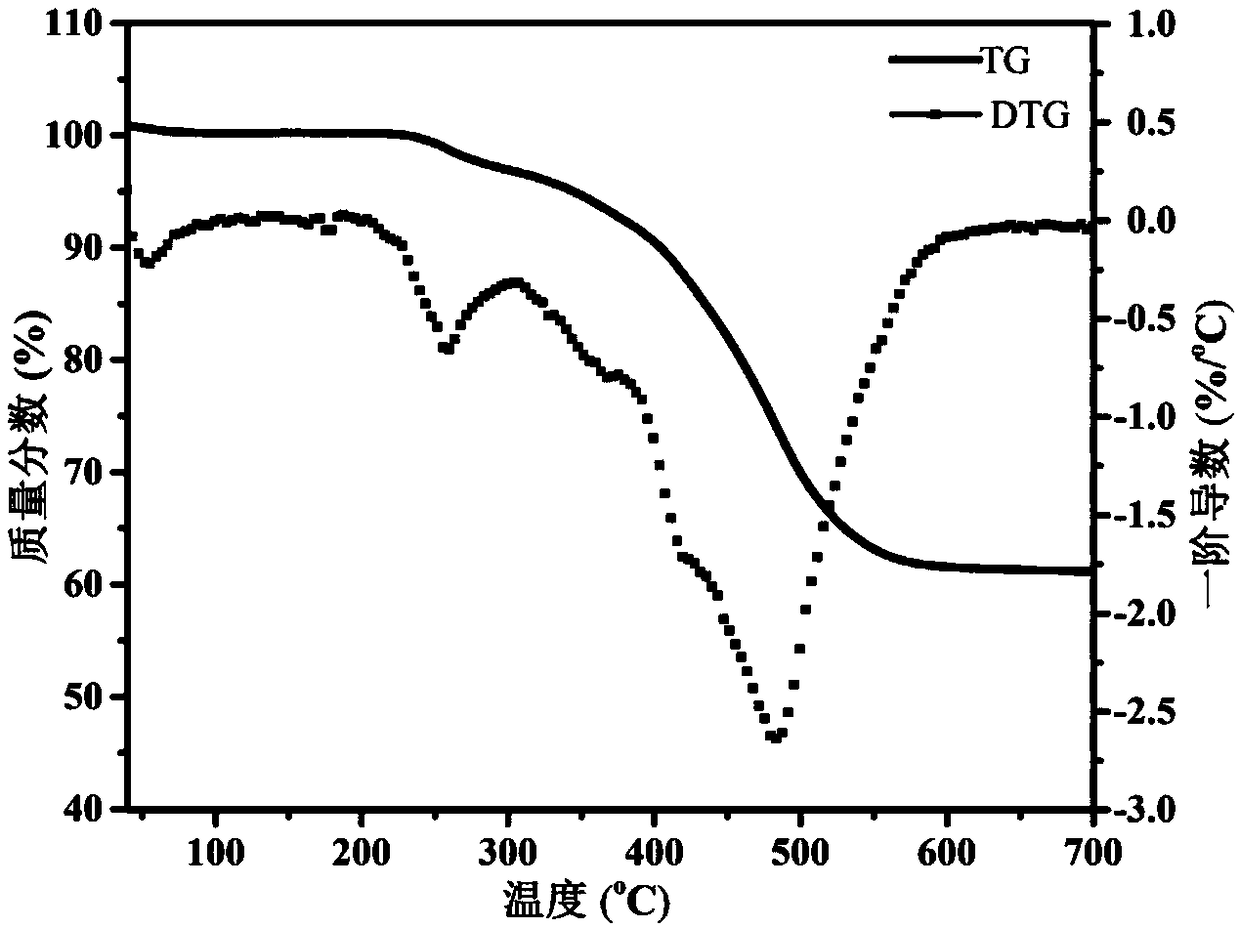

The invention relates to an expansive waterborne fireproof and flame-retardant coating for a wood material and a preparation method of the expansive waterborne fireproof and flame-retardant coating. The coating comprises water and the following components in parts by weight: 200 parts of melamine-modified urea resin emulsion, 110-120 parts of ethylene-vinyl acetate copolymer emulsion, 20-24 partsof boric acid, 36-38 parts of ammonium polyphosphate, 20-24 parts of guanylurea phosphate, 36-40 parts of pentaerythritol, 30-34 parts of melamine, 1.0-1.4 parts of sulfonated carbon, 3.6-4.0 parts ofzinc borate, 2.0-2.4 parts of ammonium octamolybdate, 16-20 parts of coating auxiliaries and 0-44 parts of pigment and filler. When heated, the expansive waterborne fireproof and flame-retardant coating is capable of greatly retarding the combustion of the wood material so as to prevent fire spreading; and the expansive waterborne fireproof and flame-retardant coating has good smoke inhibiting property and is capable of delaying the smoke generation time, reducing the release amount of smoke and the generation of poisonous gases and providing more safety time and space for escape and rescue of personnel under the condition of a fire hazard.

Owner:湘诚新材料科技有限公司

Method for preparing benzaldehyde by toluene oxidation

InactiveCN104693002AHigh yieldReduce spawn ratePreparation by oxidation reactionsOrganic compound preparationToluene oxidationBenzaldehyde

The invention discloses a preparation method of benzaldehyde. According to the method disclosed by the invention, by taking toluene as a raw material, a metal as well as a metal oxide loaded on a carrier as a catalyst, peroxide as a co-catalyst, oxygen as an oxygen source and methanol as a reaction solvent, the reaction time is 1-80 hours, the reaction temperature is 25-120 DEG C, the pressure is 0.1-6.0MPa, the conversion rate can reach 10-50% and the selectivity can reach 60-90%. The method disclosed by the invention has the advantages of simple process, low cost, environmental friendliness, low energy consumption, high authenticity of benzaldehyde, easily separable and reusable catalyst and the like.

Owner:NANJING TECH UNIV

Circulated cooling water compounded scale inhibitor and preparation method thereof

InactiveCN105036359AReduce contentReduce spawn rateTreatment using complexing/solubilising chemicalsPhosphoric Acid EstersMeth-

The invention discloses a circulated cooling water compounded scale inhibitor and a preparation method of the circulated cooling water compounded scale inhibitor. The circulated cooling water compounded scale inhibitor is prepared by weighing polyaspartic acid, 1-hydroxy ethylidene-1,1-diphosphonic acid, polyepoxysuccinic acid, amino trimethylene phosphonic acid, deionized water, sodium hexametaphosphate, a dispersing agent, polyhydric alcohol phosphate ester, organic polybasic phosphonic acid, acrylic acid-acrylic acid phosphonic hydroxypropyl acrylate and organic solvent according to a ratio in parts by weight. According to the circulated cooling water compounded scale inhibitor and the preparation method, disclosed by the invention, the content of phosphor in a water treatment agent is reduced, the generation rate of calcium phosphate scales is reduced, and the corrosion inhibition speed ranges from 0.001mm / a to 0.01mm / a; the scale inhibition rate is up to 98 to 100 percent; the expiration date is long, the circulated cooling water compounded scale inhibitor can be stored for one month under 60 to 70 DEG C, and the scale inhibition effect is up to 99 to 100 percent.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

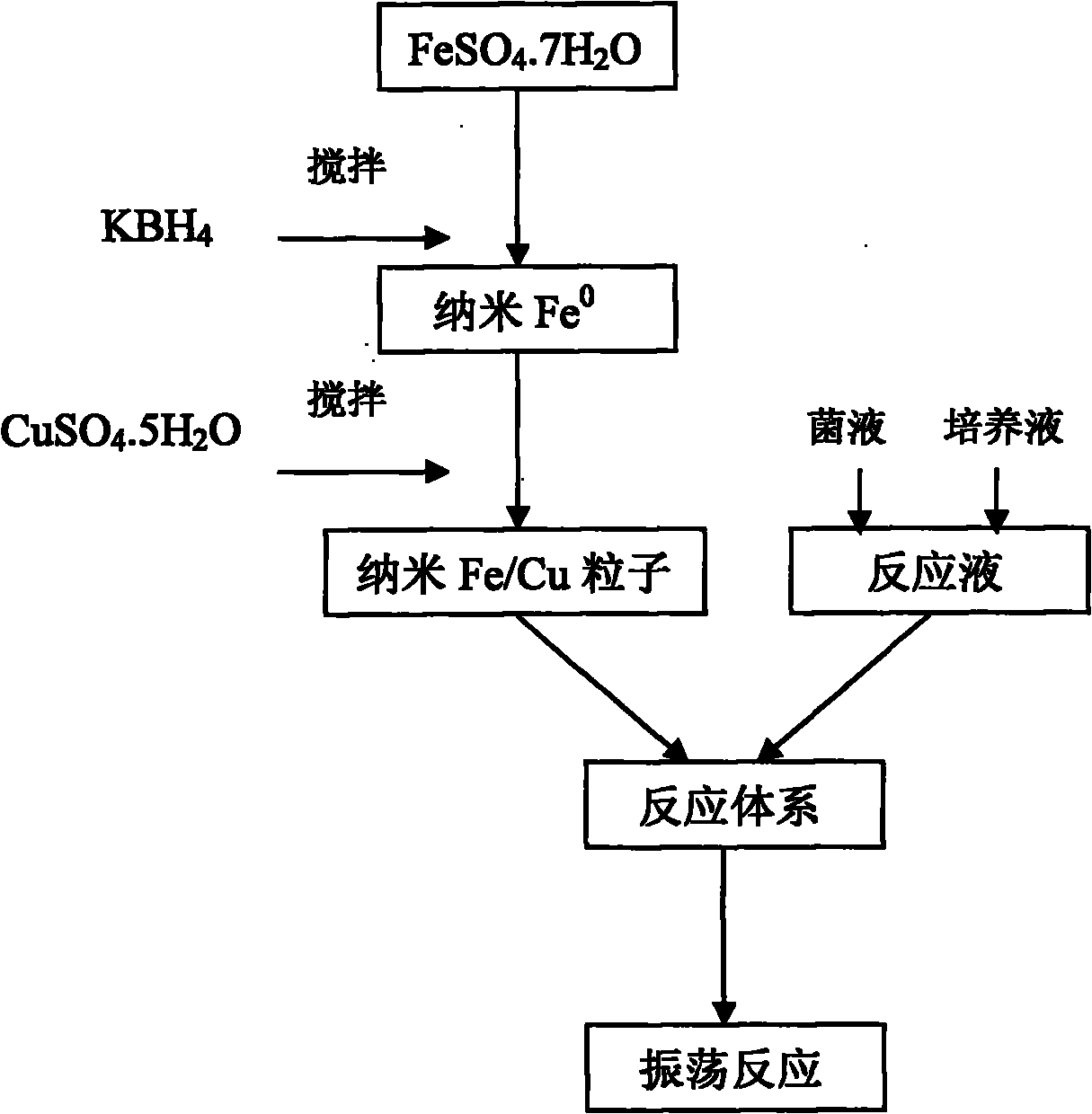

Method for remediating pollution of nitrate nitrogen in underground water

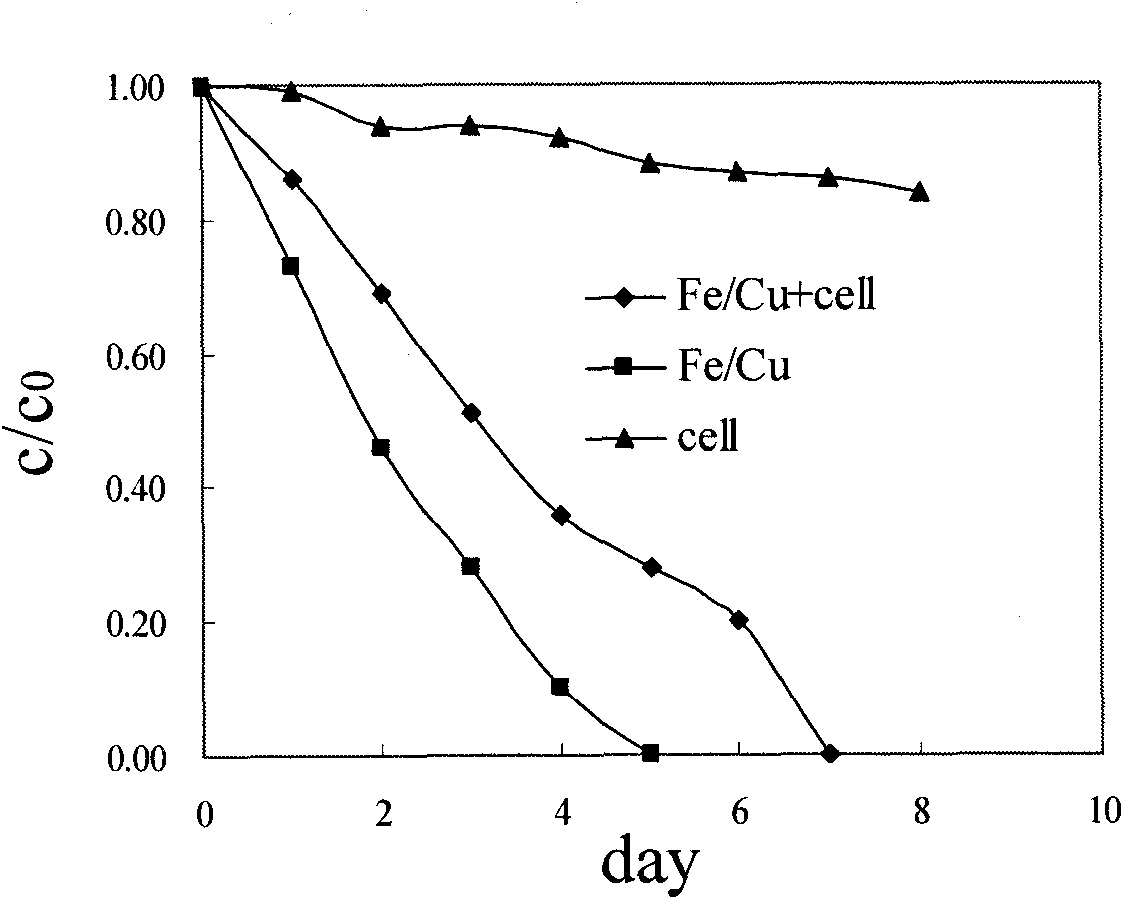

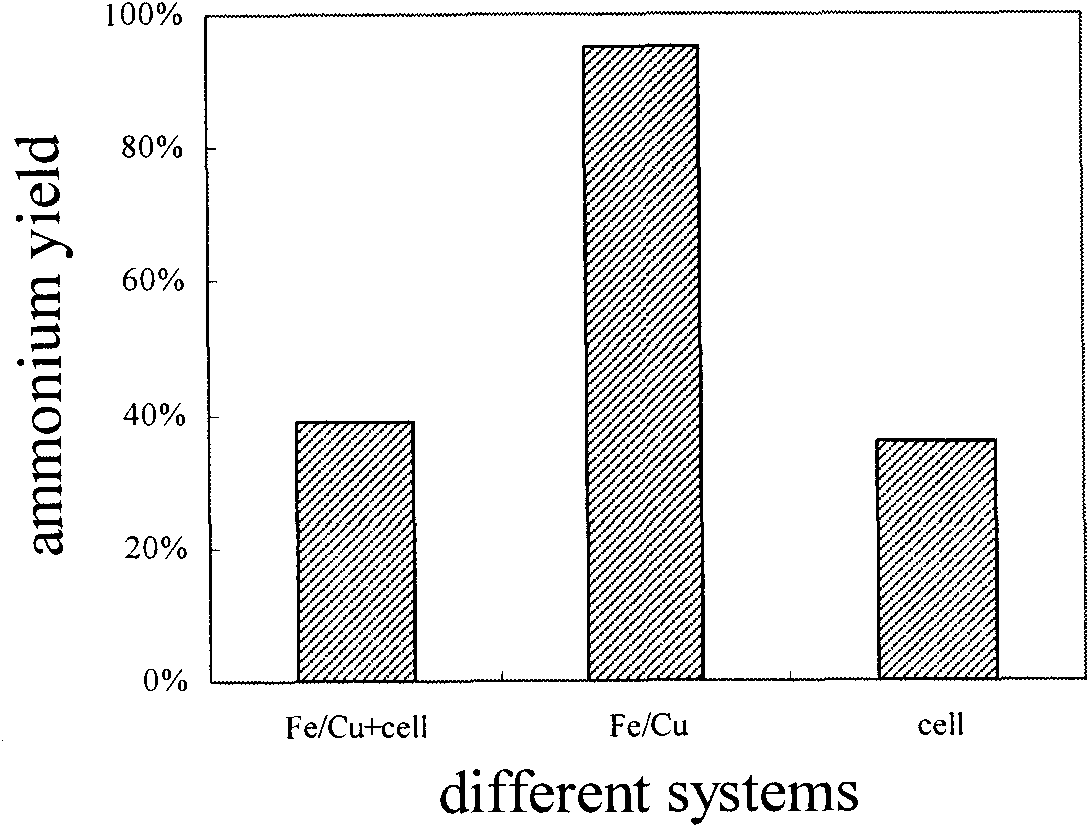

InactiveCN101805065AQuick removalReduce spawn rateWater contaminantsContaminated groundwater/leachate treatmentGroundwater nitrateNitrate nitrogen

The invention relates to a method for remediating pollution of nitrate nitrogen in underground water, which mainly comprises the following steps: firstly, preparing Fe / Cu nanoparticles by liquid phase reduction step by step: under the protection of argon gas, reducing a FeSO4.7H2O solution with a KHB4 solution to prepare FeO nanoparticles, then introducing a CuSO4.5H2O solution into the FeO nanoparticles for continuously stirring for reacting, after reacting, washing the nano Fe / Cu solution with deoxidized and deionized water, and then, selecting the Fe / Cu nanoparticles by a magnetic method; secondly, introducing the deoxidized reaction solution into the prepared Fe / Cu nanoparticles for physically mixing simply; and finally, adding underground water containing nitrate nitrogen and sealing to carry out oscillating reaction. The method has high efficiency for remediating pollution of nitrate nitrogen in underground water, has simple required equipment and convenient operation, and provides a new way for remediating pollution of nitrate nitrogen in underground water with high efficiency and low cost.

Owner:NANKAI UNIV

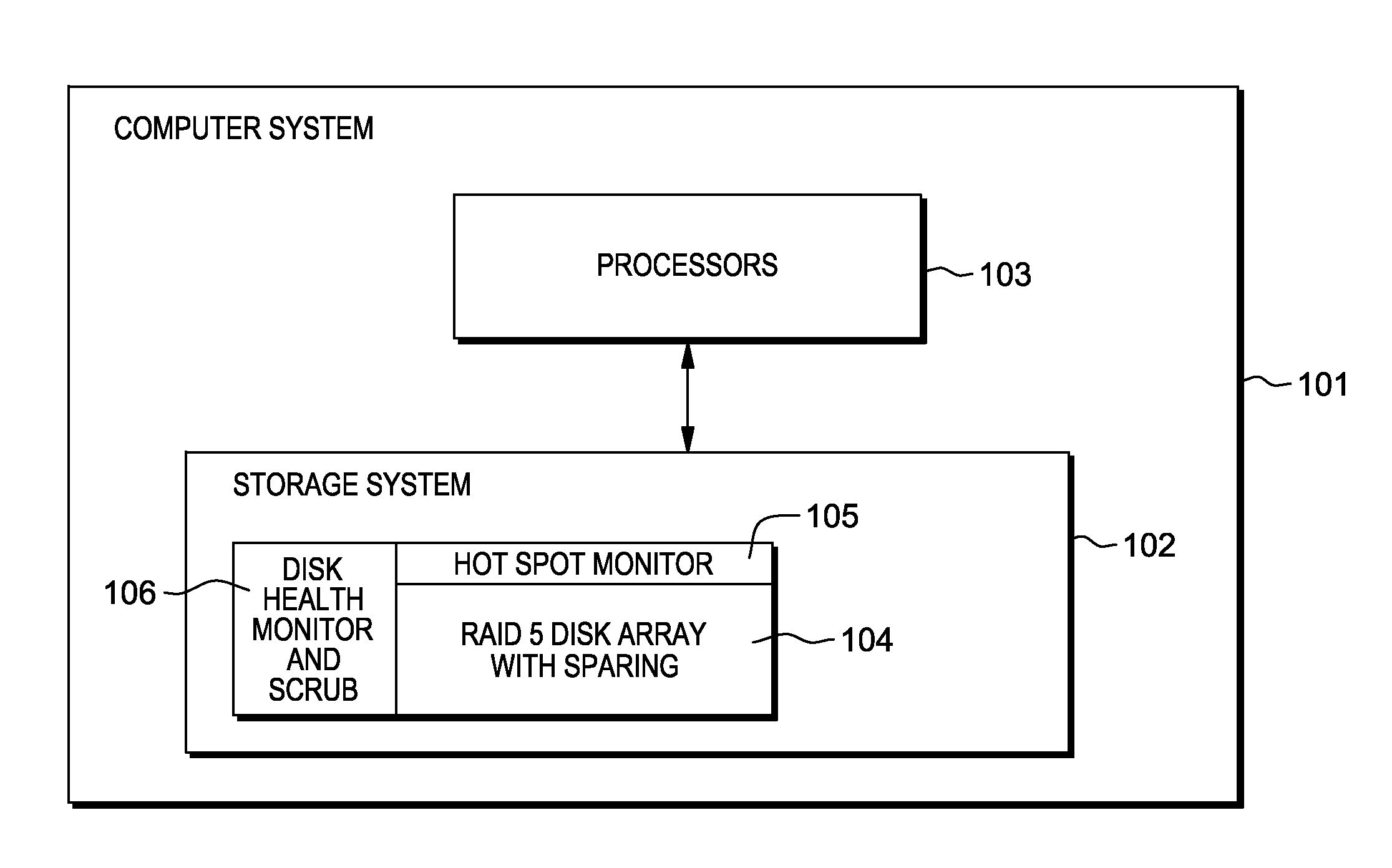

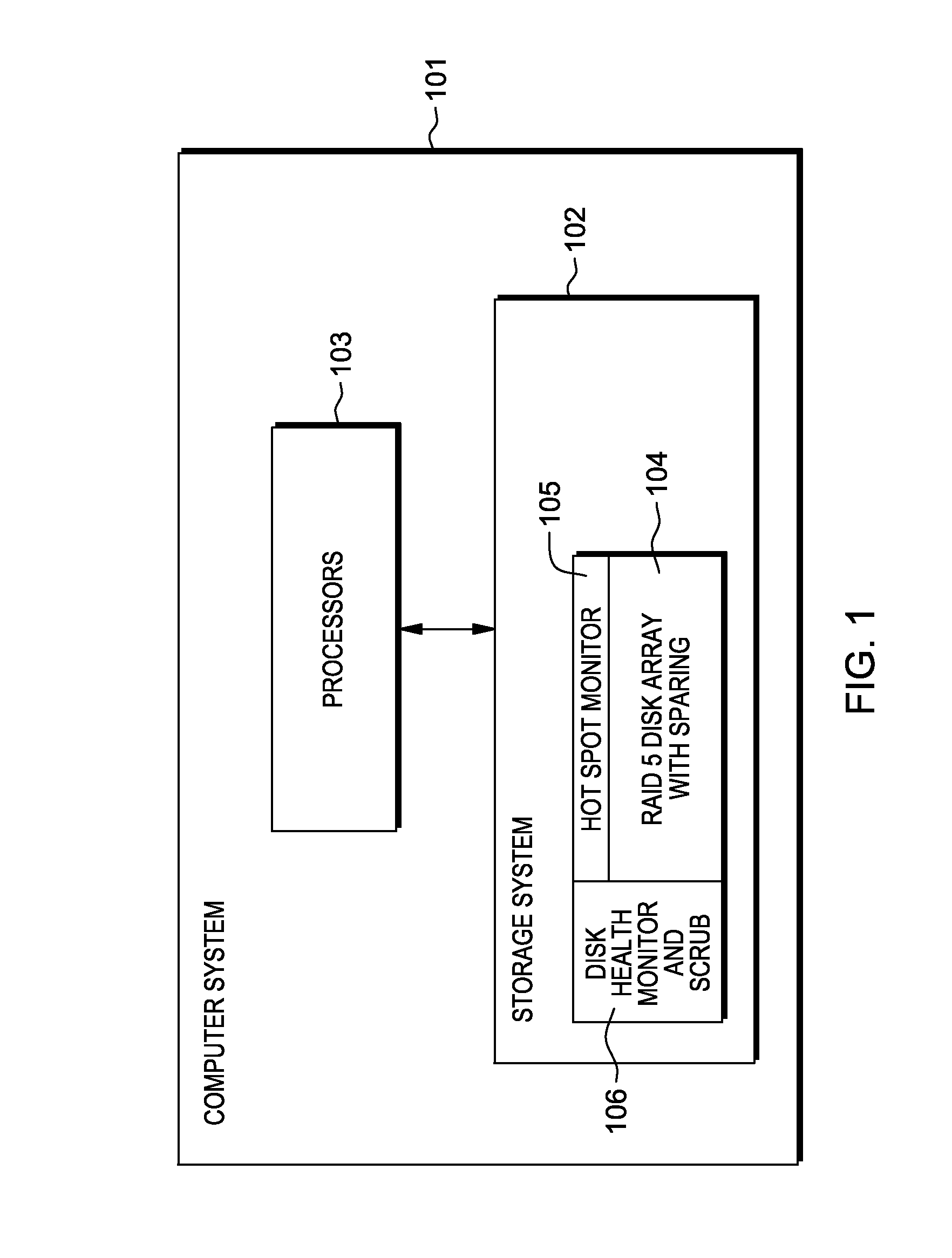

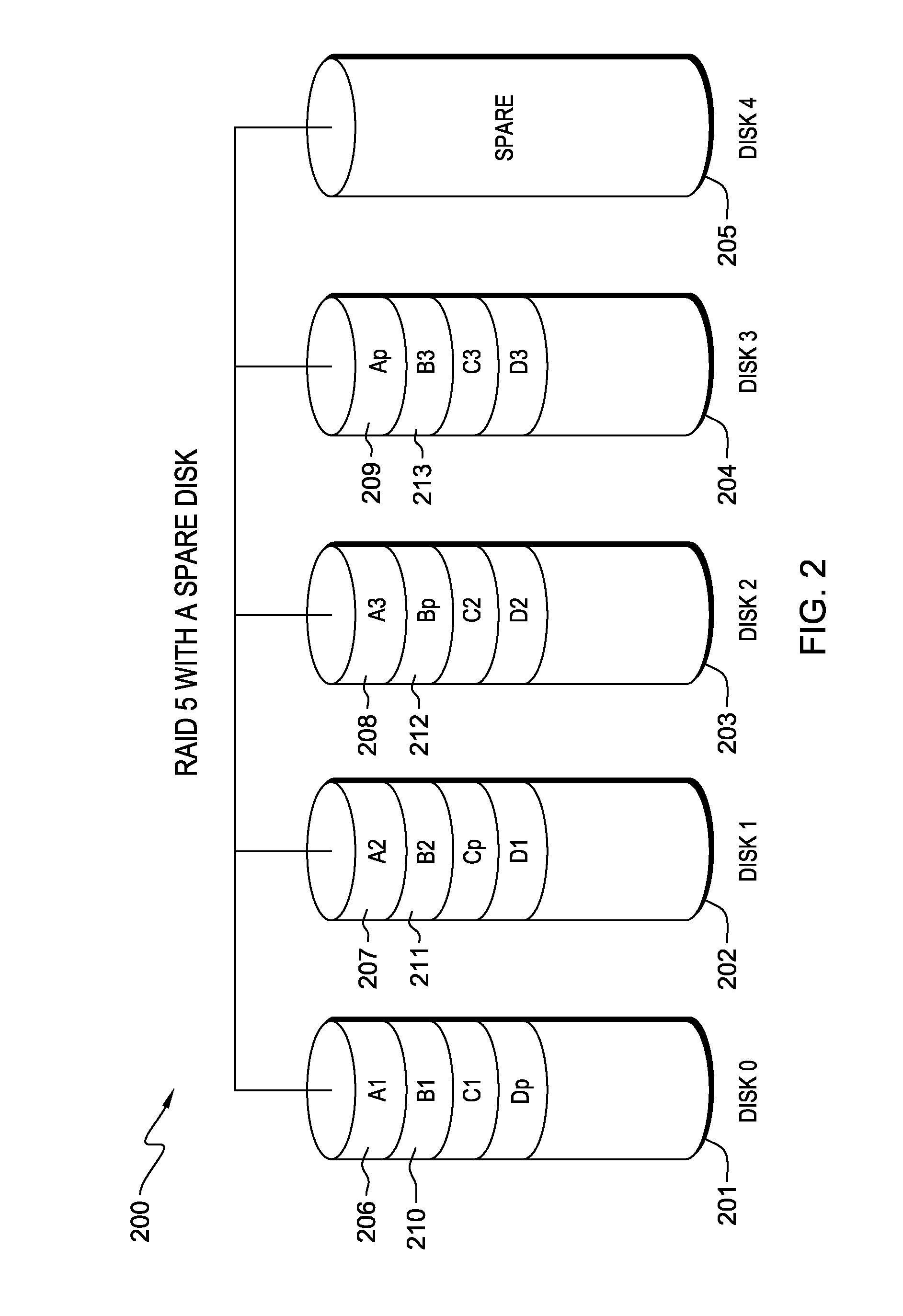

Preventing unrecoverable errors during a disk regeneration in a disk array

InactiveUS20140245062A1Reduce spawn rateIncrease the number ofRedundant data error correctionRedundant hardware error correctionDisk arrayComputer engineering

Exemplary embodiments of the present invention disclose a method and system for reducing a probability of generating an unrecoverable error on a disk array during a disk rebuild. In a step, an exemplary embodiment identifies a disk to be replaced in the disk array, the disk array including a spare disk. In another step, an exemplary embodiment locates a region in the disk array that incurs a high number of reads and writes during a period prior to replacing the disk in the disk array. In another step, an exemplary embodiment scrubs data in a region in the disk array that has incurred a high number of accesses. In another step, an exemplary embodiment replaces the disk identified to be replaced with the spare disk in the disk array. In another step, an exemplary embodiment rebuilds data on the replaced disk on the spare disk in the disk array.

Owner:IBM CORP

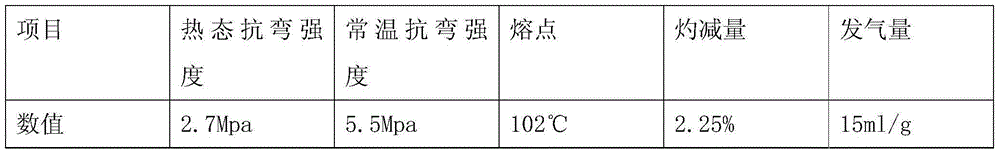

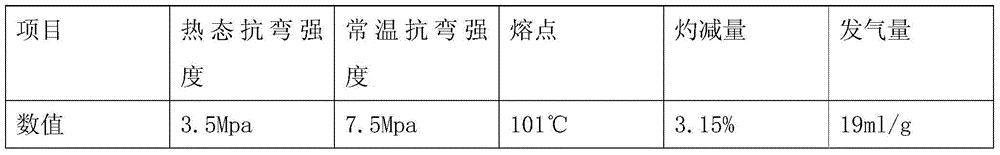

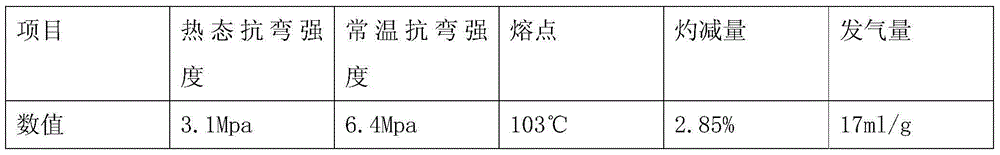

Precoated sand for casting and preparation method thereof

The invention discloses a precoated sand for casting, which comprises raw sand, an adhesive, a curing agent, a coupling agent and a plasticizer. The adhesive accounts for 2-3 wt% of raw sand, the curing agent accounts for 40-60 wt% of the adhesive, the coupling agent accounts for 0.5-0.8 wt% of the adhesive, the lubricant accounts for 40-60 wt% of the adhesive, the plasticizer accounts for 5-8 wt% of the adhesive, the raw sand comprises thermal reclaimed sand and ceramic foundry sand, and the ceramic foundry sand accounts for 30-100 wt% of the raw sand. The invention also discloses a preparation method of the precoated sand for casting. The precoated sand prepared according to the formula and preparation method has the characteristics of high strength, low gas yield and low expansion ratio, and can keep the shape. When being used for core shooting under preset conditions and used for pouring castings, the precoated sand can greatly lower the pore generation rate, ensures the structural stability of the sand mold (core) under the condition of casting, and can not easily deform, thereby ensuring the casting shape to satisfy the design requirement.

Owner:TONGLIN CASTING IND

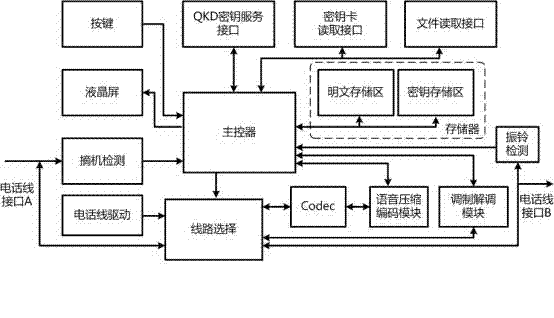

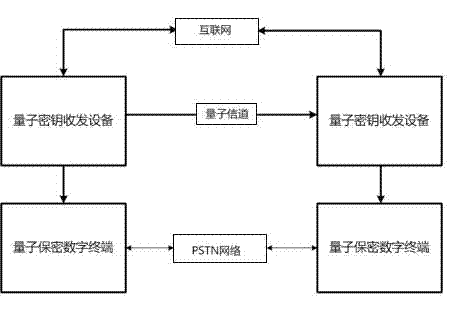

Quantum security digital terminal applied to PSTN (Public Switched Telephone Network)

InactiveCN103051444ARich application modeReduce spawn rateKey distribution for secure communicationModem deviceNetwork on

The invention discloses a quantum security digital terminal applied to a PSTN (Public Switched Telephone Network). A method for using the quantum security digital terminal comprises the steps that: when a call is received, a modulation and demodulation module converts an analog speech signal into a digital speech signal; a main controller decrypts the digital speech signal by using a quantum secret key, and converts the analog speech signal into the digital speech signal when the call is sent out, a speech compression coding module compresses the digital speech signal to from a compressed digital signal; the main controller encrypts the compressed digital signal by using the quantum secret key to form an encrypted digital signal; and the main controller converts the encrypted digital signal into an analog signal by a modulator-demodulator, and the analog signal is output through a second phone wire interface. The quantum security digital terminal applied to the PSTN is capable of using a quantum encryption technology on the PSTN, and realizes the unconditional security digital communication.

Owner:ANHUI QASKY QUANTUM SCI & TECH CO LTD

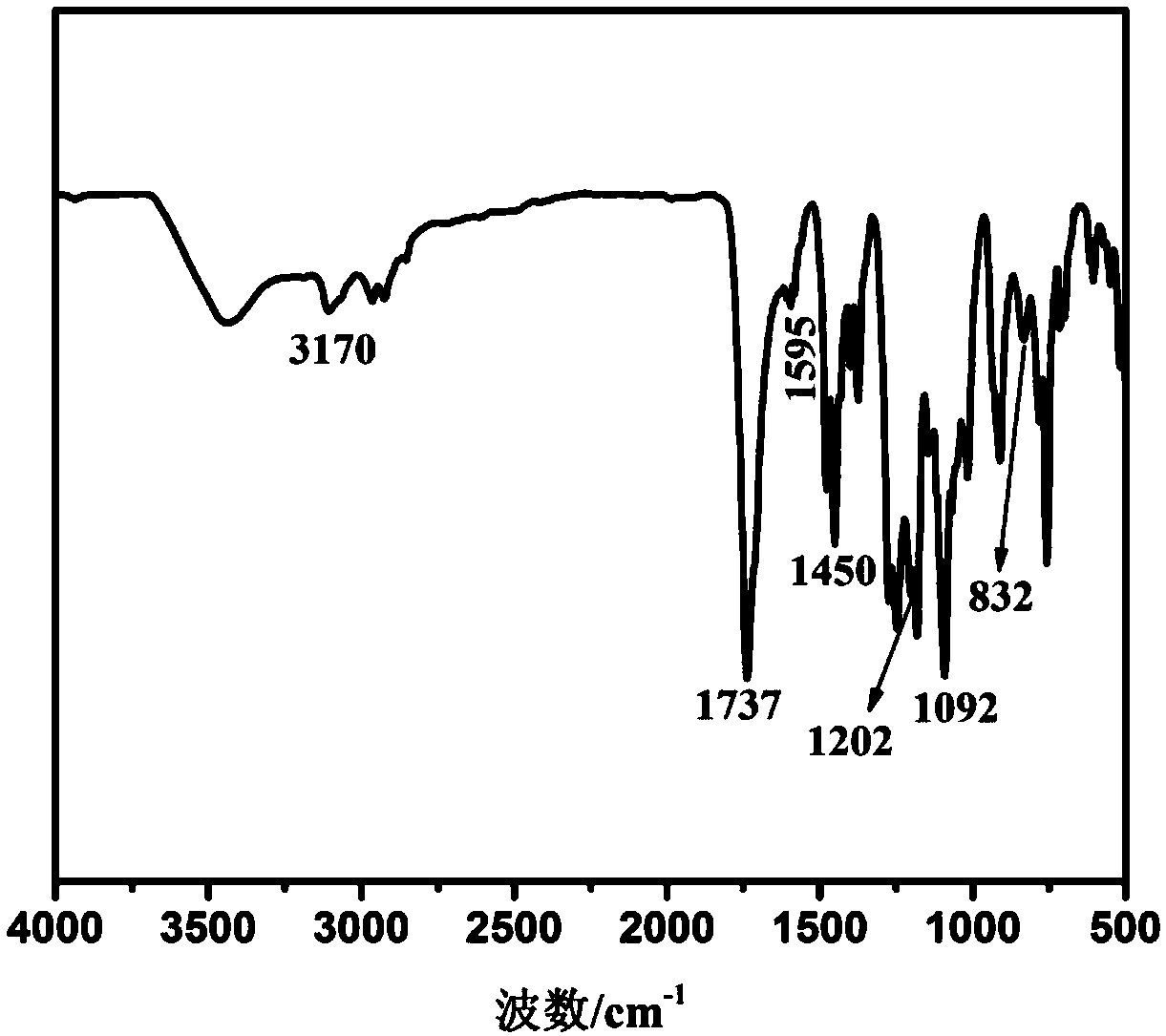

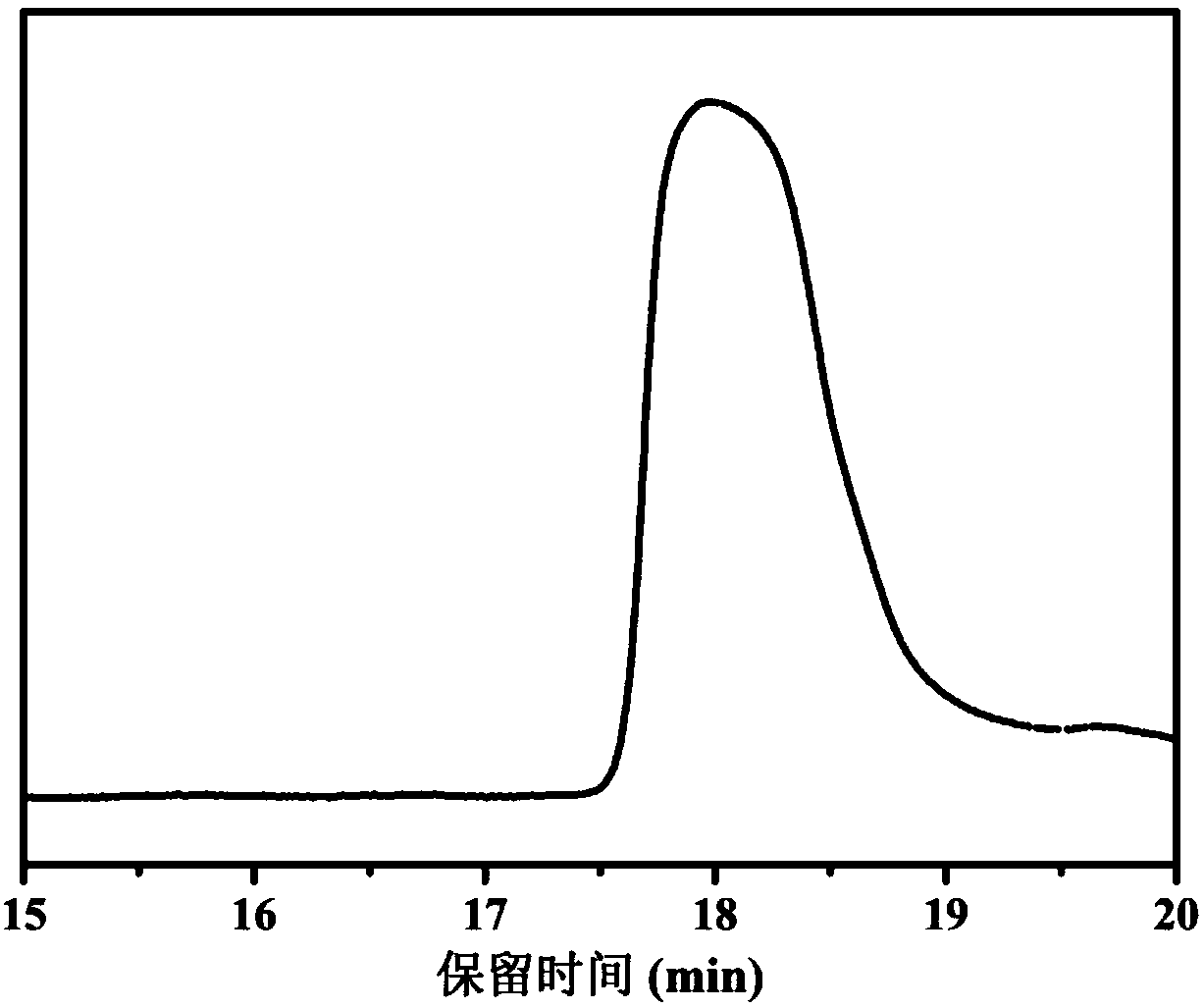

Ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, preparation method of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, and application of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent to flame retarding polymer

The invention discloses a ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent and a preparation method of the ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent. The preparation method of the polymer is as follows: putting 10-(2,5-dyhydroxyl phenyl)-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a reactor, adding a solvent,stirring for 5-10 minutes, adding an acid-binding agent; taking R1,R2'-ferrocene oxalyl chloride, adding the solvent, mixing, adding into the reactor dropwise, thermally insulating, stirring and reacting for 1-15 hours at the temperature of 0-50 DEG C under the protection of nitrogen after finishing adding dropwise; pouring a liquid obtained after the reaction into a precipitator while stirring, wherein the volume of the precipitator is 5-10 times that of the liquid, precipitating a yellow solid, carrying out suction filtration, washing a filter cake by using the precipitator, and drying to obtain the ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent. The ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent can be used to retard flame and suppress smoke of high polymer materials like polyolefins and epoxy resins.

Owner:SOUTHWEAT UNIV OF SCI & TECH

High molecular weight polyester polymers with reduced acetaldehyde

ActiveUS20080293912A1Simple yet robustReduce the temperatureAluminium compoundsPolyesterGeneration rate

Polyester compositions, especially polyethylene terephthalate homopolymer and copolymers, are disclosed containing titanium catalysts and catalyst deactivator added late in the manufacturing processing having reduced acetaldehyde generation rates. The polyester compositions are low in free acetaldehyde, making them suitable for fabrication into beverage containers for relatively tasteless beverages such as bottle water. Furthermore, the polyesters are polymerized to a high inherent viscosity in reduced processing time, without the necessity of further polymerization in the solid state, and in the absence of acetaldehyde scavengers leading to polyester polymers having reduced color.

Owner:ALPEK POLYESTER SA DE CV

Molybdenum disulfide/carbon composite material and preparation method and application thereof

InactiveCN108091837ARealize controllable regulationThorough responseSecondary cellsNegative electrodesCarbon compositesThiourea

The invention provides a molybdenum disulfide / carbon composite material and a preparation method and application thereof. The preparation method comprises the following steps: taking water as a solvent at first; adding p-aminophenol, formaldehyde and ammonia water to prepare multilayered C hollow balls; regulating the amount of the water, 3-AP, the formaldehyde and the ammonia water to regulate and control the number of the layers of the C hollow balls; taking the synthesized C hollow balls as a framework, taking ammonium molybdate as a molybdenum source, taking thiourea as a sulfur source, and using a hydrothermal method to obtain a MoS2 / C composite material. The preparation method is simple, safe in preparation process, low in energy consumption and high in operability.

Owner:BEIJING EURO & AMERICAN INST OF SCI & TECH

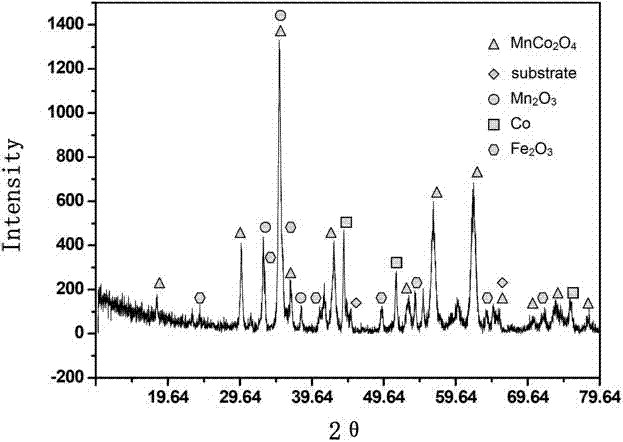

Preparation method of CoMn spinel coating on SOFC (Solid Oxide Fuel Cell) metal connector surface

ActiveCN103194713AMeet surface protection requirementsImprove production efficiencyMolten spray coatingFuel cells groupingHigh energyManganese

The invention belongs to the technology of metal surface modification and in particular relates to a preparation method of a CoMn spinel coating on an SOFC (Solid Oxide Fuel Cell) metal connector surface. The preparation method comprises the following steps of: (1), pretreating the metal surface; (2), pretreating a deposition electrode; (3), preparing a microcrystalline coating; and (4), preoxidizing a coasting to form the CoMn spinel coating on the alloy coasting surface. The preparation method of the CoMn spinel coating on the SOFC metal connector surface is free of a process for pre-synthesizing cobalt-manganese spinel, simple in process method, low in cost, capable of improving the preparation efficiency of the cobalt-manganese spinel and capable of obtaining CoMn alloy layers of different thickness and different atomic ratios by changing process parameters. The alloy coatings are combined with the base body in a metallurgical manner, so that the binding force is strong and the coating is compact; moreover, the prepared coating can be used for effectively blocking the volatilization of the Cr; and besides, the strict working conditions of the SOFC metal connector surface can be satisfied as the CoMn coating applied by high-energy micro-arc spark deposition has a thermal expansion coefficient close to the ferrite stainless steel and has good conductive performances.

Owner:兴化市青松农药化工有限公司

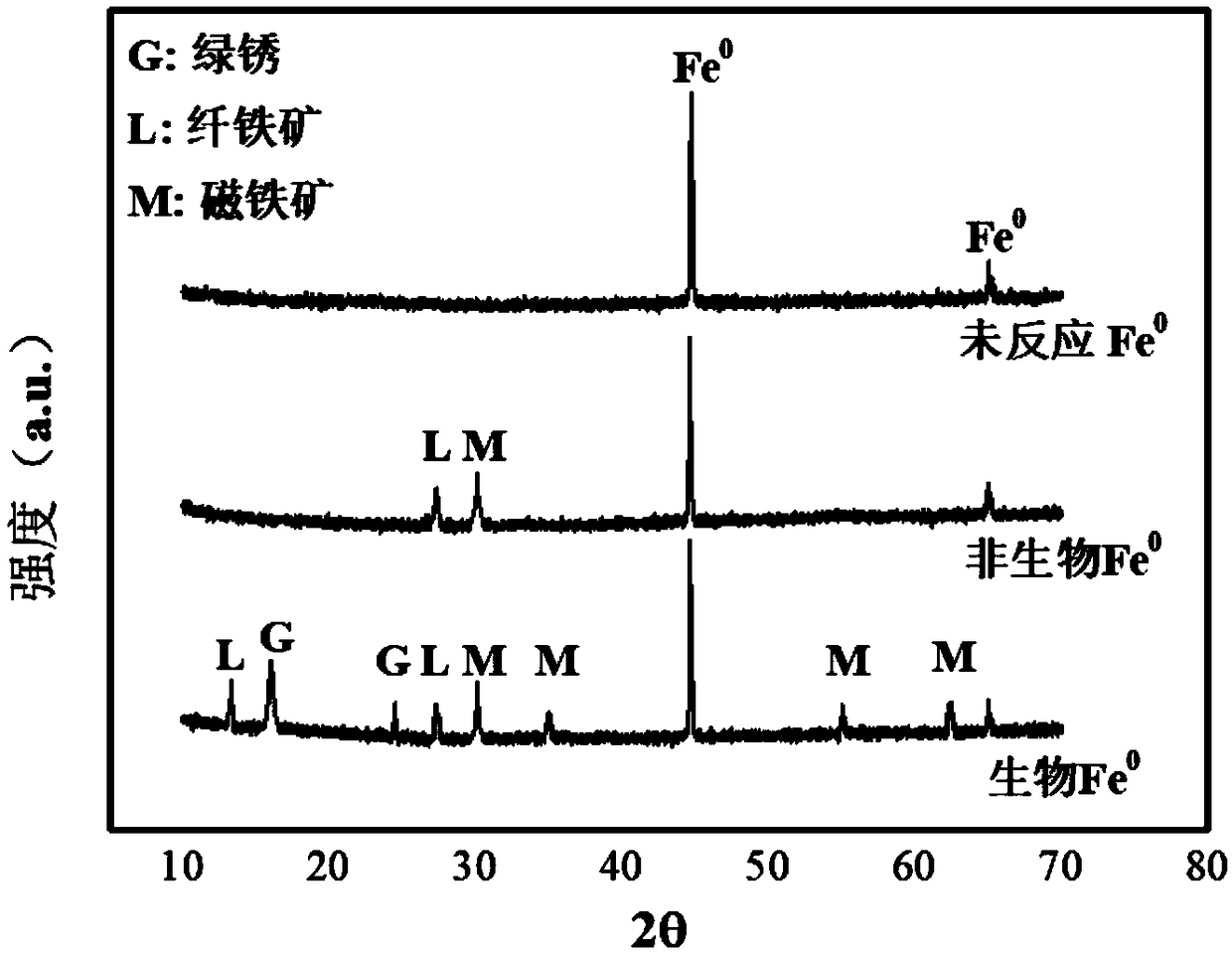

Method for remediating chromium polluted soil by enabling super fine iron powder to cooperate with microorganisms

InactiveCN109351767AReduced ability to migrateReduced bioavailabilityContaminated soil reclamationElectron donorManganese

The invention belongs to the technical field of ecological remediation, and discloses a method for remediating chromium polluted soil by enabling super fine iron powder to cooperate with microorganisms. The method comprises the following step of: sufficiently mixing the super fine iron powder and mixed bacteria with the chromium polluted soil to culture, thereby completing remediation of chromiumpolluted soil, wherein the mixed bacteria comprise chromium reducing bacteria, iron reducing bacteria and sulphate reducing bacteria. According to the method disclosed by the invention, the characteristic of corroding and releasing H2, in a remediation process, of the super fine iron powder is sufficiently utilized, and the microorganisms which take H2 as an electron donor are induced to grow andbreed on the surface, so that the microorganisms obtain energy, high-valence-state high-toxicity hexavalent chromium is reduced to be low-valence-state low-toxicity trivalent chromium, and the low-valence-state low-toxicity trivalent chromium is converted into occurrence forms, which are difficult in bioavailability, such as an iron-manganese combined form, an organic combined form and a residualform from a water-soluble form, an exchangeable form and a carbonate combined form, and therefore, transfer ability and bioavailability, in the soil, of chromium are reduced.

Owner:广东顺控自华科技有限公司

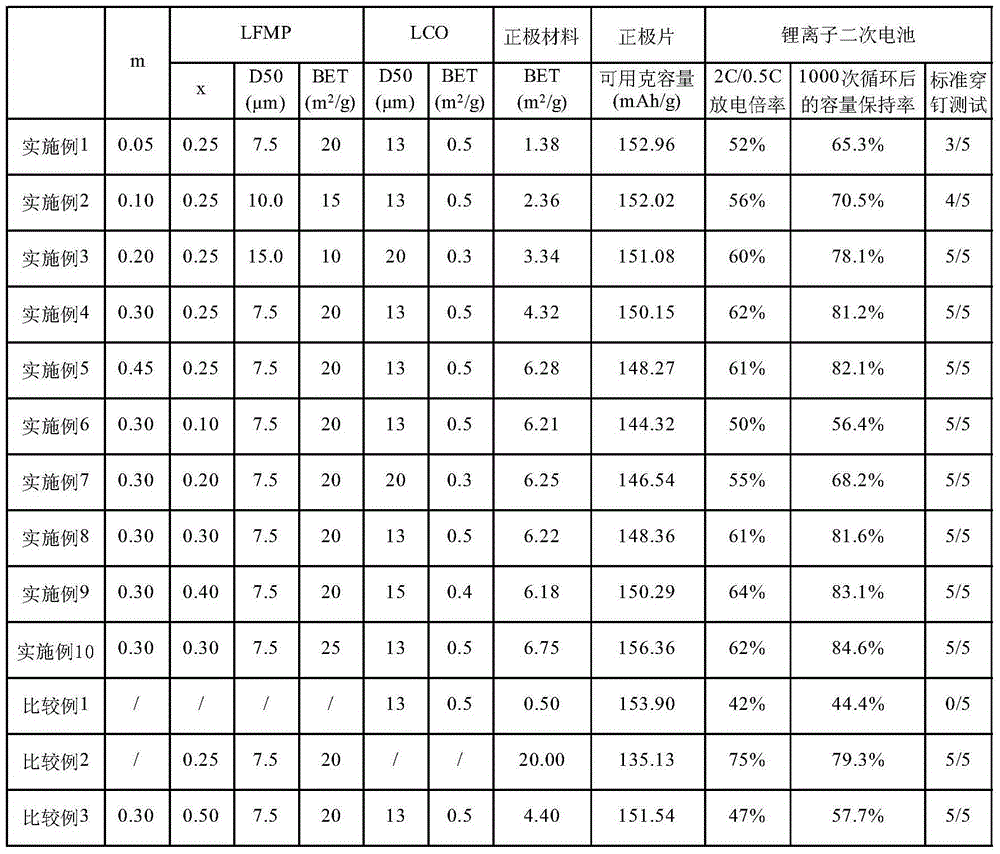

Positive electrode material and lithium ion secondary battery

ActiveCN105185987AHigh porosityIncrease the areaPositive electrodesElectrode collector coatingHigh energyPhysical chemistry

The invention provides a positive electrode material and a lithium ion secondary battery. The positive electrode material includes lithium cobaltate LiCoO2 (LCO) and lithium iron manganese phosphate LiFexMn1-xPO4 (LFMP), wherein 0<x<=0.4; the mass ratio of lithium iron manganese phosphate LiFexMn1-xPO4 to lithium cobaltate LiCoO2 is m, and 0<m<=0.45; lithium iron manganese phosphate LiFexMn1-xPO4 is polycrystalline particles having an olivine structure; lithium cobaltate LiCoO2 is polycrystalline particles having a layered structure; the average particle size D50 of the polycrystalline particles of lithium iron manganese phosphate LiFexMn1-xPO4 is less than the average particle size D50 of the polycrystalline particles of lithium cobaltate LiCoO2, and the polycrystalline particles of lithium iron manganese phosphate LiFexMn1-xPO4 are filled between the polycrystalline particles of lithium cobaltate LiCoO2. The lithium ion secondary battery includes the positive electrode material. The lithium ion secondary battery has high voltage platform and high energy density, and besides, has good multiplying power performance, cycle performance and safety performance.

Owner:NINGDE AMPEREX TECH

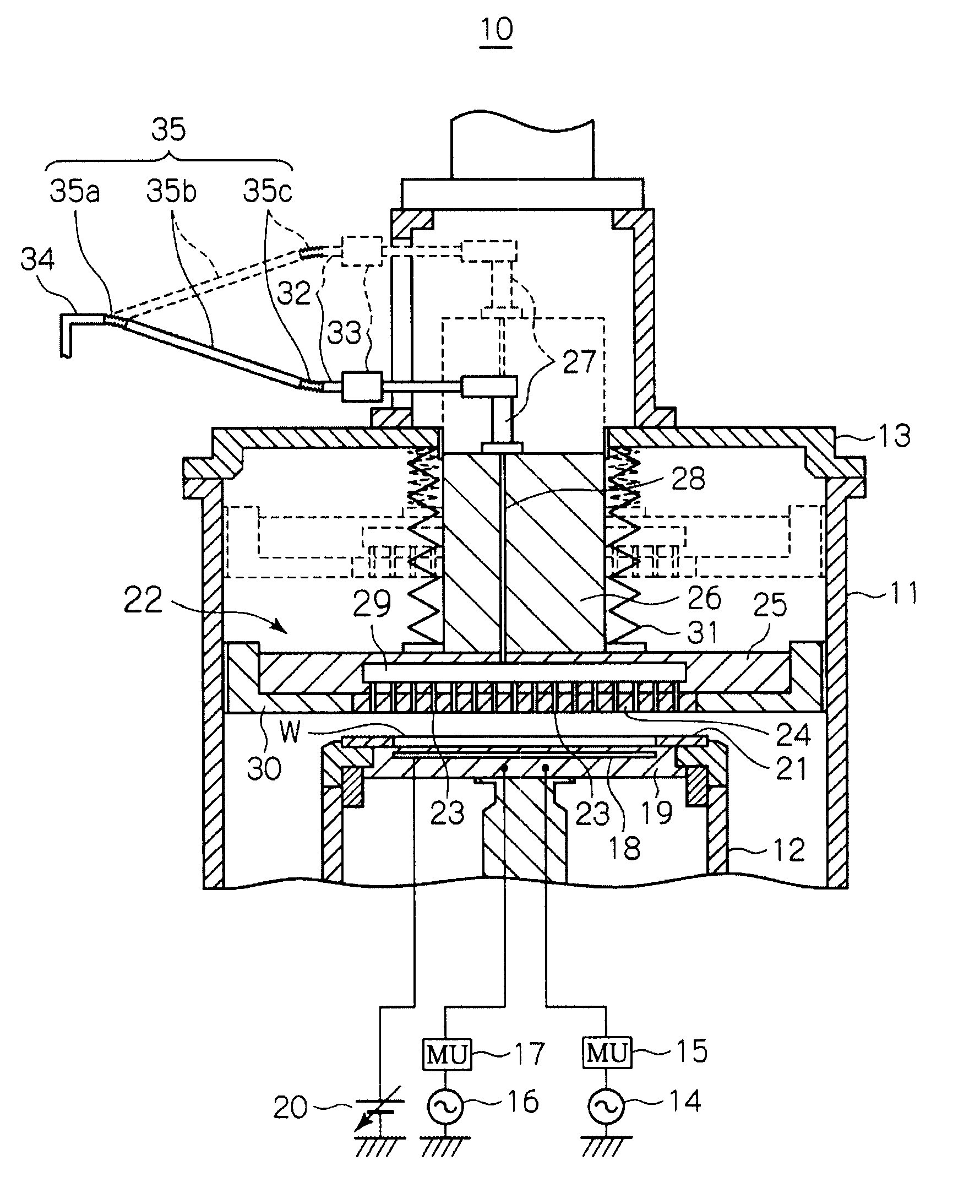

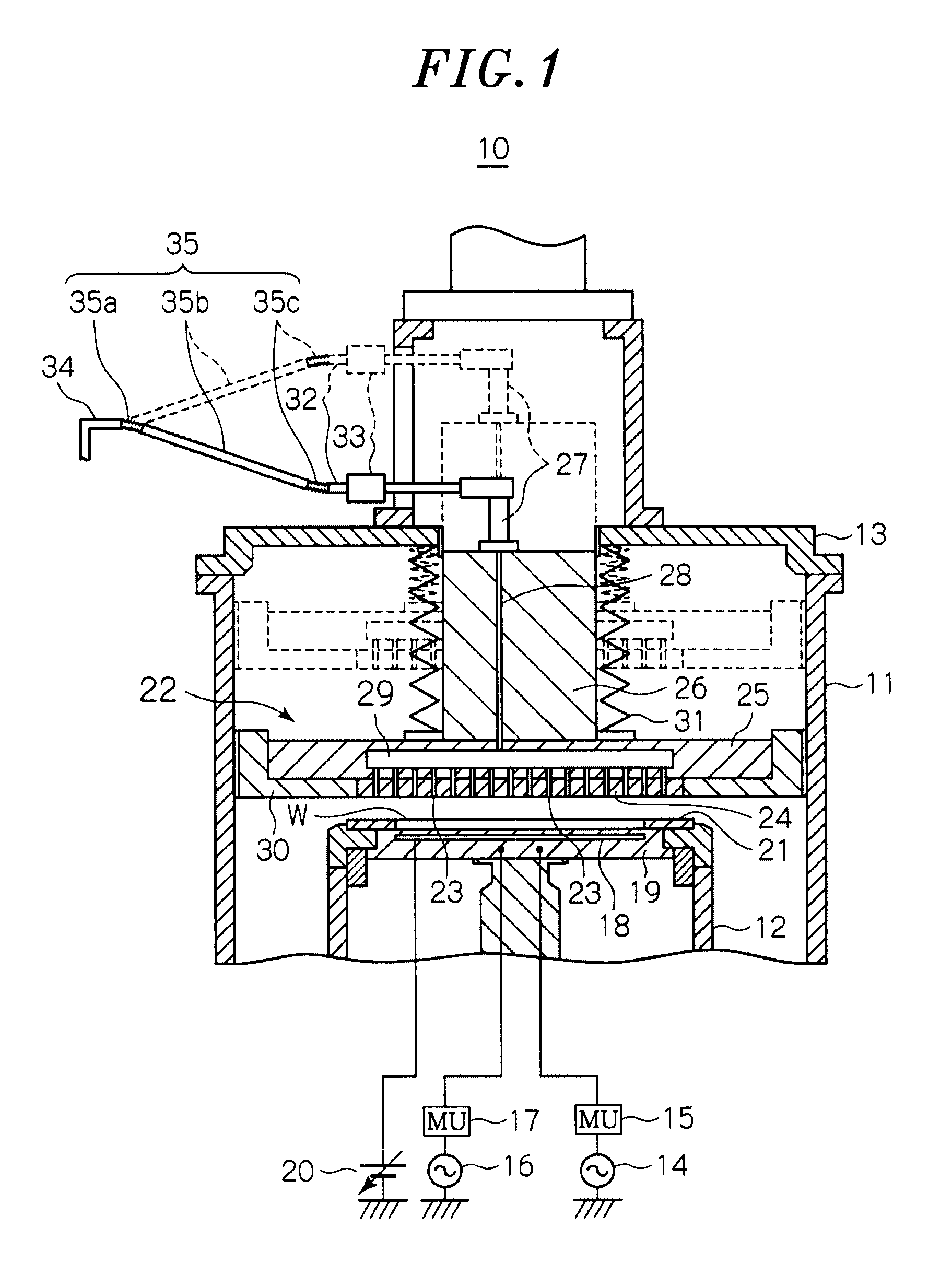

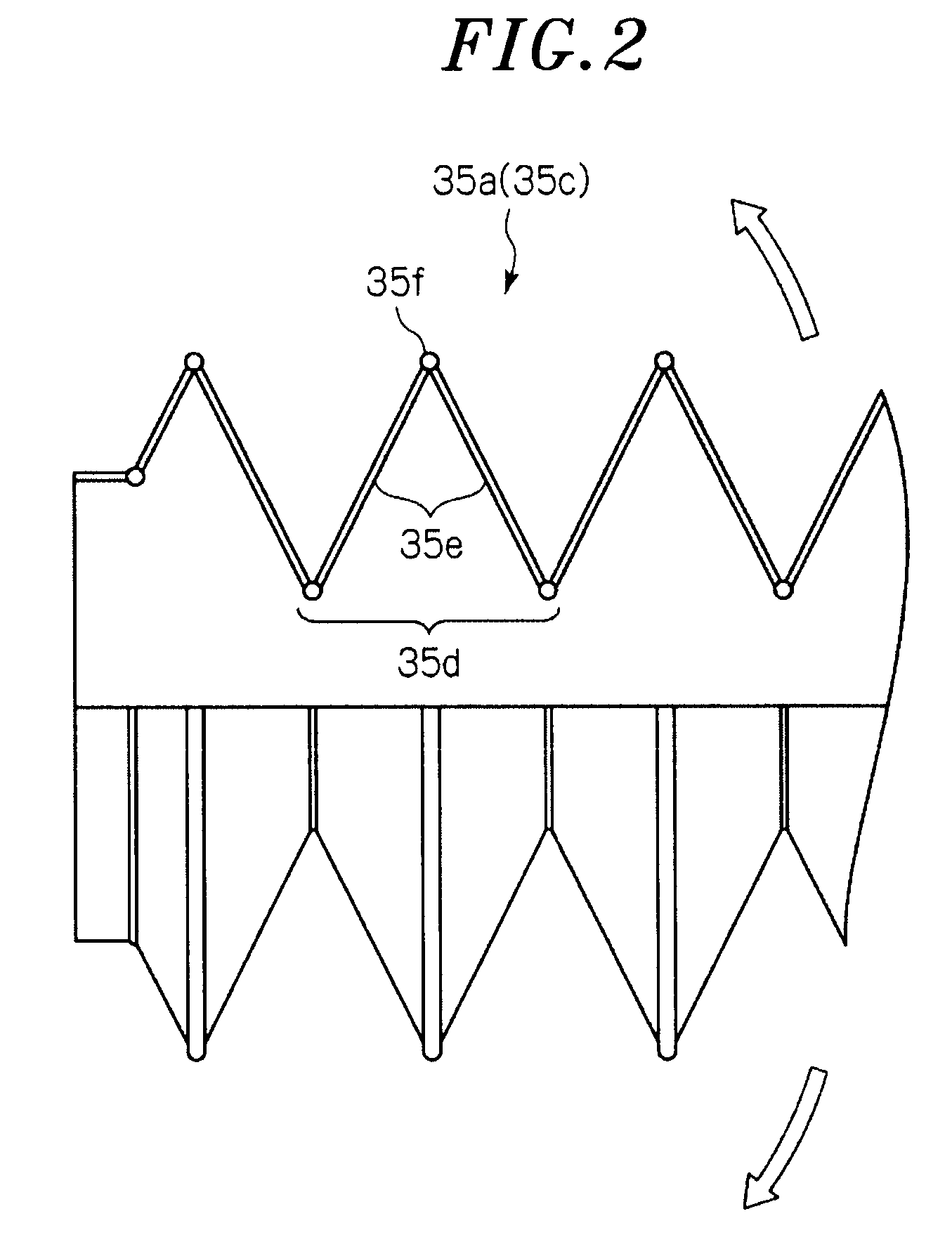

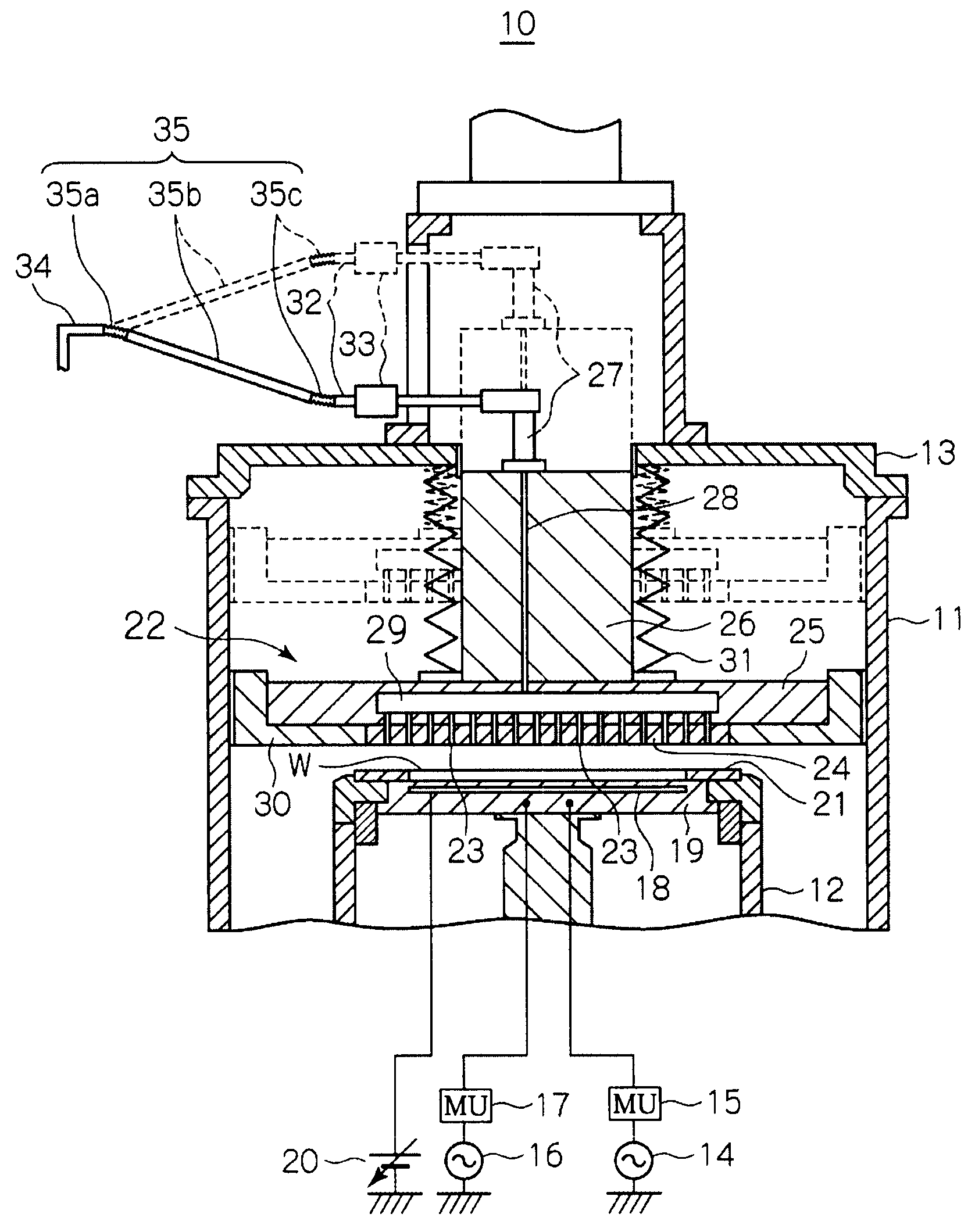

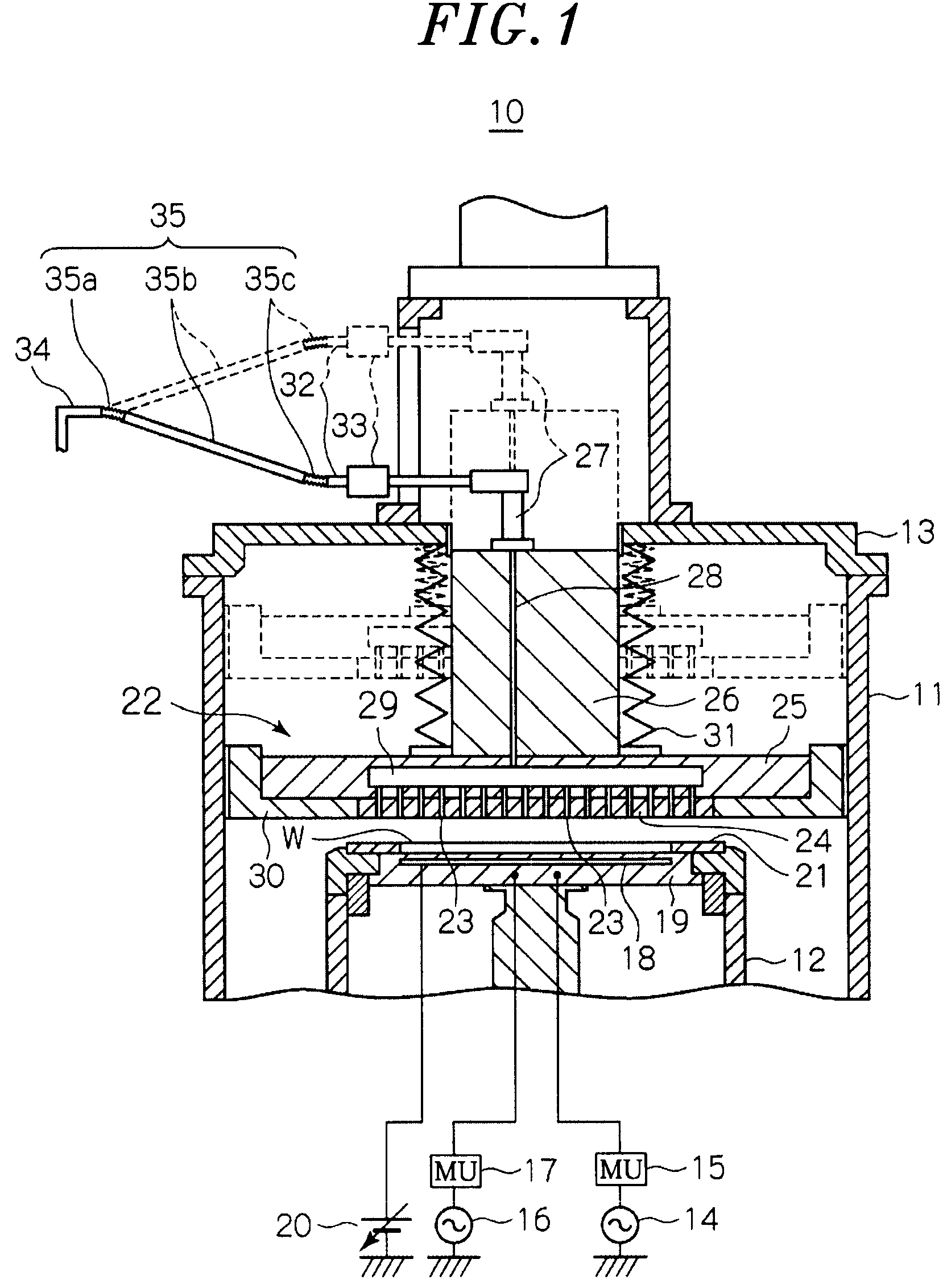

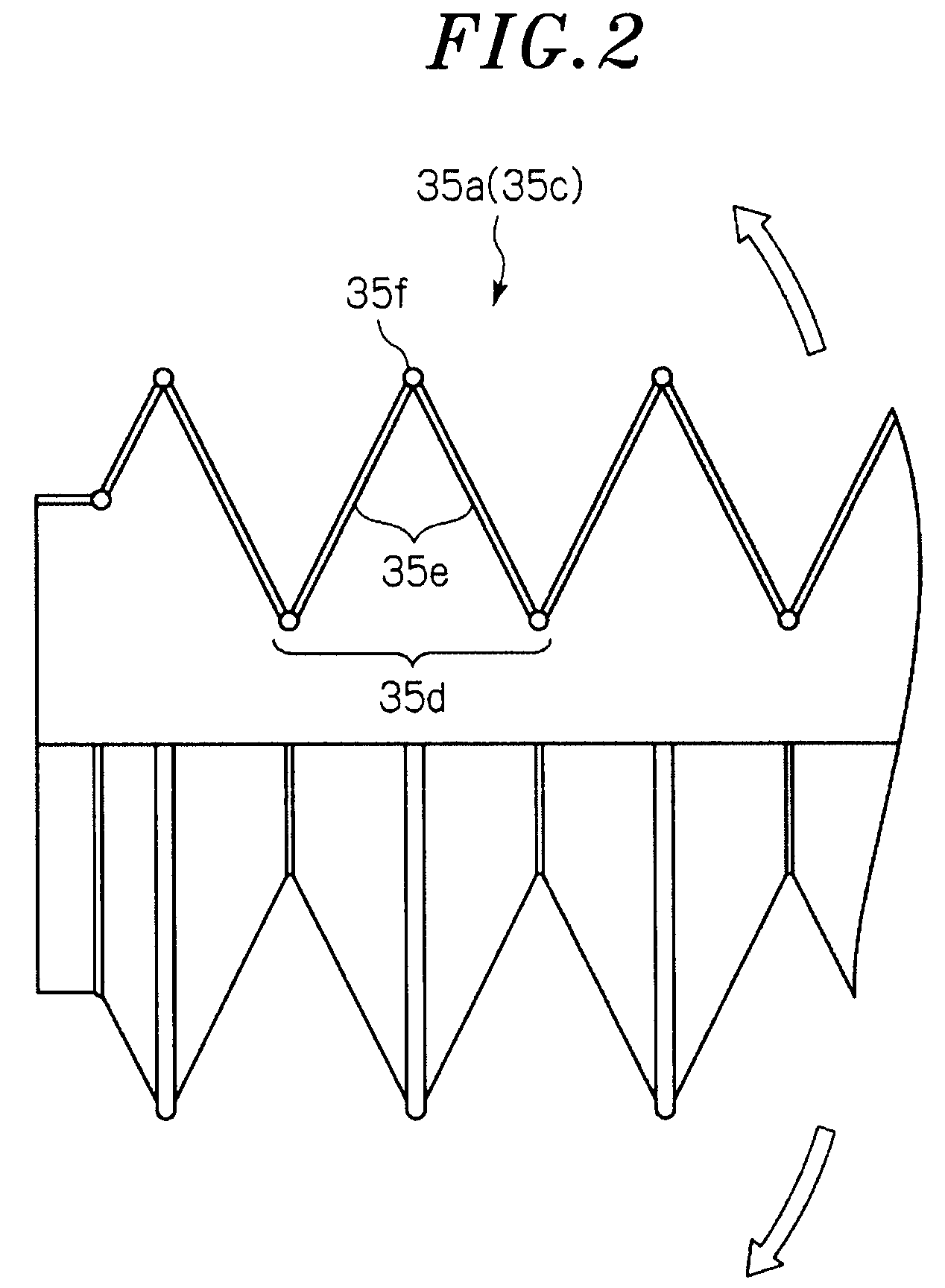

Movable gas introduction structure and substrate processing apparatus having same

ActiveUS20100043975A1Reduce particle generation probabilityIncrease freedomElectric discharge tubesSemiconductor/solid-state device manufacturingLine tubingProduct gas

In a gas introduction structure that is reciprocatingly movable in a predetermined direction, a processing gas introduction system is configured to introduce a processing gas into a processing chamber in which a substrate is subjected to a predetermined processing under a clean atmosphere; and a processing gas supply line is configured to be connected to the processing gas introduction system and an external processing gas supply source to supply the processing gas from the processing gas supply source to the processing gas introduction system, mutual relative positions of the processing gas supply source and the processing gas introduction system being changed. The processing gas supply line includes: a first bendable portion connected to the processing gas supply source; a second bendable portion connected to the processing gas introduction system; and a non-bendable pipe interposed between the first bendable portion and the second bendable portion.

Owner:TOKYO ELECTRON LTD

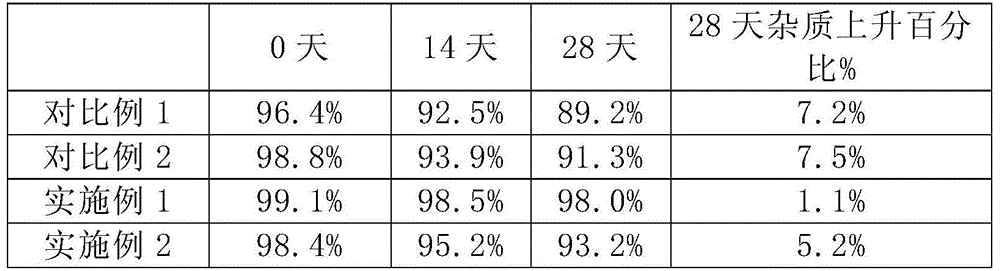

Stable anti-VEGF antibody preparation and application thereof

ActiveCN104922668AReduce spawn rateImprove physical stabilityInorganic non-active ingredientsAntibody ingredientsAnti vegf antibodySodium Acetate Trihydrate

The invention relates to a stable anti-VEGF antibody preparation and an application thereof, specifically the preparation comprises (i) therapeutically effective amounts of an anti-VEGF antibody, (ii) a buffer system containing 1.0-5.0mg / ml of sodium acetate trihydrate, (iii) an osmotic pressure regulator, and optionally (iv) surfactant, wherein the pH of the preparation ranges from 5.0 to 6.0. The preparation disclosed by the invention can be used for effectively reducing the physical and chemical degradation reaction rates of an anti-VEGF monoclonal antibody, improving antibody stability and prolonging the shelf life of a finished product; in addition, the invention also discloses a method for stabilizing the antibody and an application of the preparation.

Owner:INNOVENT BIOLOGICS (SUZHOU) CO LTD

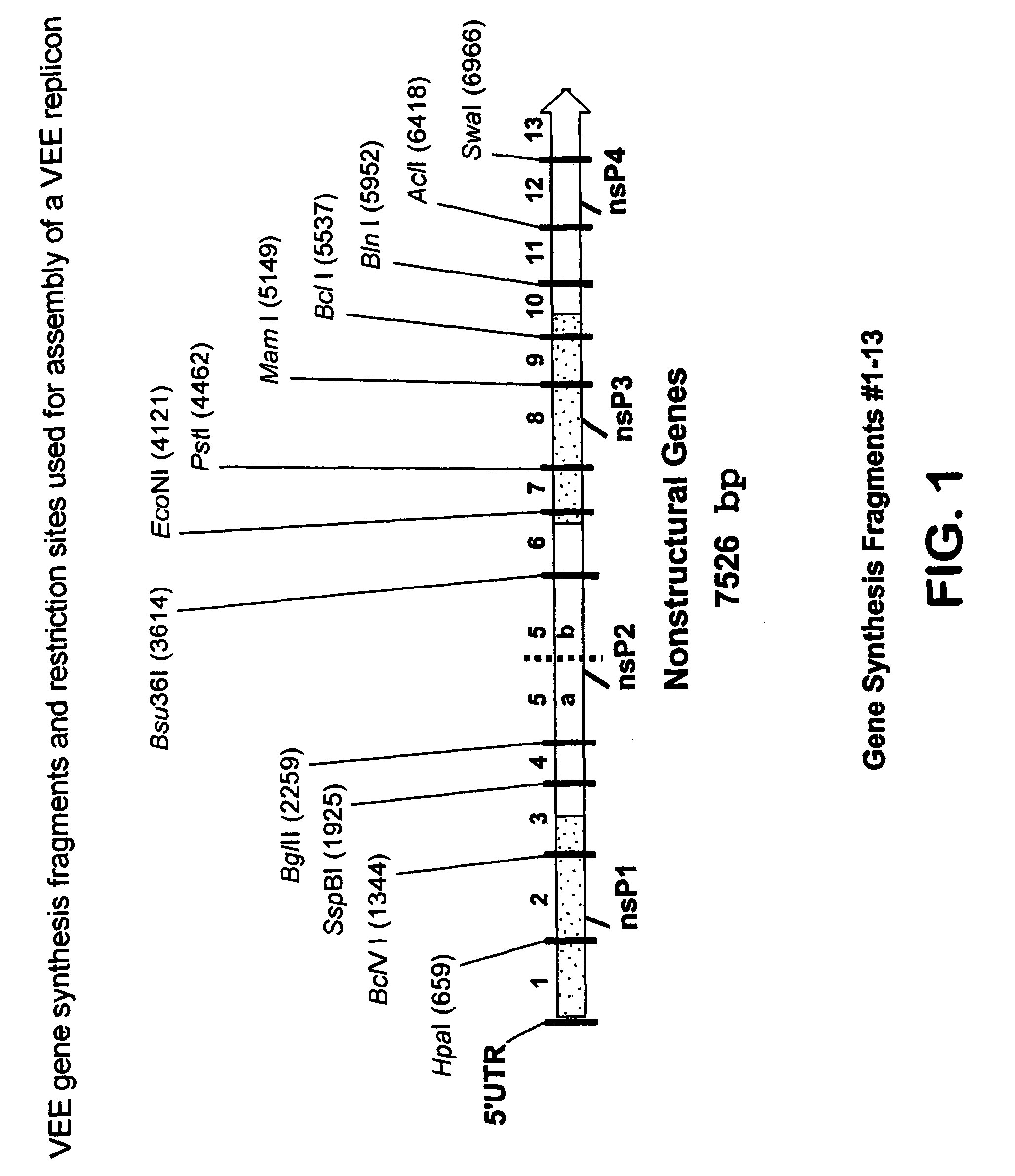

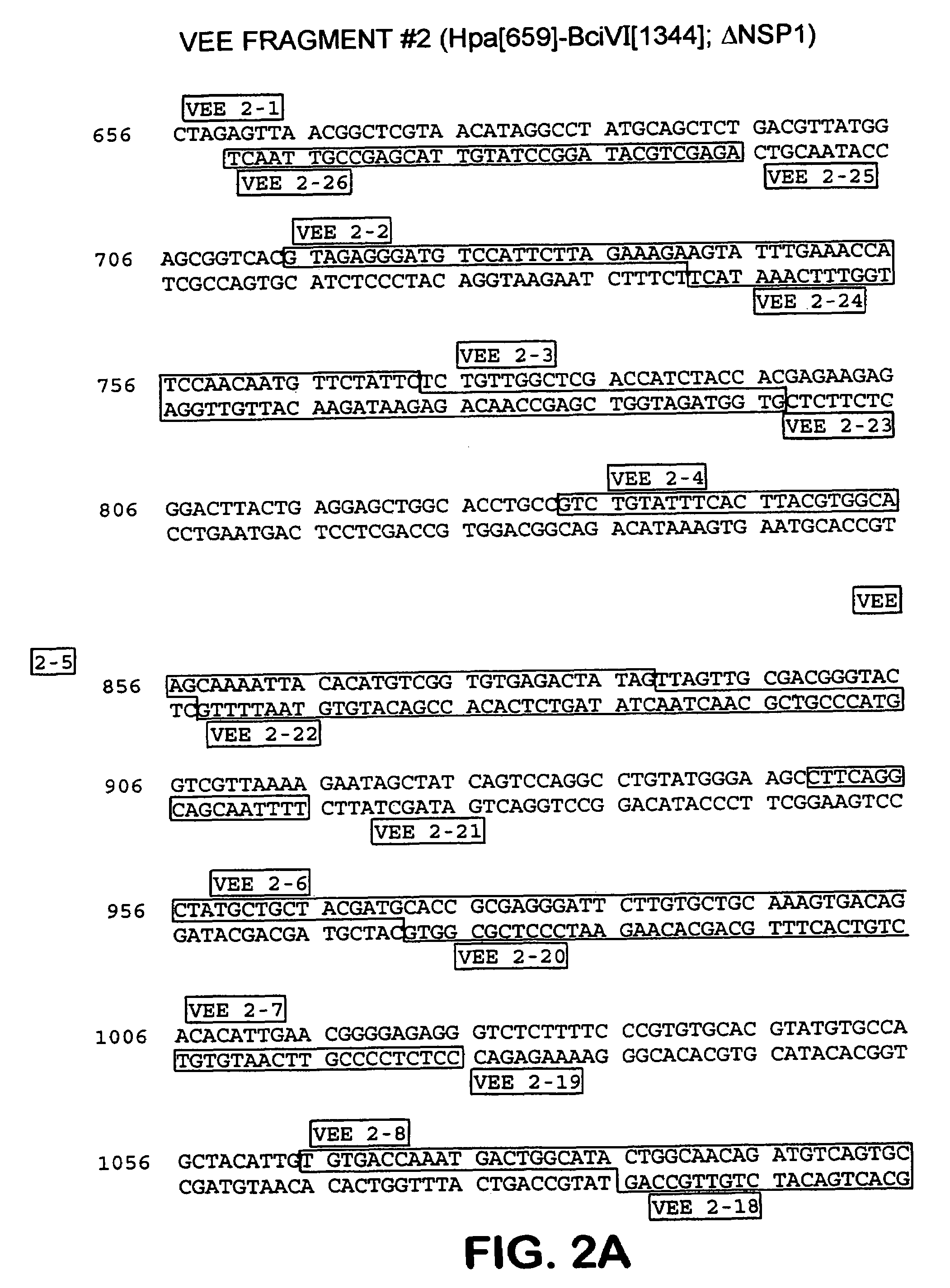

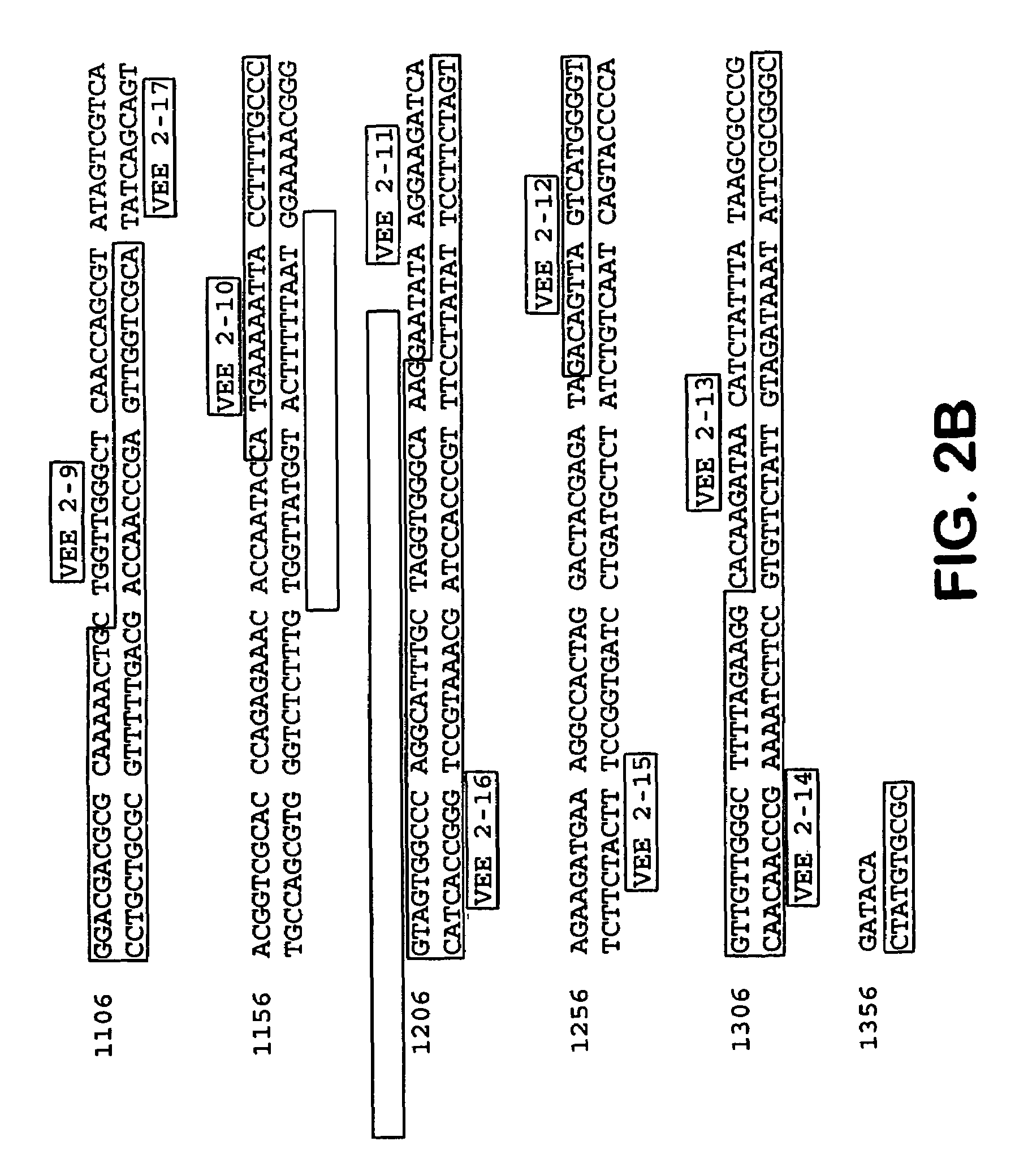

Chimeric alphavirus replicon particles

Chimeric alphaviruses and alphavirus replicon particles are provided including methods of making and using same. Specifically, alphavirus particles are provided having nucleic acid molecules derived from one or more alphaviruses and structural proteins (capsid and / or envelope) from at least two or more alphaviruses. Methods of making, using, and therapeutic preparations containing the chimeric alphavirus particle, are disclosed.

Owner:GLAXOSMITHKLINE BIOLOGICALS SA

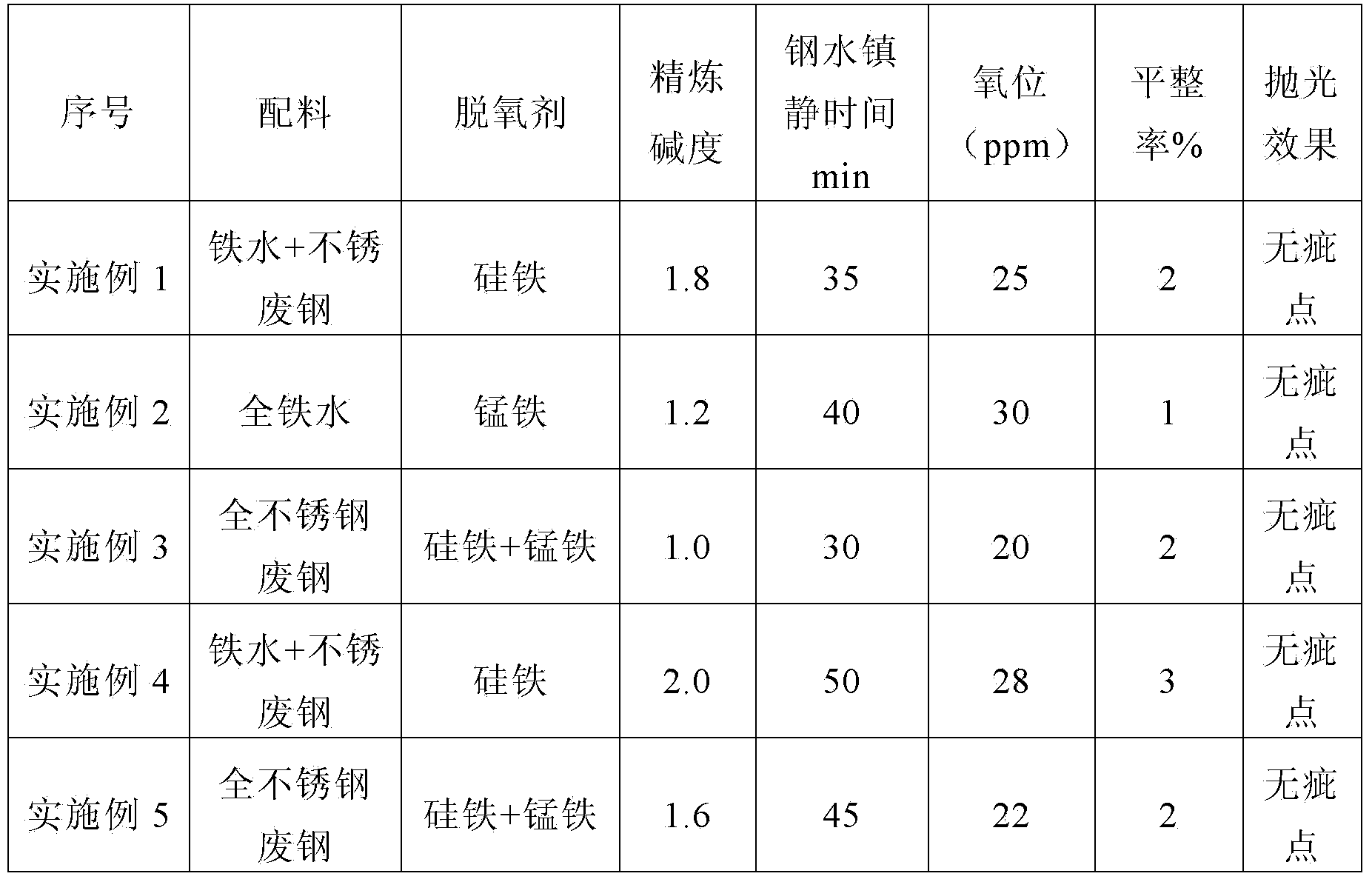

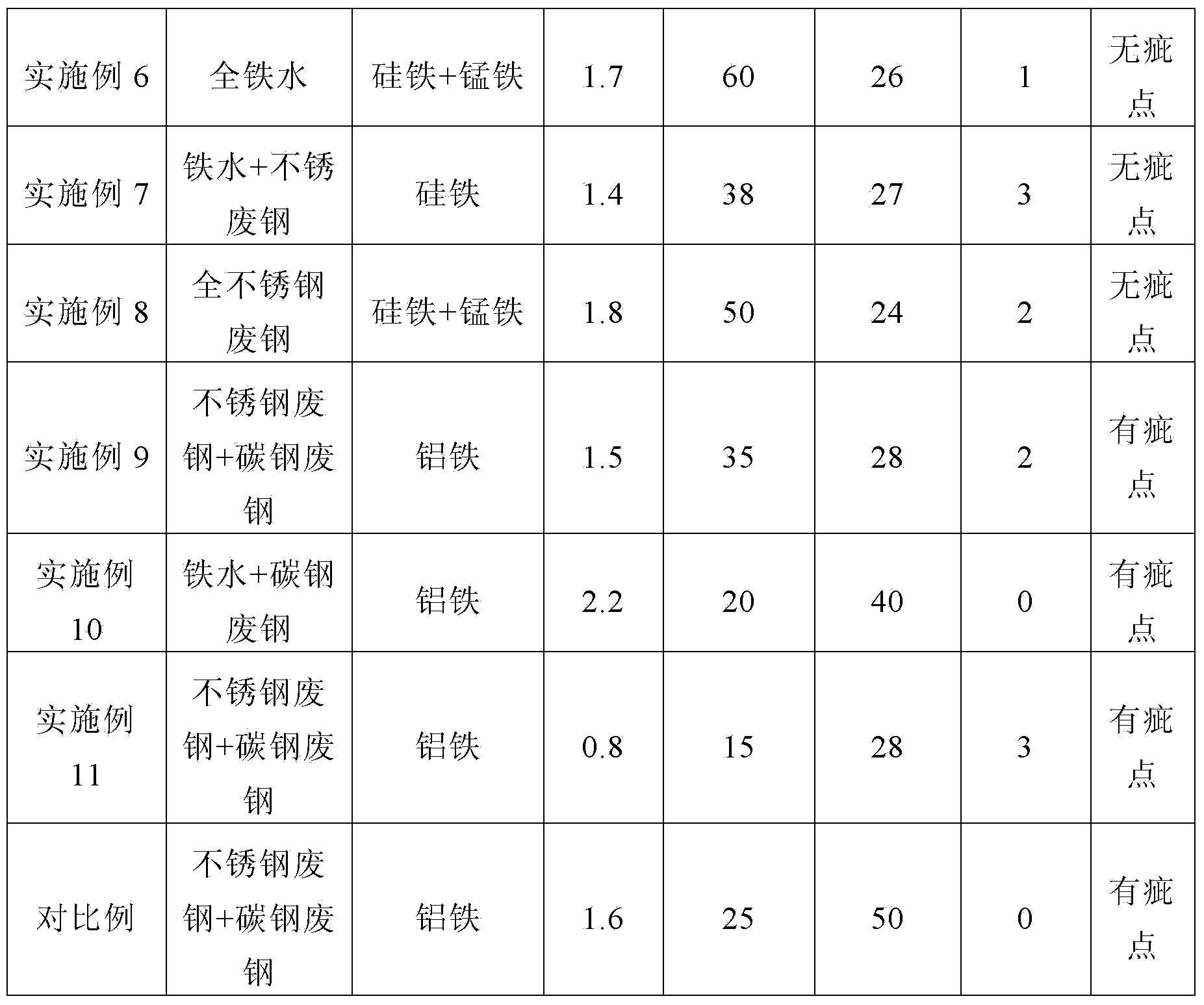

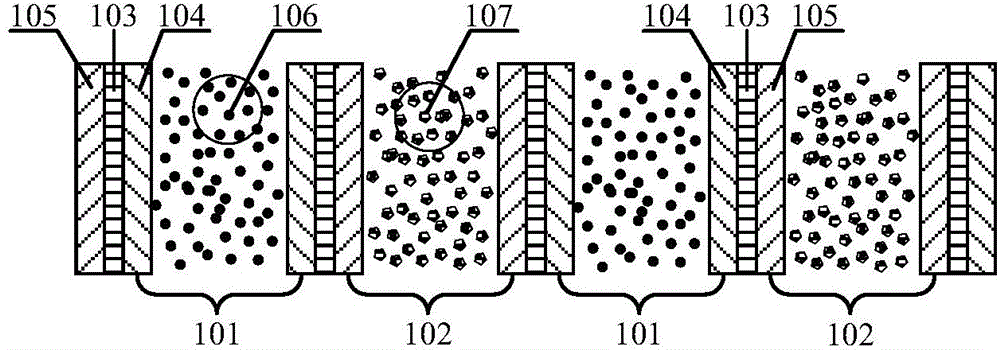

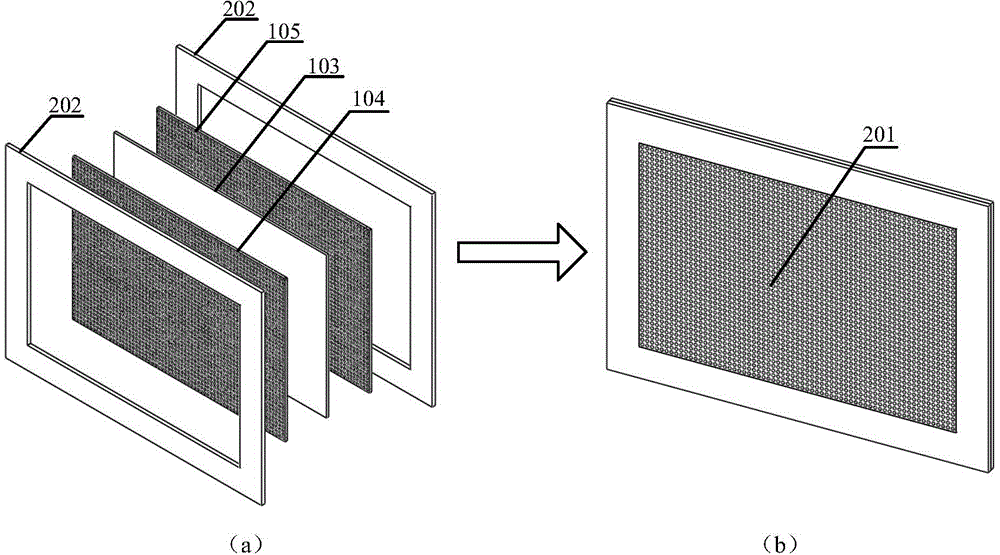

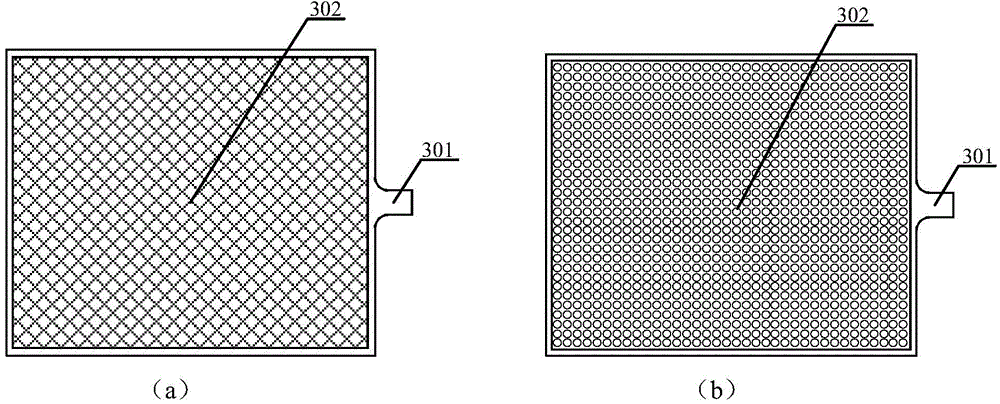

Austenitic stainless steel with excellent polishing performance and manufacturing method thereof

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Lithium ion redox flow battery reactor

ActiveCN105489912AImprove flow uniformityImprove performanceRegenerative fuel cellsFuel cell auxillariesLithiumRedox

The invention provides a lithium ion redox flow battery reactor. The lithium ion redox flow battery reactor comprises a bipolar diaphragm, a positive electrode flow deflector and a negative electrode flow deflector, wherein the flow deflector is formed by multiple flowing channel ridges in a concentric-square-shaped frame; the flow deflector is divided into multiple parallel flow diversion channels by the flowing channel ridges; a liquid inlet and a liquid outlet are formed in the flow deflector frame corresponding to the two ends of each flow diversion channels; and the adjacent positive electrode flow deflectors or the adjacent negative electrode flow deflectors are communicated in series on the same side through communicating structures. According to the lithium ion redox flow battery reactor, each battery reaction cavity is equipped with a group of liquid inlets and liquid outlets, and the electrode suspension liquid communicating structure, so that electrode suspension liquid does not need to pass through a flow division cavity and a flow confluence cavity, instead, the electrode suspension liquid directly enters the electrode reaction cavity, so that the flow division cavity and the flow confluence cavity are eliminated, the consistency among the battery units is effectively improved, the battery performance is improved, and the structure of the reactor is greatly simplified.

Owner:南京竞予能源有限公司

Movable gas introduction structure and substrate processing apparatus having same

ActiveUS8568554B2Reduce spawn rateIncrease freedomElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasProcess engineering

In a gas introduction structure that is reciprocatingly movable in a predetermined direction, a processing gas introduction system is configured to introduce a processing gas into a processing chamber in which a substrate is subjected to a predetermined processing under a clean atmosphere; and a processing gas supply line is configured to be connected to the processing gas introduction system and an external processing gas supply source to supply the processing gas from the processing gas supply source to the processing gas introduction system, mutual relative positions of the processing gas supply source and the processing gas introduction system being changed. The processing gas supply line includes: a first bendable portion connected to the processing gas supply source; a second bendable portion connected to the processing gas introduction system; and a non-bendable pipe interposed between the first bendable portion and the second bendable portion.

Owner:TOKYO ELECTRON LTD

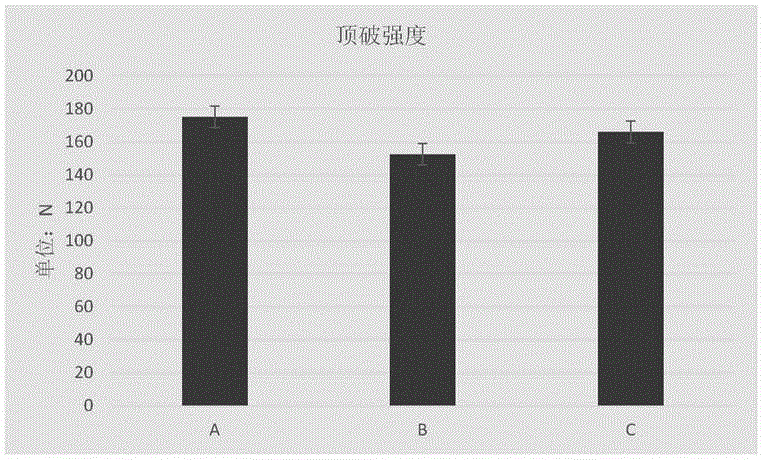

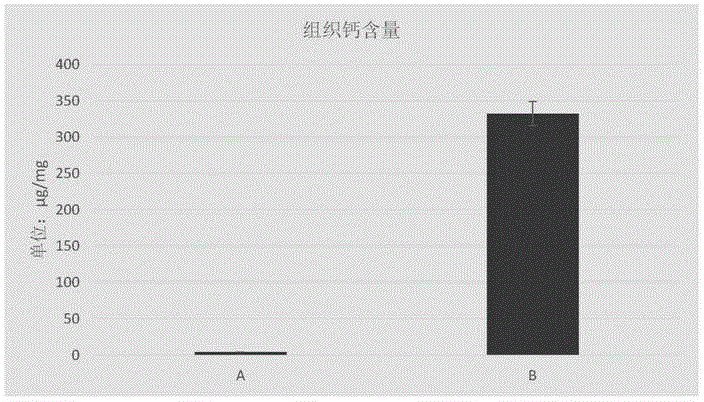

Decellularized anti-calcification heart patch and preparation method thereof

ActiveCN104998299ASuitable degradation cycleSlightly altered collagen structureProsthesisActive agentHeart chamber

The invention relates to a preparation method of a decellularized anti-calcification heart patch. The method mainly comprises the steps that raw material pericardial tissue is degreased through an organic reagent and processed by a mixed solution of a high salt, a surface active agent and alkali, and finally sterilization treatment is performed to obtain the decellularized anti-calcification heart patch. According to the obtained heart patch, due to the special decellularized anti-calcification technology, the collagenous fiber three-dimensional pore structure of the raw materials is reserved, meanwhile, cells contained in the materials are effectively removed, and the immunogenicity is lowered; the materials can guide cells to grow in the materials, scar tissue generation is reduced, and the good anti-calcification ability is achieved; the excellent mechanical property is achieved, arterio-venous pressure difference between heart chambers can be resisted, and the repair effect is ensured. The preparation method is applicable to atrial septal defects, ventricular septal defects, aortic stenosis and the like caused by the congenital heart disease.

Owner:SHAANXI BOYU REGENERATIVE MEDICINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com