Positive electrode material and lithium ion secondary battery

A cathode material and cathode current collector technology, applied in the field of cathode materials and lithium ion secondary batteries, can solve the problems of reducing the ability of lithium ion secondary batteries to absorb electrolyte, increase electrolyte consumption, poor structural stability, etc., and achieve improvement. Rate performance, improved storage performance, effect of high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

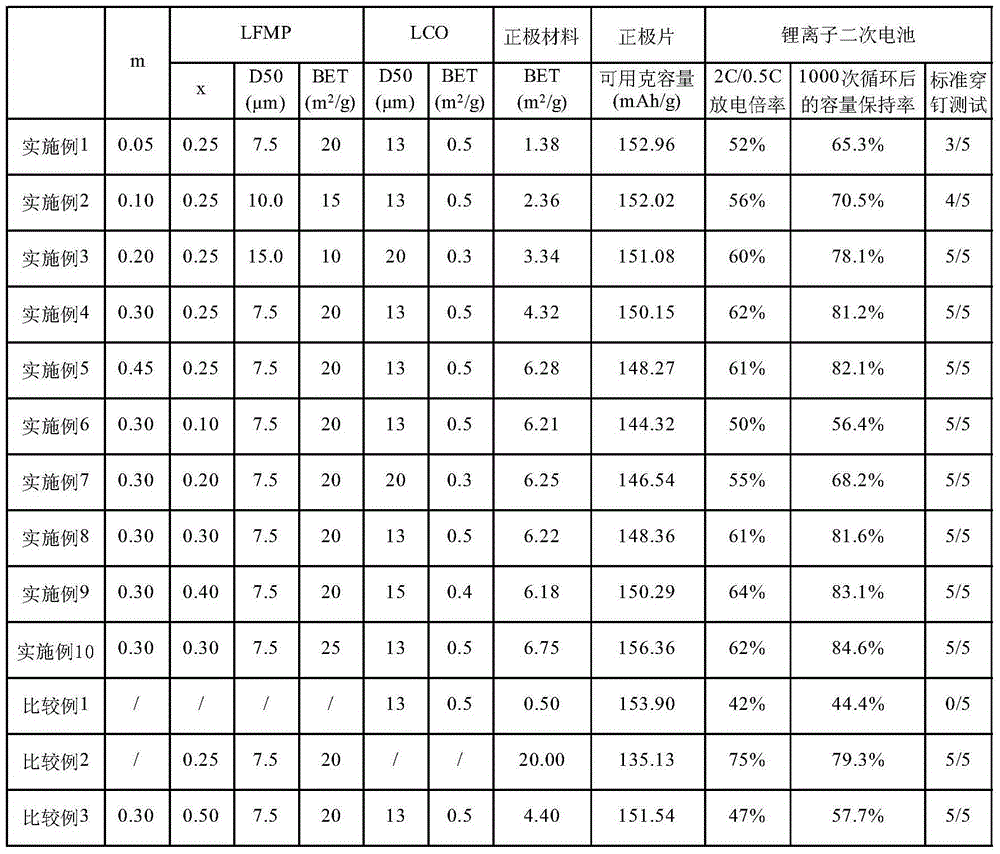

Embodiment 1

[0036] 1. Preparation of positive electrode sheets for lithium-ion secondary batteries

[0037] will include LiCoO 2 and LiFe 0.25 mn 0.75 PO 4 Cathode materials (among them, LiFe 0.25 mn 0.75 PO 4 and LiCoO 2 The mass ratio of LiCoO is 0.05; 2 The average particle size D50 of the polycrystalline particles is 13 μm, and the specific surface area BET is 0.5m 2 / g; LiFe 0.25 mn 0.75 PO 4 The polycrystalline particles are oblate secondary polycrystalline particles, the average particle size D50 of the polycrystalline particles is 7.5 μm, and the specific surface area BET is 20m 2 / g; LiFe 0.25 mn 0.75 PO 4 The polycrystalline particles in LiCoO 2 Uniform and continuous distribution between polycrystalline particles), binder PVDF, conductive agent Super-P and solvent NMP are mixed and stirred evenly at a mass ratio of 21.8:1.6:1.6:75.0 to make a positive electrode slurry, and then the positive electrode slurry is uniformly Coating on the front and back surfaces of ...

Embodiment 2

[0045] Lithium-ion secondary battery was prepared according to the method of Example 1, but in the step of preparing the positive electrode sheet of lithium-ion secondary battery (i.e. step 1), LiFe 0.25 mn 0.75 PO 4 and LiCoO 2 The mass ratio is 0.10, LiFe 0.25 mn 0.75 PO 4 The average particle size D50 is 10.0μm, and the specific surface area BET is 15m 2 / g.

Embodiment 3

[0047] Lithium-ion secondary battery was prepared according to the method of Example 1, but in the step of preparing the positive electrode sheet of lithium-ion secondary battery (i.e. step 1), LiFe 0.25 mn 0.75 PO 4 and LiCoO 2 The mass ratio of LiCoO is 0.20; 2 The average particle size D50 of the polycrystalline particles is 20μm, and the specific surface area BET is 0.3m 2 / g; LiFe 0.25 mn 0.75 PO 4 The average particle size D50 is 15.0μm, and the specific surface area BET is 10m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com