Production method of graphene-aluminum composite

An aluminum composite material, graphene technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problem that the enhancement effect of graphene is not fully reflected, the interface bonding ability is poor, the material uniformity is poor, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

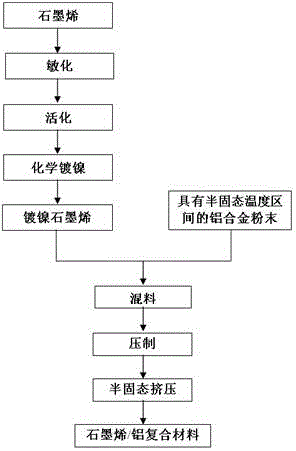

Method used

Image

Examples

Embodiment 1

[0058] (1) Graphene electroless nickel plating

[0059] a. Sensitization: control SnCl 2 Sensitizer (SnCl 2 Concentration of 15g / L, HCl concentration of 10mg / L) and temperature of 20°C, graphene was added in an amount of 11mg / mL and ultrasonically oscillated for 30min, filtered, and washed with deionized water until neutral.

[0060] b. Activation: control PbCl 2 Activation solution (PbCl 2 The concentration is 0.1g / L, the concentration of HCl is 10 mL / L) and the temperature is 20°C. Add the sensitized graphene in the amount of 11 mg / mL and ultrasonically vibrate for 30 minutes, filter, and wash with deionized water until neutral .

[0061] c. Electroless nickel plating: add the sensitized and activated graphene to the electroless nickel plating solution (the concentration of nickel chloride is 25g / L, the concentration of sodium hypophosphite is 30g / L, and the concentration of glycolic acid is 15g) / L), stirring, the pH value of the plating solution was adjusted to 8 with...

Embodiment 2

[0066] (1) Graphene electroless nickel plating

[0067] a. Sensitization: control SnCl 2 Sensitizer (SnCl 2 Concentration of 24g / L, HCl concentration of 19mL / L) and temperature of 23°C, graphene was added in an amount of 12mg / mL and ultrasonically oscillated for 35min, filtered, and washed with deionized water until neutral.

[0068] b. Activation: control PbCl 2 Activation solution (PbCl 2 The concentration is 0.4g / L, the concentration of HCl is 20 mL / L) and the temperature is 23°C. Add the sensitized graphene in an amount of 12mg / mL and ultrasonically vibrate for 35min, filter, and wash with deionized water until neutral .

[0069] c. Electroless nickel plating: Add the sensitized and activated graphene to the electroless nickel plating solution in an amount of 7mg / mL (the concentration of nickel chloride is 28g / L, the concentration of sodium hypophosphite is 33g / L, and the concentration of glycolic acid is 21g / L), stirring, the pH value of the plating solution was adj...

Embodiment 3

[0074] (1) Graphene electroless nickel plating

[0075] a. Sensitization: control SnCl 2 Sensitizer (SnCl 2 Concentration of 33g / L, HCl concentration of 28mL / L) and temperature of 25°C, graphene was added in an amount of 13mg / mL and ultrasonically oscillated for 40min, filtered, and washed with deionized water until neutral.

[0076] b. Activation: control PbCl 2 Activation solution (PbCl 2 The concentration is 0.7g / L, the concentration of HCl is 30mL / L) and the temperature is 25°C. The sensitized graphene is added in an amount of 13mg / mL and ultrasonically oscillated for 40min, filtered, and washed with deionized water until neutral.

[0077] c. Electroless nickel plating: add the sensitized and activated graphene to the electroless nickel plating solution (the concentration of nickel chloride is 30g / L, the concentration of sodium hypophosphite is 35g / L, and the concentration of glycolic acid is 27g) / L), stirring, the pH value of the plating solution was adjusted to 9 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com