Patents

Literature

34results about How to "Quarantine direct contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

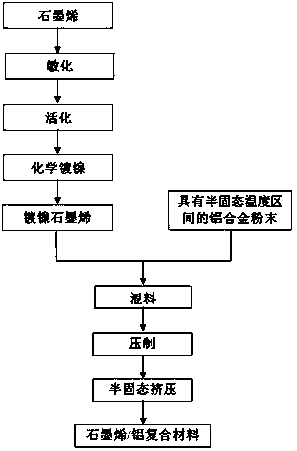

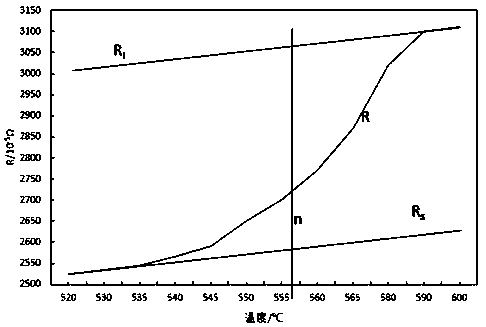

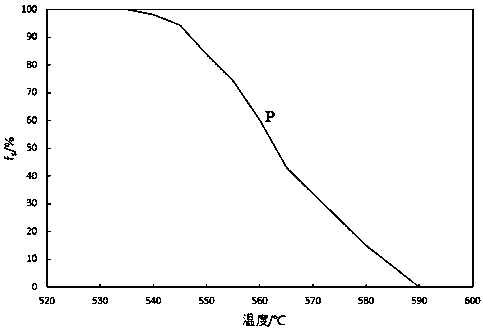

Production method of graphene-aluminum composite

ActiveCN106513621AOvercome the disadvantage of being easy to pull out from the aluminum alloy matrixTake full advantage of enhanced capabilitiesLiquid/solution decomposition chemical coatingElectricityMetal matrix composite

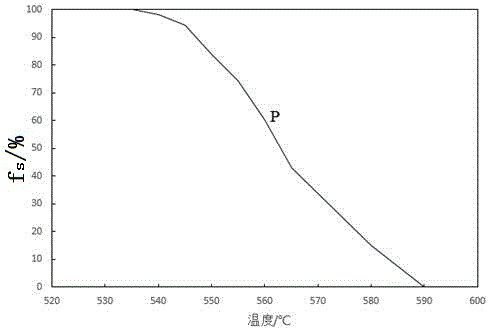

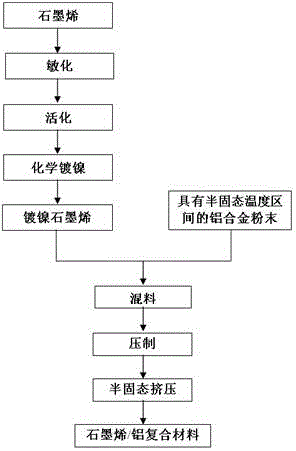

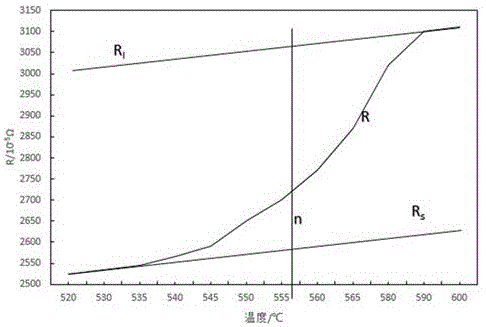

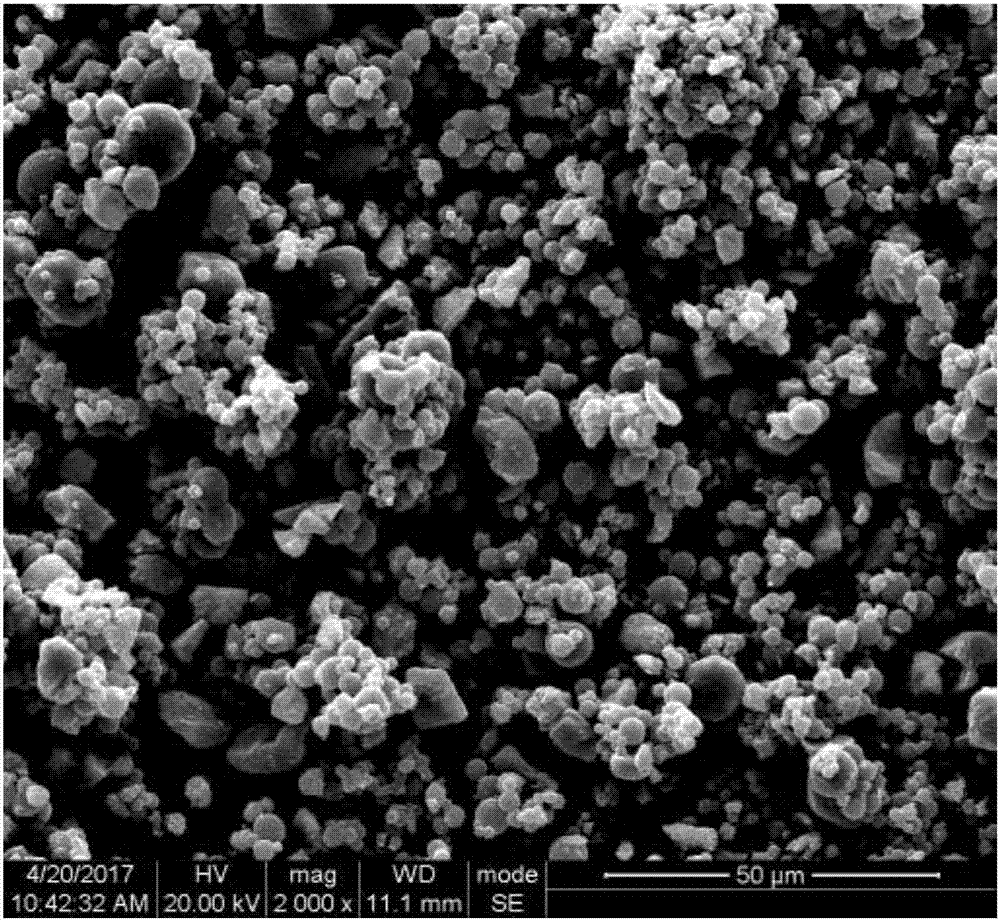

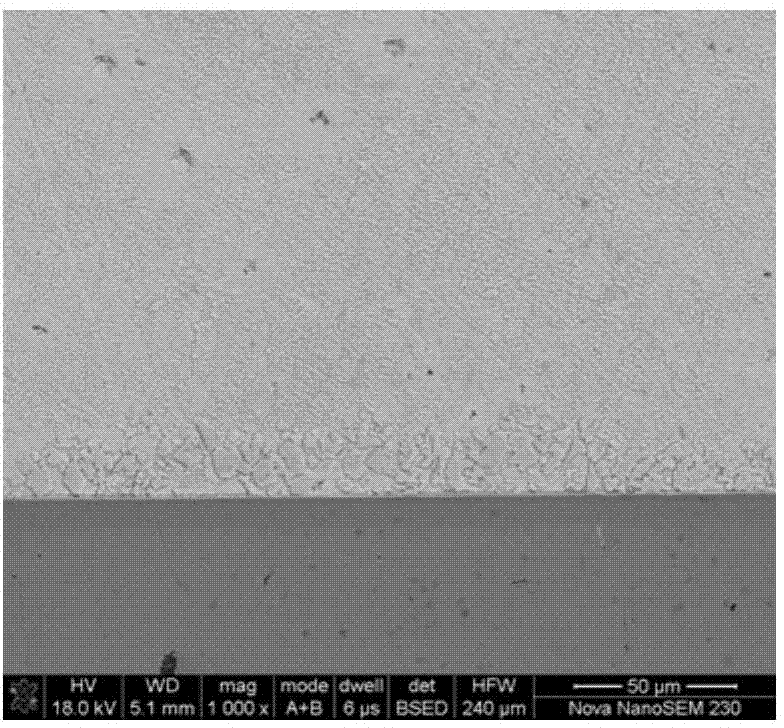

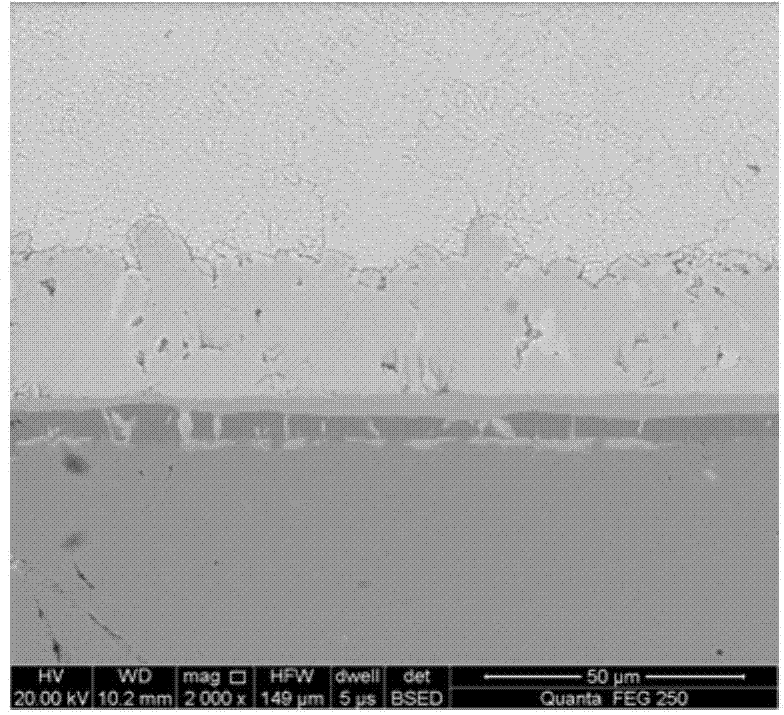

The invention discloses a production method of a graphene-aluminum composite, and belongs to the field of metal-matrix composites. Aluminum alloy powder with the semisolid temperature interval and graphene are adopted as raw materials. The method mainly includes the steps of 1, chemical nickel plating of the graphene; 2, mixing; 3, pressing; and 4, semisolid extruding. According to the graphene-aluminum composite produced through the method, the wettability and the metallurgical bonding strength of the nickel-plated graphene and aluminum alloy are high, the nickel-plated graphene is uniformly distributed in the matrix aluminum alloy, the microstructure is compact, the specific strength and the specific stiffness are high, and the thermal conductivity and the electrical conductivity are good. Thus, the graphene-aluminum composite has wide application prospects in the fields of the national defense and military industry, aerospace, electricity and heat exchange.

Owner:KUNMING UNIV OF SCI & TECH

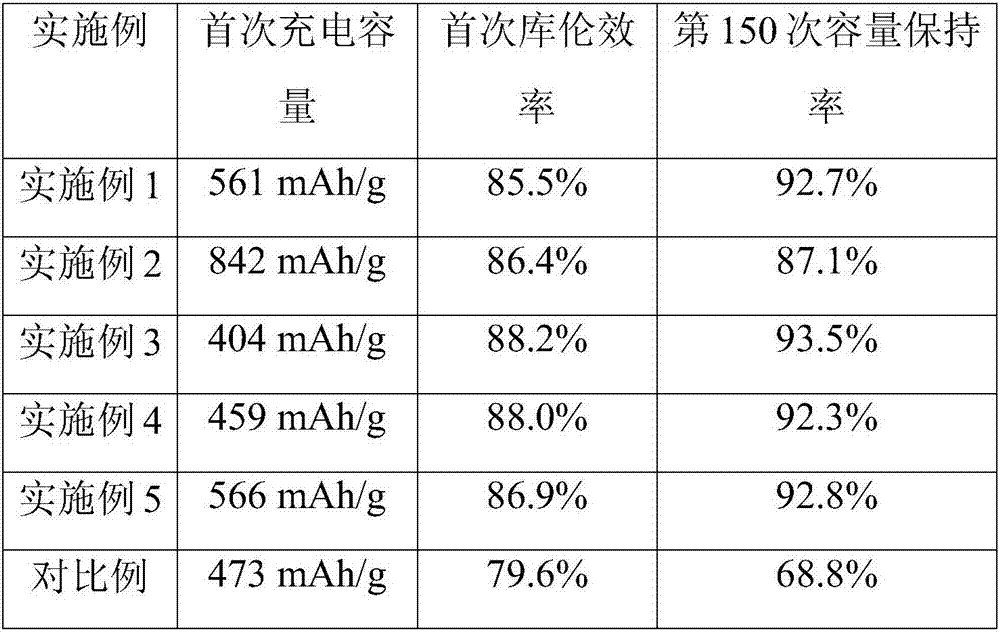

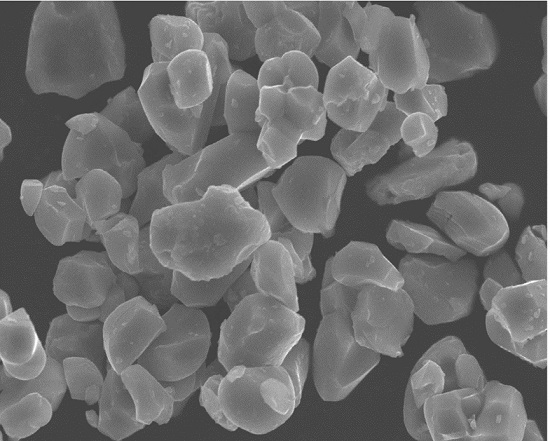

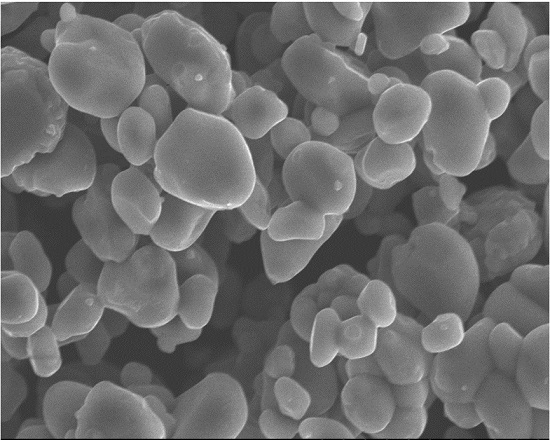

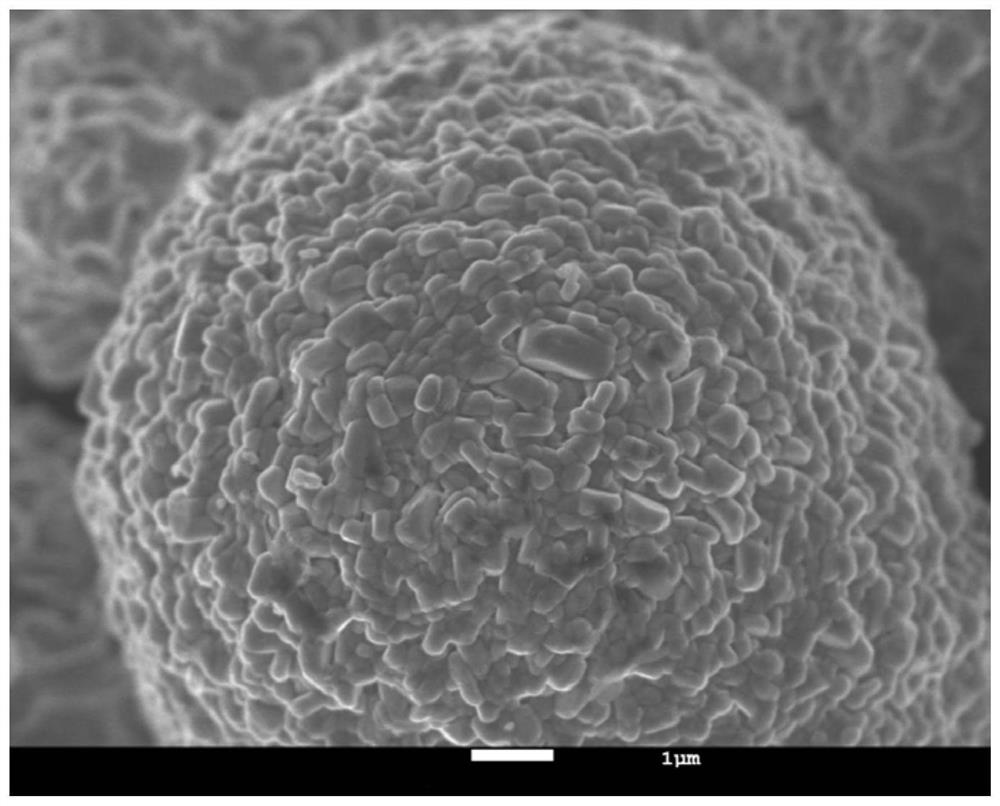

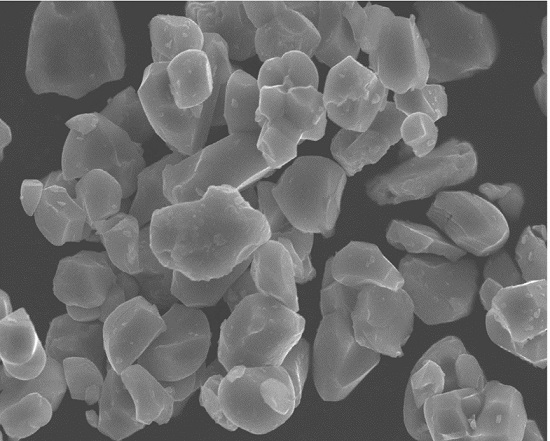

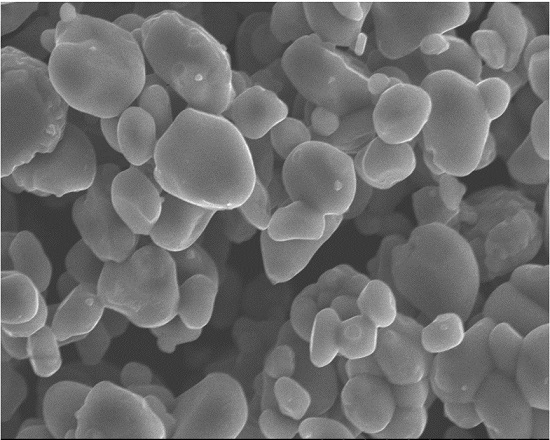

Three-dimensional spherical silicon-carbon composite negative electrode material and preparation method therefor

InactiveCN107230781ASmall specific surface areaImprove the first Coulombic efficiencyGraphiteCell electrodesCarbon sourceLithium electrode

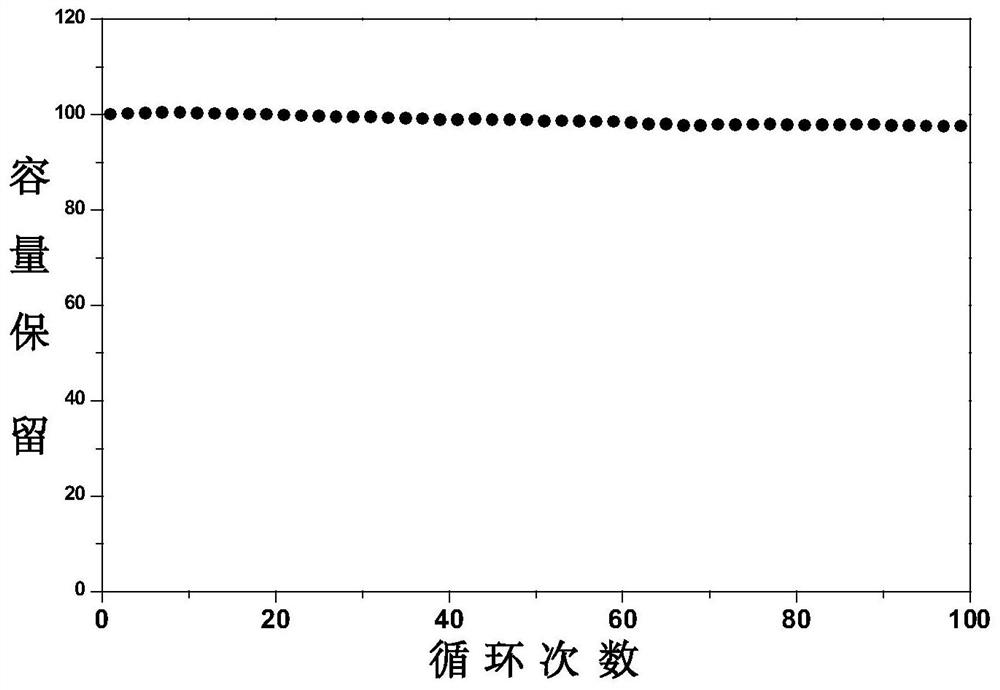

The invention discloses a three-dimensional spherical silicon-carbon composite negative electrode material and a preparation method therefor, and belongs to the field of the lithium ion battery negative electrode material. The composite negative electrode material consists of graphite, silicon and amorphous state carbon, wherein graphite and silicon are coated in the amorphous state carbon. The preparation method comprises the steps of dispersing nanometer silicon and a carbon source into an organic solvent, performing spray drying to obtain a Si@C precursor, and performing carbonization to obtain a Si@C material, wherein the volume expansion effect of silicon can be effectively relieved by the surface carbon layer; and next, dispersing the Si@C material, graphite and the carbon source into the organic solvent, performing spray drying to obtain a silicon-carbon composite negative electrode material precursor, and performing carbonization to obtain the three-dimensional spherical silicon-carbon composite negative electrode material. By virtue of the dual-layer amorphous state carbon layers, the volume expansion effect of silicon in the charge-discharge process can be effectively relieved; the amorphous state carbon layer on the outer layer has small specific surface area, so that high irreversible capacity loss is avoided; and therefore, the obtained material has relatively high specific capacity and initial efficiency and excellent cycling stability.

Owner:CHENGDU GUIBAO SCI & TECH +1

Lithium ion battery with adoption of secondary electrolyte injection

ActiveCN102255105AImprove conductivityReduce restrictionsSecondary cellsCell component detailsPropionitrileEthyl propionate

The invention discloses a lithium ion battery with adoption of secondary electrolyte injection, comprising a positive pole, a negative pole, a diaphragm, an electrolyte and an outer package. In the process of manufacturing the battery, the secondary electrolyte injection is adopted; the electrolyte solvent in the first electrolyte injection is one or a combination of more than one of EC (ethylene carbonate), PC (propylene carbonate), DMC (dimethyl carbonate), DEC (diethyl carbonate), EMC (ethyl methyl carbonate), Gamma-BL (butyrolactone), MF (methyl formate), MA (methyl acetate), EP (ethyl propionate) and THF (tetrahydrofuran) and does not contain acetonitrile and propionitrile; the secondary electrolyte injection is conducted after the formation; and the used electrolyte in the secondary electrolyte injection contains at least one of the acetonitrile and the propionitrile. The electrolyte containing the at least one of the acetonitrile and the propionitrile has the advantage of high normal-temperature conductivity (10-50mS / cm) and low-temperature conductivity (4-20mS / cm at the temperature of -20 DEG C), thereby exceeding the level of an existing electrolyte.

Owner:DONGGUAN AMPEREX TECH +1

Double-layer structure sagger for lithium battery positive electrode material and preparation method of double-layer structure sagger

ActiveCN113372105AOvercome the disadvantage of easy to take offExtended service lifeCharge supportsCordieriteCorrosion resistant

The invention relates to the technical field of sagger kiln furniture preparation, and provides a double-layer structure sagger for a lithium battery positive electrode material and a preparation method of the double-layer structure sagger. The double-layer structure sagger for the lithium battery positive electrode material comprises a base body layer and a surface coating. The preparation method of the double-layer structure sagger for the lithium battery positive electrode material comprises the steps of premixing aggregate, processing and forming, mixing and pulping a surface coating, drying, sintering at high temperature and the like. The sagger with the double-layer structure for the positive electrode material of the lithium battery, which is prepared by adopting the method, has good corrosion resistance of resisting erosion of Li<+>, Co<2+> and the like, is high in cycle use frequency, long in service life, relatively small in thermal expansion coefficient, excellent in thermal shock resistance and certain in bearing strength, the positive electrode material is easy to peel off when being in contact with the sagger, the sagger is not peeled off in the use process, no slag falling and no pollution is generated, the product is an ideal improved product of the current cordierite-mullite sagger, is suitable for the sintering process of various lithium battery cathode materials, and is beneficial to reducing the production cost and improving the economic benefit.

Owner:阳泉银宇新材料有限责任公司

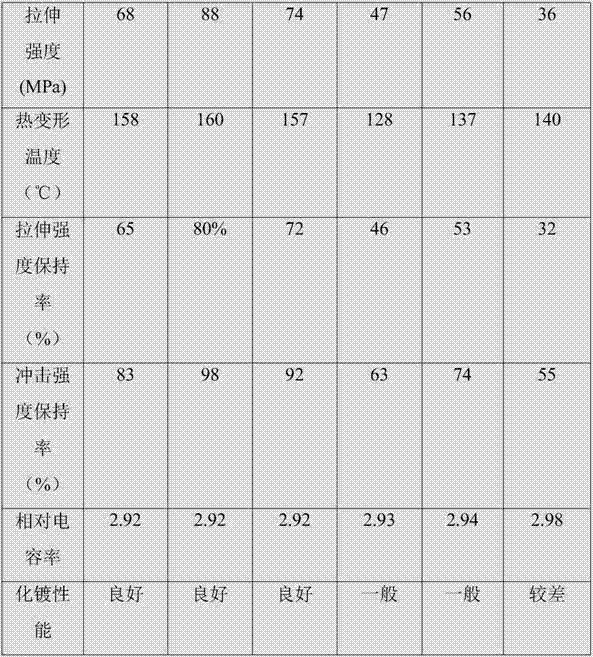

PC composite material used for laser direct forming and preparation technology thereof

The invention relates to the field of new plastic materials, and specifically relates to a PC composite material used for laser direct forming and a preparation technology thereof. The PC composite material used for laser direct forming is prepared from the following components in parts by weight: 50 to 80 parts of PC, 10 to 50 parts of basalt fiber, 3 to 8 parts of a laser additive, 0.5 to 2 parts of an antioxidant, 0.2 to 2 parts of a heat stabilizer, 3 to 8 parts of a flexibilizer, 1 to 2 parts of a lubricating agent, 1 to 2 parts of a coupling agent and 2 to 6 parts of a compatilizer; the antioxidant consists of a hindered phenol antioxidant and a phosphite ester antioxidant; the heat stabilizer consists of a metal compound, a layered double hydroxide and an ultraviolet absorber; and the laser additive is nano-copper powder modified through acrylic ester. The PC composite material used for laser direct forming disclosed by the invention is high in laser-induced electroplating performance, high in heat and oxygen resistant performance, high in aging-resistant performance and high in mechanical performance.

Owner:深圳市华盈新材料有限公司

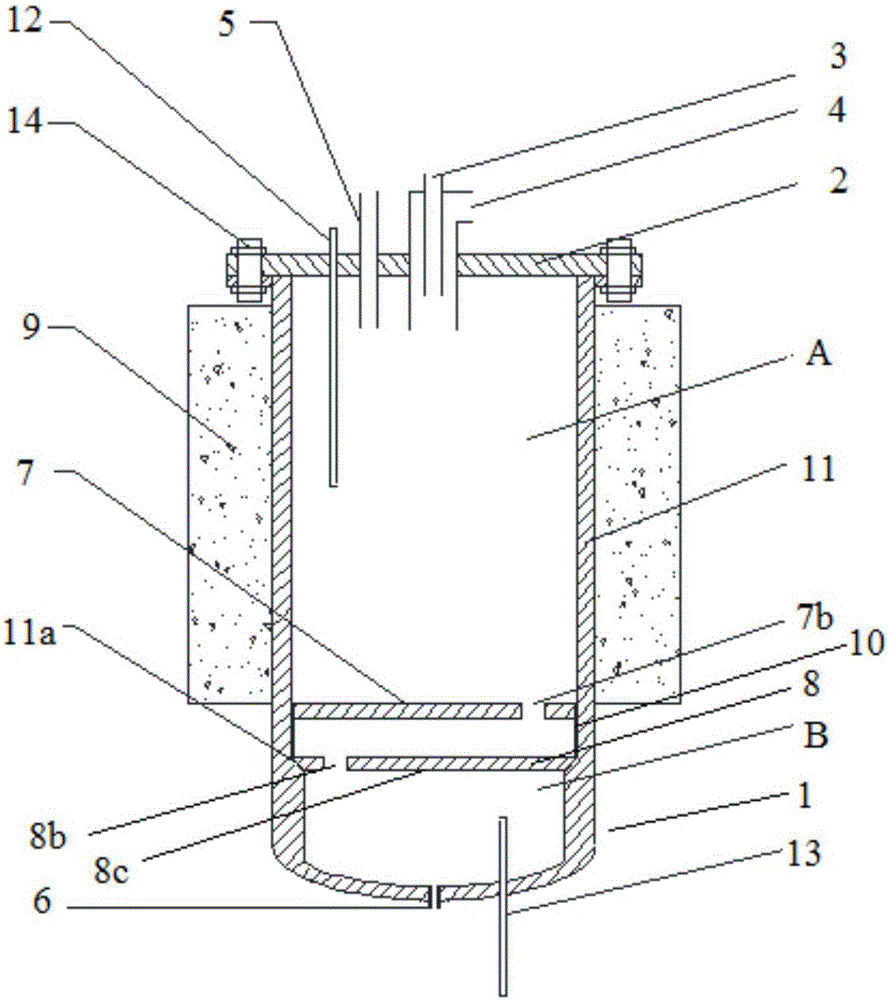

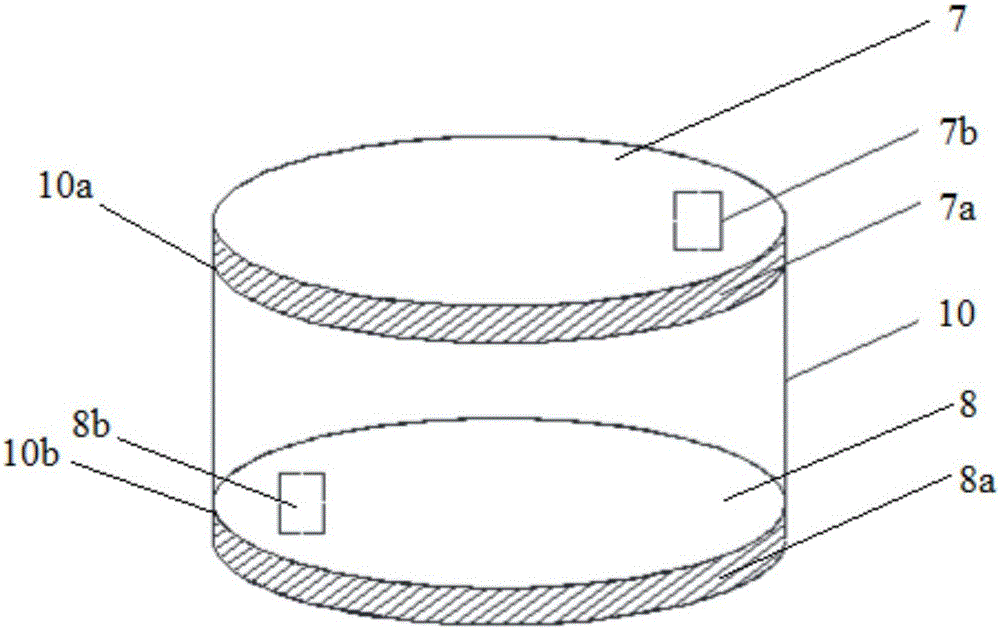

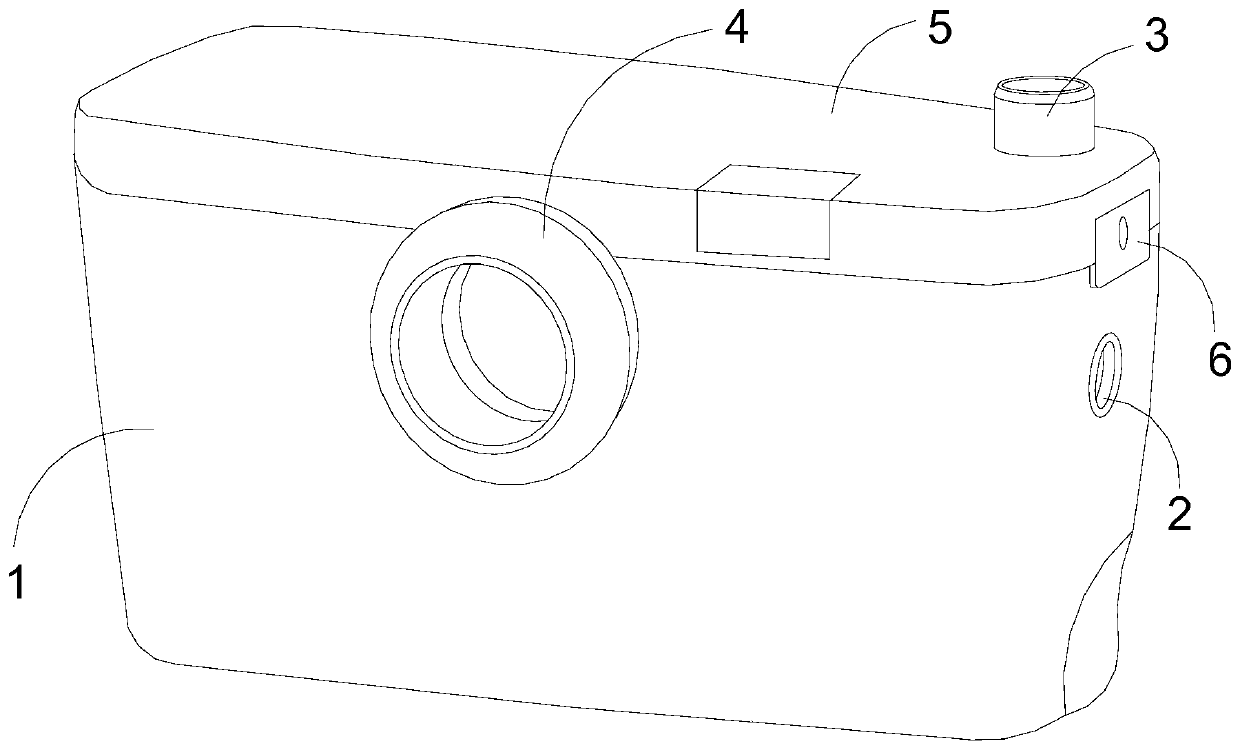

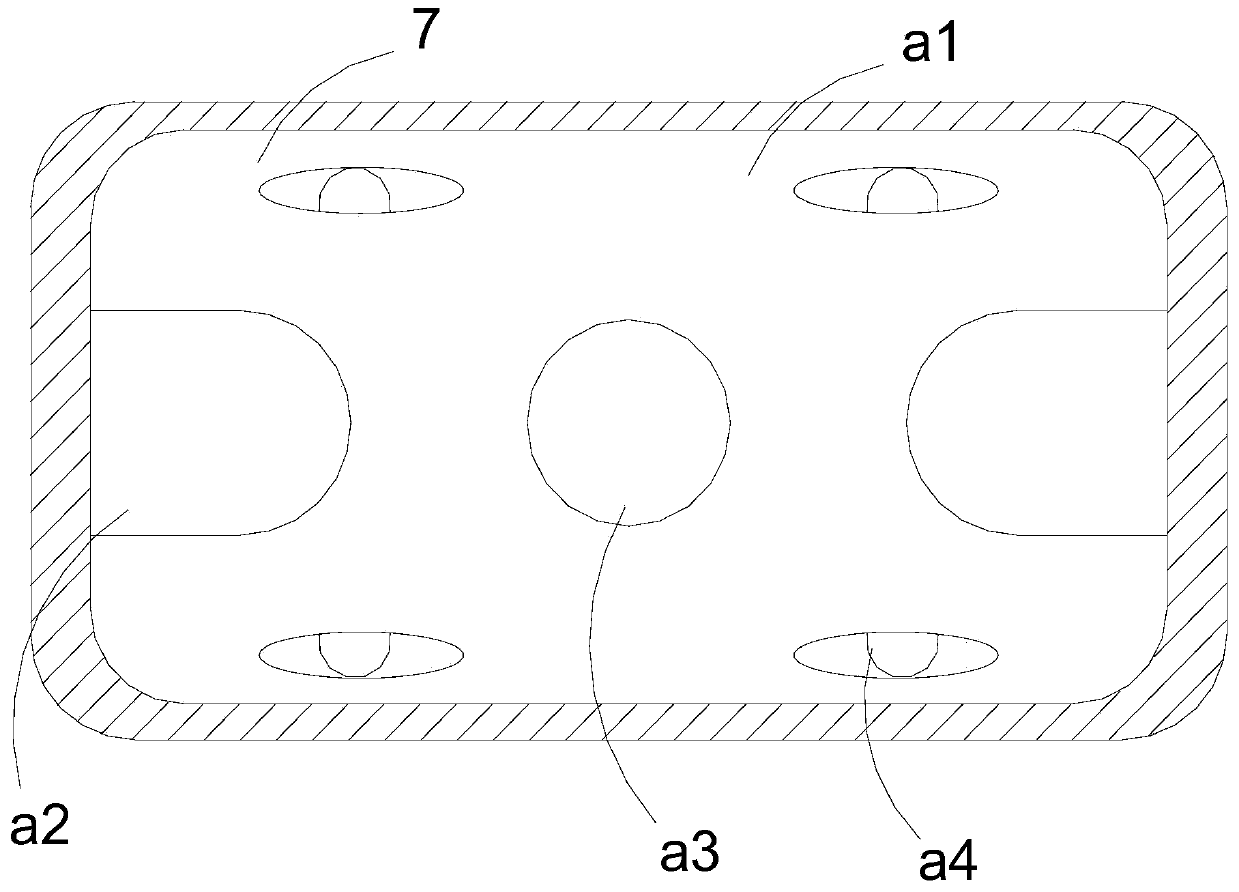

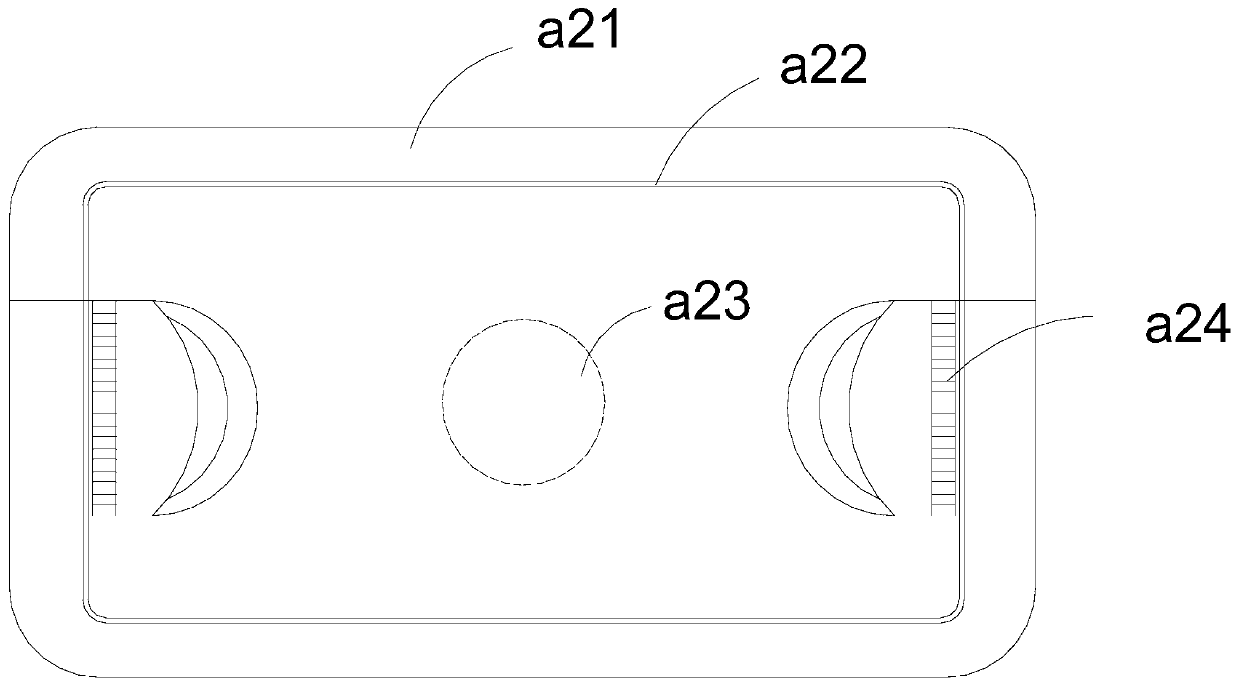

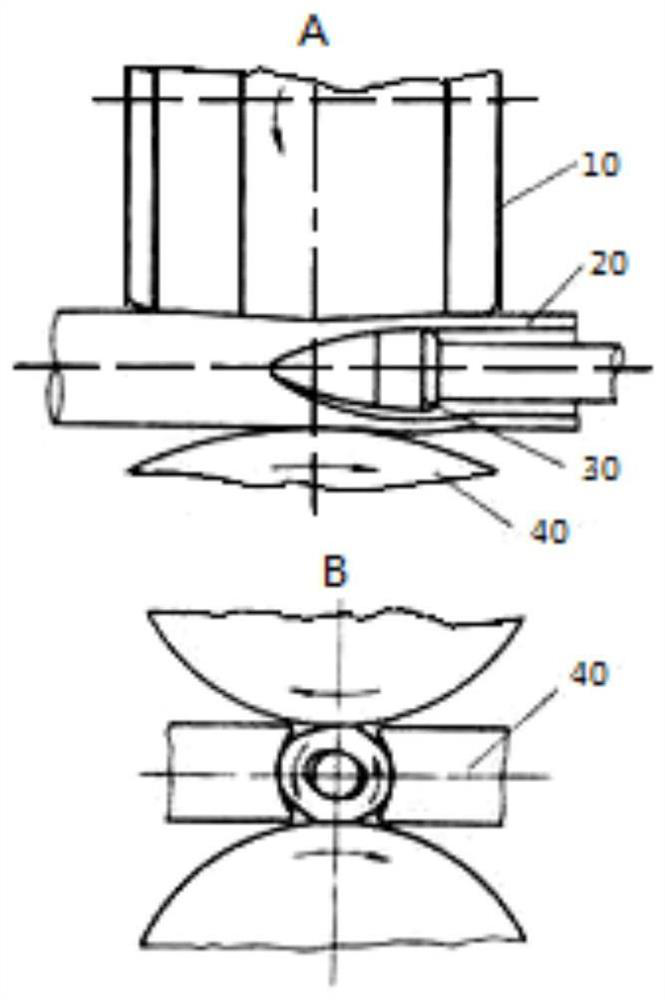

Anti-blocking super-critical water oxidation reactor

ActiveCN105692863ASolve the blockageControl reaction temperatureWater/sewage treatment by oxidationEnvironmental engineeringSupercritical water oxidation

The invention provides an anti-blocking super-critical water oxidation reactor. The anti-blocking super-critical water oxidation reactor comprises a reactor drum, and a reactor drum cover covering the reactor drum. The reactor drum cover is provided with a feed inlet, the bottom of the reactor drum is provided with a reactant outlet. The anti-blocking super-critical water oxidation reactor also comprises at least one partition extending horizontally in the reactor drum, an area above the partitions is a super-critical water oxidation area, and an area below is a sub-critical area. A heating sleeve is arranged on the outer side of the drum body of the super-critical water oxidation area. The outer side of the drum of the sub-critical area directly contacts with the air. The partitions are provided with holes communicated with the super-critical water oxidation area and the sub-critical area. Innovatively, the partitions can divide the inside of the reactor into the super-critical water oxidation area and the sub-critical area, the problem of blockage of the sediment salt to the outflow pipelines is solved, and the novel anti-blocking super-critical water oxidation reactor is provided.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

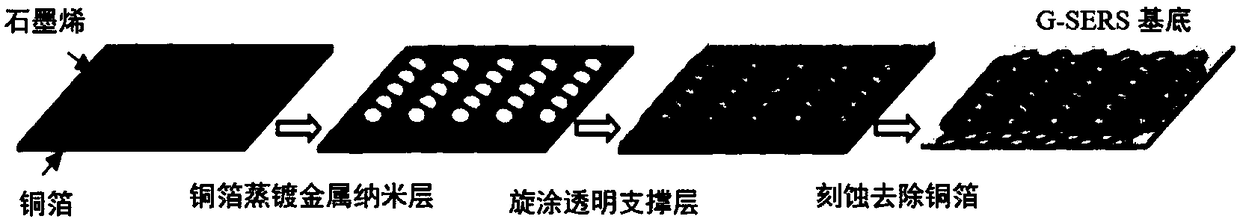

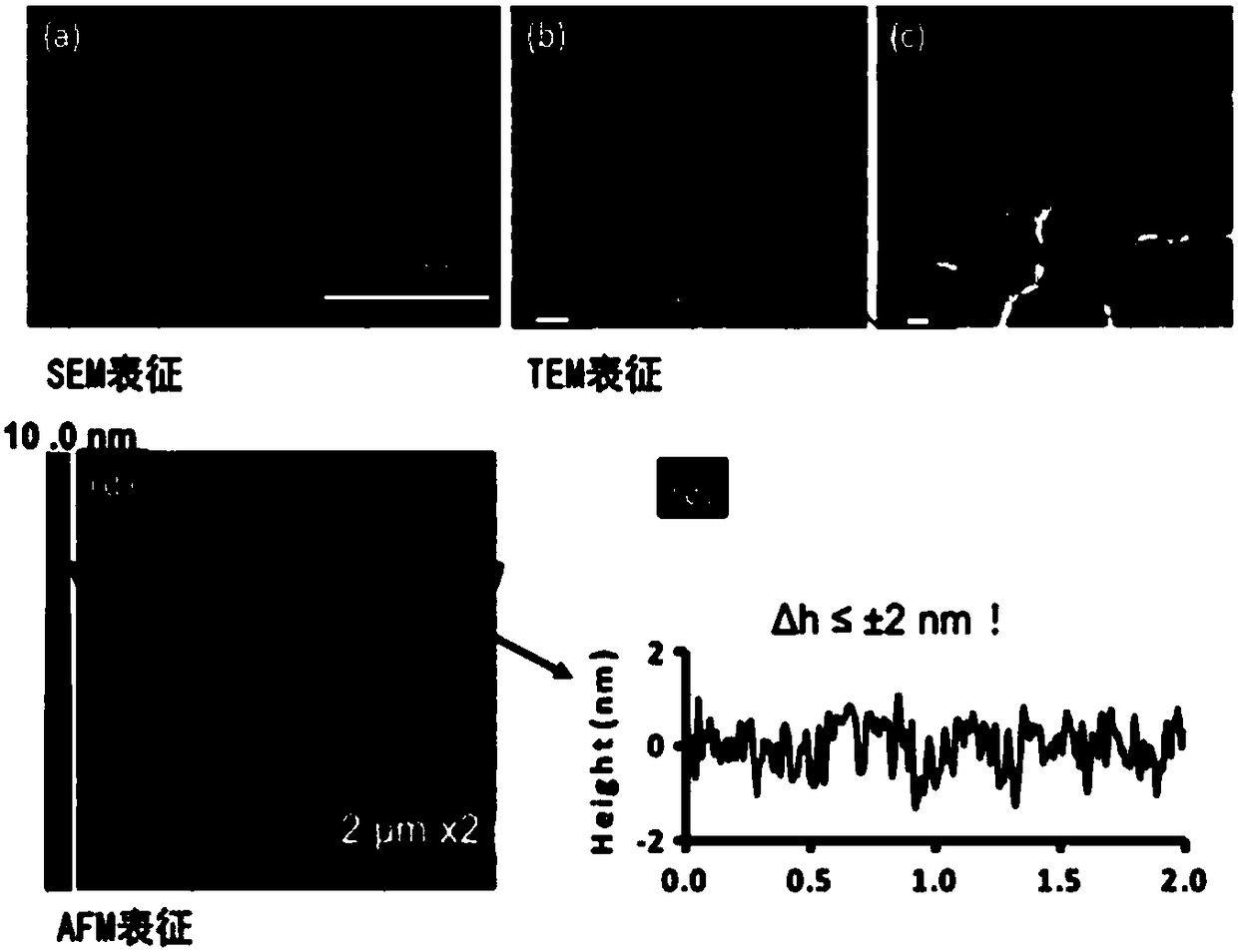

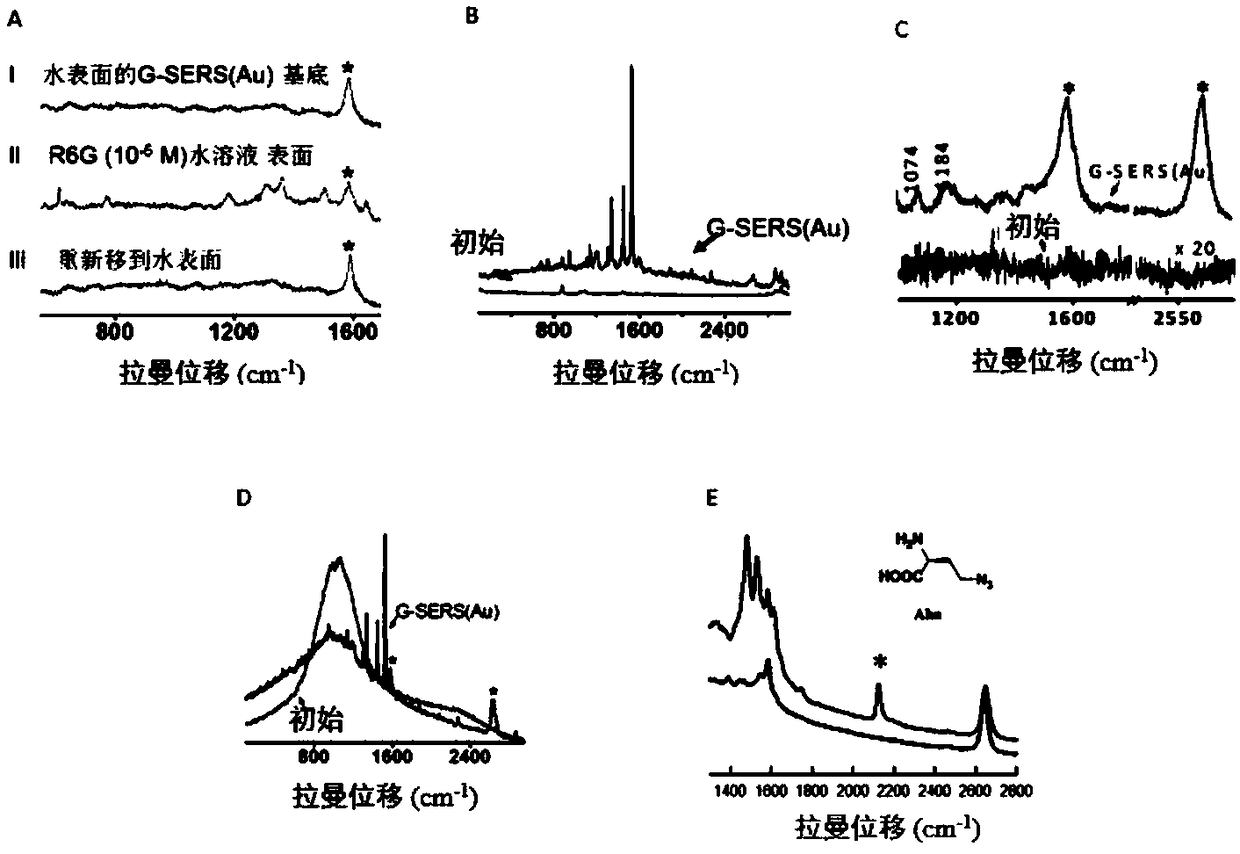

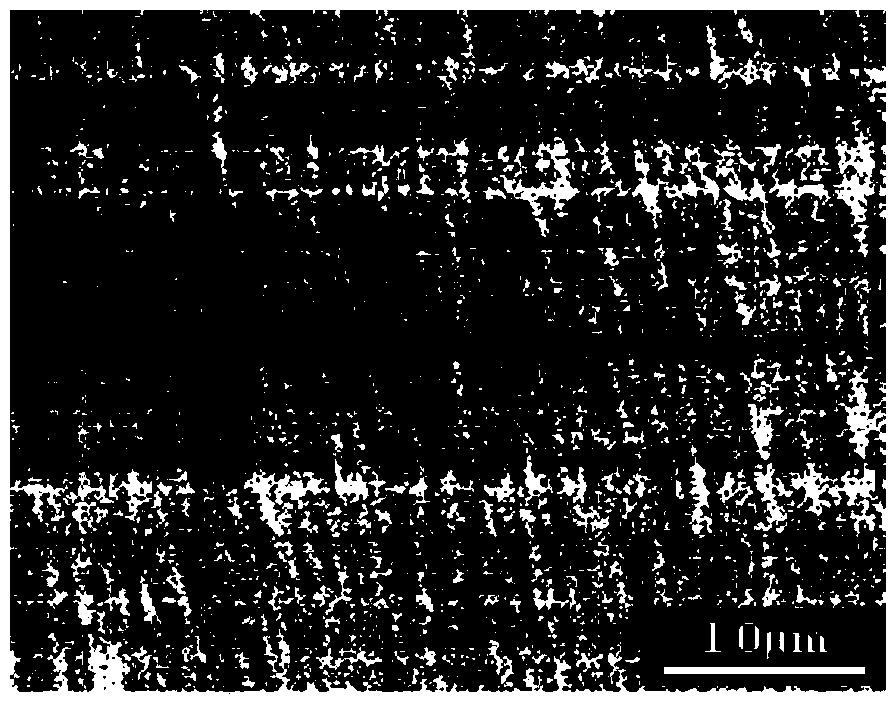

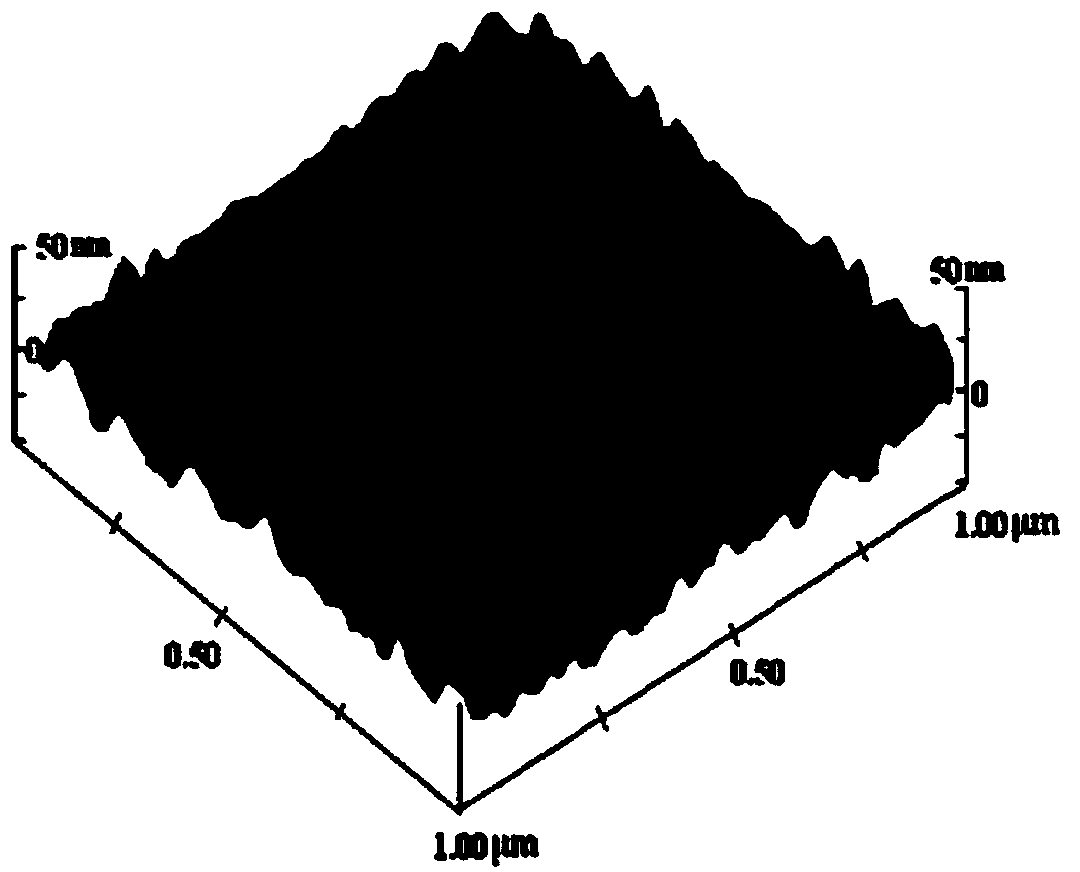

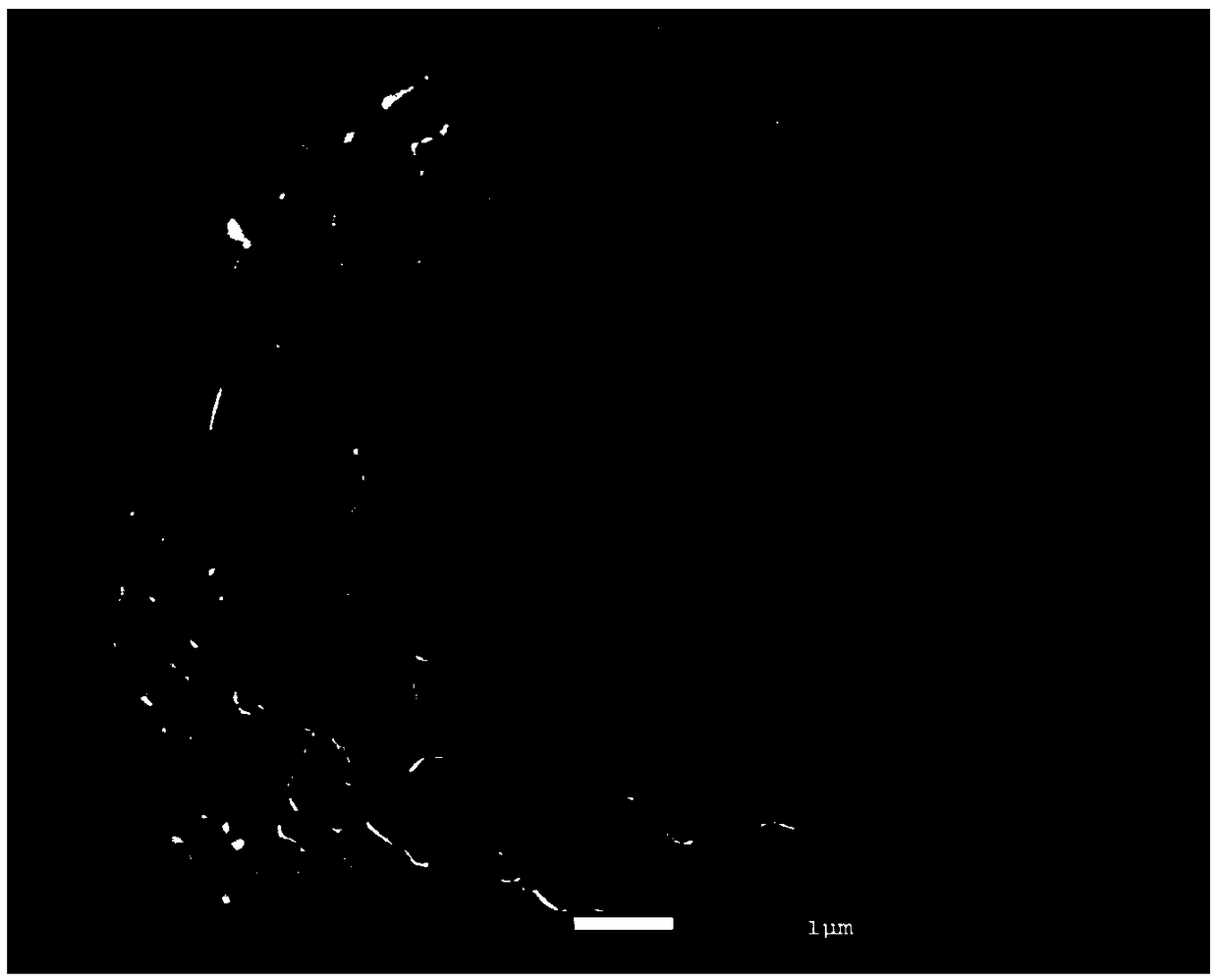

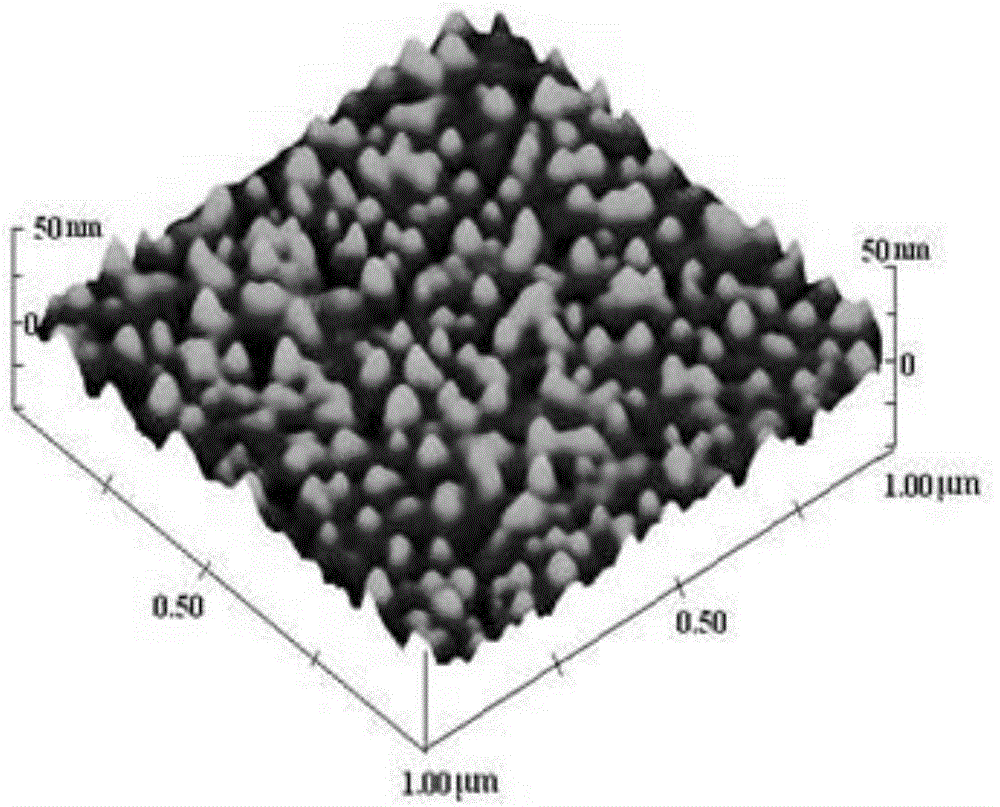

Graphene-based flexible enhanced Raman substrate and preparation method thereof, and Raman analysis method

InactiveCN108507995ARealize online quantitative analysisOvercoming Difficulties in Online Raman MonitoringLiquid surface applicatorsVacuum evaporation coatingNanoparticleCvd graphene

The invention discloses a novel graphene-based flexible enhanced Raman substrate. The flexible substrate comprises a single layer of graphene having a metal plating with a thickness of 1-100 nm; the metal plating is coated with a polymer and comprises a plurality of island-shaped particles; and the sizes of the particles are in a range of 10 to 1000 nm and the spacing among the particles is in a range of 2 to 500 nm. The graphene-based flexible enhanced Raman substrate of the invention quantitatively monitors Raman molecules in a solution on line by employing the novel two-dimensional atomic layer material graphene and utilizing the novel graphene as a substrate of a shell layer, so the application of shell-isolated nanoparticle-enhanced Raman spectroscopy (SHINERS) to the field of Raman quantitative analysis is broadened.

Owner:PEKING UNIV

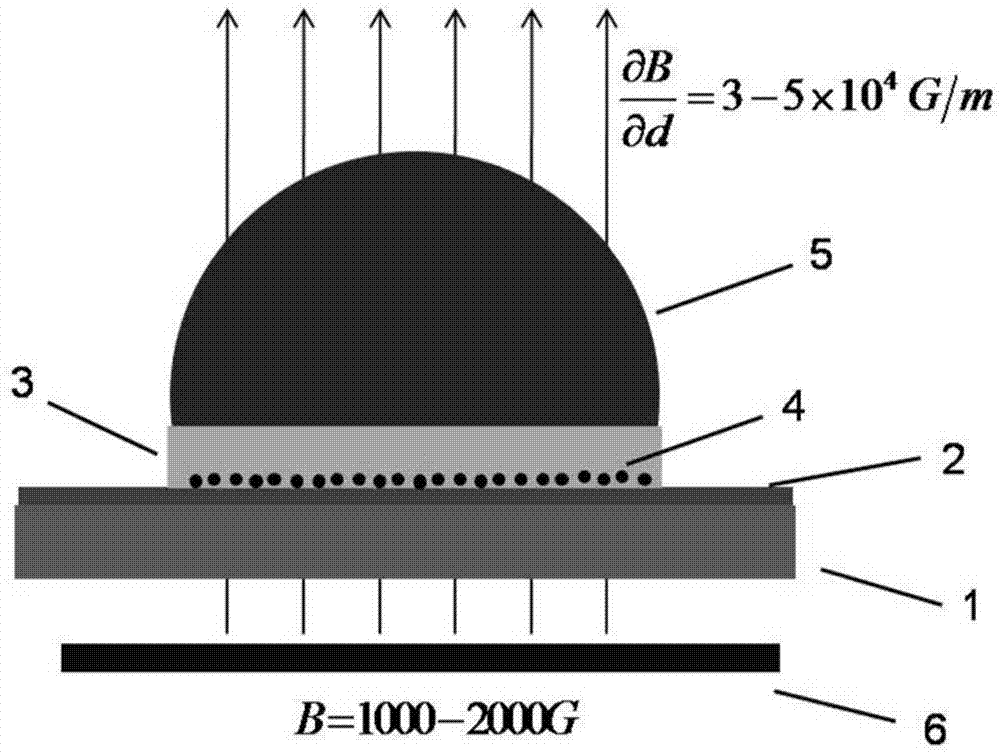

Method for packaging Ni-P substrate

ActiveCN104282582ABarrier to diffusion bondingQuarantine direct contactSolid-state devicesSemiconductor/solid-state device manufacturingElectronic packagingUltimate tensile strength

The invention relates to a method for packaging a Ni-P substrate and belongs to the technical field of electronic packaging. According to the method for packaging the Ni-P substrate, after 5-20 wt % of nano nickel powder and 80-95 wt % of scaling powder are evenly mixed, an Ni-P substrate is coated or printed with the mixture and then is coated or printed with tin-based solder, and then the substrate to be welded is obtained; the substrate to be welded is placed in a static magnetic field, and then reflow soldering is conducted, wherein the gradient of the intensity of the static magnetic field is 3-5*104 G / m, the magnetic induction intensity of the position where the substrate is located ranges from 1000 G to 2000 G, and the magnetic field source is located on the inner side of the Ni-P substrate. According to the method for packaging the Ni-P substrate, the Ni-P wear rate is greatly reduced when welding points are on service, growth of intermetallic compounds is restrained, and layering or stripping of the interface intermetallic compounds is also avoided; the reliability of the welding points is higher, cost is low, production efficiency is high, the technical stability is excellent, and the method is suitable for large-scale industrial application.

Owner:CENT SOUTH UNIV

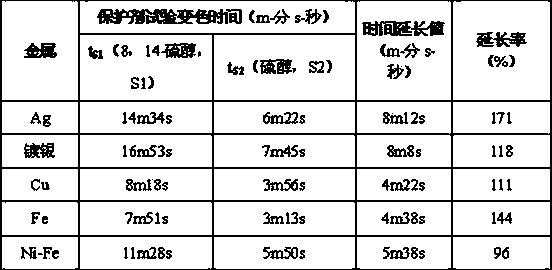

Method for preparing water-soluble molecular self-assembly film type metal protective agent

The invention discloses a method for preparing a water-soluble molecular self-assembly film type metal protective agent. The method comprises the following steps: A, mixing water and an organic solvent of which the mass ratio is (0.5-1.5);10, uniformly stirring, and preparing a mixed solvent; B, adding an emulsifier which accounts for 30-50 percent of the mass of the mixed solvent in the step A, uniformly stirring, and preparing a mixture; C, adding a film agent which accounts for 12-20 percent of the mass of the mixture in the step B, uniformly stirring, and further preparing a mixed solution; and D, adding a surfactant which accounts for 1.5-2.0 percent of the mass of the mixed solution and a reducing agent which accounts for 0.1-0.5 percent of the mass of the mixed solution in the step C, heating under water bath conditions at the temperature of 51-58 DEG C, controlling the temperature of the mixed solution, continuously stirring for 90-150 minutes, thereby obtaining the water-soluble molecular self-assembly film type metal protective agent. The method is simple in process, low in energy consumption and environmental friendly, a molecular self-assembly film can be formed on the metal surface through the protective agent, and the metal is effectively prevented from discoloring. The method is simple in process and large-scale production is easy to realize.

Owner:东莞奕创表面处理科技有限公司 +1

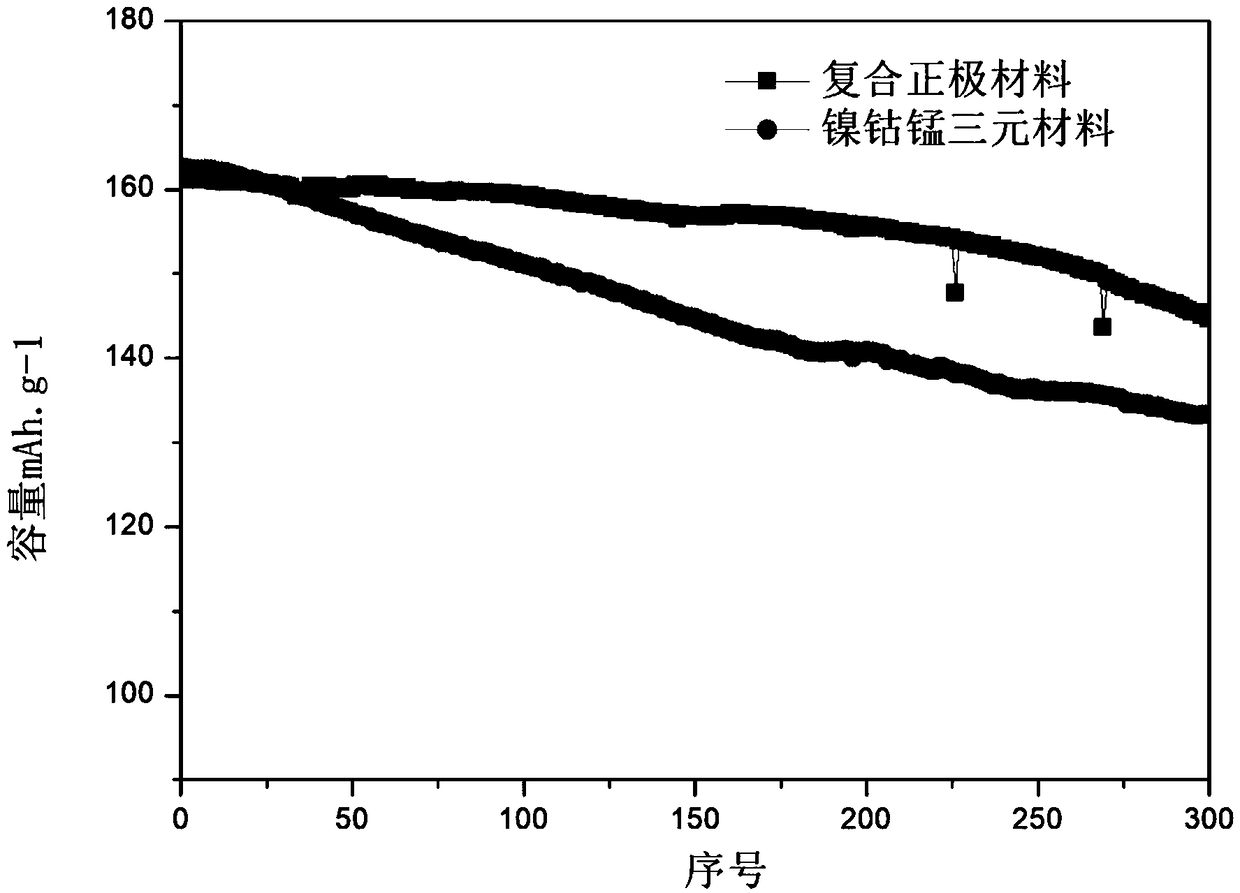

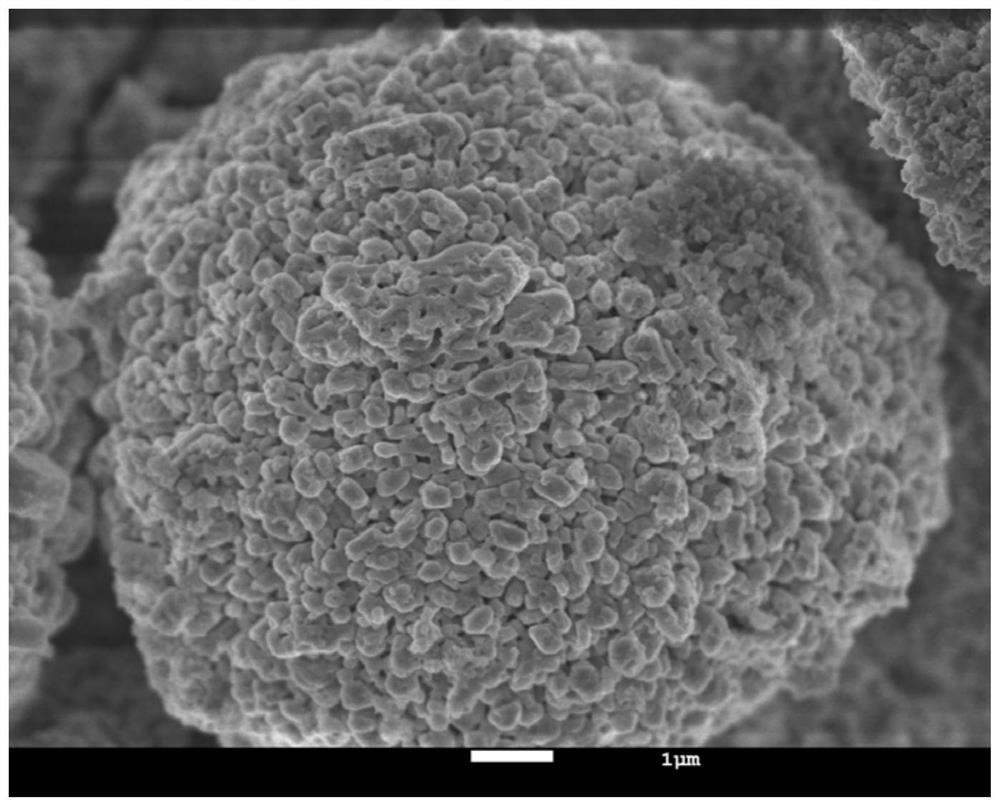

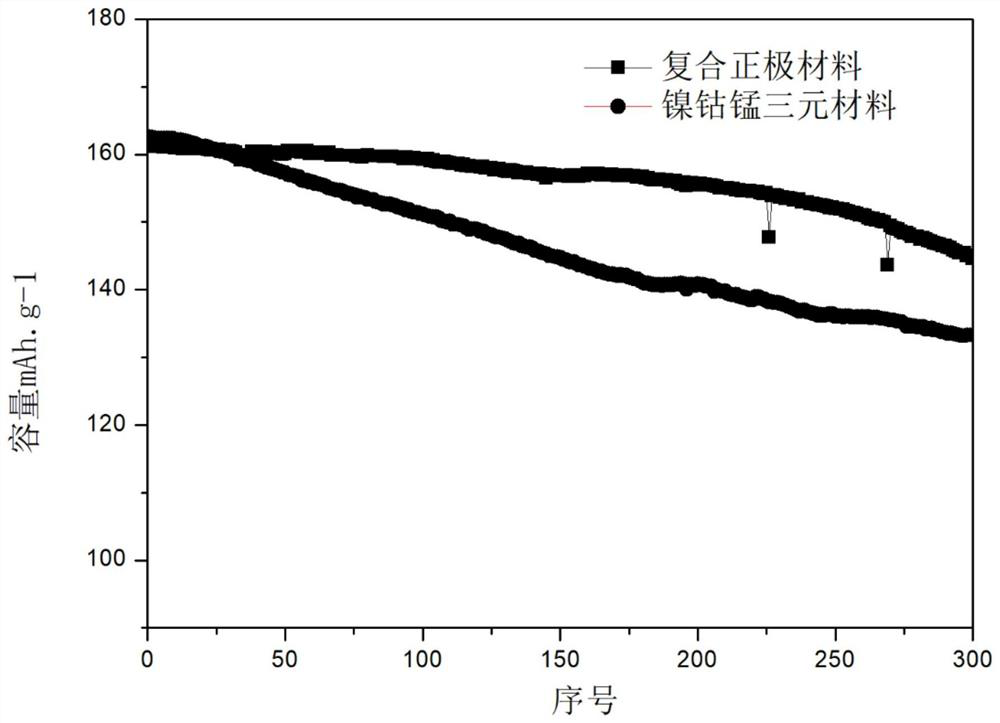

Composite positive electrode material of lithium ion battery and preparation method of composite positive electrode material

ActiveCN109449378AImprove structural stabilityLow alkali contentCell electrodesSecondary cellsLithium iron phosphatePhosphate

The invention provides a composite positive electrode material of a lithium ion battery. The composite positive electrode material comprises a ternary material matrix LiNixCoyM1-x-yO2 an iron phosphate transition layer which coats the surface of the matrix, and a lithium iron phosphate coating layer, wherein the lithium iron phosphate coating layer coats the surface of the iron phosphate transition layer; and the general formula of the composite positive electrode material is LiNixCoyM1-x-yO2.aFePOz.bLiFePO4. The invention further provides a preparation method of the composite positive electrode material of the lithium ion battery; the preparation method comprises the following steps that an iron salt and phosphate are added into water to obtain a uniform dispersion liquid; the ternary material is added into a dispersion medium to obtain a uniform turbid liquid; and slurry with uniformly mixed two liquids is further obtained, the slurry is dried to obtain a precursor, and the precursoris sintered to obtain an iron phosphate coated ternary material; and the iron phosphate coated ternary material is uniformly mixed with a lithium salt and a carbon source to be sintered under an inert atmosphere to obtain the composite positive electrode material of the lithium ion battery.

Owner:BEIJING TAIFENG XIANXING NEW ENERGY TECH CO LTD +1

Bowl holding device

InactiveCN102949068AQuarantine direct contactEnsure close contactTable equipmentsKitchen equipmentMechanical engineeringEngineering

The invention relates to a bowl holding device, which comprises a first torsional spring clip and a second torsional spring clip, wherein the first torsional spring clip is rotatably connected with the second torsional spring clip; a torsional spring is arranged on the rotatably connected part; and handles are respectively arranged on the first torsional spring clip and the second torsional spring clip. An outer wall of a bowl is clamped through the torsional spring clips, and the bowl is lifted through the handles. When the bowl holding device is used, the handles are pulled to clamp the bowl on the torsional spring clips, and then the bowl holding device is upwards taken, so that the bowl can be taken conveniently in a labor saving way; and in addition, a heat proof sleeve is also arranged on each handle and can be used for blocking high temperature of the bowl.

Owner:沈健国

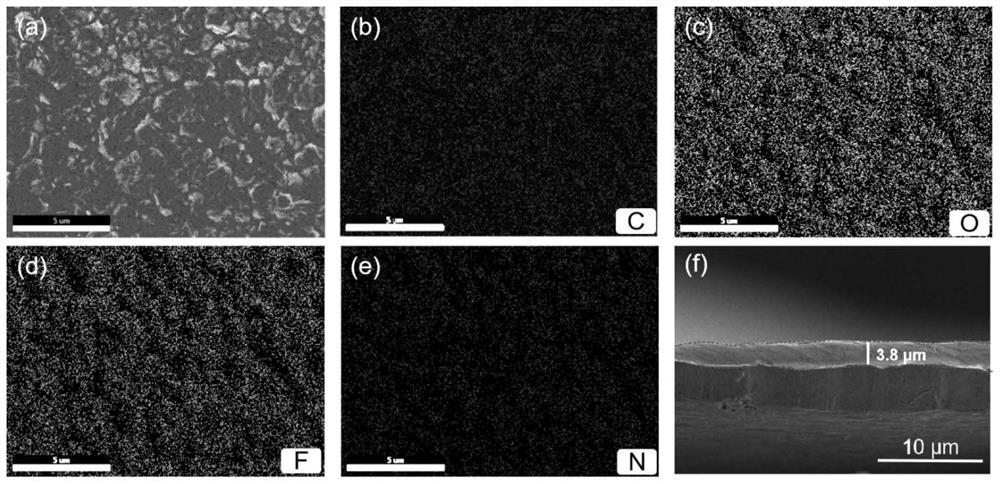

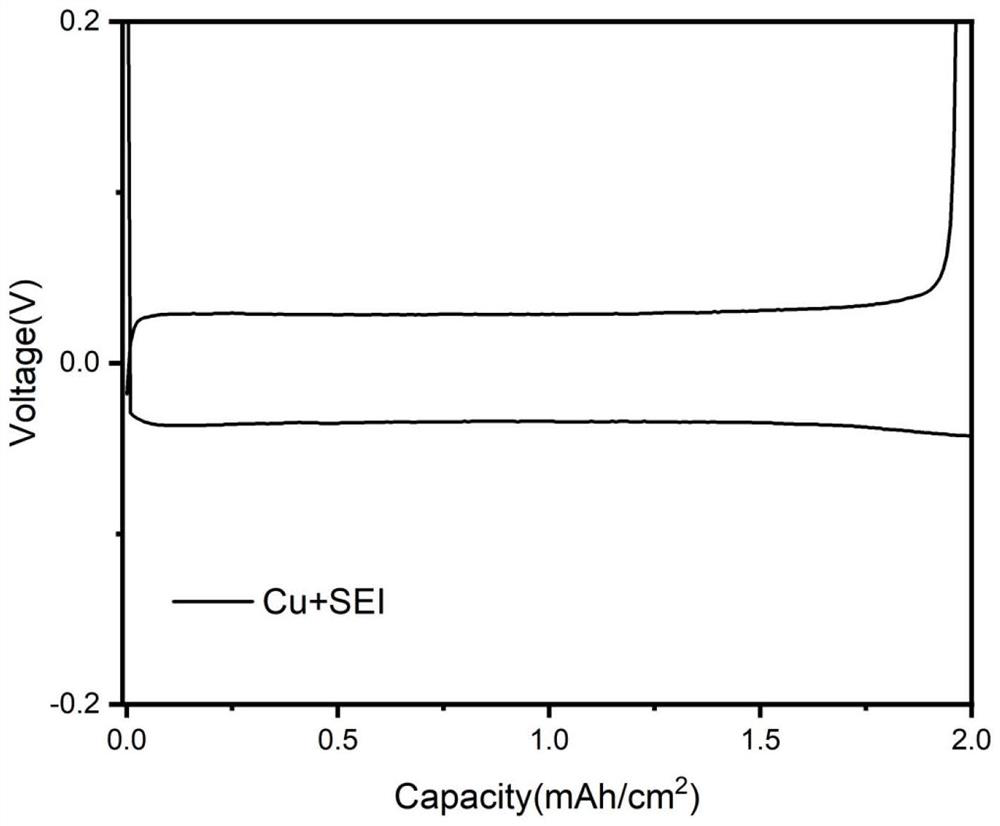

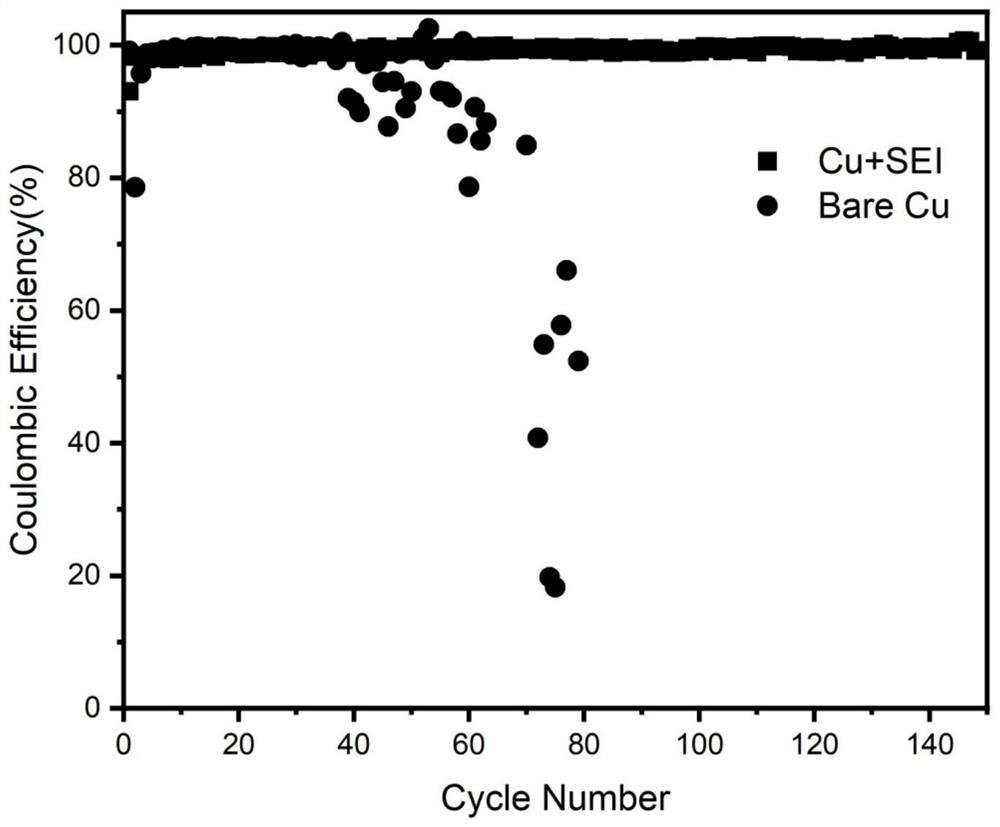

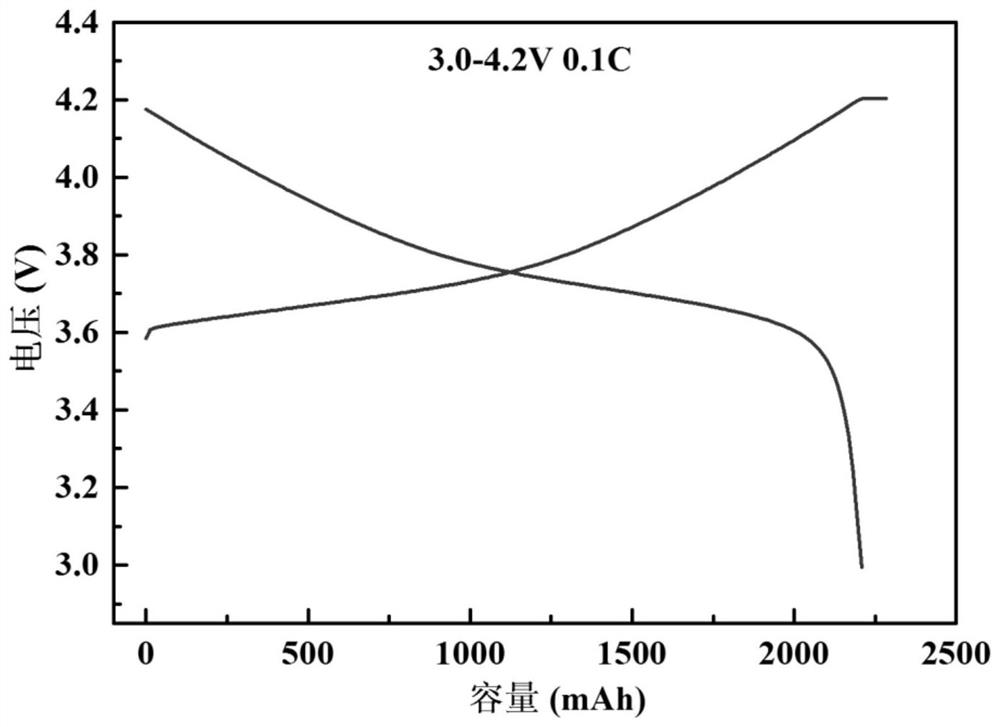

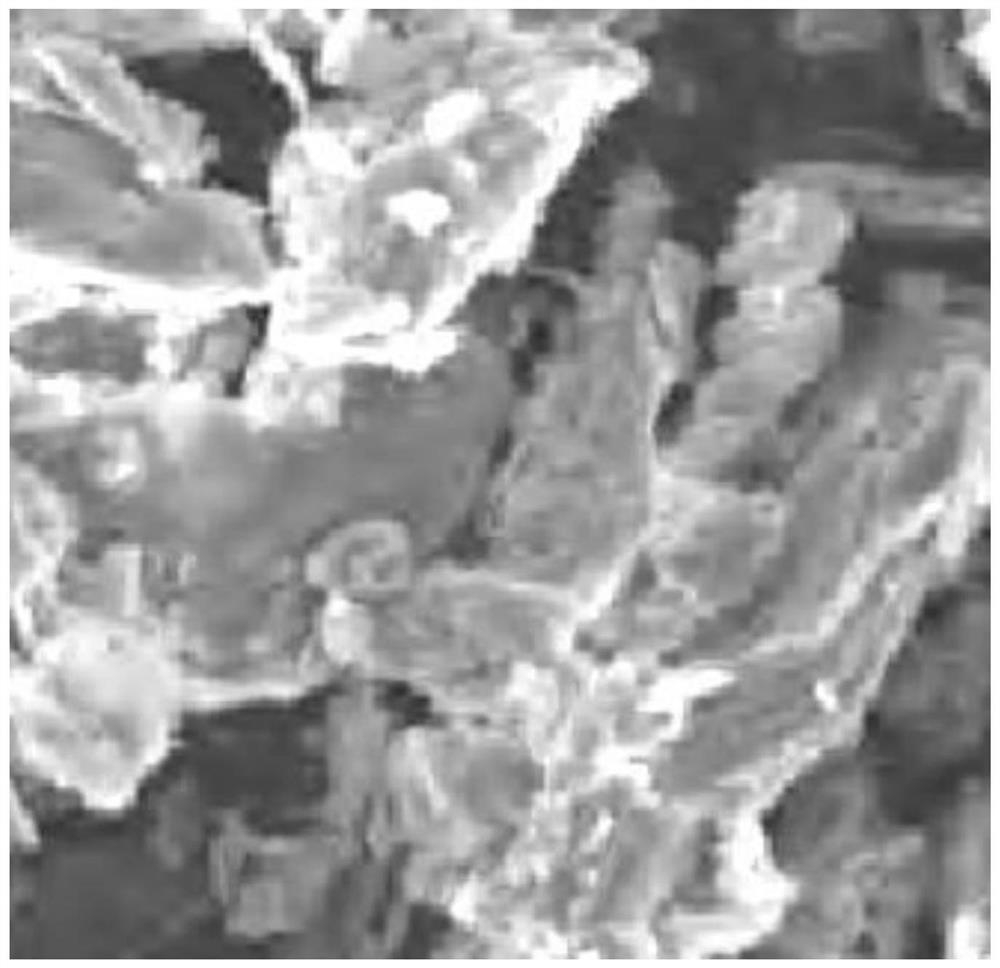

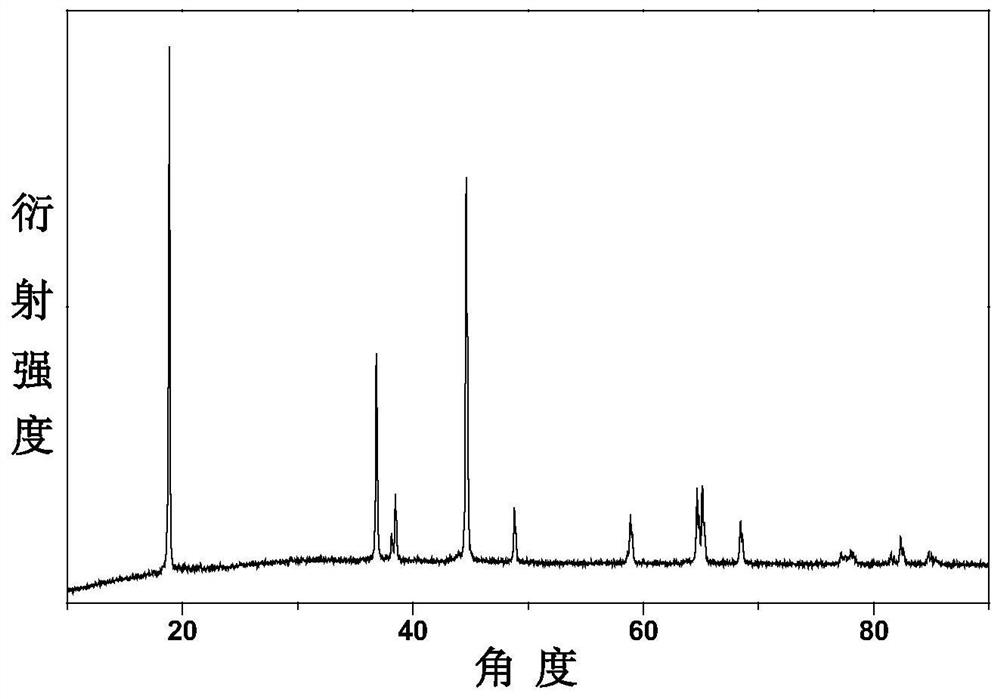

Lithium battery electrode and preparation method and application thereof

PendingCN114388731AImprove securityExtend your lifeNon-aqueous electrolyte accumulator electrodesElectrical polarityNafion

The invention discloses a lithium battery electrode and a preparation method and application thereof, the lithium battery electrode takes a lithium-loving covalent organic framework (COF) with a triazine ring and carbonyl as a multifunctional artificial SEI layer of a lithium metal battery (LMB), so that smooth deposition of lithium and formation of less lithium dendrites are ensured. Nafion-Li in the artificial SEI layer is used as a binding phase, so that excellent flexibility and mechanical property can be provided, the artificial SEI layer can effectively adapt to violent volume change in a lithium negative electrode circulation process, and the stability of the structure of the artificial SEI layer is kept; and meanwhile, the lithium ion flux is adjusted by pre-designing functional polar groups on the COF, so that smooth deposition of lithium metal is realized.

Owner:XI AN JIAOTONG UNIV

Method for avoiding thermal runaway of lithium ion battery

InactiveCN112332021AAvoid thermal runawayStop feverElectrode collector coatingNon-aqueous electrolyte accumulator electrodesPhysical chemistrySlurry

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a method for avoiding thermal runaway of a lithium ion battery. The method comprises the following steps: (1) surface activation of raw vermiculite powder: grinding raw vermiculite into powder, cleaning the raw vermiculite powder, dynamically soaking the cleaned raw vermiculite powder in an acidic solution or an alkaline solution, carrying out solid-liquid separation, and drying the material; (2) preparation of a dispersion liquid: fully mixing and dissolving a solvent, a surfactant, a dispersingagent and a binder, adding raw vermiculite powder, uniformly stirring, and then adjusting the viscosity of the slurry to 1000-20000 mPa.S; (3) coating and baking. By adopting the method, the safety performance of the lithium ion battery can be improved, and the thermal runaway phenomenon is avoided.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Core-shell composite positive electrode material coated with mixed polymer, its preparation method and application in lithium ion battery

ActiveCN107706377BLower internal resistanceGood physical compatibilityCell electrodesSecondary cellsSolid state electrolytePolyethylene oxide

The invention discloses a mixed polymer-coated core-shell composite positive electrode material, a preparation method thereof and application in a lithium ion battery. The composite positive electrodematerial comprises a positive active material core and a mixed polymer shell, wherein the mixed polymer shell is coated on a surface of the core and comprises a mixture of a conductive polymer and anorganic solid polymer. The method comprises the steps of 1) mixing polyethylene oxide and lithium hexafluorophosphate, and performing ball-milling to obtain a mixture A; 2) mixing the positive activematerial and a coupling agent, and performing dry ball-milling to obtain a mixture B; and 3) mixing the mixture A, the mixture B and the conductive polymer, and performing dry ball-milling and calcination to obtain the core-shell composite positive electrode material. The coating layer of the composite positive electrode material can be compatible with electron conductivity and lithium ion conductivity of the material, the internal resistance of the electrode material is effectively reduced, moreover, two materials in the coating layer are high in compatibility, and the coating uniformity isimproved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Film forming solution for adelomorphic protecting film

InactiveCN101195041AEasy to useStay hydratedCosmetic preparationsToilet preparationsAqueous solutionPhosphatidic acid

The invention relates to a film-forming solution of conceal protecting films, and is characterized in that the invention contains a water solution which is provided with acrylic hydroxyethyl phosphatidic acid choline with weight ratio of 1%-10% and acrylic n-butyl polymer components, the pH value of the solution is 6-8, wherein, the average molecular weight of acrylic hydroxyethyl phosphatidic acid choline and acrylic n-butyl polymer components is 600 thousand, and 2- mahogany-1 and 4-naphthoic polymer components are further contained in the solution. After the film-forming solution of conceal protecting films is daubed on the skin, a layer of protecting films which are tightly clung to the skin can be quickly formed, the protecting function of inhibiting viruses and microorganisms such as HIV and herpes from infecting is provided, and the functions of removing oily soil and delaying skin aging and the like are further provided.

Owner:DONGGUAN TAILI BIOTECH

Household sewage ecological purifier

InactiveCN111018017AQuarantine direct contactLow costWater/sewage treatment apparatusPlastic packagingSewage

The invention provides a household sewage ecological purifier structurally comprising a purification box, a side fixed groove, a water inlet connector, a water outlet, an upper sealing cover, side buckle pieces and an interlayer quick changing device; the interlayer quick changing device is arranged in the purification box; the side buckle pieces are mounted on the left and right side surfaces ofthe purification box in an embedded manner; the water outlet is formed in the middle of the front end surface of the purification box. According to the invention, when the sewage purifier is used fortreatment, a closed treatment box body can be formed by combining an inner top cover and an interlayer liner mechanism; a plastic packaging inner film is taken out and replaced, air in the interval ofthe plastic packaging inner film is pumped out through a bottom pull cover to be packaged again, replacement of the plastic packaging inner film inside is completed, and thus the best state of a treatment cavity inside the purifier can be achieved with extremely low cost.

Owner:叶钰莹

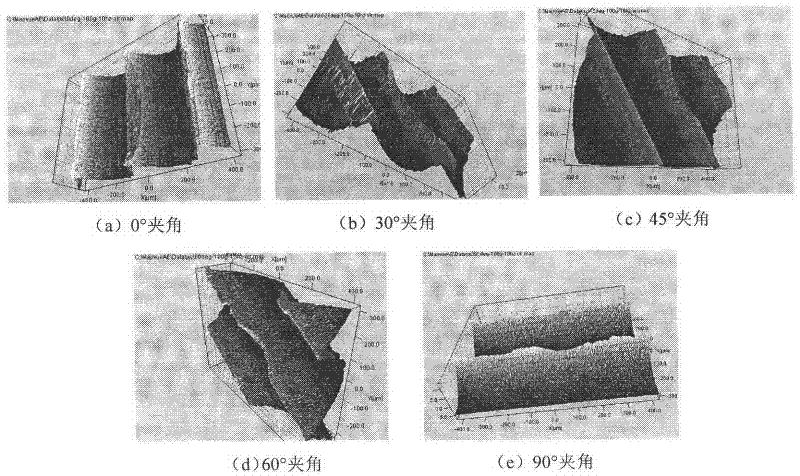

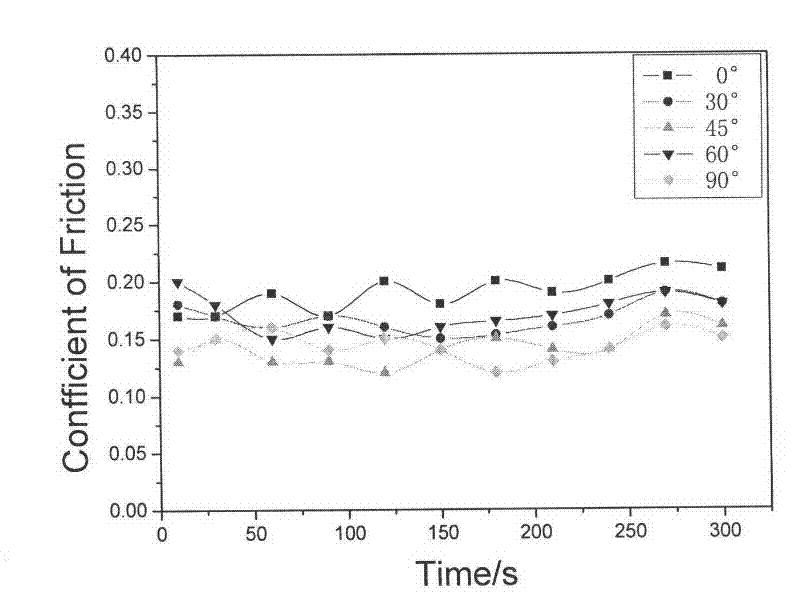

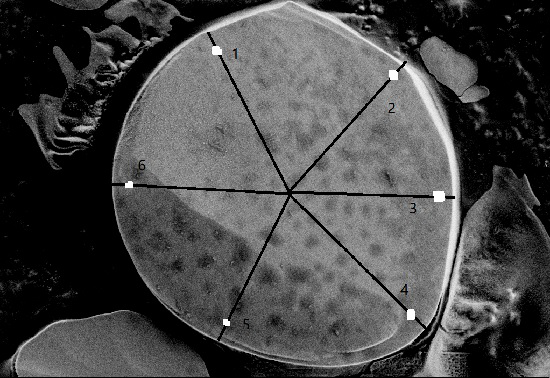

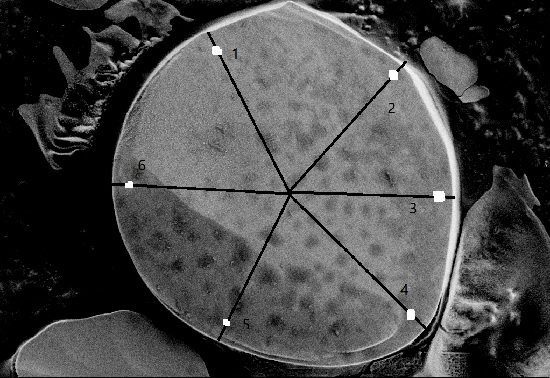

Method for improving surface friction wear performance by changing surface grain direction

InactiveCN102346120AQuick smoothQuarantine direct contactPreparing sample for investigationInvestigating abrasion/wear resistanceQuenchingCarbon steel

The invention relates to a method for improving the surface friction wear performance by changing the surface grain direction, belonging to the field of surface friction wear performance. The method comprises the following steps of: planning the surface of No.45 carbon steel to obtain the surface with the roughness of Ra3.2; carrying out hardening and tempering treatment, heating a workpiece to 840 DEG C and preserving the temperature for 2h, then fast placing the workpiece to a 10% saline solution for cold quenching, carrying out high-temperature tempering treatment on the workpiece after completely quenching, and preserving the temperature of 560 DEG C for 1.5h to obtain the No.45 carbon steel with the hardness of about 35HRC; finally processing the workpiece to form a specimen with the length 22mm*width 20mm*height 4mm; and then carrying out a friction wear test and setting a 0-90 DEG change between the surface grains of the specimen and the motion direction of a friction pair to respectively obtain a relation between the grain direction and the grinding crack depth as well as a relation between the grain direction and the friction coefficient, wherein the friction wear test is carried out on a multifunctional friction wear tester, and the setting time is 300S.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

Flame-retardant graphene titanium-based composite and preparation method

The invention provides a flame-retardant graphene titanium-based composite and a preparation method, and aims to solve the problem that graphene is hard to uniformly disperse in a titanium alloy material. The flame-retardant graphene titanium-based composite comprises the following components in percentage by mass: 0.01-1wt% of a graphene oxide and a titanium-copper series alloy. The preparation method of the flame-retardant graphene titanium-based composite comprises the following steps: at first, uniformly loading the surface of a graphene oxide nanosheet with a copper element in deionized water through a chemical method; then, uniformly mixing copper-loaded graphene oxide powder with titanium-copper series alloy powder in absolute ethanol by utilizing a mechanical stirring method; and after drying, acquiring the composite being excellent in structure property through a combination of the processes such as sheath vacuumizing treatment and hot isostatic pressing. The flame-retardant graphene titanium-based composite provided by the invention is designed to be a new-concept material; and the preparation method is simple, reliable, and broad in application prospect.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

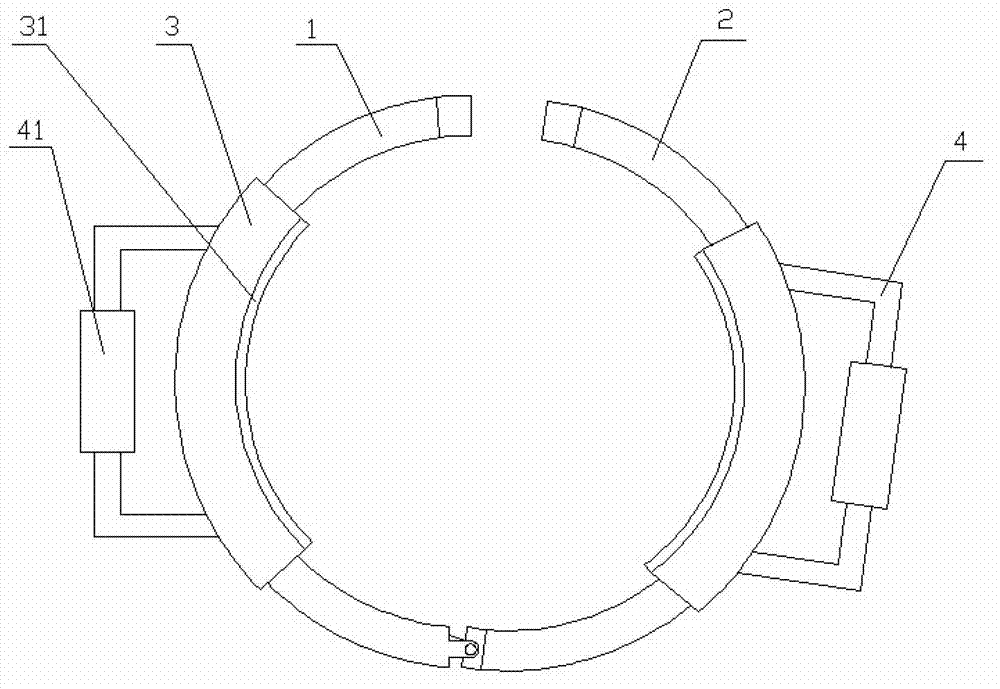

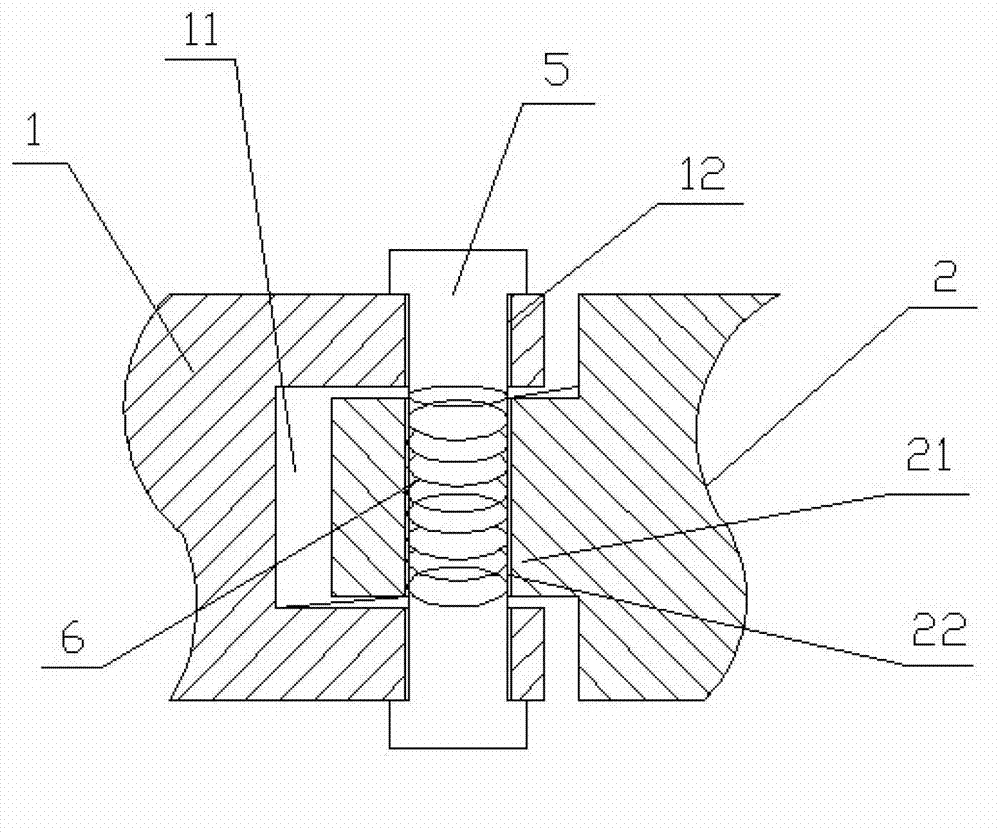

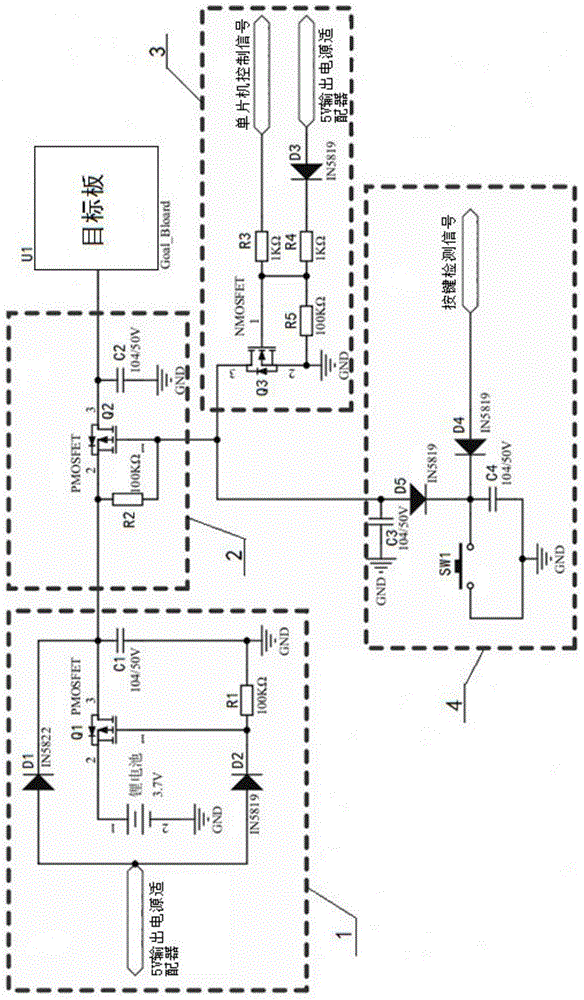

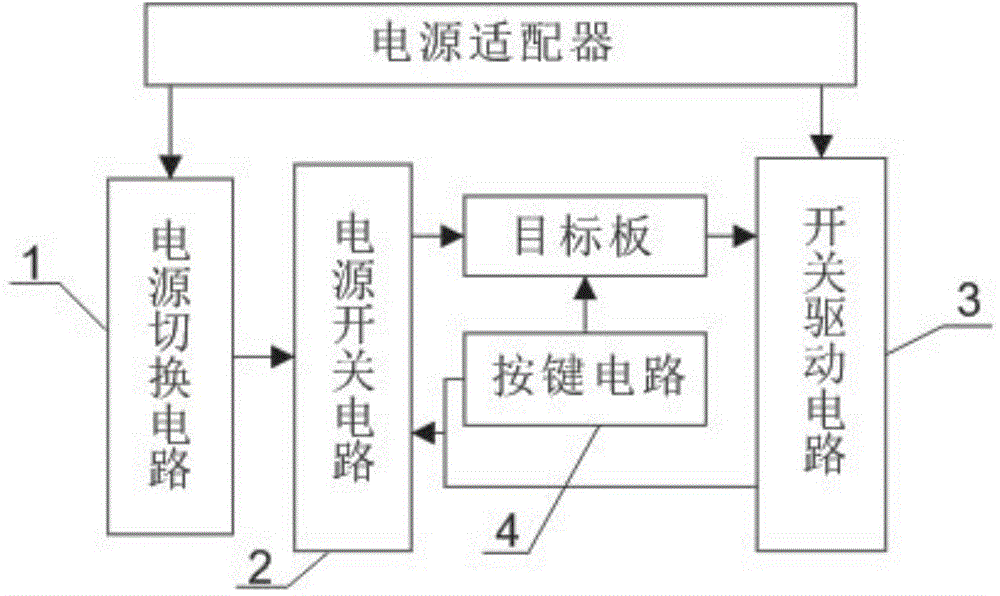

Root canal length measuring instrument startup and shutdown circuit with power switching function

InactiveCN104656519ABoot quicklyExtended service lifeProgramme controlComputer controlPower savingElectrical battery

The invention relates to a root canal length measuring instrument startup and shutdown circuit with a power switching function. The circuit comprises a power switching circuit, a power switch circuit, a switch driving circuit, a key circuit, a target board and a power adapter, wherein an input end of the power switching circuit is connected with the power adapter, an output end of the power switching circuit is connected with one input end of the power switch circuit, the other input end of the power switch circuit is connected with common terminals of the switch driving circuit and the key circuit, an output end of the power switch circuit is connected with a power input end of the target board, a single-chip microcomputer control signal end of the target board is connected with one input end of the switch driving circuit, the other input end of the switch driving circuit is connected with the power adapter, and a key detection signal end of the target board is connected with an output end of the key circuit. With the adoption of the circuit, startup is quick, and safety and power-saving effects can be realized during shutdown; the service life of a rechargeable battery is prolonged, and the safety degree of the rechargeable battery is increased; direct contract of a human body with a power supply is isolated, and the use safety degree is increased.

Owner:GUILIN WOODPECKER MEDICAL INSTR

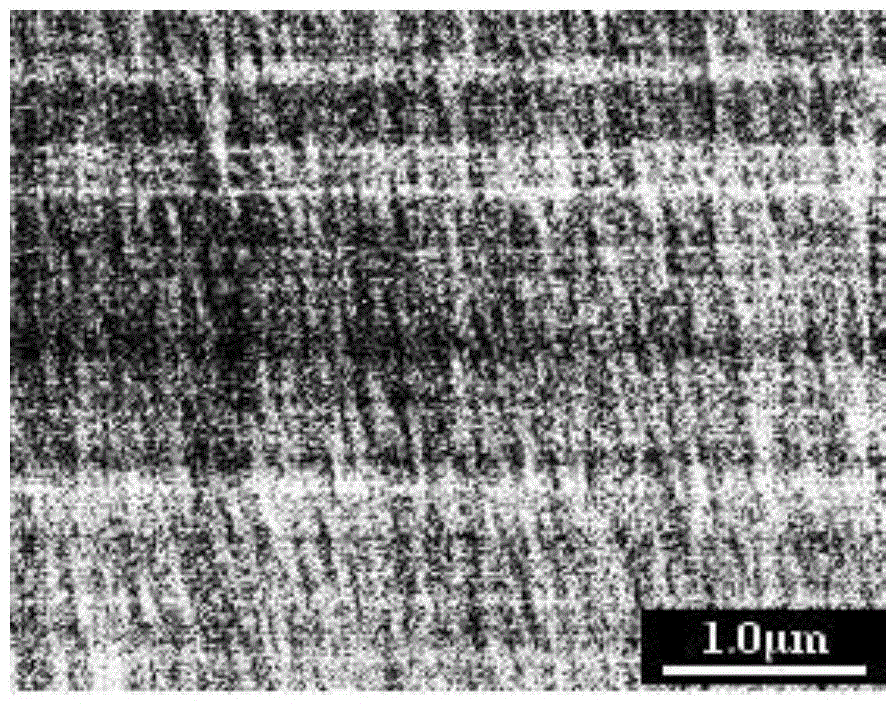

Gradient single-crystal positive electrode material, preparation method and application

ActiveCN113782736ALower resistanceAvoid structural stabilityPolycrystalline material growthElectrode thermal treatmentSingle crystalCondensed matter physics

The invention discloses a gradient single-crystal positive electrode material. The chemical formula of the single-crystal positive electrode material is LiNi<x>Co<y>A<1-x-y>O2@mLiZO<c>, wherein 0 < x < 1, 0 < y < 1, 0 < x + y < 1, 0 < m < 0.05, 0.3 < a < = 10, 1 < = b < 4, and 1 < = c < 15; and A is at least one of Mn, Zr, Sr, Ba, W, Ti, Al, Mg, Y and Nb, and Z is at least one of B, Al, Co, W, Ti, Zr and Si. The atomic proportion of the Co on the surface of the single-crystal positive electrode material particle to Ni + Co + A on the surface is greater than 0.4 and less than 0.8, and the atomic proportion of Co at a position which is 10% radius depth away from the surface of the single-crystal positive electrode material particle is not less than 0.3. The single-crystal positive electrode material is good in particle sphericity and free of sharp corners. The invention also provides a preparation method and application of the gradient single-crystal material.

Owner:HENAN KELONG NEW ENERGY CO LTD

Angle grinder provided with dustproof cover

InactiveCN109227311AQuarantine direct contactReduce the likelihood of injuryPortable grinding machinesGrinding/polishing safety devicesAngle grinderEngineering

The invention discloses an angle grinder provided with a dustproof cover. The angle grinder comprises a main angle grinder body and a cutting wheel, and the dustproof cover is arranged on the side face of the main angle grinder body. The angle grinder is reasonable in structural design, and the dustproof cover can effectively prevent the hands from being injured by various fragments generated whenthe cutting wheel of the angle grinder works.

Owner:江阴市仁鑫金属制品有限公司

A kind of lithium-ion battery composite cathode material and preparation method thereof

ActiveCN109449378BImprove structural stabilityLow alkali contentCell electrodesSecondary cellsLithium iron phosphateIron salts

The invention provides a lithium-ion battery composite positive electrode material, including a ternary material matrix LiNi x co y m 1‑x‑y o 2 And the iron phosphate transition layer and the lithium iron phosphate coating layer coated on the surface of the substrate, the lithium iron phosphate coating layer is coated on the surface of the iron phosphate transition layer; the composite positive electrode material The general formula is expressed as: LiNi x co y m 1‑x‑y o 2 ·aFePO z · bLiFePO 4 . The present invention also provides a preparation method of a lithium-ion battery composite cathode material, the steps comprising: adding iron salt and phosphate into water to obtain a uniform dispersion; adding ternary materials to a dispersion medium to obtain a uniform suspension; Then obtain a slurry uniformly mixed with the two liquids, dry to obtain a precursor, and sinter to obtain a ternary material coated with iron phosphate; after uniformly mixing it with a lithium salt and a carbon source, sinter in an inert atmosphere to obtain a composite positive electrode material for a lithium-ion battery.

Owner:BEIJING TAIFENG XIANXING NEW ENERGY TECH CO LTD +1

Adelomorphic protecting film forming solution

InactiveCN101194881AEasy to useStay hydratedCosmetic preparationsToilet preparationsChitin formationAqueous solution

The invention relates to hidden protecting film filming solution, which is characterized in that the invention comprises water solution of chitin chitosan element whose weight ratio is 1% to 10%, and PH value of the solution is 6 to 8, the degree of deacetylation of the chitin chitosan is 50% to 99%, and the average molecular weight is 2 million. The solution can further comprise 2-sulfonic acid sodium-1 and 4-naphthalene methoxy polymer. A layer of protecting film which clings to skin is quickly formed after the hidden protecting film filming solution is smeared on the skin. The invention has the protective function of inhibiting virus such as HIV, and herpes and the like, and inhibiting microbial infection, which has the function of wiping oil, and delaying skin aging and the like.

Owner:DONGGUAN TAILI BIOTECH

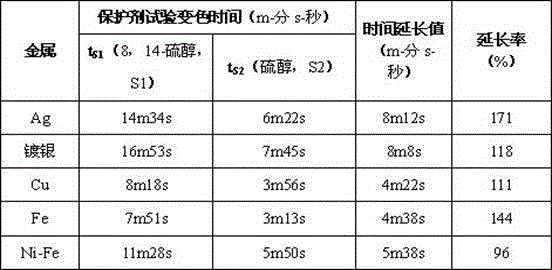

A kind of preparation method of water-soluble molecular self-assembled film type metal protective agent

ActiveCN103726056BProlong the discoloration timeQuarantine direct contactOrganic solventActive agent

The invention discloses a method for preparing a water-soluble molecular self-assembly film type metal protective agent. The method comprises the following steps: A, mixing water and an organic solvent of which the mass ratio is (0.5-1.5);10, uniformly stirring, and preparing a mixed solvent; B, adding an emulsifier which accounts for 30-50 percent of the mass of the mixed solvent in the step A, uniformly stirring, and preparing a mixture; C, adding a film agent which accounts for 12-20 percent of the mass of the mixture in the step B, uniformly stirring, and further preparing a mixed solution; and D, adding a surfactant which accounts for 1.5-2.0 percent of the mass of the mixed solution and a reducing agent which accounts for 0.1-0.5 percent of the mass of the mixed solution in the step C, heating under water bath conditions at the temperature of 51-58 DEG C, controlling the temperature of the mixed solution, continuously stirring for 90-150 minutes, thereby obtaining the water-soluble molecular self-assembly film type metal protective agent. The method is simple in process, low in energy consumption and environmental friendly, a molecular self-assembly film can be formed on the metal surface through the protective agent, and the metal is effectively prevented from discoloring. The method is simple in process and large-scale production is easy to realize.

Owner:东莞奕创表面处理科技有限公司 +1

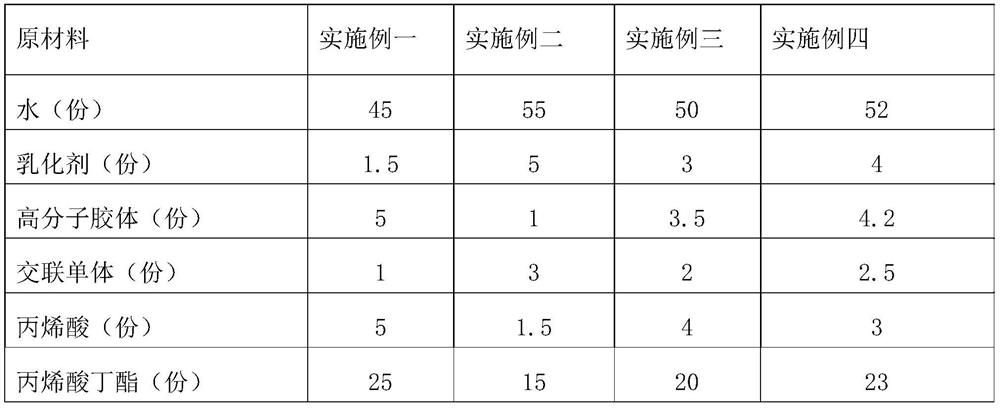

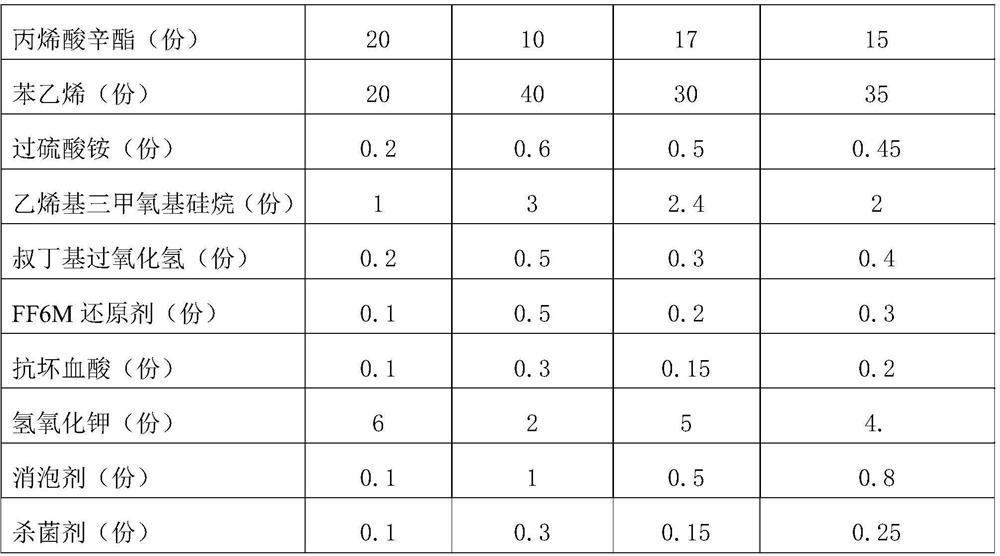

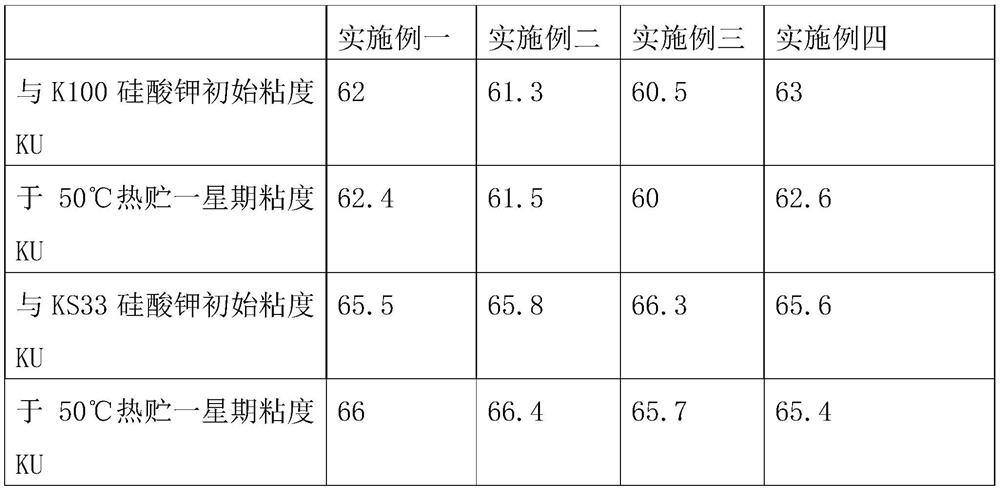

Emulsion for inorganic silicate coating and preparation method thereof

ActiveCN112251056AEffective isolation from direct contactQuarantine direct contactAlkali metal silicate coatingsPotassium hydroxideTert butyl

The invention relates to an emulsion for an inorganic silicate coating, which comprises the following components in parts by mass: water, an emulsifier, polymer colloid, a cross-linking monomer, acrylic acid, butyl acrylate, octyl acrylate, styrene, ammonium persulfate, vinyltrimethoxysilane, tert-butyl hydroperoxide, an FF6M reducing agent, ascorbic acid and potassium hydroxide. The invention relates to a preparation method of emulsion. The preparation method comprises the following steps: S01, preparing pre-emulsified liquid in a monomer bottle; S02, adding water into a reaction kettle, stirring, adding an emulsifier and a polymer colloid, and dropwise adding an emulsion and a second initiator aqueous solution; S03, adding a tert-butyl hydroperoxide aqueous solution, adding an FF6M reducing agent aqueous solution; S04, adjusting the PH value; and step S05, adding a defoaming agent and a bactericide. Therefore, the emulsion has good compatibility and storage stability with inorganic silicate.

Owner:江苏日出化工有限公司 +1

Refillable lithium-ion battery

ActiveCN102255105BImprove conductivityReduce restrictionsSecondary cellsCell component detailsPropionitrileEthyl propionate

The invention discloses a lithium ion battery with adoption of secondary electrolyte injection, comprising a positive pole, a negative pole, a diaphragm, an electrolyte and an outer package. In the process of manufacturing the battery, the secondary electrolyte injection is adopted; the electrolyte solvent in the first electrolyte injection is one or a combination of more than one of EC (ethylene carbonate), PC (propylene carbonate), DMC (dimethyl carbonate), DEC (diethyl carbonate), EMC (ethyl methyl carbonate), Gamma-BL (butyrolactone), MF (methyl formate), MA (methyl acetate), EP (ethyl propionate) and THF (tetrahydrofuran) and does not contain acetonitrile and propionitrile; the secondary electrolyte injection is conducted after the formation; and the used electrolyte in the secondary electrolyte injection contains at least one of the acetonitrile and the propionitrile. The electrolyte containing the at least one of the acetonitrile and the propionitrile has the advantage of high normal-temperature conductivity (10-50mS / cm) and low-temperature conductivity (4-20mS / cm at the temperature of -20 DEG C), thereby exceeding the level of an existing electrolyte.

Owner:DONGGUAN AMPEREX TECH +1

New cultivation method of paulownia seedlings

InactiveCN110301279ABreed fastGrow fastGrowth substratesCulture mediaTrace element compositionPaulownia

The invention discloses a new cultivation method of paulownia seedlings. The method includes following steps: S1, selecting, proportioning and treating a nutritional matrix; S2, collecting seed roots;S3, burying the roots; S4, cultivating, hardening seedlings, and transplanting, wherein compound nutrients include nitrogen, phosphorus and potassium elements, trace elements and compound amino acid,the nitrogen element is urea, the phosphorus element is potassium dihydrogen phosphate, the potassium element is potassium sulfate, the trace elements include calcium, magnesium, zinc, copper and iron which are added in a soluble compound form, and the compound amino acid is composed of alanine, arginine, cystine, glycine, lysine and proline. A standardized cultivation greenhouse and a standardized treatment process are adopted, so that a farming method of field cultivation is broken through, occupied area is reduced, lesion probability of the paulownia seedlings is lowered, seedling cultureperiod is shortened, and yield is increased.

Owner:陈政璋

A kind of graded single crystal cathode material and its preparation method and application

ActiveCN113782736BLower resistanceAvoid structural stabilityPolycrystalline material growthElectrode thermal treatmentPhysical chemistrySingle crystal

The invention discloses a gradient single crystal cathode material, the chemical formula of the single crystal cathode material is LiNi x co y A 1‑x‑y o 2 @mLi a Z b o c , where 0

Owner:HENAN KELONG NEW ENERGY CO LTD

Metal hot piercing glass lubricant and metal hot piercing method

The invention provides a metal hot piercing glass lubricant and a metal hot piercing method. The metal hot piercing glass lubricant comprises glass powder, an inorganic lubricant, a grinding agent and a separant, wherein the inorganic lubricant is one or more of boron nitride, graphite and molybdenum disulfide; and the grinding agent is carbide and / or oxide with the Mohs hardness larger than 6. By adopting the glass lubricant provided by the invention, the abrasion of a guide plate caused by high-speed rotation of a red hot rod blank in a metal hot piercing process is effectively reduced, and the phenomenon that slipping is easily caused after pure glass powder is hot-melted and spread is avoided, so that the metal hot piercing process is smoothly carried out, and direct or indirect economic loss caused by abrasion of the guide plate is effectively reduced.

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV

A kind of preparation method of graphene/aluminum composite material

ActiveCN106513621BOvercome the disadvantage of being easy to pull out from the aluminum alloy matrixTake full advantage of enhanced capabilitiesLiquid/solution decomposition chemical coatingElectroless nickelElectric power

The invention discloses a preparation method of a graphene / aluminum composite material, which belongs to the field of metal matrix composite materials. Using aluminum alloy powder and graphene with a semi-solid temperature range as raw materials, the main steps are: (1) electroless nickel plating on graphene; (2) mixing materials; (3) pressing; (4) semi-solid extrusion. The graphene / aluminum composite material prepared by the present invention has good wettability between nickel-plated graphene and aluminum alloy, high metallurgical bonding strength, uniform distribution of nickel-plated graphene in the matrix aluminum alloy, compact structure, high specific strength, With high specific stiffness, good thermal conductivity and electrical conductivity, it has broad application prospects in many fields such as national defense and military industry, aerospace, electric power, heat exchange, etc.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com