Metal hot piercing glass lubricant and metal hot piercing method

A technology of glass lubricant and metal heat, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as guide plate wear and economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

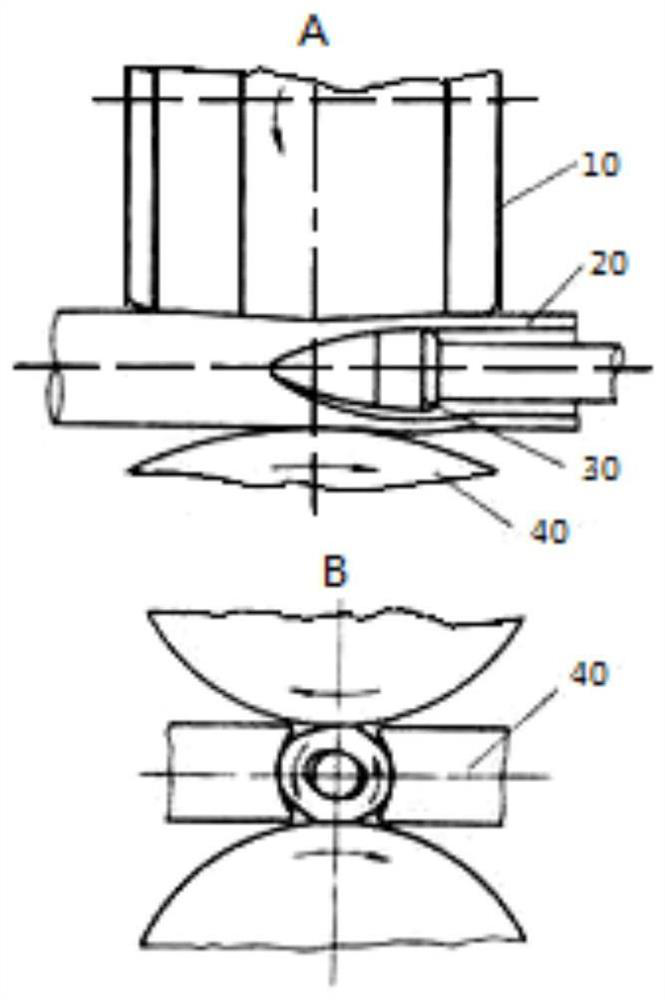

[0047] Conditions of use, in the stainless steel hot piercing process, the blank heating temperature is 1220°C, and the blank size is Φ120×2200. The piercing process is as follows: Spread the glass lubricant on the turning platform, roll the heated cylindrical metal billet over the turning platform, so that the glass lubricant adheres to its surface; The billet is sent between the roller and the guide plate, so that the guide plate clamps the cylindrical metal billet, and the cylindrical metal billet is rotated under the drive of the roller; Metal bar stock to make it into metal tube.

[0048] The formula of glass lubricant is as follows, the particle size is 400-1340 mesh;

[0049]

[0050] The above glass lubricant has a viscosity value of 5000 poise at operating temperature.

[0051] Result: 24 hours non-stop work, the number of guide plate replacements was reduced from the original minimum of 36 to 13. The thread height difference (the height difference between the l...

Embodiment 2

[0053] Conditions of use, in the nickel-based alloy hot piercing process, the billet heating temperature is 1120°C, and the billet size is Φ1100×2200. The perforation process is the same as in Example 1.

[0054] The formula of glass lubricant is as follows, the particle size is 400-1000 mesh;

[0055]

[0056] Results: Nickel-based alloys cost the most guide plates, and they work 24 hours a day without stopping the machine. The number of guide plate replacements has been reduced from the original minimum of 47 to 16. The thread height difference (the height difference between the lowest point of the threaded position and the non-threaded position) is reduced from about 0.5mm to about 0.15mm. The surface photo of the metal pipe is shown in Figure 8 . In the past, the polishing times were 4-5 times, but now 1-2 times can be completed.

Embodiment 3

[0058] Conditions of use, in the hot piercing process of titanium alloy, the blank heating temperature is 880°C, and the blank size is Φ750×1500. The perforation process is the same as in Example 1.

[0059] The formula of glass lubricant is as follows, the particle size is 400-1000 mesh;

[0060]

[0061] Results: The wear of the titanium alloy on the guide plate is not very serious, and the number of guide plate replacements has been reduced from the original minimum of 23 pieces to 14 pieces without stopping the machine for 24 hours. ), from about 0.25mm to about 0.08mm, the surface photo of the metal pipe is shown in Figure 9 . In the past, the number of polishing was at least 2 times, and now it is 1 time, even without polishing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com