Patents

Literature

244results about How to "Act as a bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound grinding roller and grinding disk

The invention discloses a preparation method for an active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound grinding roller and a grinding disk. The preparation method comprises the following steps: 1) uniformly mixing multiple active element powder, and then adding a defined amount of binding agents and fully mixing with ZTA particulates so as to uniformly cover the active element powder on the surfaces of the particulates, filling into a graphite mould, pressing, and then drying; 2) sintering, thereby obtaining a porous precast block; 3) fixing the precast block on a specific casting position and pouring molten metal, cooling and de-molding, thereby obtaining the compound grinding roller or grinding disk. According to the preparation method, the shape and size of the ZTA particulate precast block can be controlled through the mould and the technique is simple and has higher production efficiency, yield and practicability. Besides, the active element introduced into the interface can increase the wettability and binding strength of the interface and a compound layer structure with interactive distributed enhanced phase and base can ensure the longer service life of the grinding roller and the grinding disk under high stress effect.

Owner:XI AN JIAOTONG UNIV +1

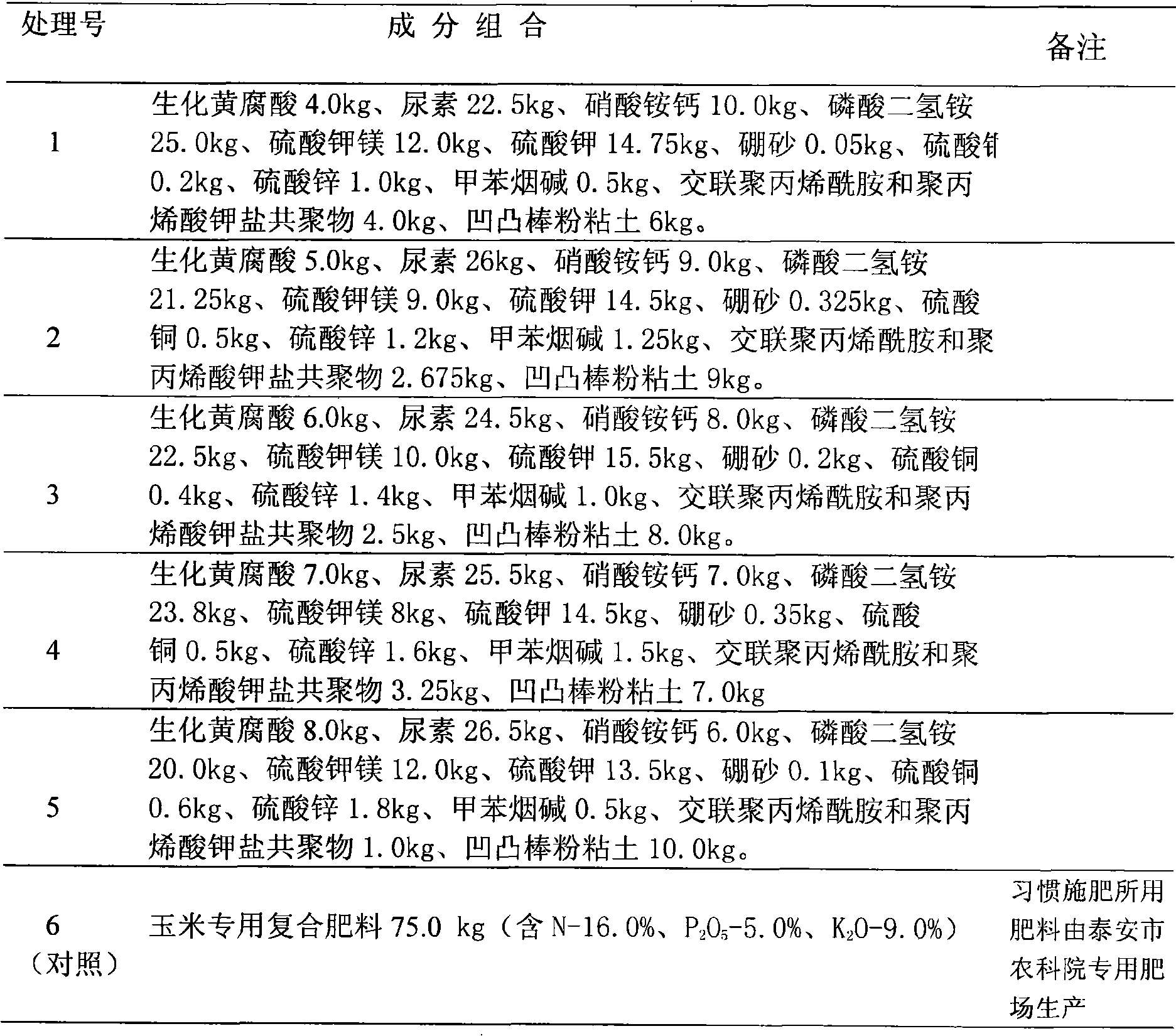

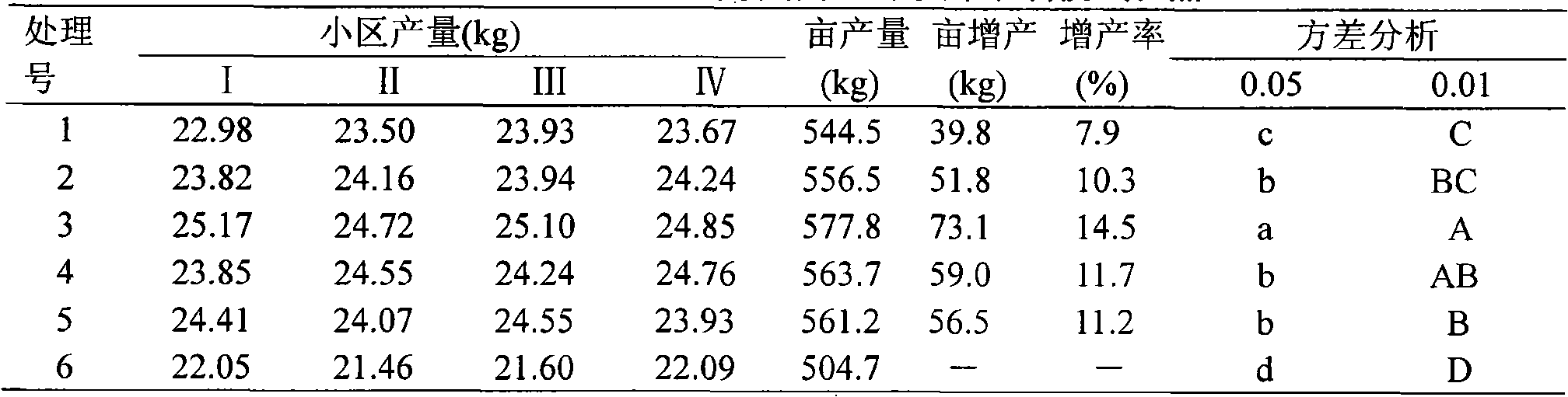

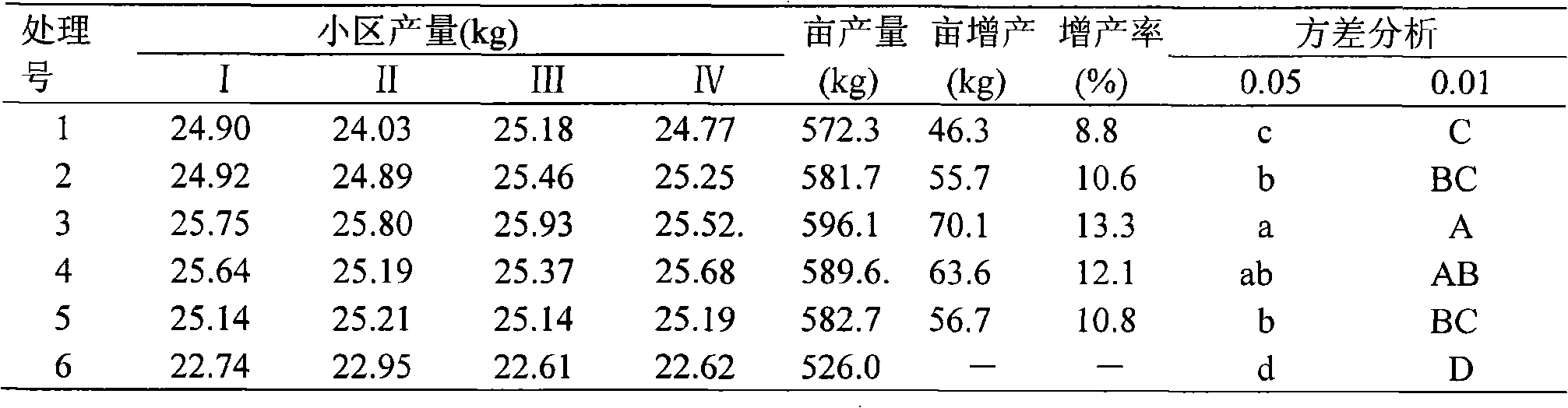

Double-effect water-protecting fertiliser and preparation method thereof

InactiveCN101585739AIncrease moisture contentImprove water use efficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateFood supply

The present invention discloses a double-effect water-protecting fertiliser and a preparation method thereof, wherein per 1000kg finished product of the double-effect water-protecting fertilizer is composed of the following components by weight: 40.0 to 80.0kg of biochemistry fulvic acid, 225.0 to 265.0kg of carbamide, 60.0 to 100.0kg of calcium ammonium nitrate, 200.0 to 250.0kg of mammonium dihydrogen phosphate, 80.0 to 120.0kg of magnesium kalium sulphuricum, 135.0 to 175.0kg of kalium sulphuricum, 0.5 to 3.5kg of borax, 2.0 to 6.0kg of copper sulfate, 10.0 to 18.0kg of zinc sulfate, 5.0 to 15.0kg of toluol methylpyrrolidine, 10.0 to 40.0kg of crosslinked polypropylene acidamide and polyacrylic acid potassium salt copolymer, and 10 to 40kg of attapulgite powder clay. the fertiliser not only meets the food supply required by the health growth of farm crops, is also capable of improving the utilization efficiency of the soil moisture and having non harm to human and animal husbandry without environment pollution.

Owner:TAIAN ACAD OF AGRI SCI

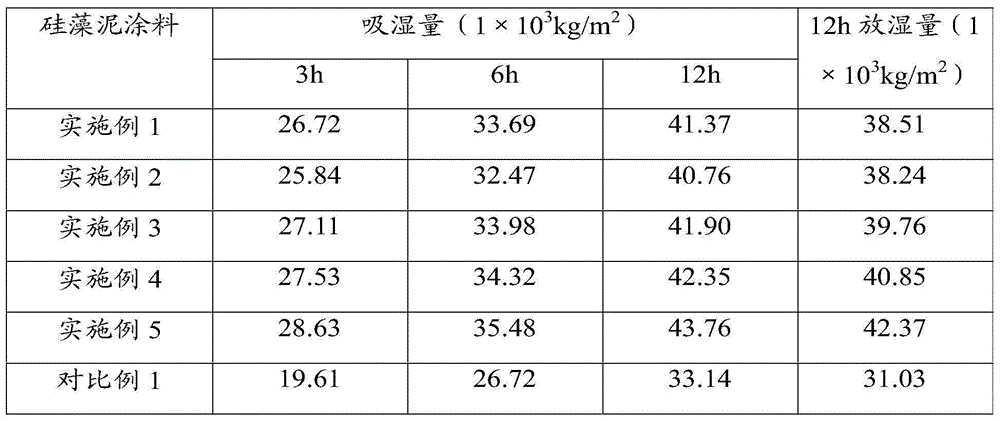

Diatom ooze coating and preparation method thereof

InactiveCN105176216AGuaranteed StrengthReduce contentAntifouling/underwater paintsPaints with biocidesEmulsionUltimate tensile strength

The invention provides a diatom ooze coating, belonging to the technical field of decoration coatings. Components of the diatom ooze coating mainly comprise synthesized emulsion, a dispersant, kieselguhr, a filler, a silver ion antibacterial agent, an additive and water and the like. The aperture of the selected kieselguhr is 280-580 meshes, and a micropore structure of the kieselguhr can be kept, and actions of humidifying and absorbing and dissolving formaldehyde can be achieved. The content of emulsion is reduced, and the strength of the coating after a wall is coated is ensured, and powder falling is avoided, and kieselguhr particles are not fully wrapped due to a formed membrane thus the micropores are not blocked, so that the functionality is not affected. The silver ion antibacterial agent is added into the coating, so the growth and propagation of microorganisms are effectively inhibited. The diatom ooze coating is obtained in a manner of charging materials in batches and stirring. Before the emulsion is added, under stirring, a thickener and a pH regulator are added, and the thickener can be fully dissolved by a shearing action, and an advanced dissolving step for the thickener is reduced.

Owner:BEIJING DAIJIN DIATOMITE NEWLY BUILDING MATERIAL

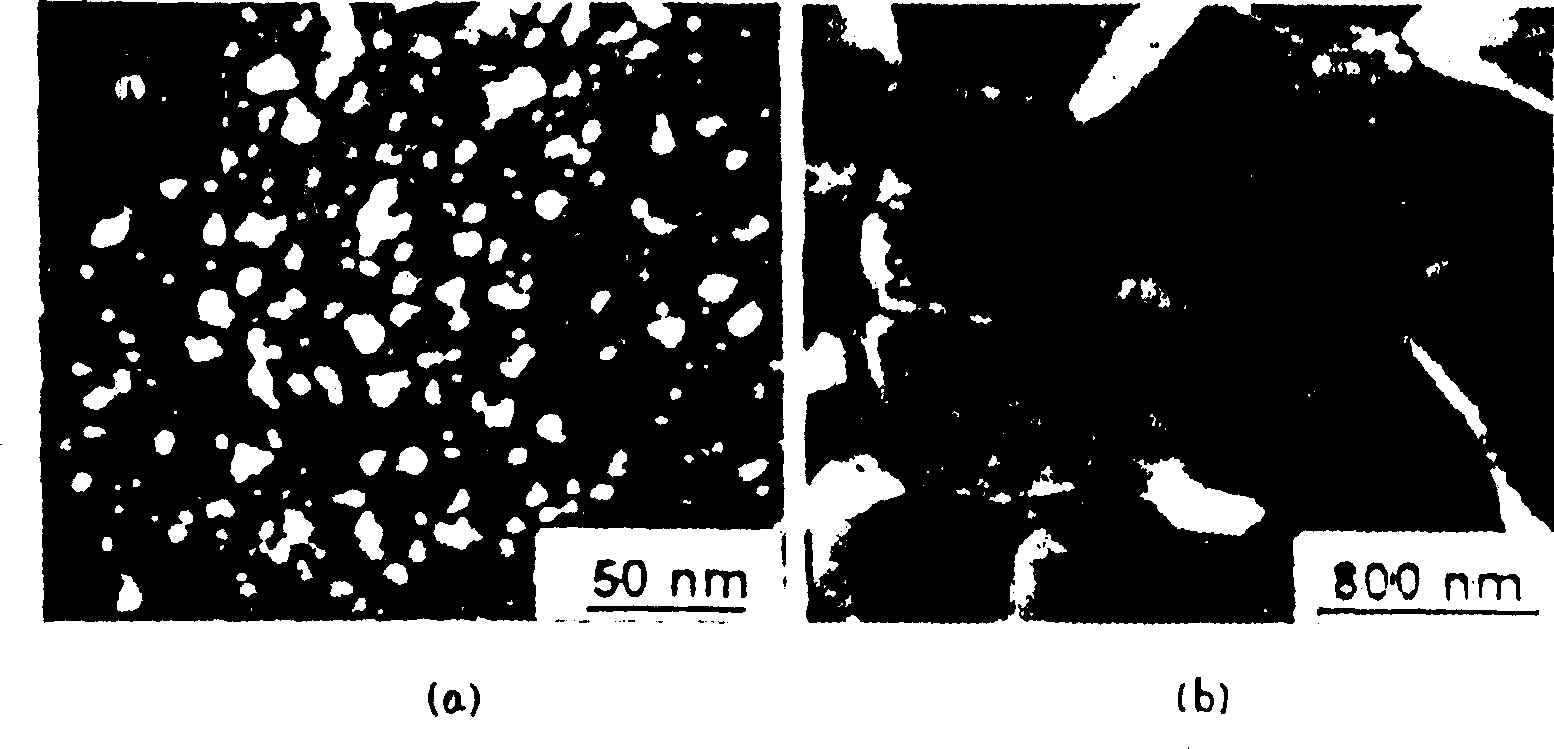

Preparation method of powder hot spray nano-material coating

InactiveCN1413774AImprove adsorption capacityHigh bonding strengthLiquid surface applicatorsCoatingsThermal sprayingCermet

A hot spray process for preparing the coated layer of nano-class powder includes such steps as cleaning the surface of substrate, activating, nano-class roughening, and hot spray of nano-class powder by large-diameter spray gun. The resultant coated layer features high mechanical properties, simple process, high deposition rate of powder and high spray efficiency.

Owner:金科

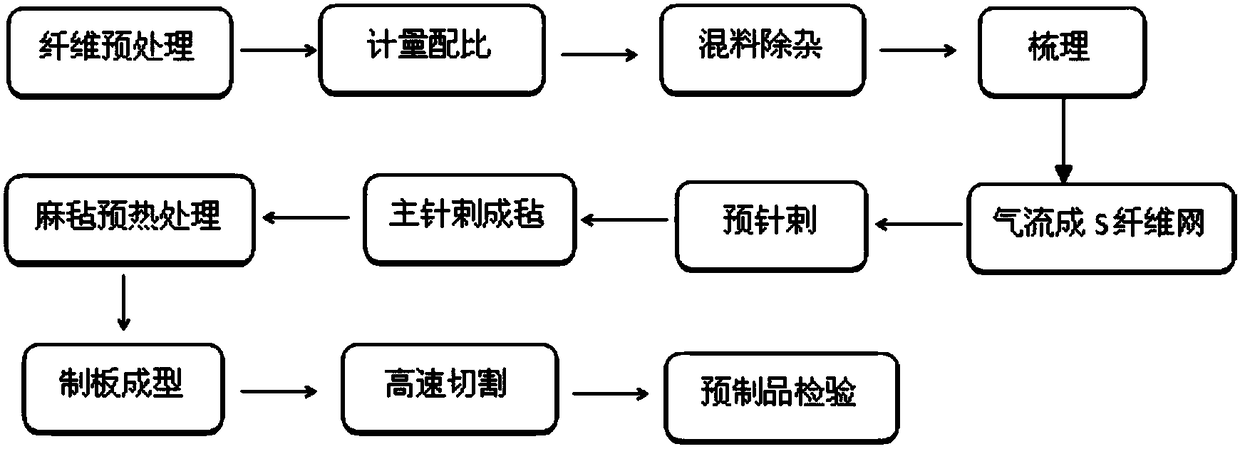

Hamburg type hemp fiber board and preparation method thereof

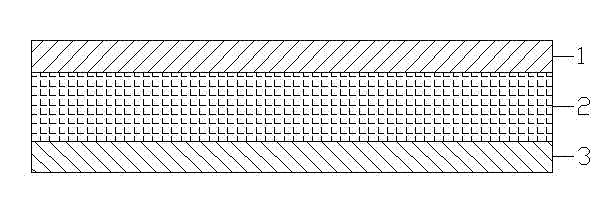

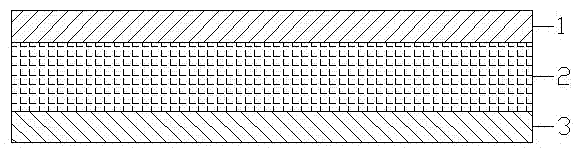

The invention relates to a hamburg type fibrilia plate and a preparation method thereof, and belongs to the technical field of automobile decoration fittings. The hamburg type fibrilia plate is characterized in that: the hamburg type fibrilia plate comprises three layers of a surface layer (1), a fibrilia felt layer (2) and a bottom layer (3). The surface layer (1) and bottom layer (3) are both needle-punched non-woven fabrics layers. Components of the needle-punched non-woven fabrics comprise, by mass, 40-60% of polypropylene fiber, 8-20% of 4080 fiber and 30-50% of polyester fiber. Components of the fibrilia felt comprise, by mass, 10-30% of palm fiber and the fibrilia, 30-40% of the polyester fiber and 40-50% of the polypropylene fiber. The preparation method comprises: 1, preparing the needle-punched non-woven fabrics; 2, preparing a composite substrate half finished product, wherein one side of the composite substrate half finished product is the needle-punched non-woven fabrics,the other side of the composite substrate half finished product is the fibrilia felt; 3, carrying out one-time mould-pressing to prepare the finished product. The prepared hamburg type fibrilia platehas characteristics of high strength, good stretching resistance, collapsing and deformation resistance, good flatness, low probability of moisten and mildewing, no toxicity and environmental protection.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

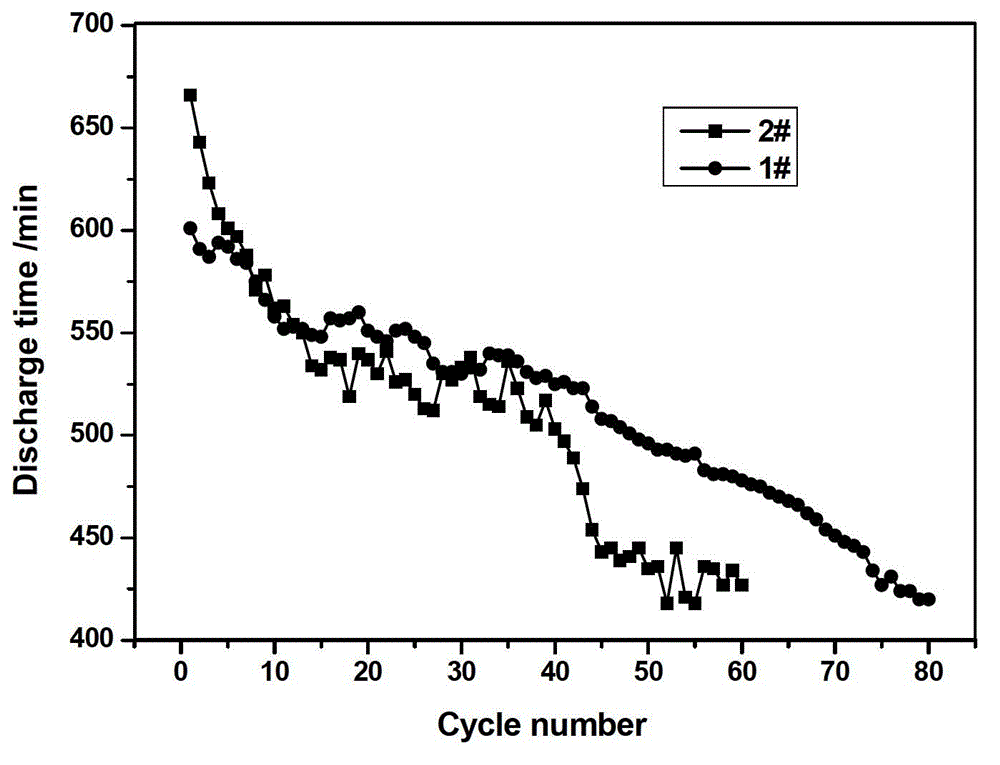

Preparation method for lead paste of negative plate of lead-acid battery and negative plate

InactiveCN102945958AImprove mixing uniformityImprove dispersion uniformityLead-acid accumulator electrodesFiberSulfate

The invention relates to a preparation method for lead paste of a negative plate of a lead-acid battery and the negative plate. The preparation method for the lead paste comprises the steps of preparation of mixed slurry of carbon powder, barium sulfate, organic additive, binder and lead powder, spray drying and mixing to obtain the paste. The prepared lead paste is coated on a negative plate gate and is then cured and dried to obtain the negative plate of the battery. Polytetrafluoroethylene is adopted as the binder, the mixed slurry is subject to the spray drying through a high-speed centrifugal spray drier, and the temperature of an air inlet is controlled to be 180-250 DEG C; and mixed solution of dispersed fibers and deionized water is added into the sprayed powder to prepare the paste. The uniformity of mixing for the negative material can be improved effectively, the contact area of the carbon powder and the lead powder can be enlarged, the conductivity of the negative plate can be improved, and the charge acceptance capacity of the battery can be improved. Meanwhile, the sulfate process of the negative plate can be effectively mitigated, the rate of utilization of active substances can be increased, and the service life of the battery can be prolonged.

Owner:SHANDONG UNIV

Juvenile freshwater crayfish feed

InactiveCN105394337AComprehensive and balanced nutritionRich variety of raw materialsFood processingClimate change adaptationNutrientProtein content

The invention discloses a juvenile freshwater crayfish feed which is prepared from the following components: fermented soybean meal, wheat bran, sweet potato powder, rice bran, dried blood, minced fillet, monochoria vaginalis, alfalfa, water hyacinth, shell powder, beewax, complex vitamin, amino acid chelate, a Chinese herbal medicine additive and a composite additive. The feed disclosed by the invention contains comprehensive and balanced nutrition, and the varieties of raw materials are abundant; according to measurement, the protein content of the feed is over 35%, the fat content is 9-12%, the carbohydrate content is 18-20% and the vitamin content is 18-20%, thereby meeting the requirement for the proportion of nutrient substances for the growth of juvenile crayfish; and given the biting type mouthpart of the freshwater crayfish, which is different from the swallowing type mouthpart of fish, the feed is specially made into a strip shape or flake shape and has certain viscosity and is convenient to eat. Most of the raw materials of the feed are pure natural green raw materials, and the phenomenon of drug residue in crayfish bodies is avoided; and moreover, the yield can be remarkably increased, and relatively good culture benefits are created.

Owner:袁生咬

Preparation method of particle drainage agent

The invention provides a preparation method of a particle drainage agent, and relates to the technical field of metallurgical fire-refractory materials. The preparation method of the particle drainageagent comprises the following steps of selecting a composition of one or more than two of chrome ore, quartz sand, corundum, zircon sand and magnesium sand with granularity smaller than or equal to 100 meshes as a raw material, weighing the applicable weight of raw materials according to the formula of the drainage agent, and uniformly mixing, so as to obtain fine powder; adding a binder into thefine powder, and uniformly mixing; extruding, granulating into particles, and drying and curing the obtained particles, so as to obtain the particle drainage agent. The particle drainage sand prepared by the method has the advantages that the components are uniform and stable, the content deviation is controlled within + / -0.5%, and the segregation of components is avoided in the production, transportation and use process. The particle drainage agent has the advantages that the granularity is uniform and stable, and the controllability is larger; in the use process, the casting effect is stable, and the automatic casting rate is stabilized to 99.5% or above.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

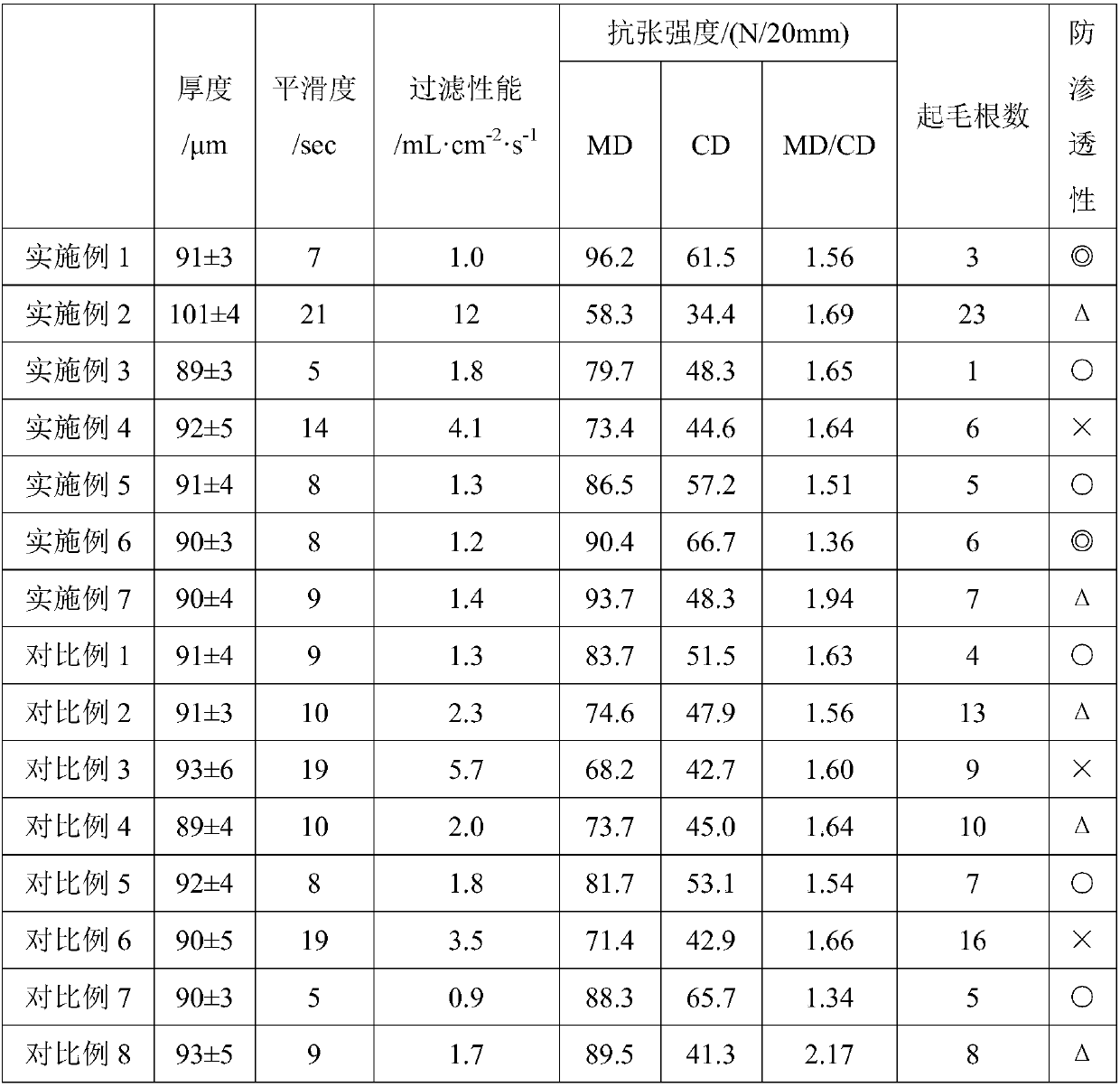

Non-woven fabric for semipermeable membrane support body

InactiveCN107558291AExcellent smoothness and breathabilityGood penetration of anti-coating liquidSemi-permeable membranesDefoamers additionDefoaming AgentsWoven fabric

The invention discloses non-woven fabric for a semipermeable membrane support body. Main ingredients of the non-woven fabric comprise main fibers, two different types of binder fibers, a dispersant, awet strength agent, a defoaming agent and the like. The non-woven fabric is prepared with a wet non-woven fabric method, firstly, raw materials are dispersed in water, used for preparing paper with pulp through an inclined wire paper machine and then treated through drying, hot pressing and other processes, and a sample is prepared. Compared with like products, the non-woven fabric for the semipermeable membrane support body is prepared with a further simplified process. The uniformity, surface smoothness and water permeability of a product are all improved and the problems of infiltration and leakage of a coating liquid can be solved by means of the provided raw material composition, proportion and processing process.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Environment-friendly ecological bast fiber integrated wall decorating plate and preparation method thereof

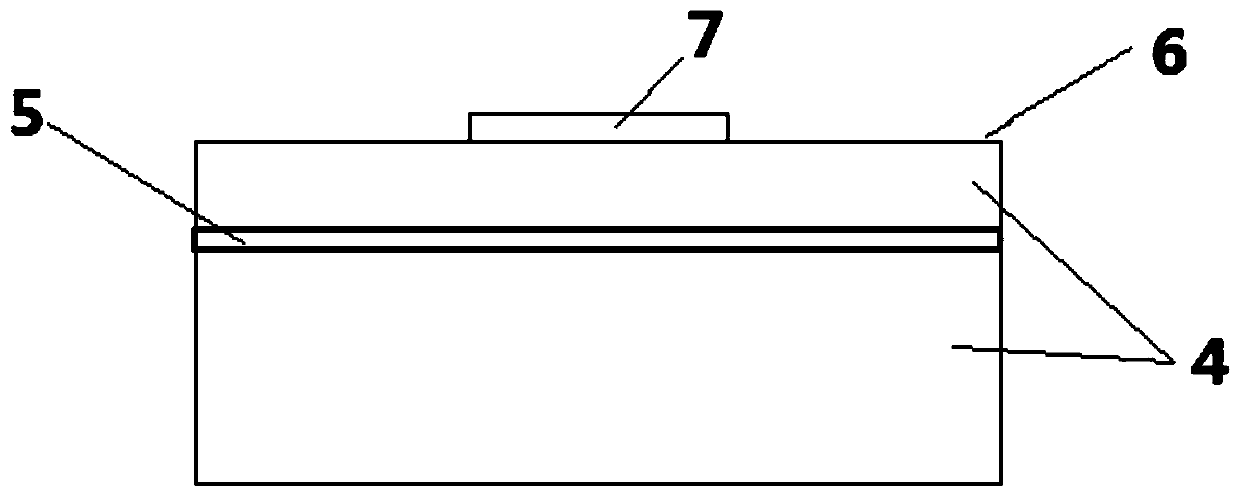

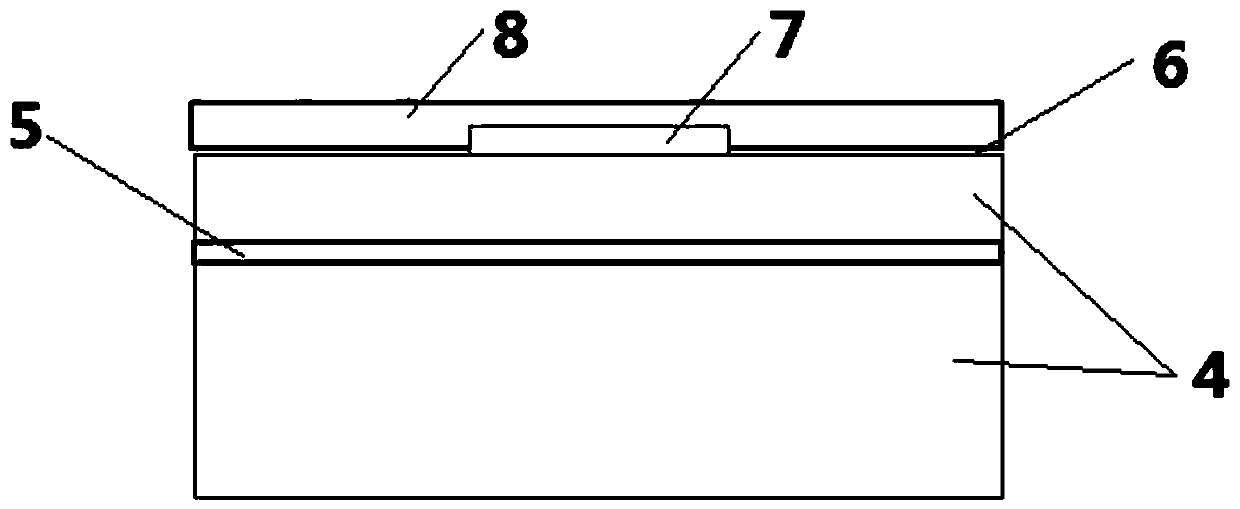

PendingCN109113289AHigh strengthAct as a bondCovering/liningsSynthetic resin layered productsEnvironmental resistancePolyester

The invention relates to the technical field of wall decorating plates for buildings and discloses an environment-friendly ecological bast fiber integrated wall decorating plate and a preparation method thereof. The bast fiber integrated wall decorating plate comprises a bottom layer, a middle layer and a surface layer which are sequentially overlapped and hot-pressed together. Both the bottom layer and the surface layer adopt polyester non-woven fabric layers, and the middle layer adopts a bast fiber felt layer. The bast fiber felt layer is formed in the mode that two or more pieces of precast and formed bast fiber felt are overlapped and preheated, the precast and formed bast fiber felt is mixed fiber felt with bast fibers and polypropylene fibers, and the bast fibers and the polypropylene fibers in the mixed fiber felt are both coiled fibers. The preparation method of the integrated wall decorating plate comprises the steps that the middle layer is manufactured; the polyester non-woven fabric layers are taken as the bottom layer and the face layer; and the bottom layer, the middle layer and the face layer are overlapped, heated and subjected to rolling forming, and the bast fiber integrated wall decorating plate is prepared after cutting. The wall decorating plate is environmentally friendly and ecological.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

Machine-made charcoal preparation method

The invention relates to a machine-made charcoal preparation method which comprises steps as follows: 1, raw material screening: a mixture of corn ear, corncobs or furfural residues is selected as a raw material; 2, raw material smashing; 3, drying; 4, stick preparation; and 5, carbonization. According to the machine-made charcoal preparation method, the mixture of the corn ear, the corncobs or the furfural residues is taken as the raw material, and by means of the characteristic of higher cellulose of the raw material, cellulose is softened into a molten state at a high temperature, so that a firewood stick is formed through pressing, a binder is omitted, the preparation cost of machine-made charcoal is reduced, and the environment is protected.

Owner:侯霄飞

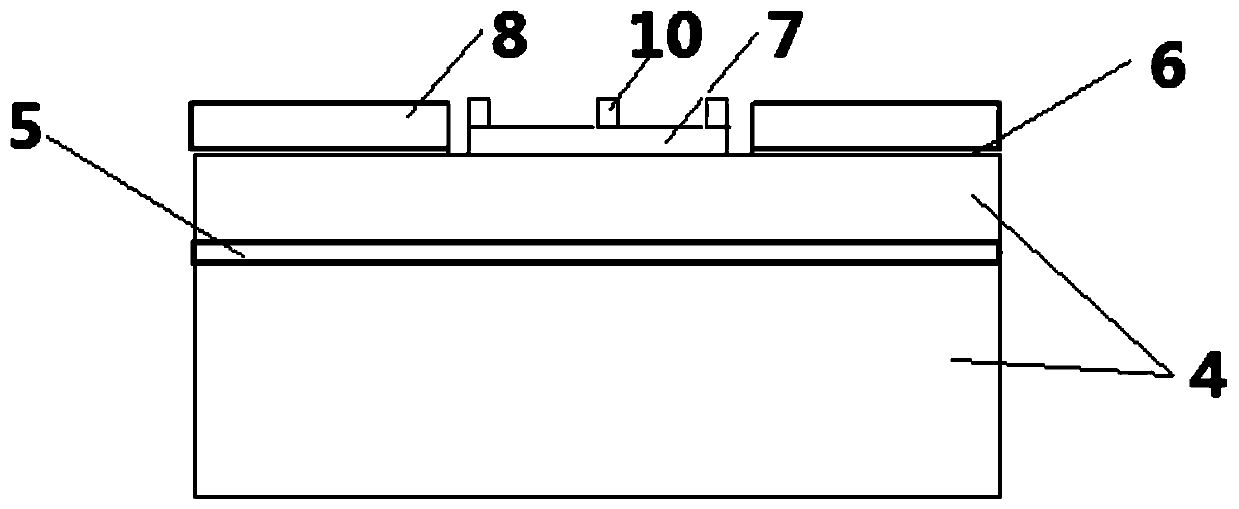

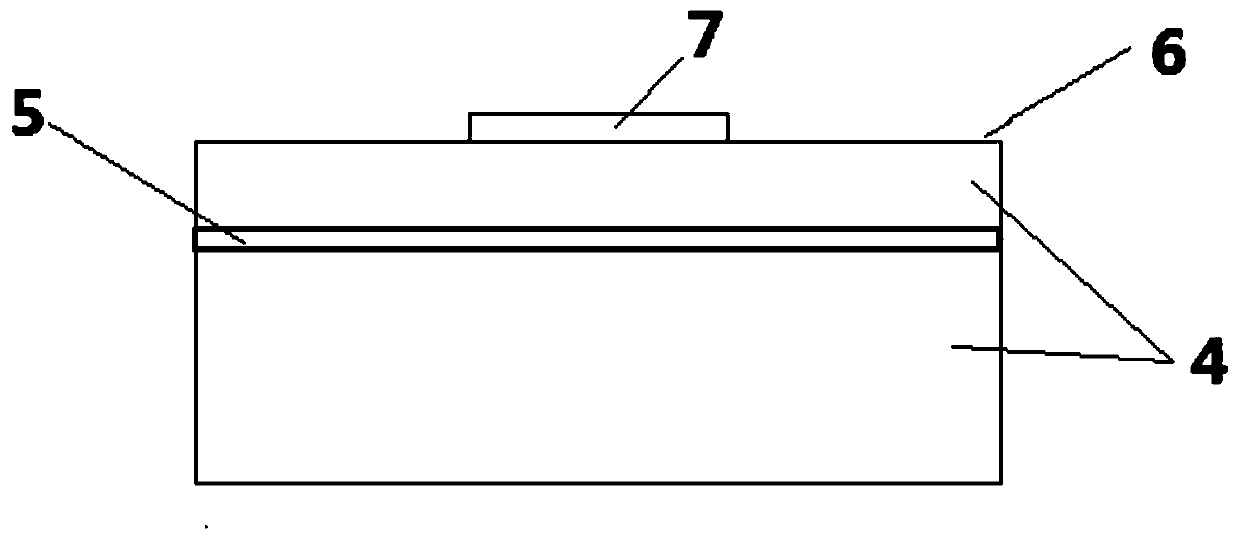

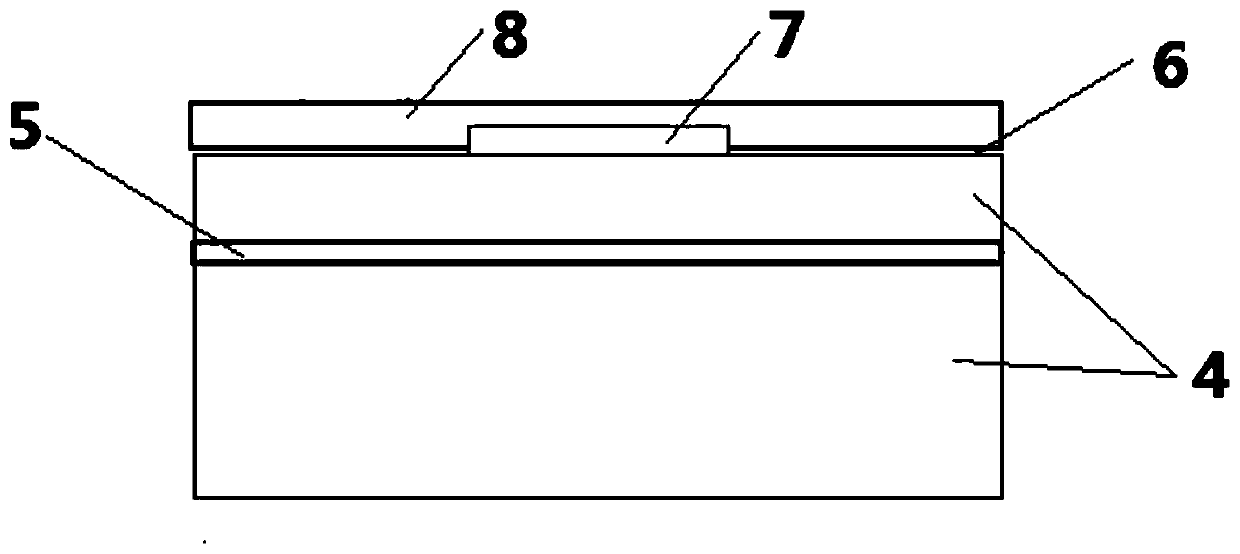

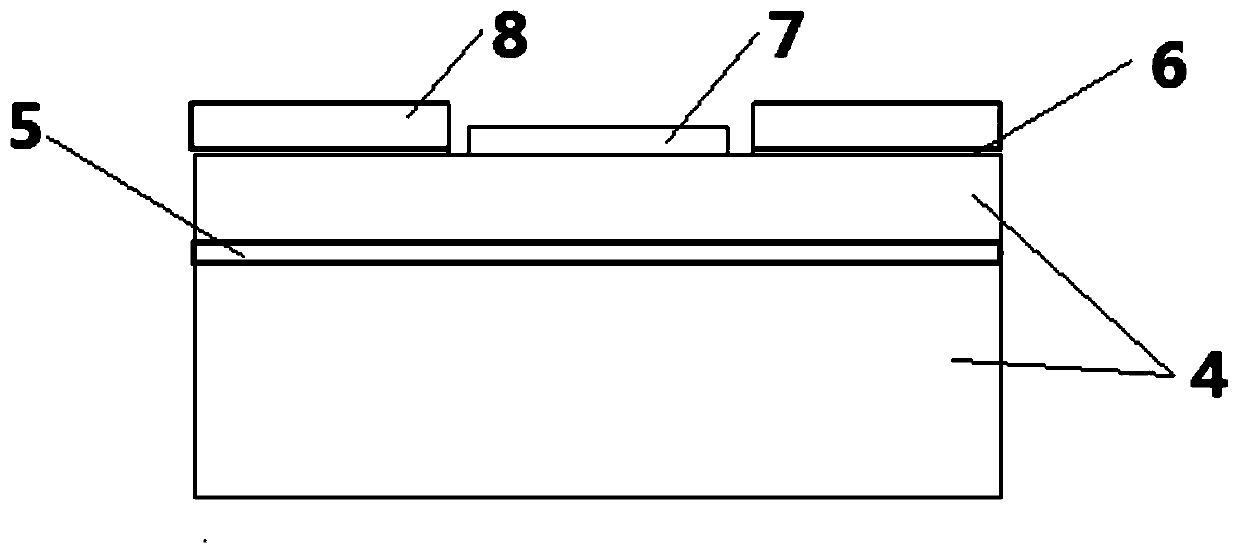

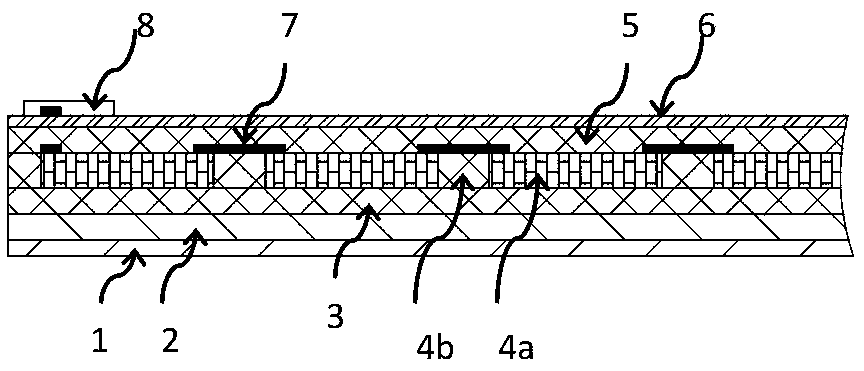

Cavity type bulk acoustic wave resonator with pillar and preparation method thereof

The invention provides a cavity type bulk acoustic wave resonator with a support column and a preparation method of the cavity type bulk acoustic wave resonator. The method comprises the following steps of: taking a piezoelectric single crystal wafer which is subjected to ion implantation and is provided with a bottom electrode; forming a plurality of supporting columns on one side, with the bottom electrode, of the piezoelectric single crystal wafer; forming a cavity at the gap of supporting columns, taking the substrate, bonding the substrate with one side of the piezoelectric single crystalwafer with the cavity, carrying out heat treatment on the substrate after bonding, stripping a film of the piezoelectric single crystal wafer, and producing a top electrode on the stripped side of the piezoelectric single crystal wafer to obtain the piezoelectric single crystal wafer. According to the technical scheme provided by the invention, a sacrificial layer does not need to be grown, etching and trepanning are not carried out on the thin film, the mechanical strength of the device is improved, and the thin film is not easily damaged; the cavity structure is formed before film formation, the rate of finished products is high, residues left by etching after film formation do not exist, and the influence of incomplete release on the device does not need to be considered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Inorganic fireproof heat insulating plate and preparation method thereof

InactiveCN102173675AShorten the production cycleIncrease productivityProduction cycleMaterials science

The invention discloses an inorganic fireproof heat insulating plate, which consists of the following components by volume: 46 to 77 parts of inorganic gelatin material, 150 to 175 parts of water, and 1,000 parts of light aggregate. A method for preparing the inorganic fireproof heat insulating plate comprises the following steps of: 1, selecting the inorganic gelatin material and the light aggregate; 2, preparing inorganic gelatin paste, wherein water is added into the inorganic gelatin material selected in the step 1, and the mixture is uniformly stirred to prepare the inorganic gelatin paste; and 3, preparing the inorganic fireproof insulating plate, wherein the light aggregate is added into the inorganic gelatin paste prepared in the step 2 to obtain a mixture, the mixture is stirred until the inorganic gelatin paste is uniformly dispersed on the surface of the light aggregate, and the mixture is filled in a mould to prepare the inorganic fireproof insulating plate. The inorganic fireproof insulating plate prepared by adopting the preparation method has short production period, excellent heat insulating performance and high fireproof performance.

Owner:SOUTHEAST UNIV

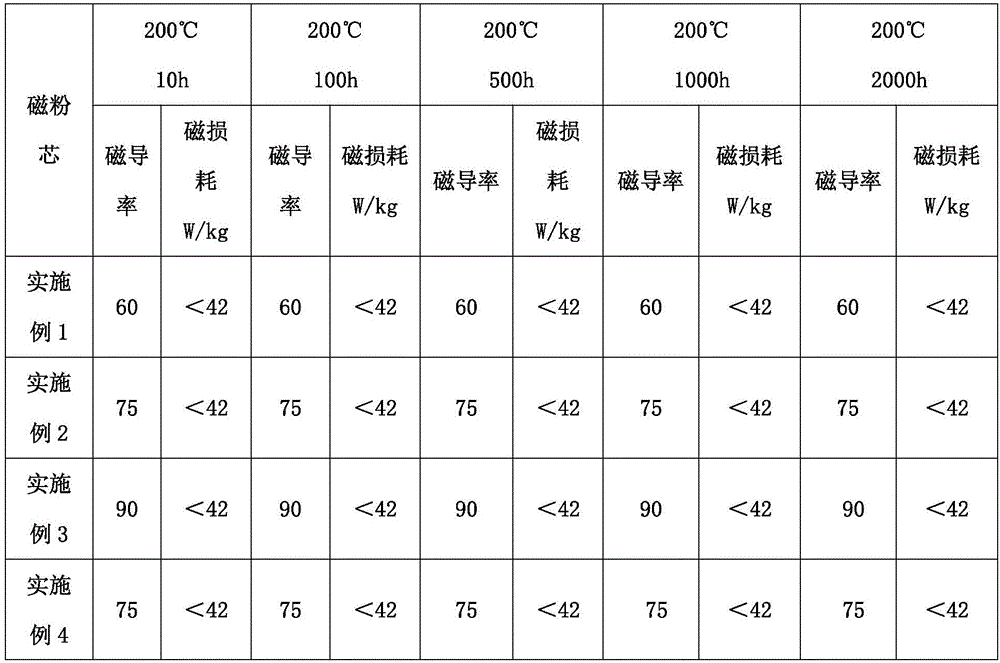

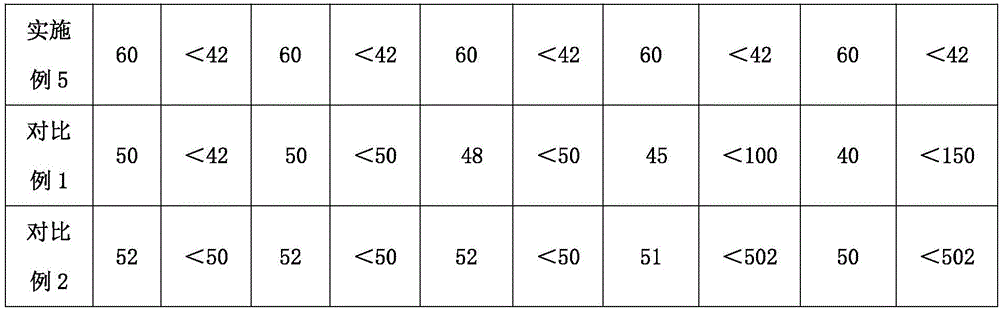

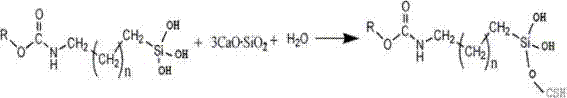

Amorphous soft magnetic composite magnetic powder core and preparation method thereof

ActiveCN106205935AGood calenderabilityExcellent magnetic propertiesTransportation and packagingMetal-working apparatusMagnetic powderPrecursor polymer

The invention belongs to the field of a metal-based soft magnetic composite material. A preparation method comprises the following steps of preparing amorphous alloy powder from an amorphous alloy thin strip; screening and compounding the amorphous alloy powder to obtain a first product; performing passivation and coupling processing on the first product to obtain a second product; mixing and stirring the second product and a ceramic precursor polymer solution to obtain composite amorphous powder; and performing formation, thermal processing and insulation layer coating on the composite amorphous powder to obtain amorphous soft magnetic composite magnetic powder. By adopting a ceramic precursor polymer as an insulation binding agent, the step of adding insulation agent powder is omitted, the problems of unstable magnetic conductivity and poor thermal stability during traditional preparation of the magnetic powder core by crashing the amorphous thin strip are solved, the production cost is reduced, and the amorphous soft magnetic composite magnetic powder can be applied to a certain electronic device with application requirements for high frequency and low loss.

Owner:张听

Manufacturing method of recombining broken meat

InactiveCN1623438AIncrease added valueIncrease the degree of cross-linkingFood preparationRaw materialChemistry

A method for preparing recombinant meat from fragmentary meat and meat blocks with irregular shapes through treating said raw material, proportionally mixing it with flavouring materials, shaping, reaction, quickly freezing and slicing.

Owner:辛海波

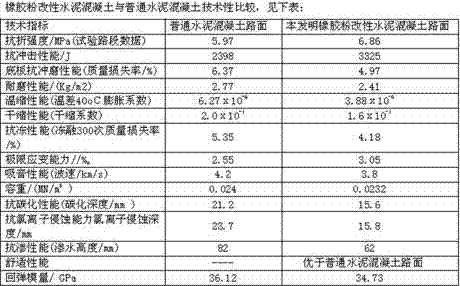

Rubber powder modified cement concrete pavement and manufacturing method thereof

ActiveCN107188488AEffective digestionExtended service lifeIn situ pavingsSolid waste managementCelluloseWear resistant

The invention discloses a rubber powder modified cement concrete pavement and a manufacturing method thereof. The rubber powder modified cement concrete pavement is characterized by being prepared from the following raw materials in parts by weight: 25 to 30kg / m<3> of rubber powder, 300 to 330kg / m<3> of 425 cement, 550 to 590kg / m<3> of river sand, 1080 to 1180kg / m<3> of broken stone, 135 to 165kg / m<3> of water, 5 to 7kg / m<3> of water reducing agents, 3 to 4kg / m<3> of phthalic ester coupling agents, 2 to 3kg / m<3> of rubber latex, 3 to 4kg / m<3> of hydrophobic modification cellulose, 15 to 20kg / m<3> of lignin, 80 to 110kg / m<3> of granulitic blast-furnace ore slag powder and the like. The raw materials are effectively mixed to obtain the concrete. The rubber powder modified cement concrete pavement has the characteristics that the properties of anti-folding intensity, anti-impact performance, bottom plate anti-impact and anti-abrasion performance, wear-resistant performance, temperature shrinkage, dry shrinkage performance, freezing resistance performance, ultimate strain capability, noise reducing performance, volume weight, corrosion resistance and the like of the rubber powder modified cement concrete pavement are superior to those of the ordinary cement concrete pavement; the later-stage maintenance cost is lower than that of the ordinary cement concrete pavement, and the like.

Owner:广西航务建设工程有限公司

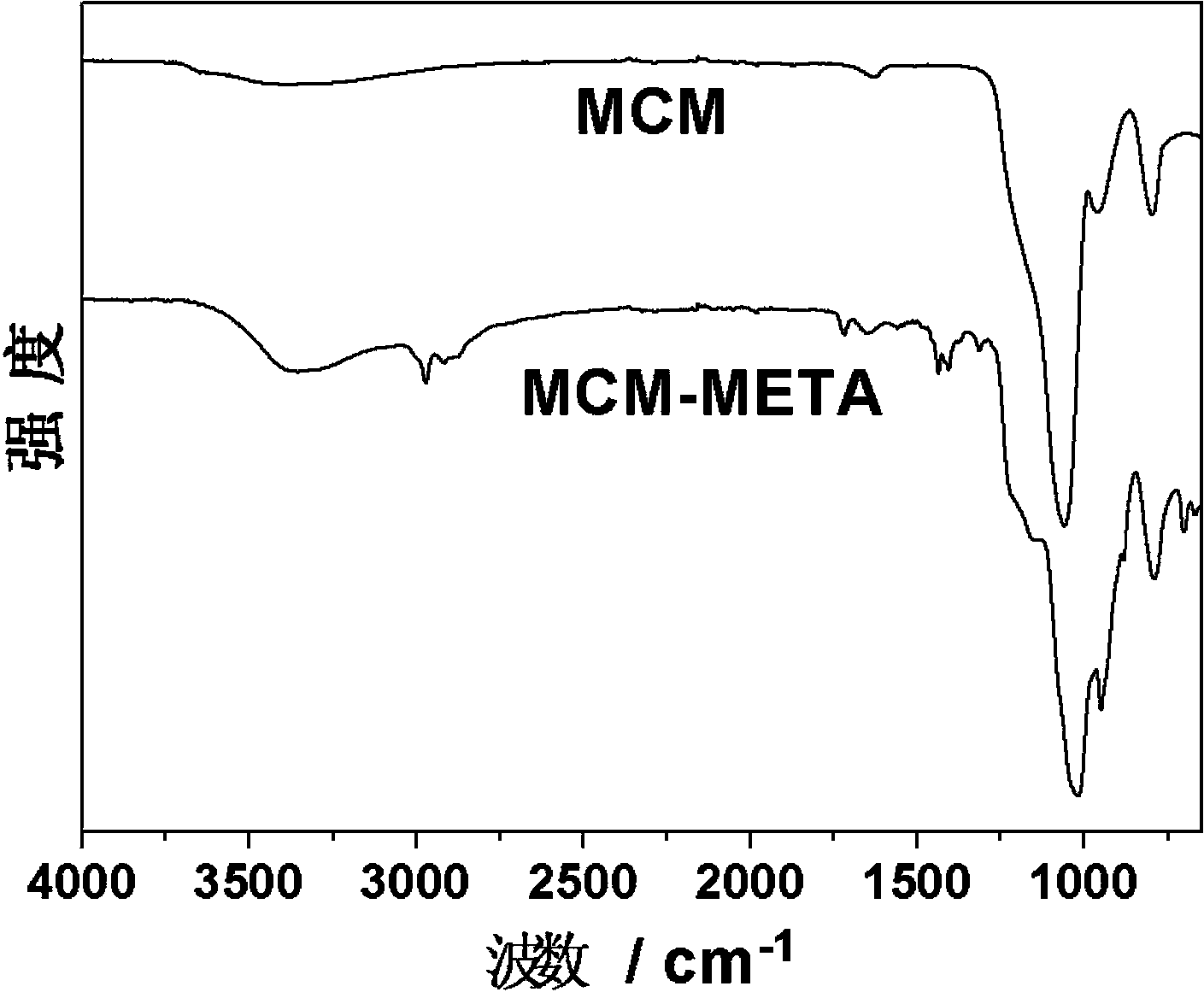

Drug-loaded mesoporous-silica-reinforced dental binder and preparation method thereof

InactiveCN103655207APorousAct as a bondAntibacterial agentsImpression capsMesoporous silicaDrug release

The invention relates to a drug-loaded mesoporous-silica-reinforced dental binder and a preparation method thereof. The binder comprises following components by weight: 40-60% of a resin component, 35-50% of a dilution component, 2-10% of an acid monomer, 0.2-0.5% of a photoinitiator, 0.1-0.3% of a promoter, a trace amount of a polymerization inhibitor and 1-10% of mesoporous silica. The binder has high strength and drug releasing property, and therefore the binder is advantaged by loading and performing controlled releasing of antibacterial agents, anti-inflammatory drugs, hemostatics, etc.. The binder not only has a binding function, but also has certain functions of treating and preventing bacterial infection, and can be used as a dentine binder in clinic.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

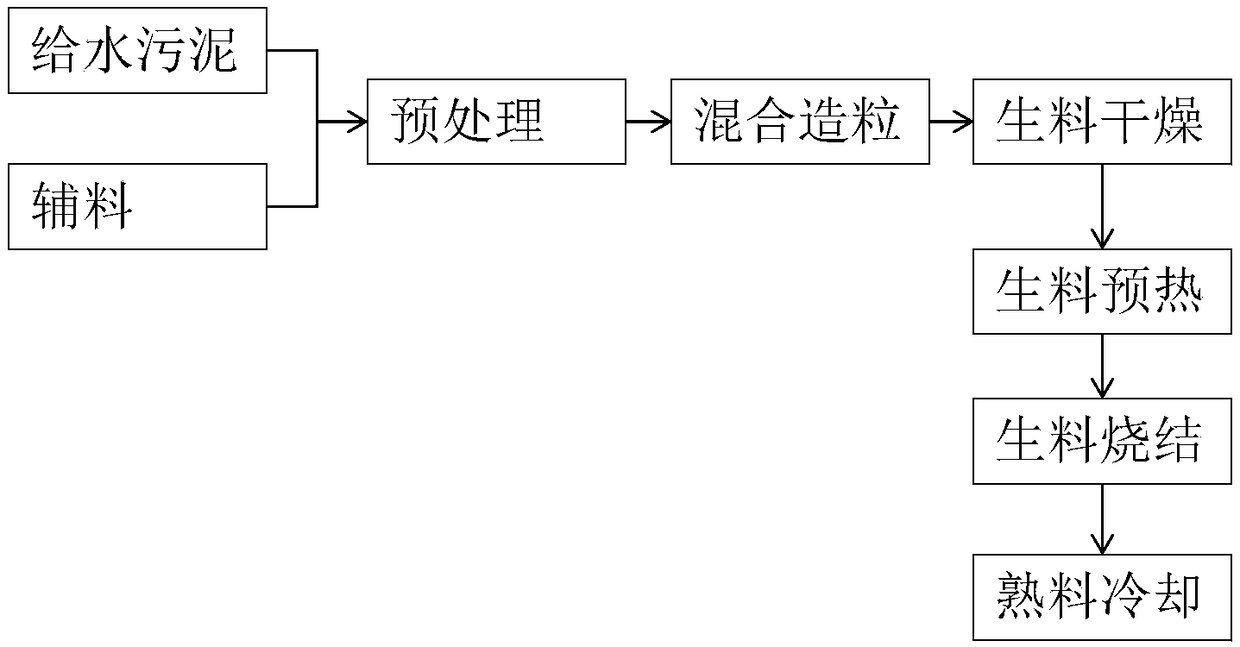

Preparation method of aluminum sludge ceramsite

PendingCN108585934ASolving Disposal ProblemsEfficient use ofCeramic materials productionCeramicwarePorositySludge

The invention relates to a preparation method of aluminum sludge ceramsite. The preparation method comprises: drying and grinding aluminum sludge with auxiliary materials such as glass powder, egg shell and fly ash; mixing and stirring the materials uniformly; then adding water as a binder; carrying out mixing granulation to obtain green ceramsite; and then drying, preheating, sintering and cooling the green ceramsite. According to the preparation method provided by the invention, the aluminum sludge and glass powder are adopted to replace clay to provide Al2O3 and SiO2, so that the manufacturing cost of ceramsite is remarkably reduced. The manufactured ceramsite has the advantages of large specific surface area, rough surface, high porosity, few dissolved substances, high water absorptionperformance, low dissolution rate and the like, can be used for large-scale disposal of aluminum sludge in water supply plants, realizes waste utilization, and saves the disposal cost of aluminum sludge. The aluminum sludge ceramsite is widely used in secondary treatment and advanced treatment of sewage, treatment of building reclaimed water, treatment of industrial wastewater, and treatment sponge city rainwater, and has a high market application prospect.

Owner:XIAN UNIV OF SCI & TECH

Carbon material forming process and formed part

The invention discloses a carbon material forming process and a formed part. The carbon material forming process comprises the following steps: (1) mixing and granulating carbon material powder and a binding agent; (2) injection-molding to obtain an injection-molded carbon material blank; (3) conducting dewaxing treatment; (4) pre-sintering at 200-800 DEG C and completely removing the binding agent to obtain a pre-sintered blank; and (5) continuously warming up to 1000-2500 DEG C in a protective atmosphere and sintering the pre-sintered blank; and preserving heat for 1-10h to obtain a sintered part. The process disclosed by the invention, by conducting dewaxing treatment on the injection-molded carbon material blank firstly, then pre-sintering stably and slowly at temperature of three stages and completely removing the binding agent added to the carbon material, can improve subsequent sintering, reduce porosity of the part as well as improve heat conductivity, electrical conductivity and overall appearance quality of the part material.

Owner:HEFEI GENIUS NEW MATERIALS

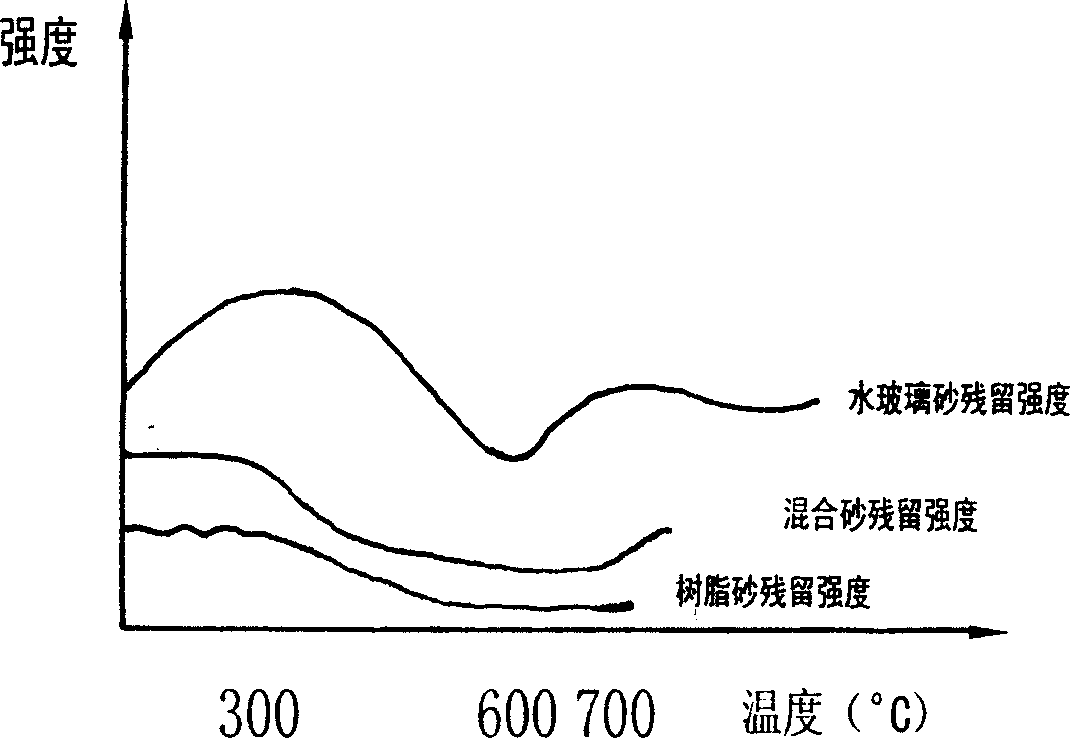

Water glass and resin mixed CO2 hardening method

ActiveCN1613573AReduce the amount addedHigh strengthFoundry mouldsFoundry coresResin adhesivePolyresin

A CO2 hardening method for the mixture of water glass and resin used for casting sand mould includes such steps as proportionally mixing the sand, water glass and resin, forming mould, and introducing CO2 gas to harden the mould. It features that after casting, the resin adhesive prepared from water glass and resin is carbonized, resulting in high collapsibility.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Light-weight non-sintered ceramsite for wastewater treatment and preparation method of light-weight non-sintered ceramsite

InactiveCN105060923ASimple preparation processWide variety of sourcesCeramicwareSodium silicateAluminium

The invention discloses light-weight non-sintered ceramsite for wastewater treatment and a preparation method of the light-weight non-sintered ceramsite. According to the preparation method, zeolite powder and coal ash are taken as main raw materials; quicklime, phosphogypsum, Portland cement, ferrous sulfide and aluminum powder are taken as auxiliary ingredients; sodium chloride, attapulgite, sodium silicate, sodium tripolyphosphate, potassiam polyoxyethylene laurylether phosphate, nanometer aluminum oxide and nanometer silicon dioxide are taken as additives. The preparation method comprises the steps of material preparation, mixing, pelletization and forming, and steam curing. The prepared light-weight non-sintered ceramsite has the advantages that the compressive strength is higher than 15 MPa, and the apparent density is lower than 0.9 g / cm<3>.

Owner:河南新封生态环境工程股份有限公司

Compounded gel used as fat substitute, and sausage made of compounded gel

The invention discloses a compounded gel used as fat substitute. The compounded gel is made through the steps of raw material selection, uniform mixing, puffing stirring, heat insulation swelling, alkali addition, heat insulation molding and heating solidification, wherein above raw materials comprise, by weight, 1 part of fine konjak powder, 40-50 parts of water, 0.15-0.20 part of carrageenan and 0.12-0.13 part of soda ash. The invention also discloses a processing method of a Chinese style sausage. The processing method comprises the steps of material choosing, cutting, preserving, sausage filling, and baking or air-drying, wherein chosen materials comprise a main material, an auxiliary material and an additive, and the main material comprises 8-10 parts by weight of pork and 0.9-2.5 parts by weight of the compounded gel. The contradiction of middle and old consumers wanting to eat but not daring go to eat due to the high fat content of the sausage is solved in the invention.

Owner:SICHUAN TOURISM UNIV

Composite water-retention fertilizer and its preparation method

InactiveCN103360166AIncrease moisture contentImprove water use efficiencyFertilizer mixturesCompound organicCorn flour

The invention discloses a composite traditional Chinese medicinal water-retention fertilizer and its preparation method, wherein the composite organic fertilizer comprises the following components: by weight, 1-4 parts of soluble chitosan, 4-8 parts of fulvic acid, 5-7 parts of corn flour and the like. The components are used in synergism, thus satisfying nutrient supply required by health growth of crops, effectively killing soil insects on crops and raising use efficiency of soil moisture. Meanwhile, the composite water-retention fertilizer is safe to human and animals and causes no environmental pollution.

Owner:SUZHOU RENCHENG BIO SCI & TECH

Cavity type bulk acoustic wave resonator without preparing sacrificial layer and preparation method of cavity type bulk acoustic wave resonator

The invention provides a cavity type bulk acoustic wave resonator without preparing a sacrificial layer and a preparation method of the cavity type bulk acoustic wave resonator. The method comprises the following steps that a piezoelectric single crystal wafer which is subjected to ion implantation and provided with a bottom electrode is taken, a cavity is formed in the side, provided with the bottom electrode, of the piezoelectric single crystal wafer, then a substrate is taken, and the substrate and the side, provided with the cavity, of the piezoelectric single crystal wafer are bonded; andheat treatment is carried out on the bonded intermediate product to strip the film of the piezoelectric single crystal wafer, and then a top electrode is produced on one stripped side of the piezoelectric single crystal wafer to obtain the cavity type bulk acoustic wave resonator. According to the preparation method of the cavity type bulk acoustic resonator without the need of preparing the sacrificial layer, the sacrificial layer does not need to be grown, etching and trepanning are not carried out on the thin film, the mechanical strength of the device is improved, and damage to the thin film is not likely to be generated; the cavity structure is formed before film formation, the rate of finished products is high, residues left by etching after film formation do not exist, and the influence of incomplete release on the device does not need to be considered.

Owner:CHIMEMS MICROELECTRONICS CO LTD

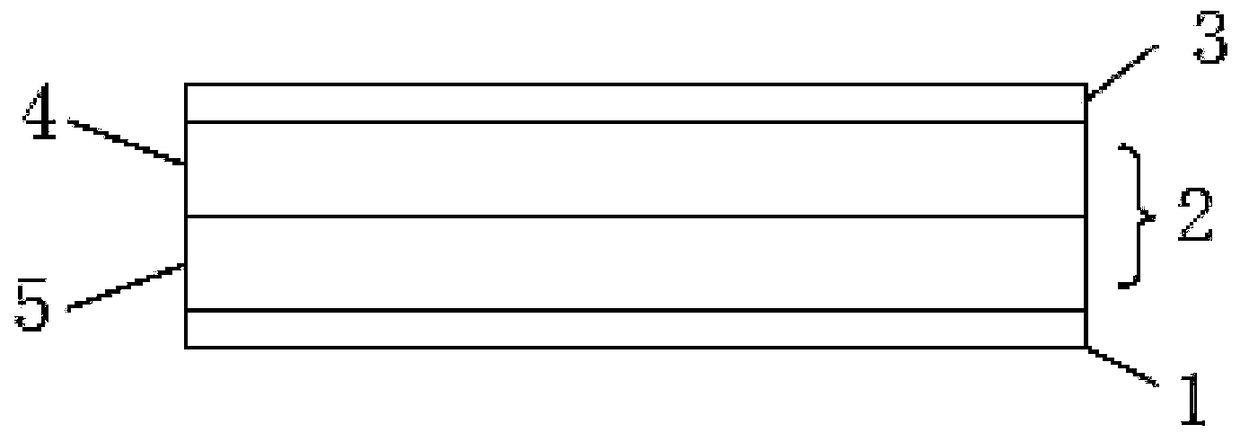

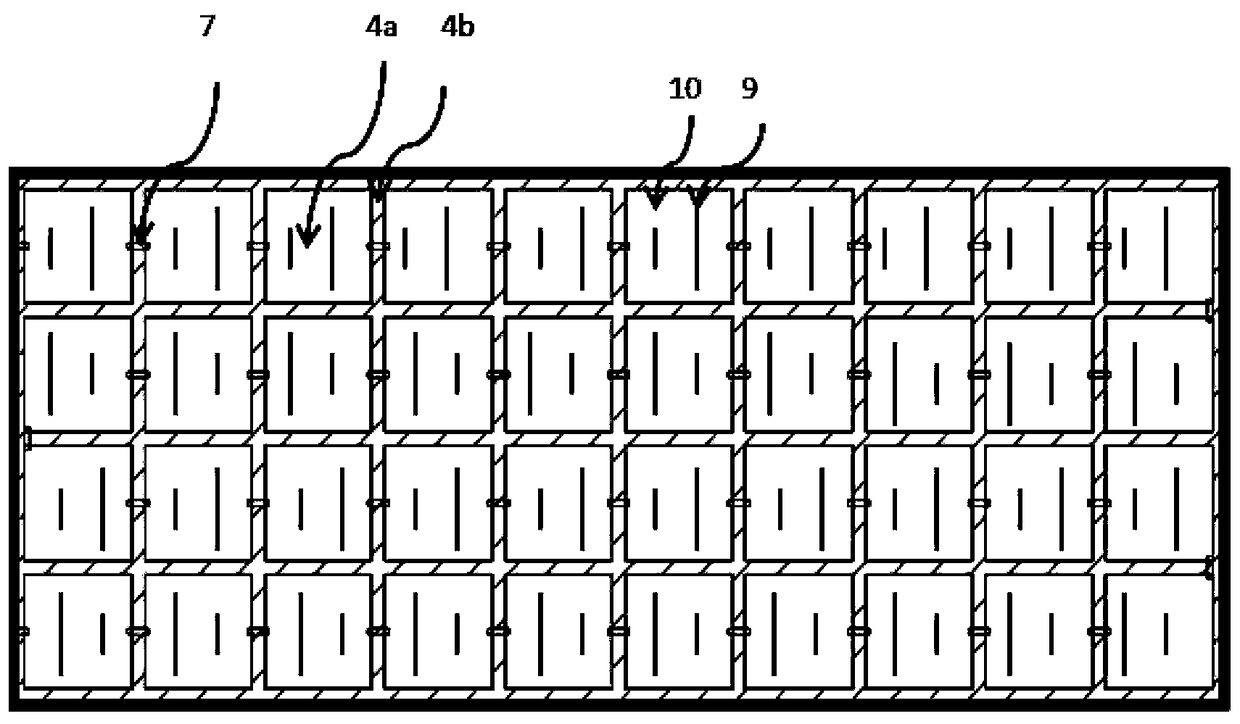

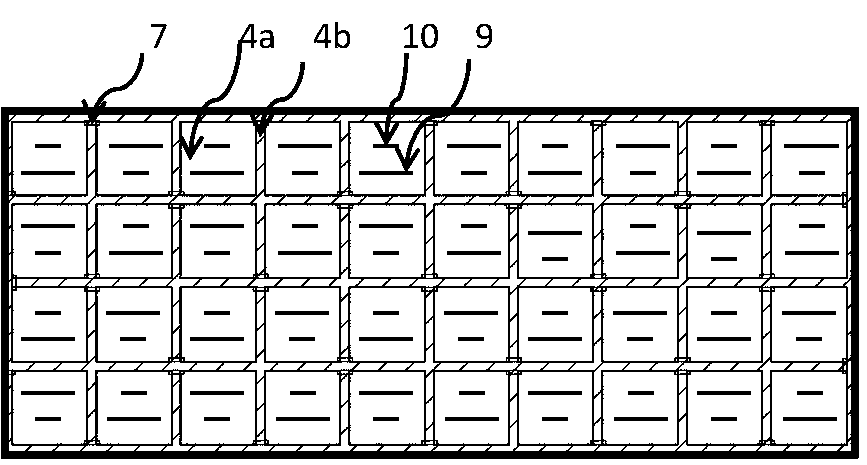

Photovoltaic module based on perovskite solar cells and packaging method thereof

ActiveCN108922973AIncrease power generationImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEngineering

The invention provides a photovoltaic module based on perovskite solar cells and a packaging method thereof. The photovoltaic module comprises a laminated piece and a frame arranged around the laminated piece, wherein the laminated piece comprises a protection layer, a first bonding layer, a perovskite solar cell string, a filling layer, a second bonding layer and a back plate layer which are overlapped in order, the perovskite solar cell string comprises a plurality of perovskite solar cells, a bottom electrode of one cell is connected with a top electrode of an adjacent cell, or bottom electrodes of adjacent two cells are connected and top electrodes of the adjacent two cells are connected, and a space between the adjacent cells is filled with the filling layer.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

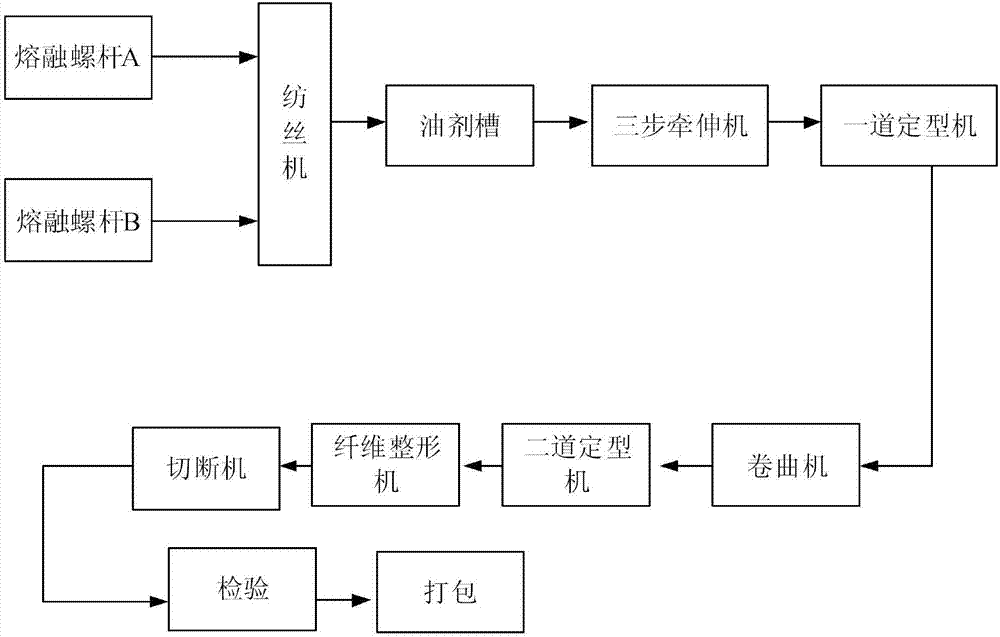

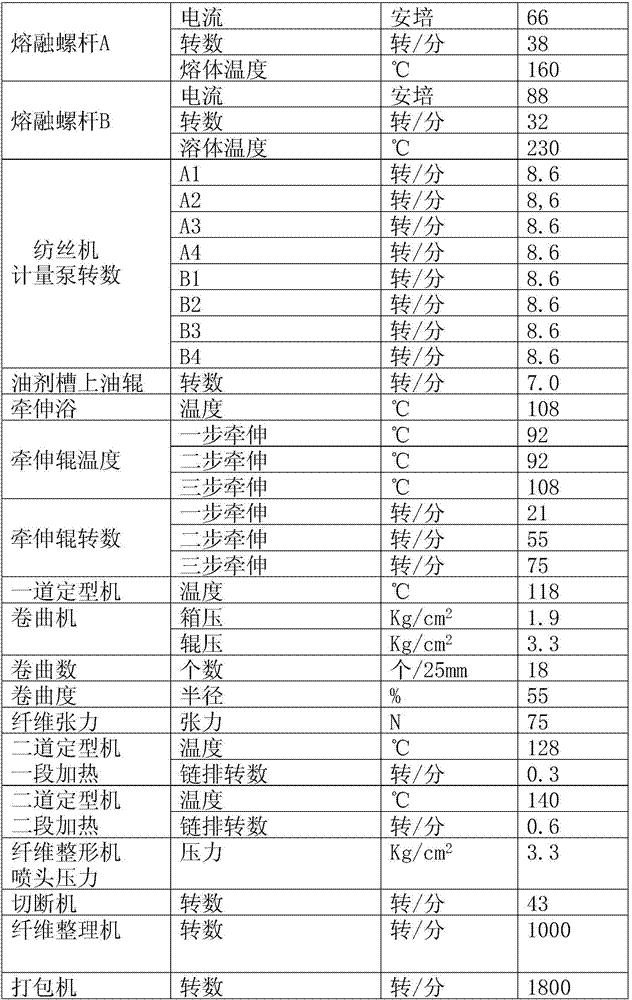

Preparation method of composite spinning skin-core structure polypropylene electrostatic staple fiber

InactiveCN106906526AAct as a bondBest filter mediaElectroconductive/antistatic filament manufactureMelt spinning methodsFiberMetering pump

The preparation method of the polypropylene electrostatic short fiber with composite spinning sheath-core layer structure of the present invention belongs to the technical field of new industrial materials. The polypropylene slices are added to the melting screw A as the skin layer, and the polypropylene electrostatic masterbatch is added to the melting screw B as the core layer. , the cortex and core layer are added to the metering pump of the spinning machine according to the mass percentage (30-70): (30-70). The fiber tow is obtained after the crimping machine and the second drafting machine are shaped; the obtained fiber tow is passed through a fiber shaping machine and a cutting machine to obtain a composite spinning sheath-core layer structure polypropylene electrostatic short fiber. The invention adopts composite spinning sheath-core layer structure electrostatic fiber as low-melting point fiber. When processing hot-melt filter net and hot-rolled non-woven fabric, sticking sticks will not occur on the carding machine and web sticking will not occur on the web-laying machine due to static electricity.

Owner:JILIN PROVINCE HUAFANG ELECTROSTATIC MATERIAL TECH CO LTD

Method for manufacturing solar double-glass assembly

InactiveCN104183669AUniform temperature transferMelted completelySemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringSurface layer

The invention discloses a method for manufacturing a solar double-glass assembly. The method includes the following steps that (1) a PVB adhesive film, a solar battery string, a PVB adhesive film and surface layer tempered glass are sequentially laid on bottom layer tempered glass, so that the solar double-glass assembly is formed; (2) whether hidden cracking pieces exist in solar battery pieces of the double-glass assembly in the first step is checked, and the hidden cracking pieces are removed; (3) the double-glass assembly is placed in a laminating machine under the -1 barometric pressure, the process is kept for 30-40 minutes, then an upper chamber of the laminating machine is placed at the pressure of -0.5 MPA, a lower chamber is placed at the pressure of -1 MPA, the process is kept for 20-30 minutes, afterwards, the temperature rises to be 140+ / -5 DEG C, and at the pressure of -0.5 MPA to -0.6 MPA, the process is kept for 20-30 minutes; (4) whether hidden cracking pieces exist in the solar battery pieces of the laminated double-glass assembly is checked, and the hidden cracking pieces are removed; (5) the double-glass assembly is fixed, the double-glass assembly is placed in an autoclave, and after a dehumidifier is used for dehumidifying, under the conditions of 20-150 DEG C and 0-1.3 MPA, the process is kept for 2-4 hours.

Owner:JIANGSU CHENDIAN SOLAR PHOTOELECTRIC TECH

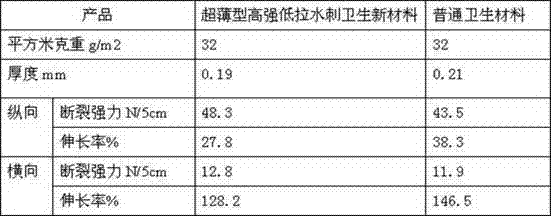

Production technology for novel ultra-thin high-strength low-stretch-rate spunlace sanitation material

The invention discloses a production technology for a novel ultra-thin high-strength low-stretch-rate spunlace sanitation material, and belongs to the technical field of textile materials. According to the production technology, the mixed fiber of ES fibers, viscose fibers and polyester fibers is used as a raw material, and the raw material is sequentially fed into a long curtain, a horizontal opener, a big bin cotton mixing box, a fine opener, a cotton storage box, an airflow cotton box, a carding machine, a spunlace machine, a drying machine, an on-line detection device and a take-up device. The novel ultra-thin high-strength low-stretch-rate spunlace sanitation material has the advantages of being light, thin, high in strength and low in stretch rate, and also has the advantages of being sanitary, soft, good in hygroscopicity and the like.

Owner:ZHEJIANG HEZHONG NONWOVEN

Organic-selenium-enriched slow release fertilizer specially used for strawberries

ActiveCN103772051AMeet the needs of selenium fertilizerPromote growthFertilizer mixturesFragariaCellulose

The invention relates to an organic-selenium-enriched slow release fertilizer special for strawberries. The organic-selenium-enriched slow release fertilizer is prepared from the following raw materials in parts by weight: 2-5 parts of selenium source (based on the content of selenium), 20-30 parts of attapulgite, 25-40 parts of sodium humate, 0.5-1.5 parts of sodium carboxymethylcellulose, 19 parts of nitrogenous fertilizer (based on the content of nitrogen), 10 parts of phosphate fertilizer (based on the content of phosphorus), 19 parts of potassium fertilizer (based on the content of potassium) and 20 parts of water. The organic-selenium-enriched slow release fertilizer can meet the requirement of the strawberries for selenium fertilizer; moreover, due to the addition of nitrogen phosphorus and potassium fertilizers, the nitrogen phosphorus and potassium fertilizers can promote strawberry growth and quality after the slow release fertilizer is applied.

Owner:NINGBO ZHONGJING BIOLOGICAL TECH

Light non-sintered ceramsite for road capital construction and preparing method thereof

InactiveCN105016767AAct as a stimulantExcellent physical and chemical propertiesSolid waste managementCeramicwarePhosphateNano al2o3

The invention discloses a method for preparing light non-sintered ceramsite for road capital construction, construction waste and industrial waste serve as main materials, quick lime, desulfurization gypsum, portland cement, ferrous sulfide and rice hull ash serve as auxiliary elements, sodium sulfate, loess, fluorite powder, sodium pyrophosphate, potassiam polyoxyethylene laurylether phosphate, nanometer aluminum oxide and nano zirconium silicate serve as additives, and the method includes the steps of preparing materials, mixing, pelleting forming and steam curing. The apparent density of the prepared non-sintered ceramsites is lower than 1.3 g / cm<3>.

Owner:黑龙江新禹水泥制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com