Environment-friendly ecological bast fiber integrated wall decorating plate and preparation method thereof

A technology of hemp fiber and integrated wall, which is applied in the field of building wall panels, can solve the problems of poor bending resistance, low toughness, and volatile harmful gases, and achieve the goal of improving physical and mechanical properties, light weight toughness, and light weight strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

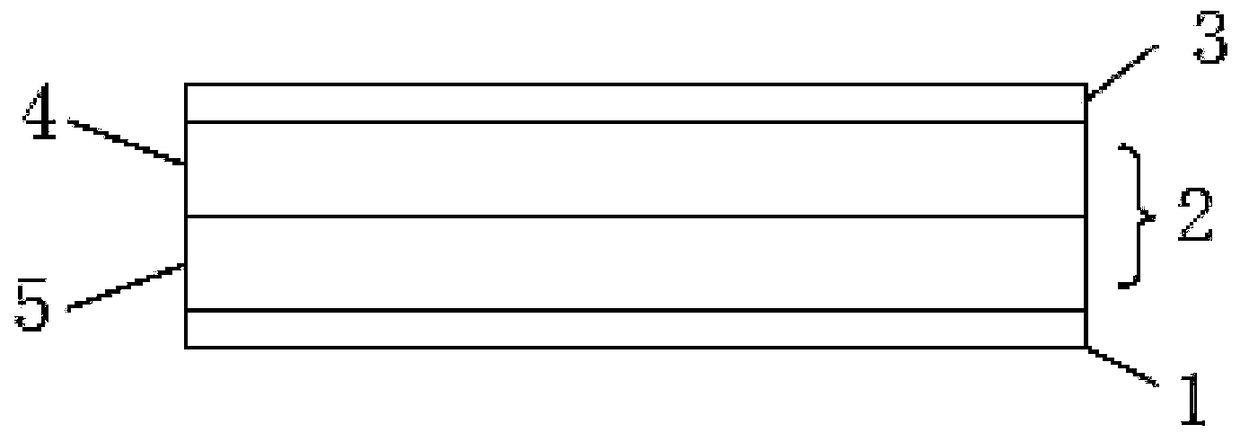

[0057] Such as Figures 1 to 5 Shown is an embodiment of a green ecological hemp fiber integrated wall decorative board of the present invention, including a bottom layer 1, an intermediate layer 2 and a surface layer 3 that are laminated and hot-pressed together, and the bottom layer 1 and the surface layer 3 are both Polyester non-woven fabric layer, the middle layer 2 is a hemp fiber felt layer, and the hemp fiber felt layer is made of two or more prefabricated hemp fiber felts 4 and 5 after stacking and preheating Hemp fiber mat layer, and the prefabricated hemp fiber mat is a mixed fiber mat of hemp fiber and polypropylene fiber, and the hemp fiber and polypropylene fiber in the mixed fiber mat are winding fibers.

[0058] As a preferred solution of this embodiment, the meandering fiber is an S-shaped meandering fiber formed by air-laying.

[0059] The above-mentioned green ecological hemp fiber integrated wall decoration board is mainly composed of the surface layer 3, ...

Embodiment 2

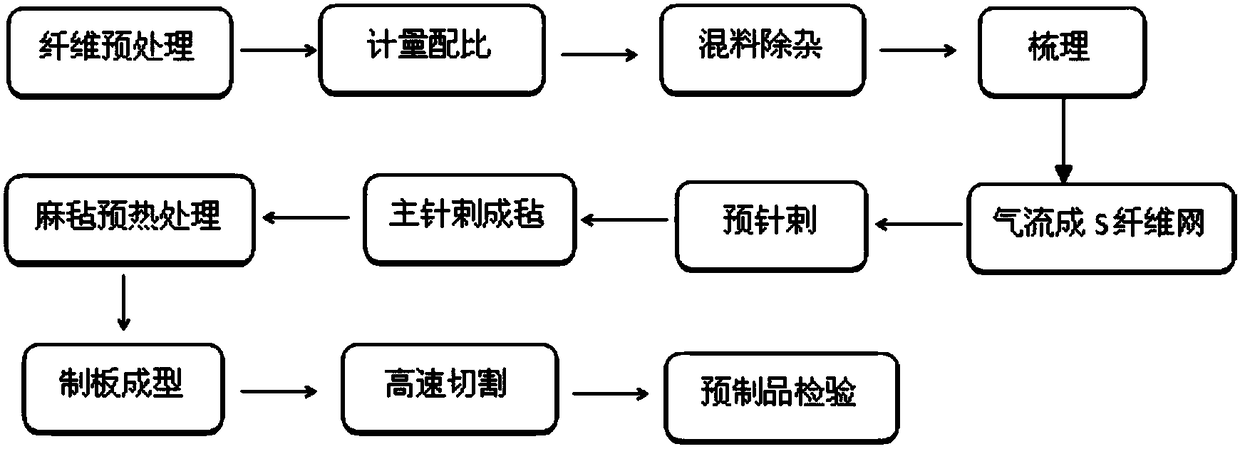

[0070] Such as Figures 1 to 5 Shown is the embodiment that adopts the preparation method of a kind of green ecological hemp fiber integrated wall decorative board of embodiment 1, comprises following method step:

[0071] The first step is to make the middle layer 2;

[0072] The second step is to take the polyester non-woven fabric layer as the bottom layer 1 and the surface layer 3;

[0073] The third step, plate making and forming: after the bottom layer 1, the middle layer 2, and the surface layer 3 are superimposed, the mechanical automatic paving method is used to heat and roll on the rolling forming machine, and the above-mentioned green color is obtained after cutting. Ecological hemp fiber integrated wall panels.

[0074] In the above preparation method, the process steps of making the intermediate layer 2 in the first step are:

[0075] Step 1. Fiber pretreatment: loosen polypropylene fibers and hemp fibers by using a bale opener and a coarse opener;

[0076] St...

Embodiment 3

[0091] Such as Figure 4 Shown, as the preparation system that adopts the preparation method of a kind of green ecological hemp fiber integrated wall decorative board of above-mentioned embodiment 2, comprise the production line that is used to prepare hemp fiber felt, the production line of described hemp fiber felt includes according to production process from input to The order of output is arranged in sequence: bale opener → rough opener → dust removal system → high-speed comber → air-laid machine → pre-looming machine → main loom → oven → roll forming machine.

[0092] As a further improvement, a vacuum deodorizer can also be arranged between the main machine and the oven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com