Patents

Literature

75results about How to "With sound absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural fiber reinforced polypropylene composite material and preparation method thereof

ActiveCN102585358AEnvironmentally friendlyWith sound absorptionPolypropylene compositesNatural fiber

The invention discloses a natural fiber reinforced polypropylene composite material and a preparation method thereof. The preparation method mainly comprises the following steps of: firstly, carrying out ultrasonic surface desorption processing on a chopped natural fiber tow; then heating by microwaves for rapid dehydrating and drying; after uniformly mixing polypropylene, a flexibilizer, a lubricant, a compatilizer and a heat stabilizer, adding the mixture into an extruder; adding fibers in a laterally feeding mode; and after melting, carrying out extrusion, cooling, air-drying and grain-sized slicing to obtain the natural fiber reinforced polypropylene composite material. The preparation method disclosed by the invention is simple and has a reasonable formula. The prepared material has the advantages of environmental friendliness, sound adsorption, heat insulation, low density, low shrinkage factor, good processing forming performance, degradable property and excellent comprehensive mechanical property.

Owner:ORINKO NEW MATERIAL CO LTD

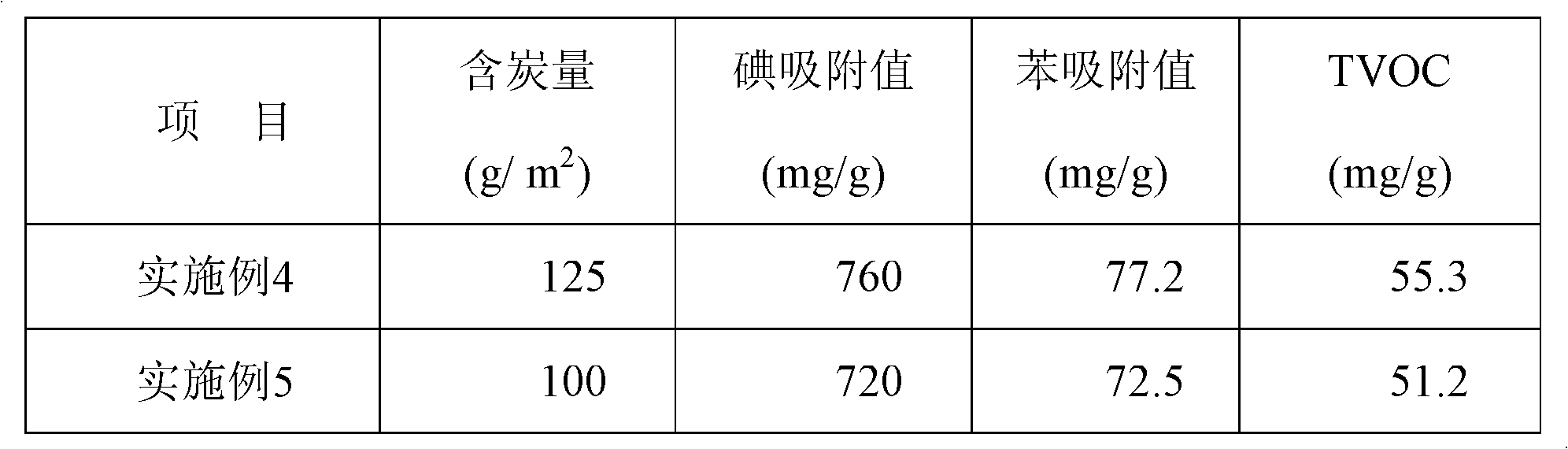

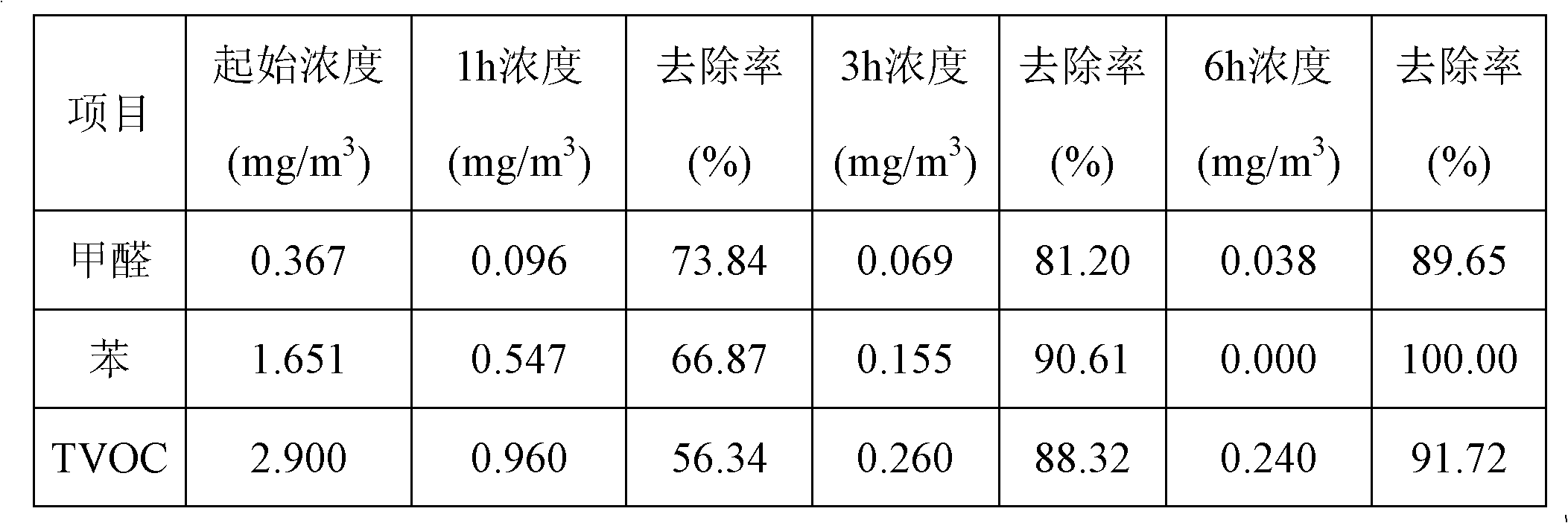

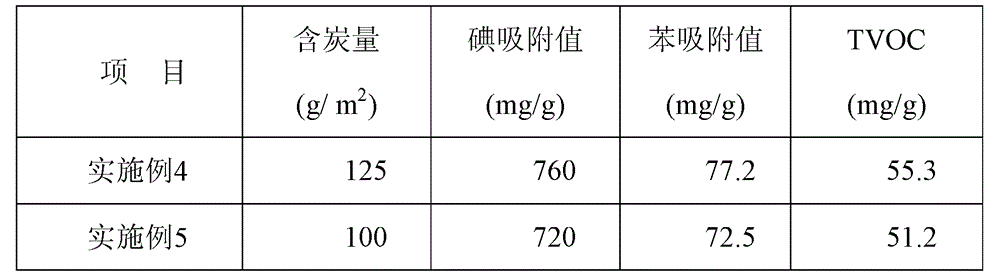

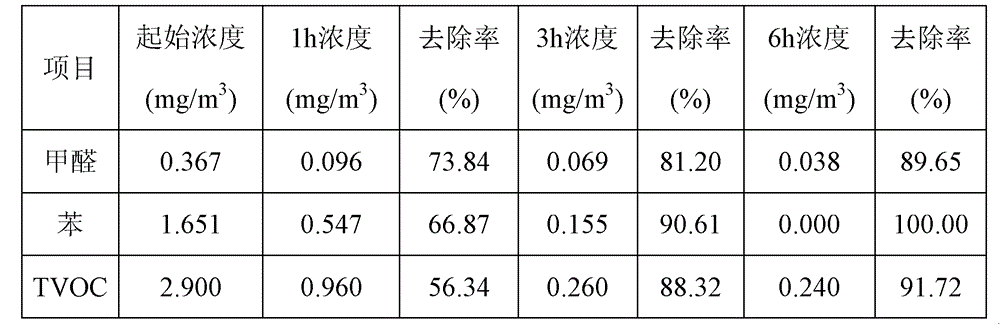

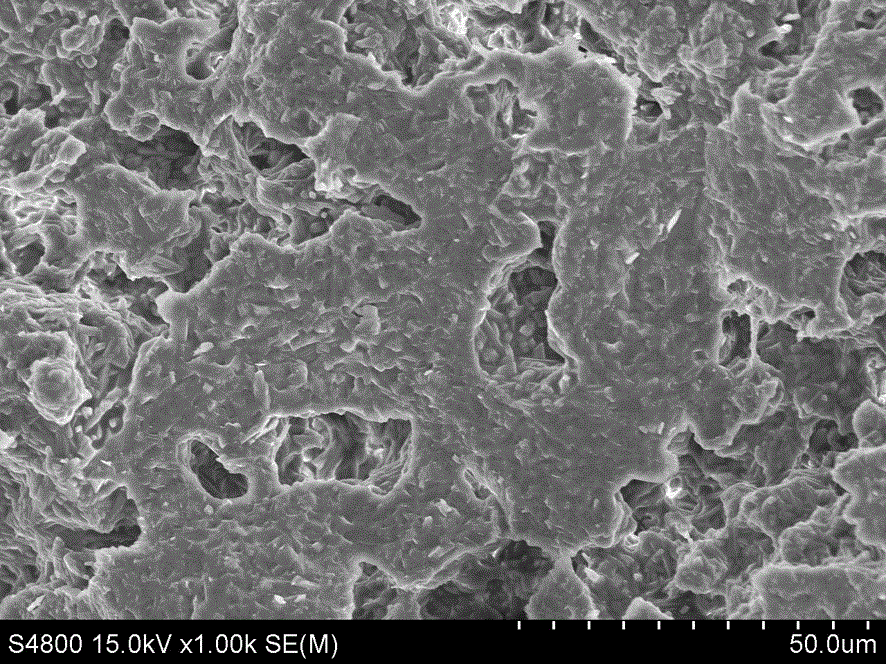

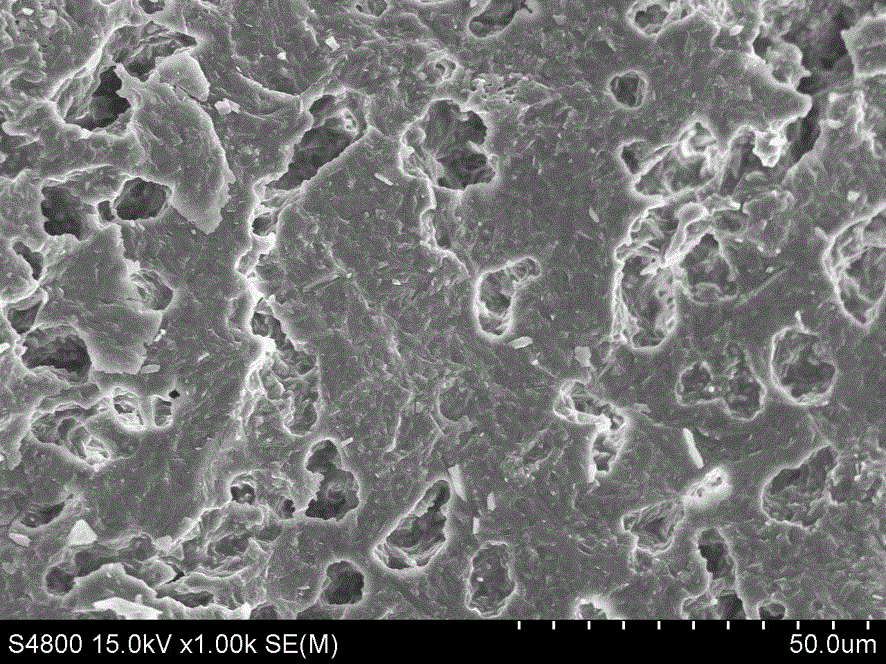

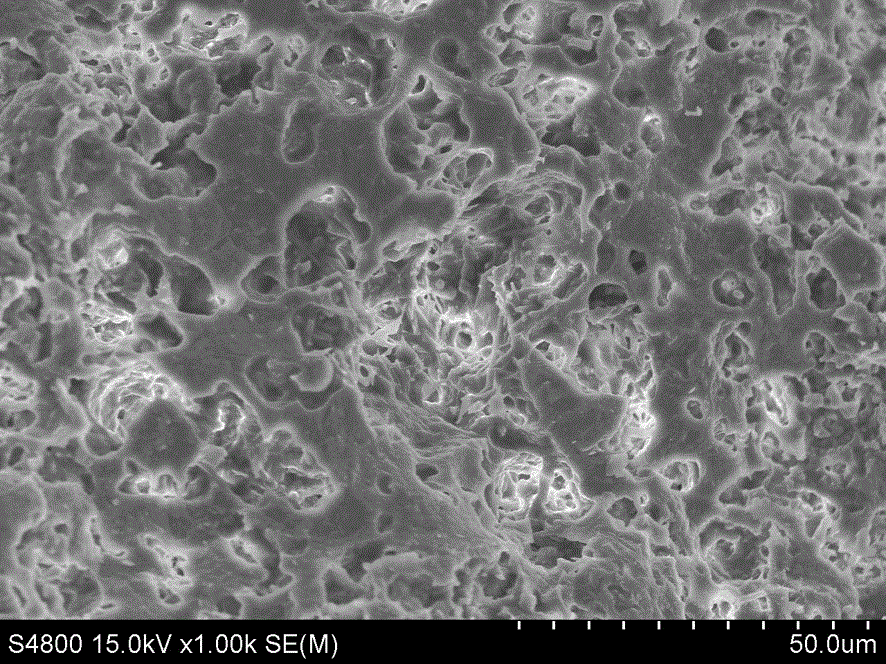

Flame-retardant activated carbon fabric and preparation method thereof

ActiveCN102529254ASimple processGood flame retardant performanceSynthetic resin layered productsActivated carbonChemistry

The invention relates to a flame-retardant activated carbon fabric and a preparation method thereof. The flame-retardant activated carbon fabric is characterized in that an activated carbon layer, a water-based adhesive film layer and a hot-melt adhesive powder particle layer are sequentially covered on a base material which is subjected to flame-retardant treatment. The preparation method comprises the following steps of: spraying or padding the base material with an environment-friendly water-based flame retardant and drying; serially coating a prepared activated carbon paste and a water-based flame-retardant hot-melt adhesive powder particle paste on the base material, and drying to obtain the final product of flame-retardant activated carbon fabric. During the drying process, the water-based adhesive film layer is formed between the carbon layer and the hot-melt adhesive powder particle layer. The preparation method of the flame-retardant activated carbon fabric is simple and environment-friendly, and the product has good flame retardant property. Owing to the good adsorption property of activated carbon, the fabric can remove formaldehyde, benzene, TVOC and other harmful gases in the air. When the fabric is used, the fabric can be cut freely and laminated thermally. The flame-retardant activated carbon fabric is easy and convenient to use and has a wide application range.

Owner:WUXI DINGHAO NEW MATERIAL SCI RES

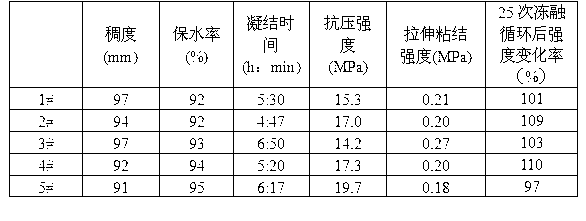

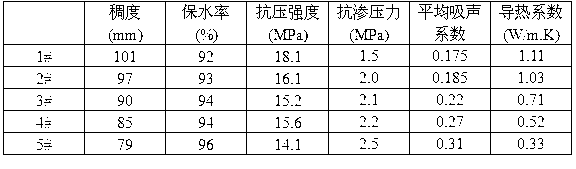

Lightweight gypsum plaster mortar

The invention belongs to building mortar, and particularly relates to lightweight gypsum plaster mortar which is the secondary development of gypsum plastered product technology. The lightweight gypsum plaster mortar is used for leveling inner sides of outer walls, inner partition walls and ceilings of buildings, and the heat-insulated effect is good. Because the flue gas desulphurized building gypsum of power plants is used, the problem of disposing and using the desulphurized gypsum is solved, and the circulating economy is developed. The method for preparing the plaster mortar comprises the following steps of: accurately weighing up the following materials in part by weight: 70 to 80 parts of flue gas desulphurized gypsum of power plants, 15 to 25 parts of vitreous hollow microsphere, 0.2 to 0.4 part of cellulose ether, 0.3 to 0.6 part of air entraining agent and 0.2 to 0.5 part of retarding agent; and putting the materials into a container, adding 60 to 120 parts of water into the container, and uniformly stirring the mixture at the normal temperature to obtain the lightweight gypsum plaster mortar. The lightweight gypsum plaster mortar has the advantages of moderate strength, unnecessary additional making of protective covering, direct leveling after plastering, high performance cost, high workability, short construction period, functions of preventing fire, absorbing sound, and adjusting air humidity and no emission of CO2 in the production process.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

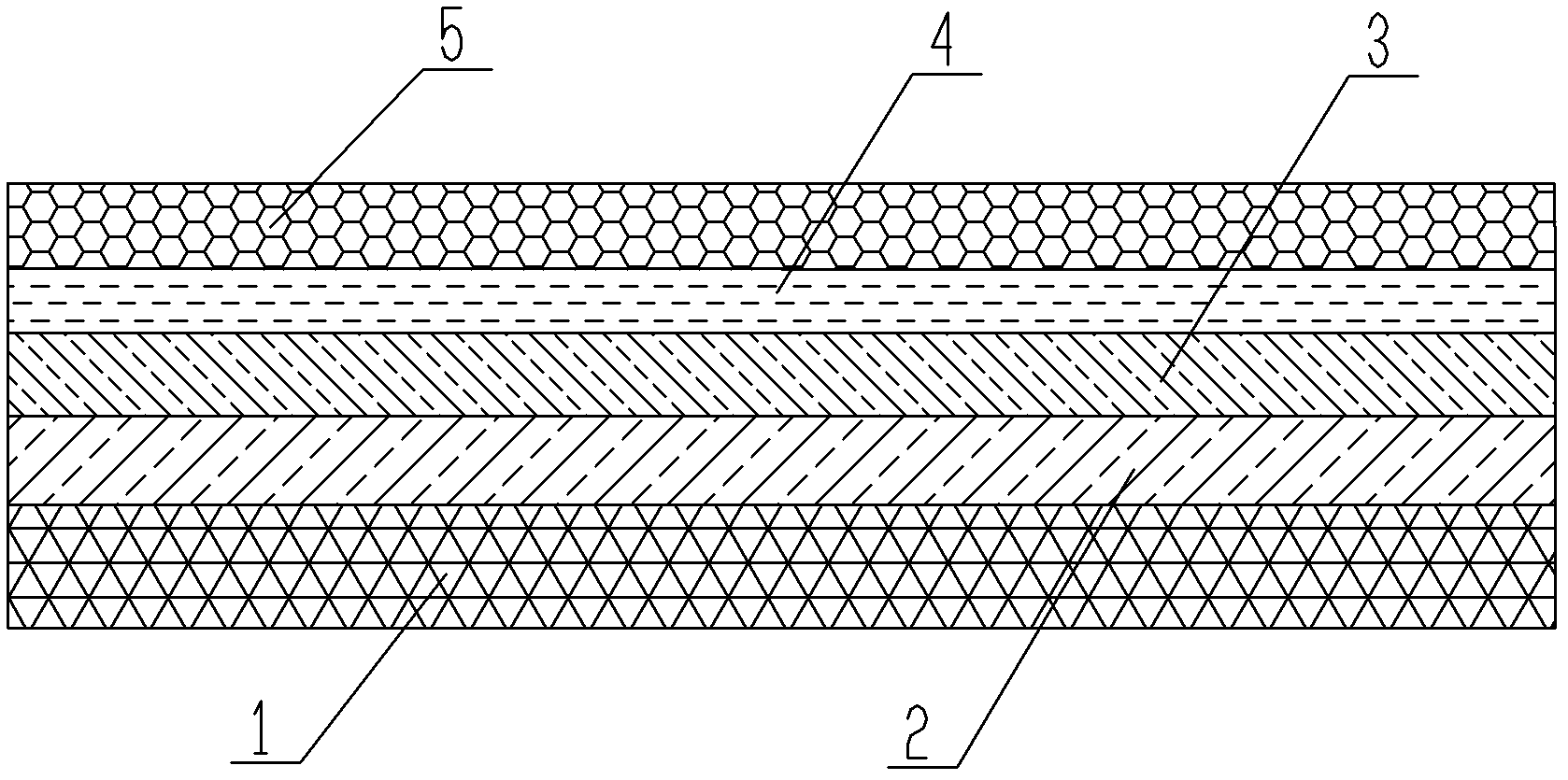

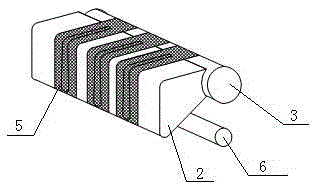

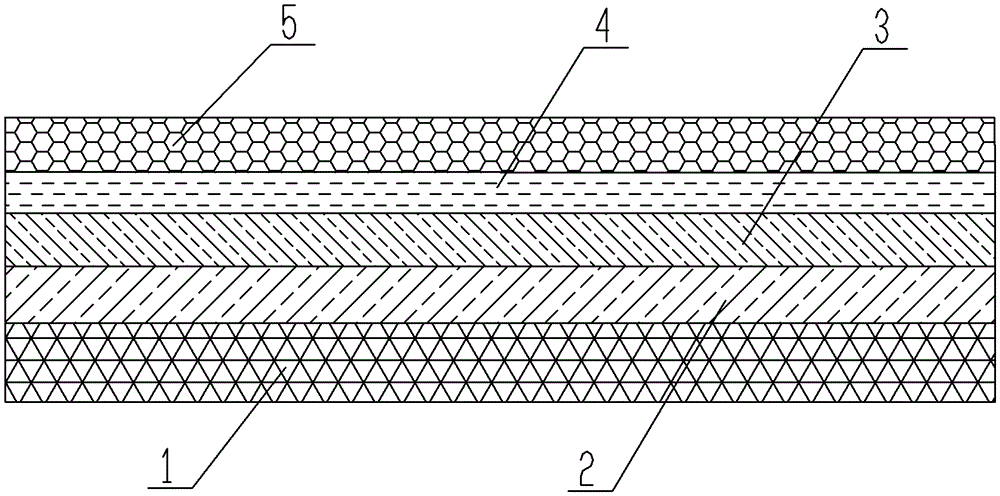

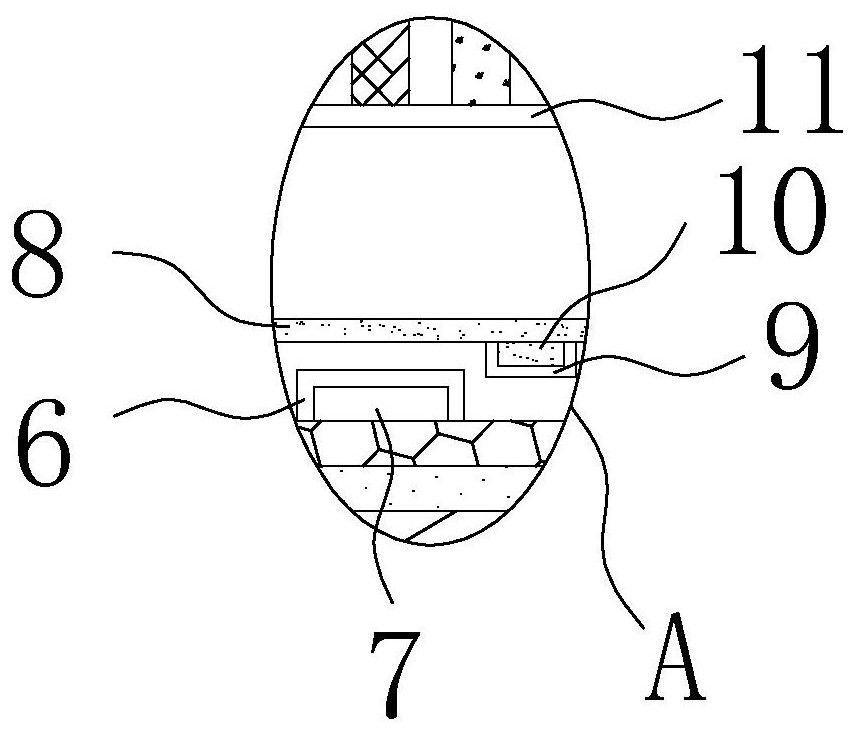

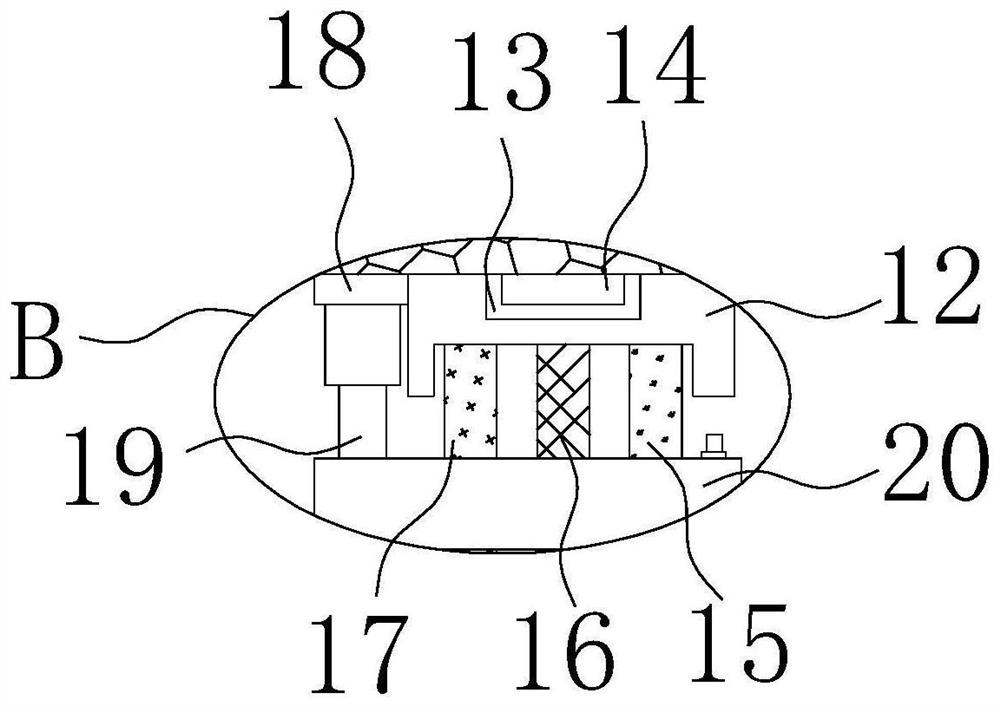

Light multifunctional composite structure

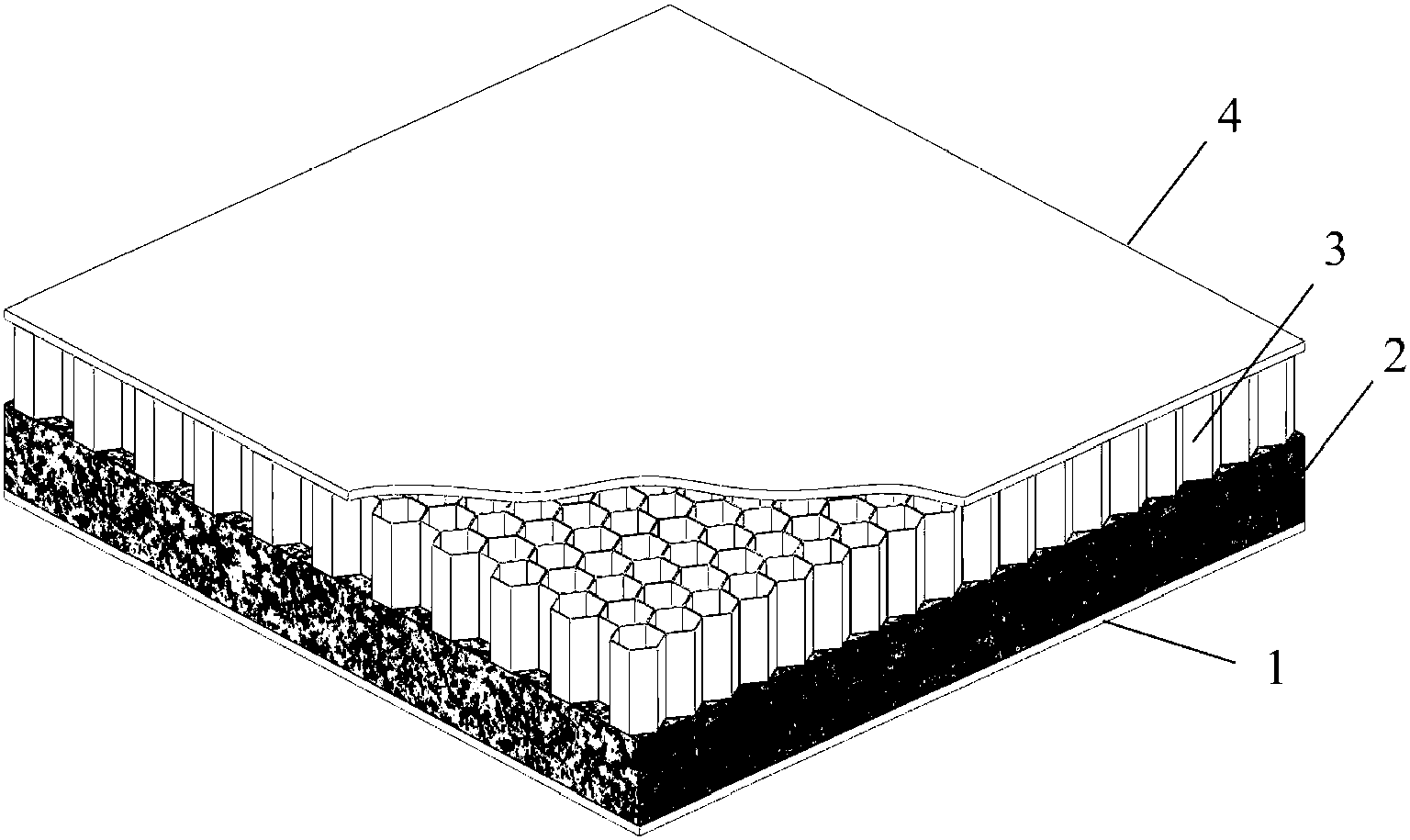

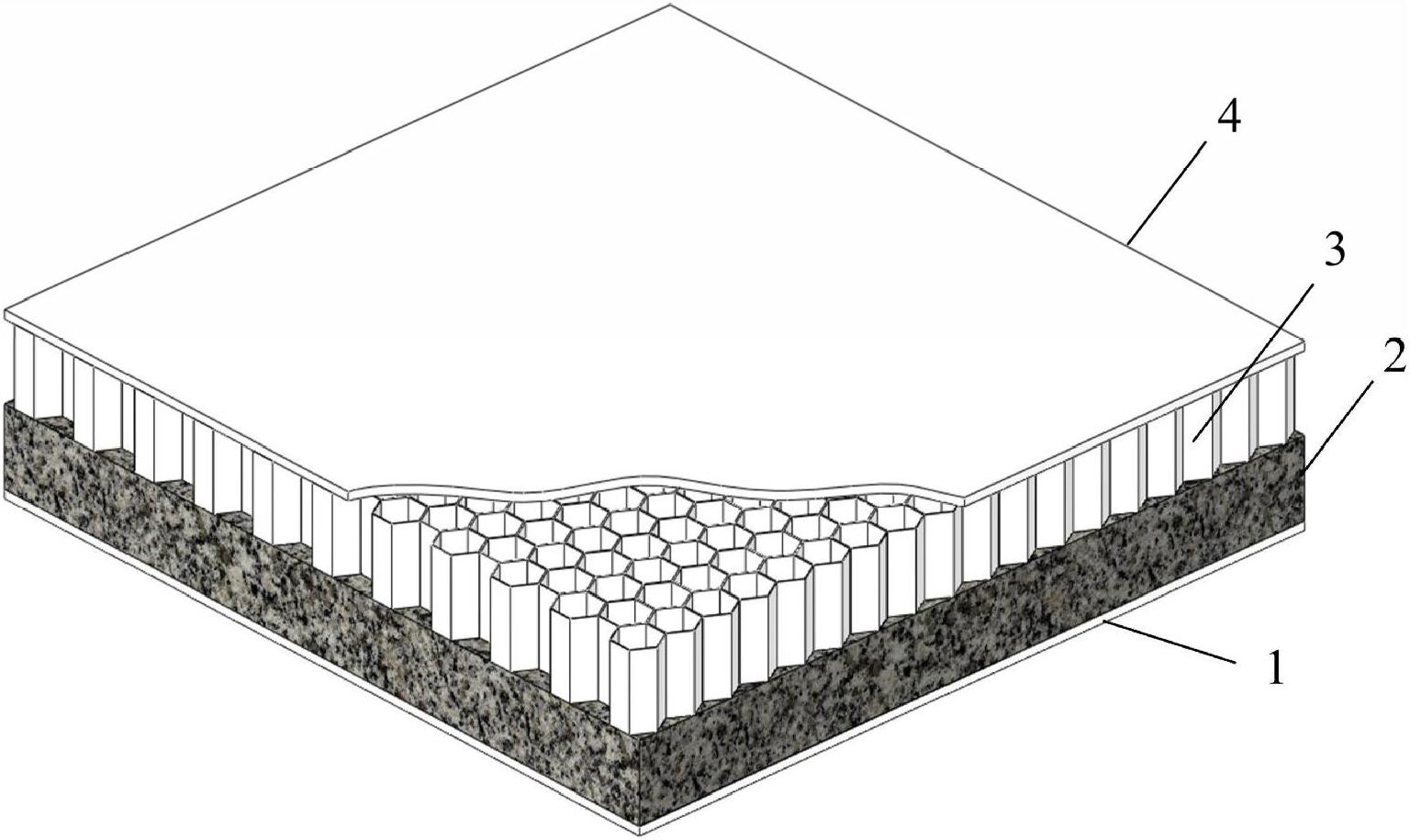

InactiveCN102700181AReduce weightGive full play to excellent performanceMetal layered productsMetallurgyAluminum honeycomb

The invention discloses a light multifunctional composite structure. The composite structure comprises a first outer surface plate, a second surface plate, a metal foam sandwich layer and a honeycomb sandwich layer, wherein the metal foam sandwich layer and the honeycomb sandwich layer are arranged between the first outer surface plate and the second surface plate, and the honeycomb sandwich layer is hexagonal aluminum honeycombs or square aluminum honeycombs. According to the sandwich structure through the composition of metal foams with the hexagonal aluminum honeycombs or the square aluminum honeycombs, the weight can be obviously reduced, and a plurality of functions such as load bearing, sound absorption, sound and heat insulation and shock resistance are provided.

Owner:XI AN JIAOTONG UNIV

Environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and preparation method thereof

The invention provides an environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and a preparation method thereof. The environment-friendly PVC foaming ceiling panel comprises the following components in parts by weight: 90-110 parts of PVC resin, 5-10 parts of polylactic acid, 7-12 parts of polycaprolactone, 10-20 parts of polyester fiber, 50-70 parts of barium sulfate, 3-7 parts of plasticizer, 5-11 parts of stabilizer, 1.7-5 parts of titanium dioxide, 0.6-2 parts of PE (Poly Ethylene) wax, 2-5.5 of processing modifier, 1.4-3.2 parts of anti-impact modifier, 0.7-1.5 parts of composite foaming agent and 20-30 parts of sepiolite. The environment-friendly PVC foaming ceiling panel provided by the invention has the characteristics of environmental friendliness, good weather fastness, high fire resistance, strong scratch resistance, sound insulation, thermal insulation, dust prevention, noise absorption, insect prevention and light reflection and is very suitable for serving as an indoor ceiling.

Owner:安徽济峰节能材料有限公司

Decorative material for removing formaldehyde

InactiveCN101874978AAvoid churnEasy to recyclePhysical/chemical process catalystsDispersed particle separationFire protectionEngineering

The invention relates to a non-toxic, environment-friendly and smellless decorative material for removing formaldehyde, which is mainly suitable for being used as a finishing material on walls, ceilings, cylindrical surfaces and the like inside buildings. 3-15g of nano TiO2 / infusorial earth composite catalysts are added in the decorative material per square meter, and the nano TiO2 / infusorial earth composite catalysts are formaldehyde removing agents. The decorative material of the invention can improve the indoor artistic environment to provide beautiful enjoyment for people, has various functions such as heat insulation, dampproofness, fire protection, sound absorption, sound insulation, and the like, and has the unique effects for absorbing and degrading free formaldehyde in the indoor air.

Owner:王秀宝

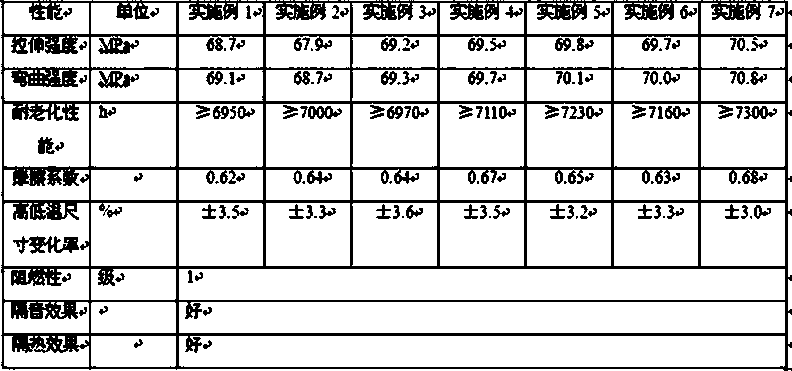

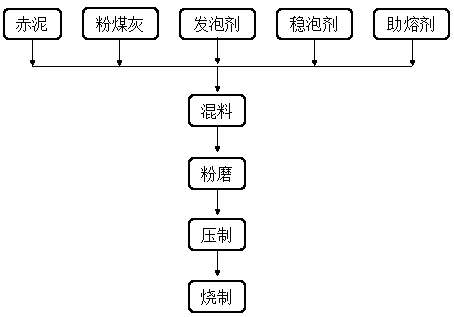

Method for preparing foam microcrystalline glass through red mud

The invention relates to a preparing method for foam microcrystalline glass, in particular to a method for preparing the foam microcrystalline glass through red mud. The preparing method aims at preparing the foam microcrystalline glass with the industrial solid waste red mud, the low energy consumption and the excellent performance. The preparing method includes the following steps that (1) industrial waste residues, fluxing agent, foaming agent and foam stabilizer are mixed to be even according to the weight ratio to form a batch mixture; (2) the mixed batch mixture is put into a ball mill and powdered; (3) the powdered batch mixture is put into a grinding tool and pressed and formed; (4) a pressed sample is put into a reacting furnace and fired. The method has the advantages that the problems that in aluminum industry of China, the discharging quantity of waste residues is large, waste residues are difficult to treat are solved, the comprehensive utilization level of the industrialwaste is improved, sustainable development of building materials in China can be achieved, and social economical benefits can be remarkably improved.

Owner:UNIV OF JINAN

Desulfurized gypsum thermal-insulation material

The invention relates to a desulfurized gypsum thermal-insulation material belonging to thermal-insulation materials. The waste pollutant desulfurized gypsum in the existing heat power plants is piled and filled in land, thereby polluting the ecological environment and influencing the safe operation of the power plants. The desulfurized gypsum thermal-insulation material provided by the invention comprises the following components in parts by weight: 80-85 parts of desulfurized building gypsum, 15-20 parts of vitrified microbead, 0.1-0.25 part of cellulose ether, 0.2-0.4 part of air entraining agent, 0.01-0.015 part of retarder and 70-100 parts of water. The components are added into water and evenly mixed to obtain the desulfurized gypsum thermal-insulation material. The desulfurized gypsum thermal-insulation material has the advantages of low coefficient of heat conductivity, thermal insulation and heat-shielding performance, energy saving, moderate strength, favorable workability and short construction cycle, has the functions of fire resistance, sound absorption, air humidity conditioning and the like, and reduces the piling and landfilling of the desulfurized waste residues as well as environmental pollution; and no CO2 is emitted in the production process.

Owner:上海城建置业发展有限公司 +1

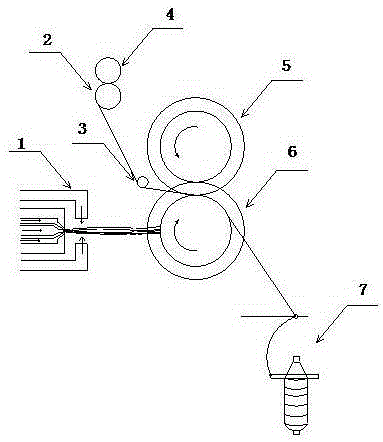

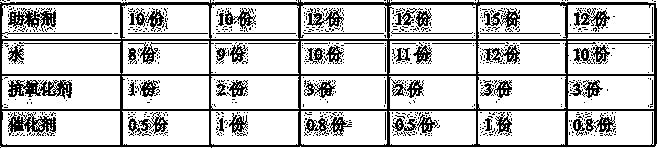

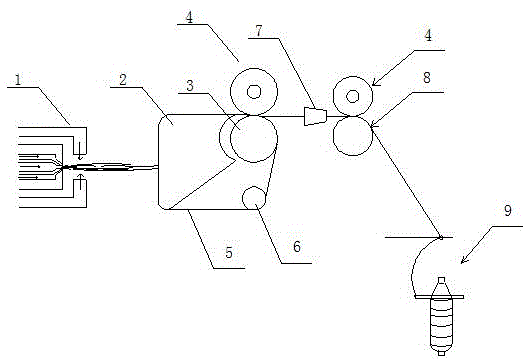

Micro-nano fiber yarn spinning device and spinning process thereof

The invention discloses a micro-nano fiber yarn spinning device and a spinning process thereof. The micro-nano fiber yarn spinning device comprises a spinning jet, a yarn feeding system, a fiber polymerization mechanism and a twisting mechanism, wherein the spinning jet is composed of a hot air pipe, a polymer melt pipe and a cold air pipe, the yarn feeding system is composed of cheese yarns, an unwinding roller and a yarn guide rod, the fiber polymerization mechanism is composed of an upper roller and a lower roller which are mutually connected in a meshed mode, a plurality of micro-pores are formed in the bottom of the groove of the lower roller, and an irregular air pipe is further arranged inside the lower roller. The micro-nano fiber yarn spinning device is reasonable in structure and process design, convenient to operate actually and capable of spinning micro-nano fiber sprayed out of the melting-spraying spinning jet into micro-nano fiber core spun yarns, the micro-nano fiber wraps the surfaces of core yarns, and the attachment rate and the working efficiency are high, so that produced yarns have the functions of microbial resistance, heat insulation, heat preservation, filtering and adsorption, sound absorption and the like.

Owner:新疆天棉基业纺织有限公司

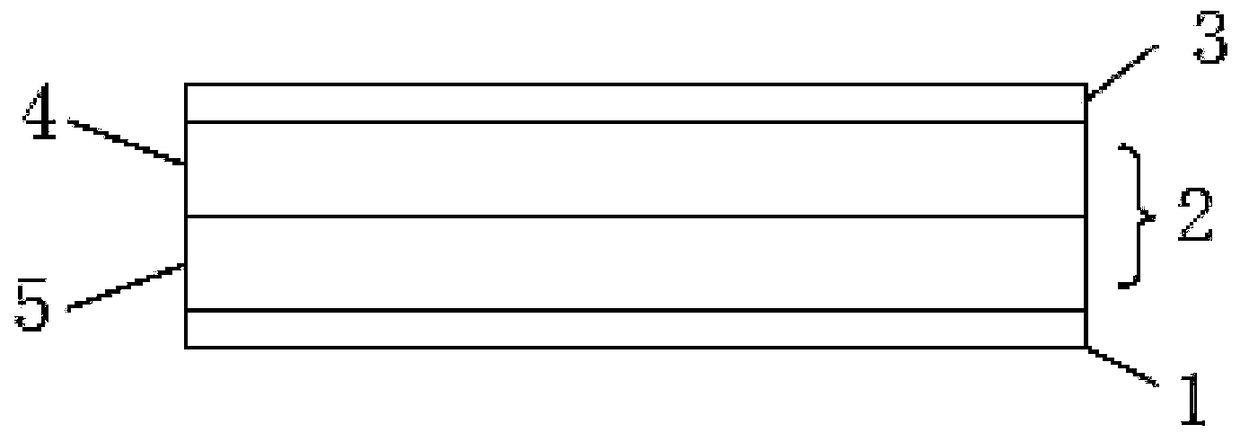

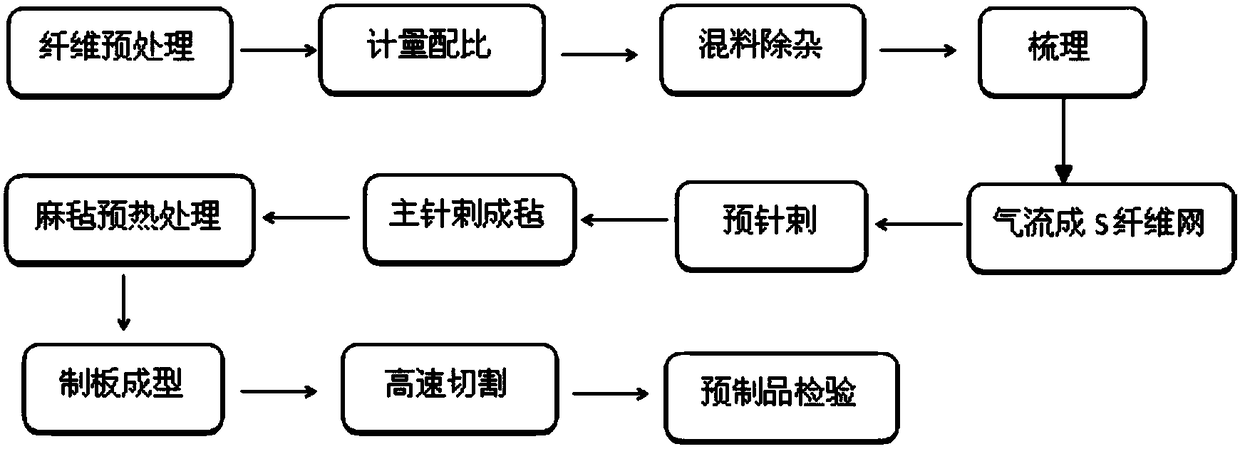

Environment-friendly ecological bast fiber integrated wall decorating plate and preparation method thereof

PendingCN109113289AHigh strengthAct as a bondCovering/liningsSynthetic resin layered productsEnvironmental resistancePolyester

The invention relates to the technical field of wall decorating plates for buildings and discloses an environment-friendly ecological bast fiber integrated wall decorating plate and a preparation method thereof. The bast fiber integrated wall decorating plate comprises a bottom layer, a middle layer and a surface layer which are sequentially overlapped and hot-pressed together. Both the bottom layer and the surface layer adopt polyester non-woven fabric layers, and the middle layer adopts a bast fiber felt layer. The bast fiber felt layer is formed in the mode that two or more pieces of precast and formed bast fiber felt are overlapped and preheated, the precast and formed bast fiber felt is mixed fiber felt with bast fibers and polypropylene fibers, and the bast fibers and the polypropylene fibers in the mixed fiber felt are both coiled fibers. The preparation method of the integrated wall decorating plate comprises the steps that the middle layer is manufactured; the polyester non-woven fabric layers are taken as the bottom layer and the face layer; and the bottom layer, the middle layer and the face layer are overlapped, heated and subjected to rolling forming, and the bast fiber integrated wall decorating plate is prepared after cutting. The wall decorating plate is environmentally friendly and ecological.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

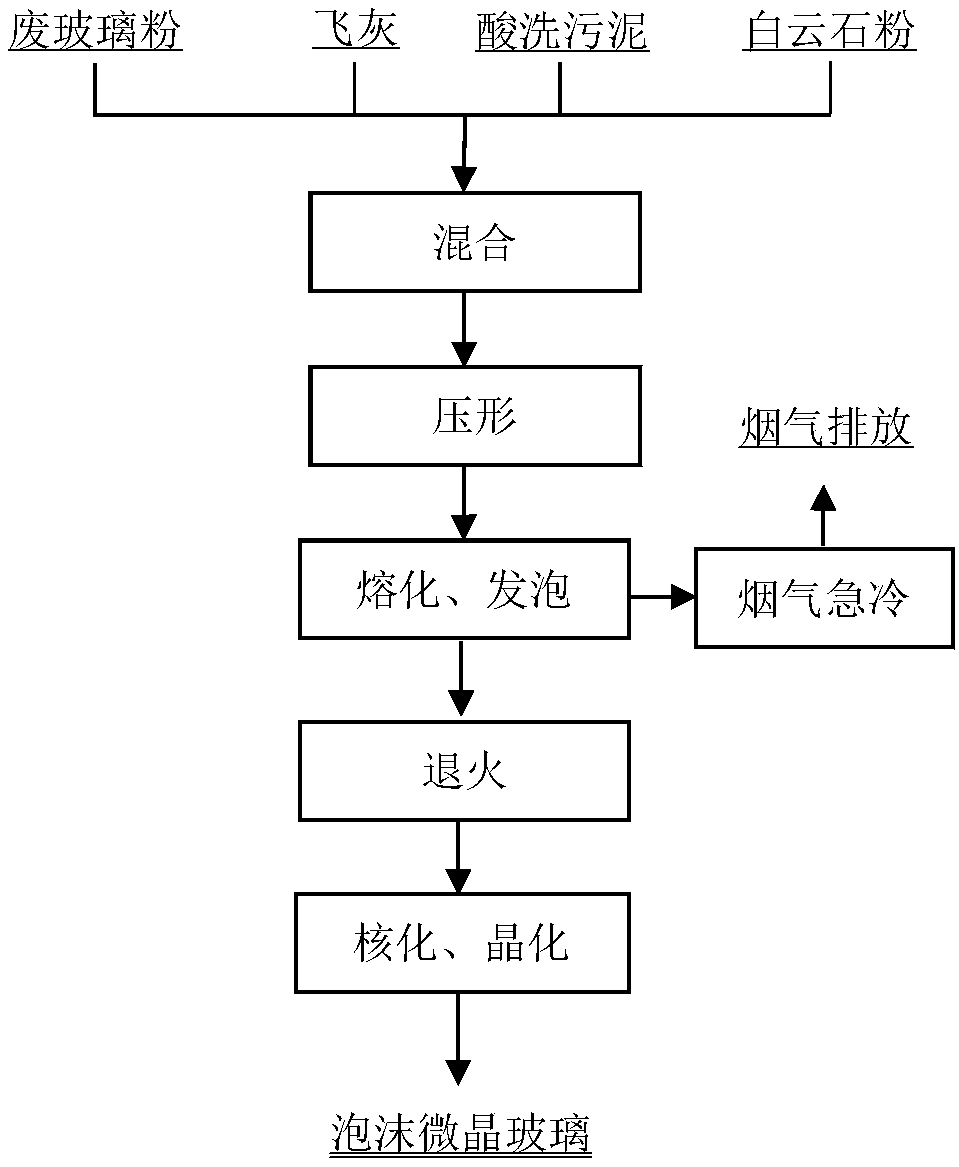

Harmless treatment method of garbage incineration fly ash dioxin

The invention discloses a harmless treatment method of garbage incineration fly ash dioxin, and belongs to the field of solid waste treatment and resource utilization. The method is characterized in that the garbage incineration fly ash is used as major raw materials to be mixed with waste glass powder, acid washing sludge and dolomite powder; shape pressing is performed; foam micro crystal glassis prepared through high-temperature fusion; meanwhile, dioxin in the fly ash is subjected to pyrolysis; chlorine atoms and alkaline earth metal oxides react to cure in the foam micro crystal glass; the generated smoke gas is fast cooled to the temperature of 200 DEG C or below through a sharp cooling device; and the synthesis of the dioxin again by residual chlorides is avoided. The harmless treatment and the high-value utilization in foam thermal insulation fireproof material of the garbage incineration fly ash dioxin can be realized; and the advantages of simple process and green and environmental-friendly effects are achieved.

Owner:UNIV OF SCI & TECH BEIJING

Sound absorption plate with fireproof and heat insulation functions and processing method thereof

InactiveCN102351495AWith insulationWith thermal insulationCeramic shaping apparatusFiberThermal isolation

The invention relates to a sound absorption plate with fireproof and heat insulation functions, which is characterized by comprising the following ingredients in parts by weight: 30 to 50 parts of expanded perlite, 20 to 30 parts of polystyrene pearl particles, 30 to 50 parts of water glass, 5 to 10 parts of glass fiber, 5 to 10 parts of zinc borate and 10 to 20 parts of lime powder. The sound absorption plate is prepared through procedures of ball milling, stirring, pressing and the like. The sound absorption plate has the advantages of heat insulation, thermal isolation, fireproof and waterproof effects, sound absorption, heat insulation, low cost and attractive appearance and is convenient to install.

Owner:南通华宏化工设备制造安装有限公司

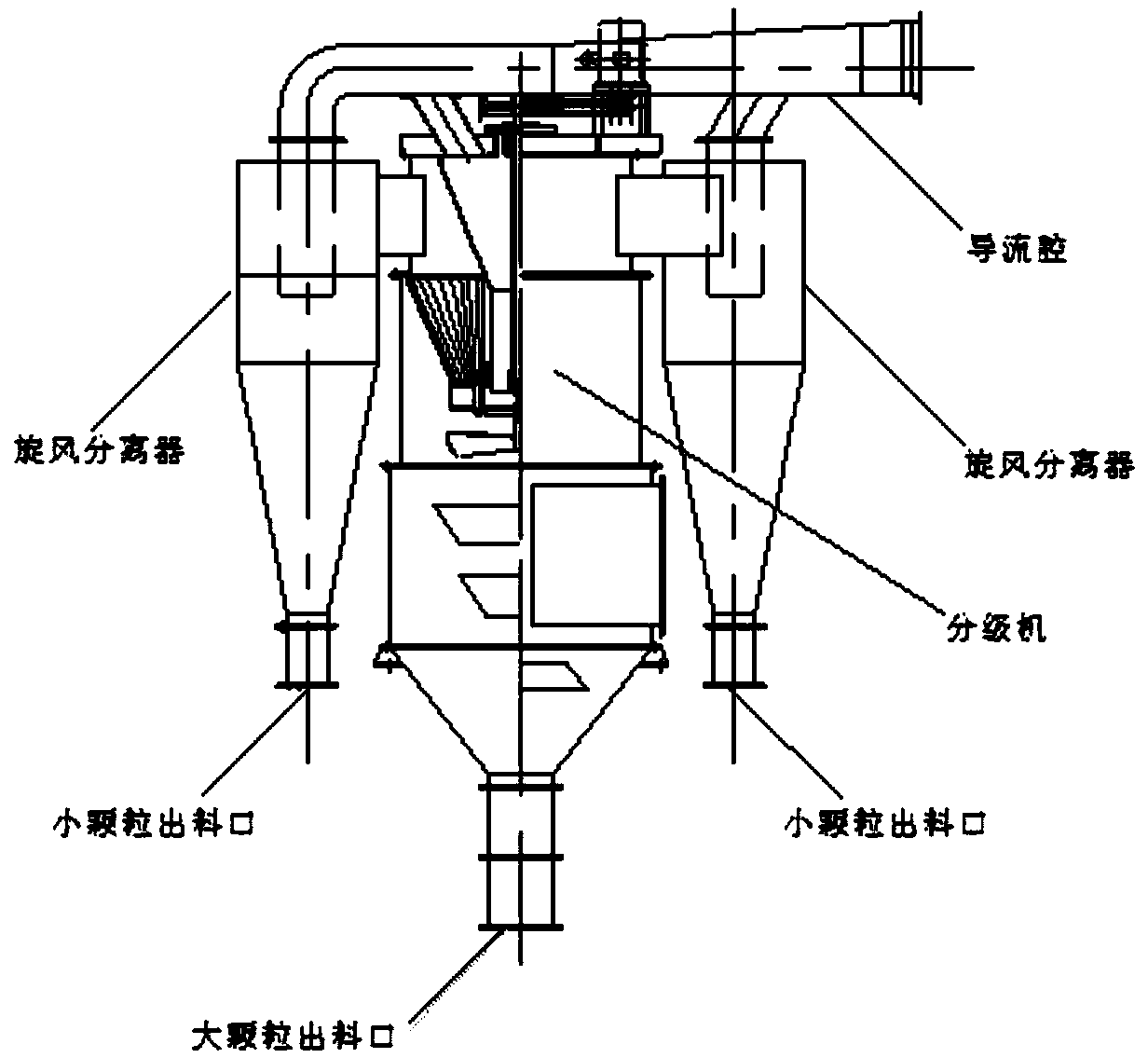

Method for recycling dust generated by casting waste sand regeneration

The invention discloses a method for recycling dust generated by casting waste sand regeneration. According to the method, firstly, a dust removal system is used for collecting high-value dust and low-value dust in groups according to effective values of the dust; then composite powder for modeling is generated through compounding, activation, drying and pulverizing after the high-value dust is sieved by a powder concentrator, and sludge generated through wet regeneration by the low-value dust, blast furnace slag and casting waste sand is subjected to raw material pretreatment, compounding, shaping, prebaking, baking, cooling and screening to generate light ceramsites; the high-value dust is dust generated during regeneration of unbaked casting waste sand, and the low-value dust is dust generated during regeneration of baked casting waste sand. The recycling method can achieve the purpose of full recycling of the casting waste sand, and has the advantages that the operation is simple,more energy is saved, and the environment is protected better.

Owner:广西兰科资源再生利用有限公司

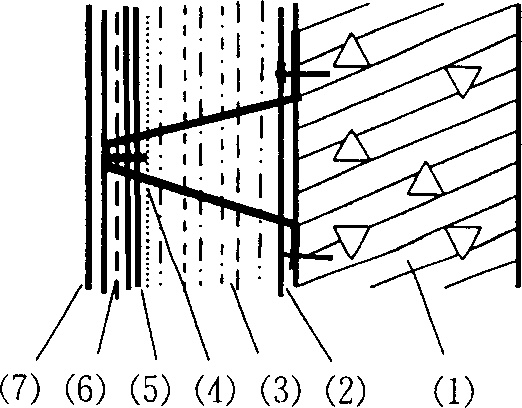

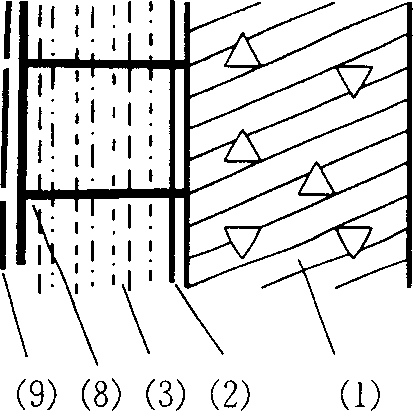

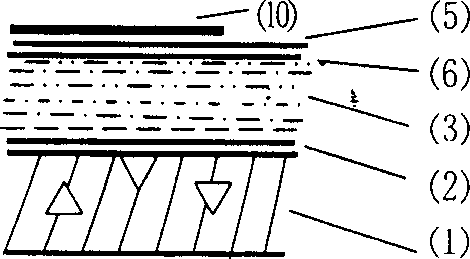

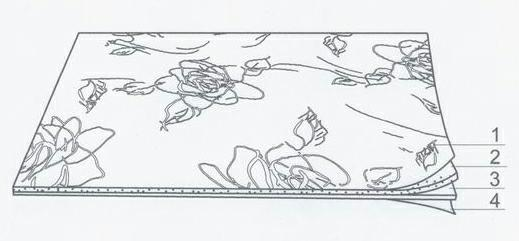

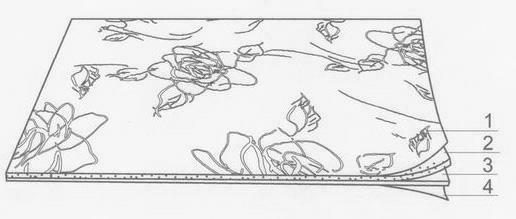

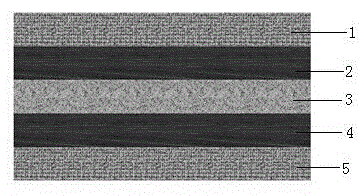

Thermal insulation system structure for mineral wool coated building

InactiveCN1807789AWith sound absorptionFire-resistantCovering/liningsWallsAbnormal shapedThermal insulation

The invention relates to a thermal-insulation system which coats the mineral wool on the construction. It comprises a construction base on which the waterproof agent is plated to form a damp-proof layer; a mineral wool thermal-insulation layer is plated on the damp-proof layer; a protective layer is laid on the thermal-insulation layer; and a ornament layer is arranged outside the protective layer. The invention can apply multi-floor and high buildings, public buildings and the workshops, especially applying variable irregular surfaces, and it can directly plate mineral wool on the surface of construction base with demanding the flatness. The thermal-insulation layer has lower heat conductive parameter, the burning property is A level, the sound adsorption effect is 1 level, the fiber is three-dimensional arranged, and the integrated property is better without any connection slit. It can meet the energy-saving demands of different areas to realize high social and economic benefits.

Owner:韩春贵

PU sponge with good air permeability and making method thereof

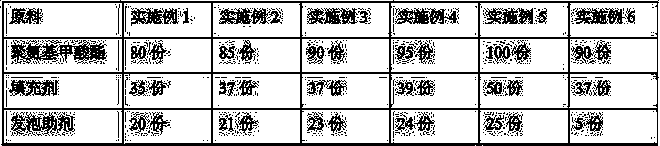

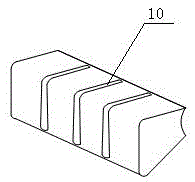

The invention provides PU sponge with good air permeability. A raw material of the PU sponge comprises the following components in part by weight: 80-100 parts of polyurethane, 35-50 parts of fillingagent, 20-25 parts of foaming aid, 10-15 parts of adhesion promoter, 8-12 parts of water, 1-3 parts of antioxidant and 0.5-1 part of catalyst, wherein the foaming aid is a mixture of a foaming agent,benzotriazole, sodium borohydride and P-octyl phenol with a mass ratio of (1-5):(1-3):(3-5):(0.5-2); the adhesion promoter is a mixture of nitrile rubber, polyether polyol and epoxy resin with a massratio of (8-12):(3-7):(1-3). The PU sponge prepared by the raw material and a process provided by the invention has a density of 0.029 / mm<3>, a 25 percent of compression hardness is above 1.9 KPa, a porosity of a above 88 percent and a rebound rate of above 47 percent, thereby being high-quality sponge.

Owner:广汉市新鸿海绵有限公司

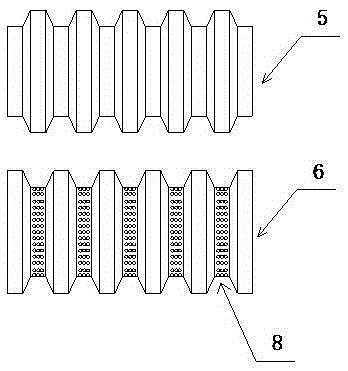

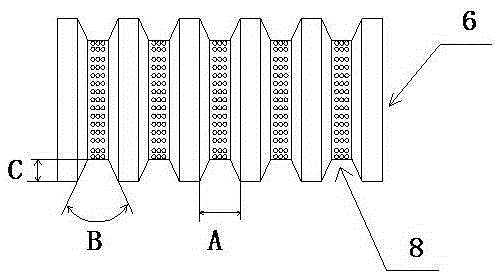

Novel micro-nano fiber yarn spinning device and technology

InactiveCN105568446AWith heat insulationImprove insulation effectDrafting machinesContinuous wound-up machinesYarnFiber

The invention discloses a novel micro-nano fiber yarn spinning device and technology. The device comprises a spinning nozzle, a fiber polymerization mechanism, a drafting mechanism and a twisting mechanism. The fiber polymerization mechanism is composed of an irregularly-shaped exhaust pipe, a grid ring and a tension frame. The drafting mechanism is composed of a first roller, a second roller, a leather roller and a cotton collector, wherein the leather roller and the cotton collector are matched with the first roller and the second roller. The novel micro-nano fiber yarn spinning technology comprises the steps that micro-nano fibers are formed at first, then reach the receiving device irregularly-shaped exhaust pipe along with airflow, are drafted finally and enter the twisting area to be twisted to form a micro-nano fiber yarn. The structure and technology design is reasonable, actual operation is convenient, super fine micro-nanoscale fibers formed through melt-blown spinning can be spun into the yarn under high fitting rate and high production efficiency, the produced yarn has the advantages of excellent heat insulation, heat preservation, adsorption, filtration, sound absorption and the like, and production of the micro-nano fiber yarn with the features and functions of bacteria resistance and ultraviolet resistance is achieved through melt component design.

Owner:SHENZHEN ZHONGSHENG LIDA TRADE CO LTD

Biomass composite material and preparation method thereof

The invention belongs to the technical field of composite materials and preparation thereof, and relates to a biomass composite material and a preparation method thereof. The biomass composite material is prepared from bio-based epoxy resin reinforced by plant fiber fabric, wherein on or two of continuous-filament woven fabric of ramie, flax, jute, China-hemp, kenaf or sisal hemp can be adopted as the plant fiber fabric; the fabric is twill, plain or satin fabric, or gridding cloth, and has the surface density of 80-300g / m<2>; the source of biomass epoxy resin is rosin, itaconic acid, gallic acid or epoxy soybean oil; an abietic anhydride-based curing agent is used as the resin; one or two of organic urea derivatives, thiourea derivatives, quaternary ammonium salts, quaternary ammonium phosphate, imidazole salts and acetylacetone metal complexes are used as accelerants; the glass transition temperature of the composite material is adjustable in a range of 80-160 DEG C. A prepreg is prepared by using a solution method or a hot melting method; the prepreg is good in viscosity and long in shelf life, and can be cured at high temperature or medium temperature.

Owner:ACC BEIJING SCI & TECH CO LTD

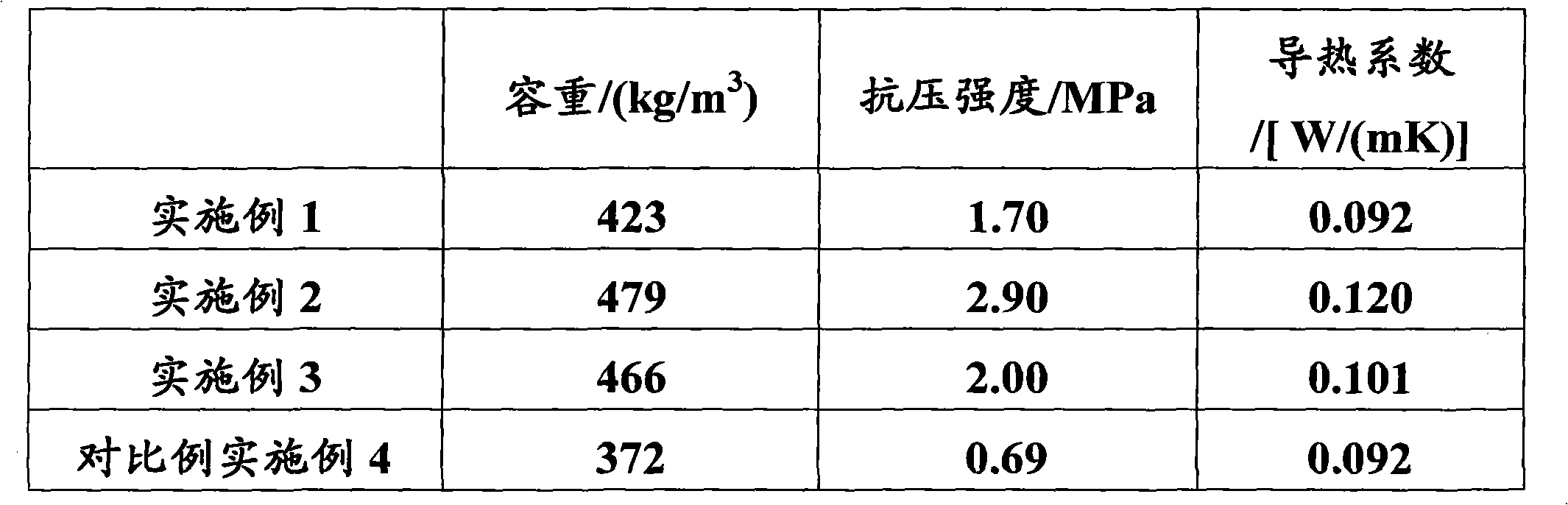

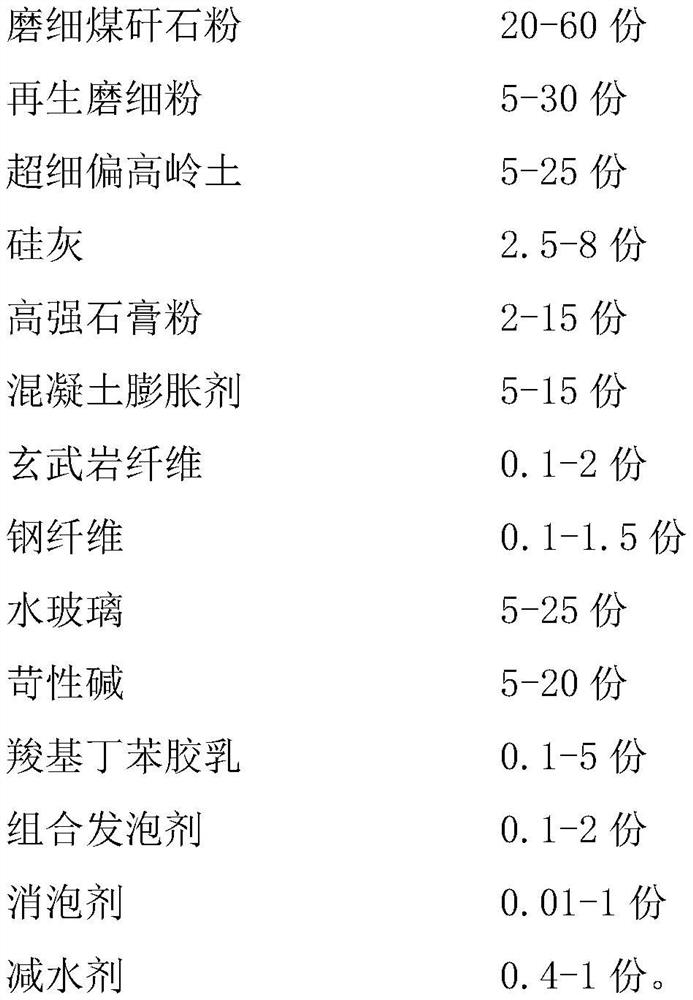

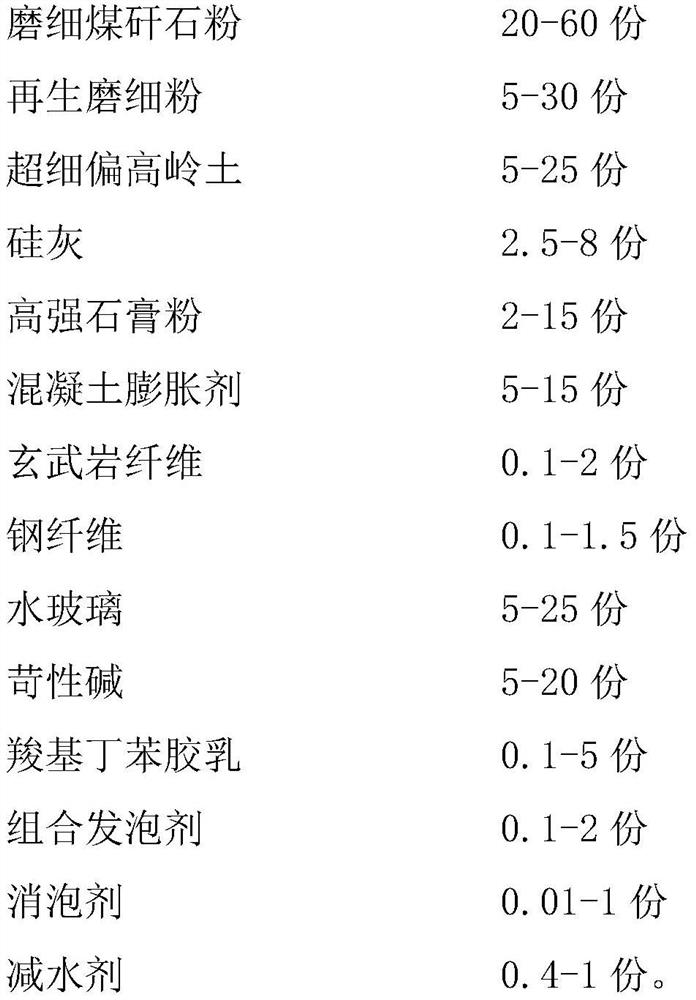

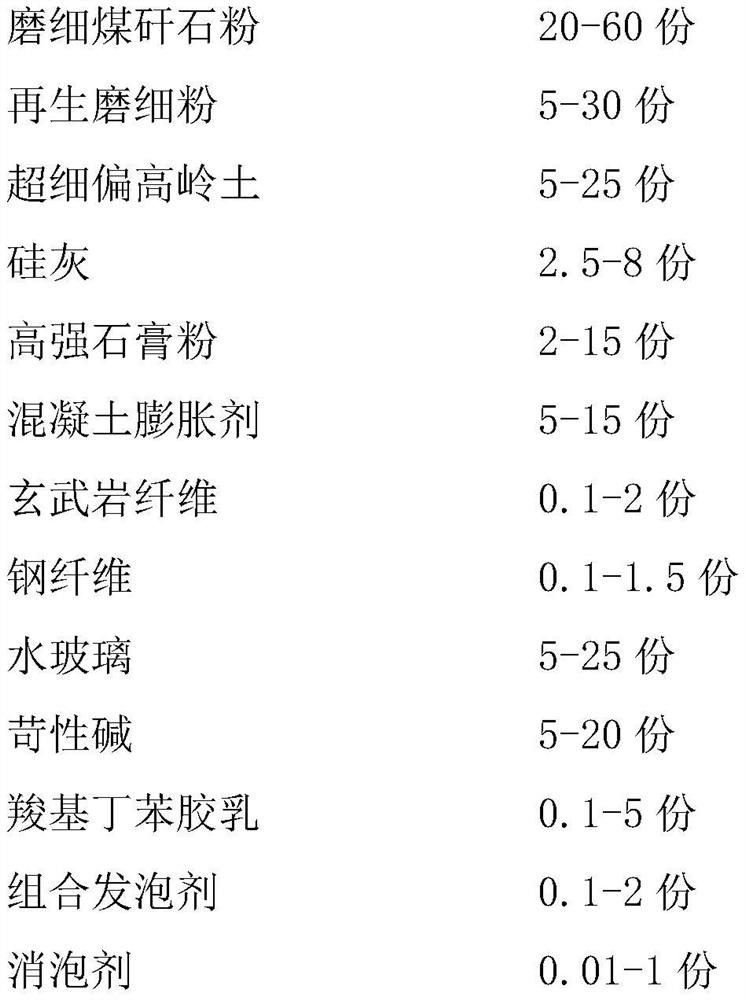

Light high-strength geopolymer material and preparation method thereof

ActiveCN112830811AAlleviate the lack of resources per capitaLight weightCement productionCeramicwareSilica fumeMetakaolin

The invention discloses a light high-strength geopolymer material and a preparation method thereof. The geopolymer material comprises the following components: ground coal gangue powder, regenerated ground powder, superfine metakaolin, silica fume, high-strength gypsum powder, a concrete expansive agent, basalt fibers, steel fibers, water glass, caustic alkali, carboxylic butadiene-styrene latex, a combined foaming agent, a defoaming agent and a water reducing agent. According to the light high-strength geopolymer material provided by the invention, industrial waste residues and old building wastes are effectively utilized; the material has the characteristics of light self weight, high strength, good toughness and the like, has the performances of sound absorption, sound insulation, noise reduction, settlement prevention and the like, and is wide in application range; and the preparation method of the light high-strength geopolymer material provided by the invention is simple in operation steps and does not need high-temperature forming maintenance.

Owner:SHANGHAI LIYANG ROAD REINFORCEMENT TECH

Modified bamboo fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a modified bamboo fiber reinforced polypropylene composite material which comprises polypropylene resin, bamboo fibers, compatilizer, coupling agent, chemical modifier and the like; first, prepared natural fibers are modified and then the fibers are mixed with other components; and the mixture is extruded and formed by a double-screw extruder. According to the preparation method, the production procedures are simple and the production efficiency is improved; and the prepared modified bamboo fibers have more excellent performance, and have the advantages of environmental friendliness, sound absorption, heat insulation, low density, low shrinkage, good processing and forming performance, degradability and excellent integrated mechanical properties.

Owner:ORINKO NEW MATERIAL CO LTD

A kind of flame-retardant activated carbon cloth and preparation method thereof

ActiveCN102529254BSimple processProcess environmental protectionSynthetic resin layered productsWater basedEnvironmental resistance

The invention relates to a flame-retardant activated carbon fabric and a preparation method thereof. The flame-retardant activated carbon fabric is characterized in that an activated carbon layer, a water-based adhesive film layer and a hot-melt adhesive powder particle layer are sequentially covered on a base material which is subjected to flame-retardant treatment. The preparation method comprises the following steps of: spraying or padding the base material with an environment-friendly water-based flame retardant and drying; serially coating a prepared activated carbon paste and a water-based flame-retardant hot-melt adhesive powder particle paste on the base material, and drying to obtain the final product of flame-retardant activated carbon fabric. During the drying process, the water-based adhesive film layer is formed between the carbon layer and the hot-melt adhesive powder particle layer. The preparation method of the flame-retardant activated carbon fabric is simple and environment-friendly, and the product has good flame retardant property. Owing to the good adsorption property of activated carbon, the fabric can remove formaldehyde, benzene, TVOC and other harmful gases in the air. When the fabric is used, the fabric can be cut freely and laminated thermally. The flame-retardant activated carbon fabric is easy and convenient to use and has a wide application range.

Owner:WUXI DINGHAO NEW MATERIAL SCI RES

Light high-strength mullite-quartz porous brick and preparation technology thereof

InactiveCN106146001ALight in massLightweight and high qualityCeramic materials productionCeramicwarePorosityBrick

The invention discloses a light high-strength mullite-quartz porous brick and a preparation technology thereof, belongs to the field of resources and environment and the technical field of building materials and aims at solving the technical problems of high brick preparation cost, low strength of the prepared bricks and easy water accumulation on brick surface in the prior art. The solution is as follows: the porous brick consists of the following raw materials in percentage by weight: 50-60% of coal gangue, 15-20% of flint clay, 5-10% of bauxite, 12-15% of fly ash and 8-12% of clay. The invention provides a technology for preparing the light high-strength mullite-quartz porous brick. In the invention, by fully utilizing the coal gangue and adding auxiliary materials into the coal gangue base material, the brick preparation cost is reduced, resource utilization of the coal gangue solid waste is realized, and the solid waste accumulation and environmental pollution are reduced; the prepared brick has the characteristics of light weight and high strength as well as good porosity and facilitates road surface drainage; and therefore, the porous brick prepared in the invention brings remarkable economic benefits and environmental benefits.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fabric inner wall decorating soft package

The invention discloses a fabric inner wall decorating soft package. The soft package comprises a substrate, wherein the substrate is made from a polyester fiber plate which is non-toxic, smell-free and doped with bamboo carbon powder; a layer of melamine foaming sponge is stuck to the upper surface of the substrate; a layer of fire-resistant decorating fabric is stuck to the upper surface of the melamine foaming sponge; and a layer of double faced adhesive tape is stuck to the back surface of the substrate. Various materials adopted in the fabric inner wall decorating soft package are environment-friendly materials, so the fabric inner wall decorating soft package has the environment-friendly performance of sound absorption, heat isolation, high temperature resistance and no harmful smell, and also has the advantages of low cost and good market prospect.

Owner:禹尔力

Multifunctional premix mortar thickening material and preparation method thereof

The invention discloses a multifunctional premix mortar thickening material and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out drying pretreatment on bentonite, kaolin and fly ash; (2) after premixing the bentonite, kaolin and fly ash obtained in the step (1) with surfactant and calcium sulfate, grinding in a grinding machine; and (3) adding hybrid modified rubber powder and the raw material obtained in the step (2) into a mixing machine, and mixing to obtain the multifunctional premix mortar thickening material. By producing the thickening material mainly from inorganic materials by a grinding technique, the invention can ensure the bonding reaction of the inorganic powder materials with the surfactant and modifier, thereby forming a novel organic / inorganic composite mortar additive; and besides, the added nano hybrid modified scrap rubber powder can effectively enhance the water permeation resistance of the mortar, improve the freezing resistance and heat-insulating property of the mortar, and enhance the strength of the mortar.

Owner:广东广业检测有限公司 +2

Inner trim board for motor car and preparing method of inner trim board

ActiveCN104153126AWith sound insulationWith sound absorptionCarbon fibresNon-woven fabricsActivated carbonKapok fiber

Owner:NANTONG UNIVERSITY

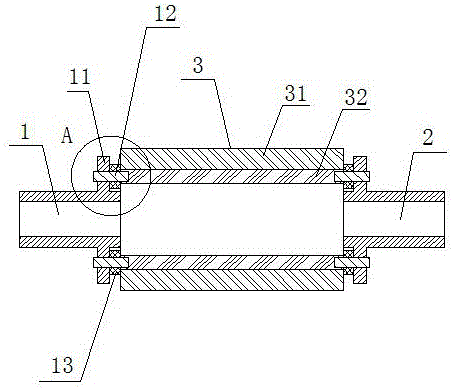

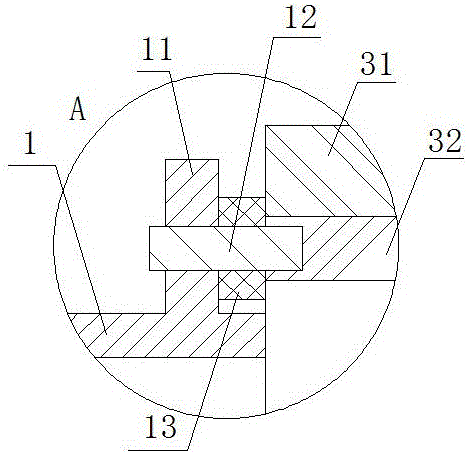

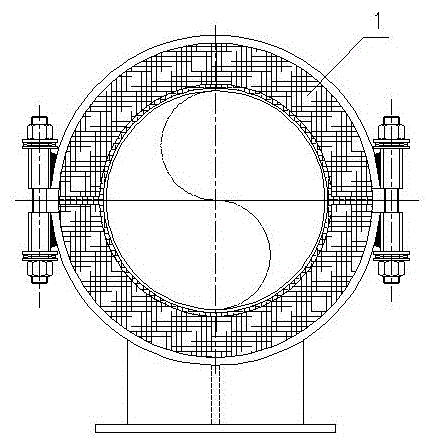

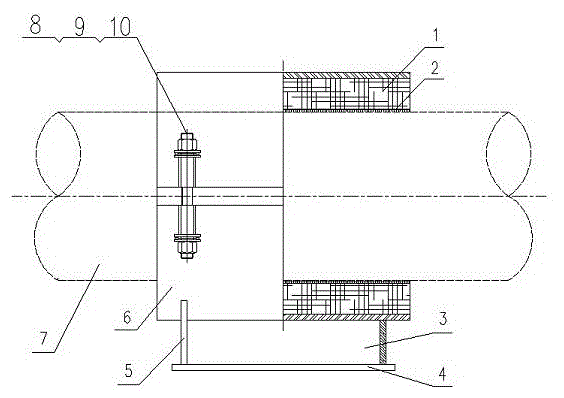

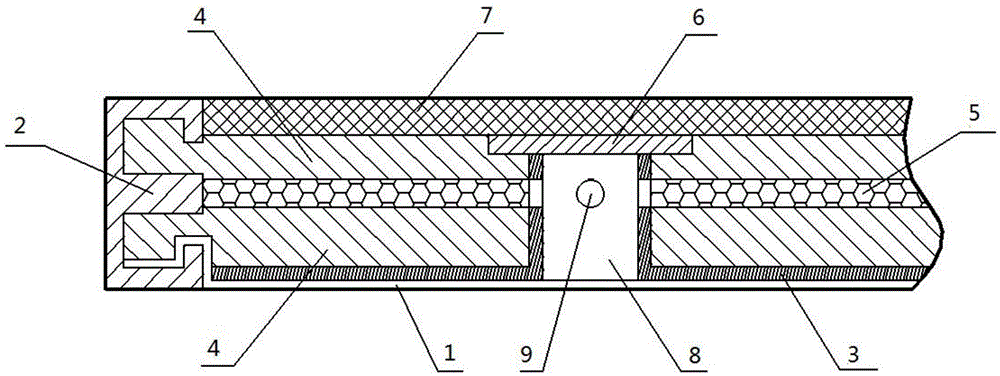

Vibration damper for automotive exhaust pipe

InactiveCN106150647AImprove driving comfort performanceSimple structureNon-macromolecular adhesive additivesExhaust apparatusUltrasound attenuationEngineering

The invention provides a vibration damper for an automotive exhaust pipe. The vibration damper comprises an intake pipe, a vibration-damping cylinder communicating with the intake pipe and an outlet pipe communicating with the vibration-damping cylinder. The vibration-damping cylinder comprises a buffering cylinder body located in the vibration-damping cylinder and a rubber cylinder located outside the buffering cylinder body. The periphery of the intake pipe and the periphery of the outlet pipe are both provided with annular connecting plates. The annular connecting plates are connected with the end face of the rubber cylinder body through bolts. Rubber blocks are arranged between the annular connecting plates and the end face of the vibration-damping cylinder and arranged on the bolts in a sleeving manner. By arranging the rubber cylinder body and the rubber blocks, the problem that vibration generated by an engine is directly transmitted to the exhaust pipe and an automobile body without attenuation is solved, the driving comfort of a whole automobile is improved, the structure is simple, and the occupied space is small.

Owner:WUHU EVERSHINE AUTOMOTIVE COMPONENT

Heat-insulation block for a shock-resistance and heat-insulation pipe bracket and a manufacturing method

ActiveCN105042279AImprove vibration resistanceImprove insulation performanceThermal insulationPipe protection by thermal insulationAluminateGlass fiber

The invention relates to a shock-resistance and heat-insulation pipe bracket and a heat-insulation block technology. A heat-insulation block for the shock-resistance and heat-insulation pipe bracket is formed by mixing lightweight aggregate, various light micro powder, coal ash, aggregate composed of vermiculite, alkali-free glass fibers, expanded perlite, aluminate cement and water according to a certain ratio, and the shock-resistance and heat-insulation pipe bracket is obtained after dry mixing, wet mixing and processing forming. The heat-insulation block can bear the high temperature of 1000 DEG C, the heat conduction coefficient under the temperature of 550 DEG C is smaller than or equal to 0.15 W / mk, the compressive strength is larger than or equal to 10 MPa, and the breaking strength is 4.5-6 MPa. Meanwhile, multiple functions of shock resistance, sound absorption, heat insulation and the like are achieved, the shock-resistance and heat-insulation pipe bracket is used for replacing a heat-insulation pipe bracket formed by processing traditional aggregate, and shock resistance and the heat insulation effect of the traditional heat-insulation pipe bracket are greatly improved.

Owner:JINAGSU SUNPOWER PIPELINE ENG TECH CO LTD

Regenerated lightweight silicon spar and preparation method thereof

InactiveCN103387339ASolve the problem of difficult recyclingEasy to handleEnvironmental resistanceFoaming agent

The invention discloses regenerated lightweight silicon spar and a preparation method thereof. The regenerated lightweight silicon spar is prepared from the materials of, by weight: 5-99.5 parts of waste glass, 3-90 parts of sand, 0.01-10 parts of a foaming agent, and 0.01-10 parts of a flux. Through steps of grinding, mixing and granulation, foaming agent and flux adding, high-temperature heating, melting, sintering, foaming, and annealing, the regenerated lightweight silicon spar is obtained. With the method provided by the invention, a problem of recycling difficulty of large amount of waste glass is solved, and waste is turned into valuable matters; waste glass processing process is simplified, washing is not needed, impurities such as labels are not needed to be removed, sorting according to color and type is not needed, and various types of waste glass can be mixed and processed together without washing and sorting; the produced regenerated lightweight silicon spar is a novel inorganic heat insulation material with an environment-protection function, and can be widely applied in the fields such as rainwater storage and utilization, barren hill, wasteland, and urban landscape greening, heat-insulation construction material, and the like.

Owner:厦门中致胜节能科技有限公司

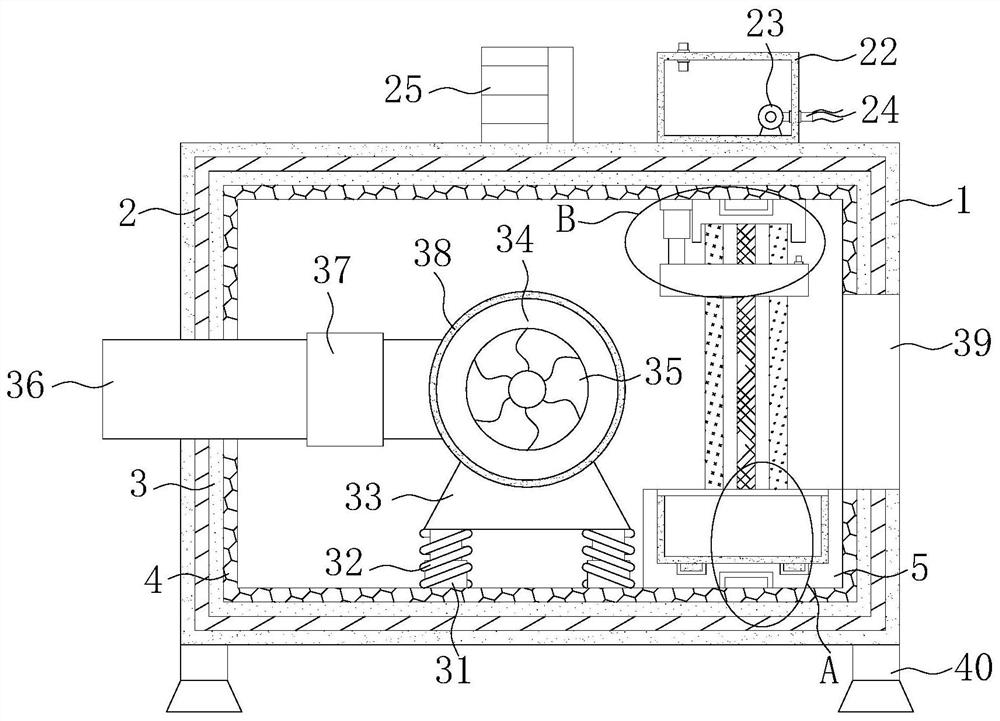

Cabinet type self-cleaning noise reduction fan

InactiveCN112065781AReduce noiseReduce vibrationPump componentsPump installationsAcoustic noise reductionStructural engineering

The invention discloses a cabinet type self-cleaning noise reduction fan and relates to the technical field of fans. The cabinet type self-cleaning noise reduction fan comprises a cabinet body, and agalvanized plate is fixedly installed on the inner wall of the cabinet body. According to the cabinet type self-cleaning noise reduction fan, the cabinet body, the galvanized plate, a macromolecule damping material plate, a porous silencing plate, a telescopic sleeve, a spring, a holding base, a fan body, an impeller, an air outlet pipe, a silencer, a foam cylinder and an air inlet are used in cooperation, the galvanized plate achieves the functions of attractiveness and rust prevention, and the macromolecule damping material plate has the functions of sound absorption, heat insulation, shockprevention and the like. The porous silencing plate is made of a silencing material, the effect of noise reduction can be further achieved, and the noise generated when the impeller operates can be reduced through the arrangement of the foam cylinder. Through the arrangement of the telescopic sleeve, the spring and the holding base, vibration generated when the fan body operates can be reduced, noise generated by the fan body is further reduced, and therefore the noise can be effectively reduced.

Owner:湖州南浔精优机械制造有限公司

Environmental protection sound absorbing and suond isolating cellulose building decoration material

InactiveCN1587171AWith sound absorptionWith sound insulationSolid waste managementSound proofingElastomerCellulose

The environment protecting, sound absorbing and isolating building decorating cellulose material consists of: waste newspaper or paper pulp 60-75 wt%, boric acid 10-20 wt%, borate 5-8 wt%, adhesive 5-10 wt% and plant fiber 5-10 wt%. The cellulose material is sprayed with a high pressure spraying apparatus onto the reflecting surface to form one kind of elastomer with excellent damping effect, excellent sound absorbing effect, fire retarding function and mothproof function.

Owner:温天佑

Automobile roof prepared from non-woven cloth and sponge

InactiveCN105538801ASimple structureWith heat insulationLayered productsSuperstructure subunitsAutomotive engineeringFiber layer

The invention relates to an automobile roof prepared from non-woven cloth and sponge, and belongs to the technical field of interior trims of automobiles. The automobile roof prepared from the non-woven cloth and the sponge comprises an automobile roof inner layer, wherein a flame retardant heat insulation layer is arranged above the automobile roof inner layer; large air vents are formed in the flame retardant heat insulation layer; a shock absorption rubber plate is arranged above the large air vents; small air vents are formed in the large air vents and are communicated with a fiber layer; a sponge layer is arranged above the flame retardant heat insulation layer. The automobile roof prepared from the non-woven cloth and the sponge is simple in structure and has the effects of heat insulation, sound insulation and sound absorption which can be realized by most automobile roofs; meanwhile, due to the bamboo carbon fiber layer connected with the air vents, the automobile roof has good effects of dehumidification and deflavoring; the sponge layer can further fully protect the head of a passenger and realize buffering in crash; the automobile roof also has the effects of flame retardancy and heat insulation, so that the environment in an automobile can be fully protected.

Owner:WUHU XINYUAN SPONGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com