Environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and preparation method thereof

A ceiling and PVC resin technology, applied in the field of ceiling and its preparation, can solve the problems of not being dust-proof, not having dust-proof, sound-absorbing, insect-proof and reflective, affecting the appearance of the ceiling, etc., achieving strong scratch resistance, sound insulation and heat insulation Good effect, the effect of improving the lighting level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

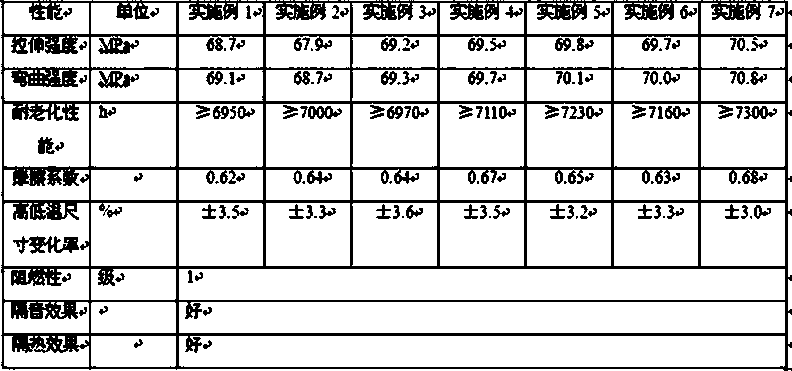

Examples

Embodiment 1

[0030] Environmentally friendly PVC foam ceiling board, including the following components in parts by mass: 90 parts of PVC resin; 5 parts of polylactic acid; 7 parts of polycaprolactone; 10 parts of polyester fiber; 50 parts of barium sulfate; 3 parts; 5 parts of zinc stearate; 1.7 parts of titanium dioxide; 0.6 parts of PE wax; 2 parts of ACR-201 processing modifier; 1.4 parts of CPE impact modifier; 0.7 parts of BTH composite foaming agent; sepiolite 20 servings.

[0031] The preparation method of environment-friendly PVC foam ceiling plate comprises the following steps:

[0032] Step 1: Screen the barium sulfate through a 160-mesh screen and add it to the mixer, then add PVC resin, polylactic acid, polycaprolactone, polyester fiber, and mix and stir for 10 minutes;

[0033] Step 2: Then add plasticizer, stabilizer, titanium dioxide, PE wax, processing modifier, impact modifier, composite foaming agent, sepiolite and mix for 20 minutes, cool down to a temperature of ≤45°C...

Embodiment 2

[0037] Environmentally friendly PVC foam ceiling board, including the following components in parts by mass: 110 parts of PVC resin; 10 parts of polylactic acid; 12 parts of polycaprolactone; 20 parts of polyester fiber; 70 parts of barium sulfate; 7 parts; 11 parts of zinc stearate; 5 parts of titanium dioxide; 2 parts of PE wax; 5.5 parts of ACR-201 processing modifier; 3.2 parts of CPE impact modifier; 1.5 parts of BTH composite blowing agent; sepiolite 30 servings.

[0038] The preparation method of environment-friendly PVC foam ceiling plate comprises the following steps:

[0039]Step 1: Screen the barium sulfate through a 200-mesh screen and add it to the mixer, then add PVC resin, polylactic acid, polycaprolactone, polyester fiber, and mix and stir for 15 minutes;

[0040] Step 2: Then add plasticizer, stabilizer, titanium dioxide, PE wax, processing modifier, impact modifier, composite foaming agent, sepiolite and mix for 25 minutes, cool down to a temperature ≤ 45°C ...

Embodiment 3

[0044] Environmentally friendly PVC foam ceiling board, including the following components in parts by mass: 93 parts of PVC resin; 5.5 parts of polylactic acid; 7.6 parts of polycaprolactone; 12 parts of polyester fiber; 50 parts of barium sulfate; 3.3 parts; 6 parts zinc stearate; 2.1 parts titanium dioxide; 0.8 parts PE wax; 2.9 parts ACR-201 processing modifier; 1.5 parts CPE impact modifier; 0.8 parts BTH composite blowing agent; sepiolite 21 servings.

[0045] The preparation method of environment-friendly PVC foam ceiling plate comprises the following steps:

[0046] Step 1: Screen the barium sulfate through a 180-mesh screen and add it to the mixer, then add PVC resin, polylactic acid, polycaprolactone, polyester fiber, and mix and stir for 12 minutes;

[0047] Step 2: Then add plasticizer, stabilizer, titanium dioxide, PE wax, processing modifier, impact modifier, composite foaming agent, sepiolite and mix for 22 minutes, cool down to a temperature ≤ 45°C and leave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com