Special black master batch for polylactic acid based degradable plastics and preparation method thereof

A technology for degrading plastics and polylactic acid bases, which is applied in the chemical industry and can solve the problems of carbon black dispersion and polylactic acid compatibility that affect the mechanical properties of polylactic acid-based degradable plastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

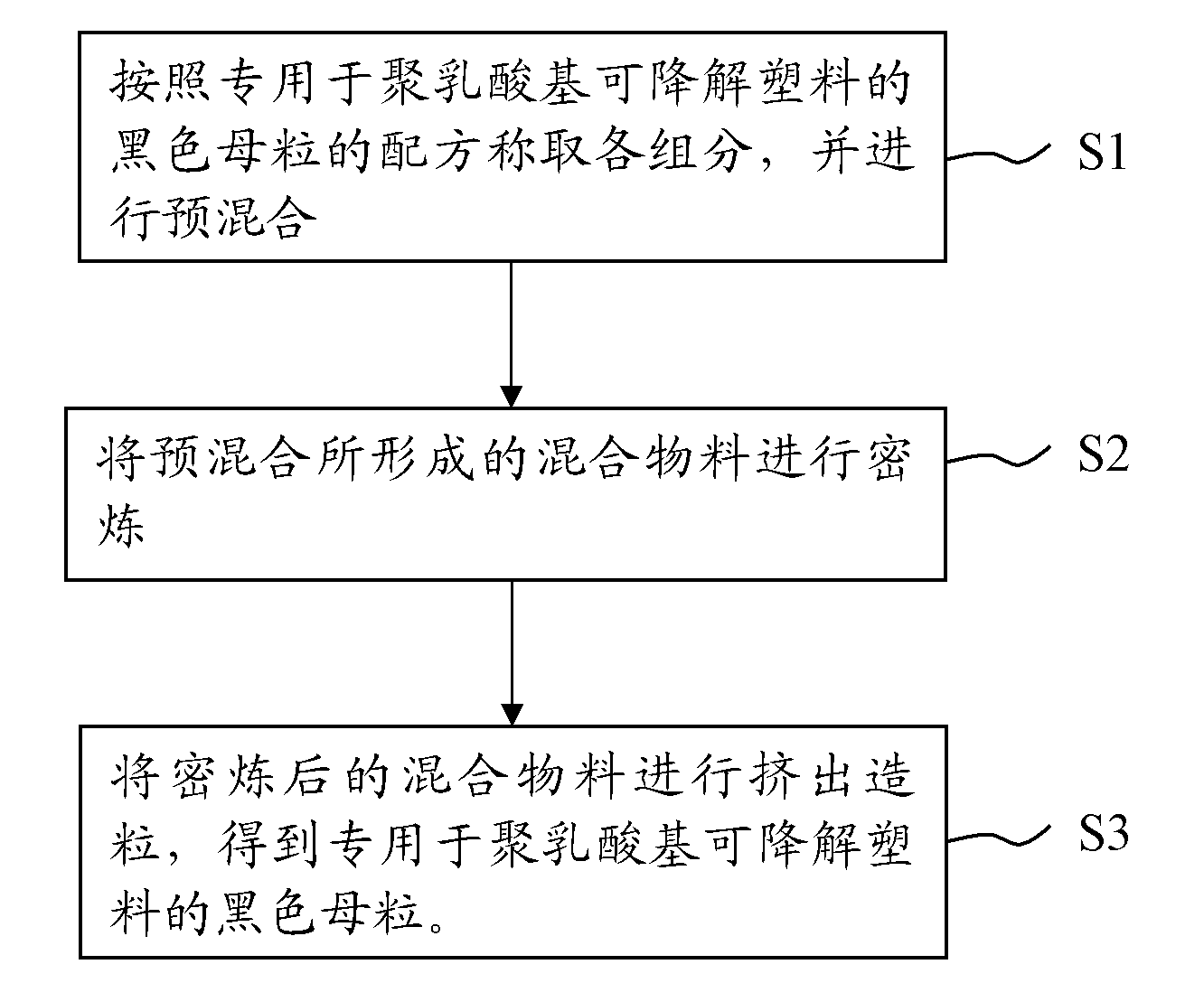

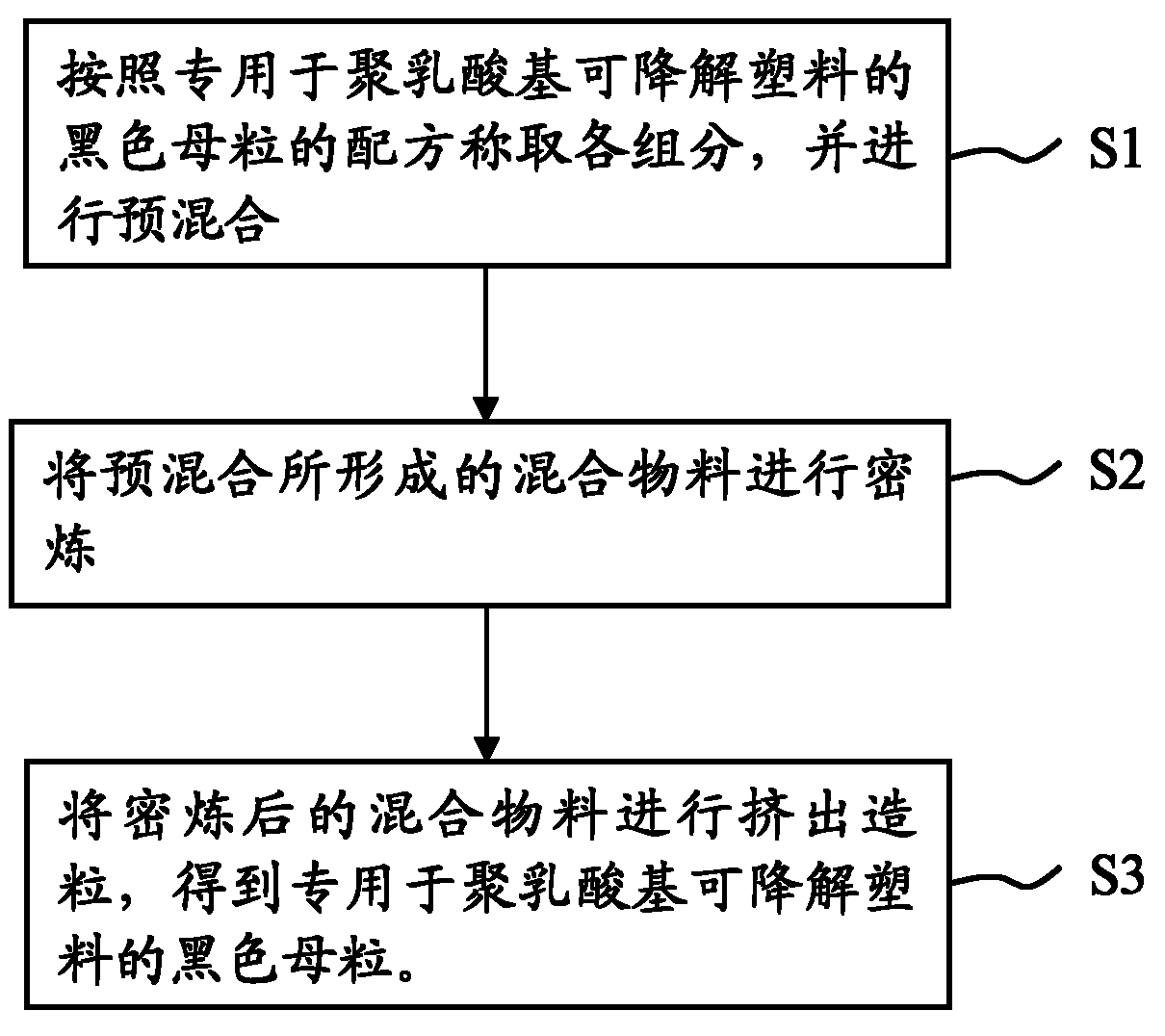

[0028] The embodiment of the present invention also provides the above-mentioned black masterbatch preparation method specially used for polylactic acid-based degradable plastics, the process flow is as follows figure 1 shown. The method comprises the steps of:

[0029] S1: Weigh and pre-mix each component according to the above-mentioned black masterbatch formula specially used for polylactic acid-based degradable plastics;

[0030] S2: banburying the mixed material formed by premixing;

[0031] S3: Extrude and granulate the mixed material after banburying to obtain the black masterbatch specially used for polylactic acid-based degradable plastics.

[0032] Specifically, in the S1 step of the above-mentioned black masterbatch preparation method dedicated to polylactic acid-based degradable plastics, the pre-mixing is to mix the components weighed according to the formula preferably at a speed of 800-2000 rpm for 5- For 30 minutes, the components were allowed to mix to form...

Embodiment 1

[0038] Black masterbatch formulation for polylactic acid-based degradable plastics:

[0039] 40% PLA plastic, 40% pigment carbon black with a particle size of 30nm, and 20% dispersed lubricant

[0040] Wherein, the composition of the dispersant is: 10% of polyethylene wax with an initial melting temperature of 100°C and a molecular weight of 5000, and 10% of EBS with an initial melting temperature of 140°C.

[0041] Its preparation method: first pre-mix the components in a high-speed mixer in proportion, the speed is 2000 rpm, and the mixing time is 5 minutes, then banburying in the internal mixer, the banburying time is 5 minutes, and then mixing The mixed material after refining is added to the twin-screw extruder for extrusion, and the required black masterbatch is obtained after cooling, drying and pelletizing. ℃, the temperature of the second stage is 220°C, the temperature of the third stage is 210°C, the temperature of the fourth stage is 180, the temperature of the fi...

Embodiment 2

[0043] Black masterbatch formulation for polylactic acid-based degradable plastics:

[0044] 65% of PLA plastic, 20% of pigment carbon black with a particle size of 10nm, and 15% of dispersed lubricant.

[0045] Wherein, the composition of the dispersant is: 5% of polyethylene wax with an initial melting temperature of 106°C and a molecular weight of 3000, and 10% of EBS with an initial melting temperature of 150°C.

[0046]Its preparation method: first pre-mix the components in a high-speed mixer in proportion, the speed is 800 rpm, and the mixing time is 30 minutes, then banburying in the internal mixer, the banburying time is 8 minutes, and then mixing The mixed material after refining is added to the twin-screw extruder for extrusion, and the required black masterbatch is obtained after cooling, drying, and pelletizing. The temperature of each section of the mixed material in the twin-screw extruder is: the temperature of the first section is 180°C , The temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com