Multifunctional premix mortar thickening material and preparation method thereof

A ready-mixed mortar, multi-functional technology, applied in the field of ready-mixed mortar water-retaining thickening materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

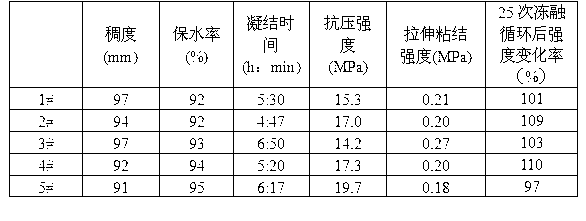

[0039] Table 1 is the raw material formula (parts by mass) for preparing the multifunctional ready-mixed mortar water-retaining thickening material according to the present invention. The bentonite in the raw material is Sihui Feilaifeng 100 type; the SiO of kaolin 2 More than 50%, Al 2 o 3 The content is 12-18%; fly ash is secondary ash; sodium dodecylbenzene sulfonate and sodium lignin sulfonate are chemical reagents; sodium sulfate is industrial grade, Na 2 SO 4 ≥99%; Hybrid modified rubber powder is prepared by the method disclosed in the invention patent "Modified rubber powder nanocomposite with sodium silicate as silicon source and its preparation method" (application number 200710032515.X, publication number CN101220179) That's it.

[0040] The raw material formula (number of parts by mass) of water-retaining thickening material of table 1

[0041] 1# 2# 3# 4# 5# Bentonite 80 80 80 80 80 Kaolin 10 10 10 10 10 fly ash 10 1...

Embodiment 2

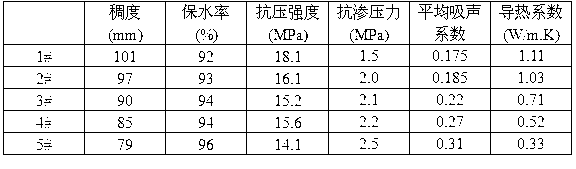

[0056] Table 4 is the raw material formula (parts by mass) for preparing the multifunctional ready-mixed mortar water-retaining thickening material according to the present invention. The bentonite in the raw material is Sihui Feilaifeng 100 type; the SiO of kaolin 2 More than 50%, Al 2 o 3 12-18%; fly ash is secondary ash; sodium dodecylbenzene sulfonate and sodium lignosulfonate are chemical pure reagents; sodium sulfate is industrial grade, Na 2 SO 4≥99%; Hybrid modified rubber powder is prepared by the method disclosed in the invention patent "Modified rubber powder nanocomposite material with sodium silicate as silicon source and its preparation method" (application number 200710032515.X, publication number CN101220179) That's it.

[0057] Table 4

[0058] 1# 2# 3# 4# 5# Bentonite 60 70 80 90 90 Kaolin 30 20 10 0 0 fly ash 10 10 10 10 10 Sodium dodecyl benzene sulfonate 0.1 0.1 0.2 0.2 0.2 Sodium lignosulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com