Black fungus ice cream and preparation method thereof

A technology of black fungus and ice cream, applied in the field of black fungus ice cream and its preparation, to achieve the effects of simple processing method, good sensory quality and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

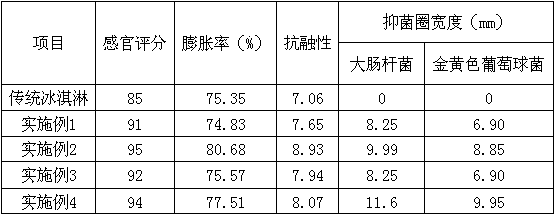

Examples

Embodiment 1

[0040] A preparation method of black fungus ice cream, characterized in that the steps are as follows (mass percentage):

[0041] (1) Pretreatment of black fungus: select high-quality dry black fungus with good shape, black color and thick flesh without mildew, soak in 20°C for 4 hours, rehydrate to soften and expand, remove impurities and drain, and dry at 50°C until Constant weight, crushed by a plant pulverizer, passed through 80 mesh, and then ultrafinely pulverized for 20 minutes, 2.0% black fungus superfine powder was added to water according to the mass ratio of 1:10, and pressure-cooked for 10 minutes under the condition of 0.1MPa , to promote the dissolution of black fungus polysaccharides, cool and set aside.

[0042] (2) Pretreatment of sodium carboxymethyl cellulose, white sugar, and milk powder: dry-mix 0.5% sodium carboxymethyl cellulose, 15% white sugar, and 8% milk powder, stir well, and set aside.

[0043] (3) Mixing of raw and auxiliary materials: dissolve 5...

Embodiment 2

[0051] This example is basically the same as Example 1, except for the pretreatment of black fungus: select high-quality dry black fungus with good shape, dark color and thick flesh without mildew, soak at 20°C for 4 hours, rehydrate, soften and expand , remove impurities and drain, dry at 50°C to constant weight, use a plant pulverizer to pass through 80 meshes, and then ultrafinely pulverize for 20 minutes, add 2.0% black fungus ultrafine powder into water according to the mass ratio of 1:20, Under the condition of 0.15MPa, cook under pressure for 20 minutes to promote the dissolution of black fungus polysaccharides, cool down, and add 15% black fungus polysaccharides to the mixture.

Embodiment 3

[0053] This embodiment is basically the same as Example 1, except that the pretreatment of sodium carboxymethyl cellulose, white granulated sugar, and milk powder: 1% sodium carboxymethyl cellulose, 12% white granulated sugar, and 10% milk powder Carry out dry mixing, fully stir and mix evenly, set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com