Patents

Literature

30results about How to "With enhanced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

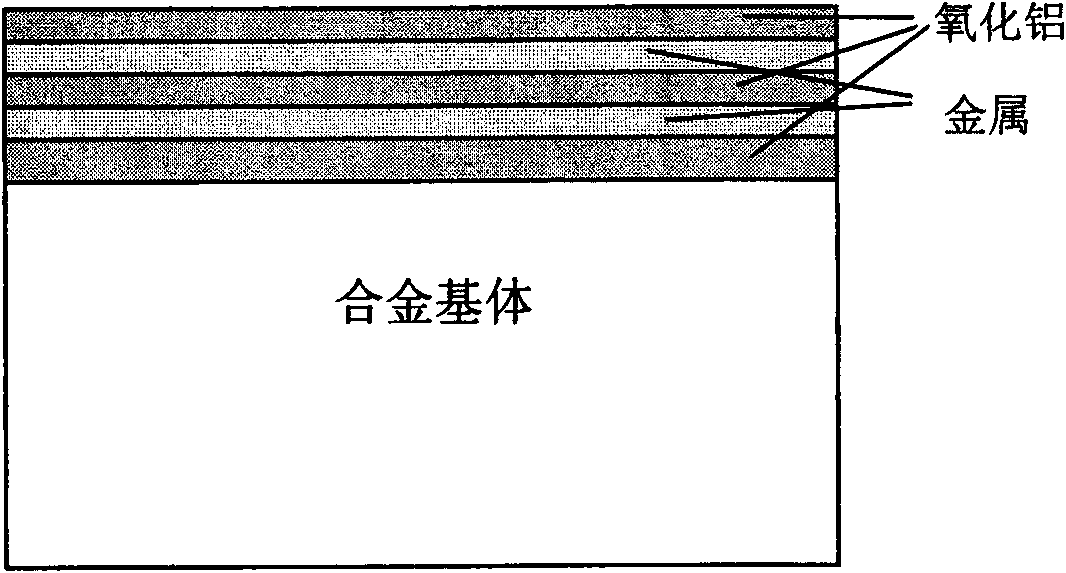

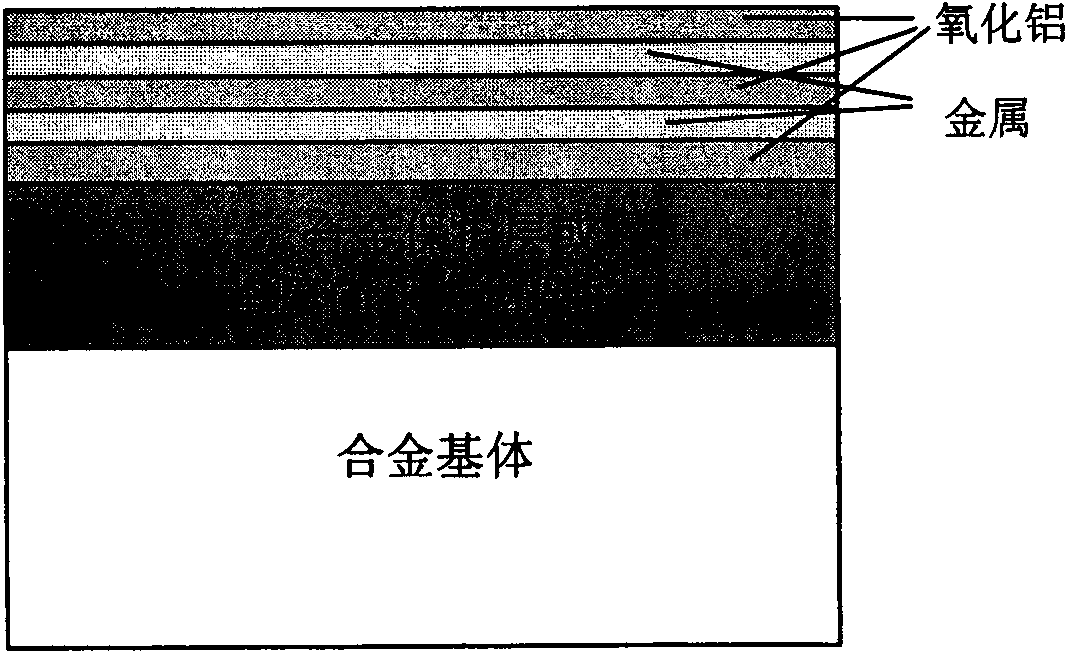

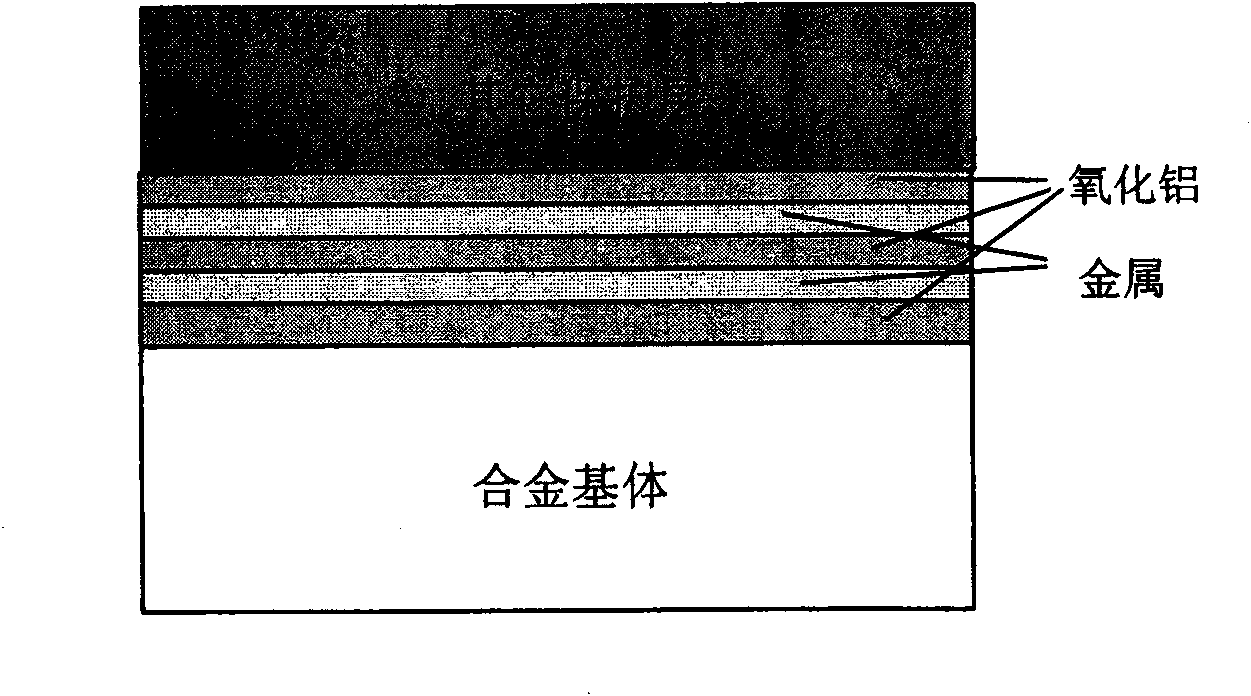

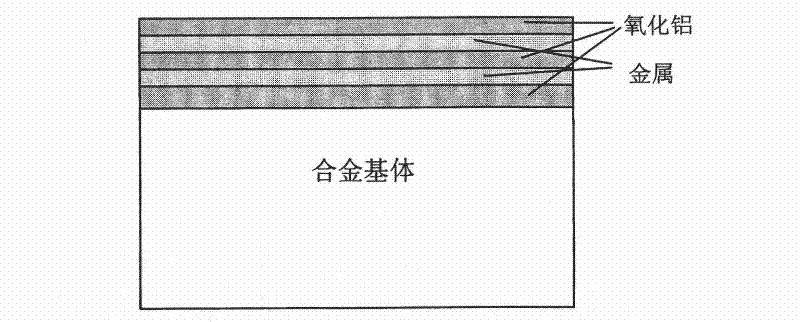

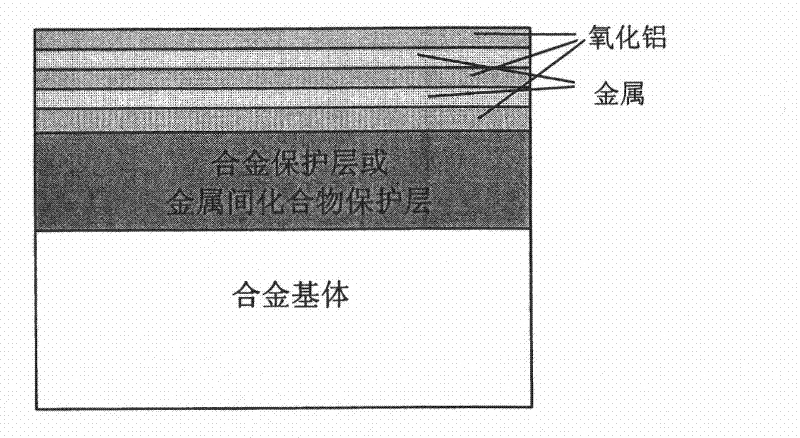

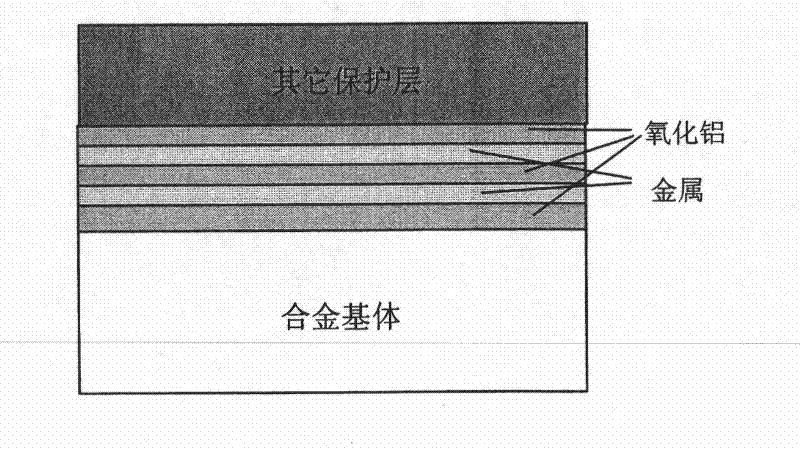

Multifunctional alumina/metal micro-laminated coating

The invention provides a multifunctional alumina / metal micro-laminated coating, which belongs to composite material made from metals and ceramic and coating technology thereof and is used for high-temperature protection, anti-tritium permeation, and anti-hydrogen damage of alloys with wide temperature scope. The micro-laminated coating adopts a high-pure alumina or alumina doped with a small amount of rear earth oxide, or alumina doped with a small amount of zirconia as an alumina coating, wherein the metals can be Pt, or Rh, or Ir, or Au, or alloys of all, or M-Cr-Al-rare earth alloy, or Fe, Co, Ni-based aluminum-containing alloy. The thickness of each laminated coating is 20-1000nm. The micro-laminated coating can be obtained by adopting a plurality of methods through the alternative sedimentation of the alumina coating and a metal coating. The micro-laminated coating has the following characteristics: (1) excellent binding force with the alloy substrate; (2) excellent high-temperature protection performance and anti-tritium penetration performance, and anti-hydrogen damage performance; (3) wide operating temperature range from room temperature to 2000 DEG C; (4) the evaporation inhibition of precious metal coatings at high temperature; and (5) and synergistic protective effect with other coatings.

Owner:UNIV OF SCI & TECH BEIJING

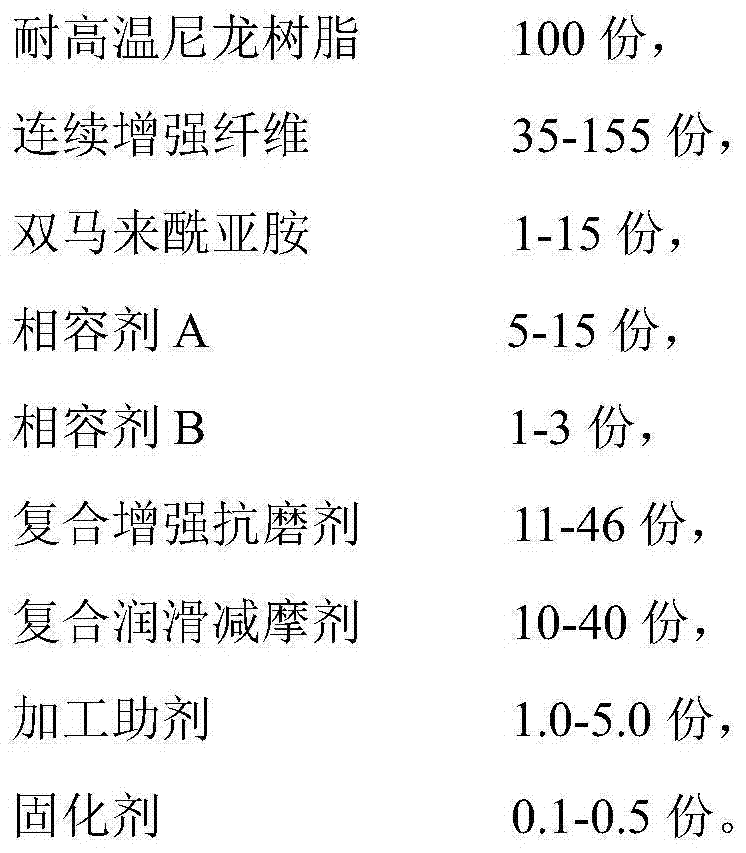

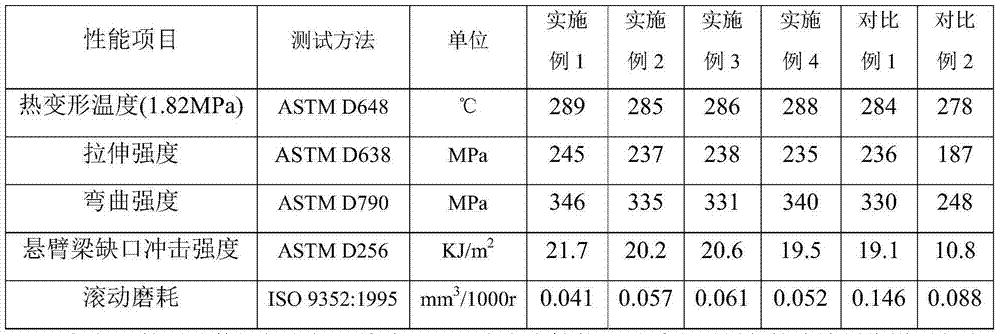

High wear resistant and high self-lubrication continuous long fiber reinforced high temperature resistant nylon composite material and preparation method thereof

InactiveCN104744926AImprove the lubrication effectImprove wear resistanceWear resistantTemperature resistance

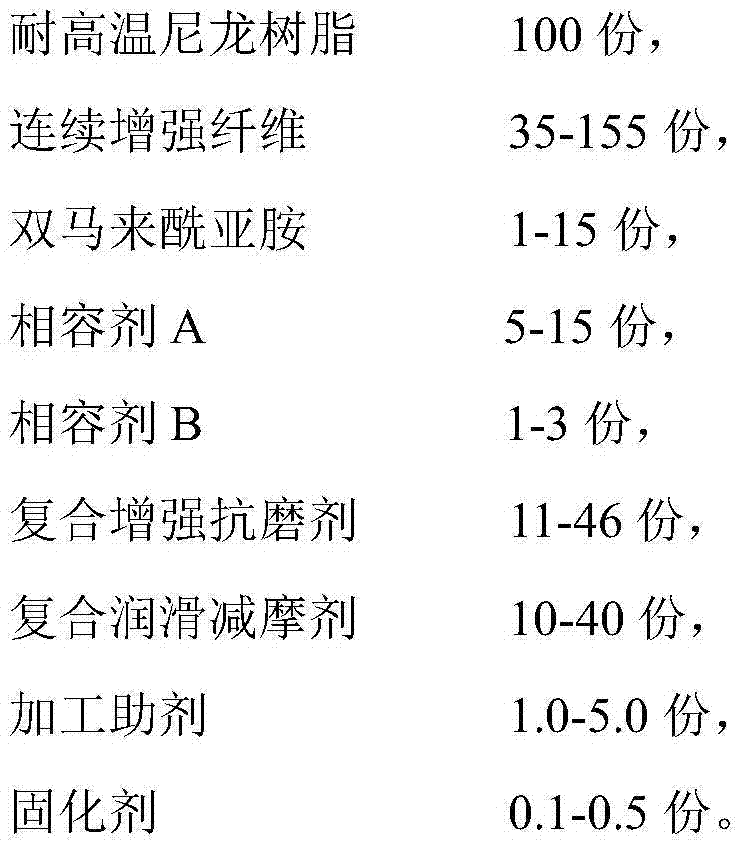

The invention belongs to the high temperature resistant nylon composite material field, and relates to a continuous long fiber reinforced high temperature resistant nylon composite material including the following components by weight: 100 parts of high temperature resistant nylon resin, 35-155 parts of continuous reinforced fiber, 1-15 parts of bismaleimide, 5-15 parts of a compatible agent A, 1-3 parts of a compatible agent B, 11-46 parts of a composite reinforced antiwear agent, 10-40 parts of a composite lubrication antifriction agent, 1.0-5.0 parts of a processing aid and 0.1-0.5 part of a curing agent. The high wear resistant and high self-lubrication continuous long fiber reinforced high temperature resistant nylon composite material has enough wear resistance, self lubrication property, mechanical properties, high temperature resistance and dimensional stability, and can be used in the manufacture of sliding parts such as gears, turbines, cam and other transmission parts and bearings, bushings, guide rails, pistons and other wear resistant, antifriction and self self-lubrication parts and general structural parts working in the high temperature environment.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Halogen-free flame-retardant dicyclopentadiene material and preparation method thereof

ActiveCN101792505AImprove appearance qualityImprove mechanical propertiesPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPhosphateAluminium hydroxide

The invention discloses a halogen-free flame-retardant dicyclopentadiene material and a preparation method thereof. The material consists of polydicyclopentadiene, flame retardant, modifier and catalyst, wherein the flame retardant is silane coupling agent, titanate coupling agent, aluminium zirconate coupling agent, organic chromium coupling agent, higher fatty acid and salt thereof, phosphate, unsaturated organic acid or organic ammonium salt modified aluminium hydroxide. The preparation method prepares the flame-retardant material by using reaction injection moulding. The oxygen index of the obtained material is 22 to 26 percent, and the horizontal combustion test can reach HB level; and the bending strength is 40 to 45MPa, the bending modulus is 1,400 to 1,700MPa, the tensile strength is 34 to 37MPa, the impact strength is 26-80kJ / m<2>, and the hardness is 74 to 76 Shaw D. The material does not contain halogen flame retardant, and has high flame-retardant performance and high mechanical property.

Owner:LIMING RES INST OF CHEM IND

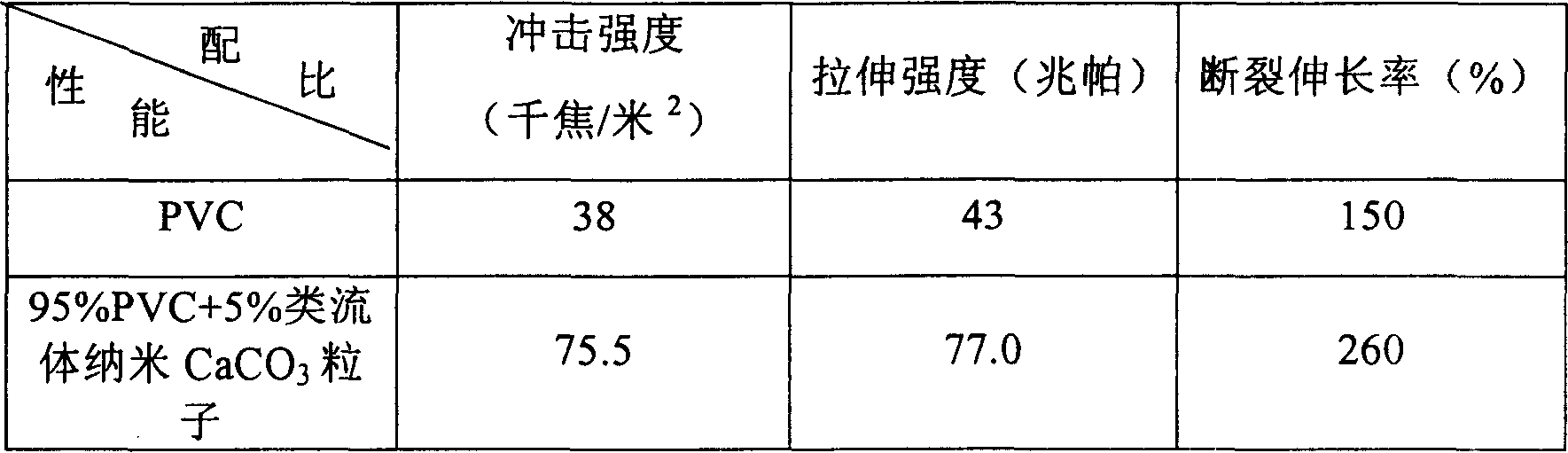

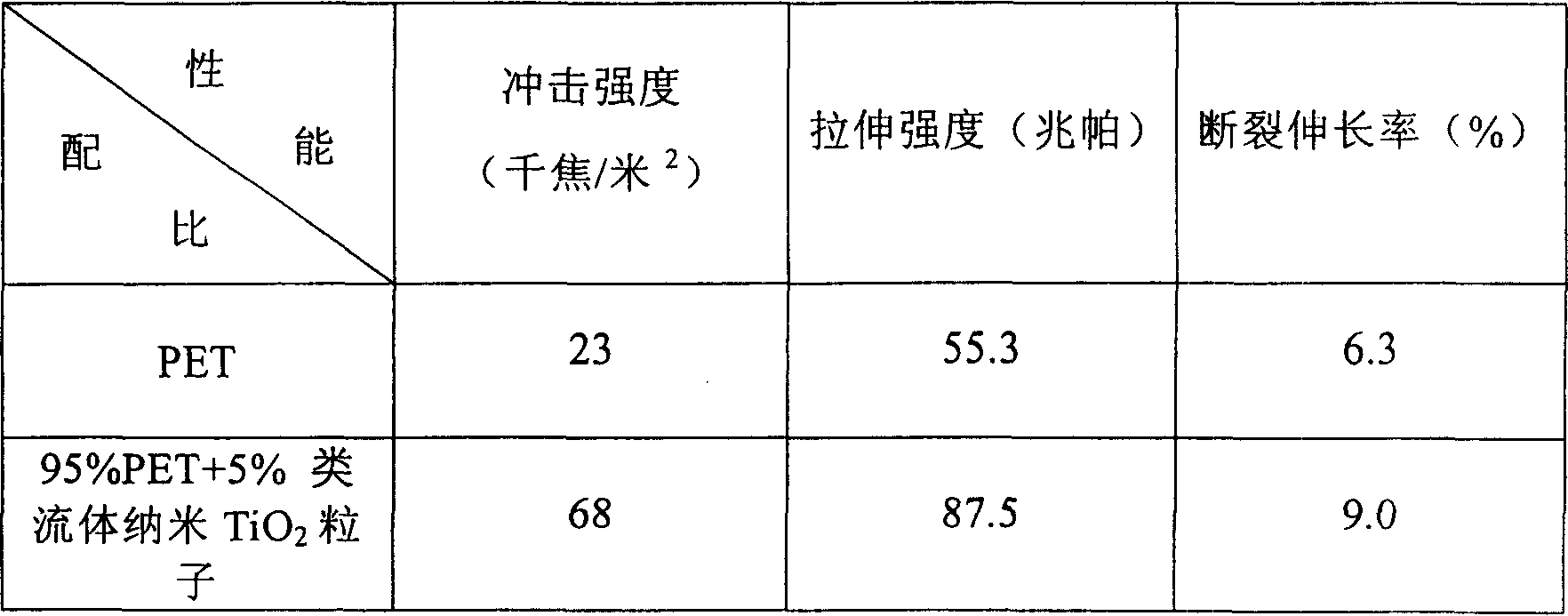

Composite material of similar fluid inorganic nano particle and polymer and preparation thereof

The invention discloses a composite material of like-fluid inorganic nanometer particle and polymer and preparing method, which is characterized by the following: the composite material is consists of m parts of like-fluid inorganic nanometer particle and 100-m parts of thermoplastic polymer, which are mixed at melting temperature+-20DEG C for once forming (0<m<=10); the polymer concludes chloroethylene, polyethylene, polypropylene, polystyrene, nylon and polyester; the inorganic nanometer particle concludes nanometer calcium carbonate, nanometer silicon dioxide and nanometer titanium dioxide.

Owner:WUHAN UNIV OF TECH

Method for producing conductive geotextile

The invention relates to a production method, in particular to a method for producing conductive geotextile. The method for producing the conductive geotextile comprises the steps of raw material selection, raw material screening, drying, fusion, spinning, cross air blow cooling, airflow drafting, swinging, net laying, mixed even feeding of metal fibers, carbon fibers and other short fibers, ironing conducted by a hot roller, shaping conducted by a pre-needle machine, reinforcing shaping conducted by a first main needle machine, repair shaping conducted by a second main needle machine, cloth containing conducted by a cloth containing machine, trimming and rolling. The geotextile produced according to the method for producing the conductive geotextile has the protective performance, the isolating performance, the waterproof performance, the filtering performance and the like of traditional geotextile, further has the conductive characteristic and is a good electrode material. According to the method for producing the conductive geotextile, the production technology is stable, control over the thickness of a material is good, the control range of the puncture density is large and is 50 to 500 stitches / cm<2>, the controllable range of the permeability performance of the material is large and is (1.0-9.9)*(10<-1>-10<-3>)cm / s, the strength of the product is high, and the thickness reaches 20mm.

Owner:大连格尔迈斯合成材料有限公司

Lucid ganoderma refined powder compound soft capsule and preparation method thereof

ActiveCN103340919ALow costImprove utilizationHydrocarbon active ingredientsAntipyreticBiotechnologyLycopersene

The invention relates to the technical field of health products, and in particular relates to a lucid ganoderma refined powder compound soft capsule and a preparation method thereof. The lucid ganoderma refined powder compound soft capsule comprises 1 to 300 parts of lucid ganoderma refined powder, 1 to 50 parts of lycopene, 1 to 50 parts of grifolan, and 1 to 500 parts of safflower oil. According to the lucid ganoderma refined powder compound soft capsule, the lucid ganoderma refined powder, lycopene, grifolan and safflower oil which are different in molecular structure are used in common and have some same pesticide effects and also have individual outstanding pesticide effects; and after being organically combined in proportion, the four materials complement and promote one another on curative effect and maximize the effects individually. A preparation in form of the soft capsule can cover the discomfort smell of the contents and effectively improve the stability of the lycopene and safflower oil, enables quick and complete intake and absorption of the healthcare components, and give full play to inflammation resistance, pain alleviating, poisonousness reducing, wound repair promoting, immunoregulation, tumor inhibition, resisting to cancer, three highs (high blood pressure, high blood sugar and high blood lipid) and cardiovascular disease, senescence delaying, improvement of liver function, organism balancing and adjusting and other effects.

Owner:东莞市味菇坊生物科技有限公司

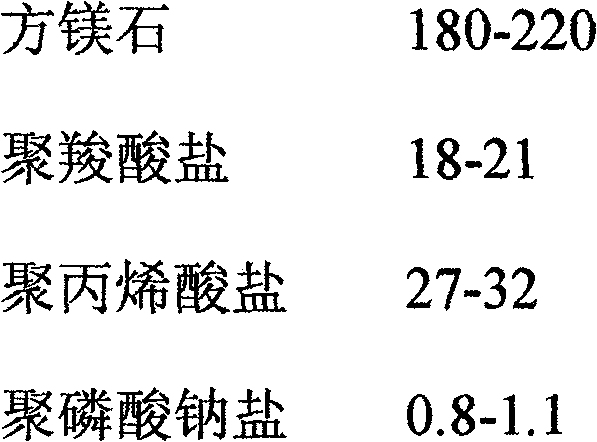

Volume stabilizer for cement-based composite material and preparation method thereof

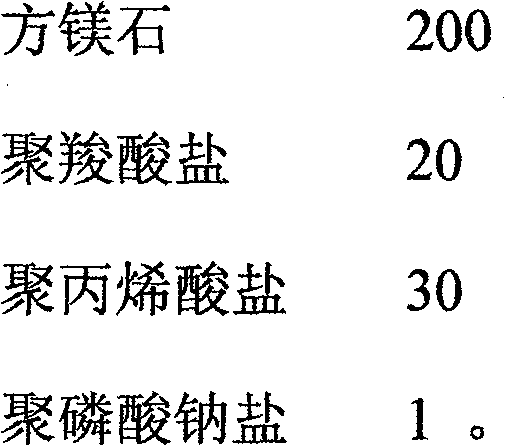

The invention discloses a volume stabilizer for a cement-based composite material and a preparation method thereof. The volume stabilizer comprises the following components in part by weight: 180 and 220 parts of periclase, 18 to 21 parts of polycarboxylate, 27 to 32 parts of polyacrylate and 0.8 to 1.1 parts of sodium polyphosphate, wherein the periclase is ground into fine powder; the fine powder is sieved by a 85mu m sieve; and residue on the sieve is less than 10 percent. The method comprises the following steps: a, grinding magnesite serving as raw materials into fine power and sieving the fine powder with the 85mu m sieve, wherein residue on the sieve is less than or equal to 10 percent; b, calcining the ground magnesite powder at the temperature of between 900 and 1,250 DEG C, preserving the heat for 30 to 120 minutes, and cooling the calcined magnesite powder to room temperature after the heat preservation is finished to prepare the periclase; c, grinding the periclase into fine powder and sieving the fine powder with a 85mu m sieve, wherein residues on the sieve is less than or equal to 10 percent; and d, mixing the periclase obtained in the step c, the polycarboxylate, the polyacrylate and the sodium polyphosphate in proportion. The volume stabilizer and the preparation method can solve the problem of cracking of cement-based materials caused by contraction.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

High-strength wood-plastic board and preparation method thereof

The invention discloses a high-strength wood-plastic board and a preparation method thereof. The high-strength wood-plastic board comprises components in parts by weight as follows: 50-80 parts of sisal dregs, 40-80 parts of waste plastics, 10-25 parts of modified phenolic resin, 6-10 parts of mineral fiber, 5-10 parts of pentalyn, 8-12 parts of nano calcium carbonate and 8-15 parts of an auxiliary. The preparation method comprises technological steps of modification pretreatment, high-speed mixing, hot-press molding and cooling for sizing. Comprehensive utilization of resources of the sisal dregs is realized, the prepared wood-plastic board has high compressive strength and wear resistance, the cost is reduced, and the service life of the wood-plastic board is long. The high-strength wood-plastic board and the preparation method have the advantages of simpleness in processing technology, short processing time, low cost and the like, and the wood-plastic board is applicable to industrial production.

Owner:许超群

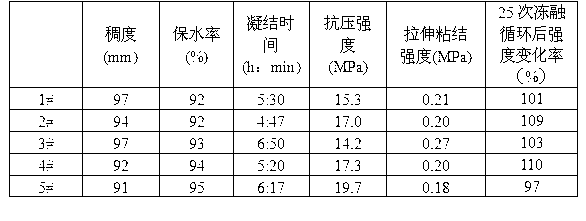

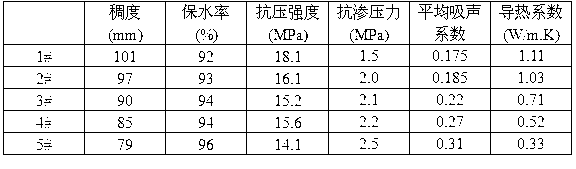

Multifunctional premix mortar thickening material and preparation method thereof

The invention discloses a multifunctional premix mortar thickening material and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out drying pretreatment on bentonite, kaolin and fly ash; (2) after premixing the bentonite, kaolin and fly ash obtained in the step (1) with surfactant and calcium sulfate, grinding in a grinding machine; and (3) adding hybrid modified rubber powder and the raw material obtained in the step (2) into a mixing machine, and mixing to obtain the multifunctional premix mortar thickening material. By producing the thickening material mainly from inorganic materials by a grinding technique, the invention can ensure the bonding reaction of the inorganic powder materials with the surfactant and modifier, thereby forming a novel organic / inorganic composite mortar additive; and besides, the added nano hybrid modified scrap rubber powder can effectively enhance the water permeation resistance of the mortar, improve the freezing resistance and heat-insulating property of the mortar, and enhance the strength of the mortar.

Owner:广东广业检测有限公司 +2

Preparation method of sepiolite-tetrapod zinc oxide whisker composite material

ActiveCN105200519AWear-resistantWith enhancedPolycrystalline material growthFrom solid stateWear resistantAntibacterial property

The invention relates to a preparation method of a sepiolite-tetrapod zinc oxide whisker composite material. Sepiolite has very high adsorption performance and good dispersing performance and can be taken as a carrier and a framework of tetrapod zinc oxide whiskers, and respective use performance is not influenced. The preparation method comprises steps as follows: the sepiolite is dissolved in ethanol, methanol or hydrogen peroxide, is stirred uniformly and dried after separation, and sepiolite powder is obtained; the sepiolite powder and zinc powder are mixed, dissolved in distilled water, ethanol, methanol or hydrogen peroxide and stirred and mixed uniformly; a solid mixture obtained after separation is placed in a drying oven for drying; dry powder is placed in a high-temperature stove for calcination treatment, and the sepiolite-tetrapod zinc oxide whisker composite material is obtained. The prepared composite material has performance including wear resistance, strength enhancement, damping performance, slip resistance, nose reduction, ageing resistance, antistatic property, antibacterial property and the like and can be widely applied to materials such as a coating, an antibacterial material, an antistatic material, a wear-reducing and wear-resistant material and the like, the operation technology is simple, and the economic cost-performance ratio is high.

Owner:唐山索朗科技有限公司

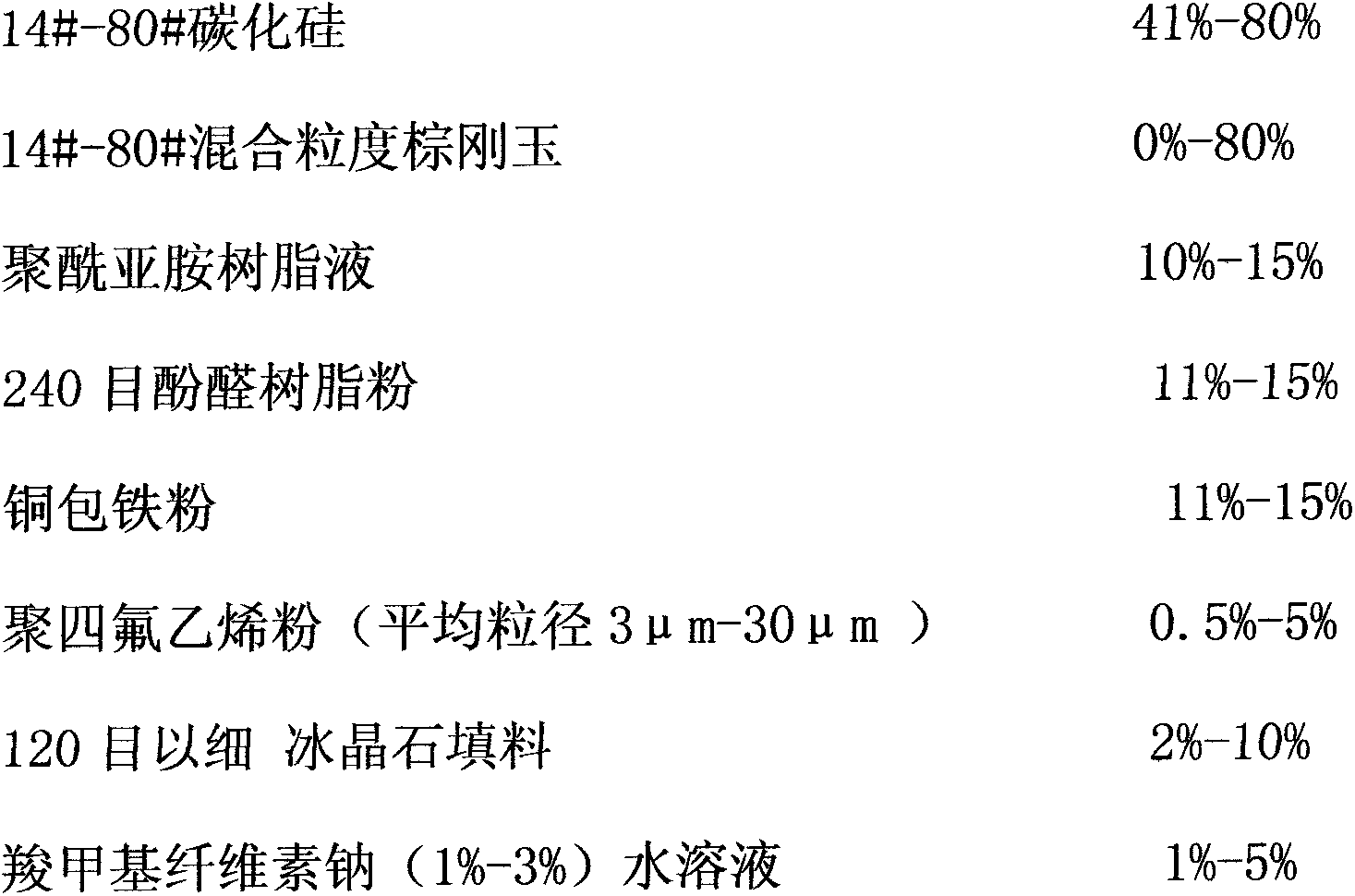

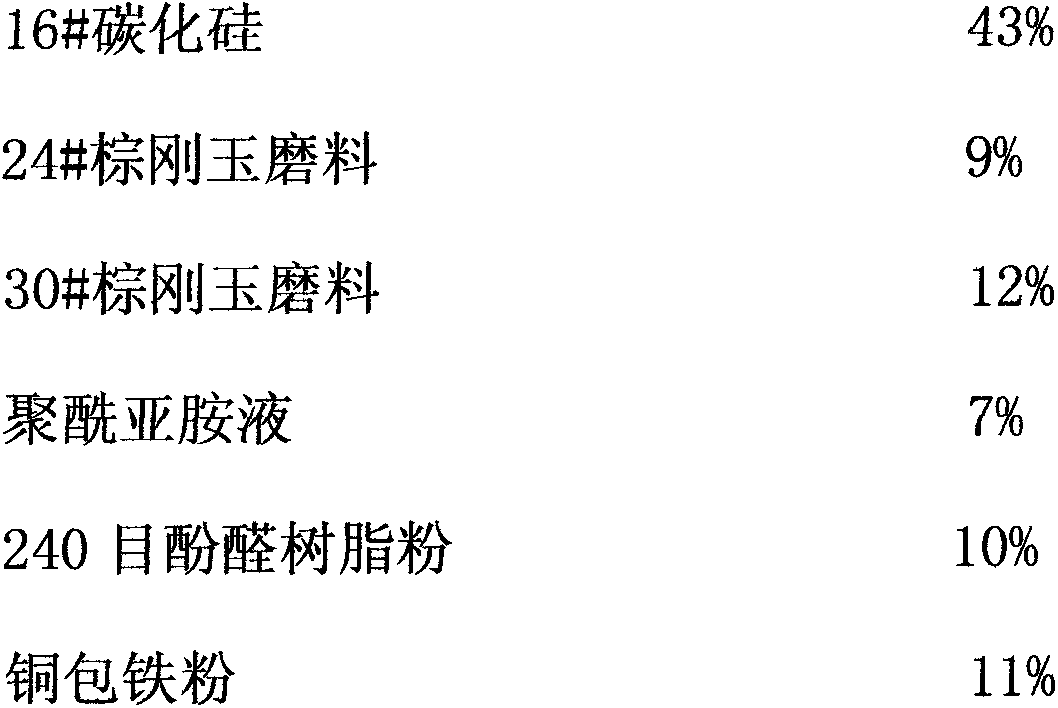

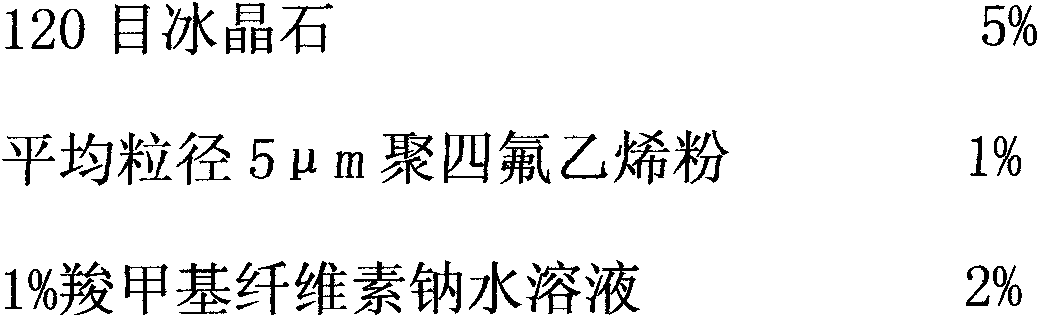

Method for manufacturing resin wheel containing sodium carboxymethylcellulose

InactiveCN103962973AWith bondingWith thickeningAbrasion apparatusGrinding devicesGrinding wheelPolytetrafluoroethylene

The invention provides a method for manufacturing a resin wheel containing sodium carboxymethylcellulose. The resin wheel comprises 41%-80% of silicon carbide, 0%-80% of brown fused alumina, 10%-15% of polyimide resin liquid, 11%-15% of 240-mesh phenolic resin powder, 11%-15% of copper-coated iron powder, 0.5%-5% of polytetrafluoroethylene powder, 2%-10% of cryolite packing and 1%-5% of sodium carboxymethylcellulose water solution. The method has the advantages that the sodium carboxymethylcellulose water solution is used as a wetting agent, nanoscale polytetrafluoroethylene powder, fine cryolite, fine phenolic resin powder and other micro powder are evenly suspended in the sodium carboxymethylcellulose water solution and attached to grinding materials, due to the macromolecular structure of the powder, the binding strength of the powder and a binding agent can be improved through intermolecular force, and therefore the strength of the resin wheel is greatly improved. Due to the water-retaining property of sodium carboxymethylcellulose, in the production process, water loss in the production process can be avoided, dust separation is further reduced, and component contents of raw materials are uniform.

Owner:武汉法山磨料磨具有限公司

Novel plastic mobile phone shell

InactiveCN105323340AHigh impactImprove heat resistanceClimate change adaptationTelephone set constructionsHeat resistanceEngineering

The invention discloses a novel plastic mobile phone shell. The novel plastic mobile phone shell comprises PC / ABS (Polycarbonate / Acrylonitrile-Butadiene-Styrene) in the uppermost layer, plastic alloy in the middle layer and organic silica gel in the lowest layer. The PC / ABS comprises polycarbonate and polyacrylonitrile alloy; the PC / ABS accounts for 64%-68% of the total weight of the novel plastic mobile phone shell; the plastic alloy accounts for 11%-12% of the total weight of the novel plastic mobile phone shell; and the organic silica gel accounts for 18%-24% of the total weight of the novel plastic mobile phone shell. The invention provides the novel plastic mobile phone shell which has the characteristics of being high in impact resistance, high in heat resistance, flame-retardant, reinforced, transparent and the like.

Owner:SUZHOU TIANQING ELECTRONICS COMM

High-strength wear-resistant fiber reinforced plastic

InactiveCN107151383ASimple preparation processThe preparation process is environmentally friendly and pollution-freePlastic/resin/waxes insulatorsPolypropyleneSilane coupling

The invention discloses high-strength wear-resistant fiber reinforced plastic. The high-strength wear-resistant fiber reinforced plastic is prepared from, by weight, 15-25 parts of polypropylene, 10-20 parts of epoxy resin, 10-30 parts of nano ceramic particles, 2-8 parts of a silane coupling agent, 5-10 parts of cyclohexanone, 2-6 parts of zirconium oxide and 15-25 parts of a wear-resistant agent. Technical simplicity, environmental friendliness and freeness of pollution in a preparation process are realized, fiber reinforced plastic prepared according to the method is high in wear resistance and has advantages of corrosion resistance and high temperature resistance, and service lives of fiber reinforced plastic cables can be prolonged.

Owner:DE RUISEN NANTONG COMPOSITE MATERIAL CO LTD

Manganese oxide-cellulose modified polylactic acid composite material and preparation method thereof

The invention discloses a manganese oxide-cellulose modified polylactic acid composite material and a preparation method thereof. The polylactic acid composite material is prepared from, by weight, 40-80 parts of polylactic acid, 7-15 parts of manganese oxide, 8-18 parts of sodium carboxymethylcellulose, 6-12 parts of gypsum whiskers, 4-11 parts of nanometer attapulgite, 3-10 parts of polyethylene glycol, 5-14 parts of divinyl benzene, 3-9 parts of vermiculite powder, 1-5 parts of gamma-amino propyl triethoxysilane and 3-8 parts of polypropylene wax. It is proved through tests that the tensile strength of the polylactic acid composite material prepared through the preparation method ranges from 55.4 MPa to 58.7 MPa, the elongation at break ranges from 13.6% to 15.8%, and the notch impact strength ranges from 9.6 kJ / m<2> to 11.4 kJ / m<2>.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

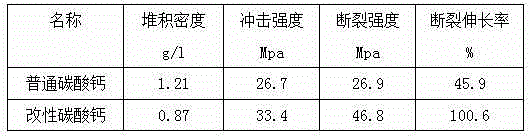

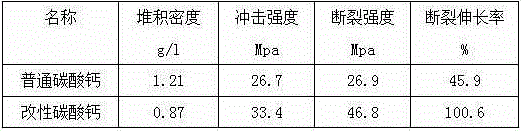

Modified calcium carbonate with good elasticity and preparation method thereof

ActiveCN104130592AImprove rigidityIncrease elasticityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSlagPolyvinyl chloride

Disclosed modified calcium carbonate with good elasticity is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 5.5-7 parts of polyvinyl chloride, 5-7 parts of transparent ABS, 4-6 parts of synthetic rubber, 2-3 parts of calcium carbide slag, 1.5-2.5 parts of crude aggregate, 3-5 parts of teflon, 2-3 parts of cationic starch, 2-3 parts of sulfonated lignin, and 2.5-3.5 parts of modified titanium dioxide. By adding transparent ABS and other macromolecular compounds, synthetic rubber and the like into calcium carbonate, calcium carbonate is substantially improved in rigidity, elasticity and stability, also has the characteristics of toughening, reinforcing and relatively good strength, and also is reduced in cost. The provided preparation method is simple and convenient to operate, and is easy to industrialize. The produced filling material is applicable to coatings, rubber, plastic and the like.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

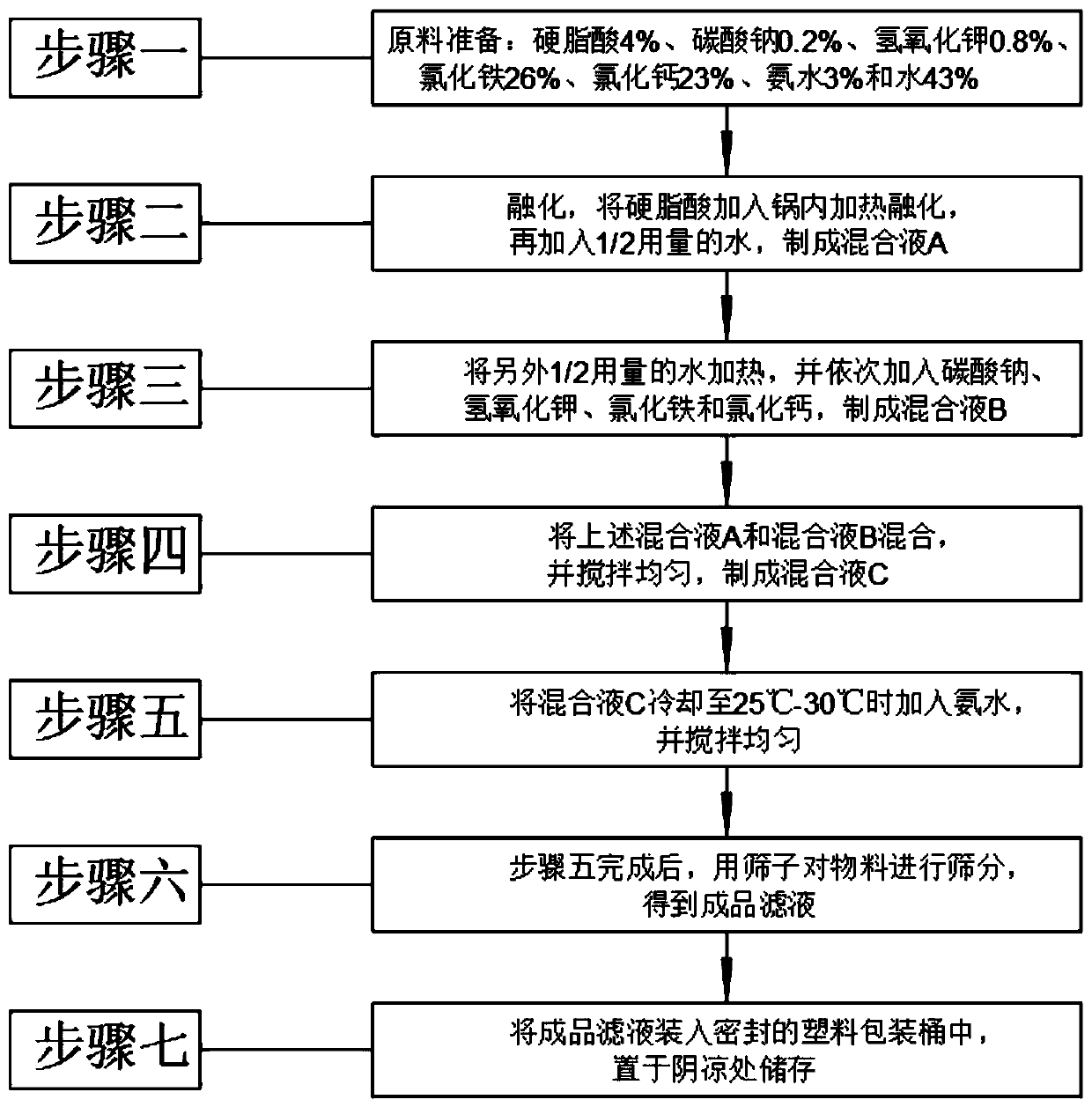

Waterproofing agent with long-lasting water resistance for walls and processing technology of waterproofing agent

InactiveCN110423036AImprove waterproof performanceLong waterproof lifePotassium hydroxideStearic acid

The invention discloses a waterproofing agent with long-lasting water resistance for walls. The waterproofing agent comprises the following components, in percentages by weight: 3%-5% of stearic acid,0.1%-0.3% of sodium carbonate, 0.7%-0.9% of potassium hydroxide, 25%-27% of ferric chloride, 22%-24% of calcium chloride, 2%-4% of ammonia water and 42%-44% of water. A processing technology comprises the following steps: preparing the raw materials, melting the raw materials, performing primary mixing on the raw materials, performing secondary mixing on the raw materials, and performing sievingto obtain the finished-product filtrate. According to the waterproofing agent for the walls provided by the invention, the stearic acid is added, so that the waterproofing agent has the advantages ofgood water resistance, long waterproof service life, low process difficulty and low costs; the alkali metal compound sodium carbonate is added, the compound has a plasticizing effect, so that a water-ash ratio can be reduced, water seepage channels can be cut off and reduced, compactness of mortar can be increased, and the mortar has a waterproof property; and the ferric chloride is added, oxidized iron sheets and powder are used as main raw materials, and the ferric chloride waterproofing agent has the functions of strengthening and early strengthening, can continuously improve the compressive strength of concrete and has relatively high impermeability in the early stage.

Owner:YANGZHOU POLYTECHNIC INST

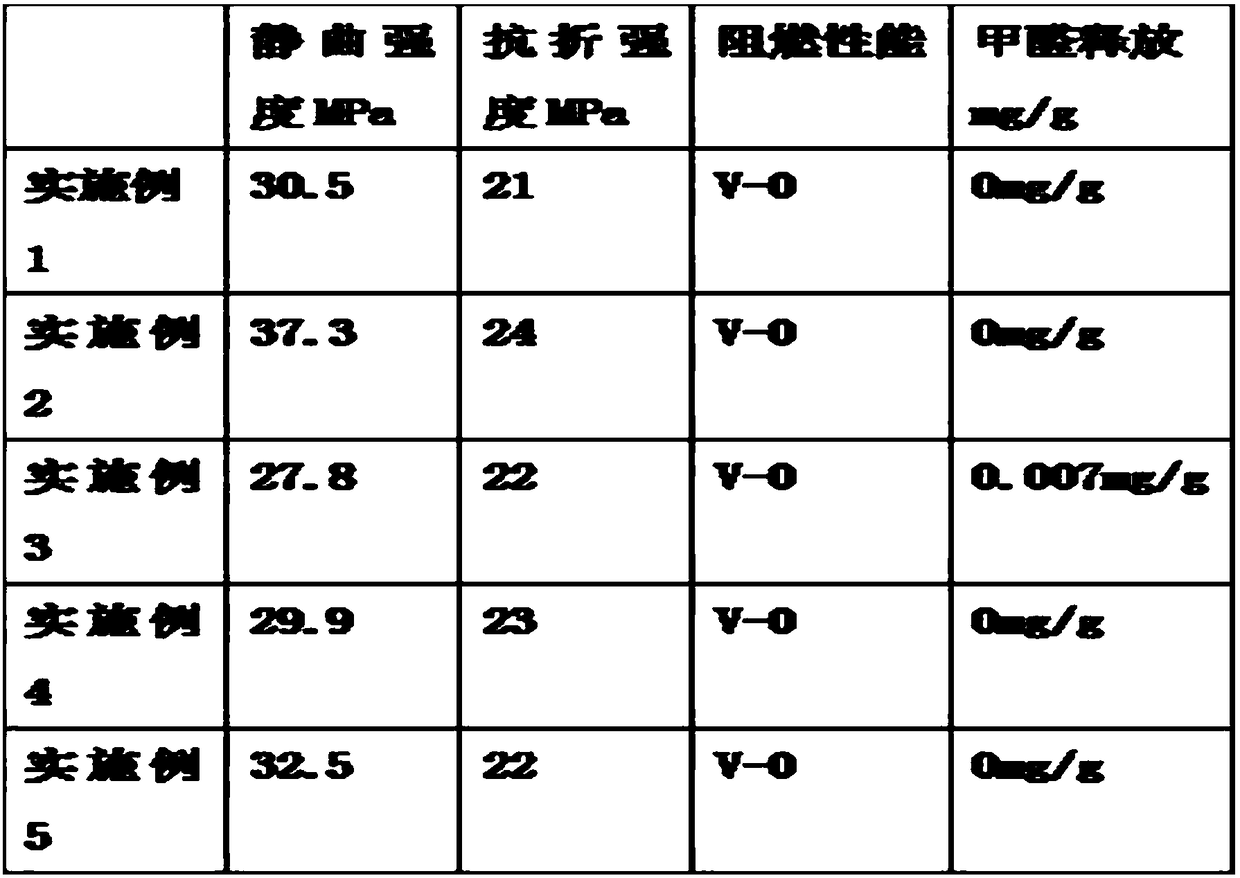

High-strength artificial board and manufacturing technology thereof

The invention relates to the technical field of wood processing preparation, in particular to a high-strength artificial board. The high-strength artificial board comprises, by weight, 30-50 parts ofcedarwood powder, 20-30 parts of sisal hemp residue powder, 20-30 parts of polyethylene, 5-10 parts of urea-formaldehyde resin adhesive, 3-5 parts of flame retardant, 3-6 parts of insect-resist agent,2-4 parts of acrylonitrile, 1-3 parts of magnesium titanate and 0.8-1 part of traditional Chinese powder for removing formaldehyde. The combination of cedarwood and sisal hemp is used as a raw material, not only can sisal hemp residues be effectively utilized, but also the strength of the wooden board can be ensured, and the compatibility of plastic and plant fibers is enhanced, so that the interaction force of an interface is enhanced, and the mechanical performance of the wood plastic board is improved.

Owner:柳州市林道科技有限公司

Multifunctional filled masterbatch for polyethylene and preparation method thereof

The invention discloses a multifunctional filled masterbatch for polyethylene and a preparation method thereof. The multifunctional filled masterbatch for polyethylene comprises the following ingredients, by weight, 10-30% of polyethylene resin, 20-40% of a composite filler, 15-25% of a fire retardant, 10-20% of an antistatic agent, 2-8% of an anti-ageing agent, 2-5% of a compatilizer, 0.5-2% of an antioxidant and 0.1-2% of EVA wax. The composite filler is a composite filler obtained by activating a mixture of heavy calcium carbonate, needle-shaped wollastonite and precipitated barium sulphate at the mass ratio of 2:1:1 by the use of an aluminium-titanium compound coupling agent. The invention has the following beneficial effects: when applied in production of polyethylene, the multifunctional filled masterbatch has multifunctional modification effects such as flame retardance, reinforcing, anti-static electricity, ageing resistance and the like on a polyethylene material; using effect of the multifunctional filled masterbatch is good and costs are low; and a preparation technology is simple and easy to operate.

Owner:QINGDAO WANLI TECH

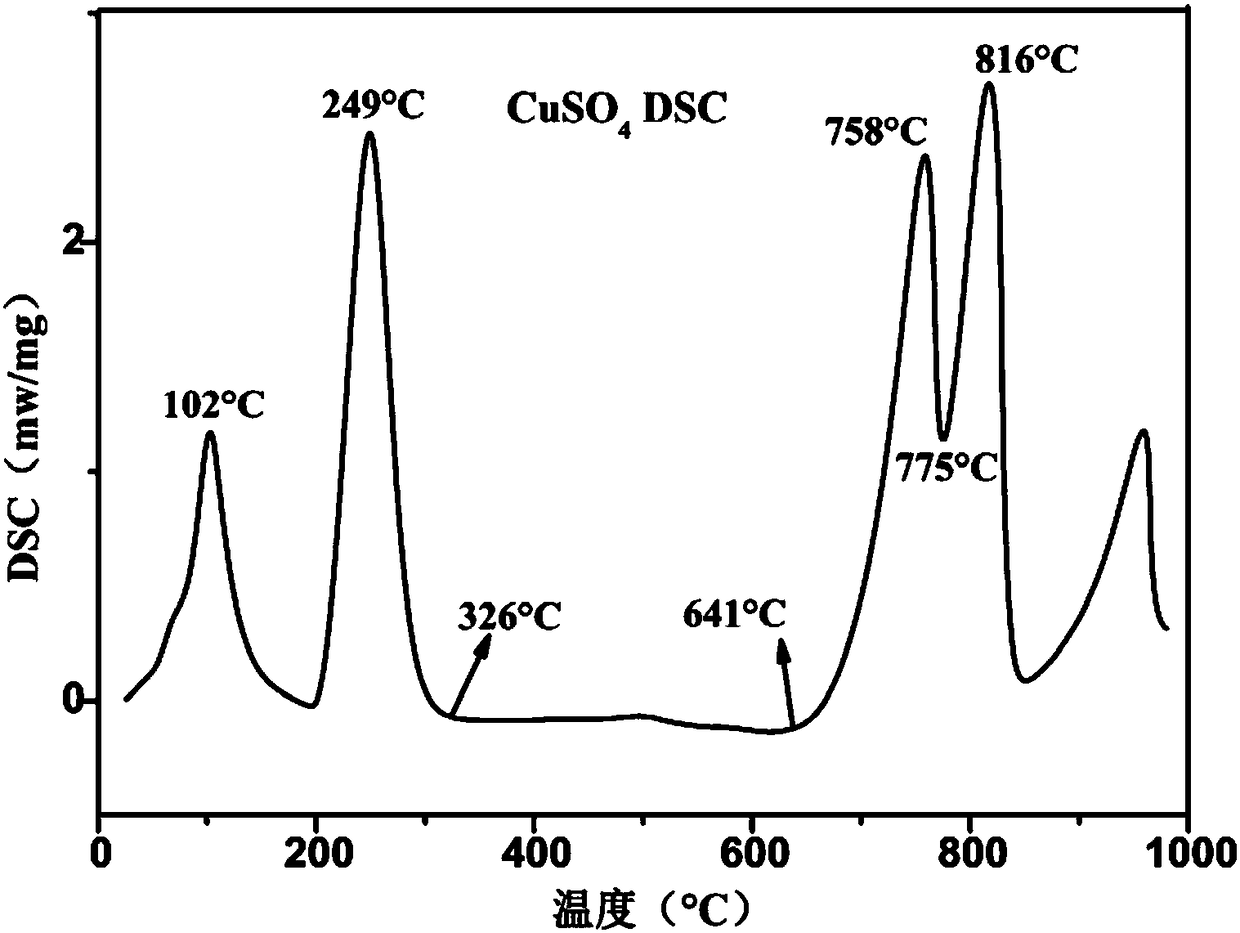

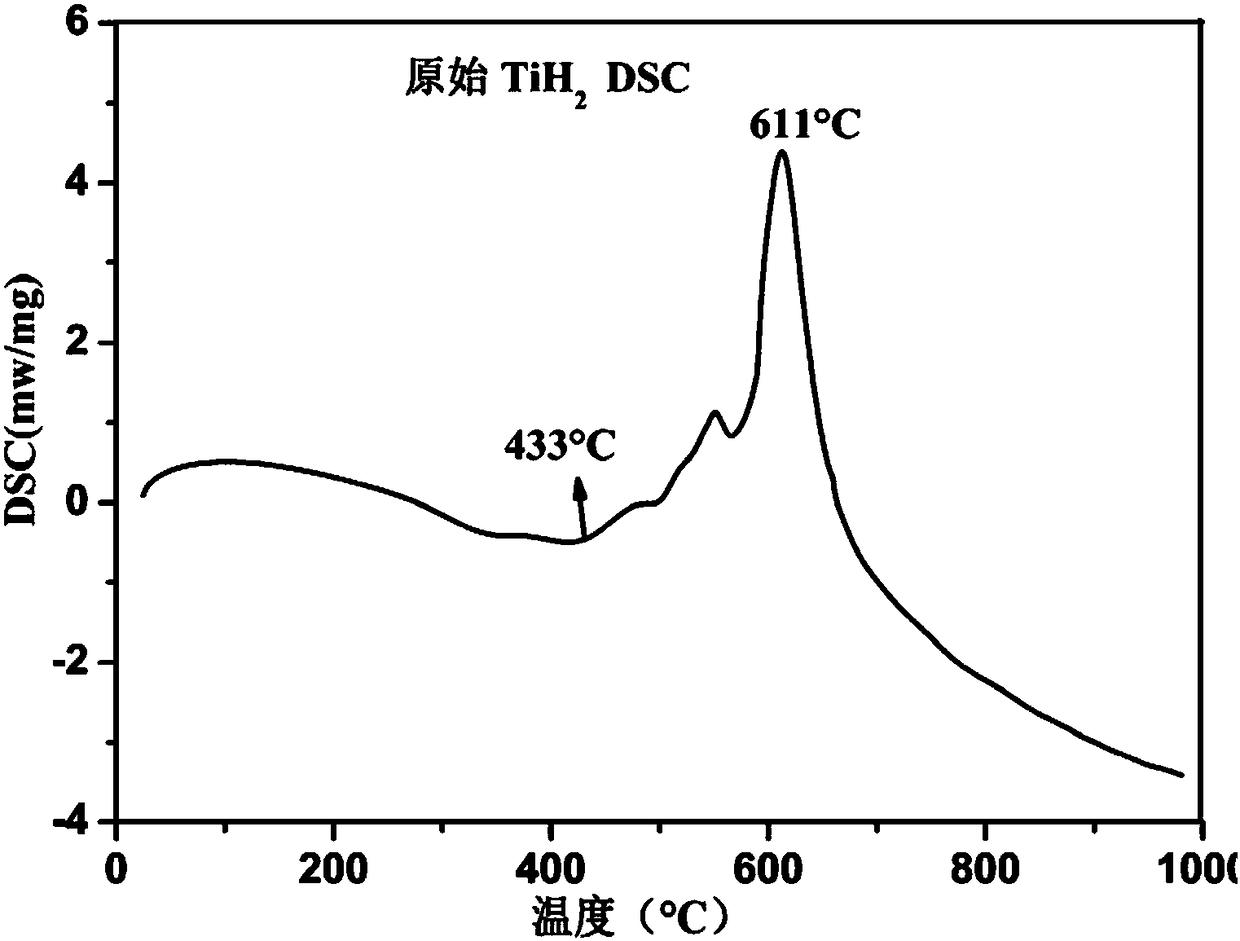

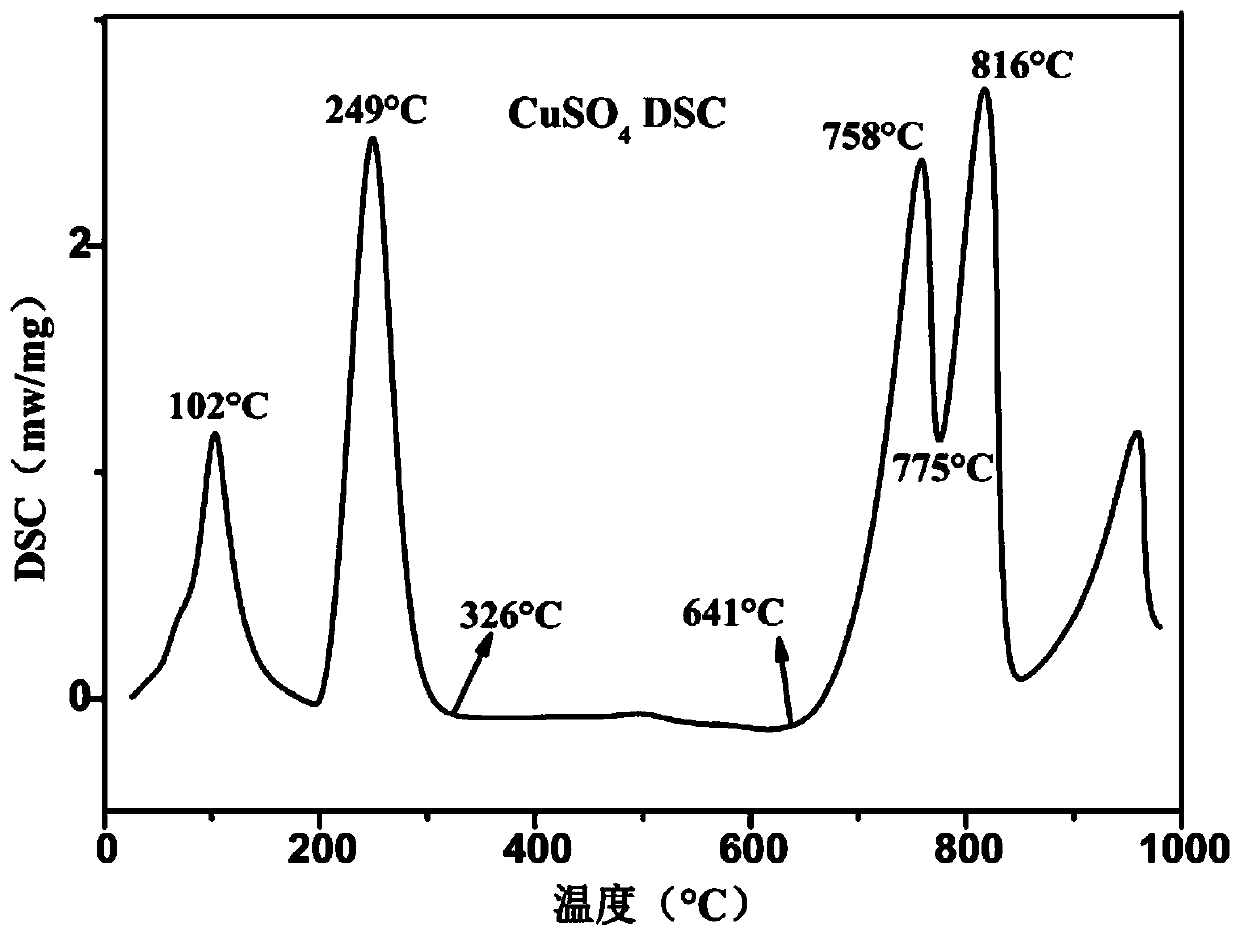

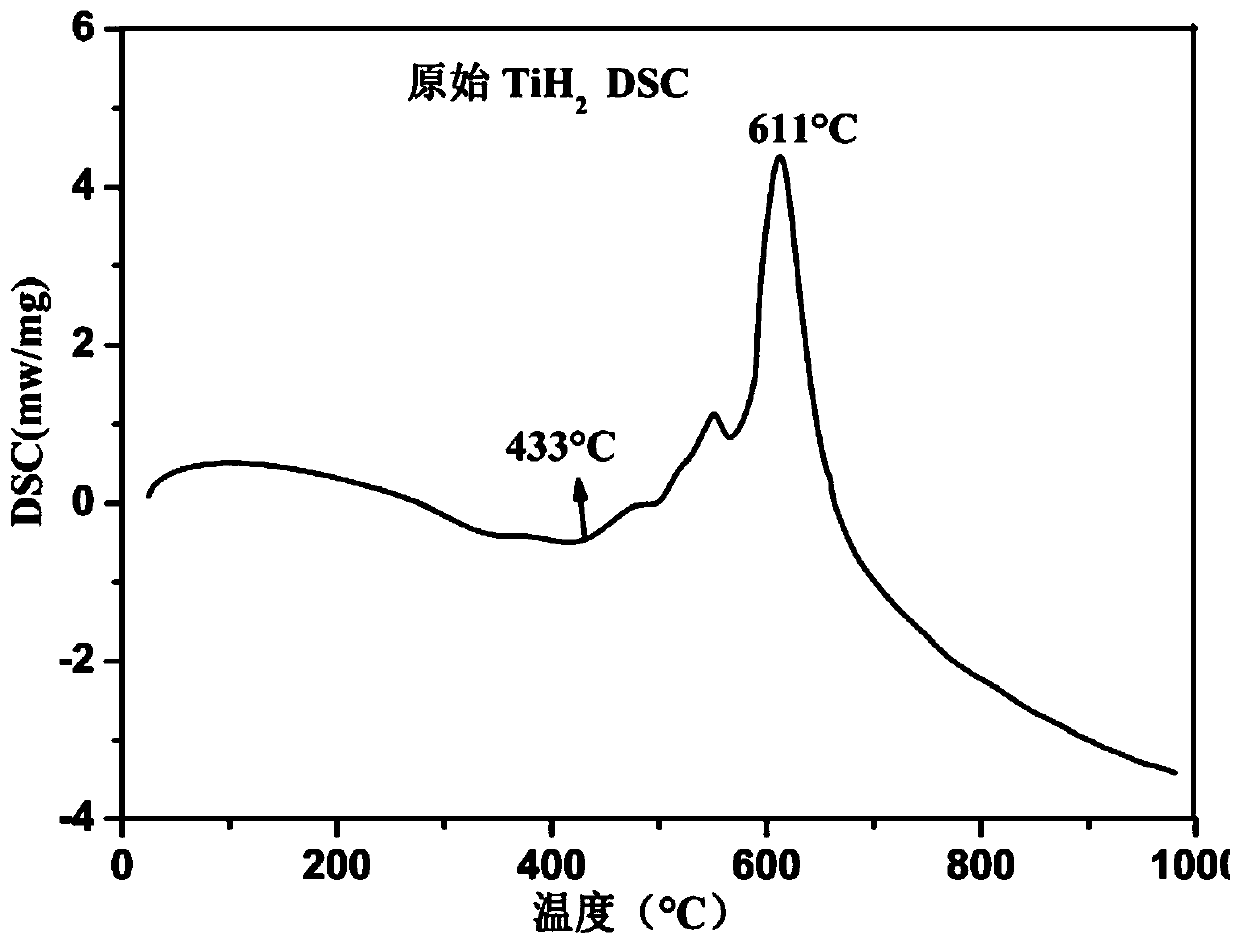

Multifunctional foamed aluminum foaming agent and method for preparing foamed aluminum using same

The invention provides a multifunctional foamed aluminum foaming agent and a method for preparing foamed aluminum using the same. The foaming agent is copper sulfate or copper sulfate related derivatives or a mixture mainly comprising a copper sulfate component. According to the method for preparing the foamed aluminum using the multifunctional foamed aluminum foaming agent, the multifunctional foamed aluminum foaming agent which is 0.5%-20% mass of foamed aluminum material aluminum metal is added in the foamed aluminum preparation process, and the multifunctional foamed aluminum foaming agentcan be applied to a melt foaming method, a powder metallurgy method and a secondary foaming method for preparing the foamed aluminum. The foaming agent has good matching performance with foamed aluminum preparation foaming temperature, long sustained release time, good dispersibility, low cost and convenient use and has the functions of viscosity increasing and strengthening.

Owner:SICHUAN UNIV

Halogen-free flame-retardant dicyclopentadiene material and preparation method thereof

ActiveCN101792505BImprove appearance qualityImprove mechanical propertiesPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPhosphateAluminium hydroxide

The invention discloses a halogen-free flame-retardant dicyclopentadiene material and a preparation method thereof. The material consists of polydicyclopentadiene, flame retardant, modifier and catalyst, wherein the flame retardant is silane coupling agent, titanate coupling agent, aluminium zirconate coupling agent, organic chromium coupling agent, higher fatty acid and salt thereof, phosphate, unsaturated organic acid or organic ammonium salt modified aluminium hydroxide. The preparation method prepares the flame-retardant material by using reaction injection moulding. The oxygen index of the obtained material is 22 to 26 percent, and the horizontal combustion test can reach HB level; and the bending strength is 40 to 45MPa, the bending modulus is 1,400 to 1,700MPa, the tensile strengthis 34 to 37MPa, the impact strength is 26-80kJ / m<2>, and the hardness is 74 to 76 Shaw D. The material does not contain halogen flame retardant, and has high flame-retardant performance and high mechanical property.

Owner:LIMING RES INST OF CHEM IND

A cement-based high-performance anchoring agent

The invention relates to a cement-based high-performance anchoring agent. The anchoring agent is uniformly prepared by mixing and stirring the following raw materials in parts by weight: 350-440 parts of sulphoaluminate cement, 250-400 parts of ordinary Portland cement, 5~10 parts of special water reducing agent, 170~285 parts of sand, 15~25 parts of low alkali expansion agent, 3~7 parts of early strength agent. The invention has strong anchoring force, is not easy to dry shrinkage, has good durability, low cost, and is easy to realize industrialized production.

Owner:GANSU ZHITONG TECH ENG DETECTION CONSULTING CO LTD +1

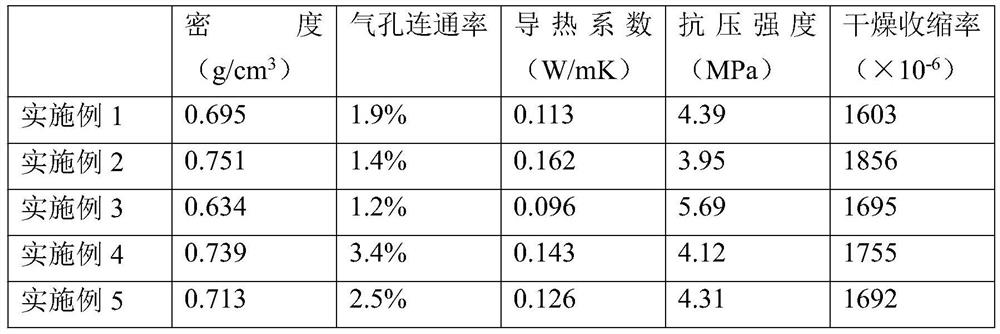

Regenerated powder-based inorganic cementing material toughening and crack-reducing foaming agent and application thereof

The invention discloses a regenerated powder-based inorganic cementing material toughening and crack-reducing foaming agent and application, the foaming agent comprises a foaming component composed of regenerated glass fiber reinforced plastic powder and strong base powder, and the strong base powder in the foaming component accounts for 0.5-20 wt% of the regenerated glass fiber reinforced plastic powder. Glass powder in regenerated glass steel powder reacts with sodium hydroxide, so that the regenerated glass steel powder has activity and becomes a part of a cementing material. Resin particles in the regenerated glass fiber reinforced plastic powder have higher toughness than a cementing material, and toughening and crack reduction of the cementing material can be achieved. A small part of other fillers can be used as a micro-filler. The foaming agent disclosed by the invention is simple to prepare. Pre-foaming is not needed in the using process, the foaming process is simple, mixing with an inorganic cementing material is easy, generated bubbles are uniform and stable, and the reinforcing and toughening effects on the inorganic cementing material are large. The prepared foaming material is low in density, low in air hole communication rate, good in heat preservation and insulation performance, high in strength and resistant to cracking.

Owner:HEBEI UNIV OF TECH

Flame-retardant and environment-friendly PBT/micrometer calcium carbonate composite material and preparation method thereof

The invention discloses a flame-retardant and environment-friendly PBT / micrometer calcium carbonate composite material. The flame-retardant and environment-friendly PBT / micrometer calcium carbonate composite material comprises the components by mass: 50%-80% of PBT, 5%-25% of micrometer calcium, 18%-25% of a halogen-free flame retardant, 0.1%-0.5% of a surface treating agent, 0.1%-1% of an antioxidant, 0.2%-1.5% of a solvent and 0-0.5% of a color material. The flame-retardant and environment-friendly PBT / micrometer calcium carbonate composite material has the beneficial effects that by blending the micrometer calcium carbonate with PBT and adding a proper amount of the halogen-free flame retardant and the surface treating agent, rigidity, heat resistance and stability of the material can be greatly increased and the material has the characteristics of toughening, reinforcing and keeping relatively good strength; the halogen-free flame retardant has smoke-suppressing, non-toxic and environment-friendly high flame-retardant performance; and the composite material has excellent comprehensive performances, high strength and good processibility. A preparation method provided by the invention is simple and convenient for operations and can realize industrialization easily.

Owner:QINGDAO XINZHAN PLASTIC

Volume stabilizer for cement-based composite material and preparation method thereof

The invention discloses a volume stabilizer for a cement-based composite material and a preparation method thereof. The volume stabilizer comprises the following components in part by weight: 180 and 220 parts of periclase, 18 to 21 parts of polycarboxylate, 27 to 32 parts of polyacrylate and 0.8 to 1.1 parts of sodium polyphosphate, wherein the periclase is ground into fine powder; the fine powder is sieved by a 85mu m sieve; and residue on the sieve is less than 10 percent. The method comprises the following steps: a, grinding magnesite serving as raw materials into fine power and sieving the fine powder with the 85mu m sieve, wherein residue on the sieve is less than or equal to 10 percent; b, calcining the ground magnesite powder at the temperature of between 900 and 1,250 DEG C, preserving the heat for 30 to 120 minutes, and cooling the calcined magnesite powder to room temperature after the heat preservation is finished to prepare the periclase; c, grinding the periclase into fine powder and sieving the fine powder with a 85mu m sieve, wherein residues on the sieve is less than or equal to 10 percent; and d, mixing the periclase obtained in the step c, the polycarboxylate, the polyacrylate and the sodium polyphosphate in proportion. The volume stabilizer and the preparation method can solve the problem of cracking of cement-based materials caused by contraction.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

A kind of modified calcium carbonate with good elasticity and preparation method thereof

ActiveCN104130592BImprove rigidityIncrease elasticityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSlagPolyvinyl chloride

Disclosed modified calcium carbonate with good elasticity is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 5.5-7 parts of polyvinyl chloride, 5-7 parts of transparent ABS, 4-6 parts of synthetic rubber, 2-3 parts of calcium carbide slag, 1.5-2.5 parts of crude aggregate, 3-5 parts of teflon, 2-3 parts of cationic starch, 2-3 parts of sulfonated lignin, and 2.5-3.5 parts of modified titanium dioxide. By adding transparent ABS and other macromolecular compounds, synthetic rubber and the like into calcium carbonate, calcium carbonate is substantially improved in rigidity, elasticity and stability, also has the characteristics of toughening, reinforcing and relatively good strength, and also is reduced in cost. The provided preparation method is simple and convenient to operate, and is easy to industrialize. The produced filling material is applicable to coatings, rubber, plastic and the like.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

A kind of production method of conductive geotextile

The invention relates to a production method, in particular to a method for producing conductive geotextile. The method for producing the conductive geotextile comprises the steps of raw material selection, raw material screening, drying, fusion, spinning, cross air blow cooling, airflow drafting, swinging, net laying, mixed even feeding of metal fibers, carbon fibers and other short fibers, ironing conducted by a hot roller, shaping conducted by a pre-needle machine, reinforcing shaping conducted by a first main needle machine, repair shaping conducted by a second main needle machine, cloth containing conducted by a cloth containing machine, trimming and rolling. The geotextile produced according to the method for producing the conductive geotextile has the protective performance, the isolating performance, the waterproof performance, the filtering performance and the like of traditional geotextile, further has the conductive characteristic and is a good electrode material. According to the method for producing the conductive geotextile, the production technology is stable, control over the thickness of a material is good, the control range of the puncture density is large and is 50 to 500 stitches / cm<2>, the controllable range of the permeability performance of the material is large and is (1.0-9.9)*(10<-1>-10<-3>)cm / s, the strength of the product is high, and the thickness reaches 20mm.

Owner:大连格尔迈斯合成材料有限公司

A kind of multifunctional foamed aluminum foaming agent and the method for using it to prepare foamed aluminum

The invention provides a multifunctional foamed aluminum foaming agent and a method for preparing foamed aluminum by using the same. The multifunctional aluminum foamed foaming agent is copper sulfate or copper sulfate related derivatives or a mixture mainly including copper sulfate components. The method of preparing foamed aluminum with multifunctional foamed aluminum foaming agent is to add 0.5% to 20% of the mass of aluminum foamed aluminum raw material aluminum metal in the process of preparing foamed aluminum. The multifunctional foamed aluminum foamed agent can be applied It is used in the melt foaming method, powder metallurgy method and secondary foaming method of preparing aluminum foam. The foaming agent provided by the invention has good matching with the foaming temperature of the prepared aluminum foam, long sustained release time, good dispersibility, low cost, convenient use, and simultaneously has the functions of thickening and strengthening.

Owner:SICHUAN UNIV

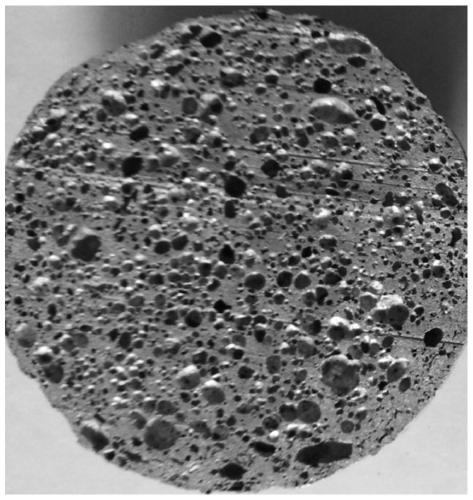

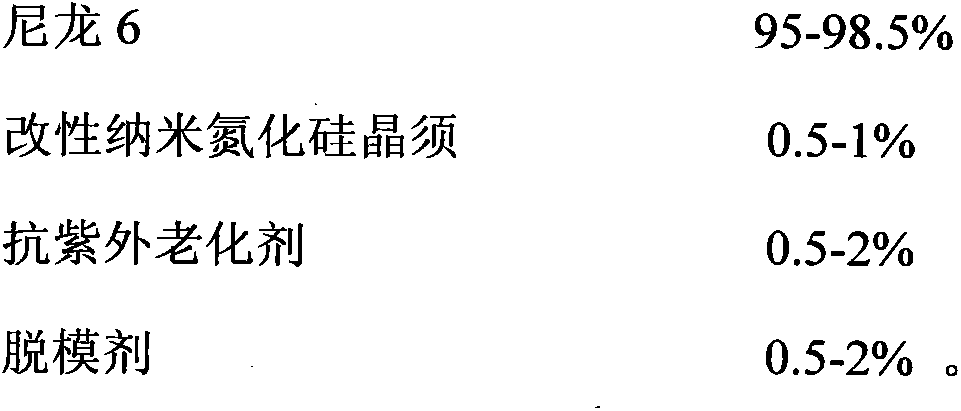

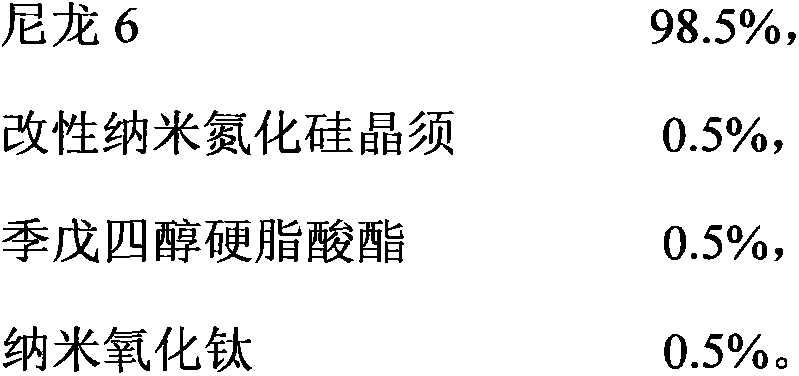

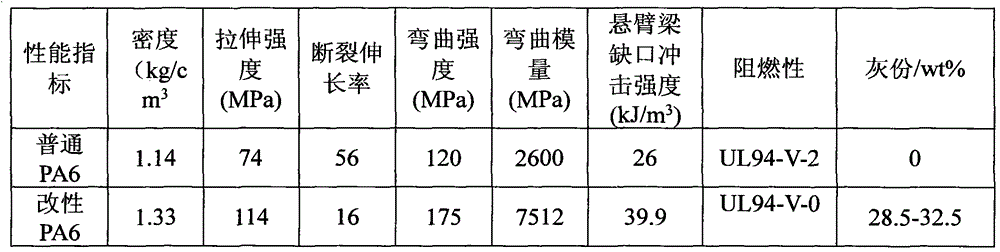

A modified optical cable winding reel and its preparation method

The invention discloses a modified optical cable wire reel and a preparation method thereof. For the modified optical cable wire reel, a nano-silicon nitride whisker is employed to perform technical treatment on ordinary engineering plastic nylon 6 by a nanotechnology, and the modified nylon 6 has the characteristics of reinforced strength, increased toughness, and resistance to aging for 10 years. The wire reel formed by injection moulding of the modified nylon 6 engineering plastic can load 500kg of optical cables, and after drop from a height of 1.6m, the wire reel does not crack and deform, its various properties do not change in a temperature ranging from -40DEG C to 70DEG C, and can be reused more than 10 times.

Owner:CHINA MOBILE GROUP ANHUI +1

Preparation method of sepiolite-tetraacicular zinc oxide whisker composite material

ActiveCN105200519BWear-resistantWith enhancedPolycrystalline material growthFrom solid stateNoise reductionCalcination

The invention relates to a method for preparing a sepiolite-tetraacicular zinc oxide whisker composite material. Sepiolite has extremely strong adsorption performance and good dispersion performance, and can be used as the carrier and skeleton of the tetraacicular zinc oxide whiskers in the present invention, and the respective performances do not affect each other. The preparation method is as follows: dissolve sepiolite in ethanol, methanol or hydrogen peroxide, stir evenly, separate and dry to obtain sepiolite powder; mix with zinc powder, dissolve in distilled water, ethanol, methanol, hydrogen peroxide, stir and mix uniformly; The separated solid mixture is dried in an oven; the dried powder is calcined in a high-temperature furnace to obtain a sepiolite-tetraacicular zinc oxide whisker composite material. The composite material prepared by the present invention has properties such as wear resistance, reinforcement, shock absorption, anti-skid, noise reduction, anti-aging, antistatic, antibacterial, etc., and can be widely used in coatings, antibacterial materials, antistatic materials, antifriction and antiwear, etc. Among the materials, the operation process is simple, and the cost performance is high.

Owner:唐山索朗科技有限公司

Multifunctional alumina/metal micro-laminated coating

The invention provides a multifunctional alumina / metal micro-laminated coating, which belongs to composite material made from metals and ceramic and coating technology thereof and is used for high-temperature protection, anti-tritium permeation, and anti-hydrogen damage of alloys with wide temperature scope. The micro-laminated coating adopts a high-pure alumina or alumina doped with a small amount of rear earth oxide, or alumina doped with a small amount of zirconia as an alumina coating, wherein the metals can be Pt, or Rh, or Ir, or Au, or alloys of all, or M-Cr-Al-rare earth alloy, or Fe,Co, Ni-based aluminum-containing alloy. The thickness of each laminated coating is 20-1000nm. The micro-laminated coating can be obtained by adopting a plurality of methods through the alternative sedimentation of the alumina coating and a metal coating. The micro-laminated coating has the following characteristics: (1) excellent binding force with the alloy substrate; (2) excellent high-temperature protection performance and anti-tritium penetration performance, and anti-hydrogen damage performance; (3) wide operating temperature range from room temperature to 2000 DEG C; (4) the evaporationinhibition of precious metal coatings at high temperature; and (5) and synergistic protective effect with other coatings.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com