Multifunctional alumina/metal micro-laminated coating

A kind of technology of aluminum oxide layer and aluminum oxide, applied in the direction of metal material coating process, coating, layered products, etc., can solve the problems of ceramic coating cracking and peeling, barrier effect can not be durable, etc., to achieve excellent anti-cracking performance , Excellent high temperature oxidation resistance, excellent thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

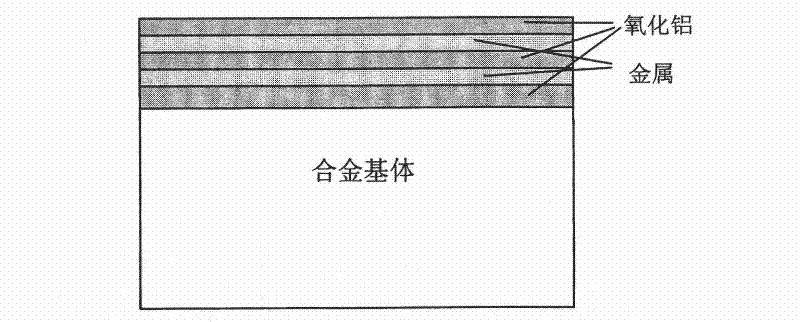

[0038] Example 1: Aluminum Oxide / Au Micro Laminate Coating

[0039] according to figure 1 In the manner shown, radio frequency magnetron sputtering is used to deposit high-purity alumina and magnetron sputtering to deposit pure Au alternately on the surface of 1Cr13 alloy, each layer has a thickness of 50 nm, and a total of 5 layers are deposited. It was oxidized in air at 900°C for 200 hours, which proved to have excellent high temperature oxidation resistance and peeling resistance. Tritium penetration test results show that it has excellent anti-tritium penetration performance, and almost no tritium penetration is detected.

Embodiment 2

[0040] Embodiment 2: Alumina / Au-Al micro-laminate coating

[0041] according to figure 1 In the shown manner, radio frequency magnetron sputtering is used alternately to deposit high-purity alumina and magnetron sputtering to deposit Au-Al (with an Al content of 2%) on the surface of the 1Cr18Ni9Ti alloy. The thickness of each layer of alumina is 100 nm, and each layer of Au-Al is The layer thickness was 40 nm, and a total of 5 layers were deposited. It was oxidized in air at 900°C for 200 hours, which proved to have excellent high temperature oxidation resistance and peeling resistance. Tritium penetration test results show that it has excellent anti-tritium penetration performance, and almost no tritium penetration is detected.

Embodiment 3

[0042] Example 3: Alumina / Pt microlaminate coating

[0043] according to figure 1 In the manner shown, radio frequency magnetron sputtering is alternately used to deposit high-purity alumina layers with a thickness of 200 nm, and magnetron sputtering to deposit pure Pt layers with a thickness of 40 nm on the surface of the Ni-based alloy, and a total of 7 layers are deposited. It was oxidized in air at 1100°C for 200 hours, which proved to have excellent high temperature oxidation resistance and peeling resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com