Patents

Literature

46 results about "Hydrogen damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen damage is the generic name given to a large number of metal degradation processes due to interaction with hydrogen. Hydrogen is present practically everywhere, several kilometres above the earth and inside the earth. Engineering materials are exposed to hydrogen and they may interact with it resulting in various kinds of structural damage. Damaging effects of hydrogen in metallic materials have been known since 1875 when W. H. Johnson reported: “some remarkable changes produced in iron by the action of hydrogen and acids”. During the intervening years many similar effects have been observed in different structural materials, such as steel, aluminium, titanium, and zirconium. Because of the technological importance of hydrogen damage, many people explored the nature, causes and control measures of hydrogen related degradation of metals. Hardening, embrittlement and internal damage are the main hydrogen damage processes in metals. Hydrogen may be picked up by metals during melting, casting, shaping and fabrication. They are also exposed to hydrogen during their service life. Materials susceptible to hydrogen damage have ample opportunities to be degraded during all these stages.

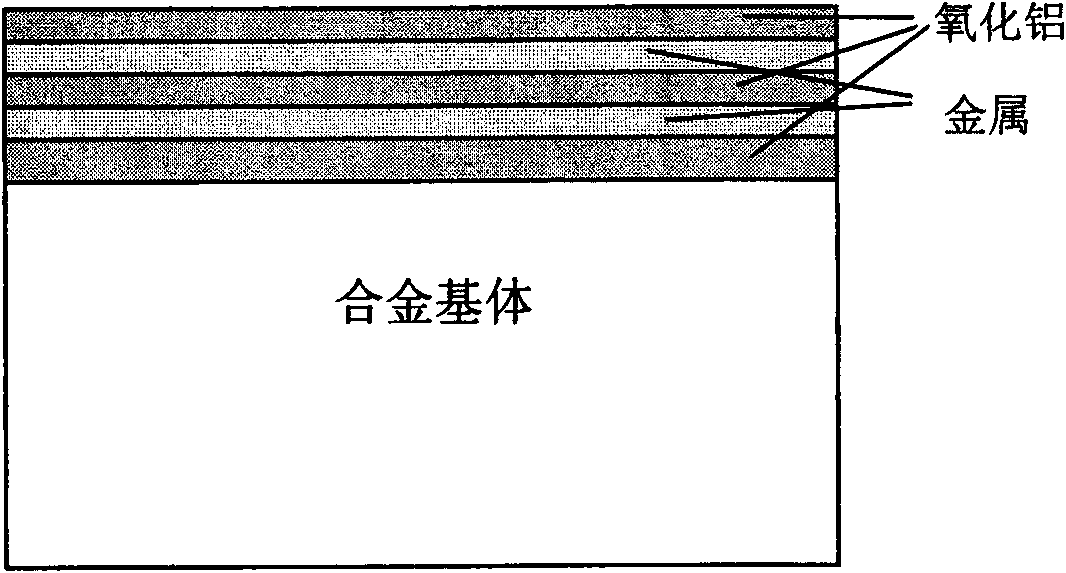

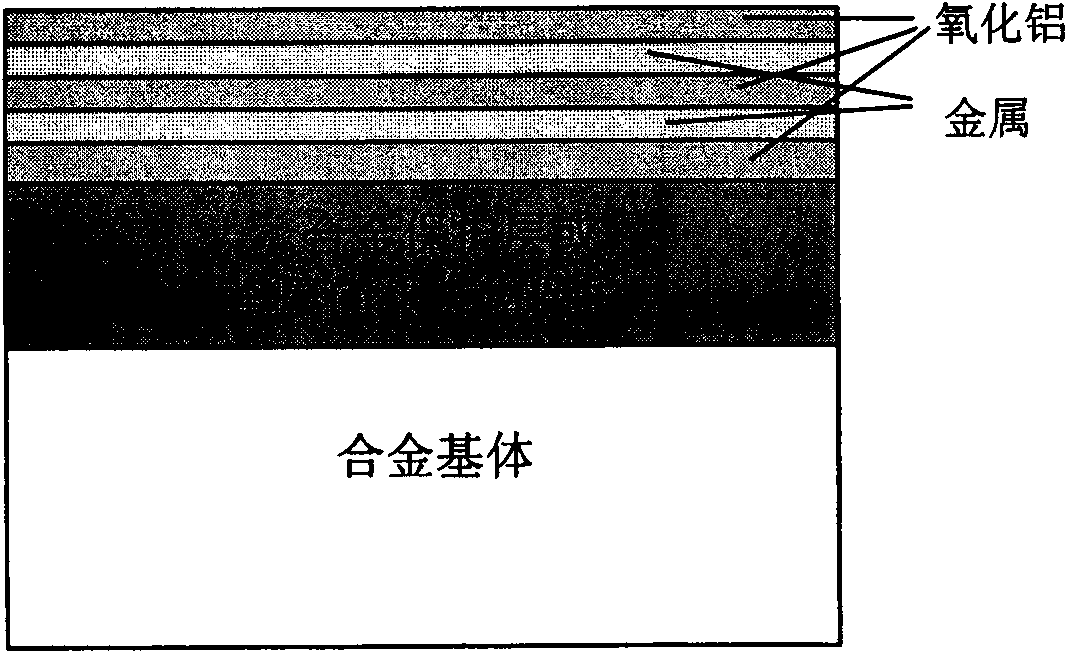

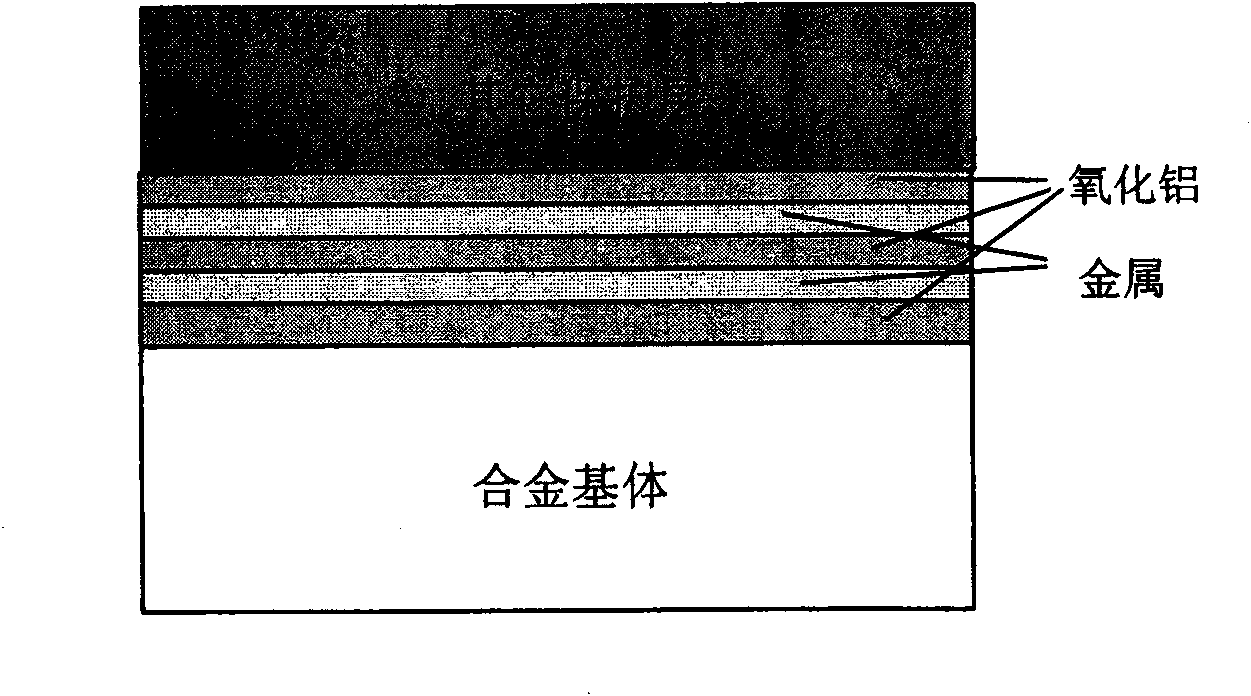

Multifunctional alumina/metal micro-laminated coating

The invention provides a multifunctional alumina / metal micro-laminated coating, which belongs to composite material made from metals and ceramic and coating technology thereof and is used for high-temperature protection, anti-tritium permeation, and anti-hydrogen damage of alloys with wide temperature scope. The micro-laminated coating adopts a high-pure alumina or alumina doped with a small amount of rear earth oxide, or alumina doped with a small amount of zirconia as an alumina coating, wherein the metals can be Pt, or Rh, or Ir, or Au, or alloys of all, or M-Cr-Al-rare earth alloy, or Fe, Co, Ni-based aluminum-containing alloy. The thickness of each laminated coating is 20-1000nm. The micro-laminated coating can be obtained by adopting a plurality of methods through the alternative sedimentation of the alumina coating and a metal coating. The micro-laminated coating has the following characteristics: (1) excellent binding force with the alloy substrate; (2) excellent high-temperature protection performance and anti-tritium penetration performance, and anti-hydrogen damage performance; (3) wide operating temperature range from room temperature to 2000 DEG C; (4) the evaporation inhibition of precious metal coatings at high temperature; and (5) and synergistic protective effect with other coatings.

Owner:UNIV OF SCI & TECH BEIJING

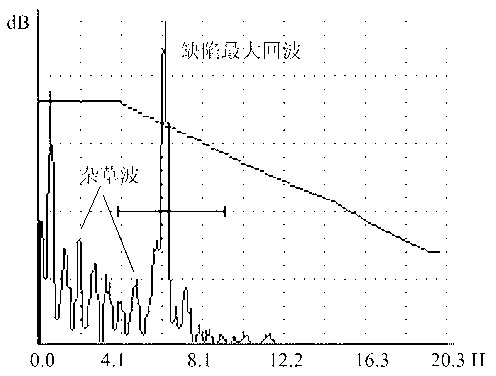

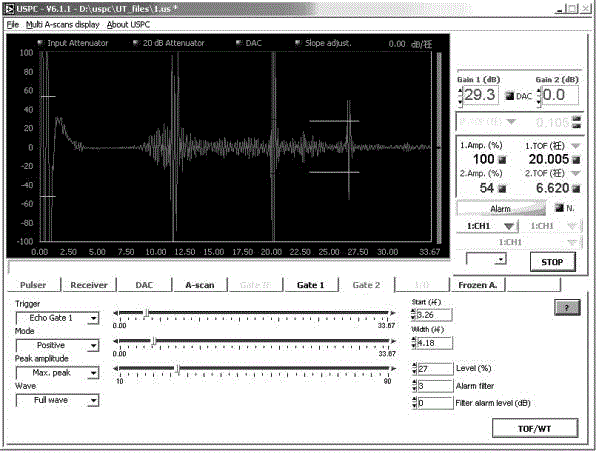

Ultrasonic detection and diagnosis method for hydrogen damages on water-cooling wall pipe of boiler

ActiveCN103293225AThe principle is simpleEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesHydrogenDiagnosis methods

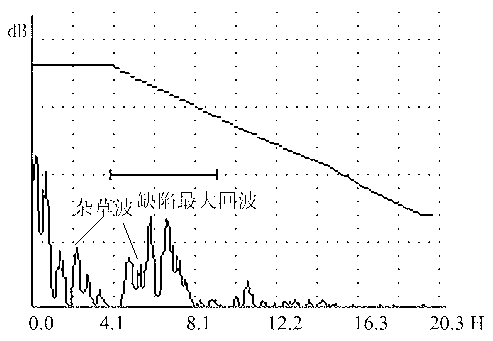

The invention discloses an ultrasonic detection and diagnosis method for hydrogen damages on the water-cooling wall pipe of a boiler. The ultrasonic detection and diagnosis method comprises the following steps of: selecting a pipeline having the same outer diameter as the water-cooling wall pipe needing to be detected and diagnosed, of the boiler, as a detected pipe sample; using an ultrasonic detection instrument with a pulse-reflection type transverse wave angle probe, and causing the probe to be in close contact with the detection surface of the detected pipe sample; preparing a DL-1 type special test block according to the material of the water-cooling wall pipe of the boiler, and calibrating the performances of the ultrasonic detection instrument and the transverse wave angle probe; drawing a distance-amplitude curve by virtue of the DL-1 type special test block; performing ultrasonic detection for transverse defects on the water-cooling wall pipe needing to be detected and diagnosed, of the boiler; analysing the waveform characteristics of ultrasonic wave and the typical waveform characteristics of hydrogen damages, if the diagnosed result is the hydrogen damages, then using the equivalent value of the maximum echo amplitude in a detection echo for evaluating the relative degree of the hydrogen damages in the defect area of the detected pipe sample. The method is a reliable, convenient and rapid ultrasonic detection and diagnosis method.

Owner:STATE GRID CORP OF CHINA +2

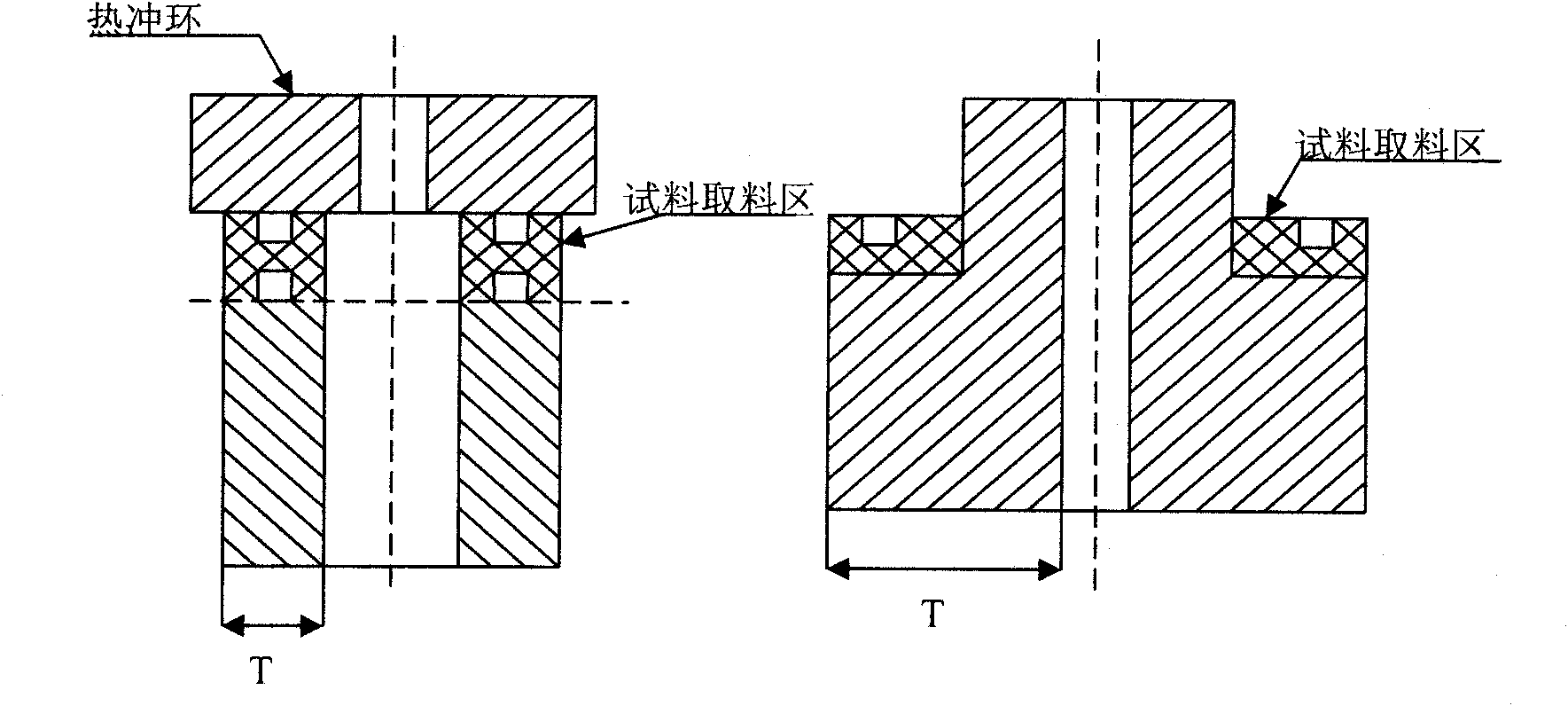

21/4Cr-1Mo-1/4V steel forging and automatic temperature-control inflation three-dimensional circulating water rapid cooling thermal treatment method thereof

InactiveCN101831595AHigh tensile strengthImprove creep strengthFurnace typesHeat treatment furnacesAutomatic controlHydrogen damage

The invention discloses an improved 21 / 4Cr-1Mo-1 / 4V steel forging which is characterized by comprising the following components in percent by weight: 0.11-0.15 percent of carbon, not more than 0.10 percent of silicon, 0.30-0.60 percent of manganese, not more than 0.01 percent of phosphorus, not more than 0.01 percent of sulfur, 2-2.5 percent of chromium, 0.9-1.10 percent of molybdenum, not more than 0.20 percent of nickel, not more than 0.15 percent of copper, 0.25-0.35 percent of vanadium, not more than 0.30 percent of titanium, not more than 0.002 percent of boron, not more than 0.07 percent of niobium, not more than 0.015 percent of calcium and the balance of iron. The invention also discloses an automatic temperature-control inflation three-dimensional circulating water rapid cooling thermal treatment method of the steel forging, which comprises the steps of: 1, an after-forging thermal treatment process: normalizing at a temperature of 890-990 DEG C, air-cooling after constant temperature is not less than 1h / 100mm, tempering at a temperature of 680-720 DEG C, furnace-cooling after constant temperature, and cooling at a limited speed at a temperature of below 400 DEG C; 2, a thermal refining process: quenching at a temperature of 900-980 DEG C, carrying out constant temperature with 1h / 100mm, rapidly cooling and quenching and tempering at a temperature of 680-720 DEG C, carrying out constant temperature with 1h / 100mm and air-cooling thickness of the forging, wherein the water temperature of thickness of the forging is not more than 10 DEG C; and 3, adopting a three-dimensional automatic control circulating water periphery inflation method. The forging has higher tension strength, temper brittleness resistance, hydrogen damage resistance and lower long-term high-temperature damage sensitivity.

Owner:抚顺加氢炼化设备有限公司

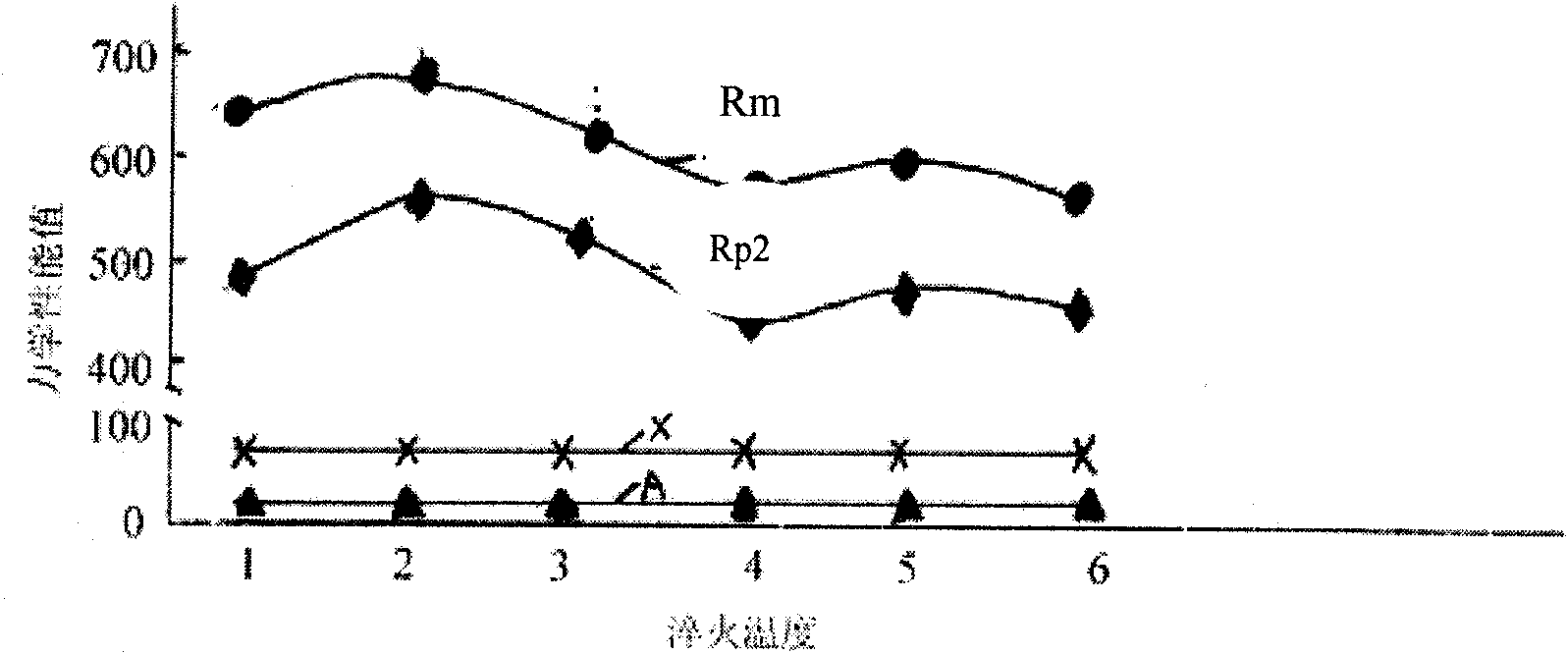

Fe-Ni base precipitation-strengthened austenite alloy and preparation method thereof

ActiveCN102086496AImprove mechanical propertiesImproved resistance to hydrogen damagePetrochemicalAlloy

The invention relates to the field of precipitation-strengthened austenite alloys, in particular to a Fe-Ni base precipitation-enhanced austenite alloy and a preparation method. The austenite alloy comprises the following elements in percentage by mass: 27 to 32 percent of nickel, 13 to 17 percent of chromium, 0.5 to 2 percent of molybdenum, 1.5 to 3 percent of titanium, 0.1 to 0.5 percent of aluminum, 0.1 to 0.6 percent of vanadium, 0.1 to 0.6 percent of silicon, 0.0005 to 0.02 percent of boron, less than 0.02 percent of carbon and the balance of iron and inevitable impurities. In the invention, the Fe-Ni alloy is taken as base, the content of the element boron in the alloy is improved, appropriate hot machining, and thermal treatment and hot hydrogen filling processes are performed, so that the crystal boundary precipitated phase of the alloy is controlled under a reasonable thermal treatment rule, and high mechanical property and high hydrogen damage resistance of a prepared alloy material are ensured. The precipitation-enhanced austenite alloy can be applied to hydrogen close environments of industries with high requirements such as aviation, nuclear energy, petrochemical industry and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

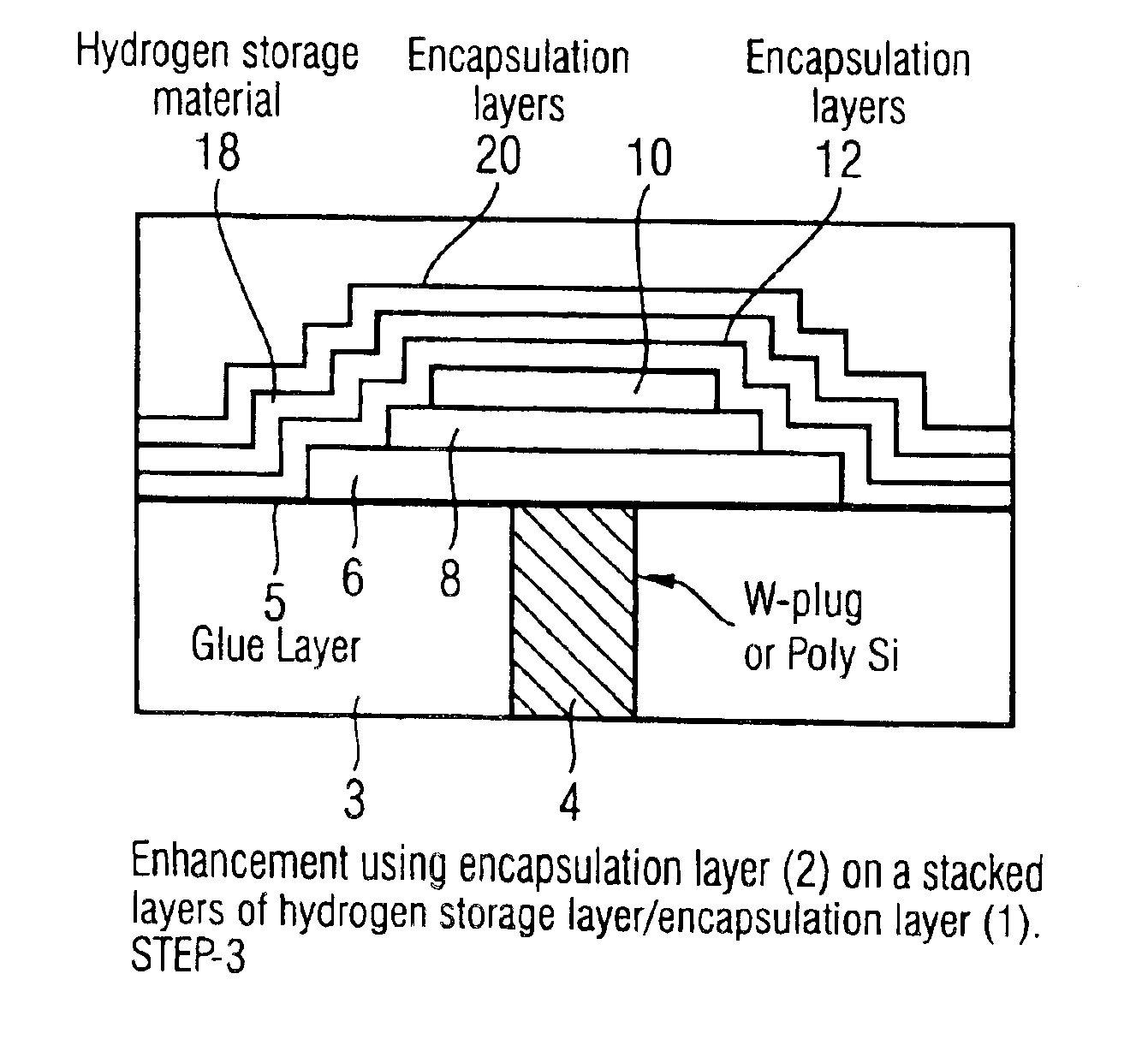

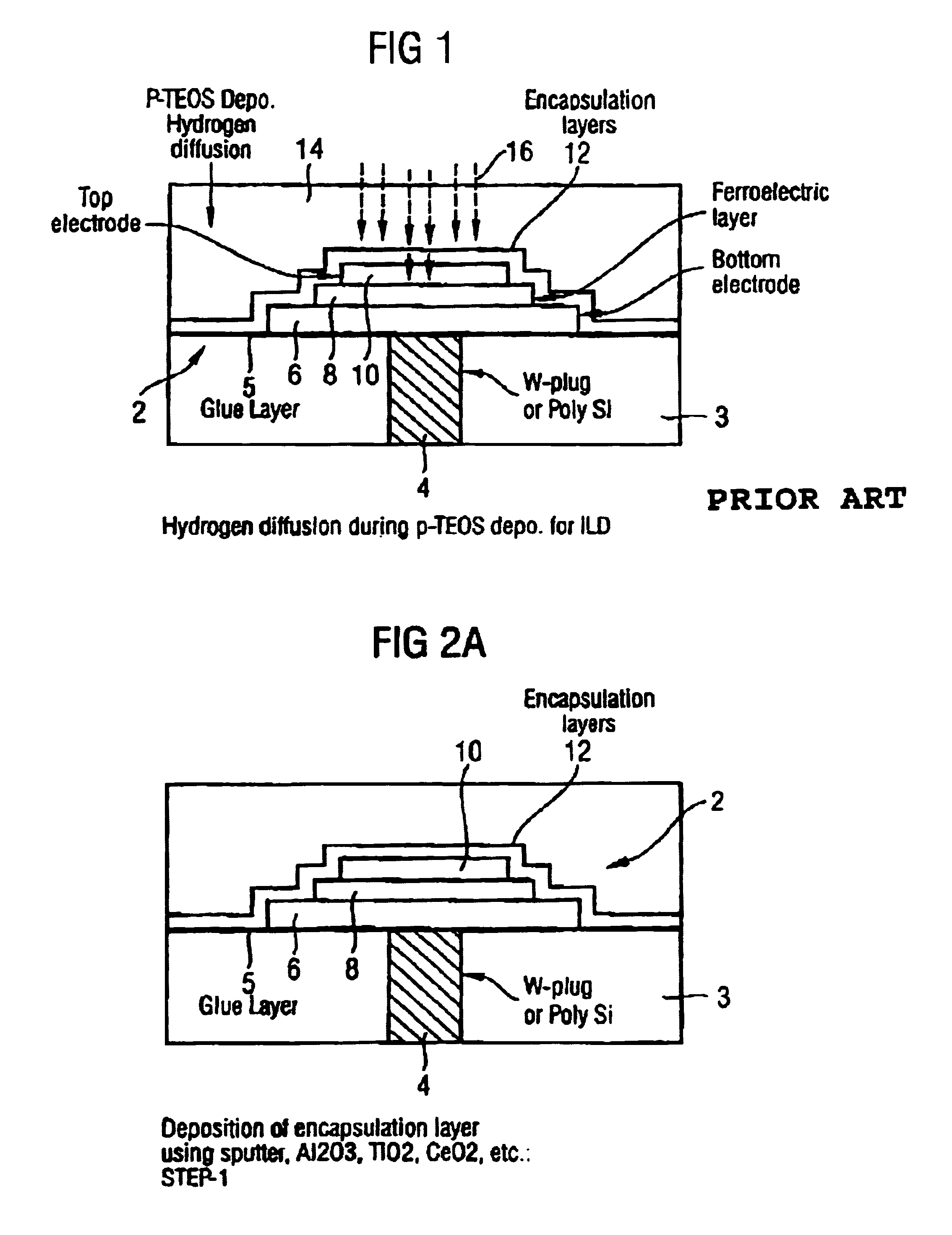

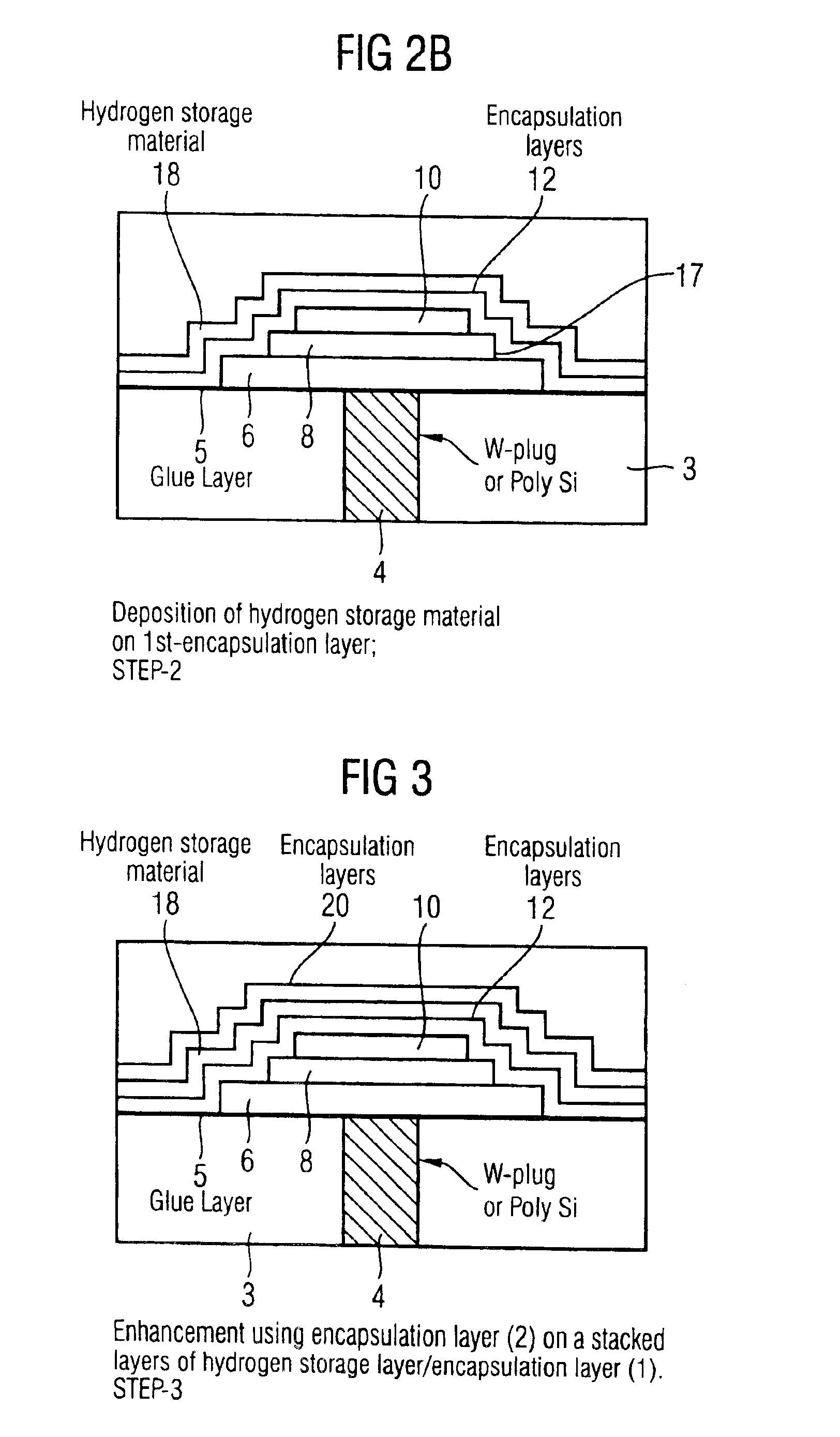

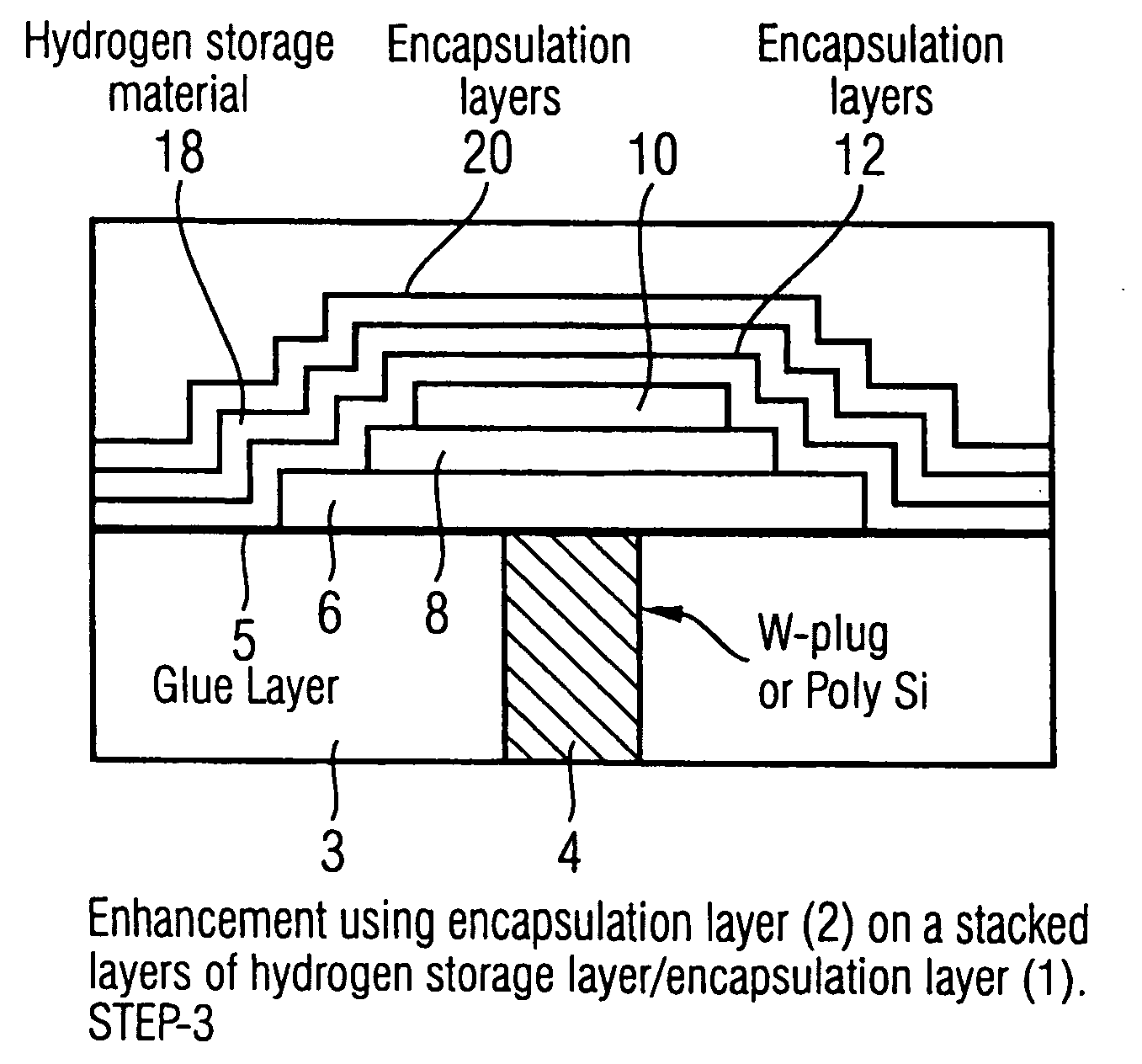

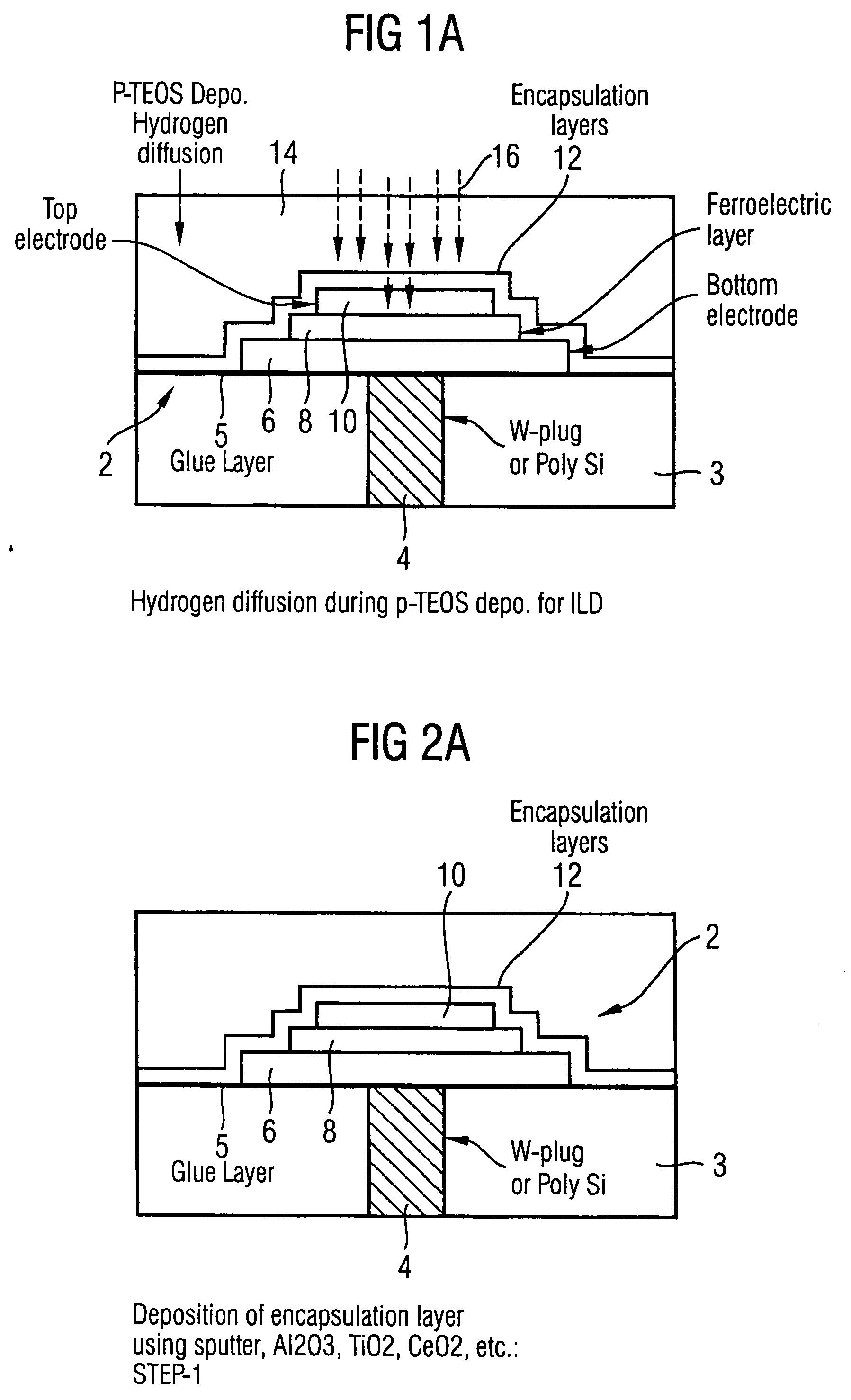

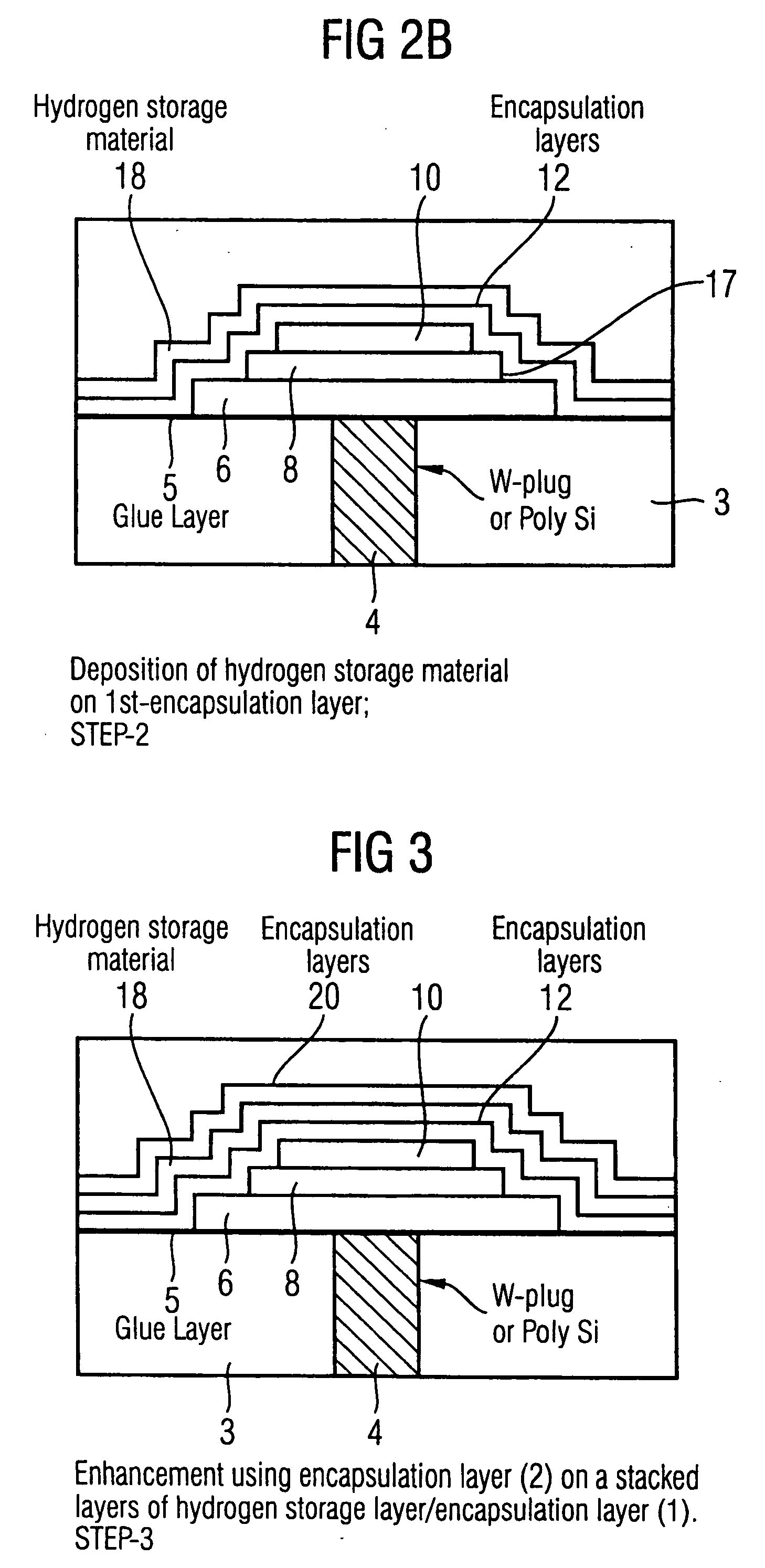

Device for inhibiting hydrogen damage in ferroelectric capacitor devices

InactiveUS7071506B2Avoid layeringInhibited DiffusionTransistorSolid-state devicesCapacitanceEngineering

A ferroelectric capacitor device comprises a substrate, a contact plug passing through the substrate, a first electrode formed on the substrate, the first electrode being electrically connected to said plug, a ferroelectric layer formed on the first electrode, a second electrode formed on the ferroelectric layer, one or more first encapsulation layers on the second electrode, the encapsulation layers extending over the device, and one or more hydrogen storage material layers on the encapsulation layers. One or more second encapsulation layers may be formed on the one or more hydrogen storage material layers.

Owner:QIMONDA

Gel composition with hydrogen absorption function and preparation technique thereof

The invention discloses a gel composition with hydrogen absorption function and a preparation technique thereof. The gel composition comprises 80-95% of oil base material, 0-10% of thixotropic agent, 2-9% of viscosity modifier, 0.2-1% of antioxidant, 0.2-1% of pour-point depressant and 0.05-5% of hydrogen absorption material. The gel composition disclosed by the invention can be filled in transformers and electrolytic capacitors to perform the function of electric insulation, and also filled into fiber loose tubes to perform the function of fiber protection; and besides the common applications, the gel composition with hydrogen absorption function can also absorb generated hydrogen. The gel composition can be widely used in other fields in which hydrogen damage may be generated.

Owner:邹斌

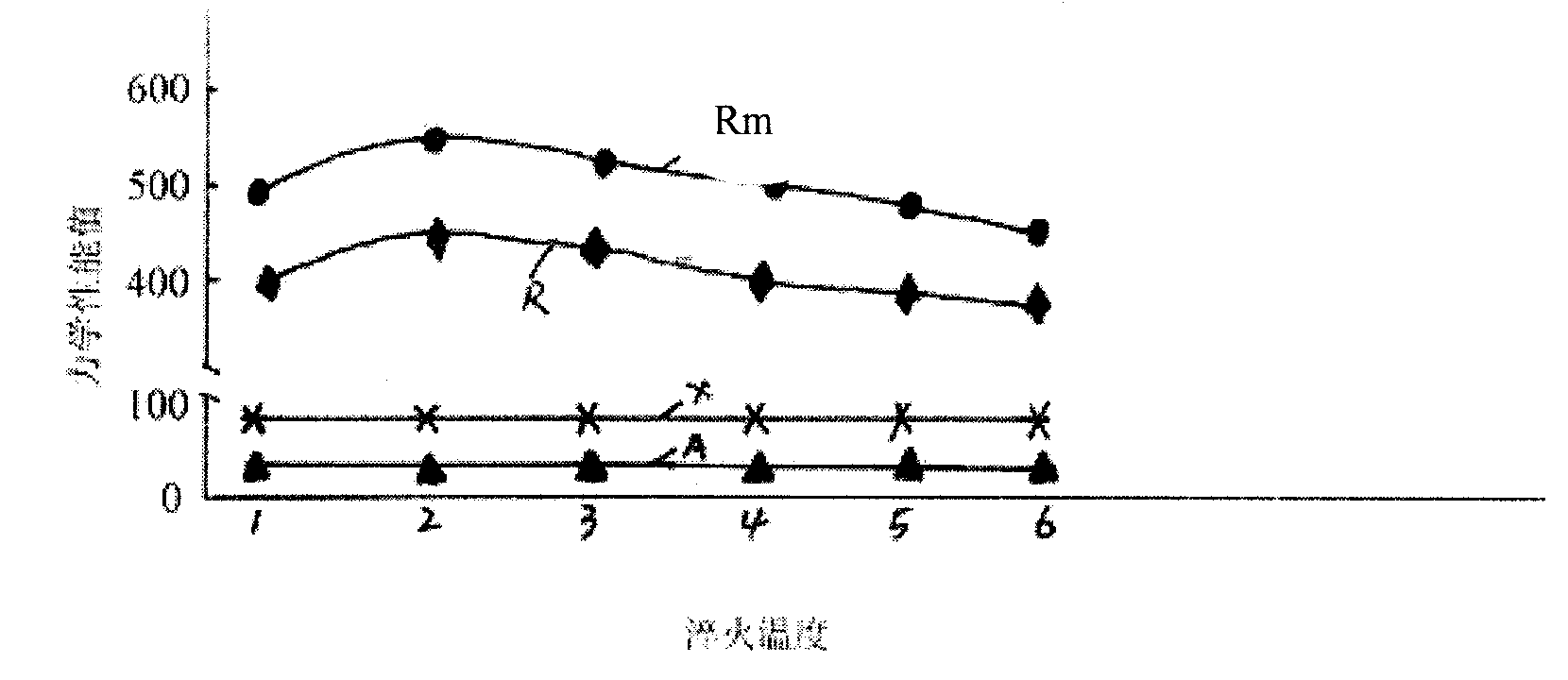

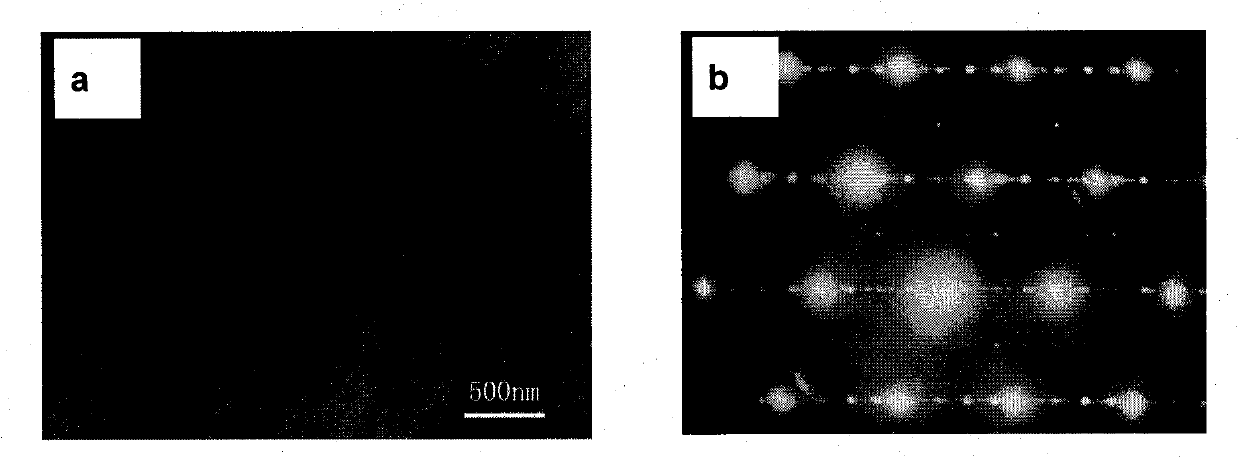

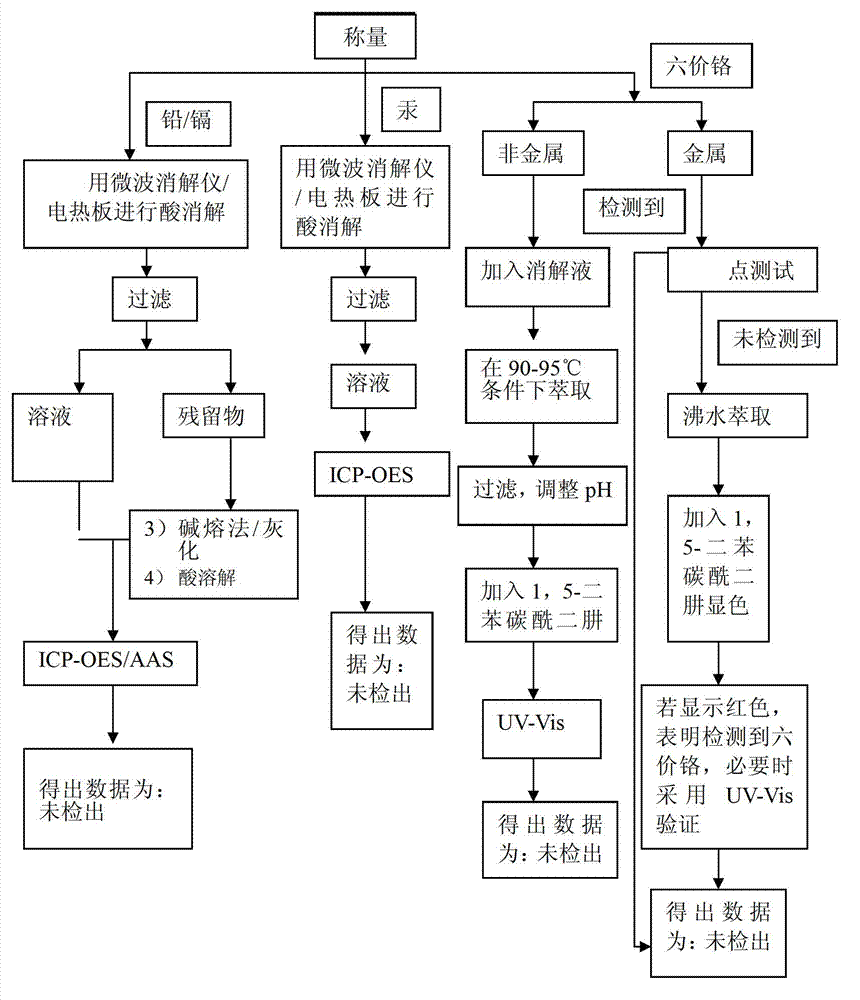

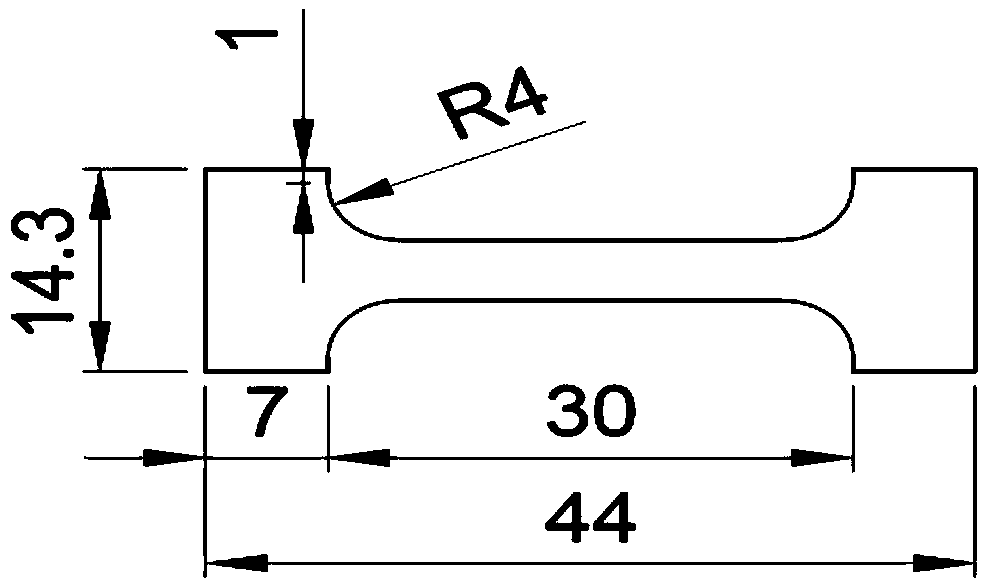

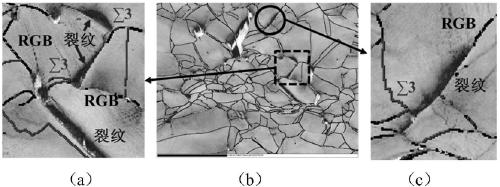

Method for improving hydrogen resistance of iron-nickel-based alloy by increasing special grain boundary ratio

ActiveCN108998649AIncrease resistanceImproved resistance to hydrogen damageGrain boundaryHeat treated

The invention relates to the field of iron-nickel-based alloy, in particular to a method for improving the hydrogen resistance of iron-nickel-based precipitation-strengthened austenite alloy by increasing the special grain boundary ratio, and solves the problems that after saturated hydrogenation of the existing iron-nickel-based alloy, hydrogen-induced grain boundary cracks are easily formed andhydrogen embrittlement sensitivity increase and elongation decrease are caused thereby. By a thermal mechanical treatment (single-step deformation heat treatment) method, the special grain boundary ratio of the alloy is increased, the initiation and expansion resistance of the hydrogen-induced cracks in the alloy is increased, and the hydrogen damage resistance of the alloy is improved; the methodcomprises the following specific technological route: performing solution treatment, predeforming, preserving heat, performing water cooling, performing aging treatment and performing air cooling. The iron-nickel-based alloy treated by the method provided by the invention has the special grain boundary ratio of 65-80% and has the room-temperature tensile elongation of 33% or above; after saturated thermal hydrogenation, the room-temperature elongation of the alloy can still keep 30% or above, and the hydrogen-induced elongation loss is reduced within 10%.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Production process of broad band low peak dispersion unshifted single-mode optical fiber

ActiveCN1594154ASafe and reliable production processConvenient and easy production processGlass making apparatusWork in processProduct gas

The invention provides a production process of broad band low peak dispersion unshifted single-mode optical fiber (G.652C / D optical fiber) which comprises, (1) drawing the broad band low peak dispersion unshifted single-mode optical fiber intermediate product, (2) intermediate product screen selecting, (3) subjecting the intermediate product to deuterium gas reaction, (4) intermediate product hydrogen damage test, (5) degassing treatment, (6) intermediate product testing, (7) packaging and warehouse-in.

Owner:ZHONGTIAN TECH FIBER OPTICS +1

Device and method for inhibiting hydrogen damage in ferroelectric capacitor devices

InactiveUS20050051819A1Avoid layeringPreventing diffusion of hydrogenSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFerroelectric capacitor

A ferroelectric capacitor device comprises a substrate, a contact plug passing through the substrate, a first electrode formed on the substrate, the first electrode being electrically connected to said plug, a ferroelectric layer formed on the first electrode, a second electrode formed on the ferroelectric layer, one or more first encapsulation layers on the second electrode, the encapsulation layers extending over the device, and one or more hydrogen storage material layers on the encapsulation layers. One or more second encapsulation layers may be formed on the one or more hydrogen storage material layers.

Owner:QIMONDA

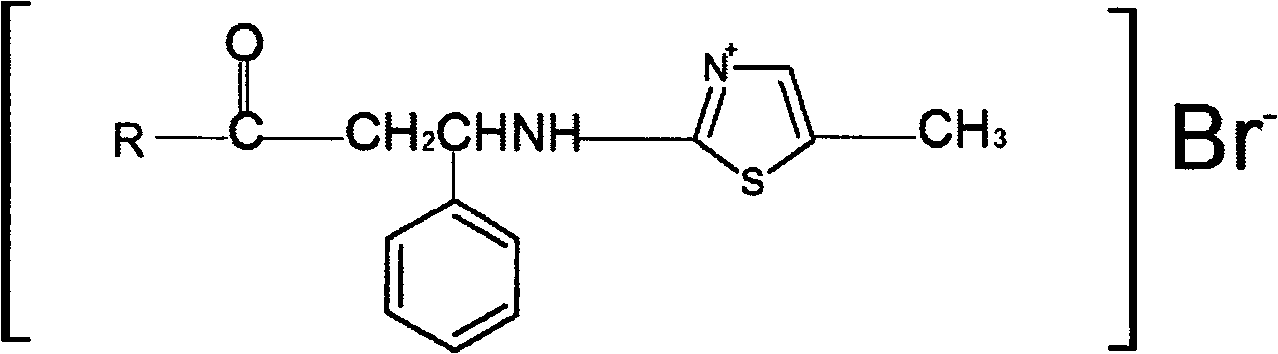

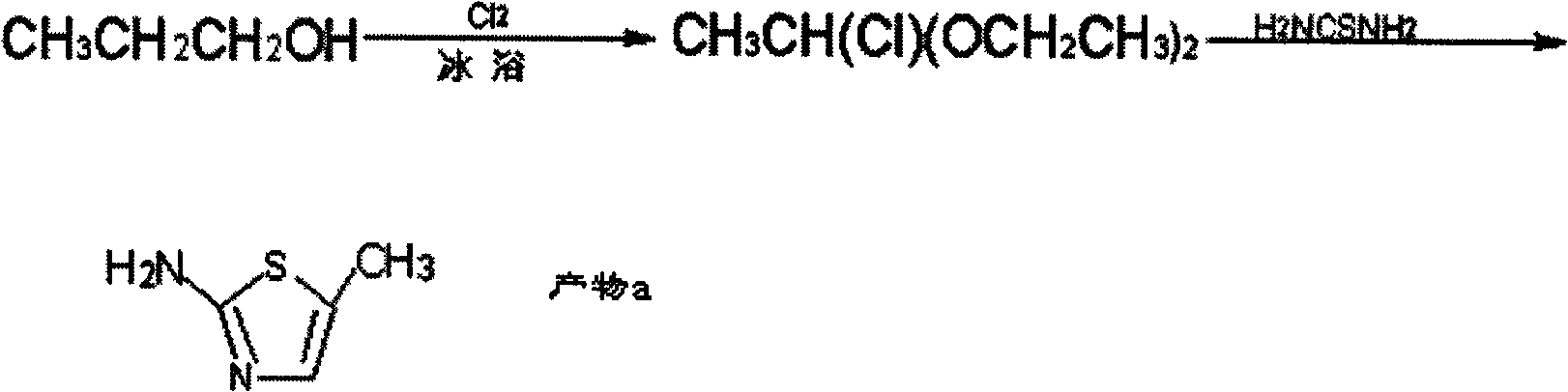

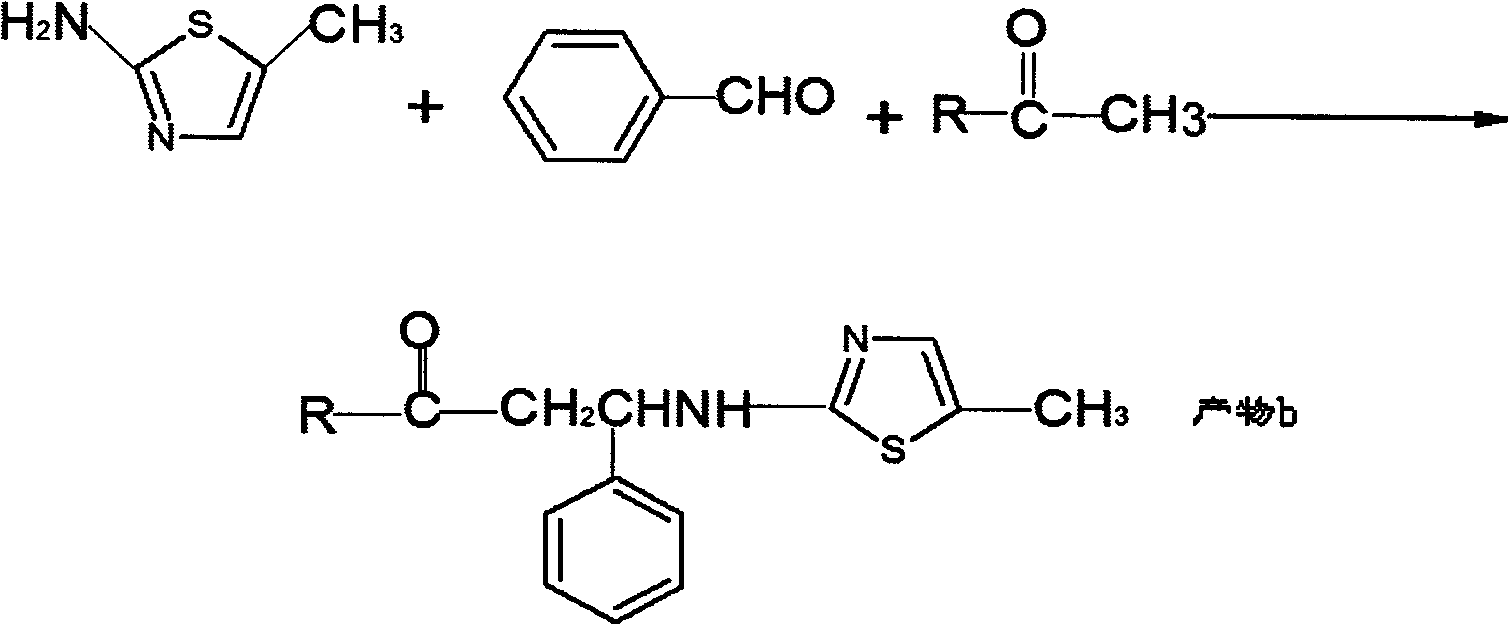

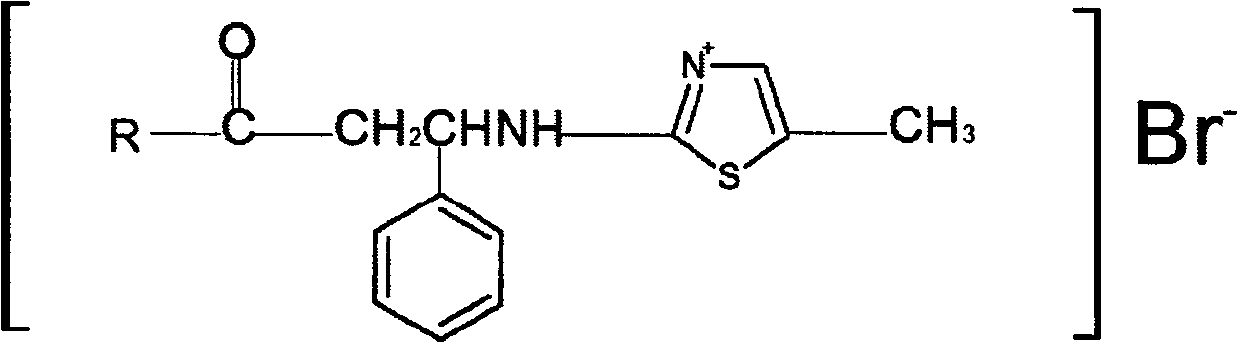

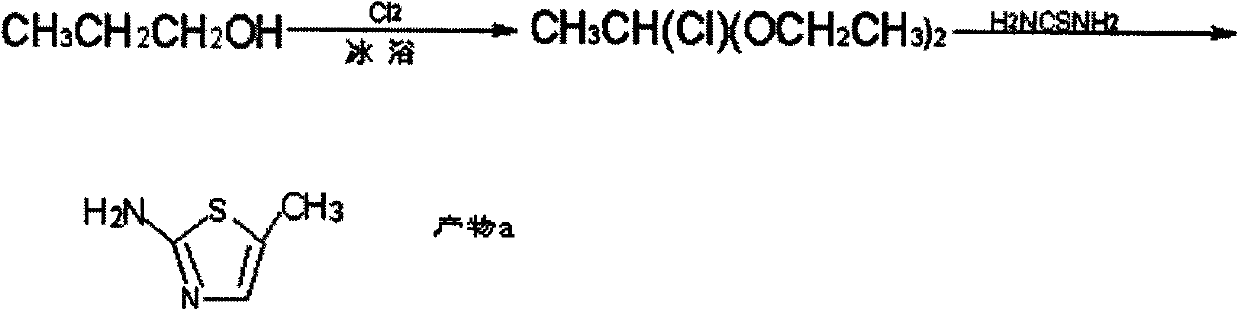

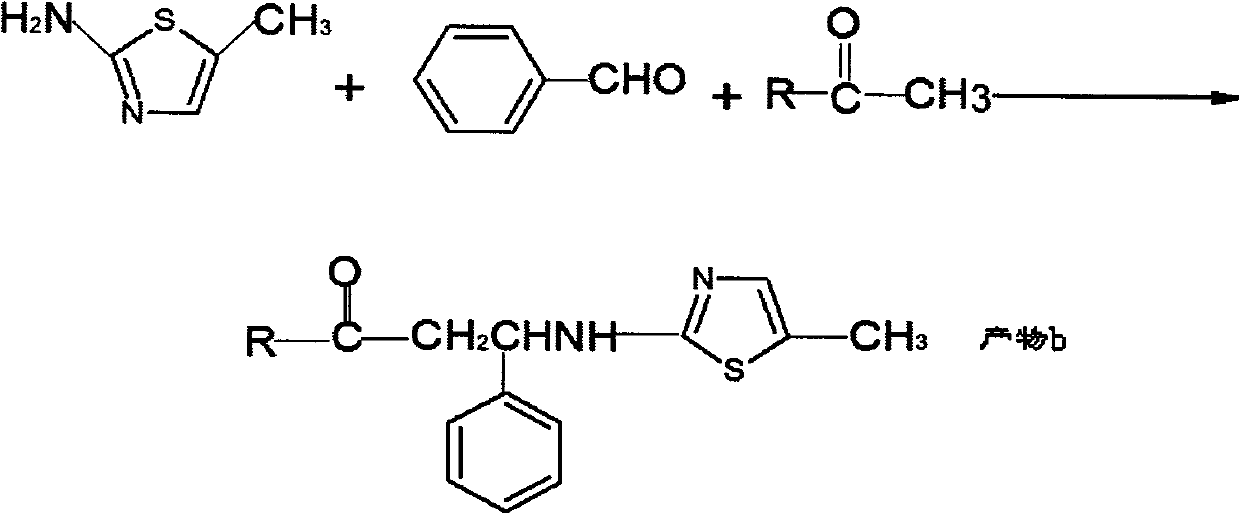

Corrosion inhibitor for controlling corrosion of high-concentration hydrogen sulfide in acid liquor medium and preparation method thereof

InactiveCN102181277AGood corrosion inhibitionStrong corrosion inhibitionOrganic chemistryBorehole/well accessoriesHigh concentrationThiazole

The invention relates to a corrosion inhibitor for controlling corrosion of high-concentration hydrogen sulfide in an acid liquor medium and a preparation method thereof, which belong to the technical field of mechanically chemical preparation. In the invention, a corrosion inhibitor finished product is prepared by synthesizing 2-amino-5-methylthiazol, synthesizing 2-amino(1,4- diphenyl-3-oxobutyl)-5-methylthiazol and brominating 2-amino(1,4-diphenyl-3-oxobutyl)-5-methylthiazol; the corrosion inhibitor contains a thiazole ring; atoms S and atoms N on the thiazole ring form multiple adsorptioncenters with the metal surface and are directly adsorbed to the metal surface, so as to enhance the adsorbing capacity of molecules; therefore, a better corrosion inhibition effect is obtained and the problems that the traditional corrosion inhibitor only works on acid corrosion or only works on H2S corrosion and the effects on hydrogen damage and stress corrosion are not ideal are solved; and the corrosion inhibition rate of the corrosion inhibitor provided by the invention in a hydrochloric acid medium can reach up to 96% while the corrosion inhibition rate in a mud acid medium can be more than 92%.

Owner:YANGTZE UNIVERSITY

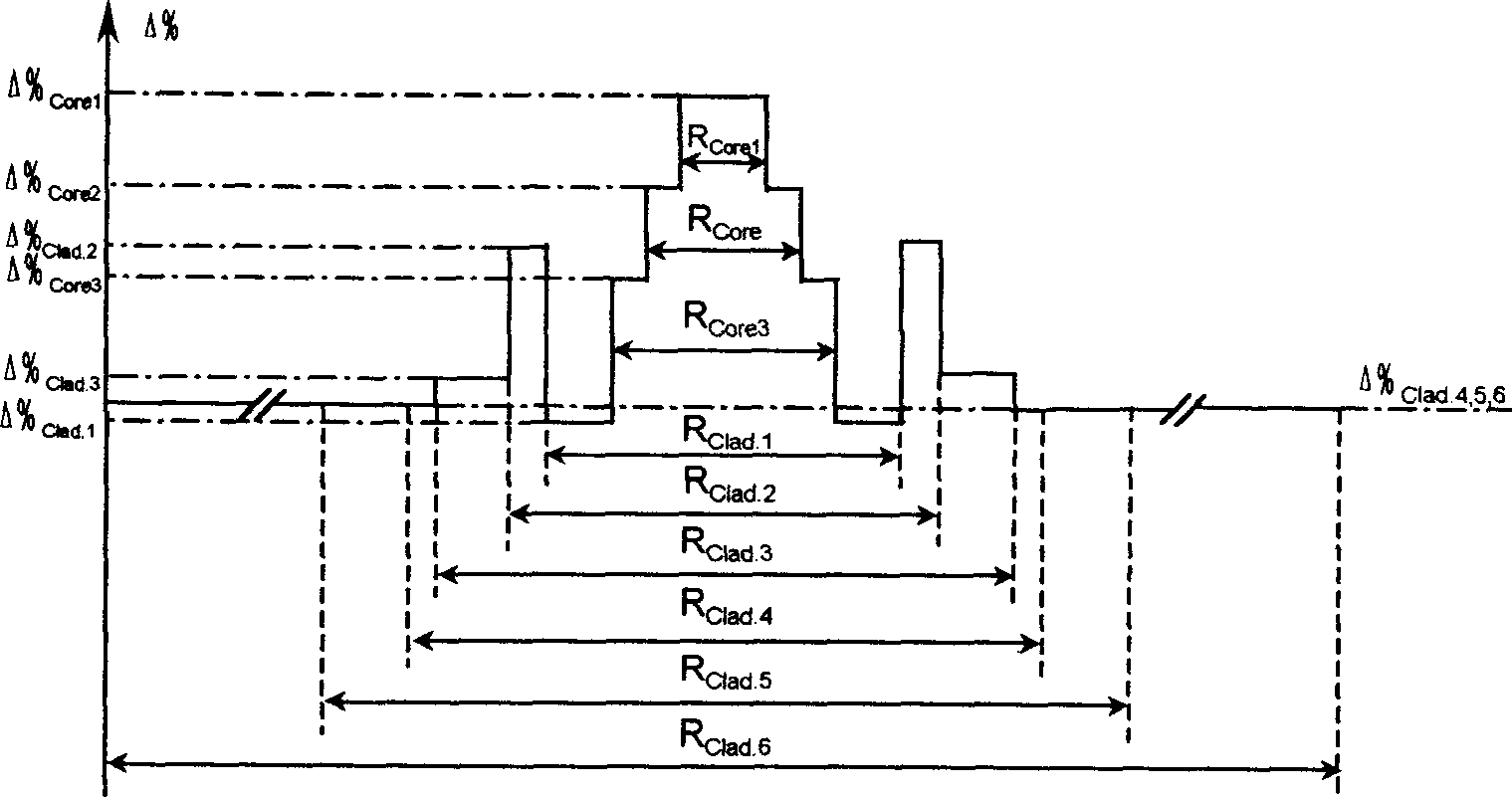

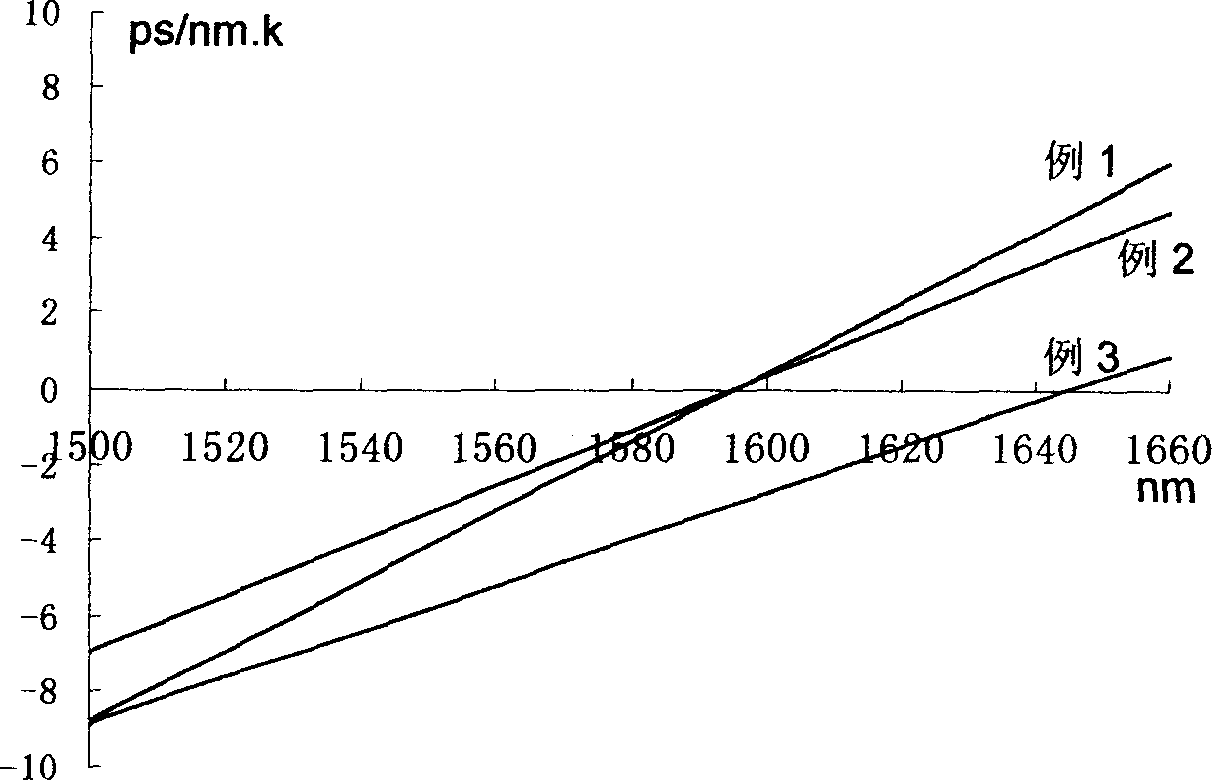

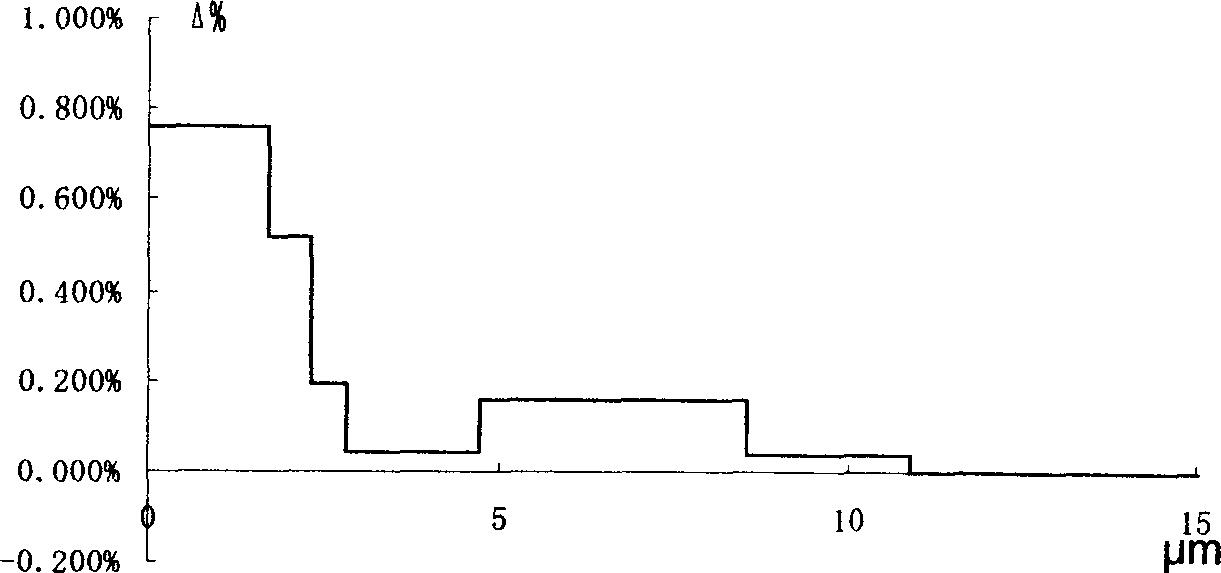

Negative dispersion monomode optical fibre

InactiveCN1395121AAvoid shockImprove roundnessElectromagnetic transmissionOptical light guidesCommunications systemOptical communication

The invention relates to the monomode fiber with negative dispersion. The fiber possesses total negative dispersion and positive dispersion slope in the C wave band of the optical communication window or in the C and L wave band at the same time. Thus, the fiber can be used for the fiber for transferring signal in the C and L wave band of the fast DWDM optical communication system. The fiber core possesses the three layers and four packet-layers provided by the PCVD technique as well as the two packet-layers provided by the OVD technique. The fiber satisfies the need of increasing the PMD value and improves the properties of counter bending and anti hydrogen damage. With positive chirp laser being used, the fiber generates the compression effect of light pulse width so as to prolong the limited distance caused by the dispersion.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP

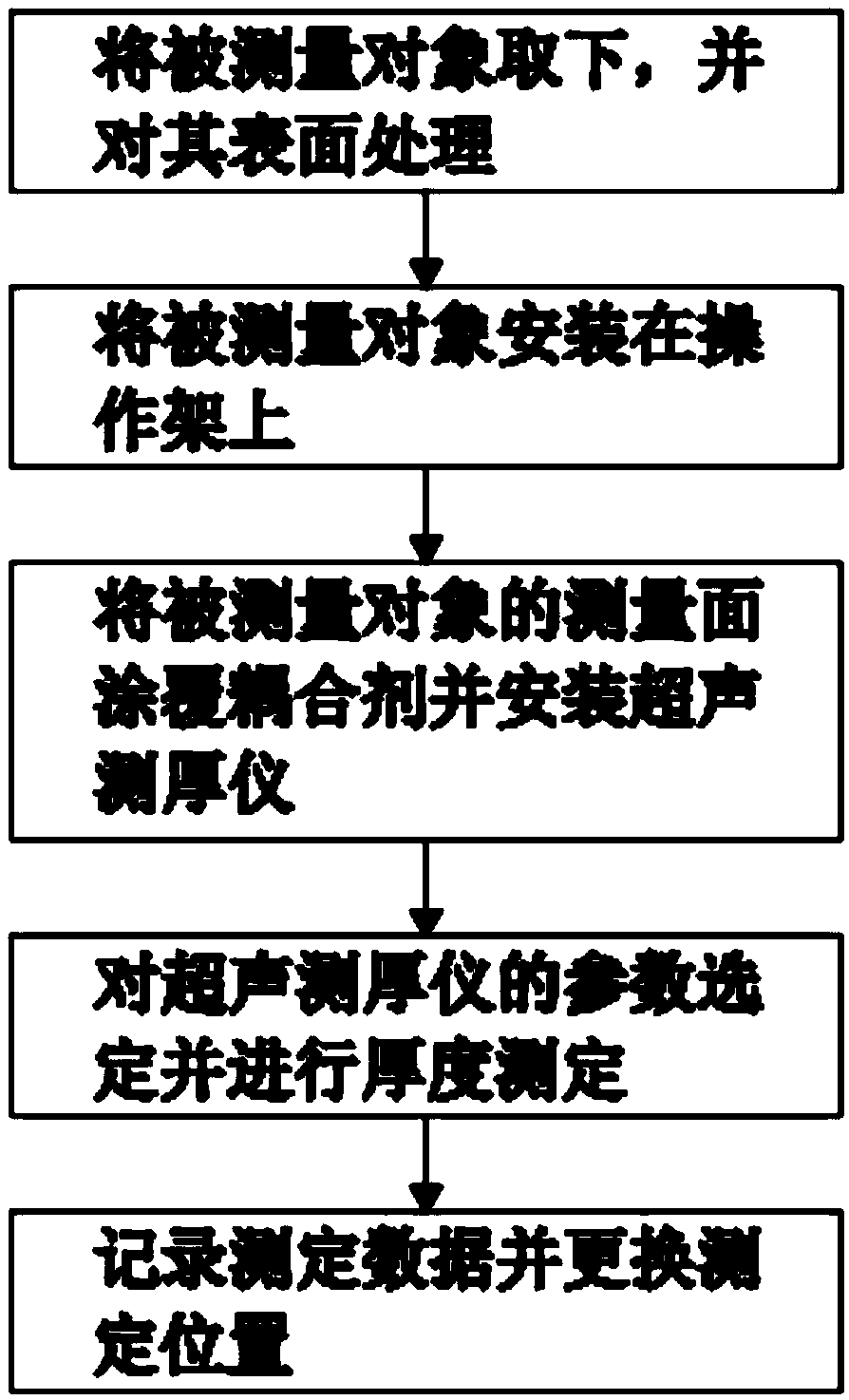

Ultrasonic detecting method of hydrogen damage of water cooling wall tube of boiler

InactiveCN108845032ASimple stepsEasy to measureAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansHydrogenCoupling

The invention belongs to the technical field of industrial detection and particularly relates to an ultrasonic detecting method of hydrogen damage of a water cooling wall tube of a boiler. The detecting method comprises the following steps: S1: taking down a measured object and performing surface treatment on the measured object; S2: mounting the measured object on an operation frame; S3: coatinga coupling agent on a measured surface of the measured object and mounting an ultrasonic thickness gauge; S4: selecting parameters of the ultrasonic thickness gauge and measuring the thickness; S5: recording measured data and changing a measured position. The scheme is simple in steps and convenient in measurement in the operation process; in addition, the operating frame is matched for use, so that the portability in detection is improved.

Owner:菏泽市产品检验检测研究院

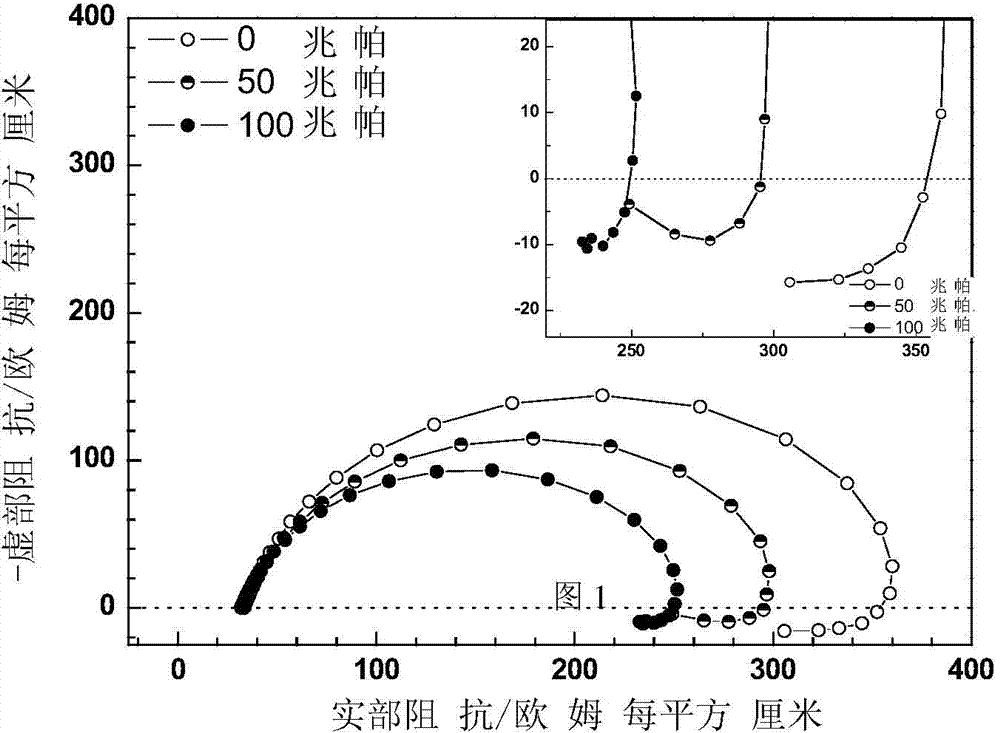

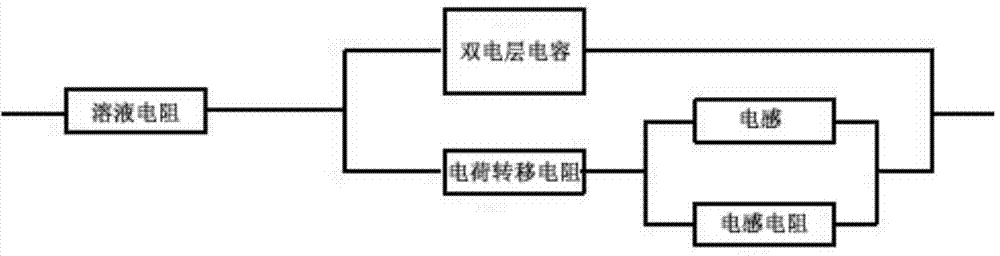

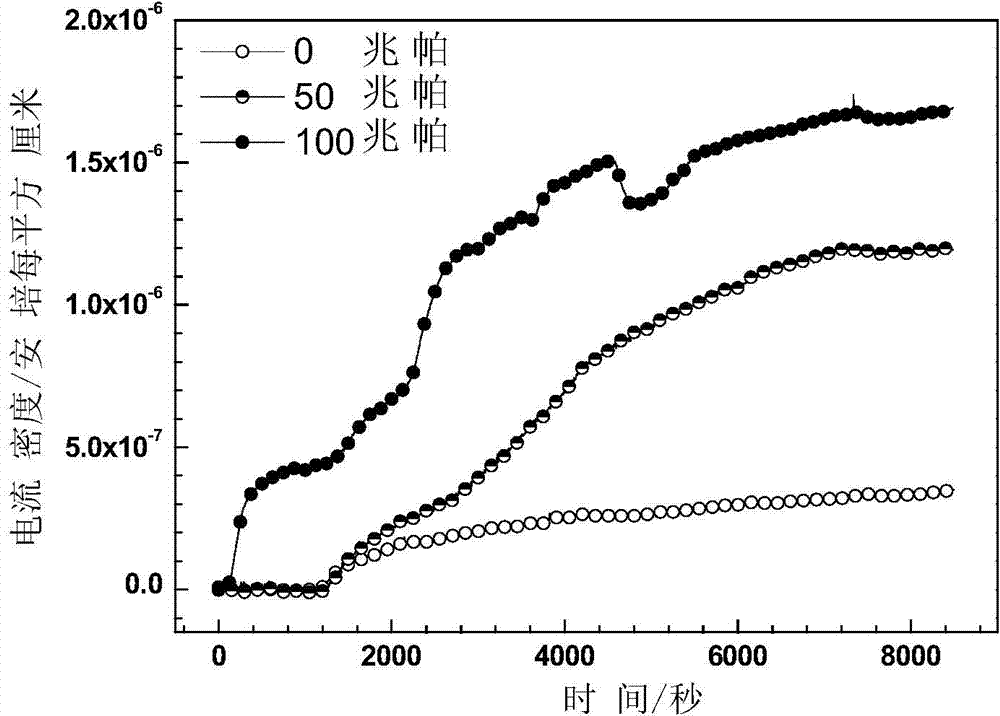

Surface adsorption hydrogen rapid detection method of high-strength steel hydrogen damages

InactiveCN103901084AAccurate evaluationReliable evaluationMaterial electrochemical variablesElectrical impedanceImpedance spectrum

The invention provides a surface adsorption hydrogen rapid detection method of high-strength steel hydrogen damages. The surface adsorption hydrogen rapid detection method comprises the following steps: measuring a low-frequency end inductive impedance arc in an acid corrosion medium of high-strength steel by using an electrochemical impedance spectrum testing method; fitting an equivalent circuit by using impedance to fit the low-frequency end inductive impedance arc so as to obtain the resistance size of an inductance resistor for representing the adsorption capability of hydrogen ions on a metal surface; and judging the hydrogen damage degree of the high-strength steel by using a measured numerical value of the inductance resistor according to a relation of the adsorption hydrogen inductance resistor, a hydrogen permeation amount and the hydrogen damages. According to the surface adsorption hydrogen rapid detection method, the adsorption capability of hydrogen on the surface of the high-strength steel is detected so as to evaluate the permeation behavior of hydrogen atoms into the high-strength steel, and furthermore, the effect of detecting the damage degree of the mechanical property of the high-strength steel by the hydrogen permeation atoms is realized. The invention provides a detection technology for rapidly and losslessly evaluating the hydrogen damages of materials in situ, and is applicable to engineering application.

Owner:HARBIN ENG UNIV

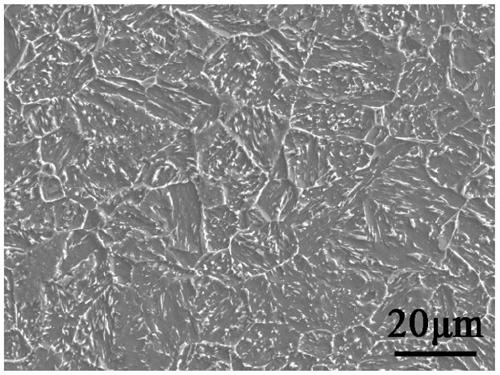

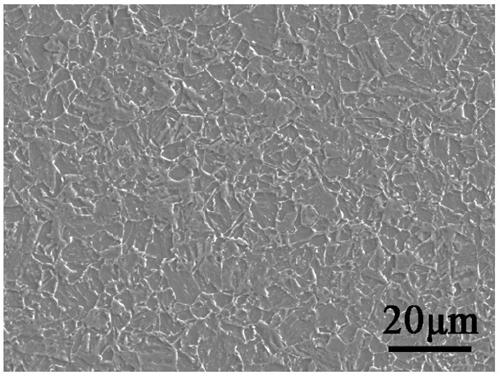

Rating method for pearlitic steel microstructure subject to hydrogen damage

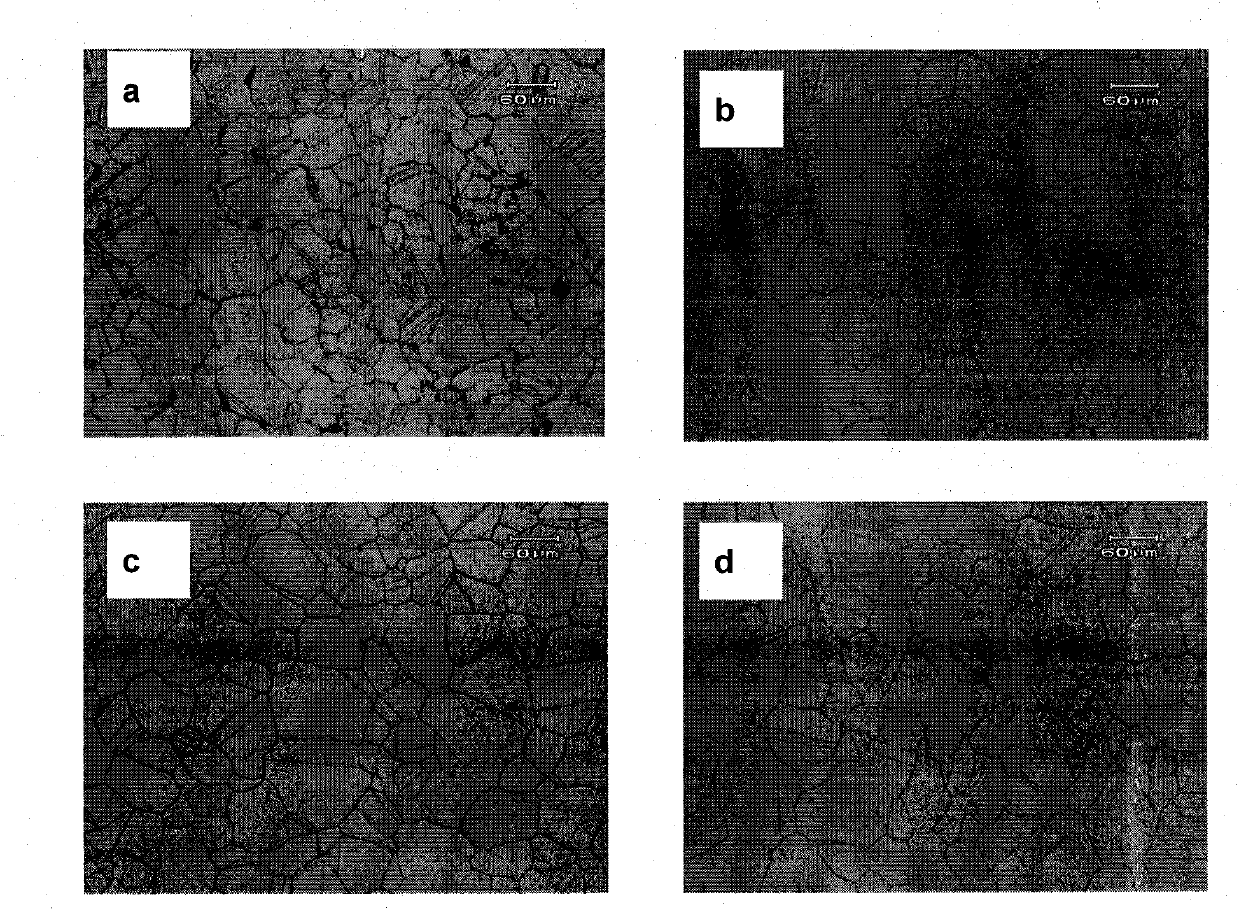

InactiveCN103969103AAccurate assessmentRapid assessmentPreparing sample for investigationOptically investigating flaws/contaminationMicroscopic observationMetallic materials

This invention introduces a rating method for a pearlitic steel microstructure subject to hydrogen damage. The rating method comprises the following steps: (1) asking for a wall material sample, and configuring a grinding machine, a polishing machine and a metallographic microscope; (2) using the grinding machine to grind till a smooth surface is achieved; (3) using sandpaper to grind till 700-900 meshes are obtained; (4) using the polishing machine or an electrolytic polishing tank for polishing; (5) smearing with an alcoholic solution containing 3-5% nitric acid; (6) using the metallographic microscope with the amplification factor of 200-1000 to observe, and photographing; (7) in the light of metal material hydrogen damage standard diagram, noting the hydrogen damage level of the microstructure. The rating method can accurately evaluate the hydrogen damage degree of the water cooled wall of a boiler in a thermal power plant, is simple in principle, convenient in operation and accurate in test, and thus is an effective method for quickly and reliably evaluating hydrogen damage to pearlitic steel-like metallic materials.

Owner:STATE GRID CORP OF CHINA +2

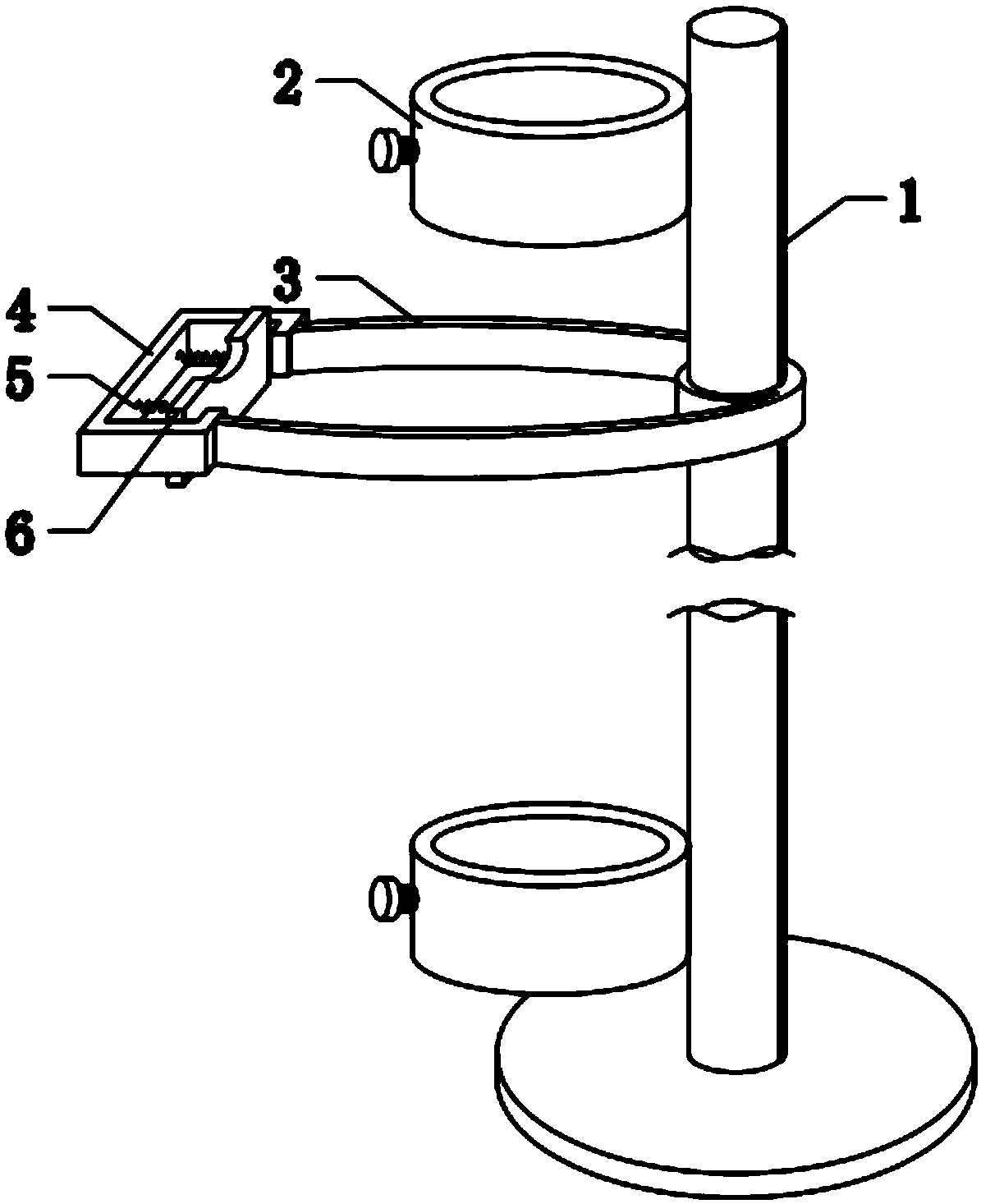

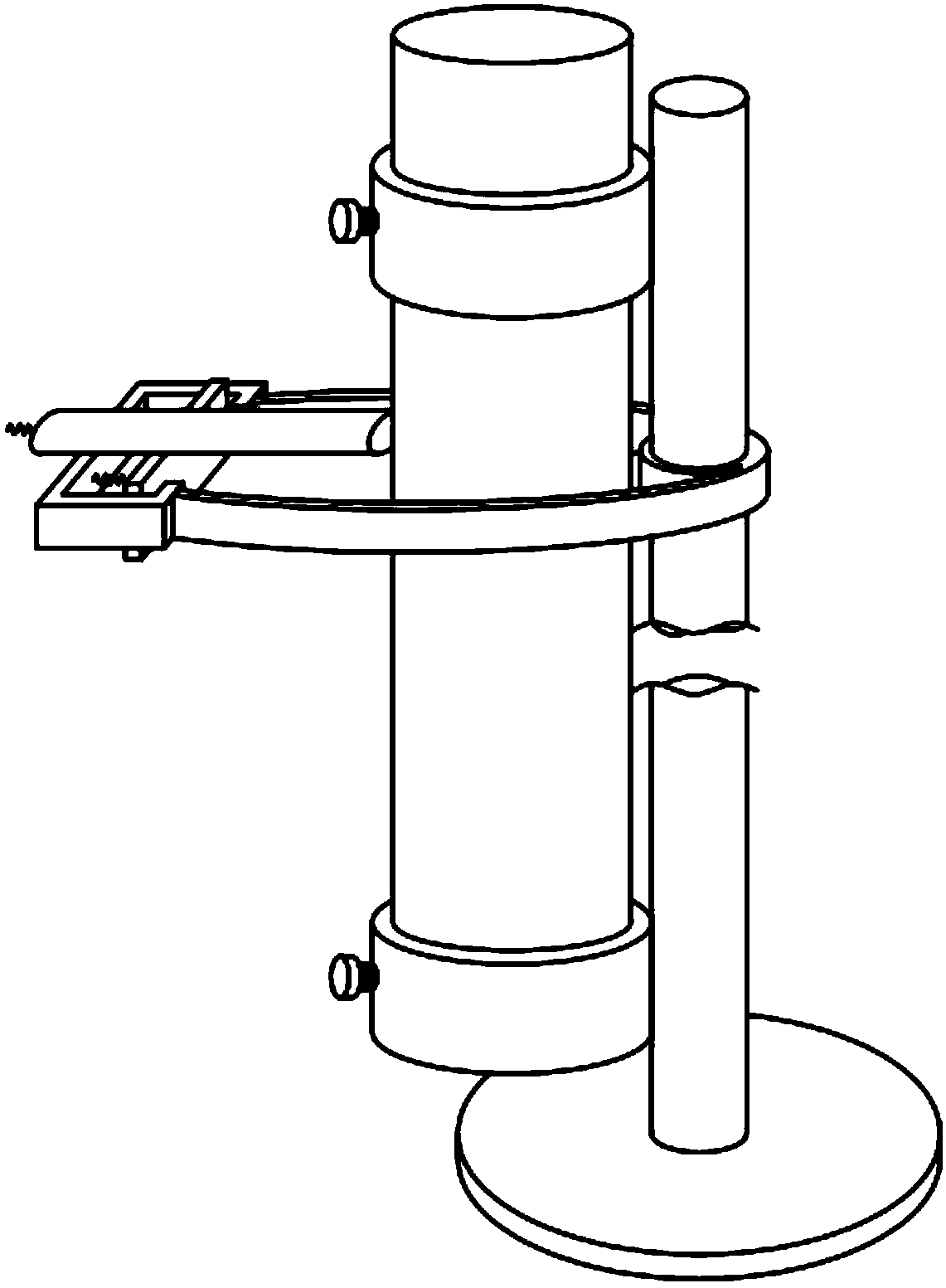

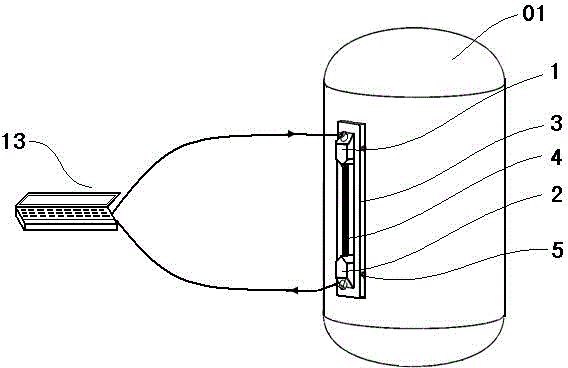

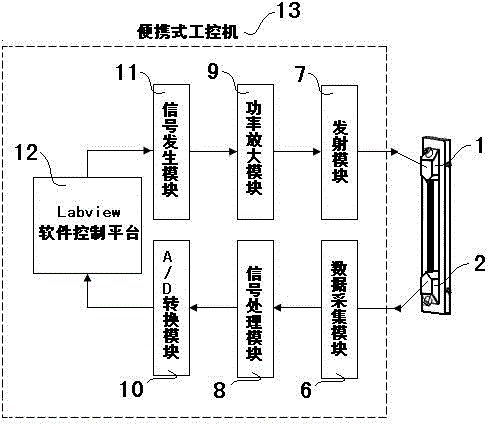

Method for detecting material hydrogen damage through ultrasonic surface waves

InactiveCN103245726BEasy to carryEasy to installAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringData acquisition module

The invention discloses a device and a method for detecting material hydrogen damage through ultrasonic surface waves. The device comprises high-frequency ultrasonic surface wave emitting and receiving probes, a substrate, a guide rail, locating nuts and a portable industrial personal computer, wherein the two probes are arranged on the guide rail at the middle of the substrate and are fixed by the locating nuts in a clamping manner, and the substrate is arranged on an apparatus or a material to be detected; and the portable industrial personal computer comprises a data collecting module, an emitting module, a signal processing module, a power amplifying module, an A / D (analog / digital) converting module, a signal generating module, a software control platform and connecting wires, and the portable industrial personal computer is used for operating and controlling. The method disclosed by the invention comprises the following steps: (1) applying the detecting device; (2) setting the software control platform; (3) generating ultrasonic surface waves; (4) propagating the ultrasonic surface waves and converting signals; (5) converting a voltage signal into a digital signal; and (6) detecting the hydrogen damage degree of the apparatus or material. The device is light, convenient to carry and capable of performing online nondestructive testing on hydrogenating and hydroreforming apparatuses and materials.

Owner:EAST CHINA UNIV OF SCI & TECH

A method for determining the equipment inspection period according to a equipment risk grade

The invention relates to a method for determining the equipment inspection period according to an equipment risk grade, which comprises the following steps: S1, confirming whether the equipment to beinspected has carried out first inspection; if not, carrying out first inspection; if the equipment to be inspected has subjected to first inspection, transferring to S2; S2, determining the inspection period correction coefficient ai=FRi x FCi x FM x FL of each part of the equipment to be inspected by the following formula; S3, confirming the corrosion mechanism of the equipment to be inspected and calculating the reasonable inspection period of the equipment to be inspected. The invention has the beneficial effects that the risk assessment is carried out on the equipment according to the API581 standard, and the assessment results include the management level score, the failure probability and failure consequence of each component of the equipment, the sensitivity of the equipment damage (stress corrosion cracking, high-temperature hydrogen damage), and the like, and the reasonable inspection period of the equipment is formulated according to the inspection and detection results ofthe equipment.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Steel for ultrahigh-strength marine hose and preparation method of steel

The invention discloses a steel for an ultrahigh-strength marine hose and a preparation method of the steel. The steel for the ultrahigh-strength marine hose comprises the following components, by weight, 0.04-0.10% of C, less than of equal to Si, 0.4-1.0% of Mn, less than or equal to 0.01% of P, less than or equal to 0. 003% of S, 1.0-1.5% of Cr, 1.0-1.5% of Mo, 0.2-0.5% of Ni, 0.035-0.045% of Nb, 0.01-0.015% of Ti, and the balance Fe and inevitable impurities; the method comprises the following steps that a casting blank is prepared according to a set component; heating of the casting blankis carried out to a corresponding temperature and then the temperature preservation is carried out, then hot rolling is carried out to form a coiled strip, and the coiled strip is cooled to the room temperature; when iron oxide skin is removed, several passes of cold rolling are carried out to obtain flat steel; and two thermal refining are carried out to obtain a finished product. The preparationmethod is simple in process, easy to control, and capable of saving energy consumption; the prepared finished product has ultrahigh strength and good hydrogen damage resistance, the anti-stress corrosion cracking performance is especially excellent, and the performance requirement of the marine hose serving under a severe environment can be met.

Owner:NORTHEASTERN UNIV +1

Sheet-shaped copper-tin alloy powder auxiliary catalyst

ActiveCN102941100AHigh activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsMetal impuritiesScanning electron microscope

The invention provides a sheet-shaped copper-tin alloy powder auxiliary catalyst. With the adoption of a constant quantity analysis, the content of Cu is 40-95 wt% and the content of Sn is 5-60 wt%; with the adoption of an ICP (Inductively Coupled Plasma) detection, Pb is less than or equal to 200 ppm, Fe is less than 500 ppm, each other metal impurity single item is less than or equal to 50 ppm, each other non-metal impurity single item is less than or equal to 30 ppm and the content of a surfactant is 0.1-10%; a hydrogen damage meter is used for detecting and the content of oxygen is less than or equal to 0.4%; a scanning electron microscope is used for detecting and the shape of a grain is in a scale shape or a slightly-coiled shape; the sheet thickness is 0.1-1.0 micron and the surface roughness of the grain is large; and a microcosmic specific surface area is large. The specific surface area is large, the purity is high and the content of harmful impurities is low; the effect of the auxiliary catalyst is better, the contact activity is improved, the selectivity of dimethyl dichloro-silane is improved and a reaction process is optimized; and the silicon powder conversion rate and the space-time yield are improved, the consumption is reduced, the cost is saved and the benefit is improved.

Owner:湖南省天心博力科技有限公司

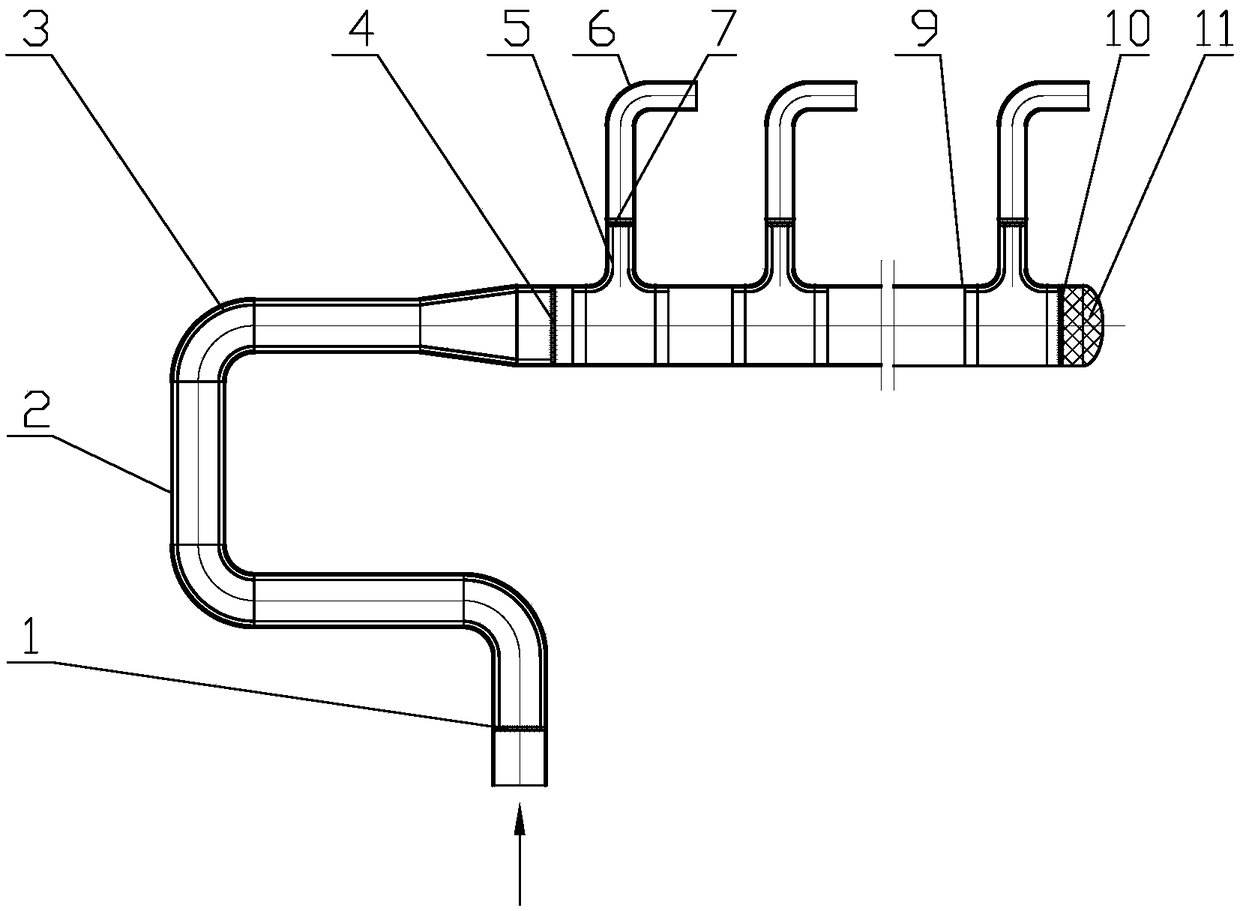

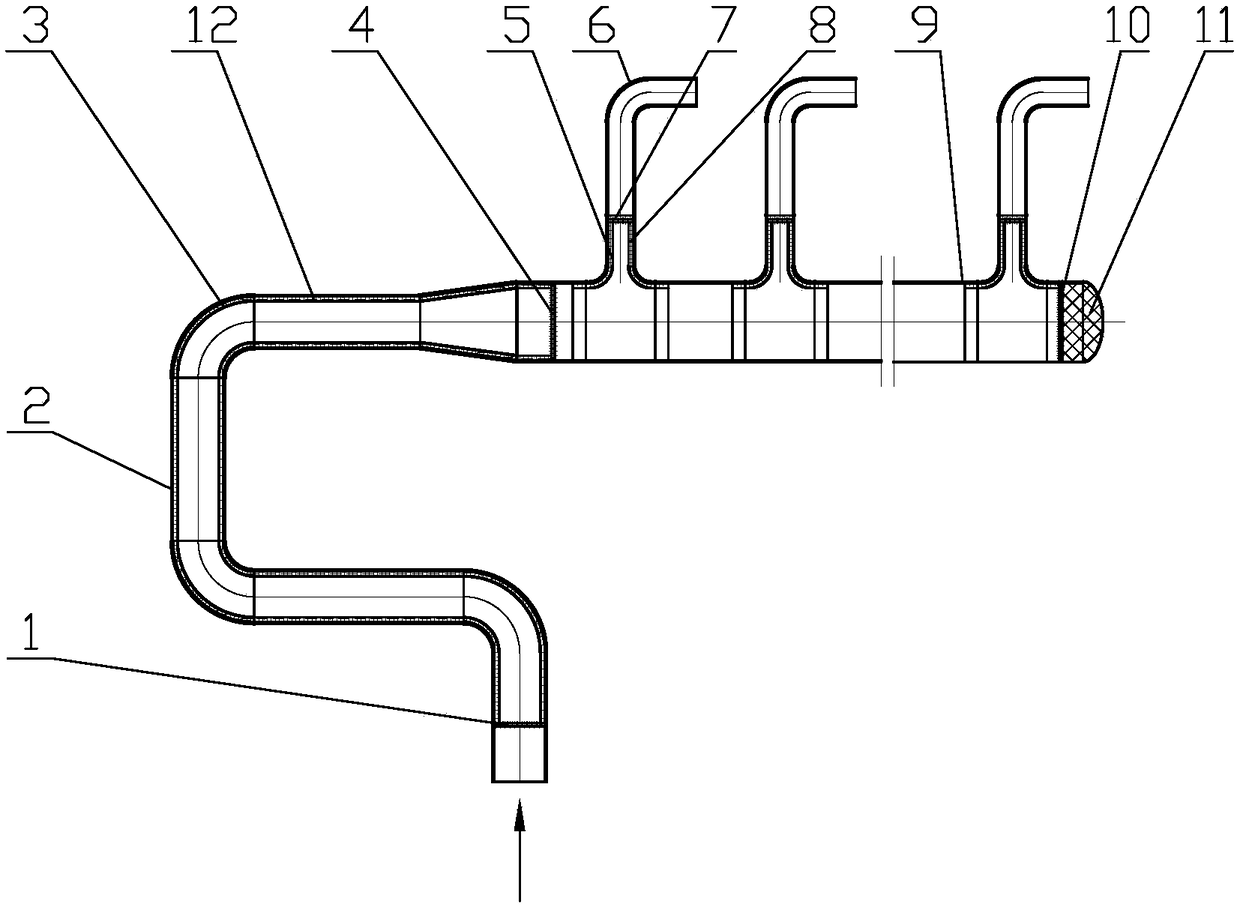

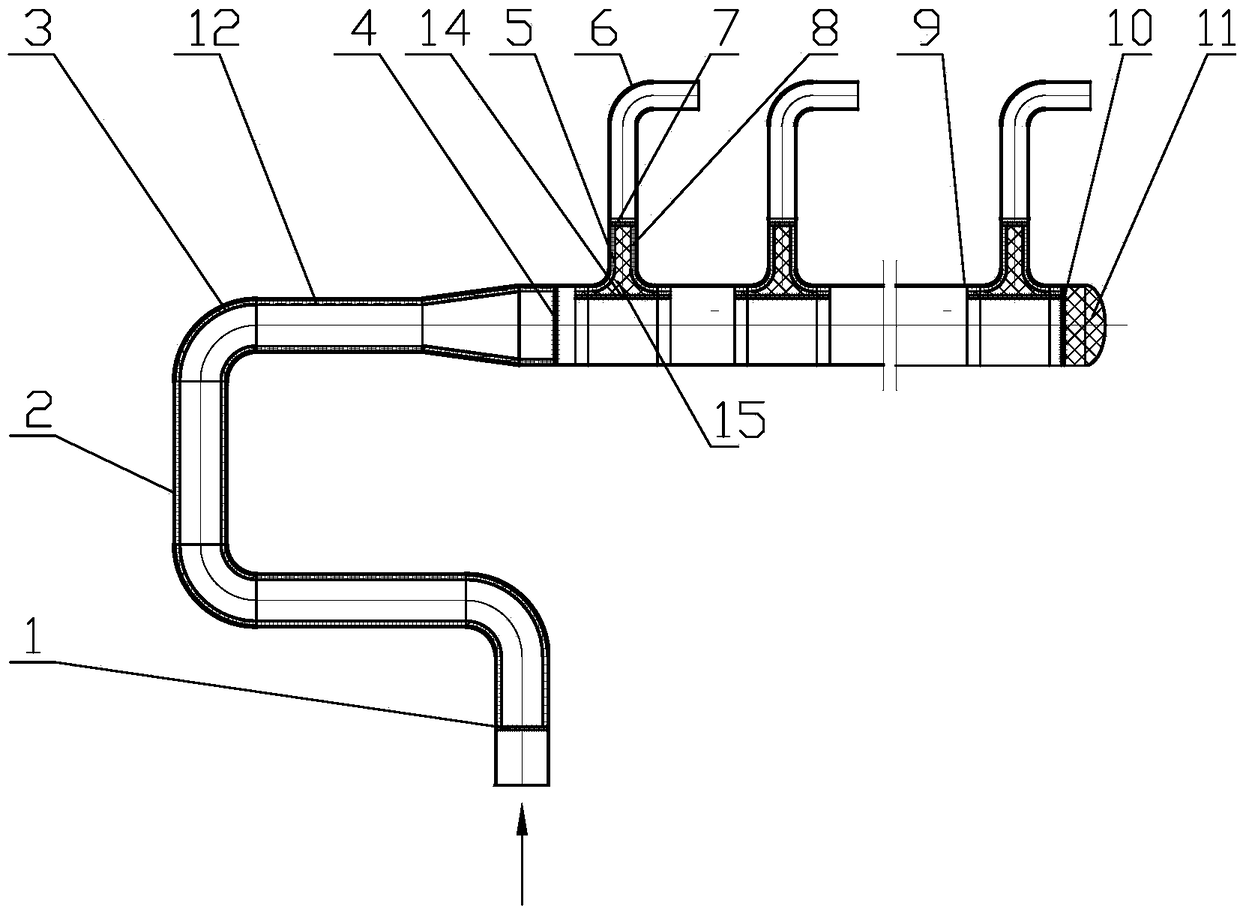

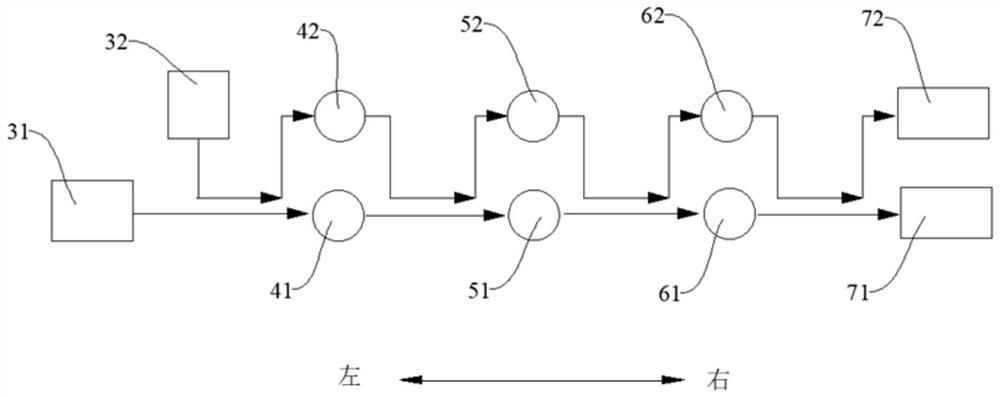

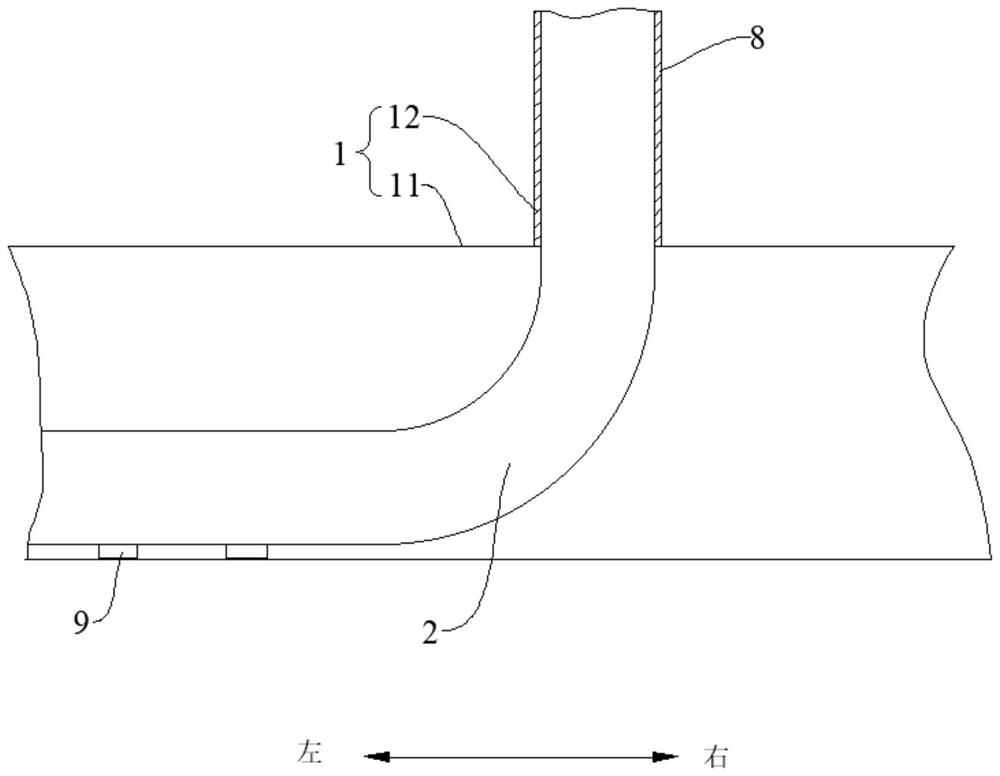

Method for preventing pipeline hydrogen damage, and oil transfer line and manifold of oil refining and hydrogen production reformer applying method

InactiveCN108709041AExtended service lifeAvoid crackingBranching pipesPipe protection against damage/wearThermodynamicsDehydrogenation

The invention relates to a method for preventing pipeline hydrogen damage, and an oil transfer line and a manifold of an oil refining and hydrogen production reformer applying the method. The method is characterized in that a hollow isolation layer playing a role in isolating is arranged on the inner wall of a pipeline, padding having a buffer effect is arranged at the tail end of the pipeline, and a pore plate supporting the isolation layer is arranged in the pipeline. The oil transfer line and the manifold of the oil refining and hydrogen production reformer applying the method comprises theoil transfer line and the manifold, and the side face of the manifold is connected with branch pipes. The oil transfer line and the manifold are characterized in that the hollow isolation layer is arranged on the inner wall of the pipeline of the oil transfer line, the padding is arranged at the tail end of the manifold, and hollow isolation layers are arranged on the inner wall of the branch pipes and the inner walls of the connecting portions of the branch pipes and the manifold. The method is not only suitable for the oil transfer line and the manifold of the oil refining and hydrogen production reformer, but also suitable for pigtail tubes, propylene dehydrogenation tubes, isobutene dehydrogenation tubes, and other chemical device pipelines having hydrogen damage problems. Pipelines applying the method have the advantages of being long in service life and not liable to cracking.

Owner:徐桂根

Assessment method of hydrogen damage to water wall tube of boiler

ActiveCN103529127AEasy to measureQuick measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesAttenuation coefficientEngineering

The invention discloses an assessment method of hydrogen damage to a water wall tube of a boiler. The method comprises the steps as follows: 1), a sampling tube in the water wall tube of the boiler is assessed; 2), a test object is selected; 3), a supersonic detector is equipped, 4), the test object is subjected to supersonic detection; 5), according to the step 4), a product logarithmic function and a sonic path distance graph are established; 6); a supersonic attenuation coefficient a0 of the test object is obtained; 7), supersonic detection of the sampling tube is performed; 8), according to the step 7), a product logarithmic function and a sonic path distance graph are established; 9), a supersonic attenuation coefficient a1 of the sampling tube is obtained; 10), a hydrogen damage degree factor value delta of the water wall tube of the boiler is obtained; and 11), an assessment conclusion of the hydrogen damage to the water wall tube of the boiler is drawn. According to the method, special processing of the tested material is not required, the process is simple, the operation is convenient and rapid, the conclusion is accurate, the requirement for the detection environment is less strict, and the efficiency is substantially improved.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Hydrogen delivery system and hydrogen delivery method

The invention discloses a hydrogen conveying system and a hydrogen conveying method. The hydrogen conveying system comprises a first pipeline and a second pipeline, the second pipeline is arranged in the first pipeline and extends in the extending direction of the first pipeline, the interior of the second pipeline is used for conveying hydrogen. a conveying space is formed between the first pipeline and the second pipeline, and the interior of the conveying space is used for conveying fluid resources. The hydrogen conveying method comprises the following steps of conveying the hydrogen in the second pipeline; conveying a fluid resource within the conveying space between the first pipeline and the second pipeline; and the hydrogen pressure in the second pipeline is equivalent to the pressure of the fluid resource in the conveying space. According to the hydrogen conveying system and the hydrogen conveying method, hydrogen damage caused by hydrogen to the pipeline can be avoided, purification is not needed, and the cost is low.

Owner:STATE POWER INVESTMENT CORP RES INST

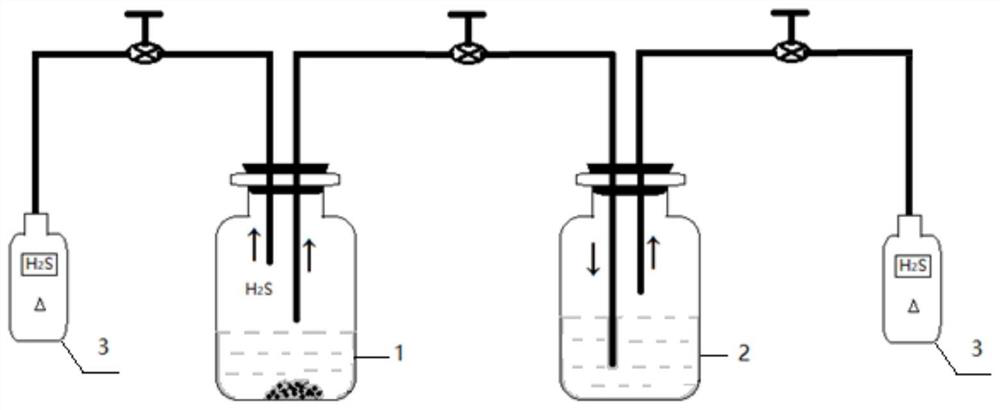

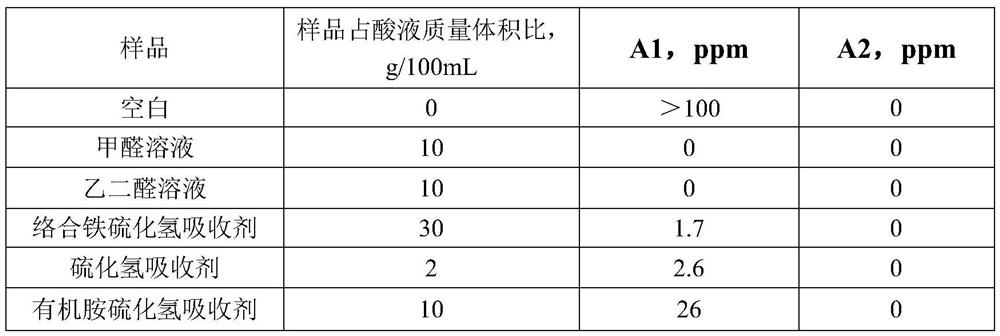

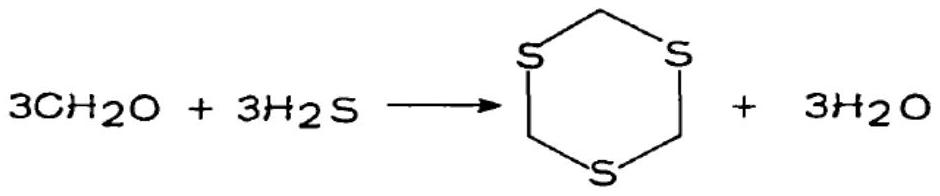

A hydrogen sulfide absorbent for pickling and its application method

ActiveCN109772104BFix damagePrevent overflowDispersed particle separationHexamethylenetetramineTriazine

The invention discloses a hydrogen sulfide absorbent for pickling and its use method. The hydrogen sulfide absorbent for pickling is composed of the following components in terms of mass ratio: ammonium chloride: urotropine: hydroxyalkyl triazine : peroxide: complexing agent = 37: 37: 18: 1: 7. The absorbent can absorb the hydrogen sulfide gas component produced by the dissolution of inorganic scale containing sulfide through reaction during the pickling process of the wellbore or pipeline, prevent the overflow and dispersion of the hydrogen sulfide gas component, and solve the problem of sulfide in the pickling process. Hydrogen damage problem.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Environment-friendly explosion-resistant material for rapidly and efficiently inhibiting hydrogen explosion

ActiveCN114773917AEasy to getEasy to replaceFireproof paintsPipe protection against damage/wearThermodynamicsCombustion

The invention relates to an environment-friendly explosion-resistant material for rapidly and efficiently inhibiting hydrogen explosion. The explosion-proof material is composed of sodium alginate and sodium silicate and smeared on the outer side of the porous iron-nickel alloy structure in the pipe gallery, hydrogen explosion can be further restrained, hydrogen leakage is reduced, and the possibility of hydrogen embrittlement and hydrogen damage is restrained. The sodium alginate is [C6H7O6Na] n, the sodium silicate is Na2SiO2. 9H2O and Na2O, the content of the sodium silicate is 19.3-22.8% of that of the explosion-proof material, and the ratio of the content of the Na2O to the content of the SiO2 is 1.03 + / -0.03. The material is smeared on the outer side of a porous iron-nickel alloy structure, the defect of the porous structure in space can be overcome, combustion and explosion of the porous structure can be directly and powerfully prevented at the hydrogen leakage position, the explosion resistance effect can be enhanced, and the hydrogen leakage possibility is reduced. The high-temperature-resistant coating is suitable for being smeared on places such as pipe galleries for conveying H2, hydrogen refueling stations, hydrogen storage containers, new energy vehicles existing in limited spaces and the like which have the possibility of hydrogen leakage and have the danger of burning explosion.

Owner:UNIV OF SCI & TECH BEIJING +2

A kind of flaky copper-zinc alloy powder promoter

ActiveCN102962072BIncreased space-time yieldLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsSide effectFluidized bed

The invention discloses a sheet type copper-zinc alloy powder promoter. By adopting constant analysis, the Cu content is 50 to 95 wt percent; the Zn content is 5 to 49 wt percent; by adopting ICP detection, Pb is less than or equal to 120 ppm, Fe is less or equal to 500 ppm, and other metal impurity monomers are less than or equal to 50 ppm; other non-metal impurity monomers are less than or equal to 30 ppm; the surface treating agent is 0.1 to 1.0 wt percent; by adopting hydrogen damage meter detection, the oxygen content is less than or equal to 0.5 percent; and by adopting scanning electron microscope observation, the thickness is 0.1 to 1.0 micron. The sheet type copper-zinc alloy powder promoter is high in specific area, high in purity and low in harmful impurity and is applied to organic silicon monomer; side effects of harmful impurities and gathered carbon in a reaction process are avoided; a promotion effect is relatively good; the activity of a contact, the silicon powder conversion rate and the space time yield of a fluidized bed are improved; the cost is reduced; and the benefit is increased.

Owner:湖南省天心博力科技有限公司

Novel medium-high temperature solar energy heat collecting tube and preparation method thereof

InactiveCN106931665AExtended service lifeSolve problems that cannot be tightly coupledSolar heating energySolar heat devicesHydrogenHeat losses

The invention discloses a novel medium-high temperature solar energy heat collecting tube and a preparation method thereof. The novel medium-high temperature solar energy heat collecting tube comprises a metal pipe made of austenitic stainless steel; and the inner wall of the metal pipe is provided with an aluminum oxide coating. Compared with a traditional medium-high temperature solar energy heat collecting tube, the novel medium-high temperature solar energy heat collecting tube has the good hydrogen resistance, the problems of vacuum failure, heat loss increasing and efficiency decreasing caused by hydrogen permeation are solved completely, hydrogen damage to the metal pipe is reduced, and the service life of the heat collecting tube is prolonged and is four times that of the traditional heat collecting tube. When an aluminum oxide layer of the hydrogen preventing coating of the novel medium-high temperature solar energy heat collecting tube is prepared, the method of preparing a pure aluminum coating and then conducting oxidation is adopted, according to the coating preparation method, the problem that the aluminum oxide coating and a matrix cannot be tightly combined is solved, the prepared aluminum oxide coating is compact and complete, and the good hydrogen permeation resisting performance is achieved.

Owner:CANGZHOU TRX SOLAR TECH

Evaluation Method for Hydrogen Damage of Boiler Water Wall Tubes

ActiveCN103529127BEasy to measureQuick measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesAttenuation coefficientHydrogen

The invention discloses an assessment method of hydrogen damage to a water wall tube of a boiler. The method comprises the steps as follows: 1), a sampling tube in the water wall tube of the boiler is assessed; 2), a test object is selected; 3), a supersonic detector is equipped, 4), the test object is subjected to supersonic detection; 5), according to the step 4), a product logarithmic function and a sonic path distance graph are established; 6); a supersonic attenuation coefficient a0 of the test object is obtained; 7), supersonic detection of the sampling tube is performed; 8), according to the step 7), a product logarithmic function and a sonic path distance graph are established; 9), a supersonic attenuation coefficient a1 of the sampling tube is obtained; 10), a hydrogen damage degree factor value delta of the water wall tube of the boiler is obtained; and 11), an assessment conclusion of the hydrogen damage to the water wall tube of the boiler is drawn. According to the method, special processing of the tested material is not required, the process is simple, the operation is convenient and rapid, the conclusion is accurate, the requirement for the detection environment is less strict, and the efficiency is substantially improved.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Corrosion inhibitor for controlling corrosion of high-concentration hydrogen sulfide in acid liquor medium and preparation method thereof

InactiveCN102181277BGood corrosion inhibitionStrong corrosion inhibitionOrganic chemistryBorehole/well accessoriesHigh concentrationThiazole

The invention relates to a corrosion inhibitor for controlling corrosion of high-concentration hydrogen sulfide in an acid liquor medium and a preparation method thereof, which belong to the technical field of mechanically chemical preparation. In the invention, a corrosion inhibitor finished product is prepared by synthesizing 2-amino-5-methylthiazol, synthesizing 2-amino(1,4- diphenyl-3-oxobutyl)-5-methylthiazol and brominating 2-amino(1,4-diphenyl-3-oxobutyl)-5-methylthiazol; the corrosion inhibitor contains a thiazole ring; atoms S and atoms N on the thiazole ring form multiple adsorptioncenters with the metal surface and are directly adsorbed to the metal surface, so as to enhance the adsorbing capacity of molecules; therefore, a better corrosion inhibition effect is obtained and the problems that the traditional corrosion inhibitor only works on acid corrosion or only works on H2S corrosion and the effects on hydrogen damage and stress corrosion are not ideal are solved; and the corrosion inhibition rate of the corrosion inhibitor provided by the invention in a hydrochloric acid medium can reach up to 96% while the corrosion inhibition rate in a mud acid medium can be more than 92%.

Owner:YANGTZE UNIVERSITY

Sheet-shaped copper-tin alloy powder auxiliary catalyst

ActiveCN102941100BHigh activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsMetal impuritiesScanning electron microscope

The invention provides a sheet-shaped copper-tin alloy powder auxiliary catalyst. With the adoption of a constant quantity analysis, the content of Cu is 40-95 wt% and the content of Sn is 5-60 wt%; with the adoption of an ICP (Inductively Coupled Plasma) detection, Pb is less than or equal to 200 ppm, Fe is less than 500 ppm, each other metal impurity single item is less than or equal to 50 ppm, each other non-metal impurity single item is less than or equal to 30 ppm and the content of a surfactant is 0.1-10%; a hydrogen damage meter is used for detecting and the content of oxygen is less than or equal to 0.4%; a scanning electron microscope is used for detecting and the shape of a grain is in a scale shape or a slightly-coiled shape; the sheet thickness is 0.1-1.0 micron and the surface roughness of the grain is large; and a microcosmic specific surface area is large. The specific surface area is large, the purity is high and the content of harmful impurities is low; the effect of the auxiliary catalyst is better, the contact activity is improved, the selectivity of dimethyl dichloro-silane is improved and a reaction process is optimized; and the silicon powder conversion rate and the space-time yield are improved, the consumption is reduced, the cost is saved and the benefit is improved.

Owner:湖南省天心博力科技有限公司

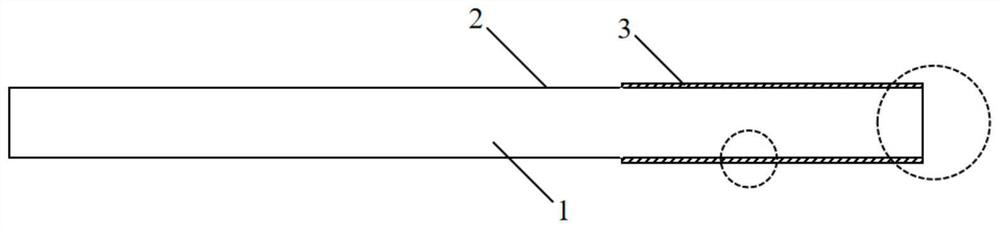

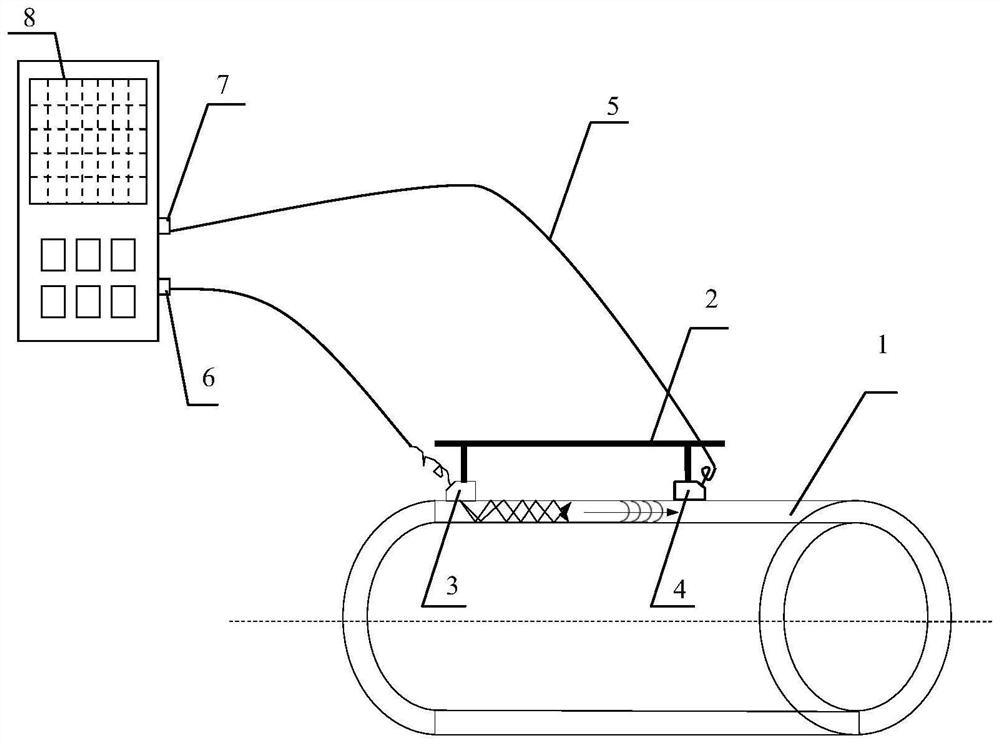

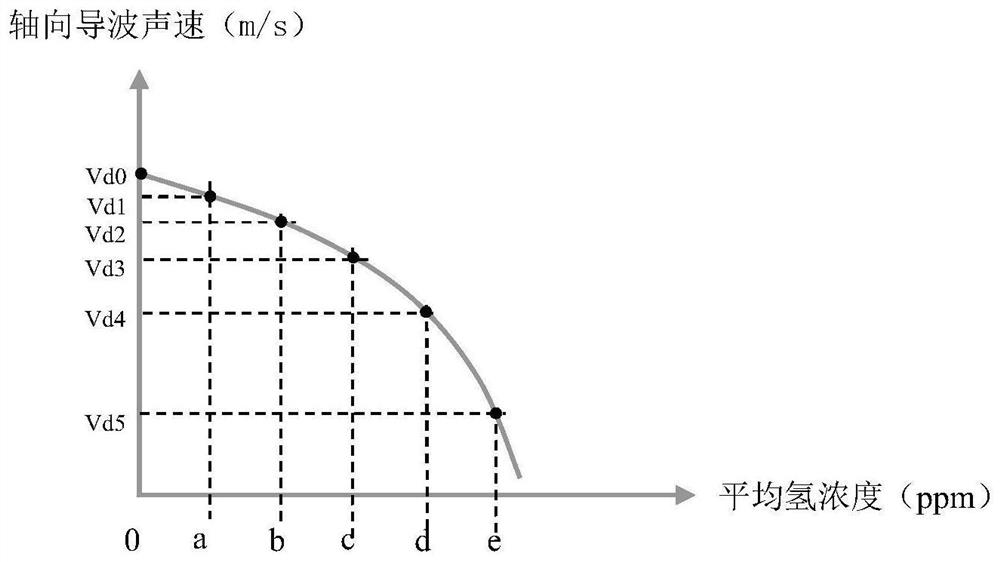

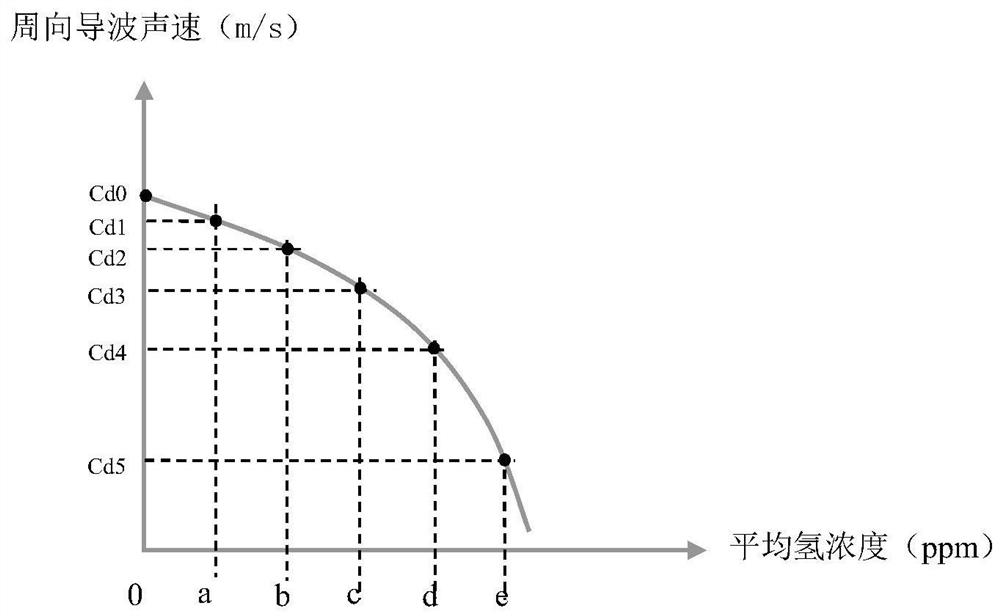

Method for detecting hydrogen damage of material through ultrasonic axial guided wave sound velocity

ActiveCN113176332AWide range of testsEasy to installAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationHydrogen concentrationEngineering

The invention discloses a method for detecting hydrogen damage of a material through ultrasonic axial guided wave sound velocity. The method comprises the following steps: manufacturing a group of original reference blocks, carrying out a hydrogen permeation test on the original reference blocks, manufacturing an axial hydrogen damage reference block group, erecting an ultrasonic axial guided wave sound velocity detection system, testing the axial guided wave sound velocity of the axial hydrogen damage reference block group, measuring the average hydrogen concentration, drawing an axial guided wave sound velocity-average hydrogen concentration reference curve, and detecting the hydrogen damage degree of the in-service to-be-detected hydrogen equipment. According to the method, the corresponding relation between the axial guided wave sound velocity change and the material hydrogen damage degree is found out, a material axial guided wave sound velocity-material average hydrogen concentration reference curve is drawn, and then the hydrogen damage condition of chemical oil refining hydrogenation and hydrogen-contacting equipment which is small in in-service inner diameter and cannot enter or stop is evaluated. According to the method, the detection process is low in cost, the detected in-service hydrogen-contacting equipment does not need to be shut down, and the method has a very positive effect on hydrogen damage monitoring of the in-service chemical oil refining hydrogen-contacting equipment.

Owner:国能锅炉压力容器检验有限公司

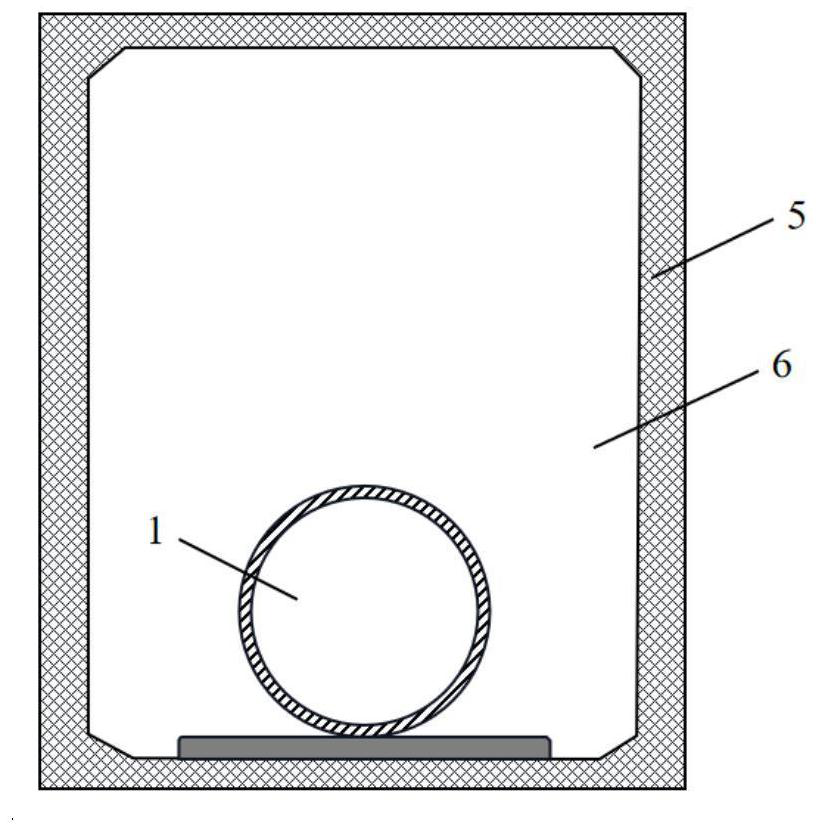

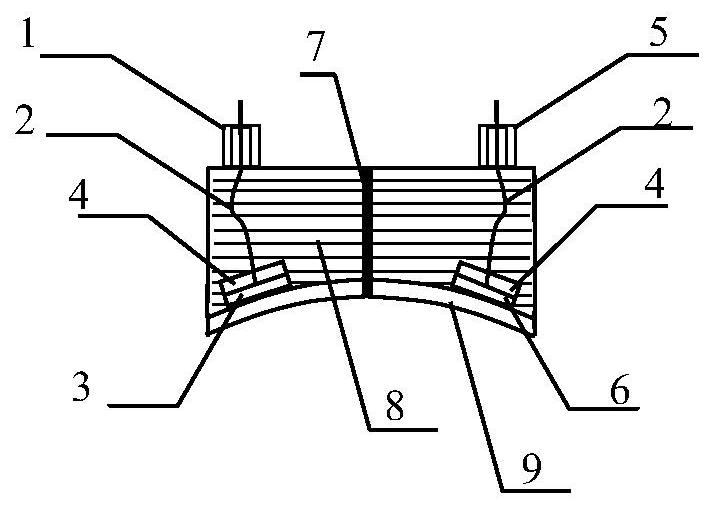

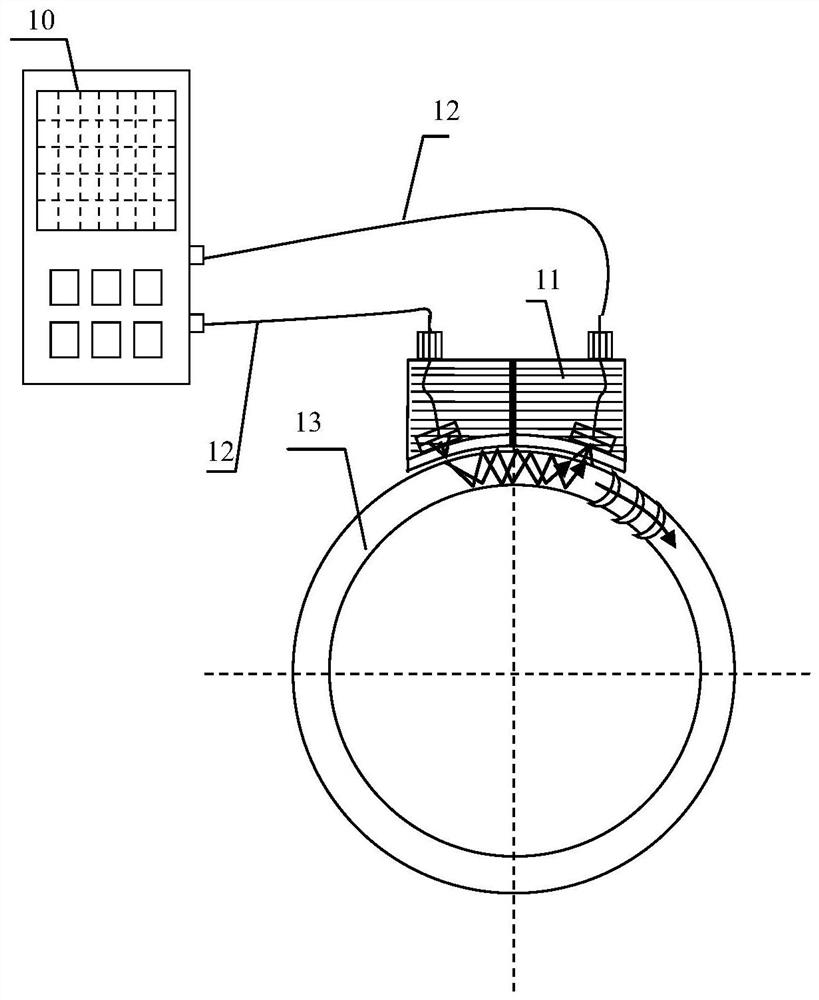

Method for detecting hydrogen damage of material through ultrasonic circumferential guided wave sound velocity

ActiveCN113176331AEnhanced couplingWide range of testsAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationHydrogen concentrationEngineering

The invention discloses a method for detecting hydrogen damage of a material through ultrasonic circumferential guided wave sound velocity. The method comprises the following steps: manufacturing a group of original reference blocks, carrying out a hydrogen permeation test on the original reference blocks, manufacturing a circumferential hydrogen damage annular reference block group, setting up an ultrasonic axial guided wave sound velocity detection system. testing the circumferential guided wave sound velocity of the circumferential hydrogen damage annular reference block group, determining the average hydrogen concentration, drawing a circumferential guided wave sound velocity-average hydrogen concentration reference curve, and detecting the hydrogen damage degree of the in-service hydrogen equipment to be detected. According to the method, the corresponding relation between the sound velocity change of the circumferential guide waves and the hydrogen damage degree of the material is found out, a reference curve of the sound velocity of the circumferential guide waves of the material and the average hydrogen concentration of the material is drawn, and then the hydrogen damage condition of chemical oil refining hydrogenation and hydrogen-contacting equipment which is small in in-service inner diameter and cannot enter or stop is evaluated. According to the method, the detection process is low in cost, the detected in-service hydrogen-contacting equipment does not need to be shut down, and the method has a very positive effect on hydrogen damage monitoring of the in-service chemical oil refining hydrogen-contacting equipment.

Owner:国能锅炉压力容器检验有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com