Patents

Literature

377results about How to "Wide range of tests" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Simulation test equipment and method for moonlet attitude control reliability validation

InactiveCN101344788AWithout breaking integrityImprove test accuracyElectric testing/monitoringControl signalPrice ratio

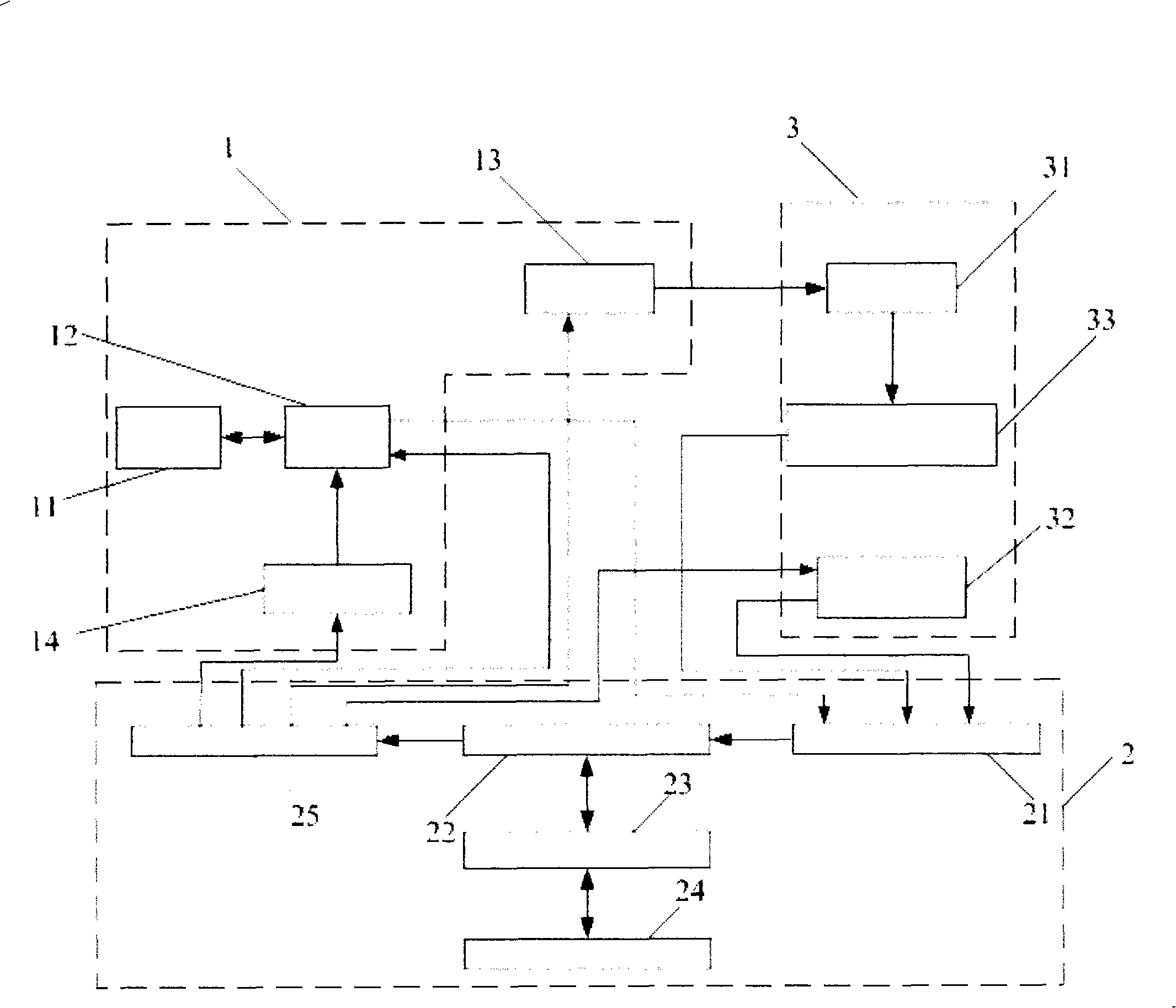

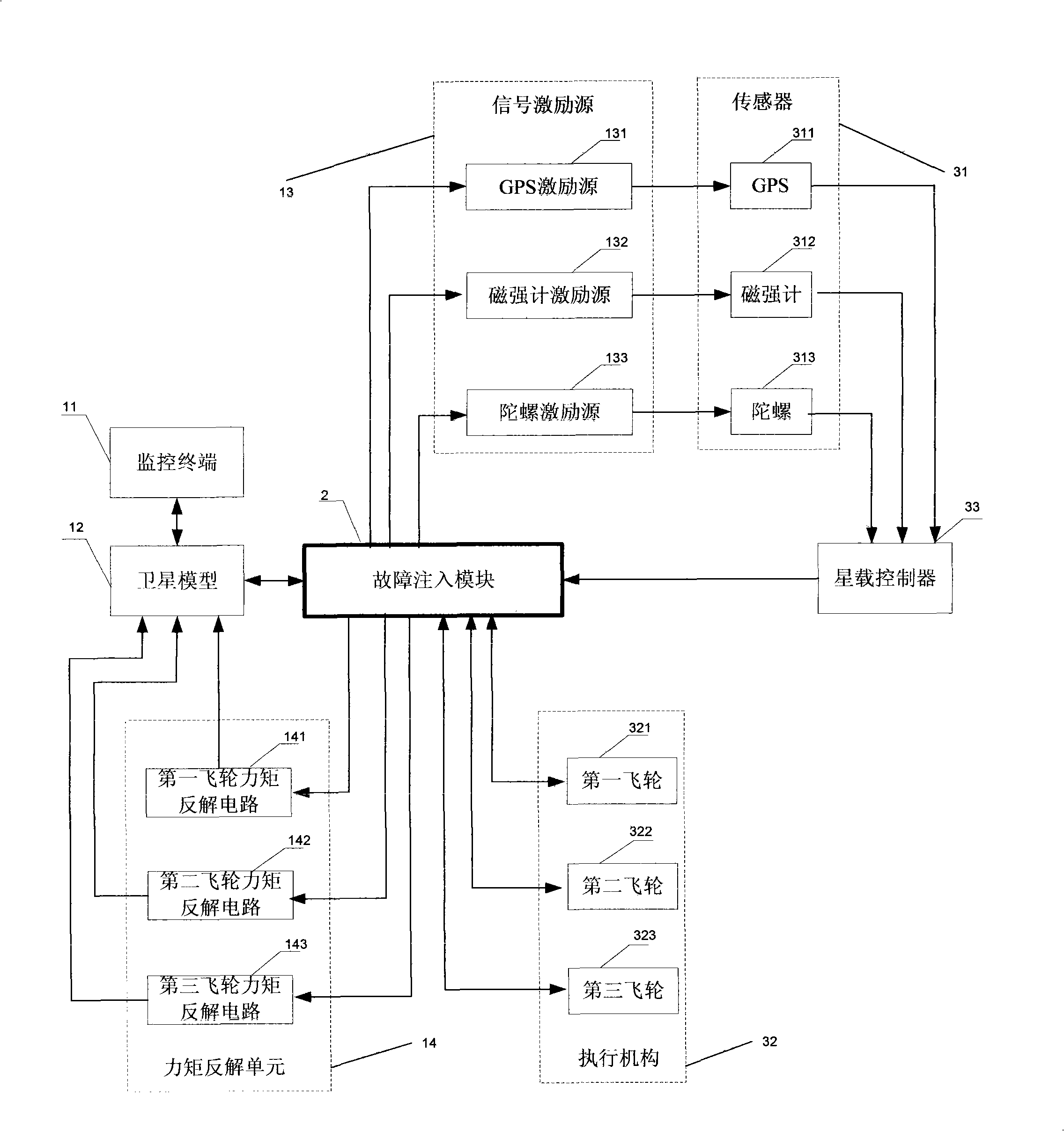

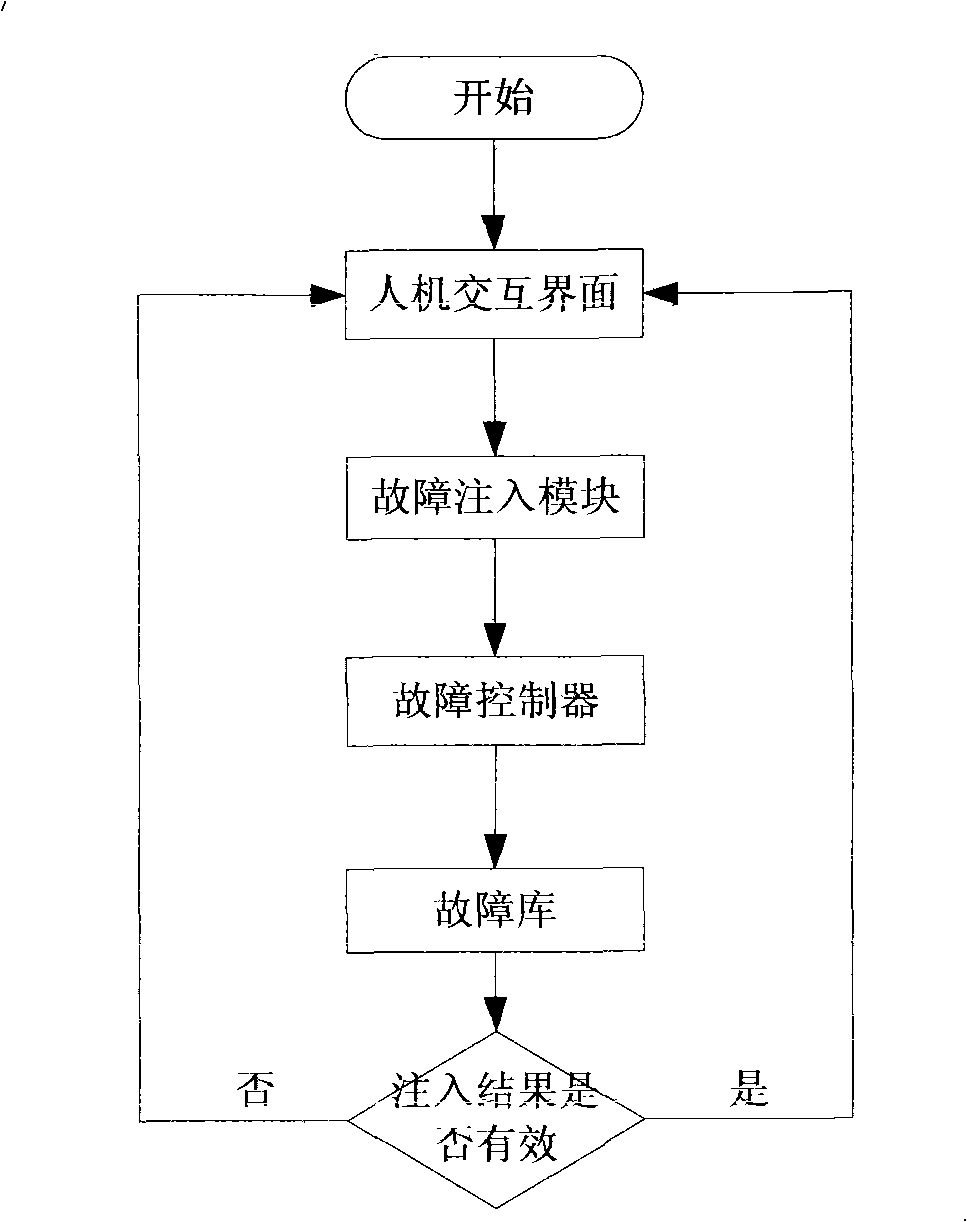

Simulation test equipment for validating the reliability of satellite attitude control and a test method thereof belong to the field of satellite attitude control. The test equipment comprises a ground simulation support module, a fault injection module and a satellite-born module, wherein, the ground simulation support module includes a monitoring terminal, a satellite model, a signal exciting source and a moment reverse-solution unit; the fault injection module includes an analog-to-digital converter, a signal transfer circuit, a fault injection processor, a man-machine interface unit and a digital-to-analog converter; and the satellite-born module includes a sensor, a satellite-born controller and an actuator. The test method comprises the following steps of: fault model setting; satellite initialization; orbit and attitude information renewal; the satellite-born controller collects signals of the sensor and outputs actuator command signals to the fault injection module; the actuator receives actuator pseudo command signals and outputs feedback signals to the fault injection module; the moment reverse-solution unit collects the pseudo feedback signals output by the fault injection module and outputs moment control signals to the satellite model. The equipment and the method of the invention have high feasibility and high performance-price ratio.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

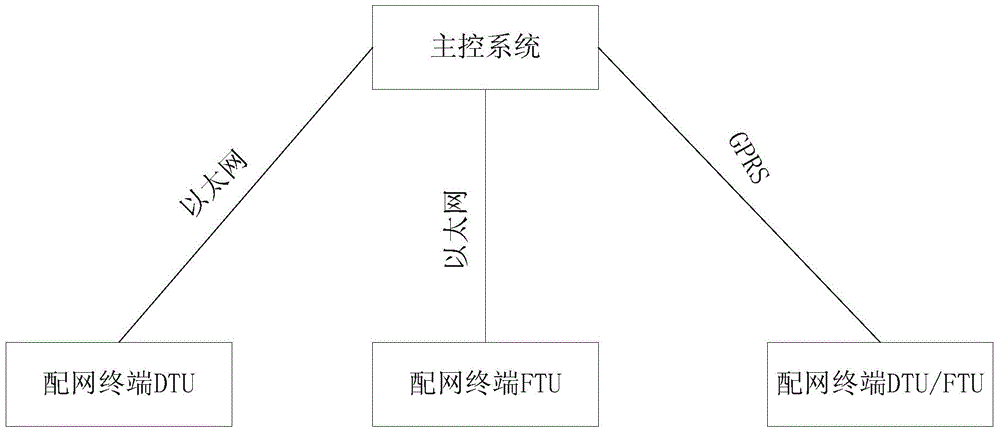

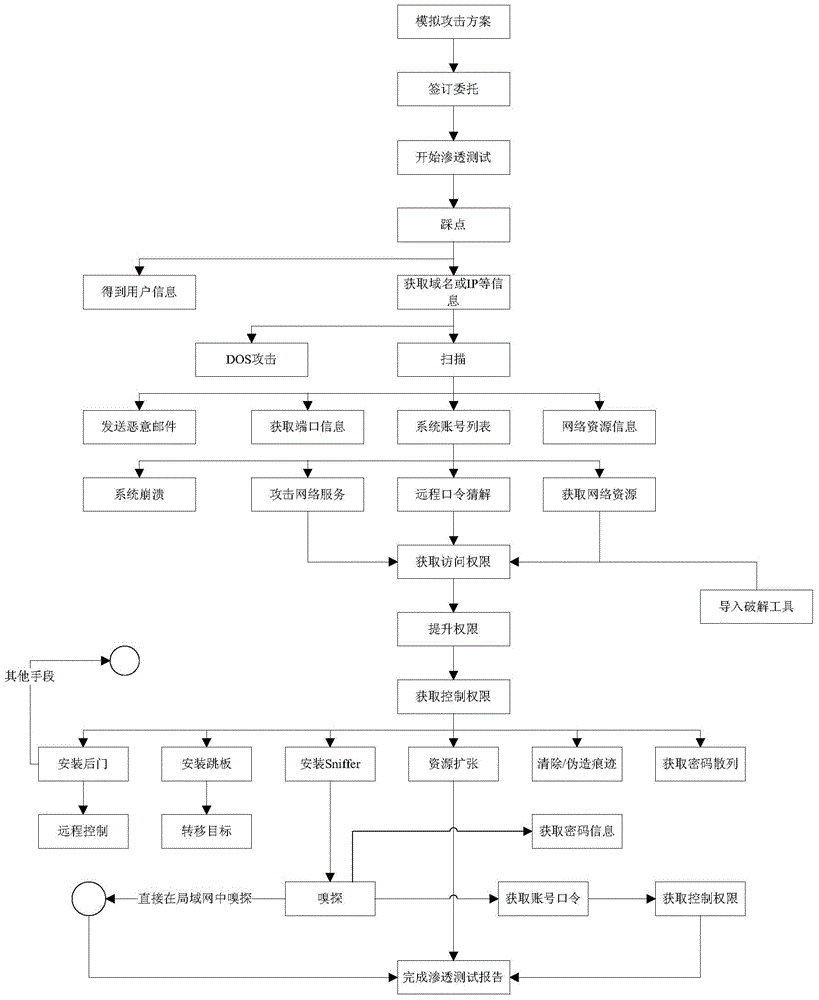

Information safety penetration testing method for distribution automation system

ActiveCN104468267AAchieve consistencyImplementations should be consistent withData switching networksThe InternetMaster station

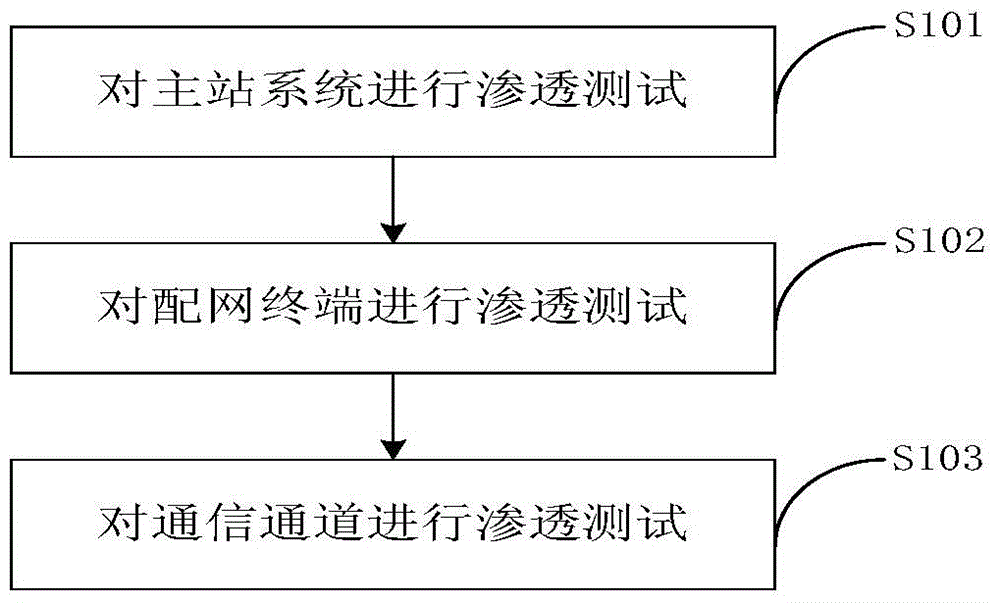

The invention discloses an information safety penetration testing method for a distribution automation system. Penetration testing is carried out on a master station system, a distribution network terminal and a communication channel, the information system vulnerability penetration testing technology is fully used, the safety of the distribution automation system is evaluated by simulating the attack method of a hacker, and the information safety penetration testing method includes the active analysis for any weakness, technical defects or loopholes of the master station system, the communication circuit and the distribution network terminal. The information safety penetration testing method for the distribution automation system can be used for safety risk analysis work before the distribution automation system is connected to the internet, guidance is provided for finishing problem rectification and reformation and retest work of manufacturers with safety risks, and the method is high in pertinence and wide in test range. Compared with a traditional penetration testing method, the test time can be largely shortened, offline repairing events caused by safety problem failures after equipment is on line are reduced, the information safety penetration testing for the distribution automation system is realized, and the information safety penetration testing method can be applied to industrial control systems inside and outside the industry.

Owner:STATE GRID CORP OF CHINA +1

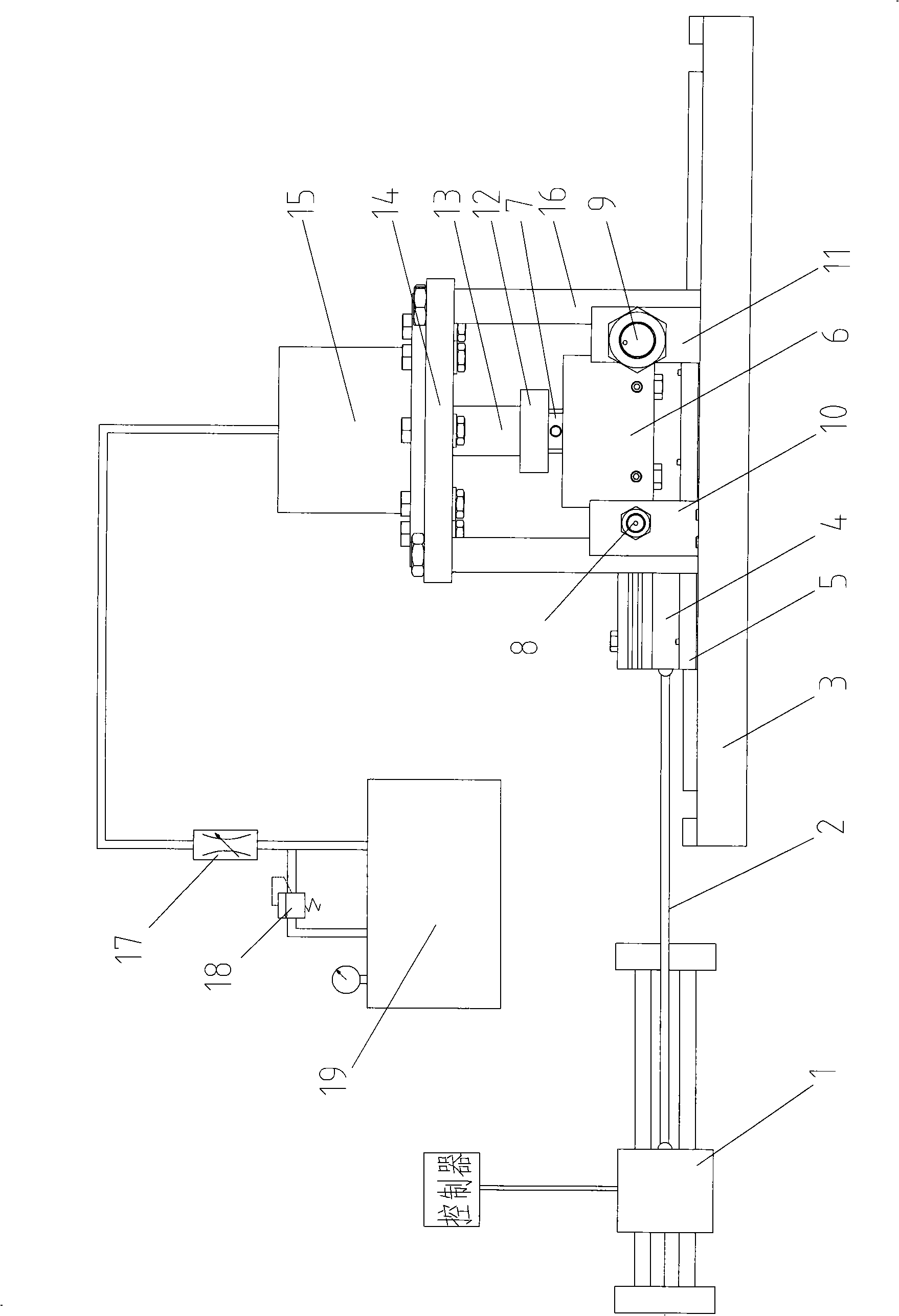

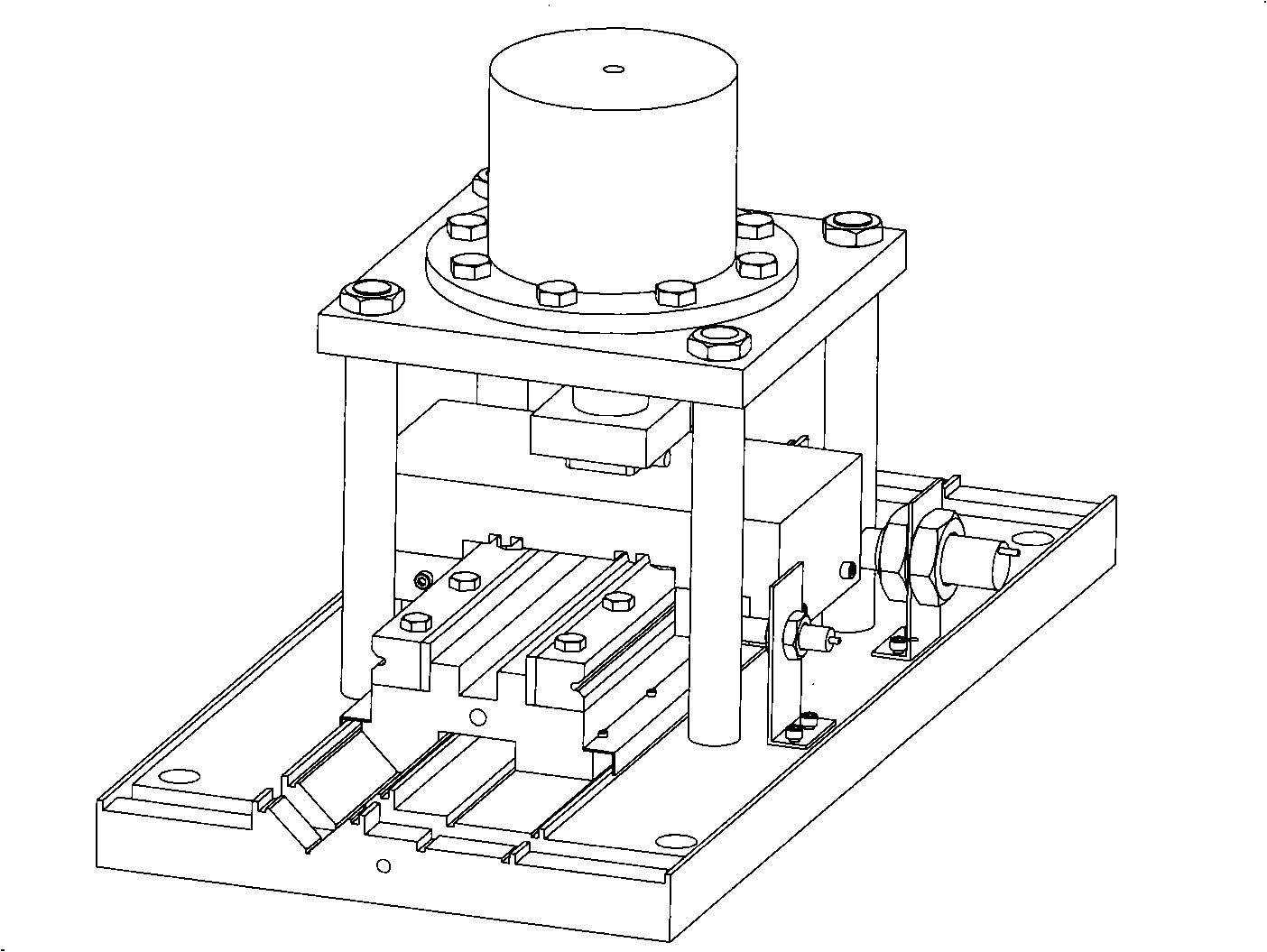

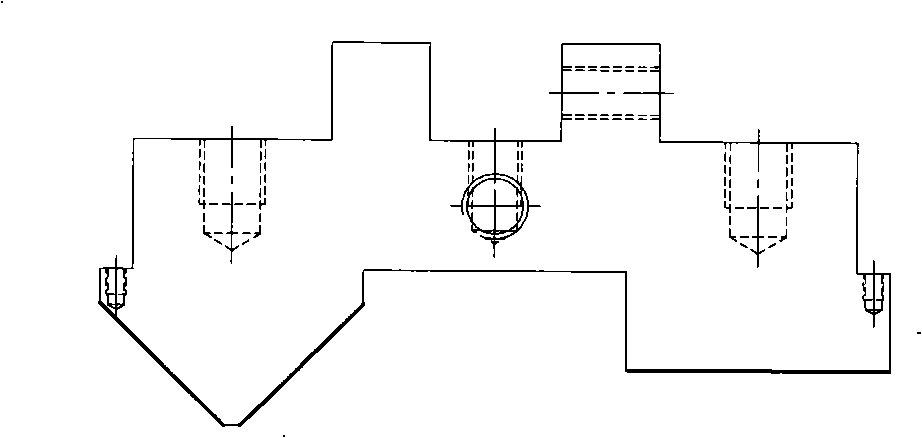

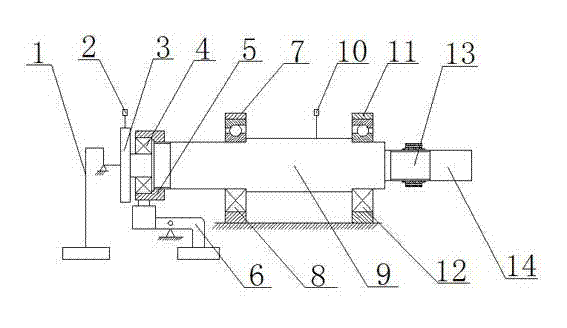

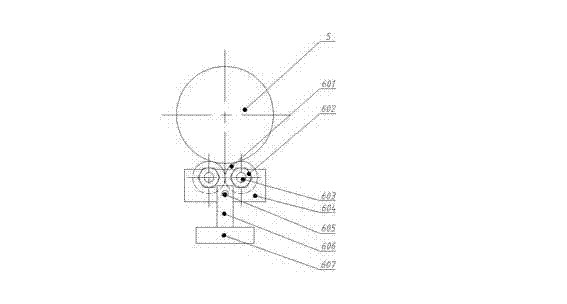

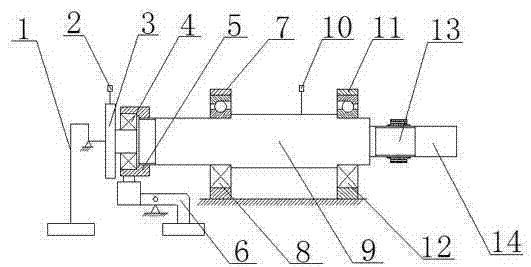

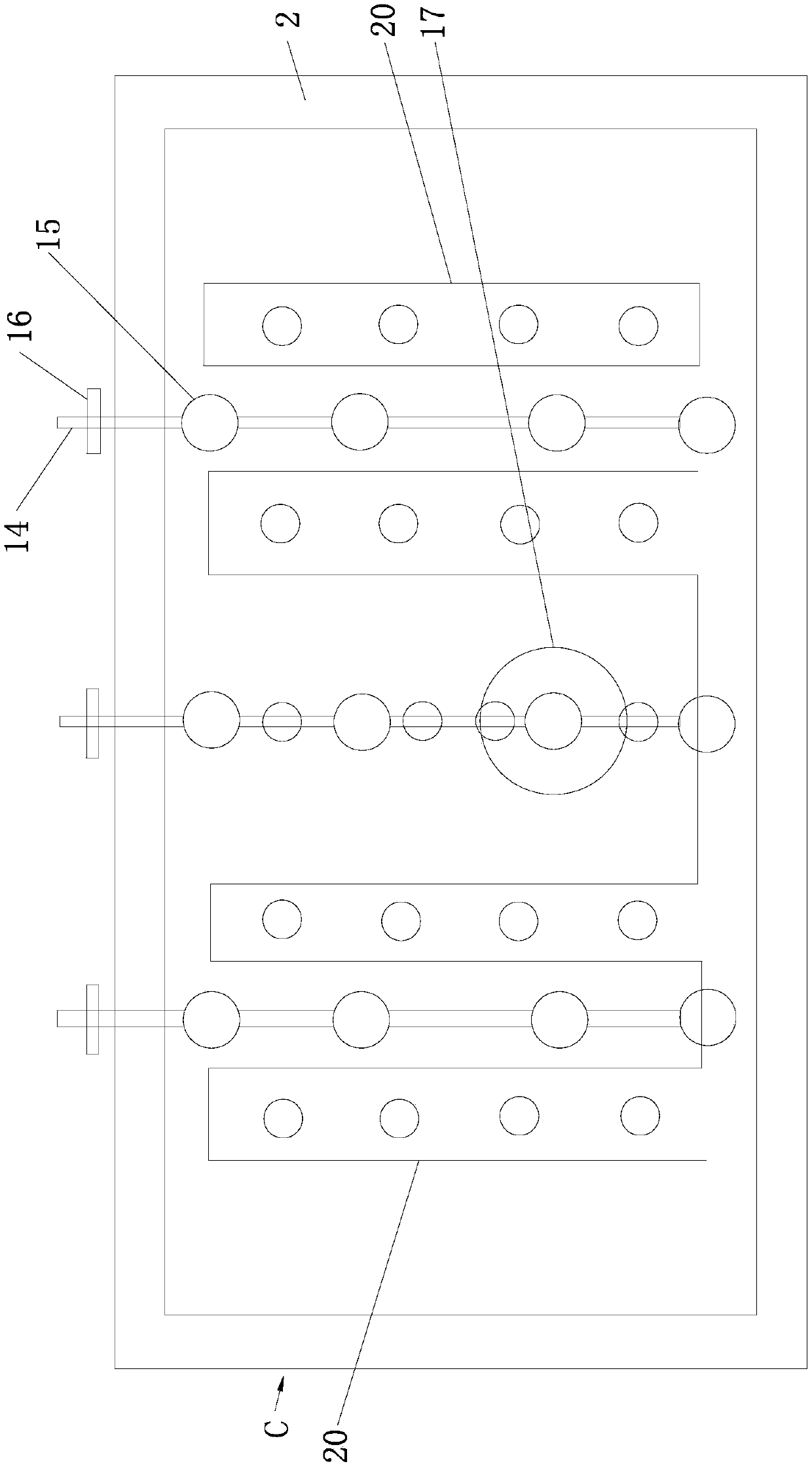

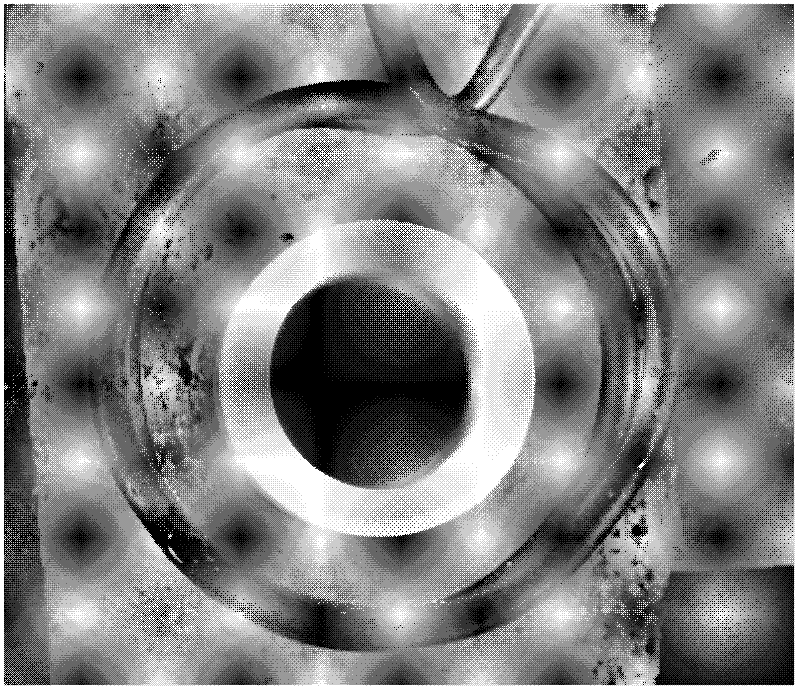

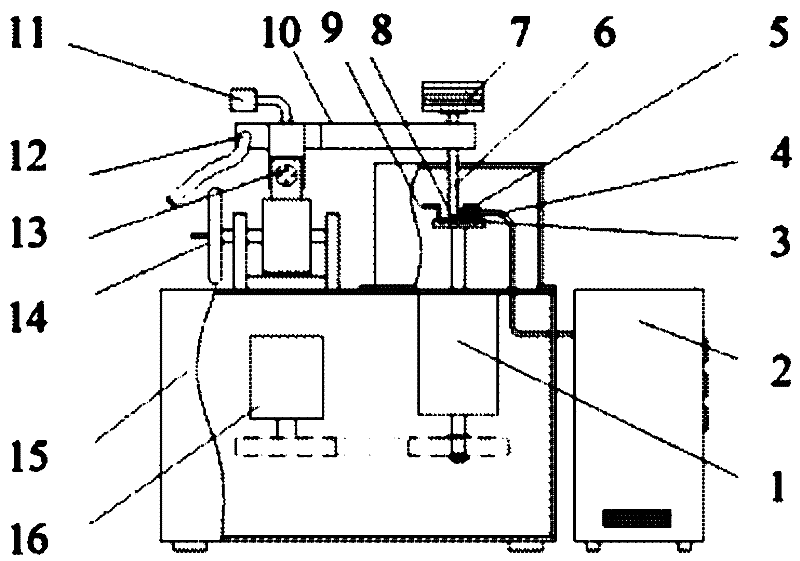

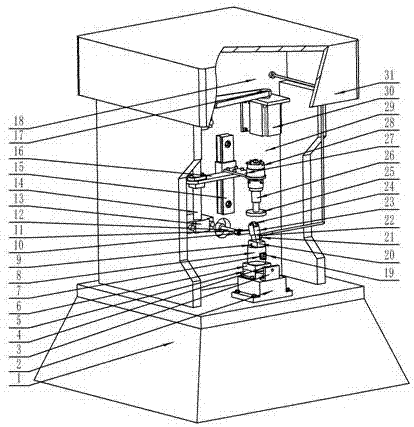

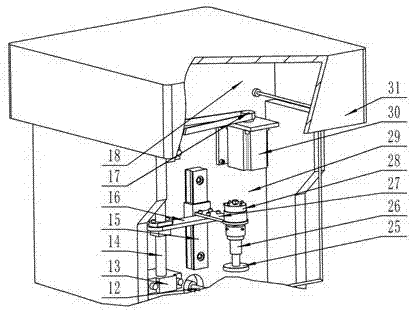

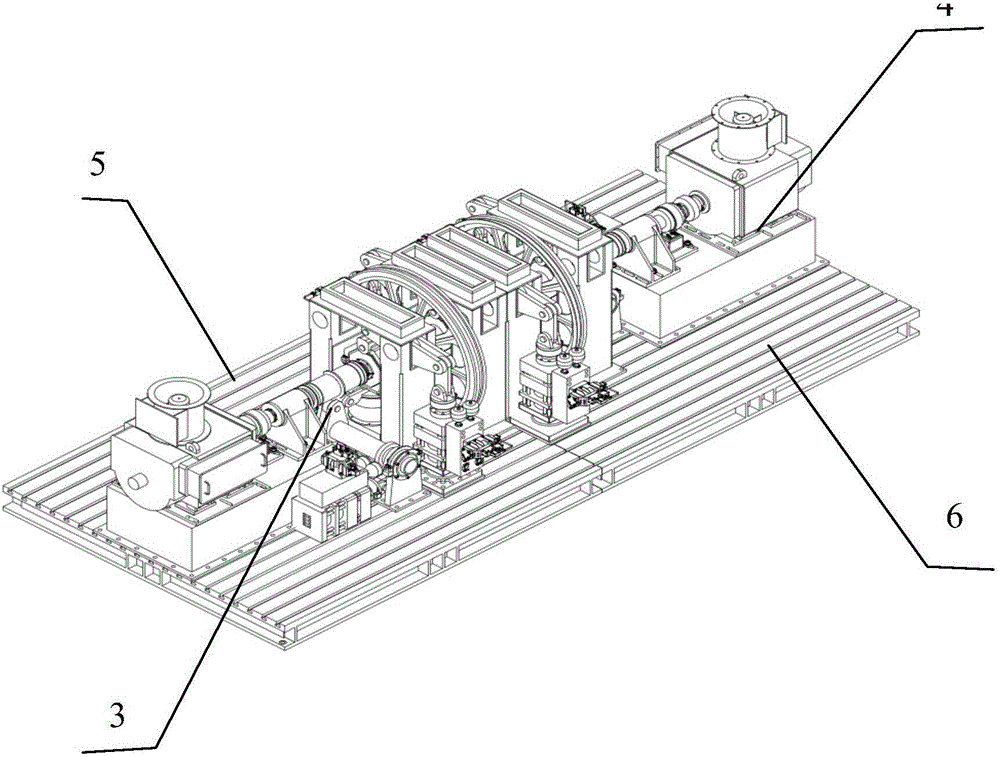

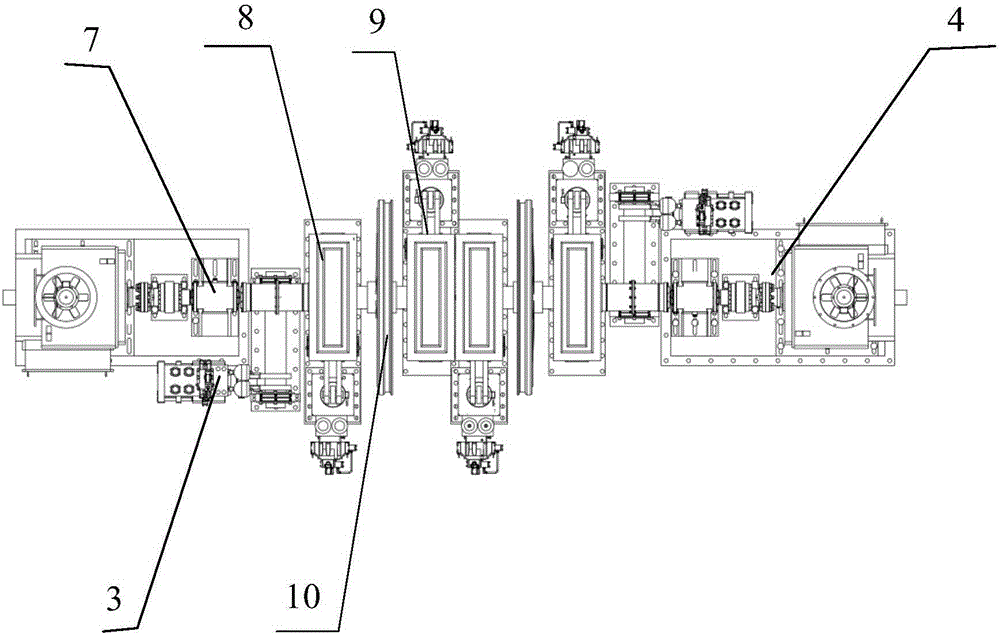

Machine tool guiding rail friction wear testing machine

InactiveCN101339112ABreakthrough the shortcoming of short lifeReduce coefficient of frictionMachine part testingInvestigating abrasion/wear resistanceWear testingEngineering

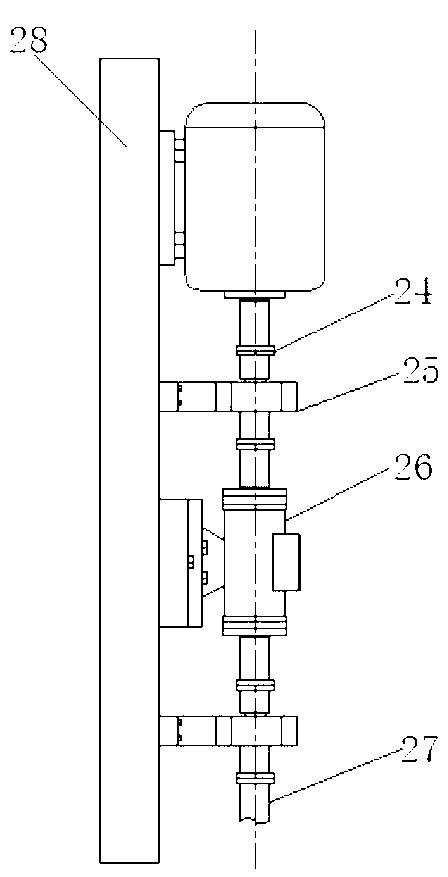

The invention provides a friction and wear testing machine of guide rail of machine tool and relates to a friction and wear testing device of guide rail pair, belonging to the technological field of tribology. The testing device comprises a testing system and a measuring system. An oil blocking plate in the testing system is provided with an upper sample platform, an oil blocking plate, a lower sample platform, a first sensor mounting bracket and a second sensor mounting bracket; the first sensor mounting bracket and the second sensor mounting bracket are respectively arranged on a base; a flat V guide rail is arranged between the lower sample platform and the base; an upper sample fixture is arranged between the first sensor mounting bracket and the second sensor mounting bracket; the first sensor mounting bracket and the second sensor mounting bracket are connected with a cover plate respectively by a support rod. The novel friction and wear testing machine of the machine tool can simulate the actual working condition, and directly adopt the guide rail as the sample. Moreover, the testing machine can not only be used for rapidly assessing the material of the guide rail pair and the lubricating medium, but also can be used for the accelerated life test of the straight guide rail pair and the rolling guide rail pair.

Owner:SOUTHEAST UNIV

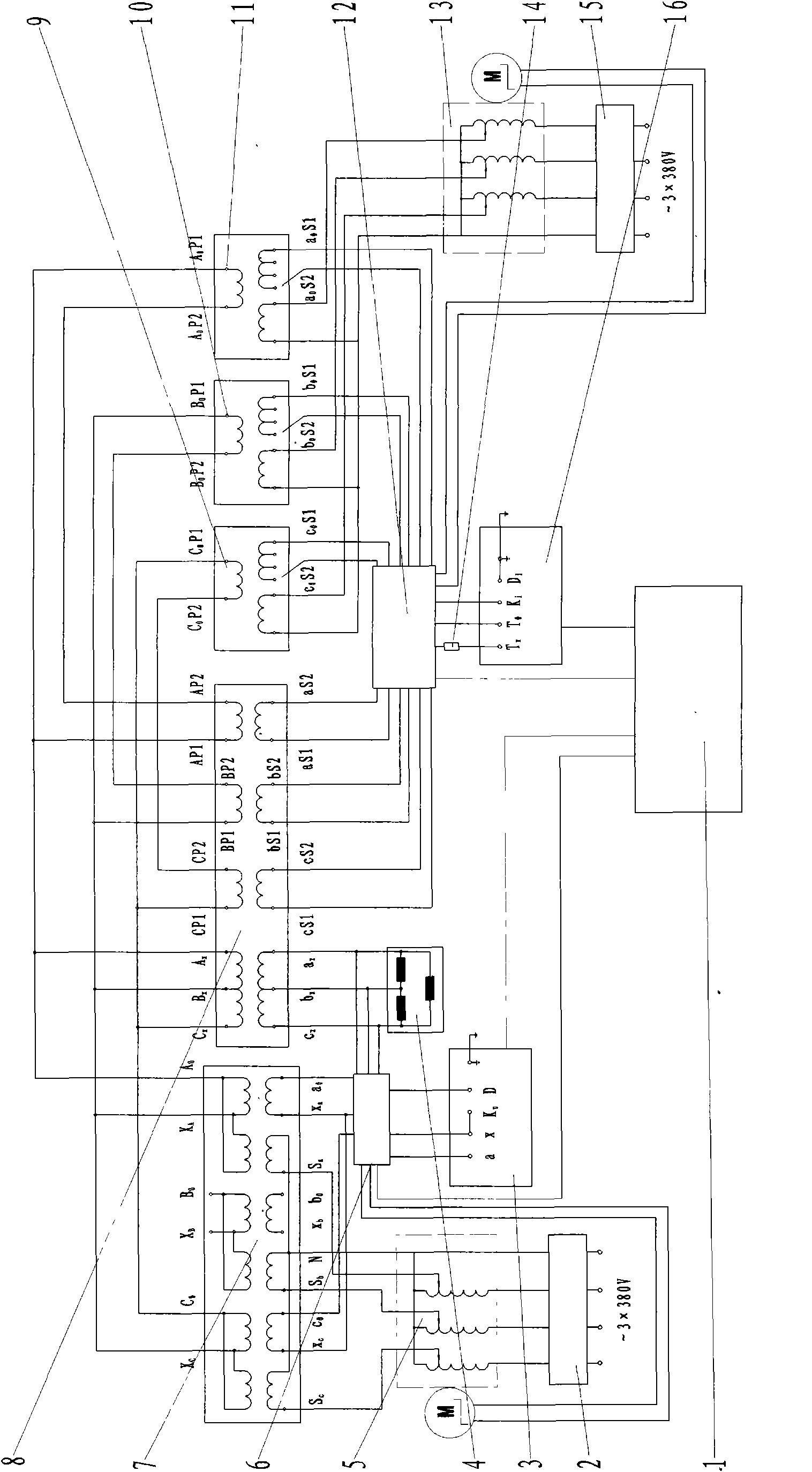

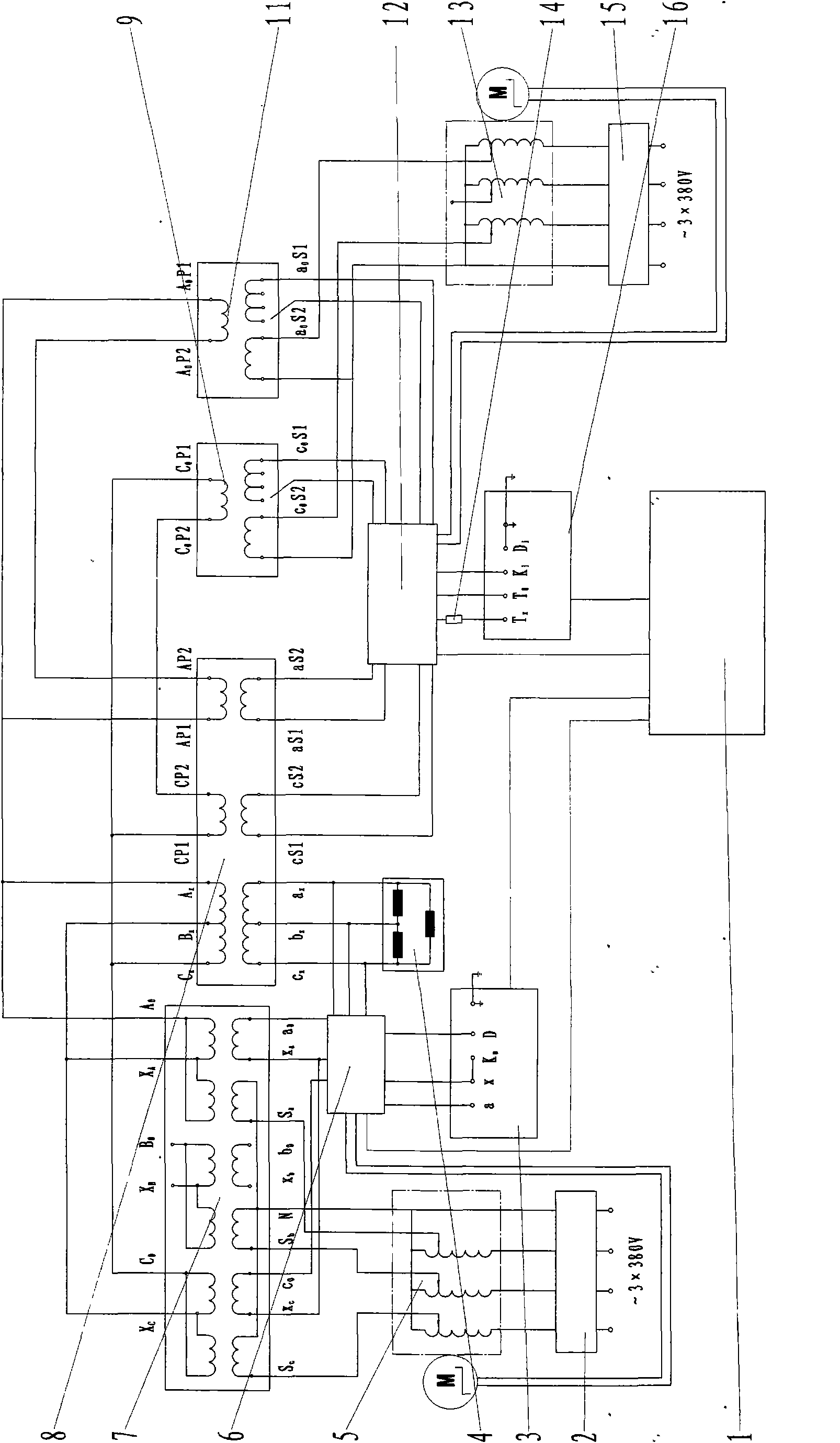

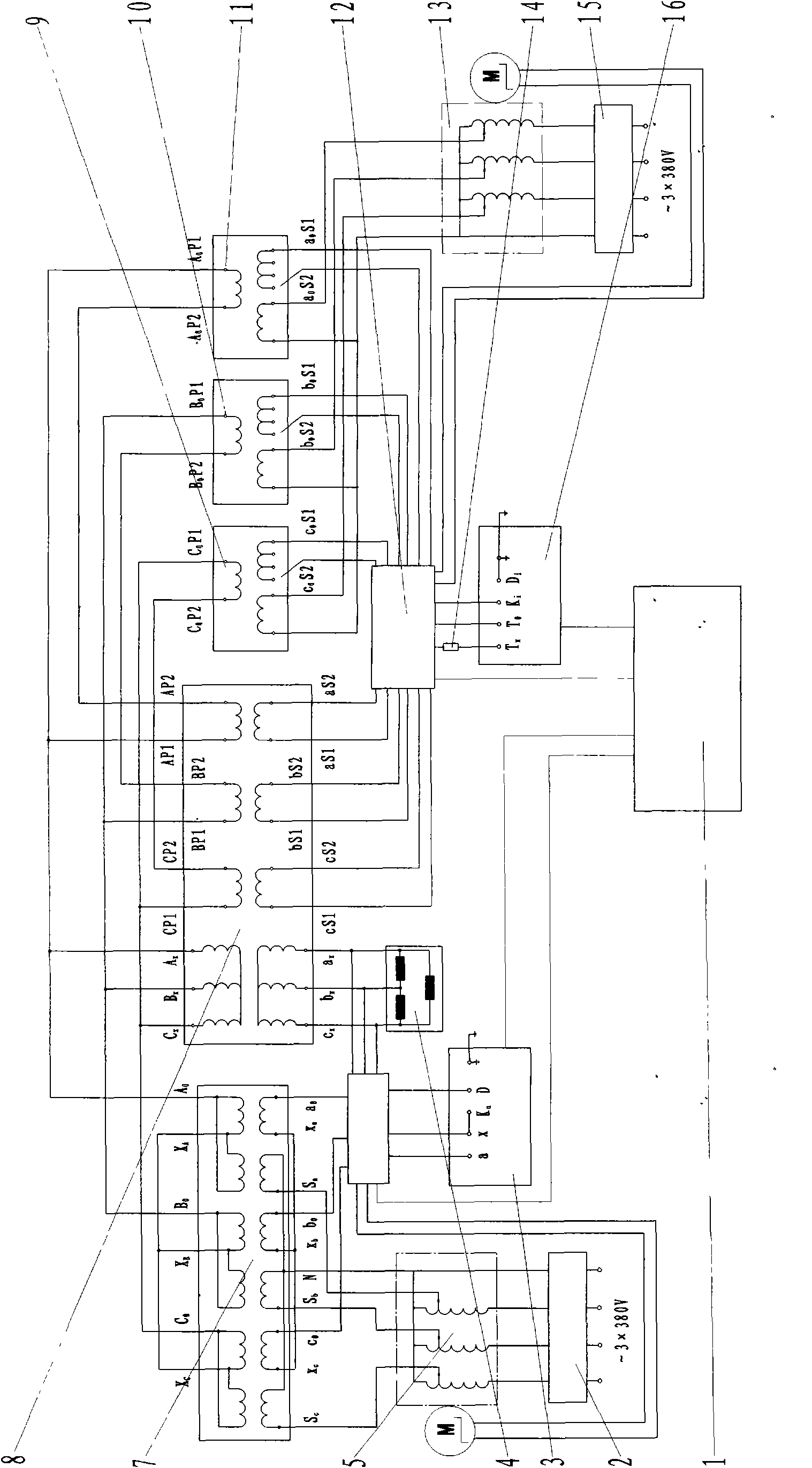

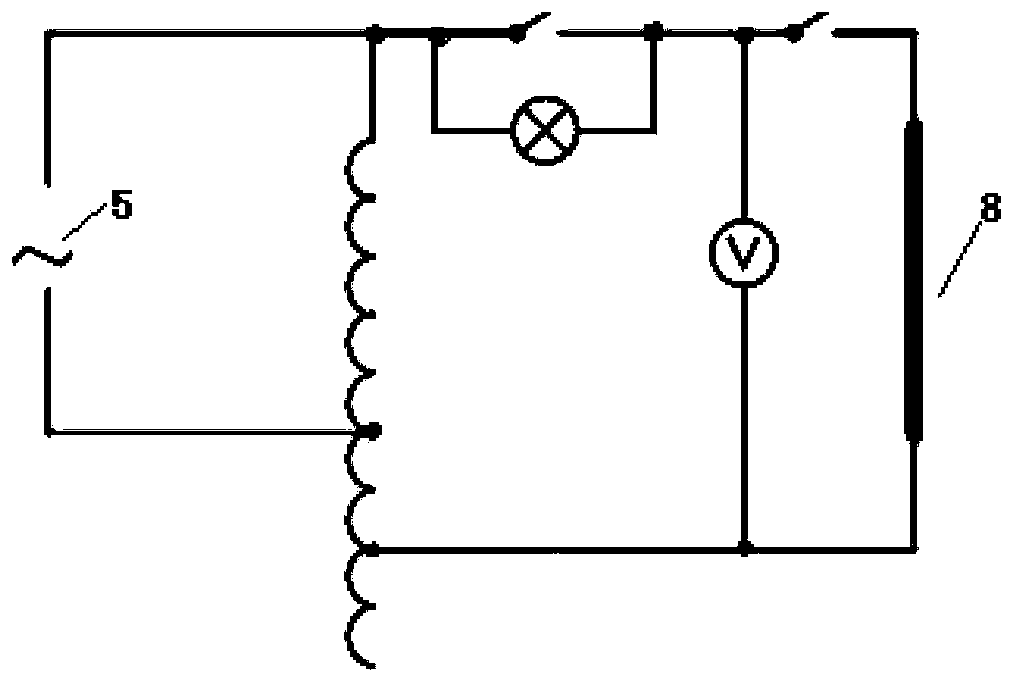

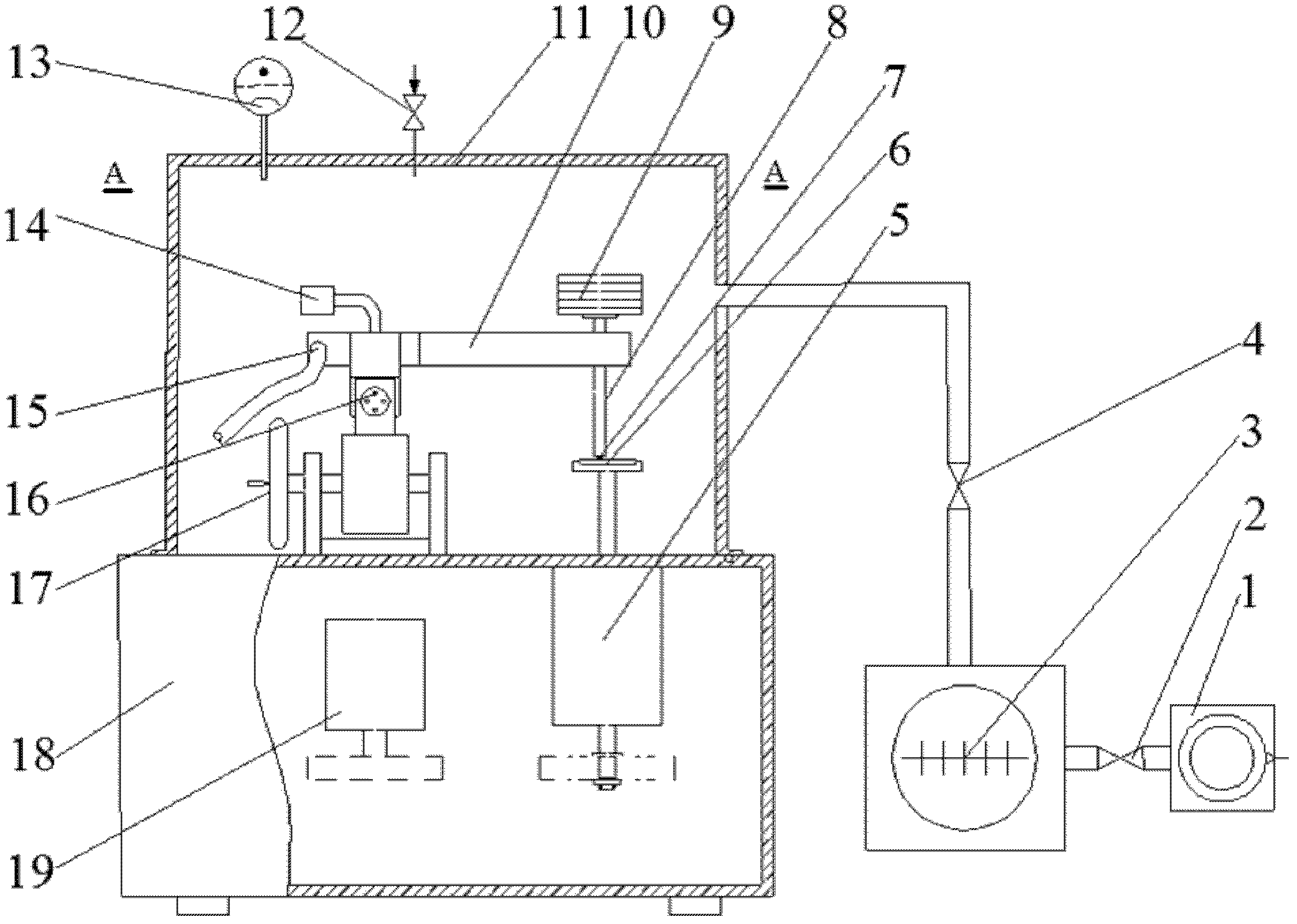

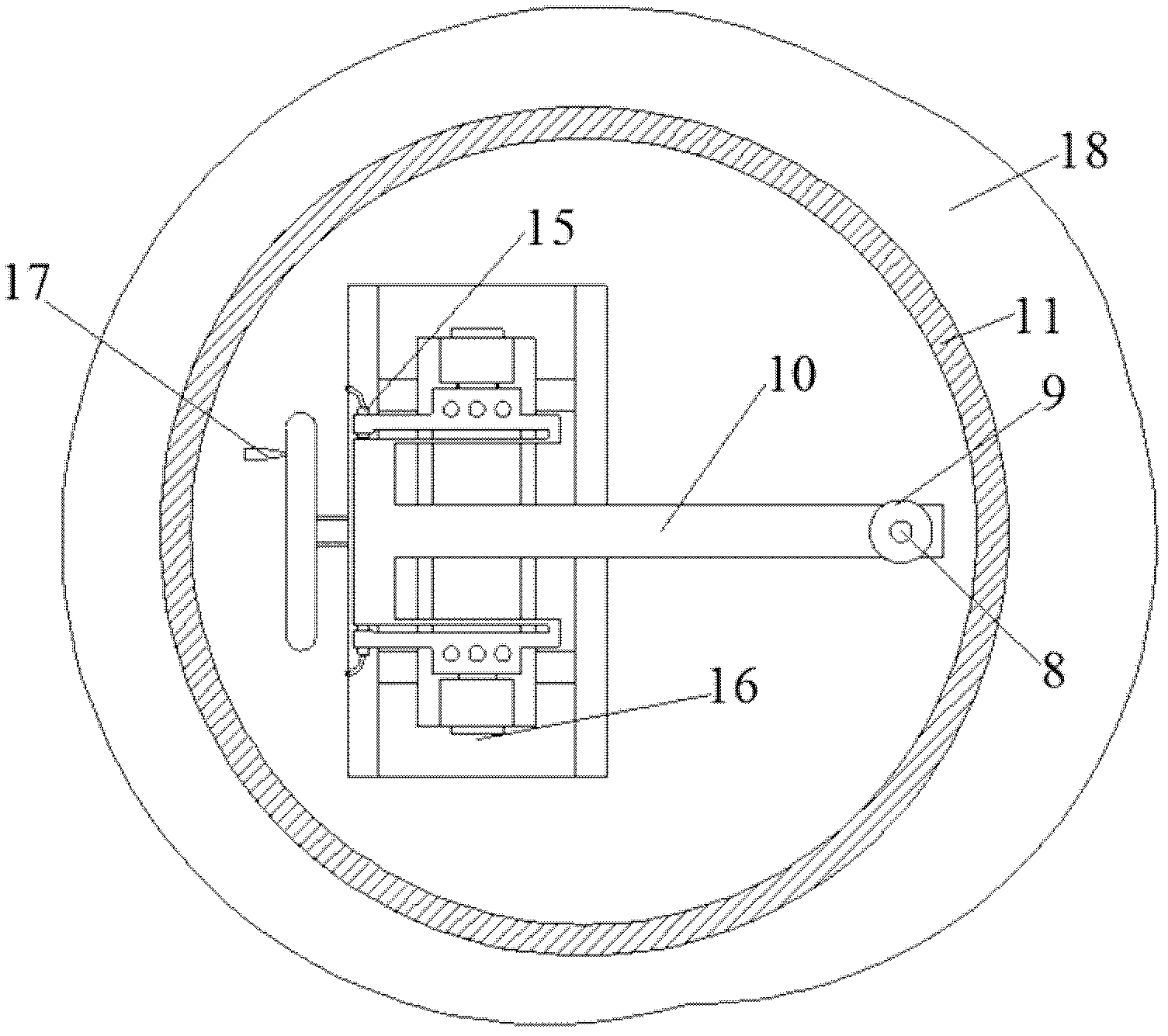

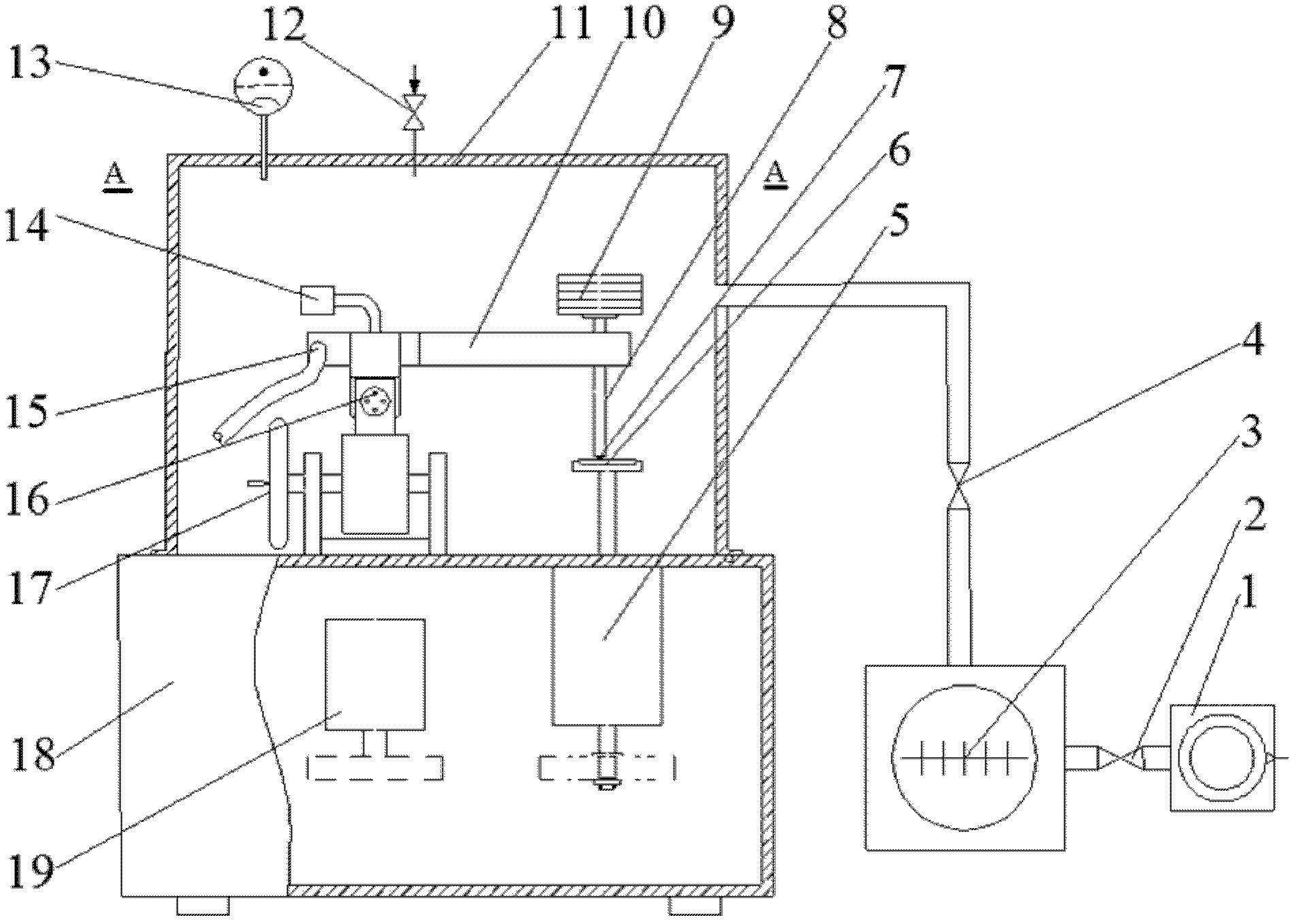

Testing device for high-voltage three-phase combination transformer

ActiveCN101625403AEasy to implement inspectionCheck trueElectrical measurementsTransformerEngineering

The invention discloses a testing device for a high-voltage three-phase combination transformer, in order to solve the problems of low working efficiency caused by multiple times of wiring experiments and errors caused by not considering the interferences between phases in the existing single-phase calibration method, and stimulates the condition of actual work to test the error change when the combination transformer works. The testing device comprises a computer control and information management system (1), a zero position and over-load protection module (2) of a voltage circuit, a single-phase voltage transformer calibrator (3), a three-phase voltage load box (4), an electrical three-phase voltage regulator (5) used by a voltage transformer, a three-phase voltage transformer conversion and control module (6), an integrated three-phase self-contained booster standard voltage transformer (7) and the voltage part of a three-phase combination transformer (8) under test; a three-phase power supply is connected into the electrical three-phase voltage regulator (5) used by the voltage transformer through the zero position and over-load protection module (2) of the voltage circuit; and the electrical three-phase voltage regulator (5) used by the voltage transformer is wired with the booster part of the integrated three-phase self-contained standard voltage transformer (7) by adopting YN and yn. The testing device can solely form a system, and on-site test is fast and efficient.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

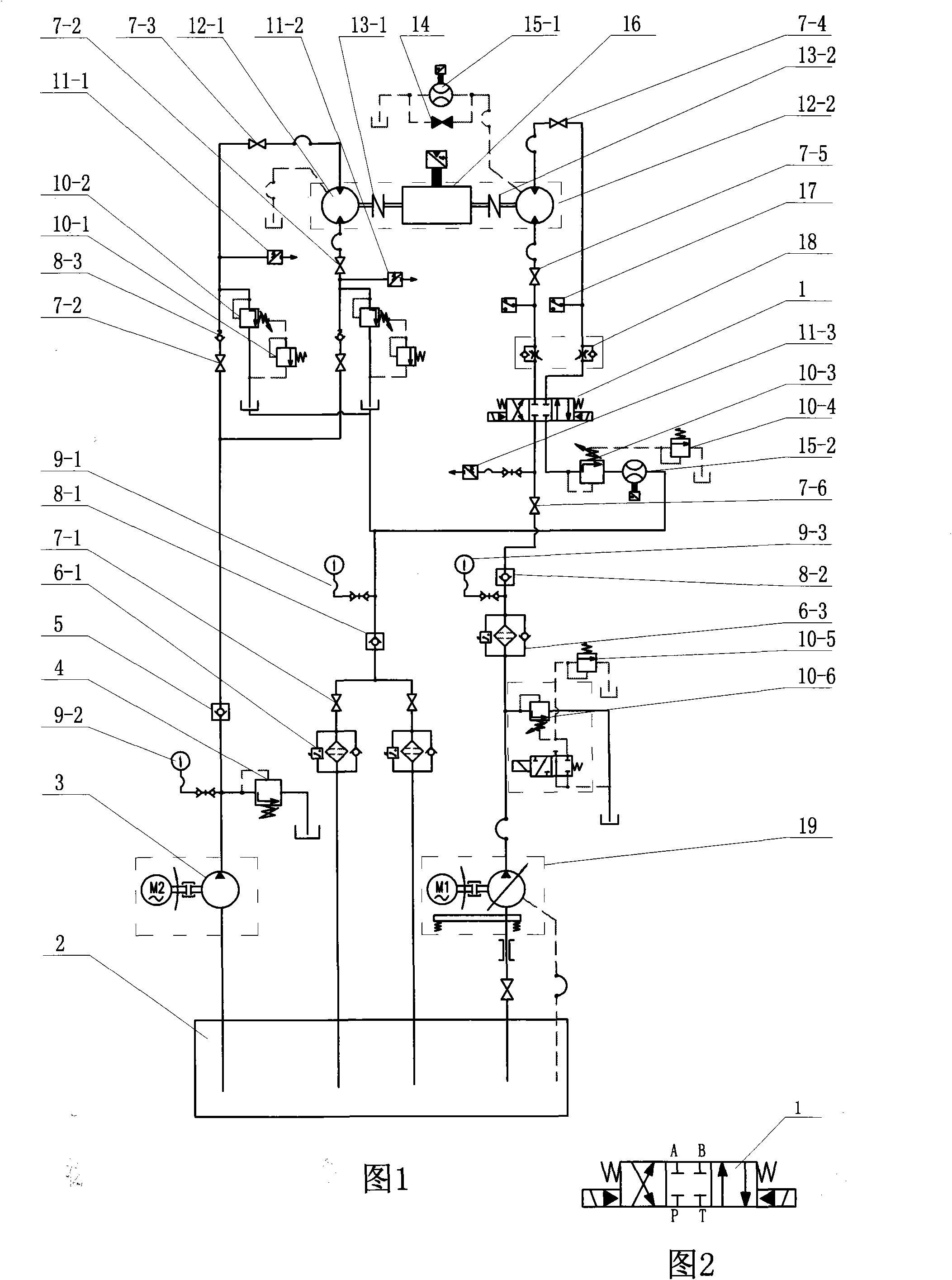

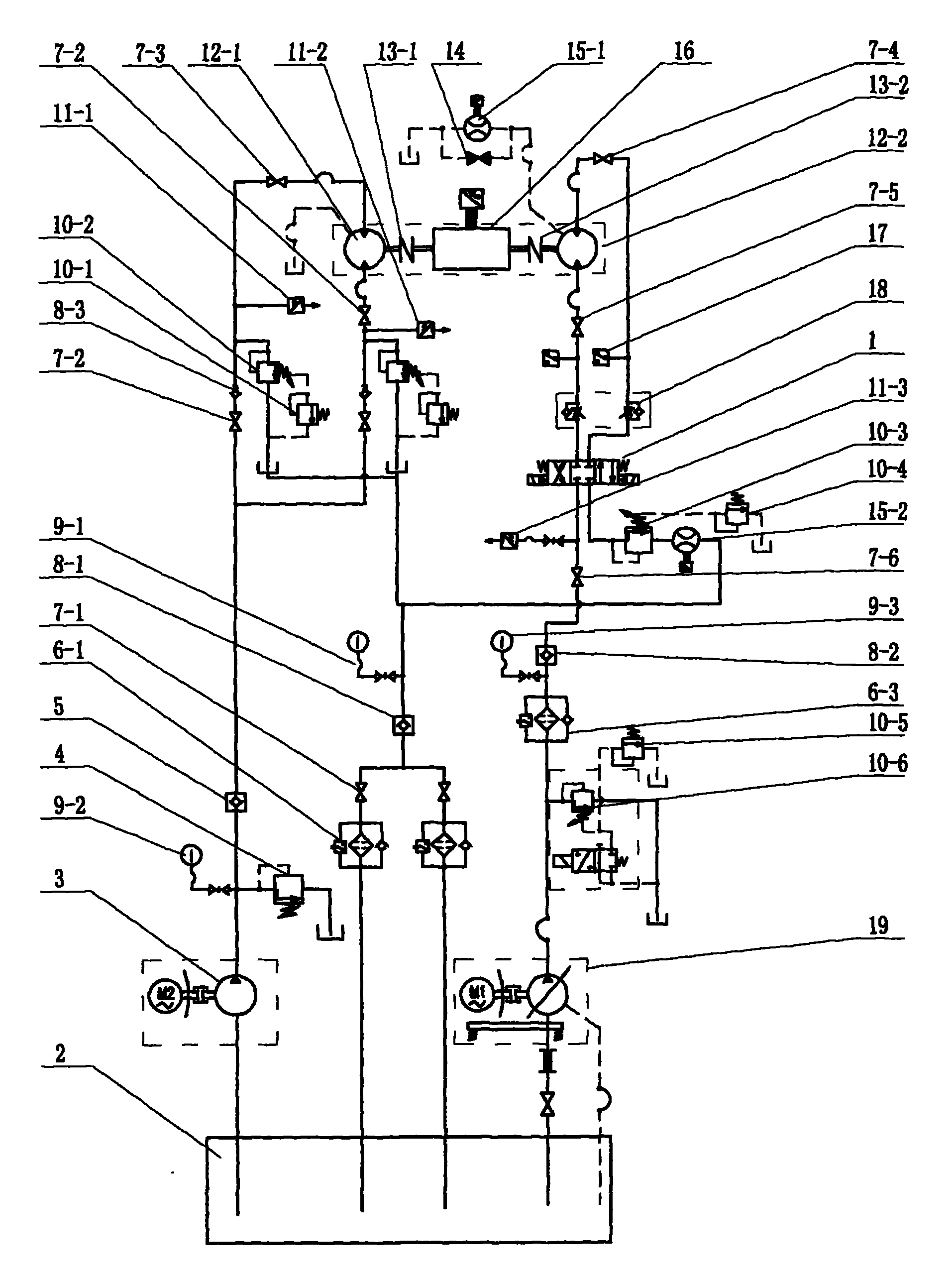

Loading device of hydraulic motor test board

ActiveCN101871478AConvenience to workReduce labor intensityFluid-pressure actuator testingHydraulic motorRemote control

The invention relates to a loading device of a hydraulic motor test board, which is characterized in that a high-pressure oil pump which is connected with an oil tank is connected with an electro-hydraulic reversing valve, a bi-direction retaining throttling valve and a test motor oil inlet through a high-pressure filter and an oil inlet retaining valve, a test motor oil outlet forms a test loop with an oil return retaining valve and an oil return filter oil return box after being connected with a remote counterbalance overflow valve, a flow-rate sensor, through the bi-direction retaining throttling valve and an electro-hydraulic reversing valve oil outlet. A loader is formed by joining a loading motor and a testing motor respectively with a rotation speed torque instrument through a coupling joint, at the same time, a low-pressure pump which is connected with the oil tank enters two ends of the loading motor through two retaining valves, the testing motor rotates to drive the loading motor to rotate, the oil outlet retaining valve is automatically closed, and the outlet oil forms a loading circuit through the counterbalance overflow valve, the remote overflow valve, the oil return retaining valve and the oil return filter oil return box. The loading motor is used for substituting an original magnetic powder loader, so the size is greatly reduced, the energy consumption is reduced, the remote control adjustment is convenient for test personnel to work, the loading force is large, torque of 60000 N.m can be tested, the testing range is wide, and the practicability is strong.

Owner:宁波恒通诺达液压股份有限公司

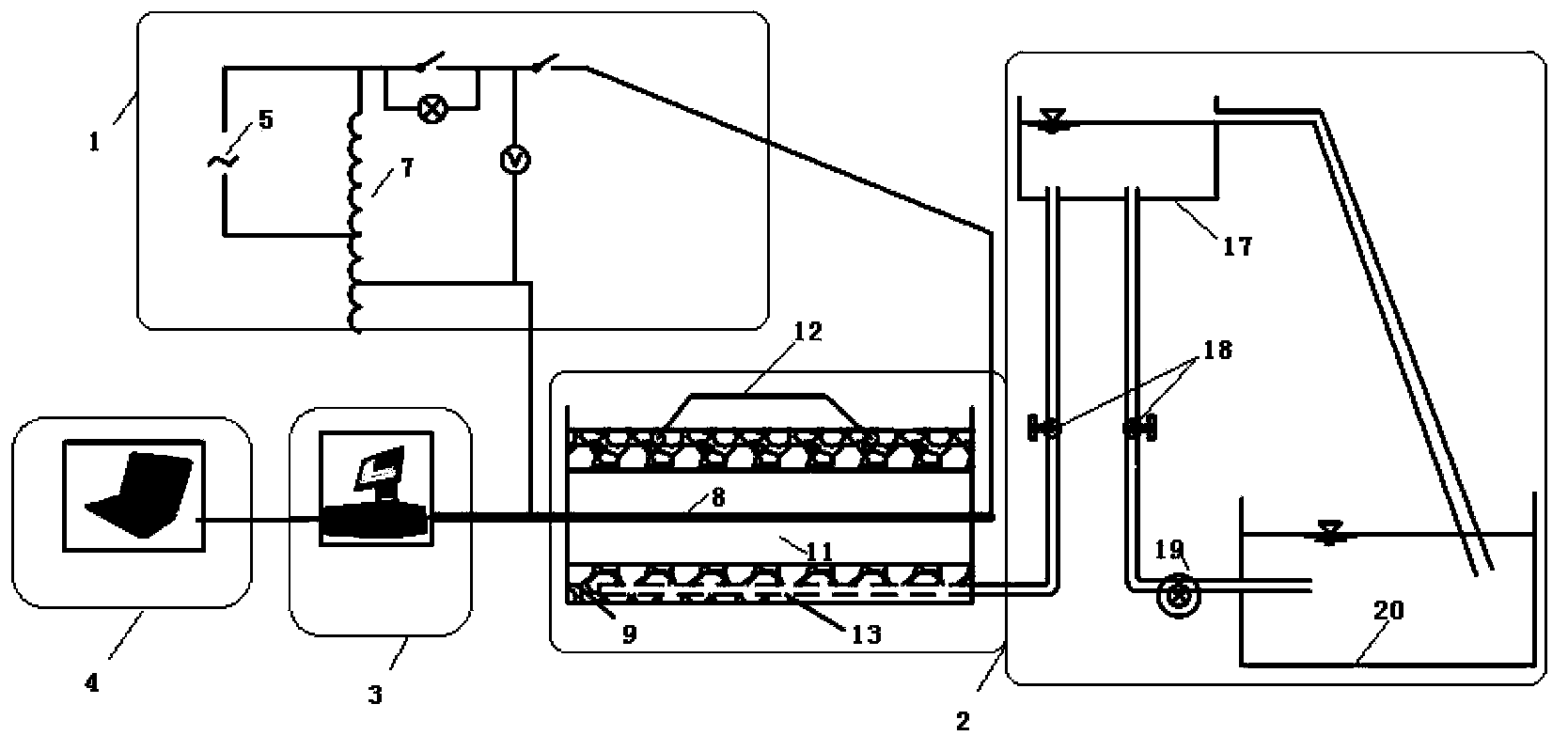

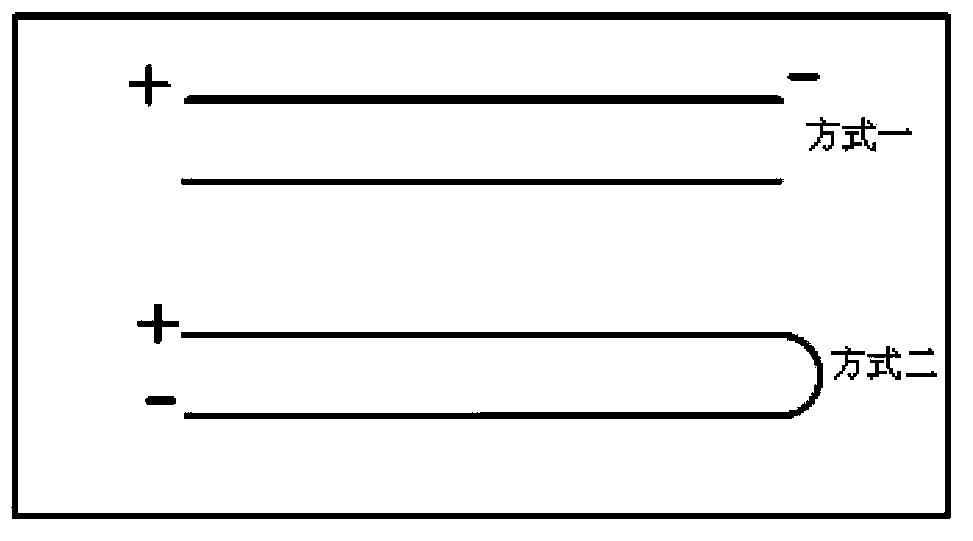

Distributed optical fiber test platform for monitoring earth rock dam seepage condition

ActiveCN103364321AImprove engineering applicabilityThe design concept is complete and novelPermeability/surface area analysisPorous mediumGeophysics

The invention discloses a distributed optical fiber test platform for monitoring an earth rock dam seepage condition. The distributed optical fiber test platform comprises a heating system, a seepage system and a DTS system; the distributed optical fiber test platform is a practical platform having strong operability, aimed at dam seepage monitoring and based on construction of a dam seepage monitoring two-field coupling simplified model; with combination of the DTS system, the distributed optical fiber test platform provides a possibility for a practical application of seepage monitoring engineering of a porous medium structural body, such as an earth rock dam and a dyke-dam, and builds a reliable test platform for various related test researches; and the distributed optical fiber test platform has the advantages of wide test range, high precision, simple layout, low monitoring cost, high working efficiency, strong engineering applicability and the like.

Owner:HOHAI UNIV

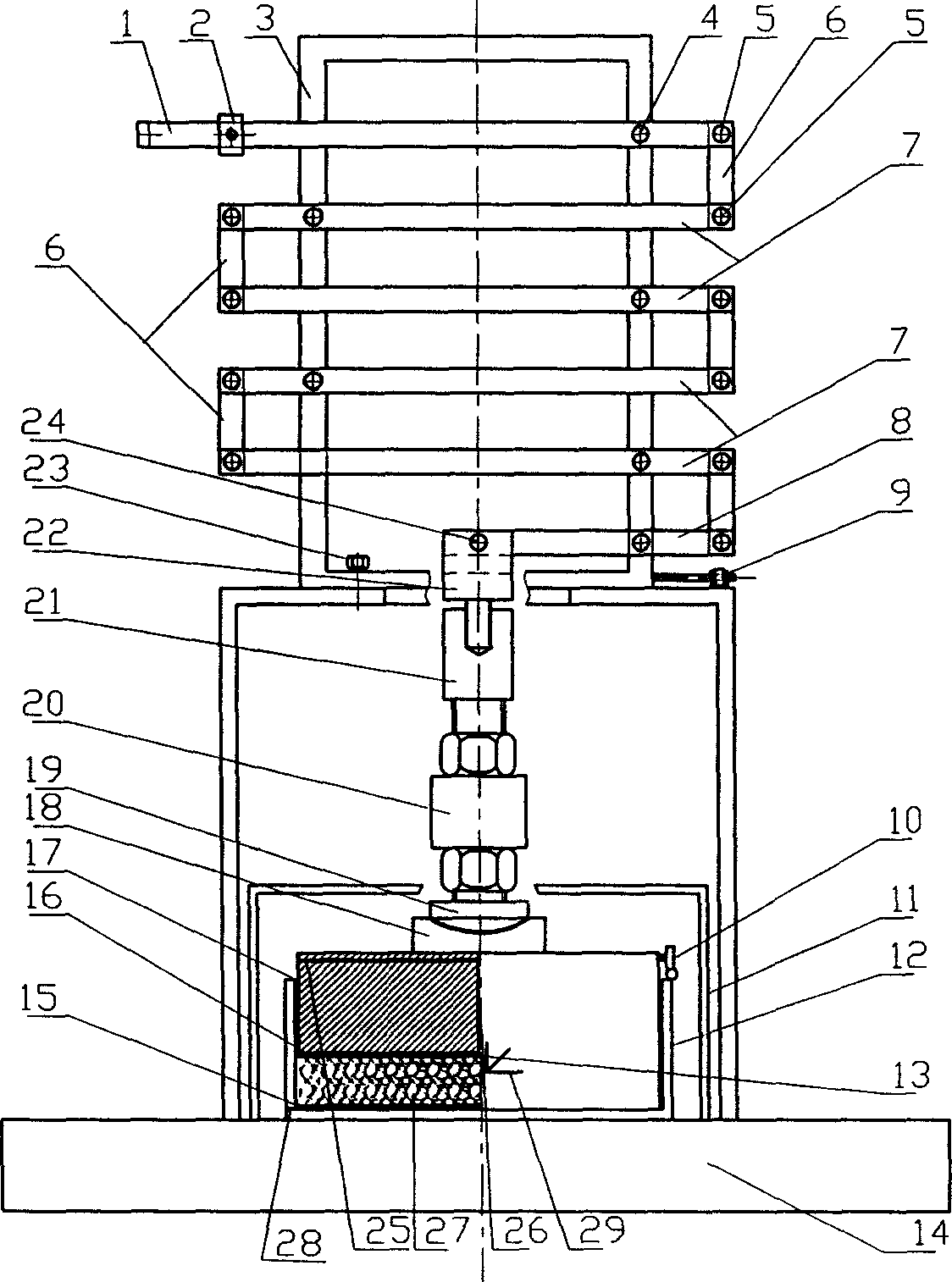

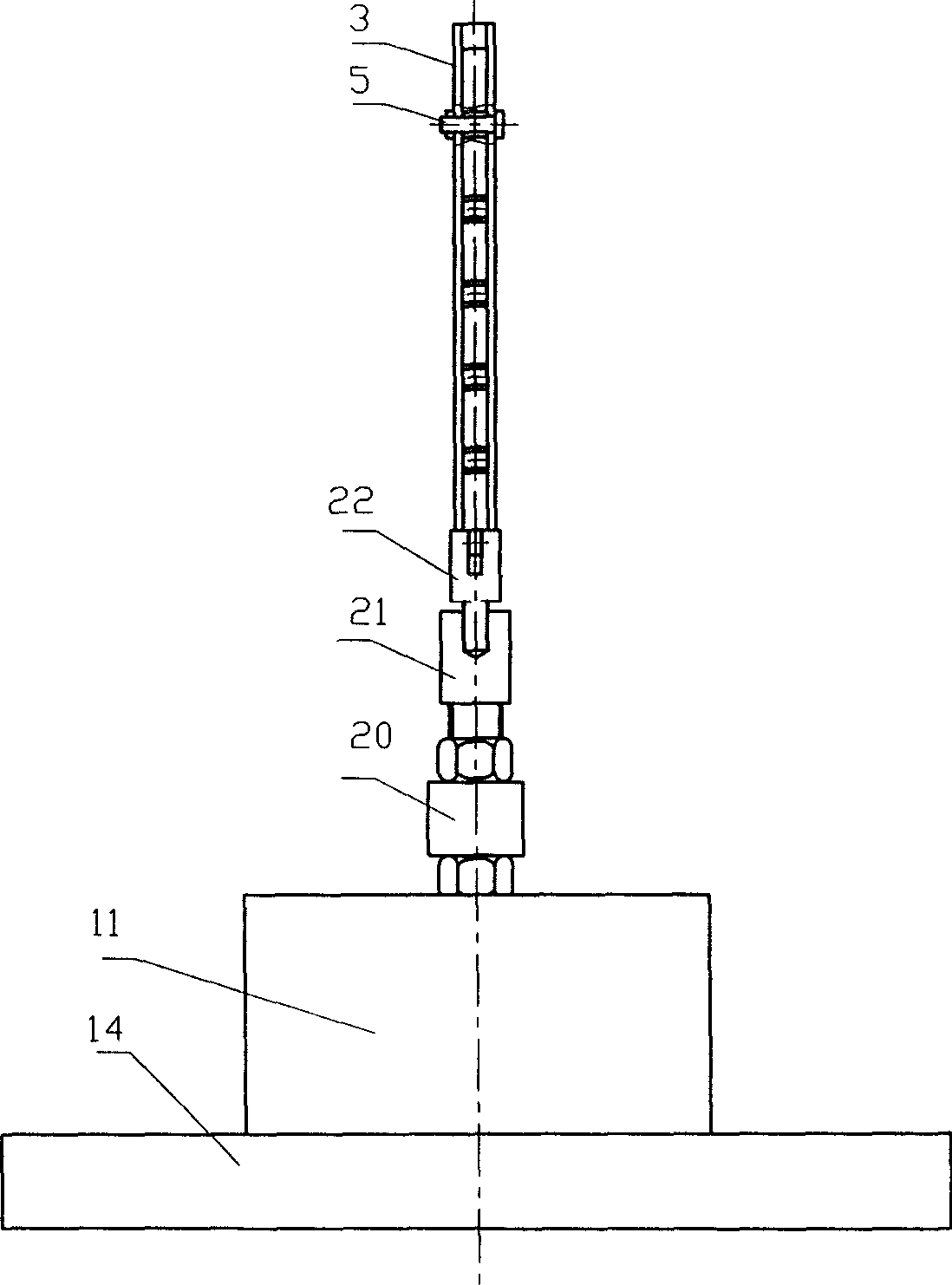

Testing method of polyphase coupling creep of fragmented rock body and equipment thereof

InactiveCN1687739ABulkyHigh precisionEarth material testingInvestigating material ductilityCouplingEngineering

The invention is the multi-phase couple creep testing method of the broken rock and the equipment. The invention adopts the multi-phase lever driving device, the loading device connecting the driving device and the compressing device under the loading device. The lever loading makes the beam wind the hinge of the framework; add the charge conveyed by the lever system on the samples through the adjusting screw, the force sensor, the ball hinge pressing head and the infiltrator; implement worm misshaping test to the sample in the high-low temperatures. The invention is stable, simple, small, convenient and precise.

Owner:CHINA UNIV OF MINING & TECH +1

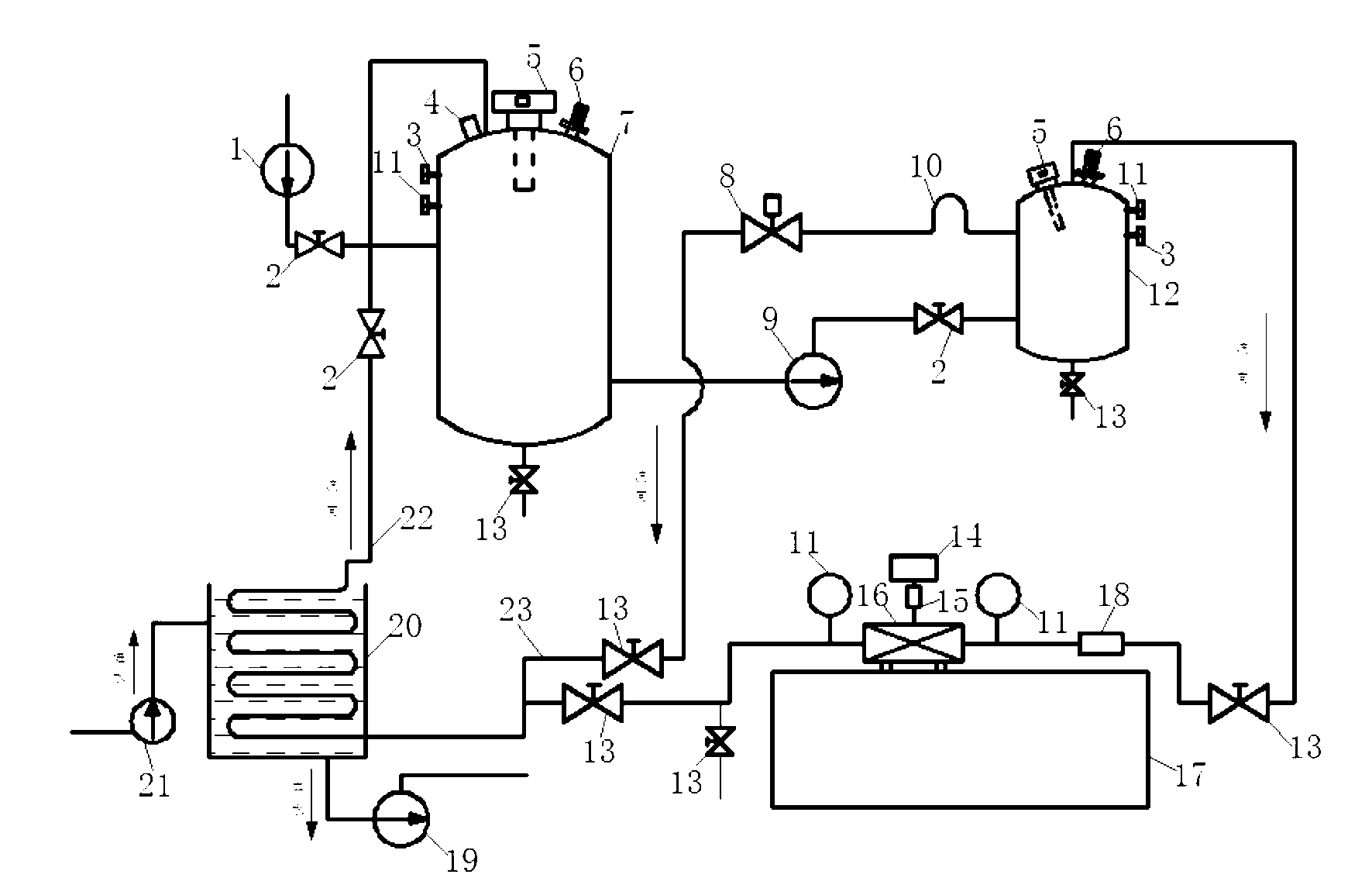

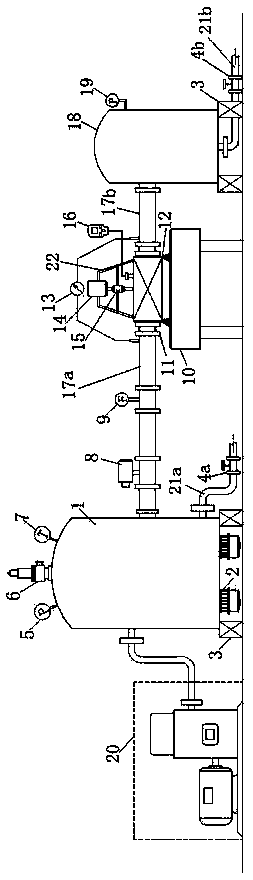

High temperature valve detecting and testing system

InactiveCN103308293ASimple structureHigh precisionMachine part testingFluid-tightness measurement using fluid/vacuumBuffer tankEngineering

The invention discloses a high temperature valve detecting and testing system, comprising an oil feed pump, an oil storage tank, a pressure pump, a buffer tank, a detecting device and a condensing device, wherein an electric heater and a pressure transmitter are installed on the top part of the oil storage tank; the bottom part of the oil storage tank is connected with the buffer tank through a third trunk pipeline; another pressure transmitter and a temperature sensor are installed on the inner side wall of the buffer tank; the buffer tank is connected with an oil inlet of a to-be-detected valve through a fourth trunk pipeline; the detecting device comprises a detecting table and a torque testing device; the valve rod of the to-be-detected valve is connected with the torque testing device; and the oil outlet of the to-be-detected valve is connected with the oil storage tank through a fifth trunk pipeline, the condensing device and a second trunk pipeline in sequence. The high temperature valve detecting and testing system is simple in structure and convenient to operate; and by the adoption of the detecting and testing system, the resistance coefficient and the torque performance of a high temperature valve and the flow characteristic can be tested, and the leakage amount can be detected.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

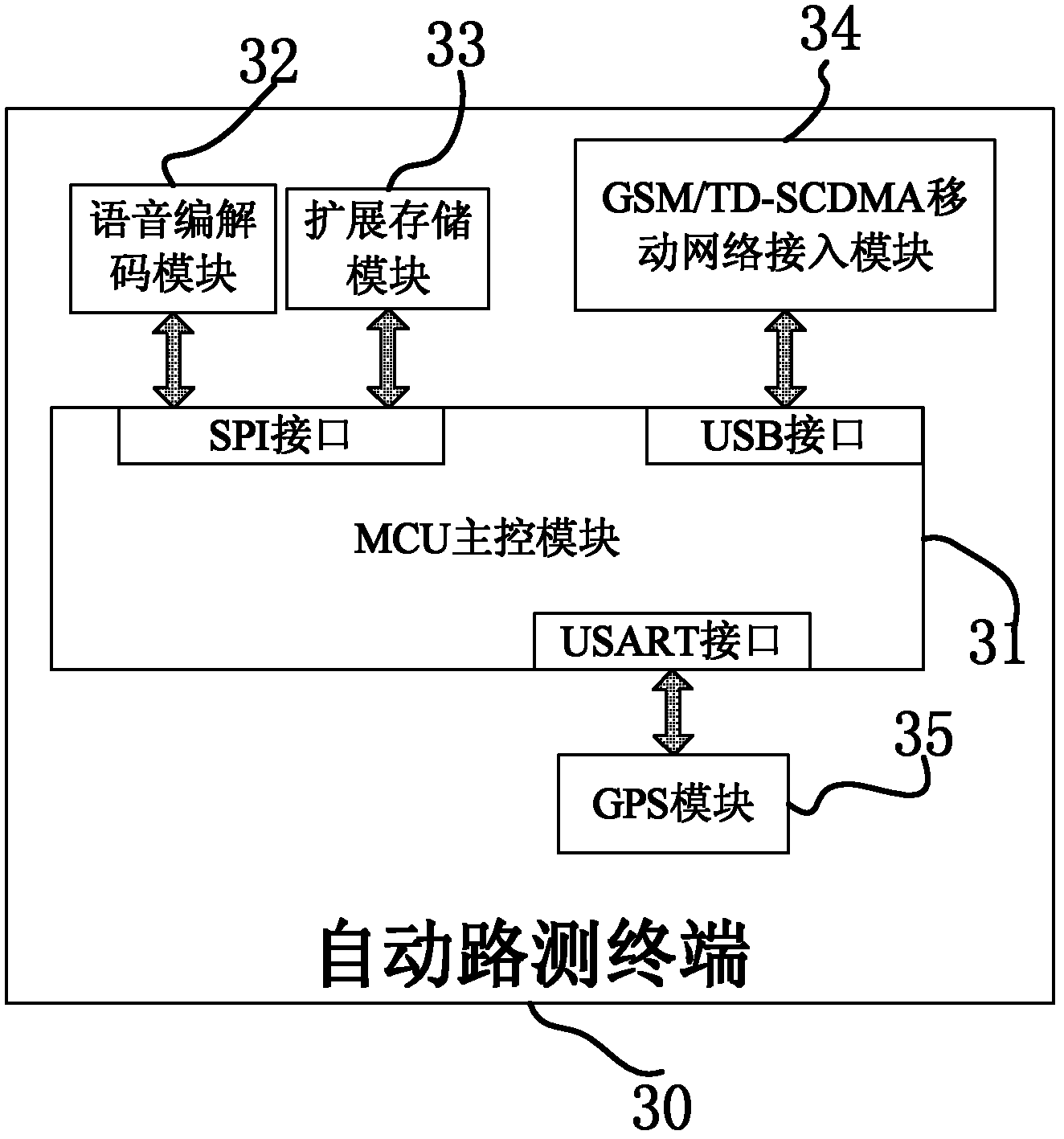

Mobile network quality automatic monitoring system and method for GSM and 3G

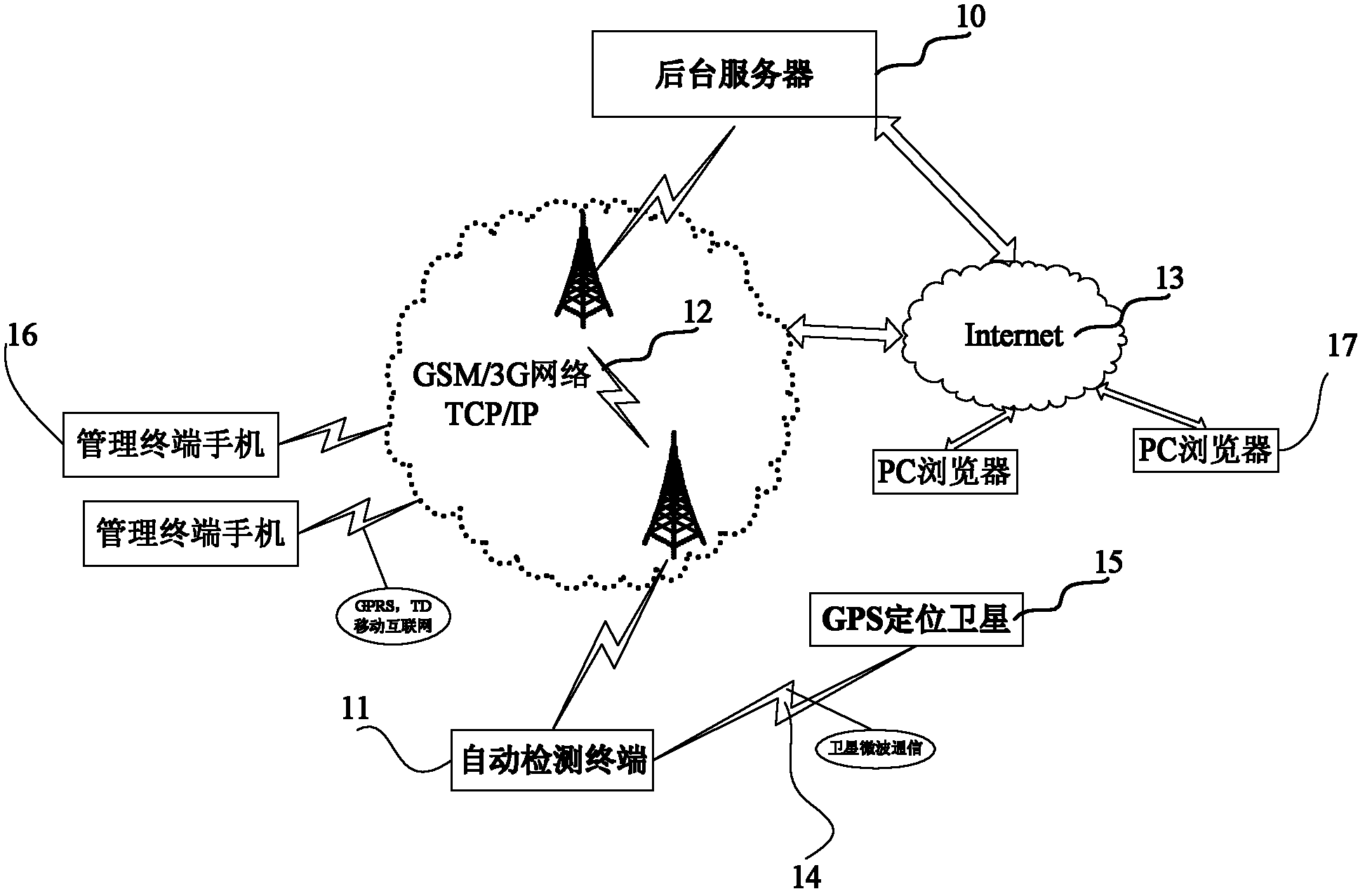

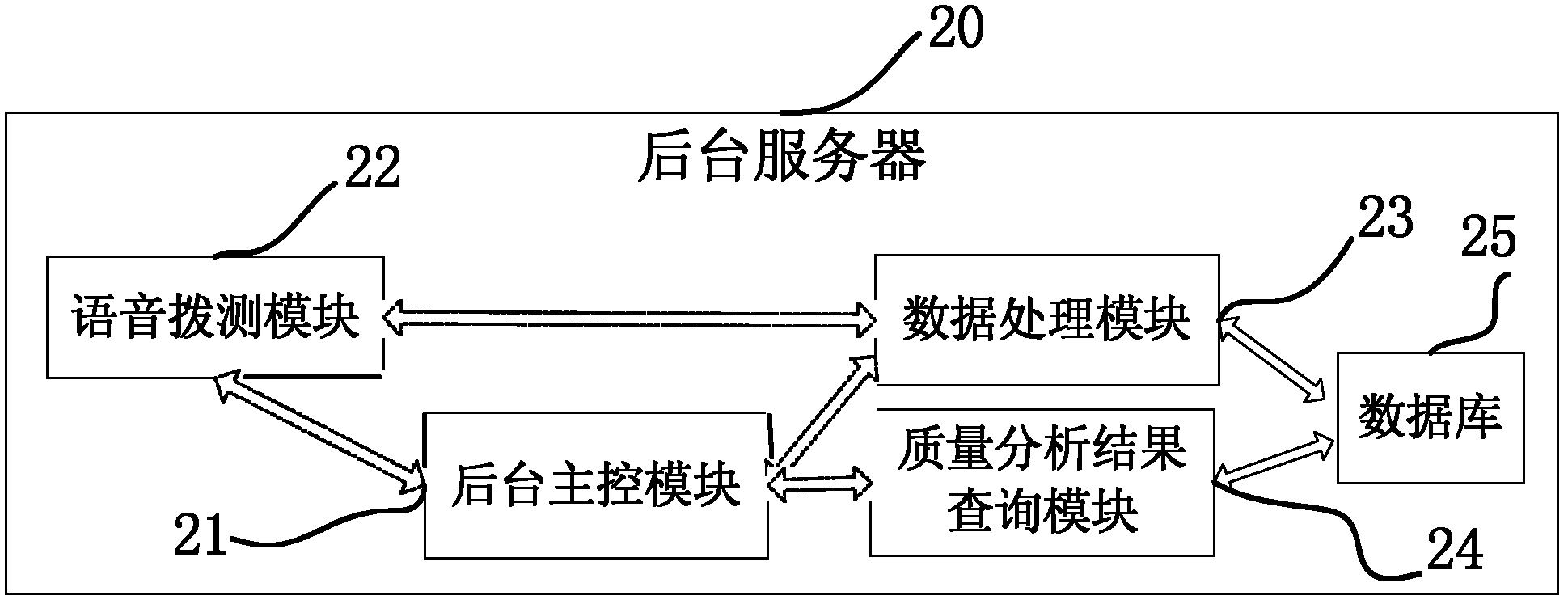

ActiveCN102333334ASave manpower and material resourcesStrong real-timeWireless communicationGeneral Packet Radio ServiceThird generation

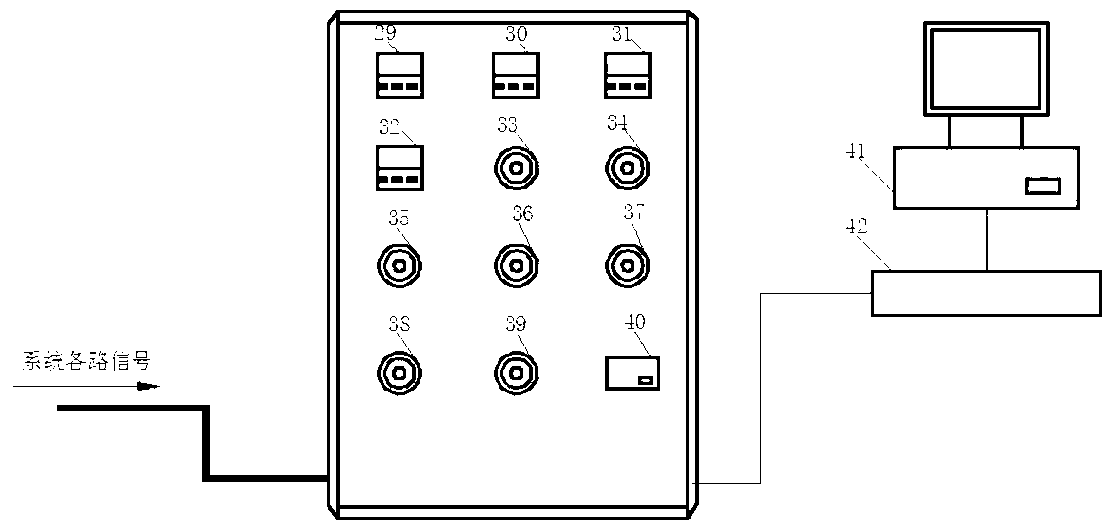

The invention discloses a mobile network quality automatic monitoring system and a method for the GSM (Global System for Mobile Communications) and the 3G (The 3rd Generation Telecommunication). The system comprises a background server and more than one automatic detecting terminal based on ARM (Advanced RISC Machines) embedded; and the background server is connected with all the automatic detecting terminals based on ARM embedded. The monitoring method comprises the following steps of: automatically obtaining various network quality parameters of a wireless network access module in the GSM / TD-SCDMA (Time Division-Synchronization Code Division Multiple Access) network, executing service test to acquire service quality parameters related to voice telephone traffic, and transmitting the acquired parameters to the background server through a TCP / IP protocol of the GPRS / TD (General Packet Radio Service / Time Division) wireless network when the system is idle so as to analyze and evaluate every parameter of the network quality. The background server processes and stores the network quality parameters returned back by the automatic detecting terminals, which is convenient for managers to access data, and analyze network conditions and solve problems in time.

Owner:SOUTH CHINA UNIV OF TECH

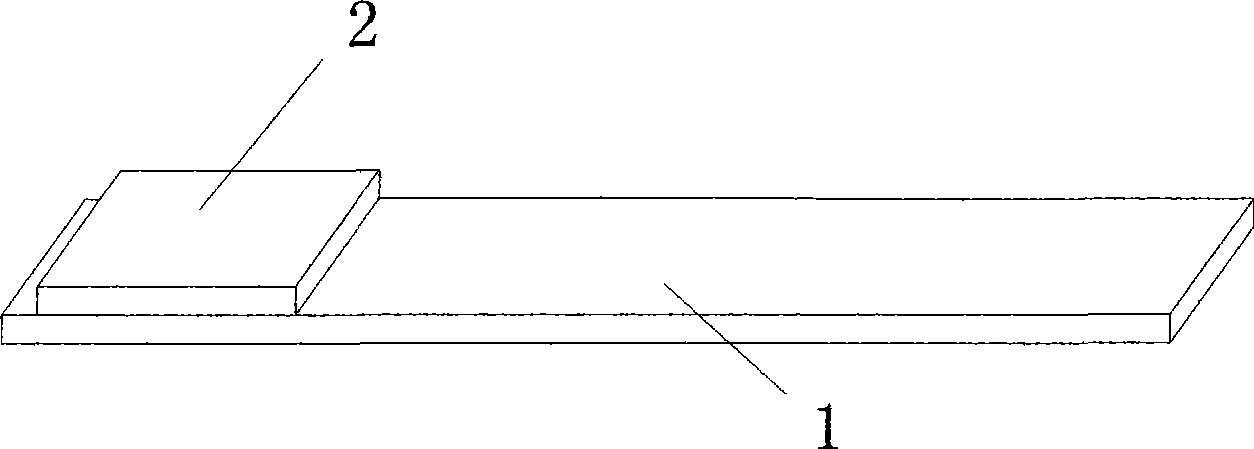

Copper ion test paper and method for preparing same

InactiveCN101545867ARealize detectionEasy to makeMaterial analysis by observing effect on chemical indicatorSteepingPotassium sodium tartrate

The invention discloses a copper ion test paper, which comprises a substrate (1) and chromogenic test paper (2) fixed on the substrate (1), and is characterized in that the chromogenic test paper (2) is prepared by steeping filter paper in a steeping fluid, taking out the filter paper from the steeping fluid and drying the filter paper, wherein the steeping fluid consists of the following components by weight: 0.07 to 1.4 percent of sodium diethyl dithiocarbamate, 5.7 to 11.4 percent potassium sodium tartrate, 0.036 to 0.71 percent of soluble starch, and 86.49 to 94.194 percent of distilled water. The invention also provides a method for preparing the copper ion test paper. The test paper has the advantages of simple fabrication, low cost, convenient use, no pollution to the environment, and favorability for environmental protection; and besides, the test paper has wide test range, is not required to be operated by a professional, and is particularly applicable to quick field test of copper content.

Owner:KUNMING BOYIN SCIANDTECH CO LTD

Friction torque measurement apparatus of horizontal bearing

InactiveCN102519639AAvoid eccentric load vibration problemsAppropriate to the actual working conditionsWork measurementTorque measurementFriction torqueElectric machine

The invention relates to a friction torque measurement apparatus of a horizontal bearing. A velocity sensor is arranged on a main shaft and a rotating speed is read by a digital indicator. An input terminal of a data collection card is connected with a force transducer by a strain gauge; the data collection card is installed in a main board of a PC machine; and the main board is connected with a display. The main shaft is arranged horizontally; one end of the main shaft is provided with a bearing replacing sleeve; and the other end of the main shaft is connected with a motor main shaft. A tested bearing is arranged in the bearing replacing sleeve; and an inner ring is provided with a force transmission rotary table that is connected with the force transducer by a dowel bar. A load output bulb of an axial loading apparatus is contacted with a vertical point of a table surface of the force transmission rotary table; and a load output terminal of a radial loading apparatus and an outer peripheral surface of the bearing replacing sleeve are mutually compacted and rolled. According to the invention, the apparatus employs a horizontal structure; and loading at two directions can be realized simultaneously. Therefore, an actual working condition of a bearing can be simulated approximately; and a problem of main shaft offset load vibration due to a belt drive mode of the main shaft can be solved. Besides, the apparatus has advantages of simple structure and strong practicality.

Owner:HENAN UNIV OF SCI & TECH

Device and method for detecting and testing high-temperature valve based on air heating system

InactiveCN103954441AReasonable structural designReasonable test temperatureMachine part testingDifferential pressureBuffer tank

The invention provides a device for detecting and testing a high-temperature valve based on an air heating system. The device comprises an air compressor, a heating tank, a detection device and a buffer tank. The air compressor is connected with the heating tank through a steel pipe. A pressure sensor and a temperature sensor of the heating tank are arranged at the top of the heating tank. An air heater is arranged at the bottom of the heating tank. The heating tank is connected with an inlet of the valve to be tested through a first test pipeline. The first test pipeline is provided with an electric check valve. The detection device comprises a detection table and a test device. The valve to be tested is arranged on the detection table. The test device comprises a high-temperature flow meter, a torque test device, a differential pressure gauge and an ultrasonic leakage detector. An outlet of the valve to be tested is connected with the buffer tank through a second test pipeline. The device can simulate the actual working condition in a factory and detect the high-temperature medium circulation performance of the high-temperature valve.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Vacuum friction abrasion test device

InactiveCN102621060AEasy to operateFlexible controlUsing mechanical meansMaterial analysisCantilevered beamDrive shaft

The invention relates to a vacuum friction abrasion test device, which comprise a base, wherein a vacuum cover is arranged on the base, a vacuum meter and an inflating valve are arranged on the vacuum cover, a driving motor is arranged in the base, the upper end of a driving shaft of the driving motor is provided with a movable specimen disc, a fixed specimen is arranged above the movable specimen disc in a contact way and is fixed by a fixed specimen clamp, the fixed specimen clamp is arranged on a U-shaped cantilever beam, a loading weight is placed above the fixed specimen clamp, one end of the U-shaped cantilever beam is provided with a balance weight, linear displacement sensors are symmetrically arranged on the U-shaped cantilever beam, a radial feeding system is fixedly arranged on the base, a regulation rotating shaft is arranged above the radial feeding system, and the U-shaped cantilever beam is connected with the regulation rotating shaft through a connecting element. The vacuum friction abrasion test device has the advantages that according to experiment requirements, the data collection and recording of parameters such as friction force and time can be realized in vacuum environment, in addition, curves of the friction coefficient changed along with the time are drawn, the operation of the device is simple, and the use is convenient.

Owner:XI AN JIAOTONG UNIV

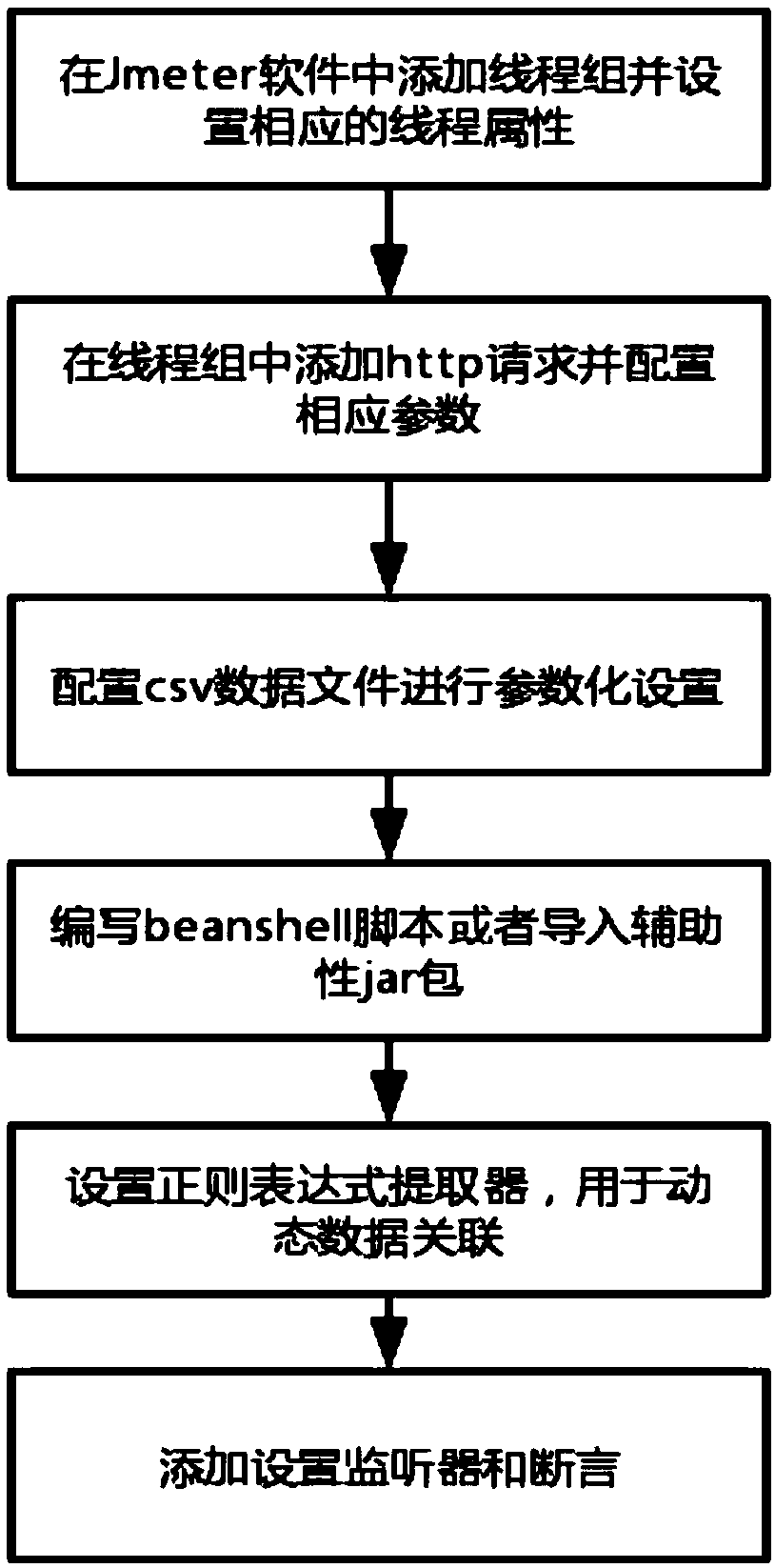

An automatic interface testing method based on Jmeter

InactiveCN109597761AThe test is accurateWide range of testsSoftware testing/debuggingComputer hardwareData file

The invention discloses an automatic interface testing method based on Jmeter. a Jmeter test software tool is used; a thread group to configure its number of concurrent, number of loops, thread starttime parameters, etc. are added to simulate the normal user to send a request to carry out stress test on the server interface,; secondly, c a csv data file is configured to carry out parameterizationsetting so that an interface is accurately tested;, a beanshell script is written or an auxiliary jar packet is imported, and finally a monitor and assertion are added to judge whether a result corresponding to a request is an expected result or not, so as to complete the automatic test of the interface. The method provided by the invention can solve the problems that errors are easy to fill whenrequest data are configured manually during testing at present, the workload of finding and modifying the errors is large, test requests cannot be concurrent, and test data cannot be changed.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

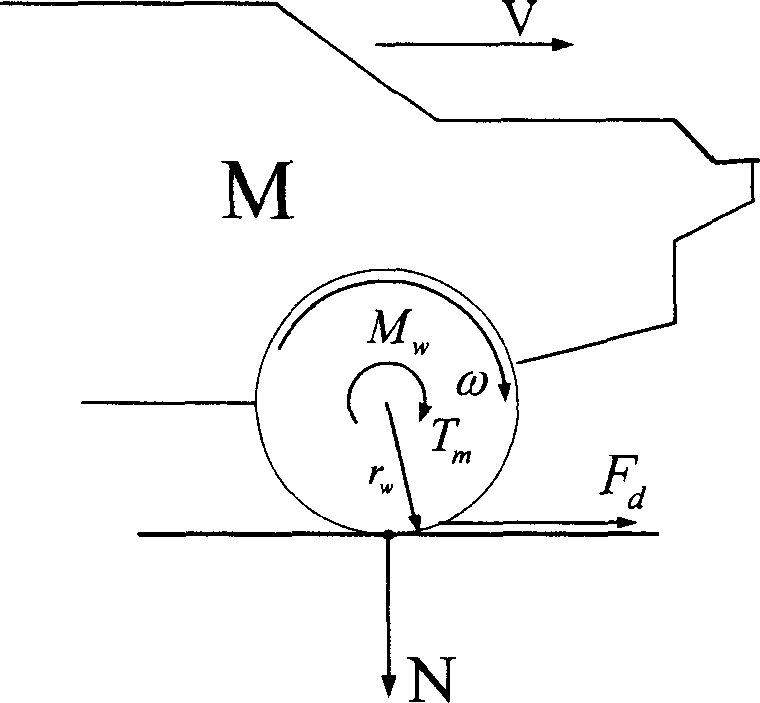

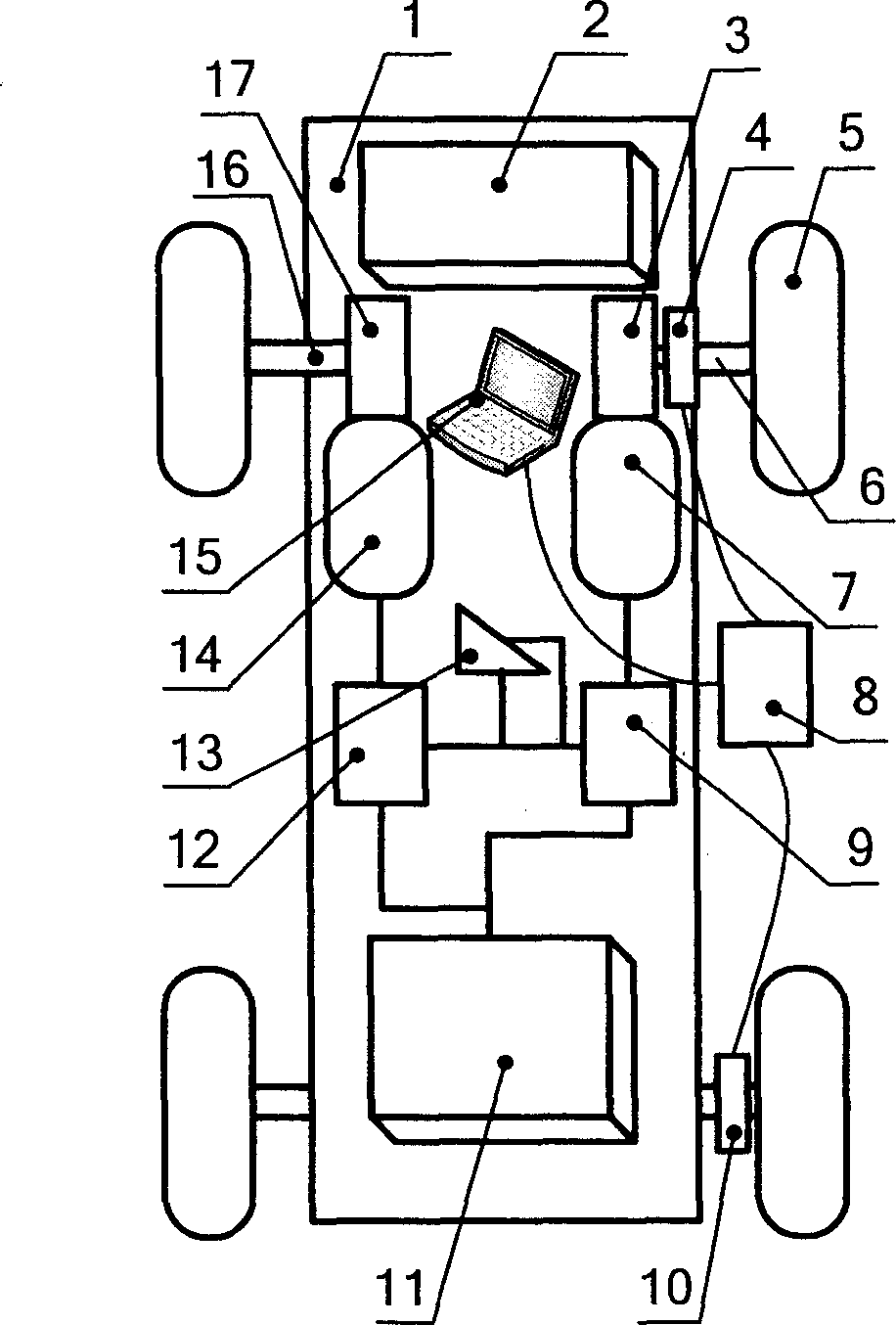

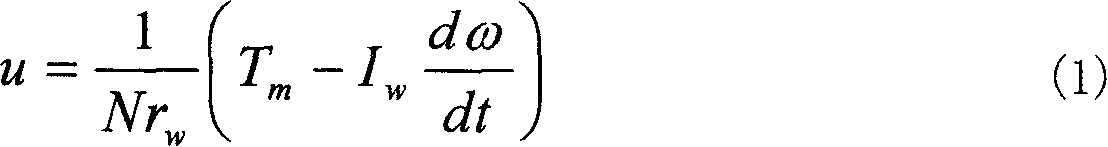

Real-time measuring method for longitudinal attachment characteristic of tyre and pavement and measuring vehicle therefor

InactiveCN1865895AAdhesion properties can be testedWide range of testsUsing mechanical meansVehicle tyre testingAdhesion coefficientDrive wheel

The related real-time test method for vertical adhesion feature between tyre and road comprises: arranging the testing tyre on a wheel of running test vehicle, detecting the drive torsion and wheel rate by sensor fixed on vehicle drive wheel, and obtaining the wheel rate omega of driven wheel by the sensor on driven wheel; according to the normal pressure N and wheel radius rw, calculating the adhesion factor mu and drive wheel trackslip rate lambda by formula (1) and (2). Wherein, it uses a data process SCM programmed as (1) and (2) to receive rate and torsion signal, calculate target value and send to note-book to record, store and display.

Owner:JILIN UNIV

Method for testing peeling strength of coated abrasive tool

ActiveCN101694452AWide range of testsRepetitiveUsing mechanical meansMaterial analysisAdhesiveMetallurgy

The invention relates to a method for testing the peeling strength of a coated abrasive tool, comprising the following stepsof sticking a coated abrasive tool sample on a base plate by using adhesives; solidifying and then fixing the base plate stuck with the coated abrasive tool sample by using a clamp; and then testing the average force required for peeling the coated abrasive tool sample from the base plate. The invention standardizes the test method and the test standard, and the average value of data is accurate and has repeatability; the invention has wider test range including coated abrasive products, fabricbase material, paper base material, plastic base material and the like; and with the method, not only the adhesion performance of different adhesives and base materials can be compared, but also the final adhesion performance of different coated abrasive tool products can be directly known, so that the method is universal and practical.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

System for testing comprehensive performance of metal roof

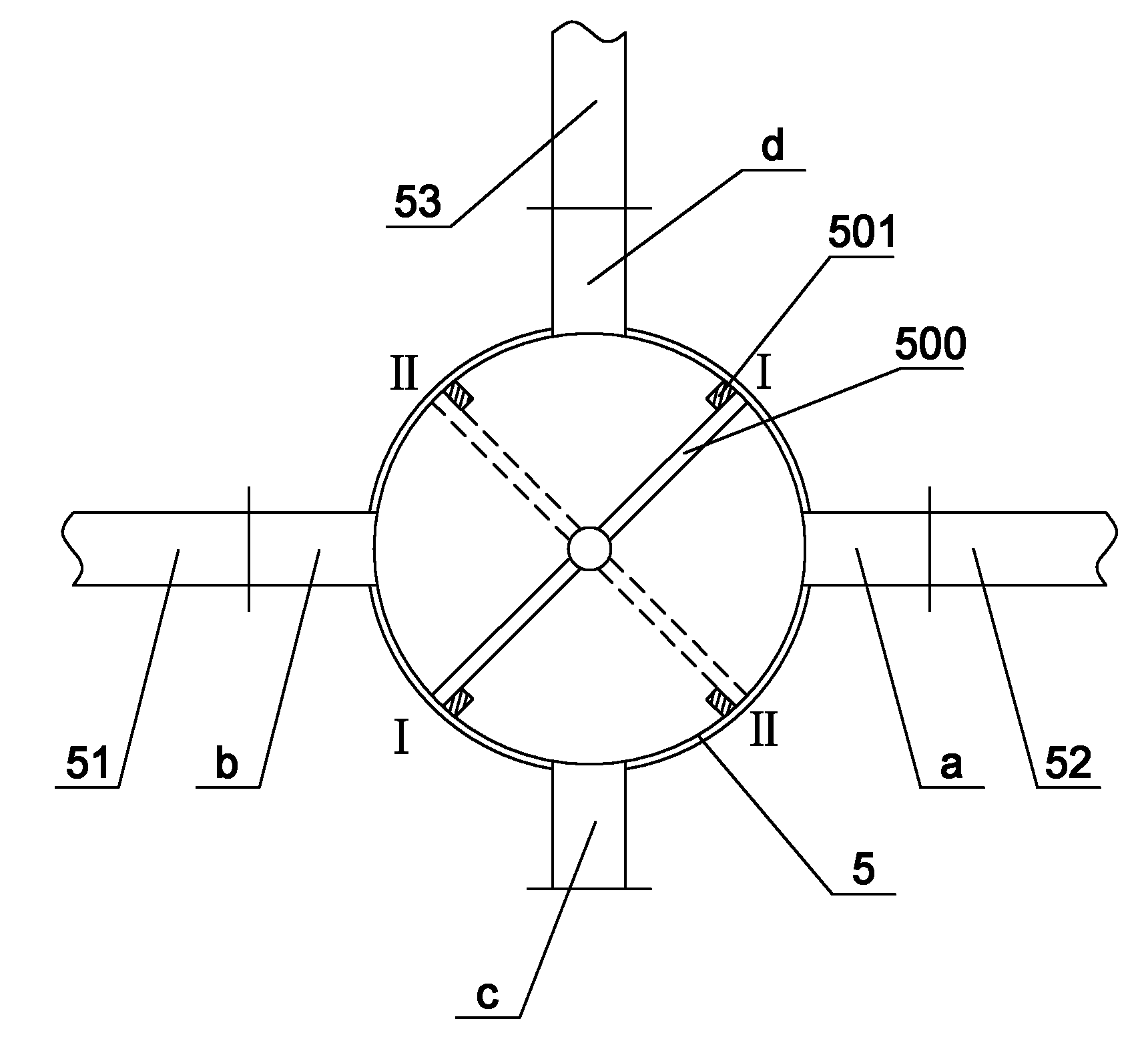

InactiveCN102183380ADetectable watertightnessDetectable cold and heat expansion performance indicatorsFluid-tightness measurement using fluid/vacuumEngineeringElectric control

The invention discloses a system for testing comprehensive performance of a metal roof. The system comprises an upper tank body (1), a lower tank body (2), a sealing piece (18), a support (21), a first air supply / exhaust device, a pump (6), a shower pipe (60), a shower nozzle (61), a refrigerator (7), a refrigerating pipe (71), an electric control device (9), a hanging rod (11), a displacement sensor (12), an electric heater (13), a net rack (14), a temperature / humidity sensor (15), and a wind pressure sensor (91), wherein a closed space is formed by the upper tank body (1) and a metal roof testing piece (8); a closed space is formed by the lower tank body (2) and the metal roof testing piece (8); the first air supply / exhaust device comprises a first fan (3) and a reversing valve (5); a reversing device is arranged in the valve body of the reversing valve (5); when the reversing device is in a first reversing state, the first fan (3) exhausts air from the upper tank body (1); and when the reversing device is in a second reversing state, the first fan (3) supplies air to the upper tank body. The system for testing the comprehensive performance of the metal roof can be widely applied to the field of test of metal roofs.

Owner:BAIANLI STEEL STRUCTURE APPL SCI TECH

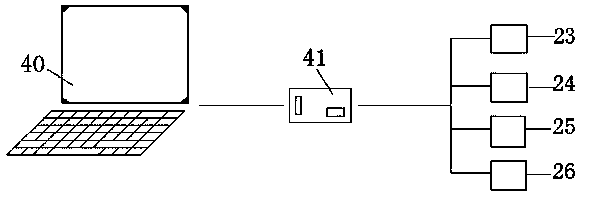

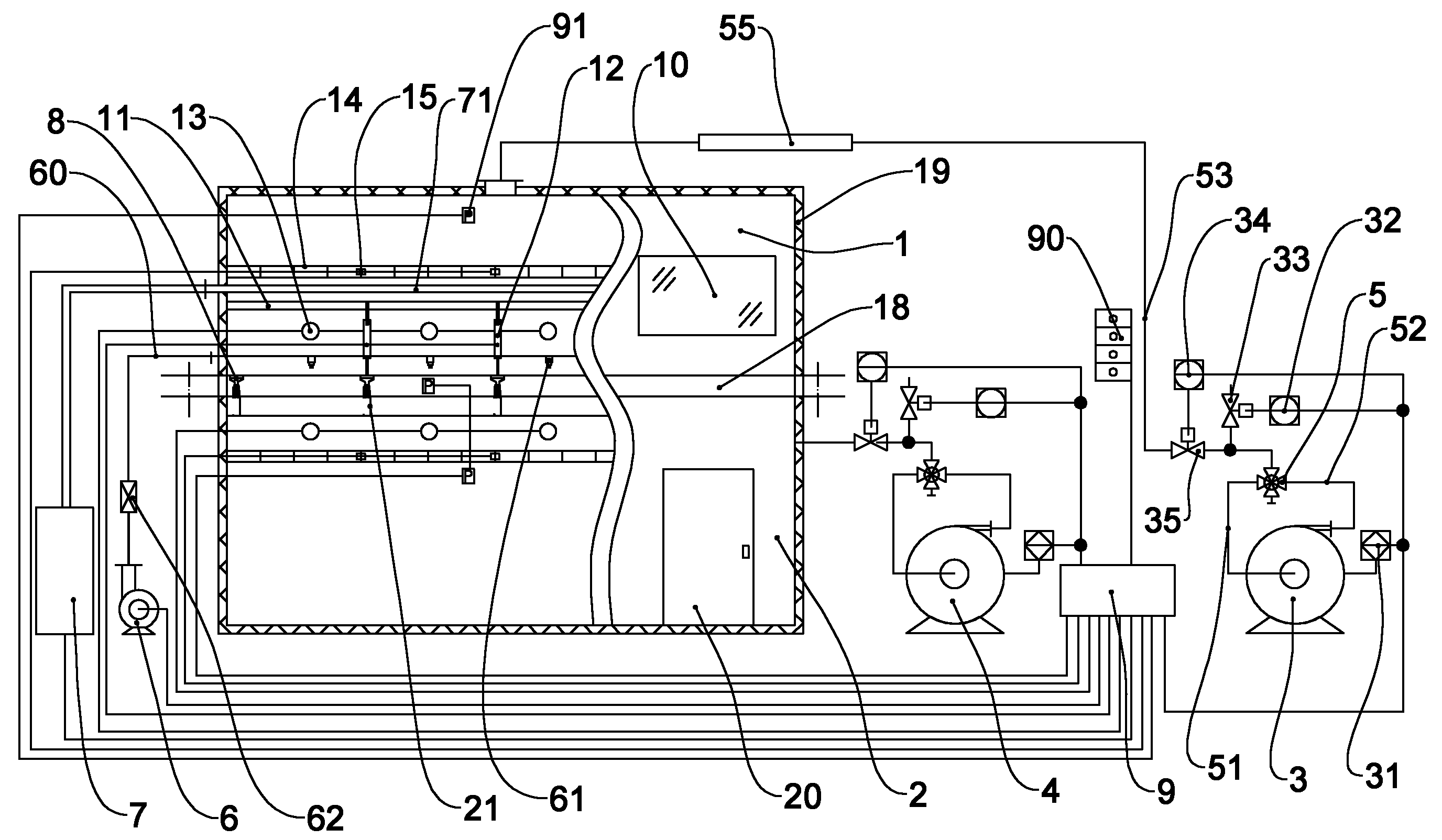

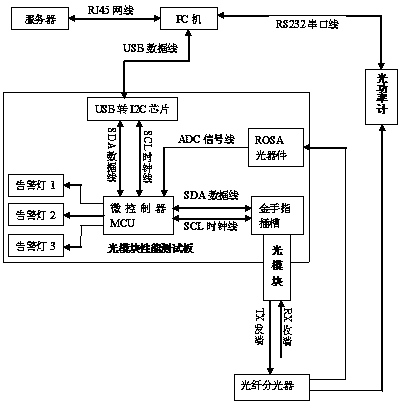

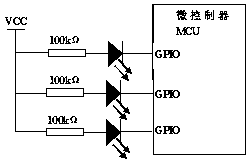

Device for testing performance of optical module

InactiveCN108365888ASimplify the test environmentReduce testing workloadElectromagnetic transmissionOptical ModuleOptical power meter

The invention discloses a device for testing the performance of an optical module and aims at providing a convenient and quick test environment. The invention is realized by the following technical scheme: a PC is connected to a server through an RJ45 network cable, is connected to an optical module performance test board through a USB data line, and is connected to an optical power meter throughan RS232 serial line, the optical power meter is connected to an ROSA optical device through an optical fiber splitter, a tested optical module is connected to the test board through a gold finger slot, the average optical power of the TX end of the tested optical module is divided into two by the optical fiber splitter, one path is sent to the ROSA optical device, and the other path is sent to the optical power meter, the PC obtains the average optical power value of the optical module measured by the optical power meter, and then compares the average optical power value with an optical powerthreshold that have been configured by the server, and determines whether the average optical power value of the tested optical module is within a normal range by using the comparison result. An alarm light visually displays various performance test results of the tested optical module.

Owner:四川泰瑞创通讯技术股份有限公司

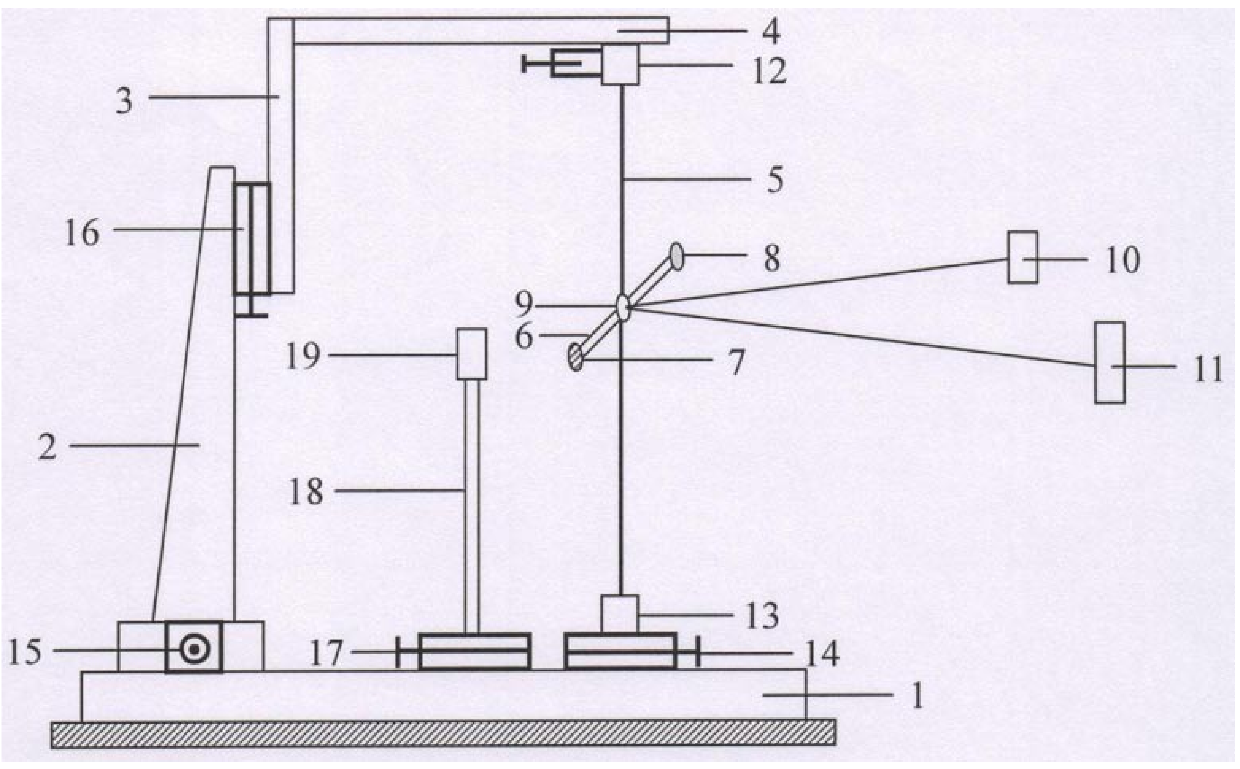

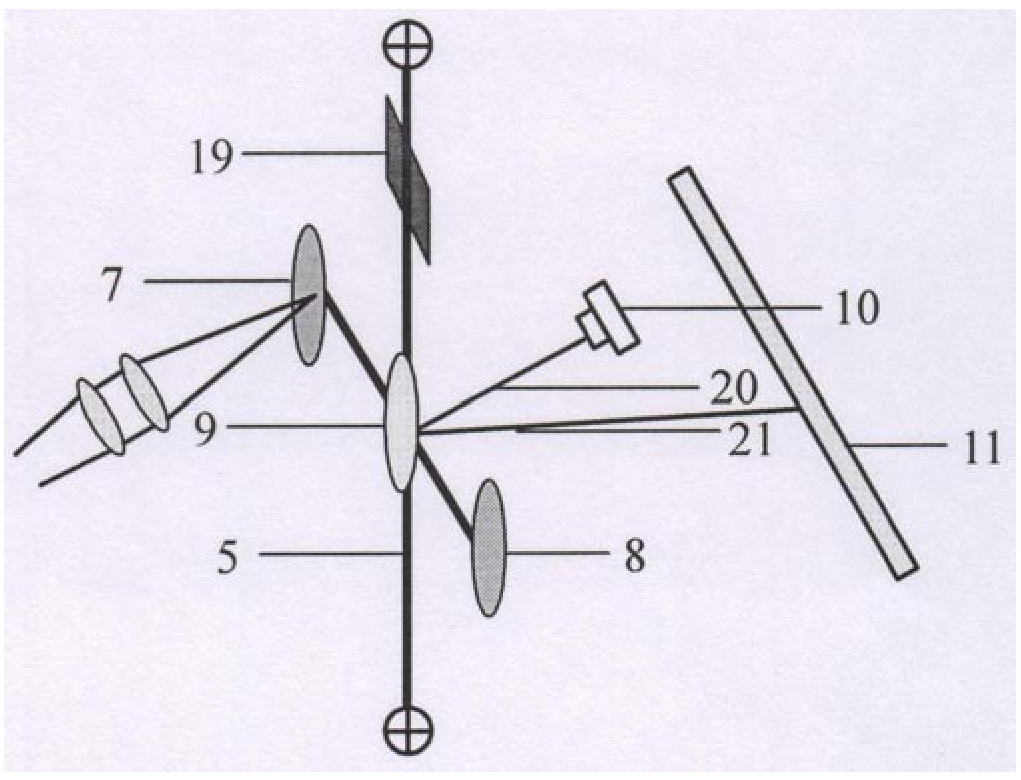

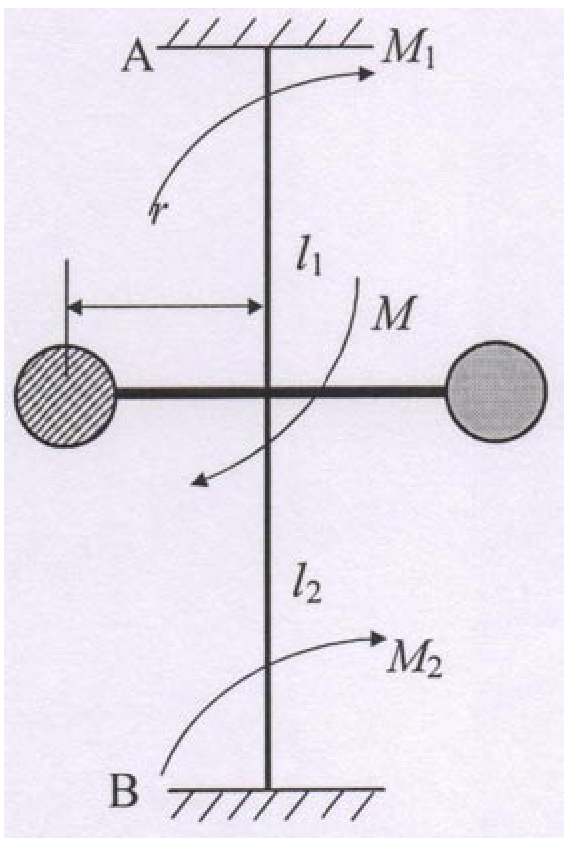

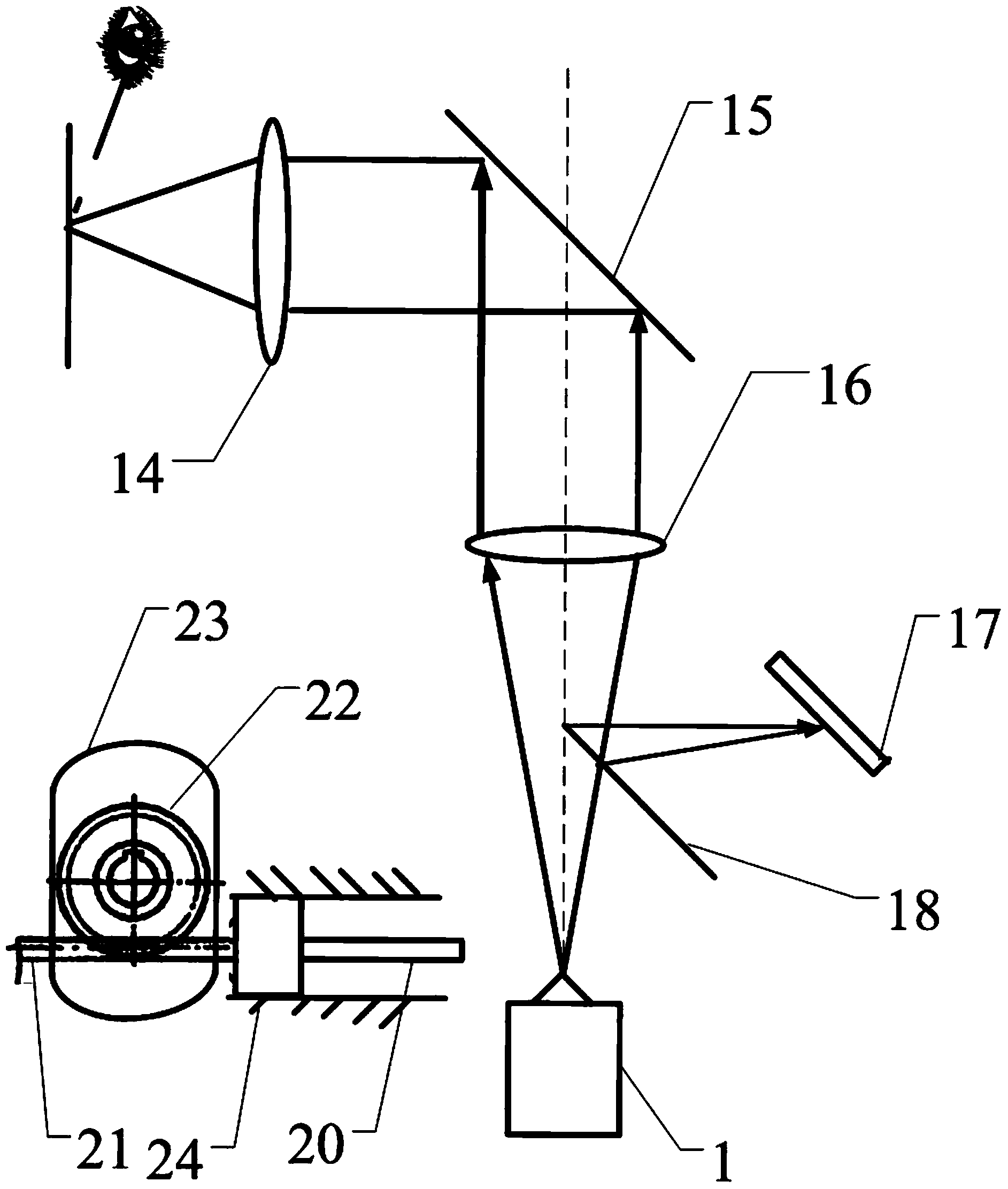

Laser thruster micro-impulse test device

ActiveCN106507921BImprove test accuracyImprove calibration accuracyApparatus for force/torque/work measurementLight beamEngineering

The invention relates to a micro-impulse testing device for a laser thruster. It includes a ㄈ-shaped frame composed of a base plate, a vertical bar and a cross bar. A vertical swing wire is suspended between the base plate and the cross bar of the ㄈ-shaped frame. A beam perpendicular to the swing wire is fixed in the middle of the swing wire. The other end is a counterweight, and the crossbeam at the intersection with the pendulum wire is equipped with a reflector, the laser that irradiates the mirror, and the scale that receives the detection laser beam, and the upper and lower ends of the pendulum wire are fixed by the clamping mechanism. The calculation model of the impact force impulse of the laser thruster micro-impulse test device is given. The advantage is that the measuring range is wide, the testing precision is high, the device is easy to implement, and the parameter calibration method is simple and easy.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

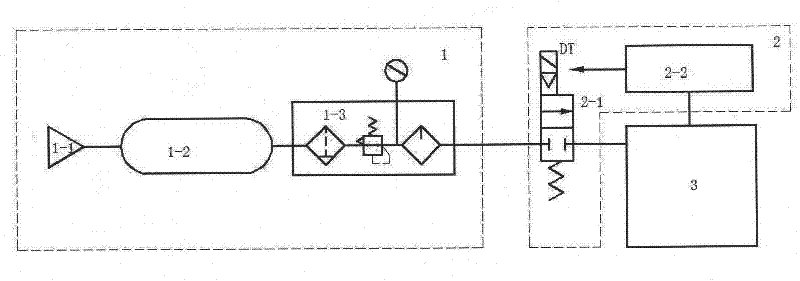

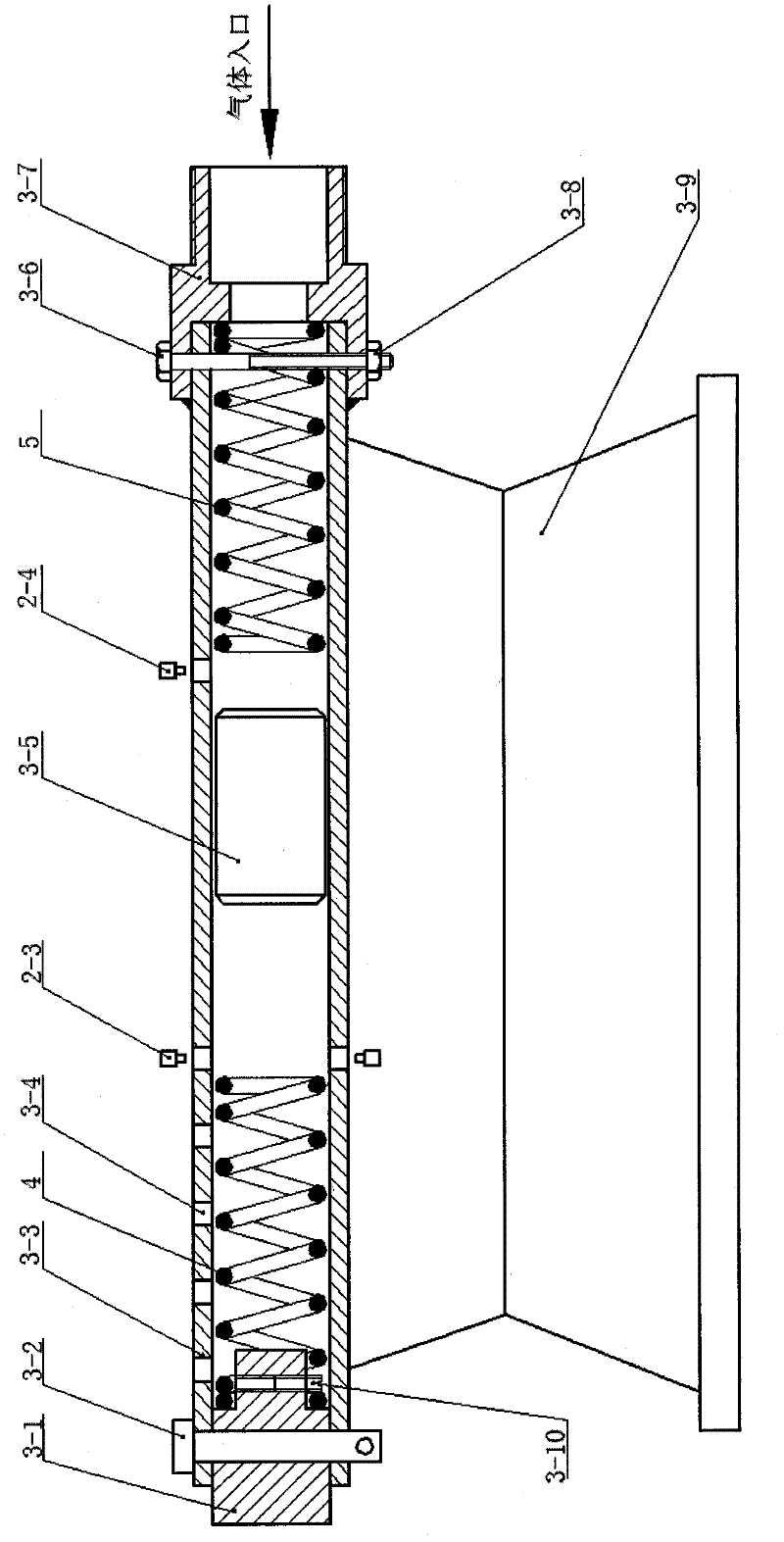

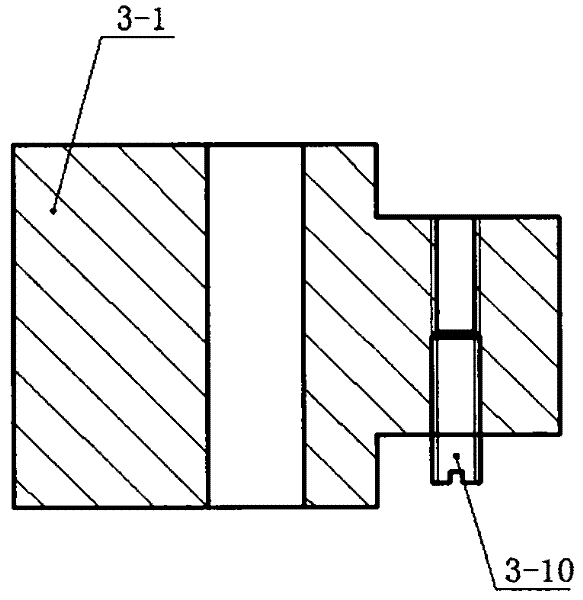

Spring fatigue test device for continuous impact of high-pressure gas

InactiveCN102297754ASimple structureLow priceMaterial strength using repeated/pulsating forcesShock testingElectrical controlCoil spring

The invention relates to a test apparatus for fatigue of a spring under continuous impact of high pressure gas, more particularly to a test apparatus for fatigue life of a cylindrical helical spring. The apparatus comprises a high pressure gas dynamic portion, an electrical control portion and a mechanical portion. According to the invention, the apparatus has advantages of simple structure and easy operation; besides, stable impact loads can be continuously put on a testing spring and precision of detection on fatigue life of a spring is high. The apparatus provided in the invention can be widely applied to a test on fatigue life of a cylindrical helical spring that bears a high-speed, high-frequency and high-load impact load, especially to a test on fatigue life of a stranded-wire helical spring.

Owner:CHONGQING UNIV

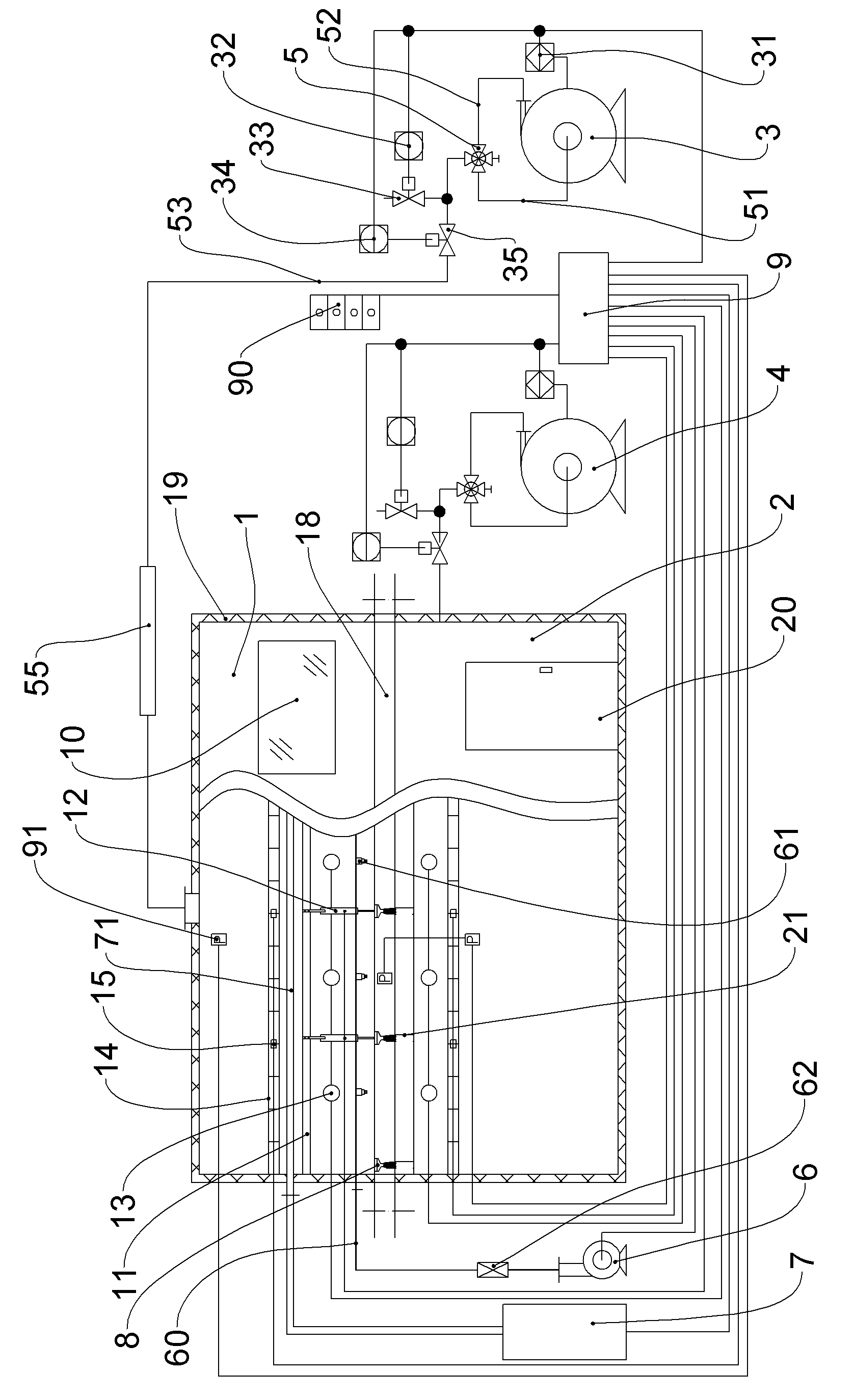

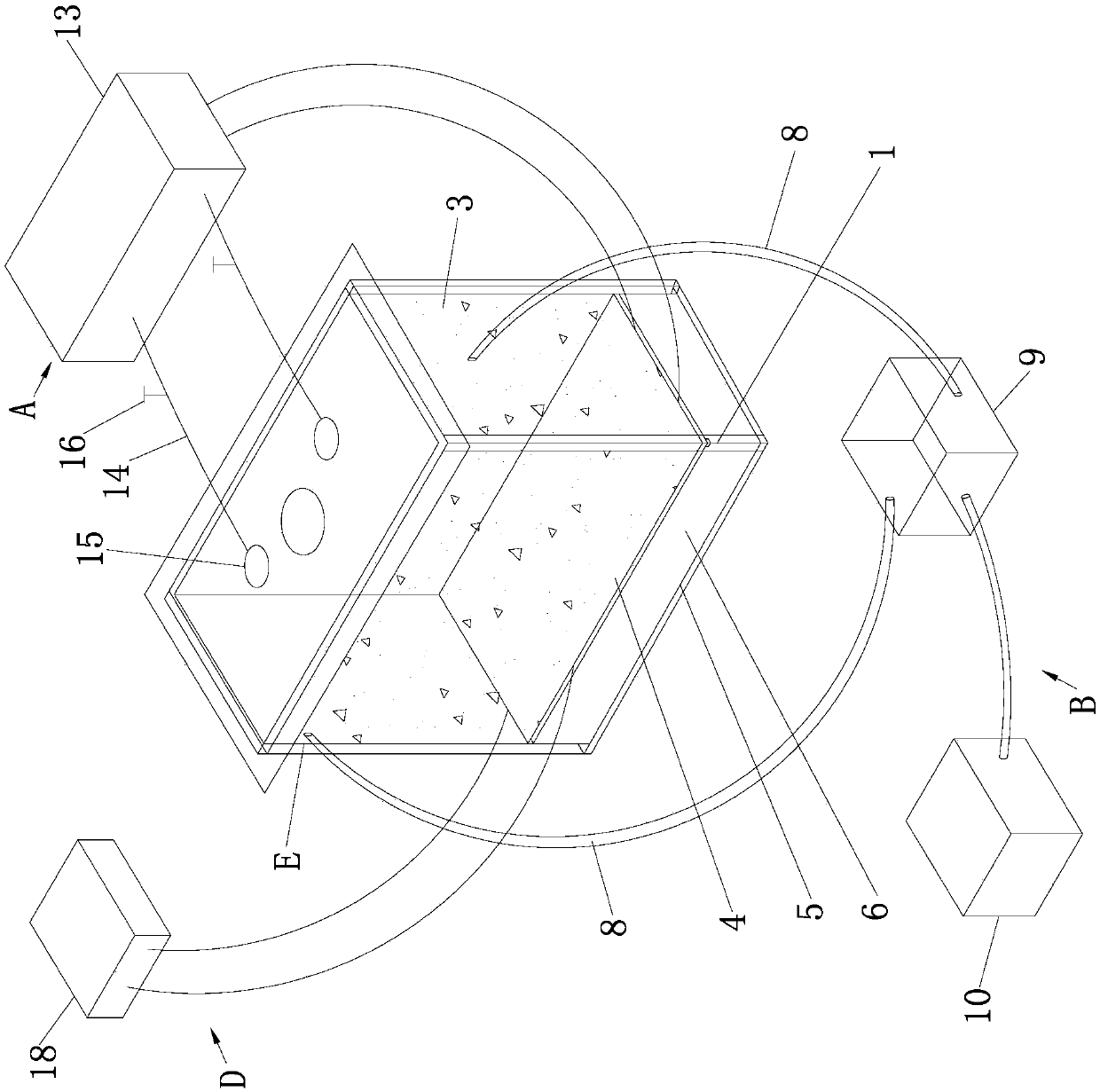

Multifunctional geotechnical model testing system and method

PendingCN107907662ASave spaceEasy to testPreparing sample for investigationEarth material testingRainfall simulationSoil science

The invention provides a multifunctional geotechnical model testing system and method and relates to a geotechnical model testing system and method, aiming at solving the problem that an existing model box cannot simulate conditions of a temperature field. The multifunctional geotechnical model testing system comprises an outer framework, the model box, a rainfall simulation mechanism, a refrigerating mechanism, a heating mechanism and a data acquisition system, wherein the model box is mounted on the outer framework; a water outlet of the rainfall simulation mechanism is arranged at the top of the model box; the refrigerating mechanism and the heating mechanism can provide environment temperature to the model box; the data acquisition system is used for acquiring frozen soil working condition indexes in the model box. The method comprises the following steps: 1, determining the size and the model similarity ratio of the model box and the length and the slope ratio of a roadbed model;2, preparing a soil body material for simulation; 3, establishing a corresponding simulation procedure; 4, acquiring and displaying data. The multifunctional geotechnical model testing system and method are used for a frozen soil test.

Owner:NORTHEAST FORESTRY UNIVERSITY

Thin film high-temperature friction and wear testing device

InactiveCN102519816AImprove heating efficiencyEven heat distributionPreparing sample for investigationInvestigating abrasion/wear resistanceCircular discCantilevered beam

A thin film high-temperature friction and wear testing device comprises a casing, a driver is arranged in the casing, a moving test sample round disc is arranged on the drive shaft of the driver, a magnetizer, an induction heating coil and an infrared temperature measurement instrument are arranged above the moving test sample round disc in a non-contact manner, a fixed test sample is arranged above the moving test sample round disc in a contact manner and fixed by a fixed test sample fixture, the fixed test sample fixture is mounted on a U shaped cantilever beam, a loading weight is arranged on the fixed test sample fixture, a counter weight is arranged at one end of the U shaped cantilever beam, a linear displacement sensor is symmetrically arranged on the U shaped cantilever beam, a radial feeding system is fixed on the casing, an adjusting rotation shaft is disposed above the radial feeding system, and the U shaped cantilever beam is connected with the adjusting rotation shaft via a connection member. The invention adopts induction heating manner to directly generate heat on a workpiece surface and provide high power density, can achieve the temperature required for testing in short time, and has features of high heating efficiency, high speed, simple heating part and flexible control.

Owner:XI AN JIAOTONG UNIV

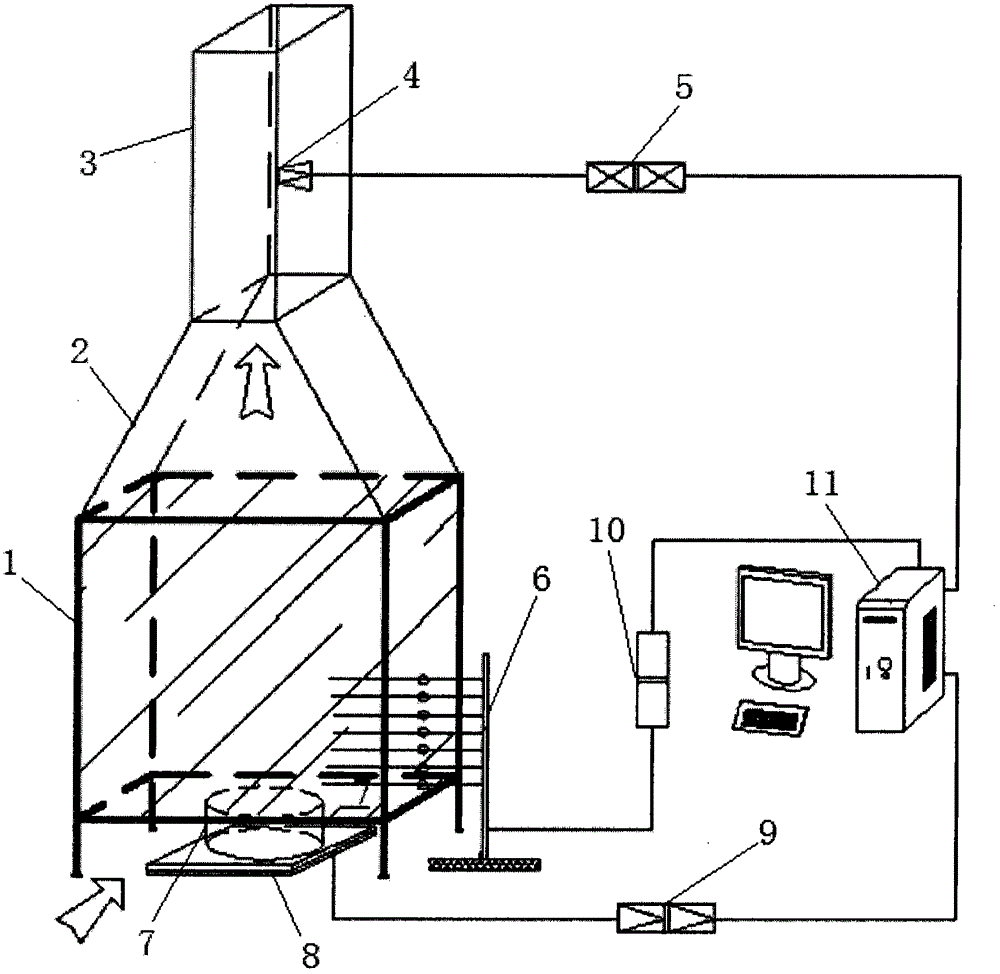

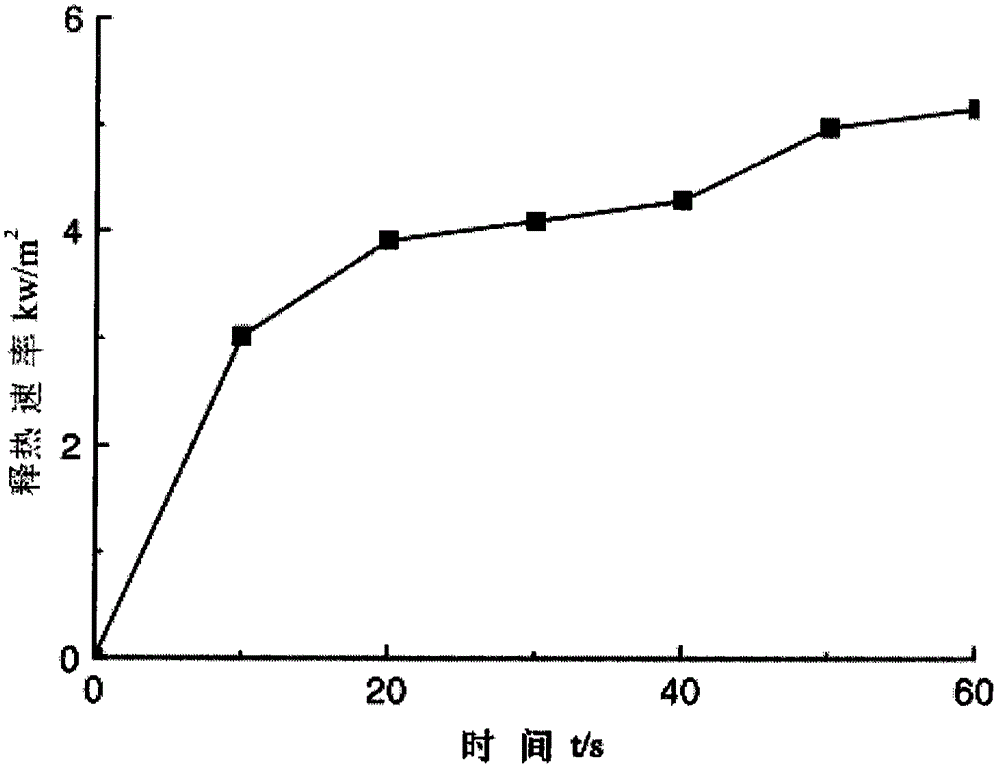

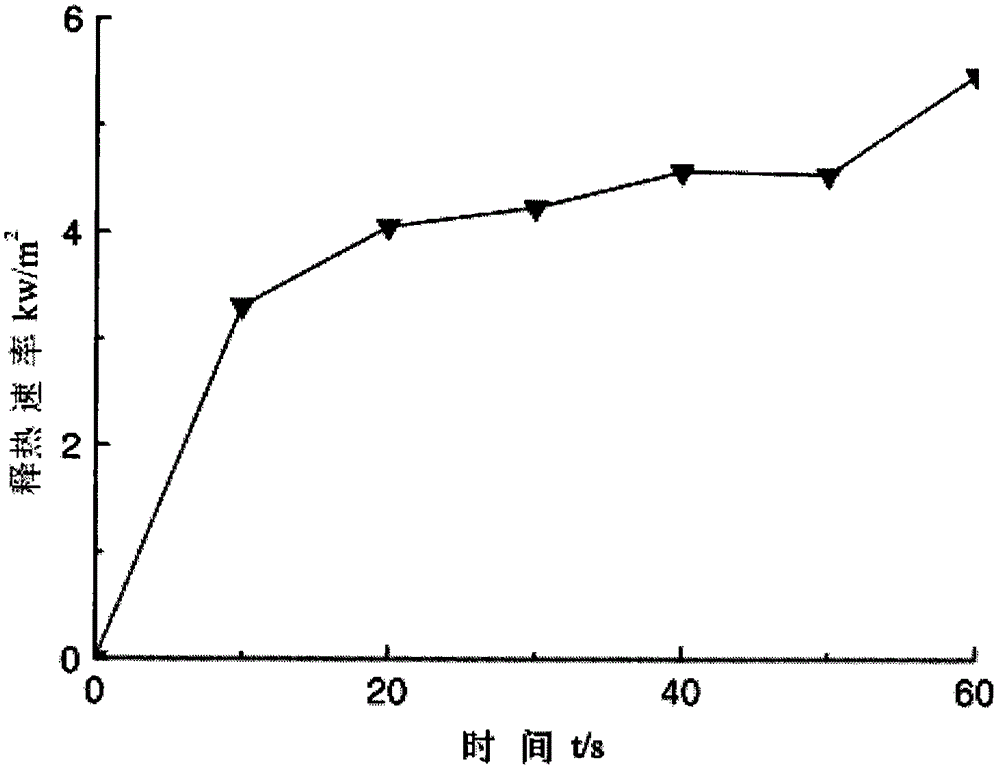

Mass loss rate-based combustible liquid heat release rate testing system

InactiveCN104977222AOther factors have little influenceHas practical significanceMaterial heat developmentMaterial weighingLoss rateThermal insulation

The invention discloses a mass loss rate-based combustible liquid heat release rate testing system, and belongs to the field of testing systems used for determining combustible matter heat release rate in fire disaster developing processes. According to the mass loss rate-based combustible liquid heat release rate testing system, a thermal insulation exhaust fume collecting hood and a natural-type discharge flue are arranged on the upper part of a steel structured flame resistant glass restricted space; the center of the steel structured flame resistant glass restricted space is provided with a pool fire combustion platform which is arranged on a recording balance with heat exposure protection; the recording balance with heat exposure protection is connected with a microcomputer via a mass change collector; a temperature measuring thermocouple tree is arranged on the steel structured flame resistant glass restricted space via penetrating, and is connected with the microcomputer via a temperature data collector; a flue gas sampling probe is arranged on the center line of the natural-type discharge flue, and is connected with the microcomputer via a flue gas component analyzer . Processing and assembling of unit modules of the mass loss rate-based combustible liquid heat release rate testing system are simple; using method and operation processes are simple; and the mass loss rate-based combustible liquid heat release rate testing system possesses certain practical significance and economic application value.

Owner:HENAN POLYTECHNIC UNIV

Rubber friction experiment machine and experiment method

InactiveCN107449732AContinuous Dynamic Friction RealizationEffective detection of temperatureUsing mechanical meansMaterial analysisExperimental methodsEngineering

The invention discloses a rubber friction experiment machine and an experiment method. Problems that the existing abrasion test machine can not conduct the rubber friction research under the conditions of high temperature, high pressure and humidity are solved. The rubber friction experiment machine comprises a base, a rubber fixing device, a rubber movement amplitude detecting device, a rubber pressure loading device, a rubber friction loading device and a signal collecting and processing device, wherein the rubber fixing device is fixed on the base, the rubber movement amplitude detecting device is directly or indirectly fixed on the base, the rubber pressure loading device, the rubber friction loading device are fixed on a shell body, the shell body is fixed on the base, the signal collecting and processing device is connected with a control circuit of the rubber fixing device, the rubber movement amplitude detecting device, the rubber pressure loading device and the rubber friction loading device. The rubber friction experiment machine has the advantages of reasonable structure design, wide test range, anti-damage and accurate measurement of experimental data.

Owner:ANYANG INST OF TECH

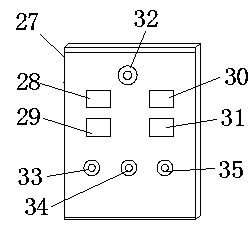

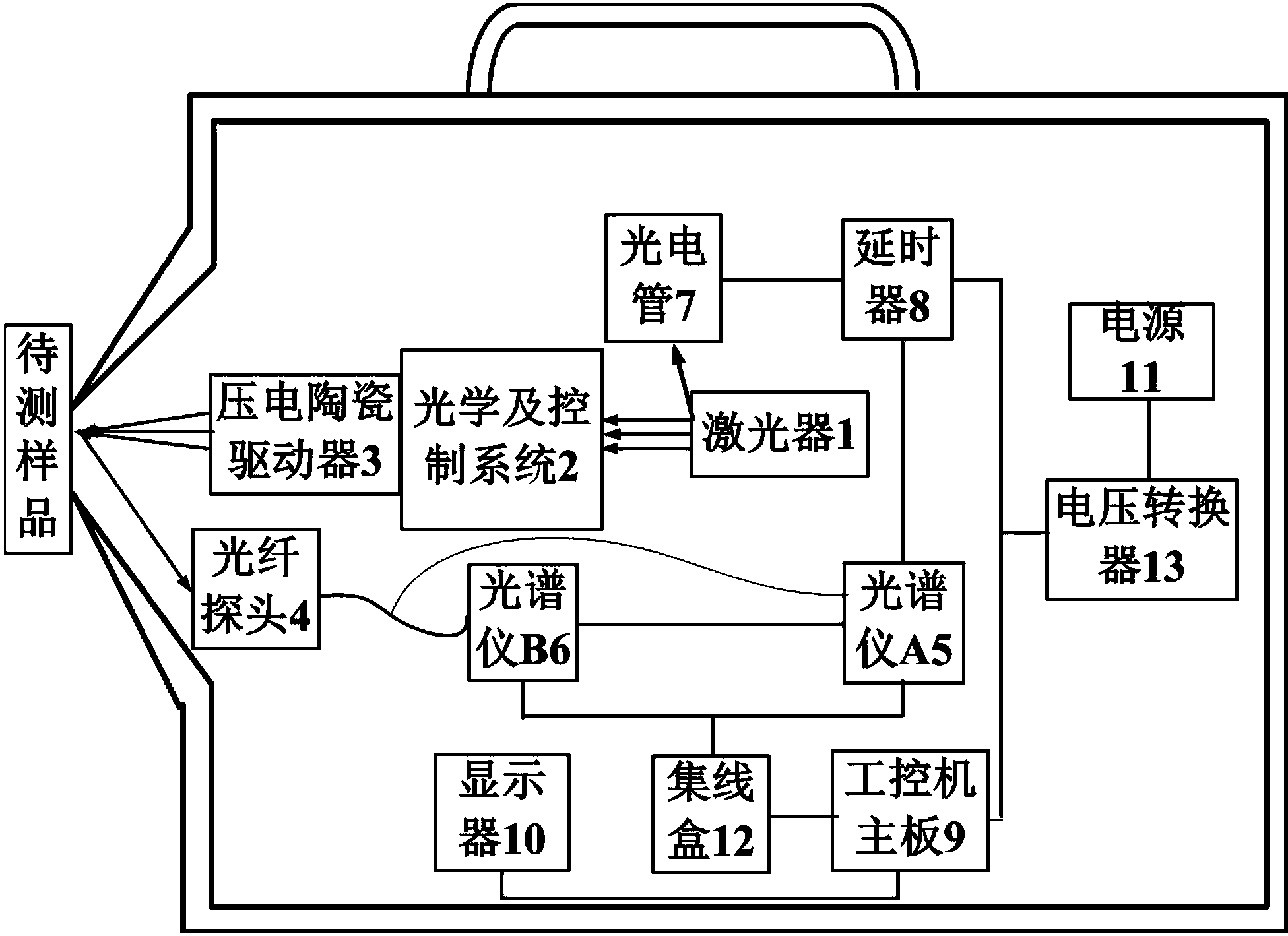

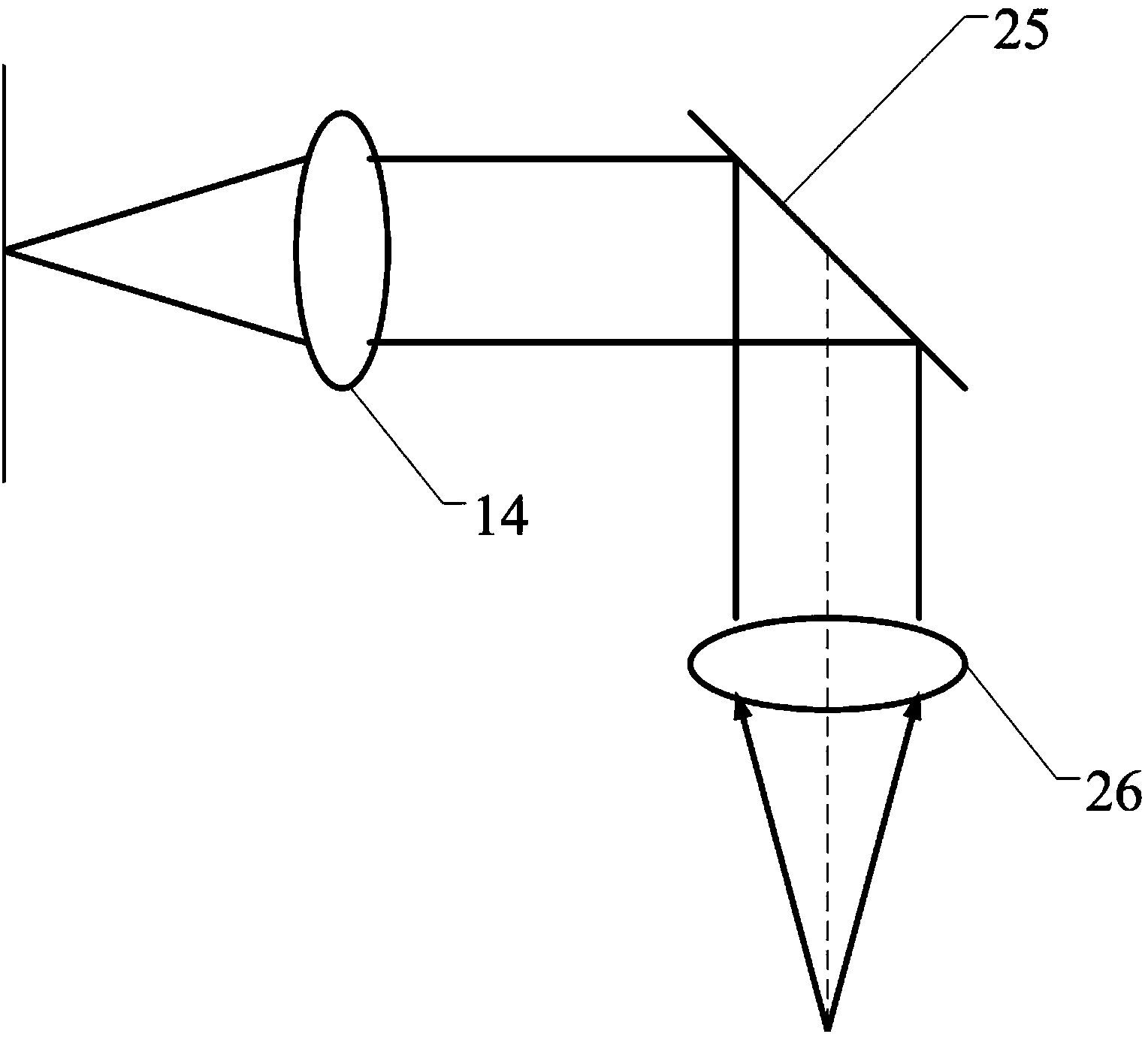

Portable elementary composition analysis device based on laser-induced breakdown spectroscopy technology

ActiveCN104007090AWide range of testsFast testAnalysis by material excitationDisplay deviceSpectrograph

The invention discloses a portable elementary composition analysis device based on a laser-induced breakdown spectroscopy technology. The portable elementary composition analysis device comprises a laser 1, an optical and control system 2 positioned at the front end of the laser 1, a piezoelectric ceramic driver 3 connected with the optical and control system 2, an optical fiber probe 4, a spectrograph A5 and a spectrograph B6 which are connected with the optical fiber probe 4, a phototube 7 positioned in an irradiation range of the laser, a time delayer 8 connected with the phototube 7, and a spectrograph B6 connected with the time delayer 8, wherein the spectrograph A5 and the spectrograph B6 are connected with an industrial personal computer mainboard 9 through a concentrating box 12; the industrial personal computer mainboard 9 is connected with a display 10; the industrial personal computer mainboard 9 is connected with the time delayer 8; the portable elementary composition analysis device also comprises a voltage converter 13; the voltage converter 13 is connected with a power supply 11, the industrial personal computer mainboard 9 and the time delayer 8; all the parts are integrated in a portable suitcase. The elementary composition analysis with outdoor online in-situ detection requirements can be met, the device can be automatically focused to the surface of a sample to be detected, and the type and content of elements contained in the sample are measured.

Owner:SICHUAN UNIV

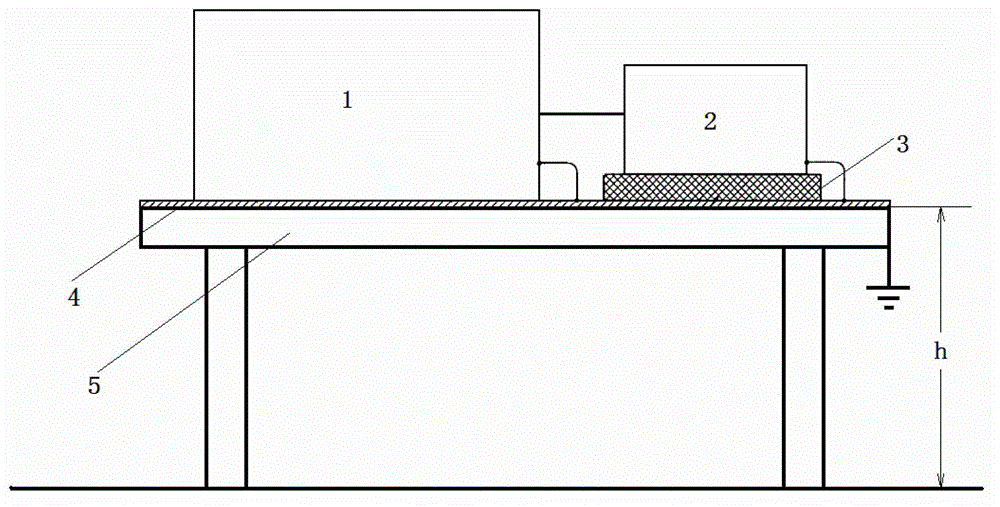

Electromagnetic compatibility test method and device for electric power online monitoring equipment

ActiveCN102914713AWide range of testsRealize remote monitoringElectrical testingComputer hardwareComputer science

The invention relates to an electromagnetic compatibility test method and device for electric power online monitoring equipment. The method comprises the following steps of: (1) performing communication connection on a tested sample and an electromagnetic compatibility tester, and judging whether the connection is successful, if the connection is successful, executing the step (2), or otherwise, continuing executing the step (1); (2) testing the electromagnetic compatibility of the tested sample through the electromagnetic compatibility tester, encrypting tested data and transmitting the tested data to an upper computer through a wireless transmission network; and (3) decrypting the tested data received by the upper computer, and matching and comparing the test data with the data in a database to obtain a rest result of the tested sample, wherein the device comprises the electromagnetic compatibility tester, the upper computer, an insulation support, a grounding reference plane and a non-metal pedestal. Compared with the prior art, the electromagnetic compatibility test method and device have the advantages of wide test range, capability of remote monitoring, high test precision and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

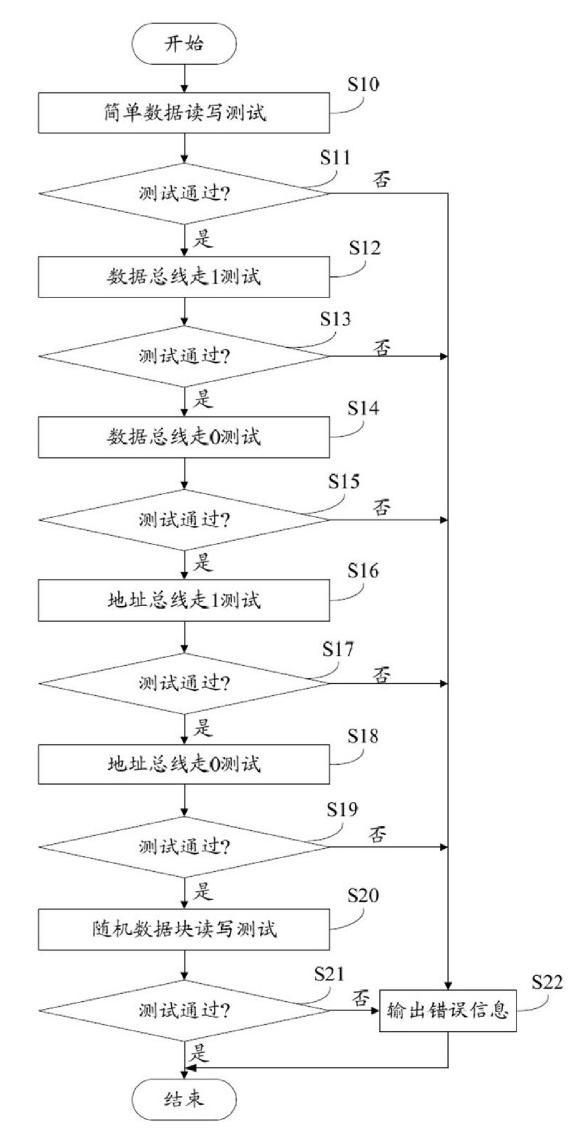

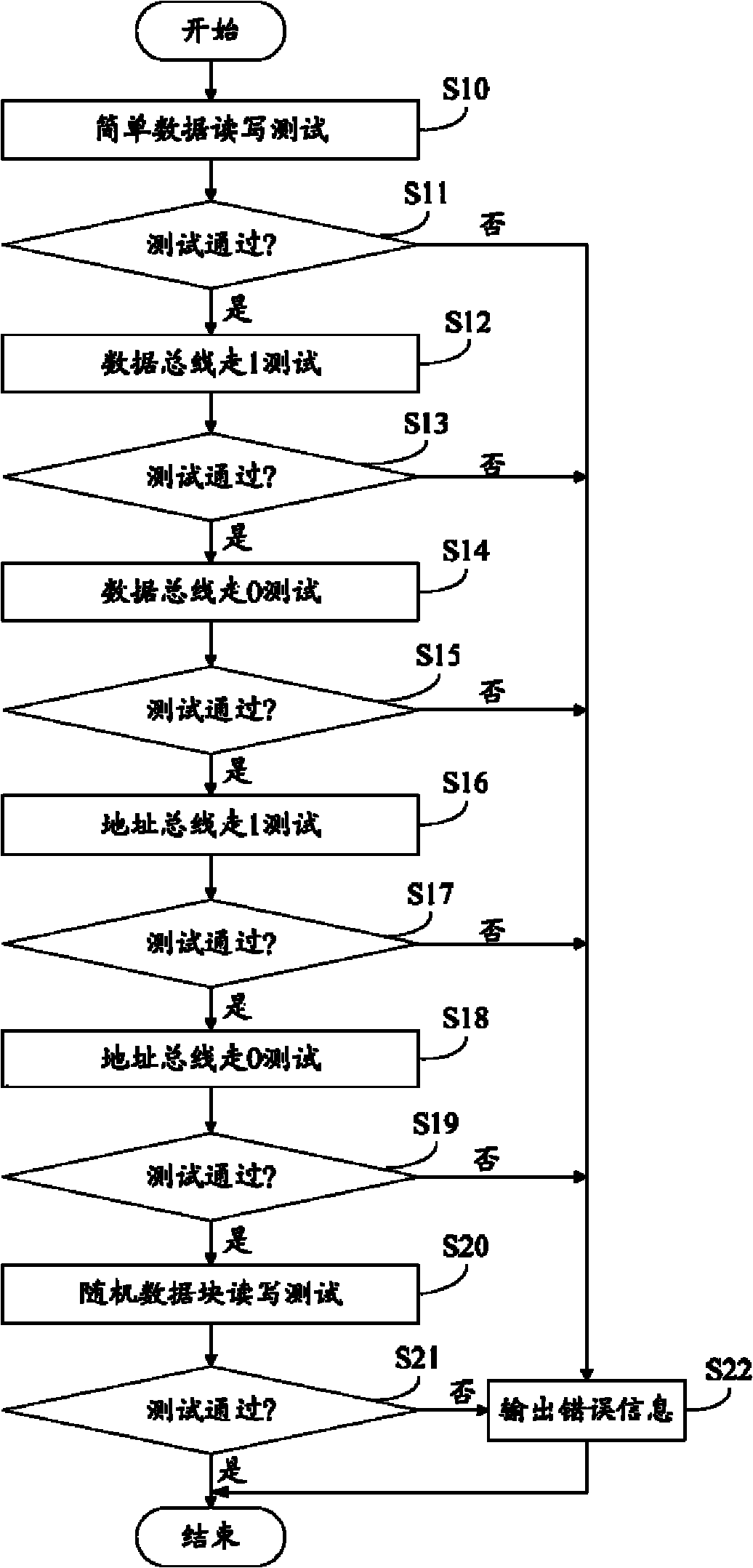

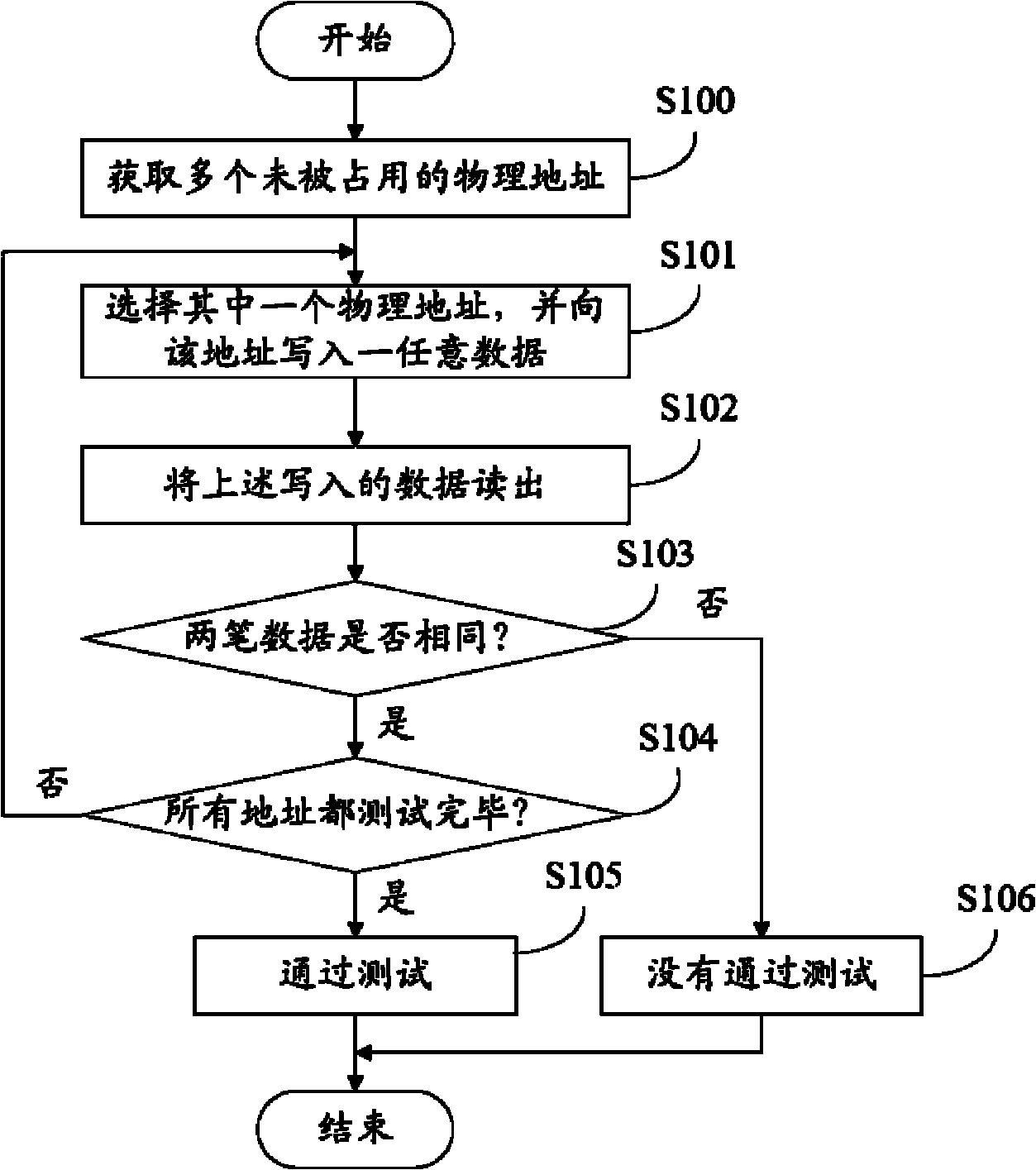

Memory test method

InactiveCN101814050AMany test itemsWide range of testsSoftware testing/debuggingStatic storageComputer hardwareAddress bus

The invention provides a memory test method, comprising: carrying out simple data write and read test on the memory; carrying out a data bus walking 1 / 0 test to the memory; carrying out an address bus walking 1 / 0 test to the memory; and carrying out the write and read test on the random data block of the memory. The invention provides a precise and comprehensive memory test method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

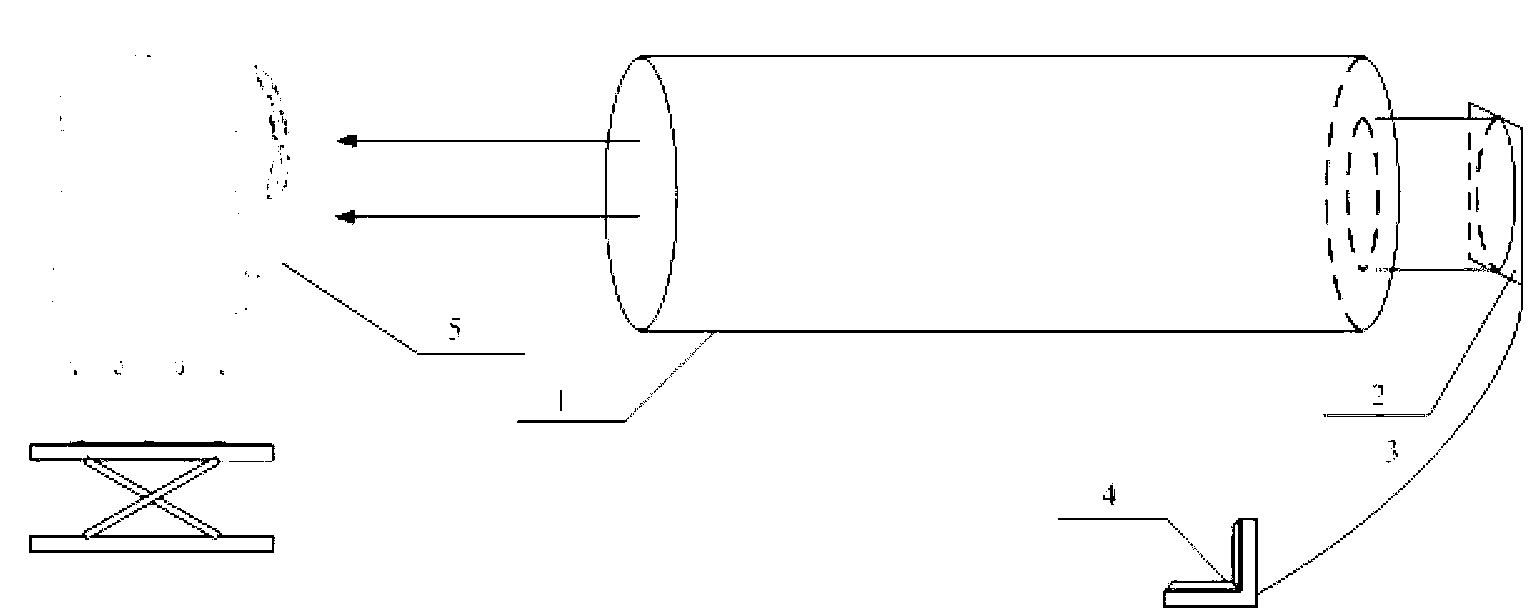

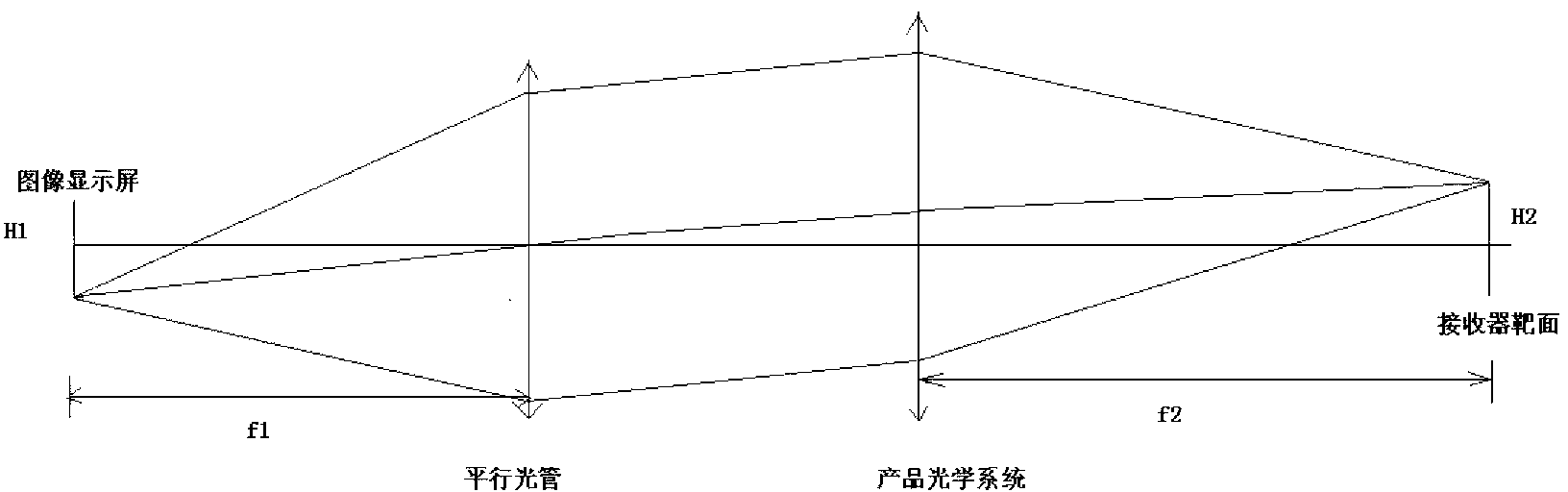

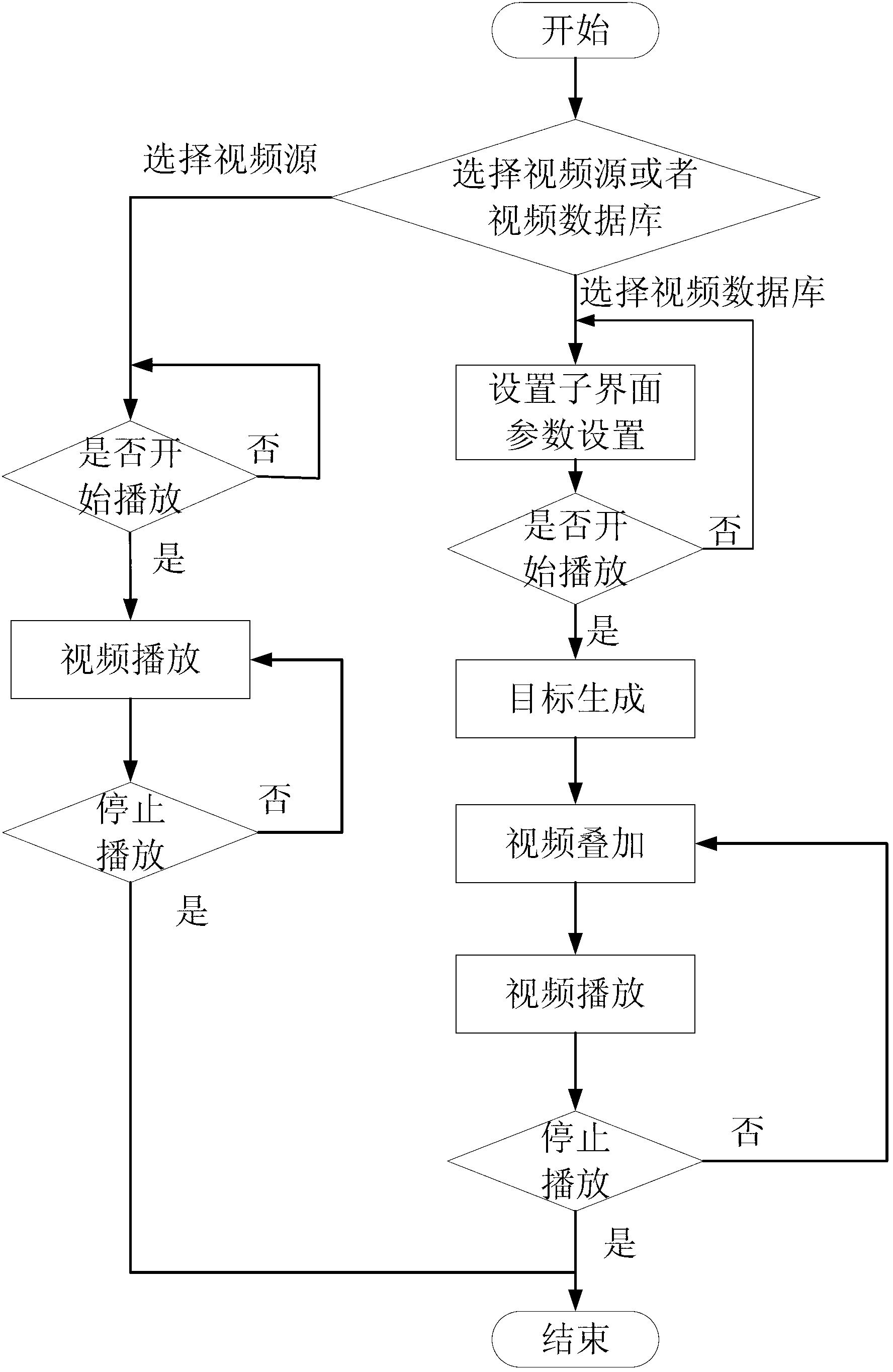

Testing device for tracking performance of photoelectric stabilization tracking platform

The invention discloses a testing device for tracking performance of a photoelectric stabilization tracking platform. The device comprises a collimator tube, a display screen and a video management computer, wherein the video management computer can directly output a practically recorded video image containing a true target and a background, and can also output a video image which is generated by software superposition and contains a simulated target and the background; the display screen is placed on a focal plane of the collimator tube, and displays the video image which is output by the video management computer and contains the background and the simulated target; and the collimator tube sends the collimated video image into a view field of the to-be-tested photoelectric stabilization tracking platform. The device can test the servo tracking loop performance of the photoelectric stabilization tracking platform, and can also test the performance of a video tracker according to variations of the background and the simulated target of the image on the display screen, so that the comprehensive tracking performance testing of the photoelectric stabilization tracking platform is achieved. The testing device has the advantages that the testing device is simple in structure, easy to operate, and wide in testing range.

Owner:西安应用光学研究所

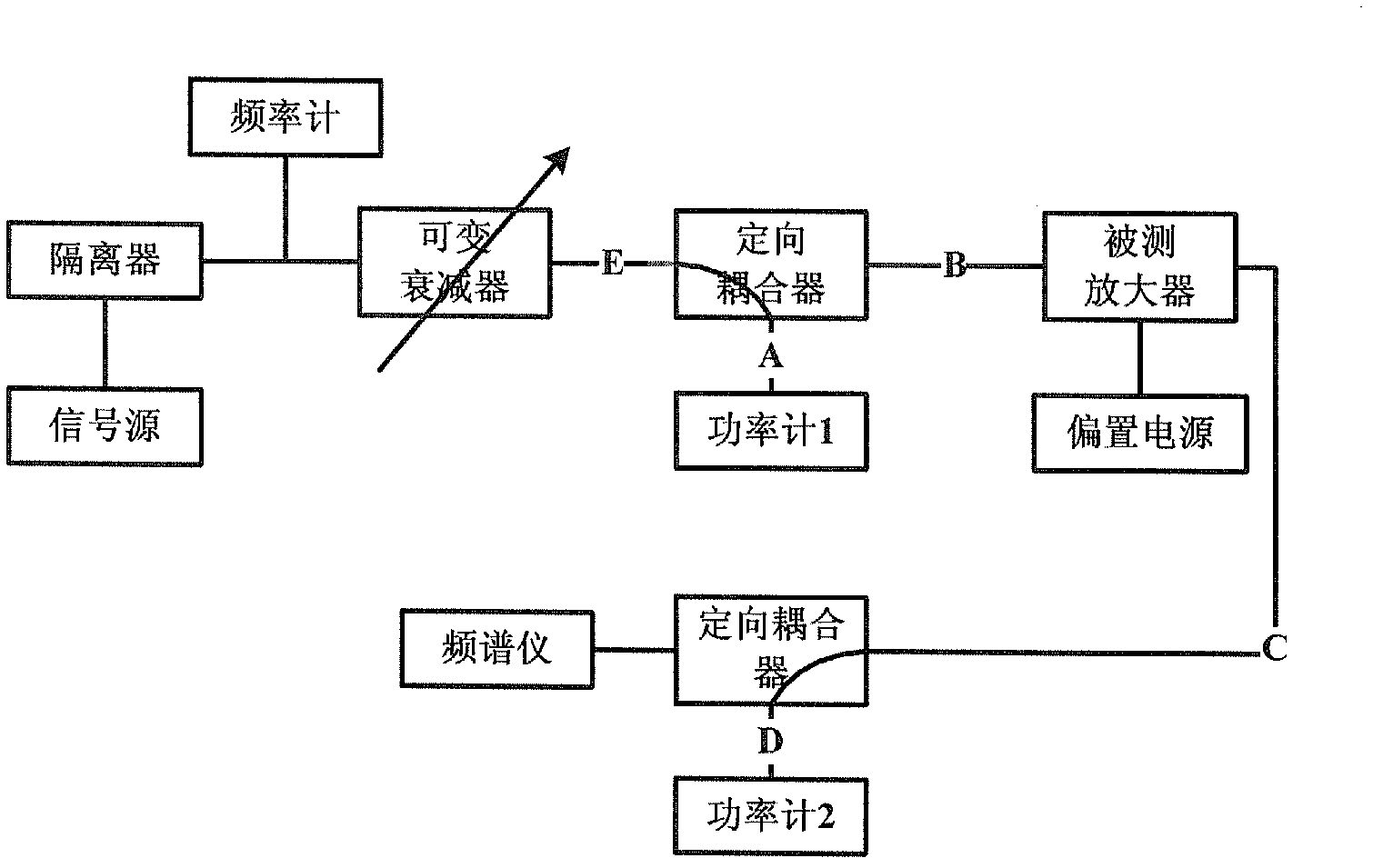

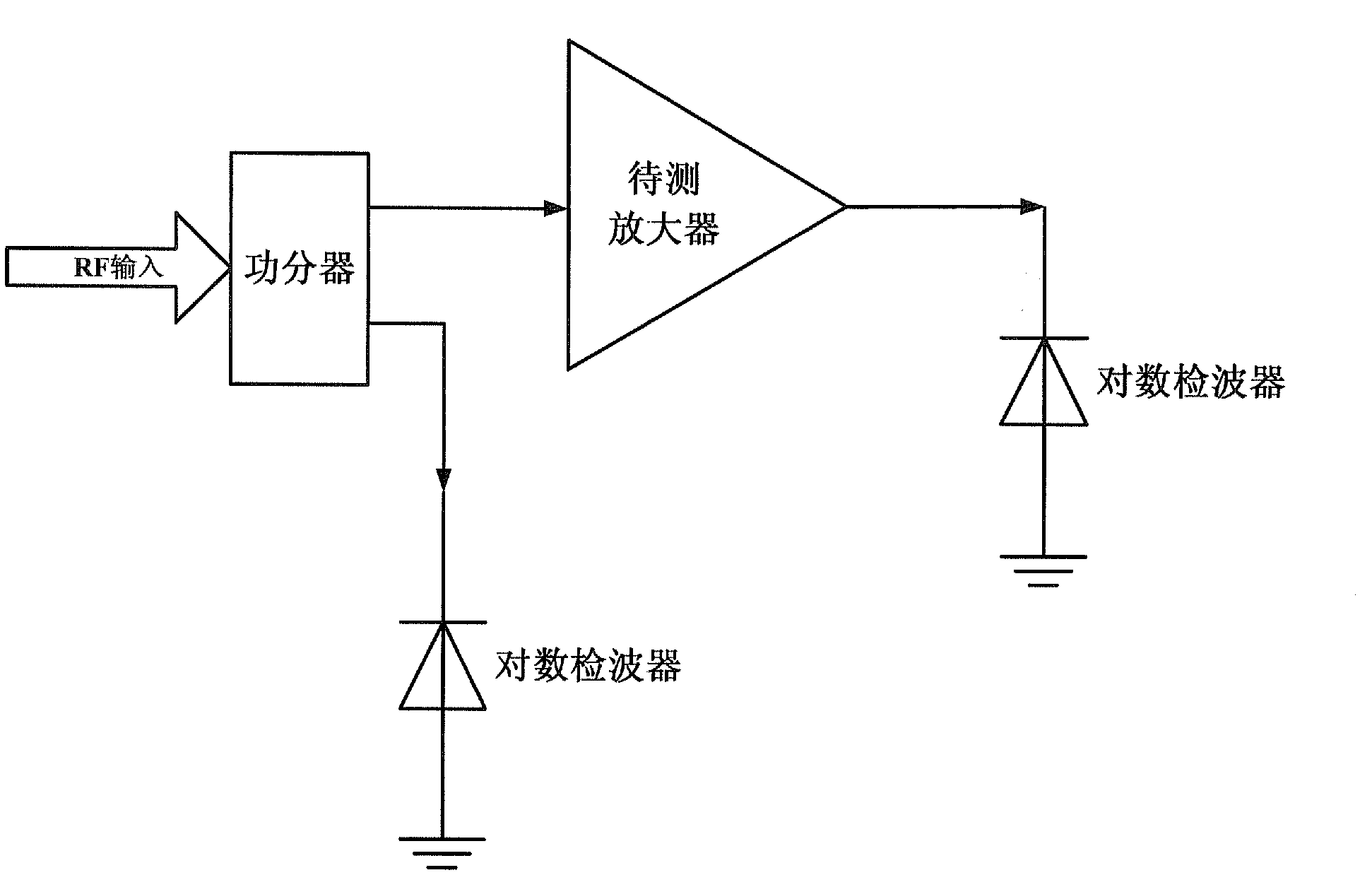

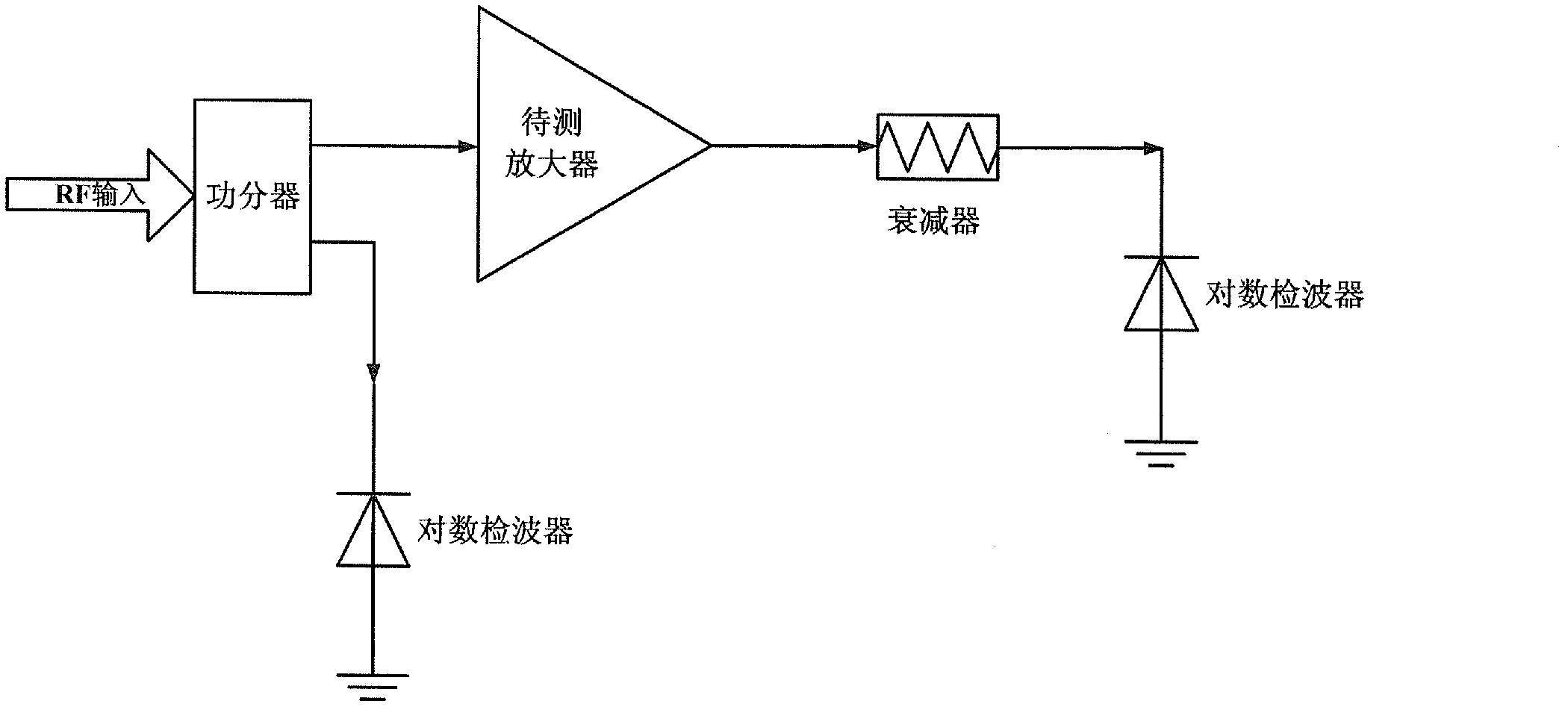

Device and method used for testing radio frequency amplifier gain

The invention discloses a device and a method used for testing radio frequency amplifier gain. The device for testing the radio frequency amplifier gain comprises a power divider, a first logarithm detector and a second logarithm detector, wherein the power divider is provided with two output ends, one output end is connected with the first logarithm detector, and the other output end is connected with the second logarithm detector through an under-tested amplifier. The device and the method used for testing the radio frequency amplifier gain test power by replacing power meters by the logarithm detectors, so that the cost of the under-tested system is shapely reduced. The device used for testing the radio frequency amplifier gain has the advantage of being simple in structure, low in cost, high in accuracy, wide in testing range, and capable of testing the gain of the amplifier in a range of wide band and power.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

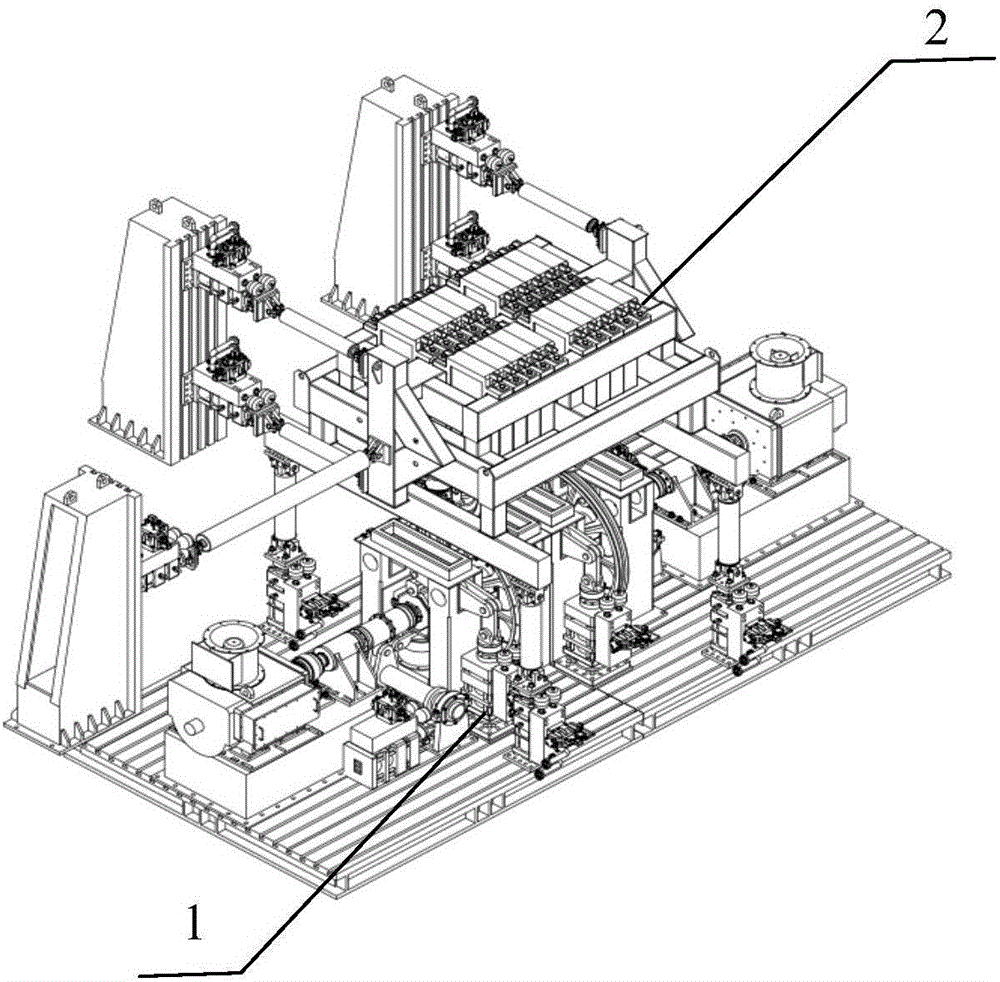

Three-degree-of-freedom wheel rail relation test stand for high-speed track

PendingCN106840718ARealize irregularitiesGuaranteed accuracyRailway vehicle testingVibration testingControl systemThree degrees of freedom

The invention relates to a three-degree-of-freedom wheel rail relation test stand for a high-speed track. The test stand comprises dual three-degree-of-freedom track wheel system devices (1) and a weight vehicle and six-degree-of-freedom pose control system device (2); the weight vehicle and six-degree-of-freedom pose control system device (2) is mounted on a No. 1 T-shaped groove platform (5) and a No. 2 T-shaped groove platform (6) through 2 No. 1 vertical actuator and connecting rod assemblies and 2 No. 2 vertical actuator and connecting rod assemblies. The test stand can be used to accurately simulate the vibration of opposite wheel sets on the track when a high-speed bullet train runs on an actual track; two track wheels are not directly connected and achieve three-degree-of-freedom movement respectively through six actuators, namely transverse movement, vertical movement and rotational movement around a longitudinal axis; and the simulation of unsmooth phenomenon on the high-speed train track can be realized. Therefore, the problem that wheeltrack reliability tests cannot be directly conducted in an actually running train is solved.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com