Multifunctional geotechnical model testing system and method

A geotechnical model and test system technology, which is used in soil material testing, material inspection products, preparation of test samples, etc., can solve the problem that the model box cannot simulate the temperature field, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

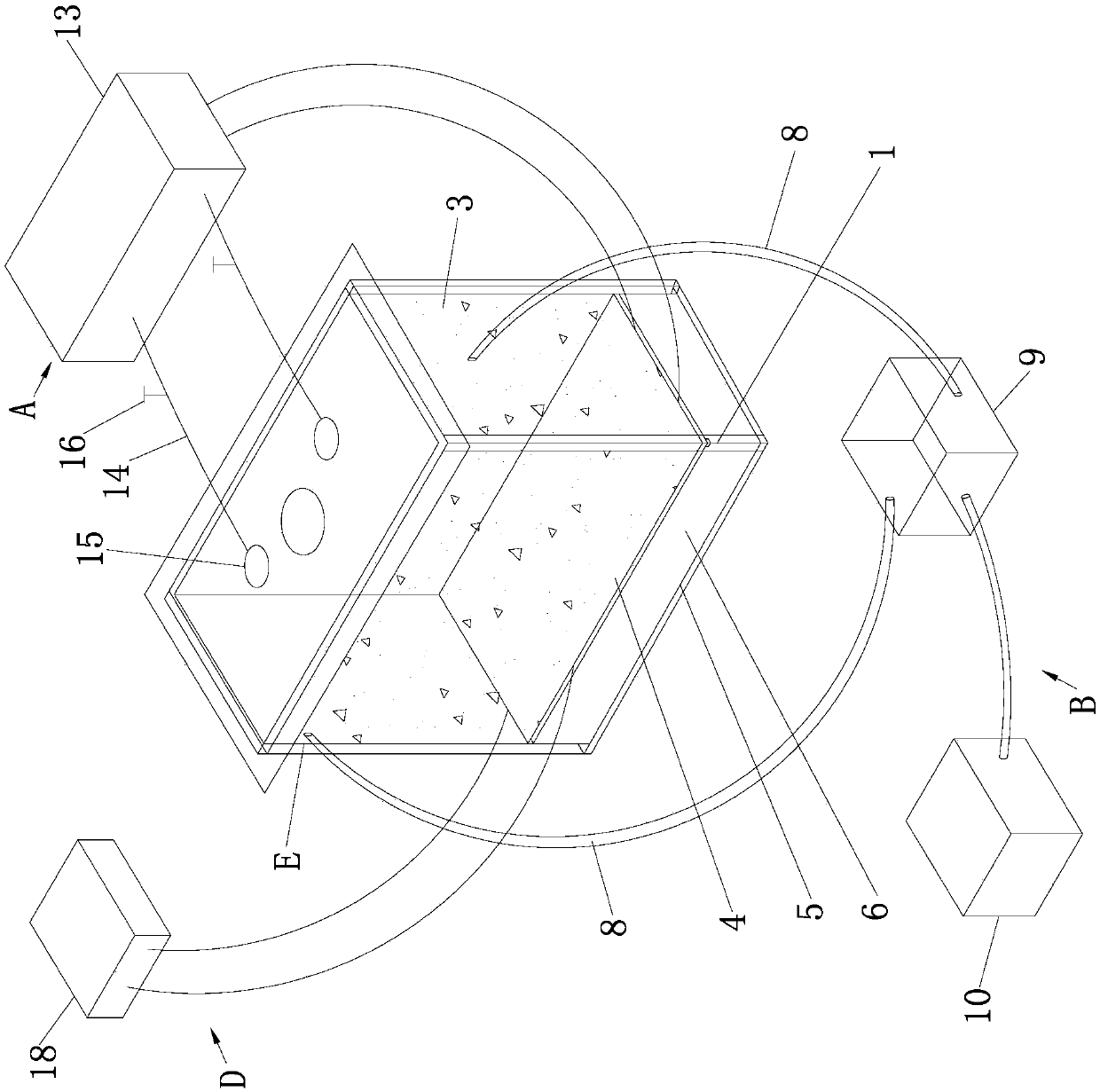

[0034] Example 1: Simulation of Post-construction Behavior of Highway Soft Soil Foundation in Seasonally Frozen Areas

[0035] Step 1: According to the aforementioned content and the needs of the test conditions, it is necessary to determine the size of the model: length × width × height = 1.2m × 0.6m × 0.9m, the similarity ratio of the model is 1:50, the length of the subgrade model is 0.52m, and the slope The ratio is 1:1.5, and the model box is made according to the content of the invention and the established size, and a loading mechanism and a water supply mechanism are installed on the upper part of the model box;

[0036] Step 2: prepare simulated soil materials, take a sufficient amount of muddy clay and ordinary clay from the construction site for use;

[0037] Step 3: Paste a film ruler on the observation surface of the side wall of the model box, paste a layer of filter paper on the upper bottom plate 4, and start filling the simulated muddy clay material. After fil...

Embodiment 2

[0041] Example 2: Stability Simulation of Highway Soil Slope

[0042] Step 1: According to the aforementioned content and the needs of the test conditions, it is necessary to determine the size of the model: length × width × height = 1.2m × 0.6m × 0.9m, the similarity ratio of the model is 1:50, the length of the subgrade model is 0.52m, and the slope The ratio is 1:1.5, and the model box E is made according to the content of the invention and the size formulated, and the top plate 2 of the model box E is equipped with a water supply mechanism;

[0043] Step 2: First remove the top plate 2 of the model box E, fill the soil subgrade inside the model box E, build the slope model, bury the earth pressure sensor at the predetermined position, connect the sensor wiring through the small hole on the side wall and collect the data Connect the instrument 18, cover the top plate 2, adjust the temperature through the temperature control panel on the refrigeration compressor 10, make the...

Embodiment 3

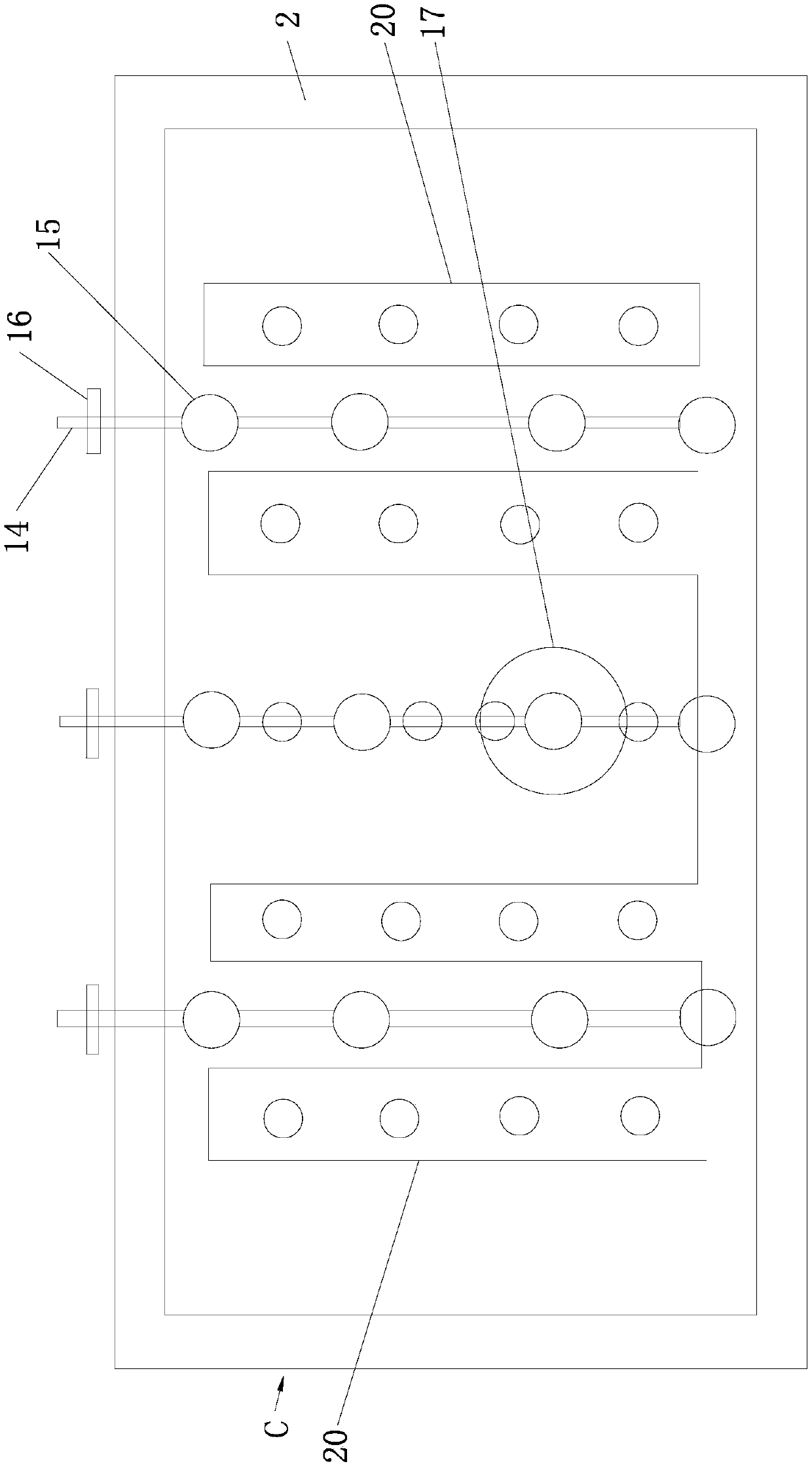

[0046] Example 3: Simulation of dry-wet cycle characteristics of highway expansive soil

[0047] Step 1: According to the aforementioned content and the needs of the test conditions, it is necessary to determine the size of the model: length × width × height = 1.2m × 0.6m × 0.9m, the similarity ratio of the model is 1:50, the length of the subgrade model is 0.52m, and the slope The ratio is 1:1.5, and the model box E is made according to the content of the invention and the size formulated, and the top plate 2 of the model box E is equipped with a water supply mechanism A and a heating mechanism C;

[0048] Step 2: first remove the top plate 2 of the model box E, fill the expansive soil embankment inside the model box E, build the slope model, cover the top plate 2, adjust the heating temperature of the heating pipe 20 through the control panel, and make the model When the ambient temperature inside the box E reaches the simulated temperature, open the main valve of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com