Mass loss rate-based combustible liquid heat release rate testing system

A mass loss rate and rate testing technology, applied in the direction of measuring devices, material thermal development, instruments, etc., can solve the problems of complex price of instruments, difficult heat insulation device, low heat release rate, etc., and achieve simple test system, simple processing and assembly, The effect of the method of use and the ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

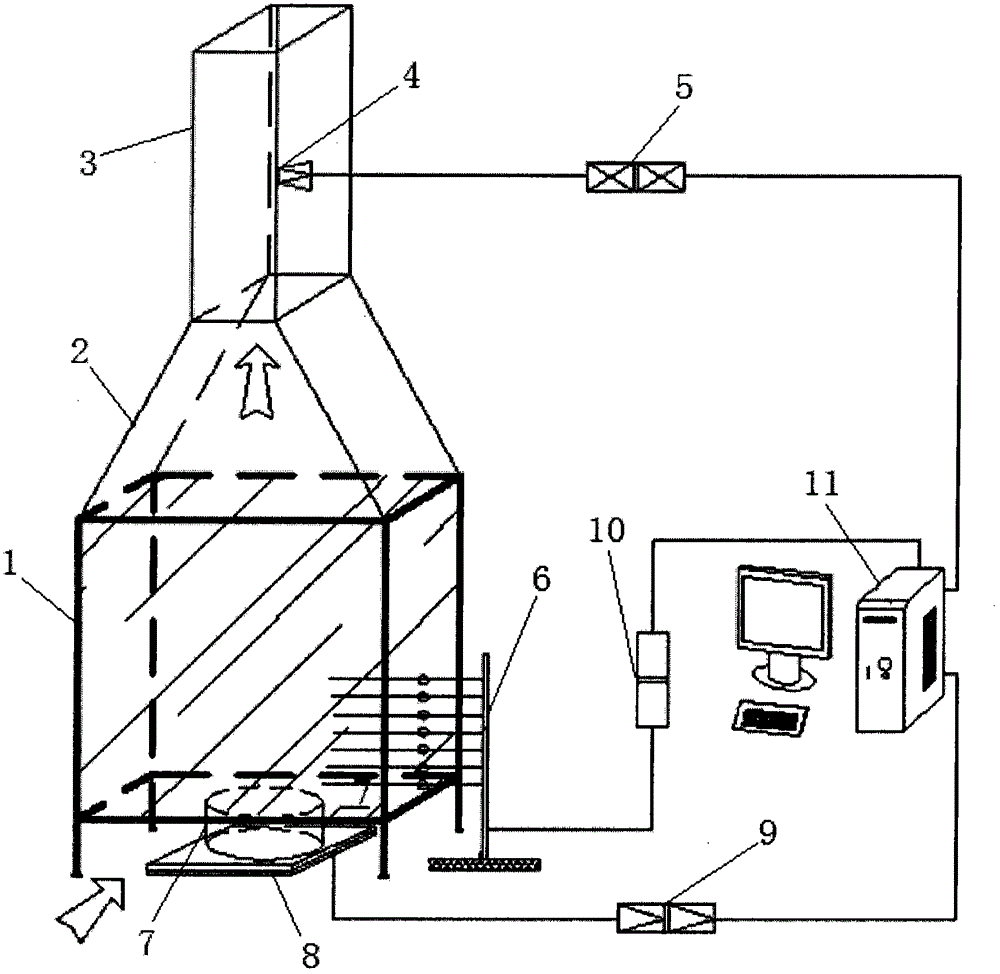

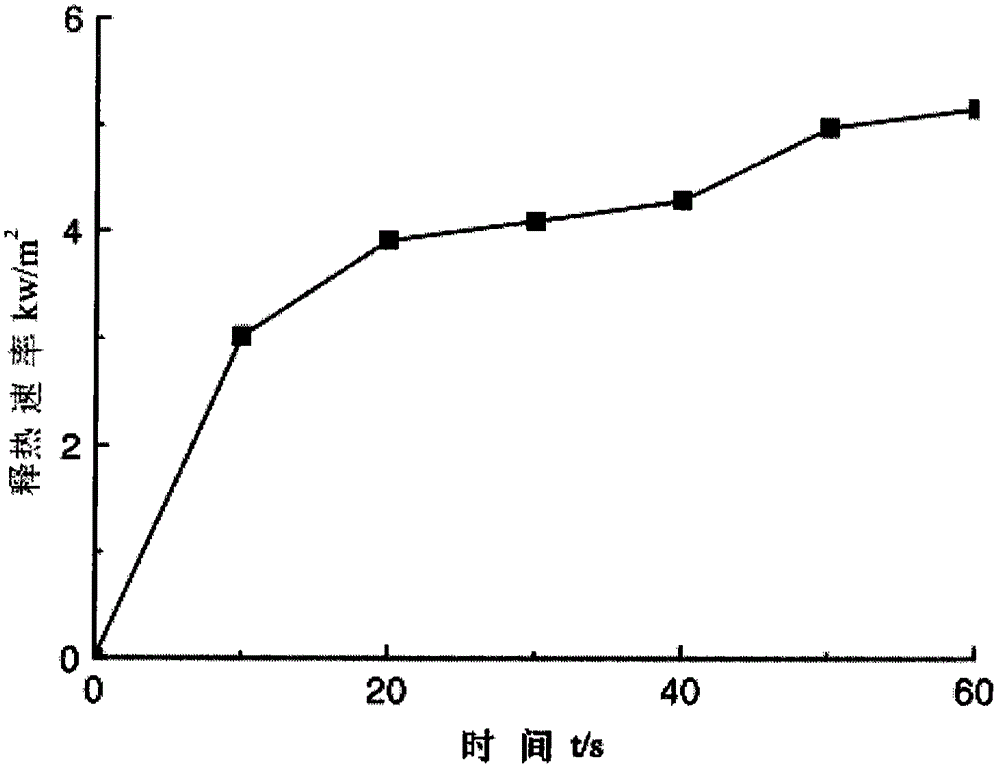

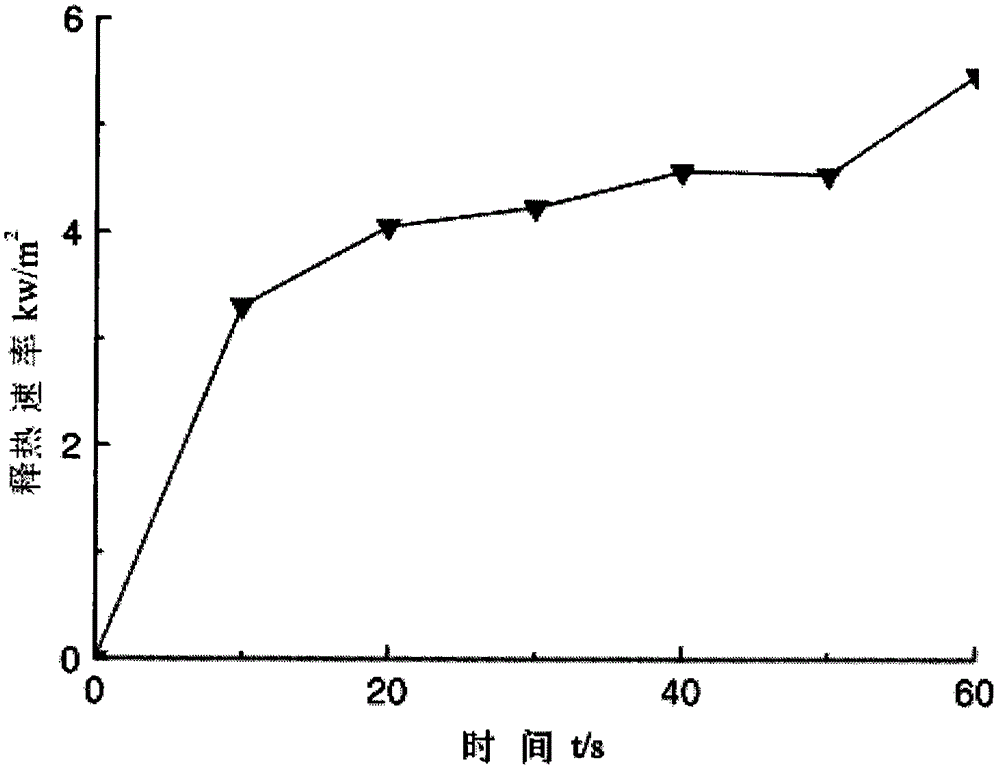

[0025] refer to Figure 1-6 , the specific embodiment adopts the following technical solutions: a test system for the heat release rate of flammable liquids based on the mass loss rate, including a confined space and a pool fire combustion platform, a flame temperature acquisition unit, a mass change test unit and a combustion smoke test unit , the confined space and the pool fire combustion platform are composed of a steel structure fire-resistant glass confined space 1, a heat-insulating smoke collection hood 2, a natural flue exhaust 3 and a pool fire combustion platform 7, and the steel structure fire-resistant glass is installed above the confined space 1 There is a heat-insulated fume-collecting hood 2, and a natural flue exhaust duct 3 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com