A test device and test method for foam concrete bubble stability

A foam concrete and testing device technology, applied in the field of foam concrete, can solve the problems of long time consumption, low accuracy, difficult quantitative evaluation of bubble stability, etc., and achieve the goals of shortening the test cycle, high reliability and accuracy, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

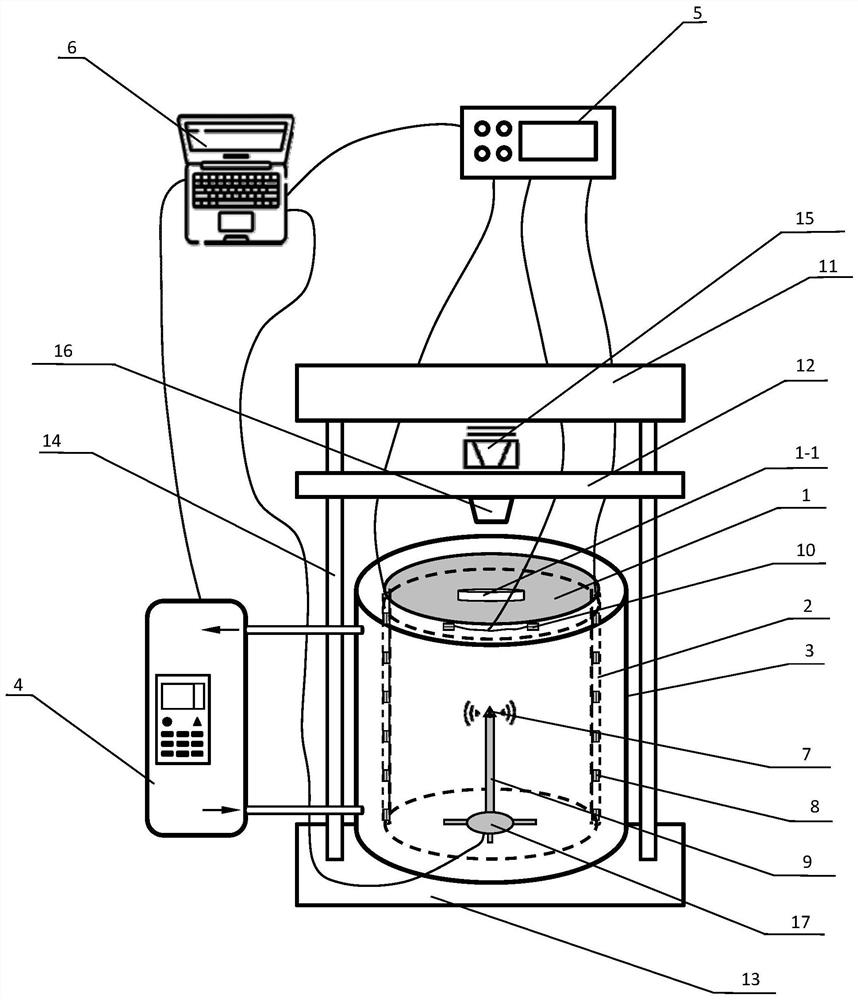

[0039] Specific embodiment one: combination Figure 1 and Figure 2 Illustrating the present embodiment, a foam concrete bubble stability test apparatus, which comprises a pressurized assembly, a sealed piston plate 1, an inner cylinder container 2, an outer cylinder container 3, a water bath temperature control device 4, a data acquisition device 5, a microcomputer control device 6, an acoustic signal transmitter 7 and a plurality of acoustic signal receivers 8,

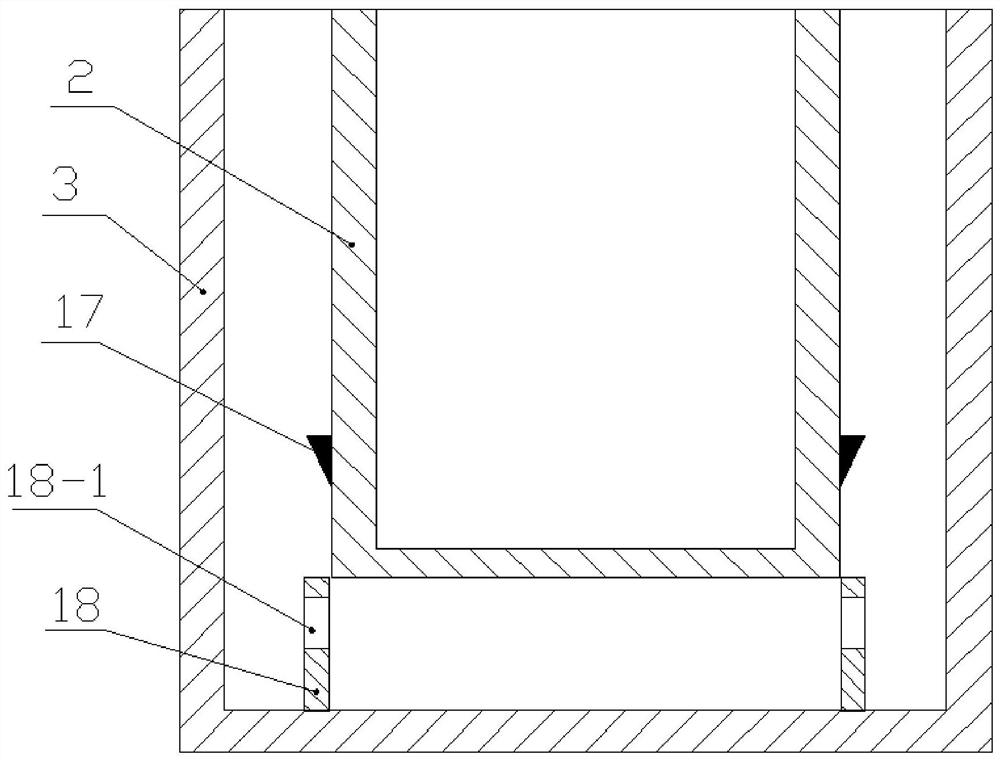

[0040] Outer cylinder container 3 coaxial sleeve is located outside the inner cylinder container 2, the outer cylinder container 3 inner wall and the inner cylinder container 2 outer wall between the formation of a closed cavity, the outer cylinder container 3 of the cylinder wall is provided with two circulation interfaces, the cavity and the water bath temperature control equipment is connected, the bottom coaxial of the inner cylinder container 2 is provided with a pole 9, the acoustic signal transmitter 7 is installe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com