Vacuum friction abrasion test device

A friction and wear test, vacuum technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of vacuum system pollution, increase the difficulty of vacuum extraction, pump oil backflow and other problems, achieve easy operation and disassembly, simple structure , the effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

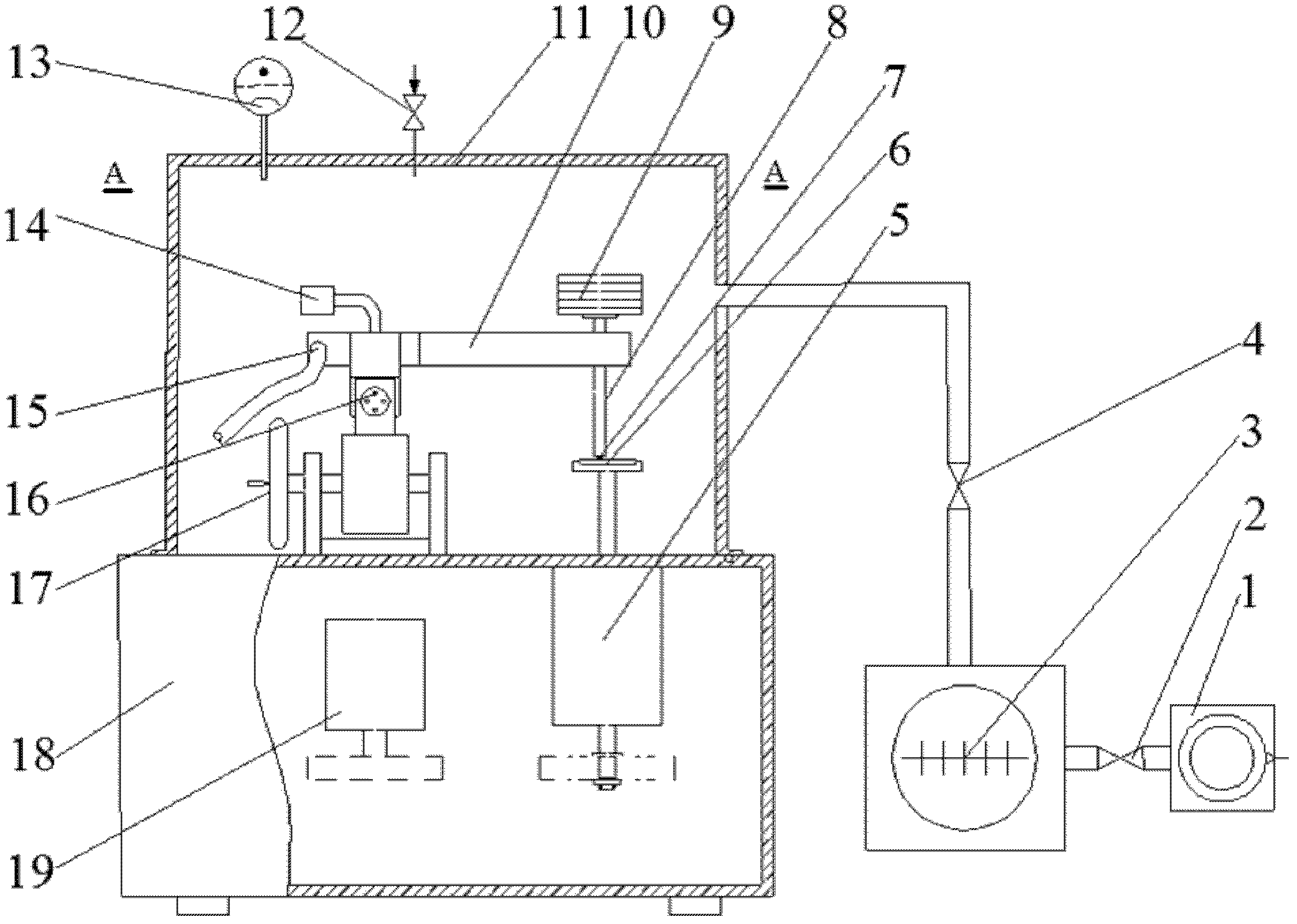

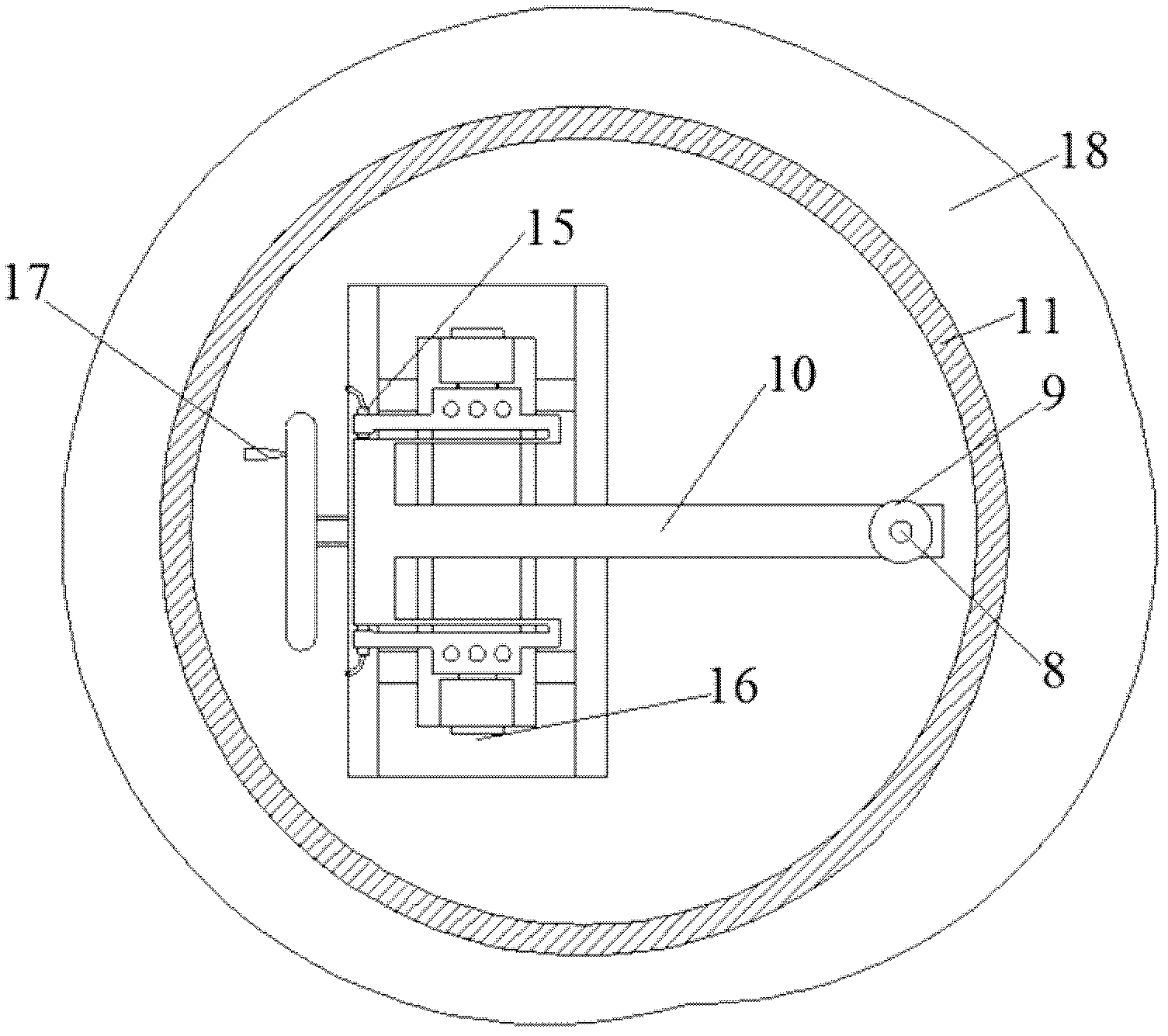

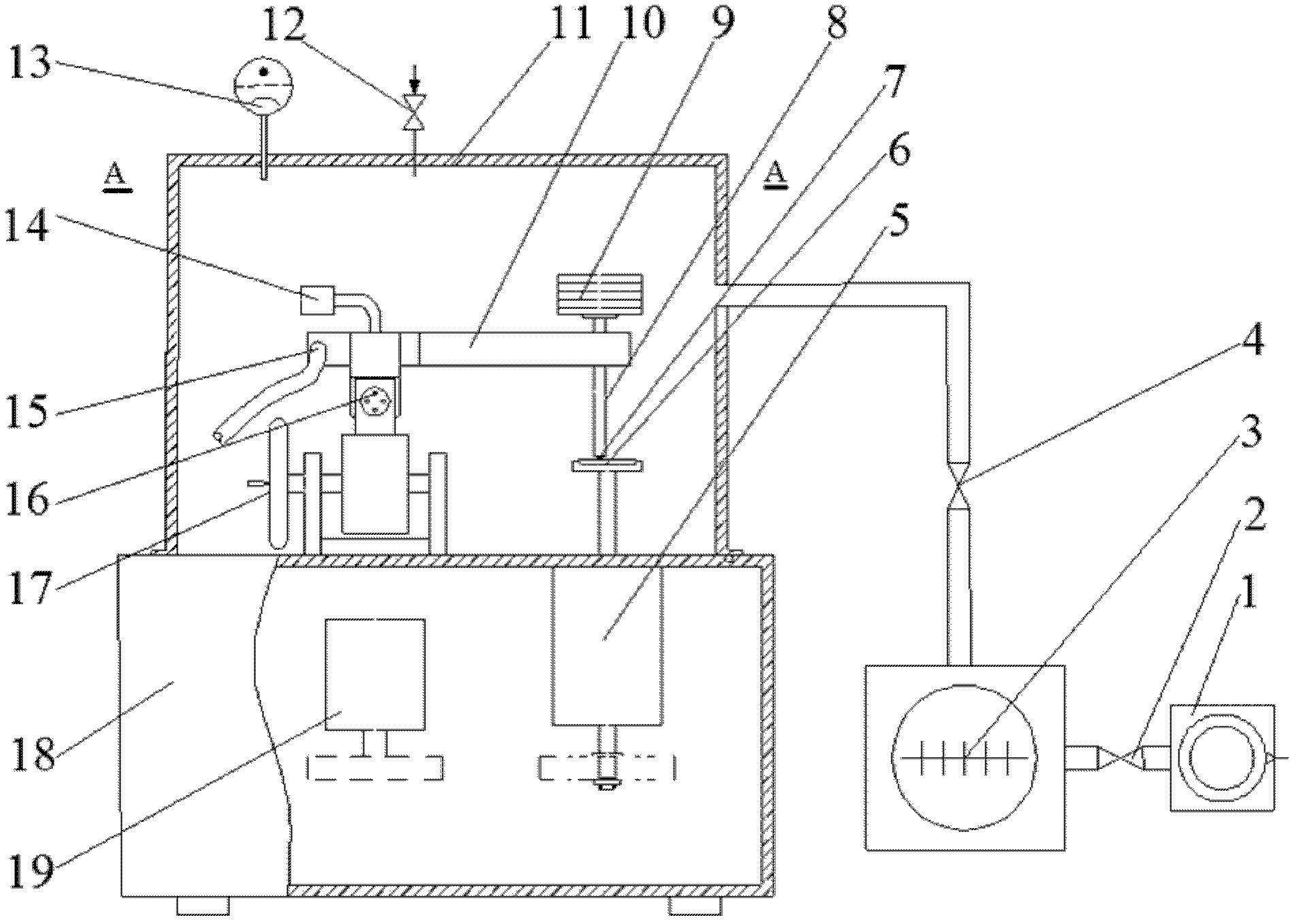

[0016] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] With reference to accompanying drawing, a kind of vacuum friction and wear test device comprises base 18, and vacuum cover 11 is arranged on base 18, and vacuum gauge 13 and inflation valve 12 are installed on the top of vacuum cover 11. The vacuum gauge 13 is used to measure the degree of vacuum in the vacuum cover 11, and the filling valve 12 is used to input the atmosphere inside when the vacuum system is opened. The base 18 is provided with a driving motor 19, and the driving shaft 5 of the driving motor 19 is provided with a moving sample disk 6, and the driving shaft 5 drives the moving sample disk 6 to rotate. The fixed sample 7 is fixed by the fixed sample clamp 8, and the height of the fixed sample 7 is obtained by adjusting the height of the fixed sample clamp 8. The fixed sample fixture 8 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com