Rubber friction experiment machine and experiment method

A technology of testing machine and rubber, which is applied in the field of friction testing machine, can solve problems such as inability to study rubber friction, and achieve the effect of stable and accurate measurement results and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be further described in detail below.

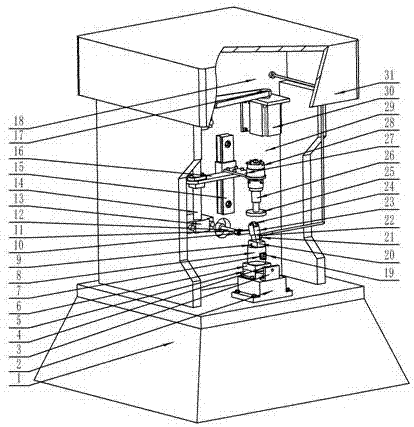

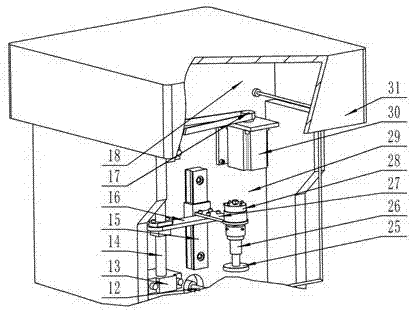

[0045] according to Figure 1-14 Detailed description of the specific structure of the present invention, the rubber friction testing machine includes a base 1, a rubber fixing device, a rubber movement range detection device, a rubber pressure loading device, a rubber friction loading device, a signal acquisition and processing device, the rubber fixing device Fixed on the base 1, the rubber movement range detection device is directly or indirectly fixed on the base 1, the rubber pressure loading device and the rubber friction loading device are fixed on the housing 29, the housing is fixed on the base 1, and the signal acquisition The processing device is connected to the control circuit of the rubber fixing device, the rubber movement range detection device, the rubber pressure loading device, and the rubber friction force loading device, and is used to measure the heating temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com