A temperature monitoring device and a power supply device

A monitoring device and battery module technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of shortening the life of the battery module, inability to accurately detect the internal temperature of the module, etc., and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

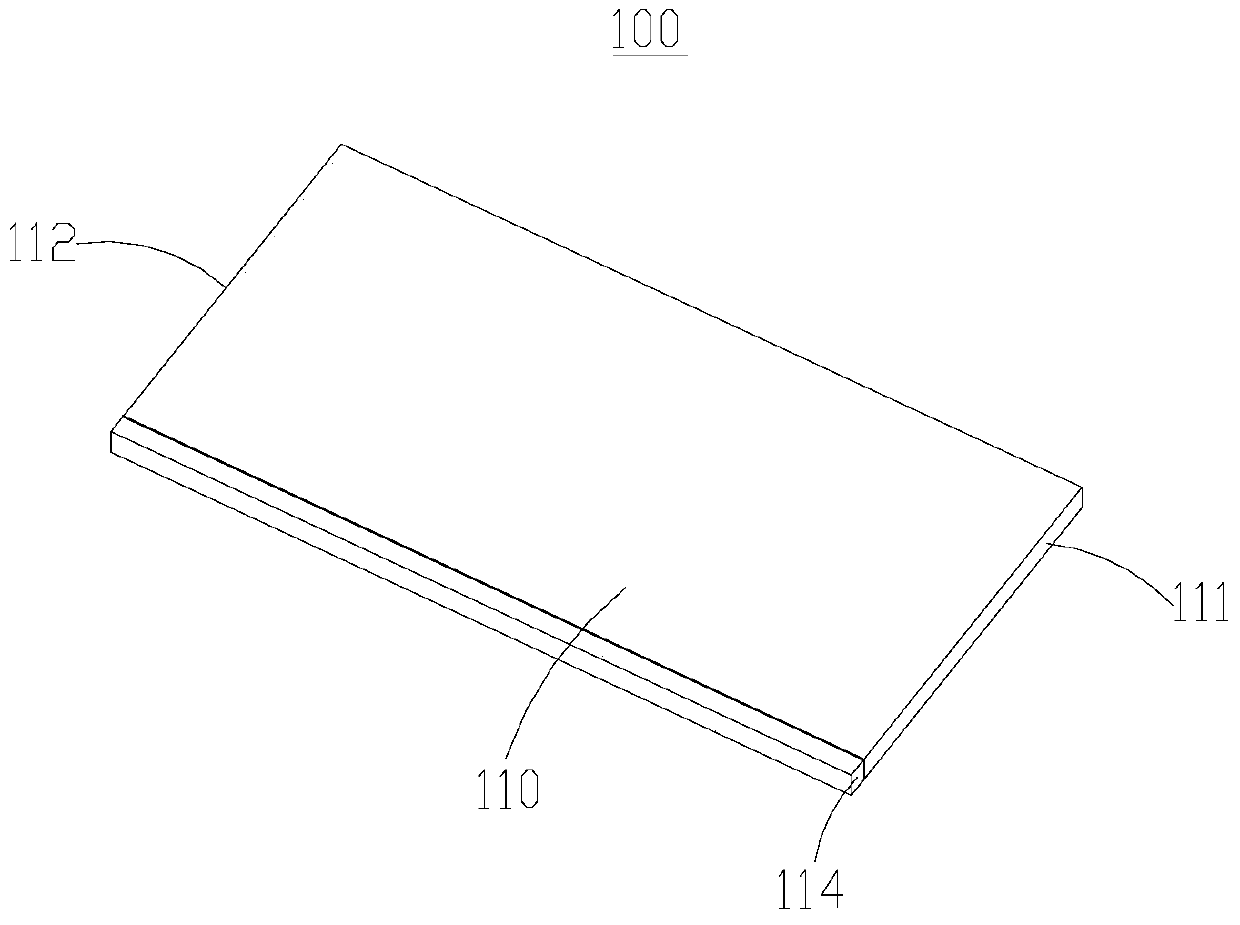

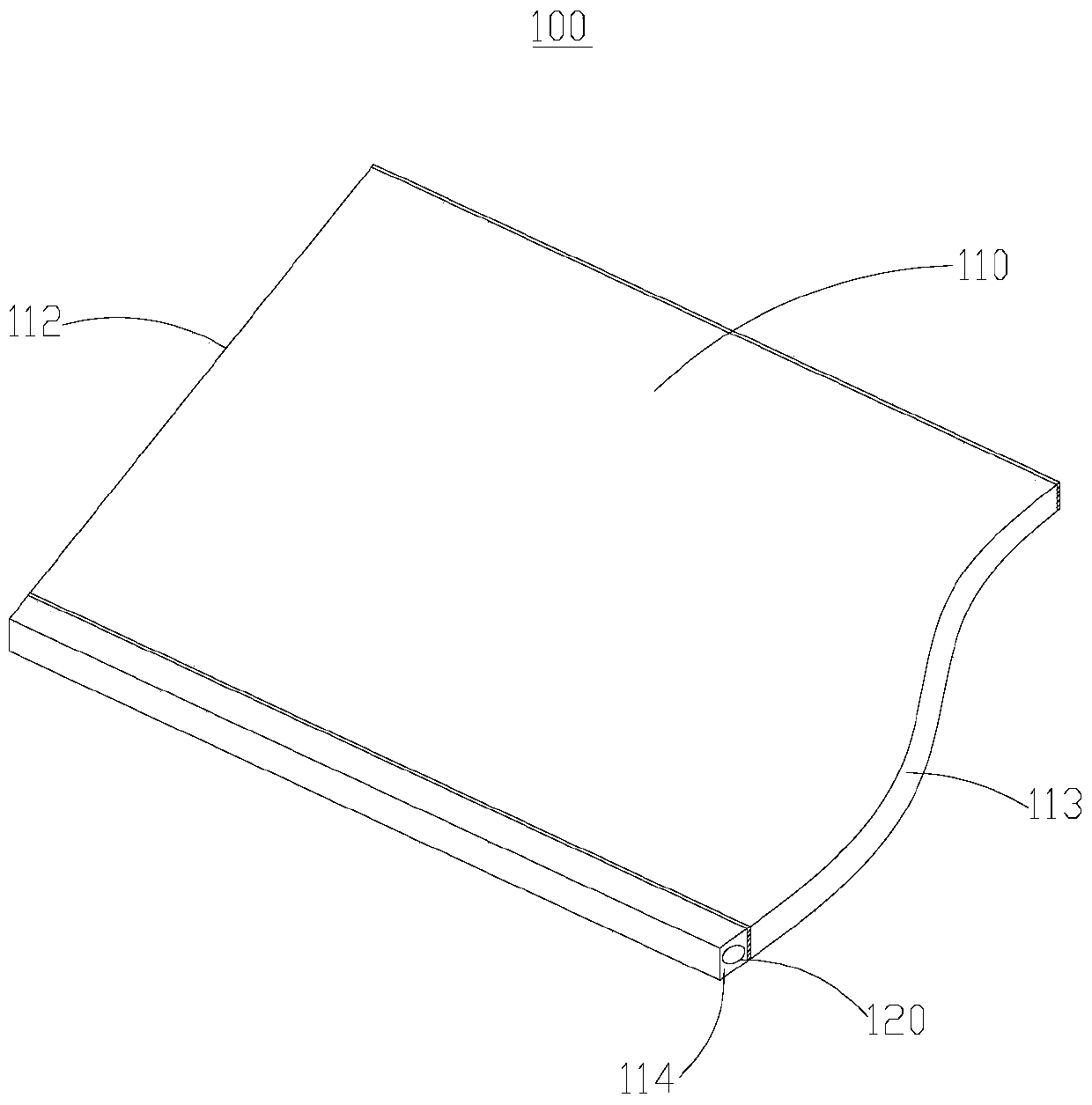

[0044] For a first example, see Figure 1 to Figure 4

[0045] The temperature monitoring device 100 provided in this embodiment includes a liquid-cooled flat tube 110 and at least one temperature detection unit 120. For details, please refer to figure 1 The three-dimensional structural schematic diagram of the temperature monitoring device 100 shown and figure 2 The three-dimensional cross-sectional view of the temperature monitoring device 100 is shown. Wherein, the liquid-cooled flat tube 110 includes a liquid inlet 111 , a liquid outlet 112 , and a coolant circulation channel 113 communicating with the liquid inlet 111 and the liquid outlet 112 . The liquid-cooled flat tube 110 is further provided with a wiring groove 114 along the flow direction of the cooling liquid on one side of the cooling liquid circulation channel 113 , and the at least one temperature detection unit 120 is arranged in the first wiring groove.

[0046] Such as image 3 As shown in FIG. 1 , it is ...

no. 2 example

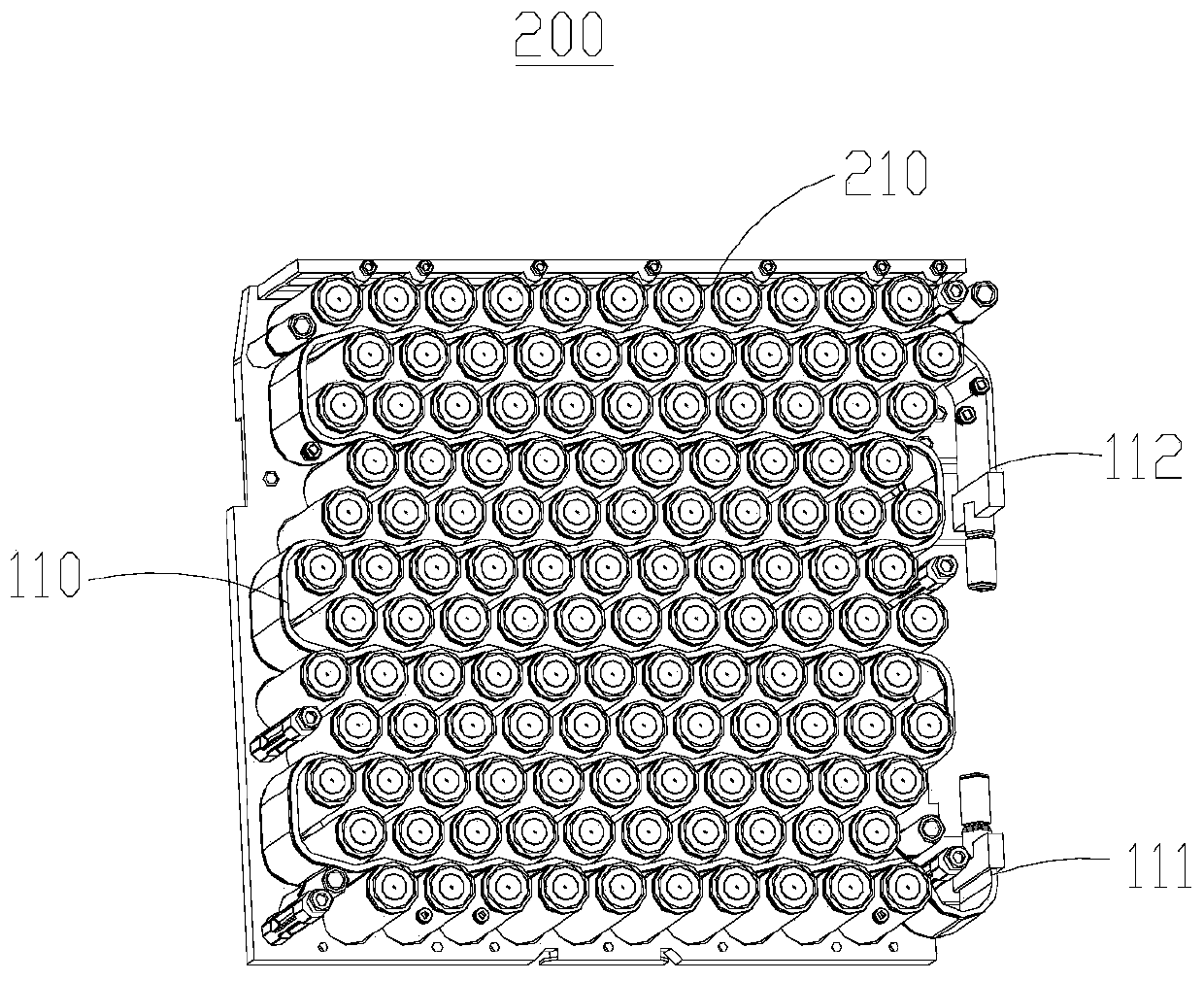

[0053] For a second example, see Figure 5 to Figure 10

[0054] The temperature monitoring device 100 and the power supply device 200 provided by the second embodiment of the present invention have the same realization principles and technical effects as those of the first embodiment. For a brief description, for what is not mentioned in the second embodiment, please refer to the first Corresponding content in the embodiment.

[0055] Figure 5 It is a three-dimensional structural diagram of the temperature monitoring device 100 provided in the second embodiment. Image 6 yes Figure 5 The three-dimensional cross-sectional view of the temperature monitoring device 100 is shown. Such as Figure 5 with Image 6 As shown, in this embodiment, the liquid-cooled flat tube 110 is provided with a wiring groove 114 on both sides of the cooling liquid circulation channel 113 along the flow direction of the cooling liquid, and the two sides of the liquid-cooled flat tube 110 are ...

no. 3 example

[0060] For a third embodiment, see Figure 11 to Figure 12

[0061] The temperature monitoring device 100 provided in this embodiment is different from the above embodiments in that the liquid-cooled flat tube 110 is not provided with the wiring groove 114 , but is provided with a plurality of installation parts 116 instead. Each of the installation parts 116 is used to install one of the temperature detection units 120 , specifically, the temperature sensor is disposed inside the installation part 116 , and the data transmission line is routed inside the battery module 210 .

[0062] There are many ways to set up the installation part 116. Optionally, such as Figure 11 As shown, a plurality of installation parts 116 are arranged at intervals on one side of the cooling liquid circulation channel 113, or as Figure 12 As shown, a plurality of installation parts 116 are arranged at intervals on both sides of the cooling liquid circulation channel 113, and even when the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com