Chemical vapor deposition equipment and surface temperature detection method of top board thereof

A technology of chemical vapor deposition and detection method, which is applied in the field of chemical vapor deposition equipment and its roof surface temperature detection, and can solve the problems of ineffective detection of surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

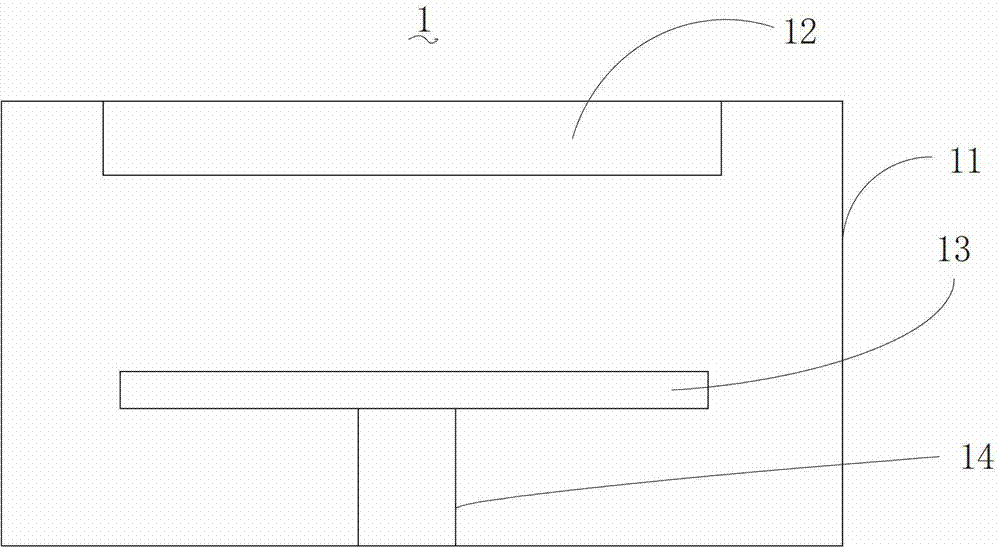

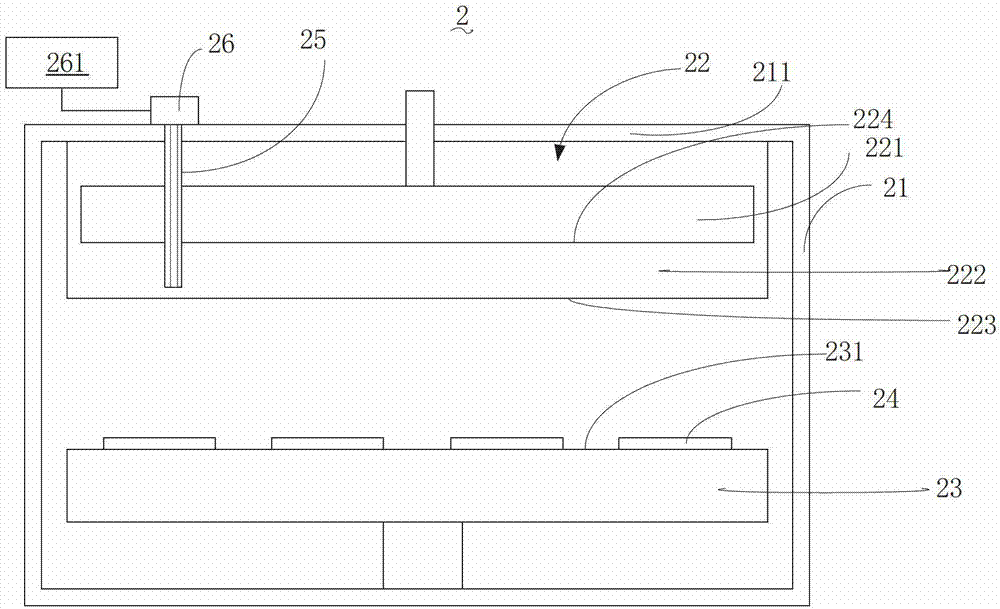

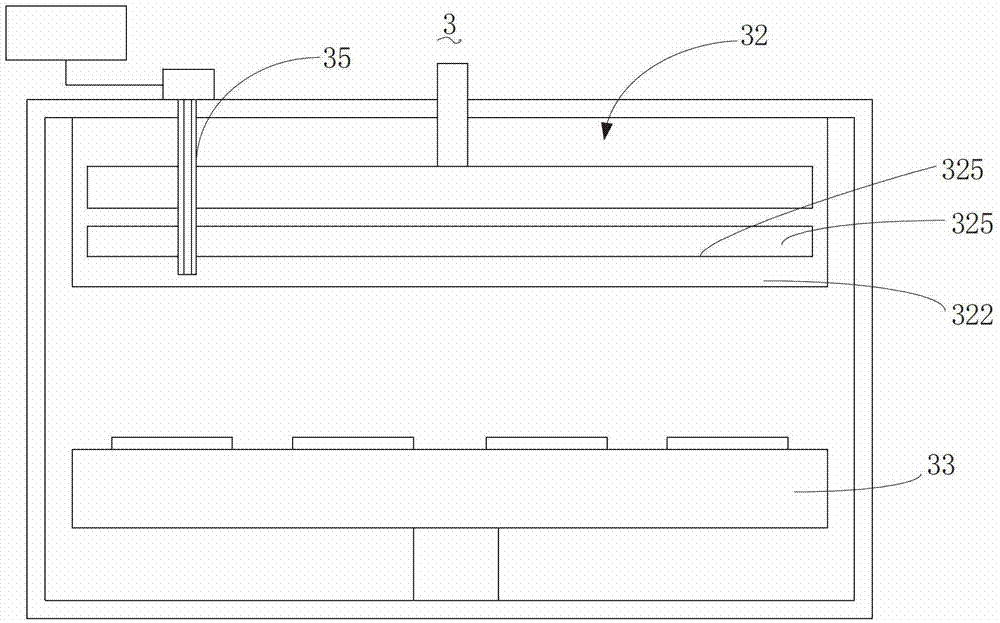

[0017] The chemical vapor deposition equipment in the prior art has a surface disposed opposite to the substrate support, and the temperature of the surface will affect the distribution of the reactive gas flow between the surface and the substrate support and the temperature distribution of the substrate support surface However, the chemical vapor deposition equipment in the prior art has the problem of not being able to effectively detect the temperature of the surface opposite to the substrate support. In order to solve the problems existing in the chemical vapor deposition equipment in the prior art, the present invention provides a chemical vapor deposition equipment; the chemical vapor deposition equipment includes a cavity, a top plate and a substrate support seat arranged in the cavity, the top plate and the The substrate support seat is oppositely arranged, the substrate support seat has a substrate support surface facing the top plate, and the top plate has a first su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com