Patents

Literature

74results about How to "Control temperature changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

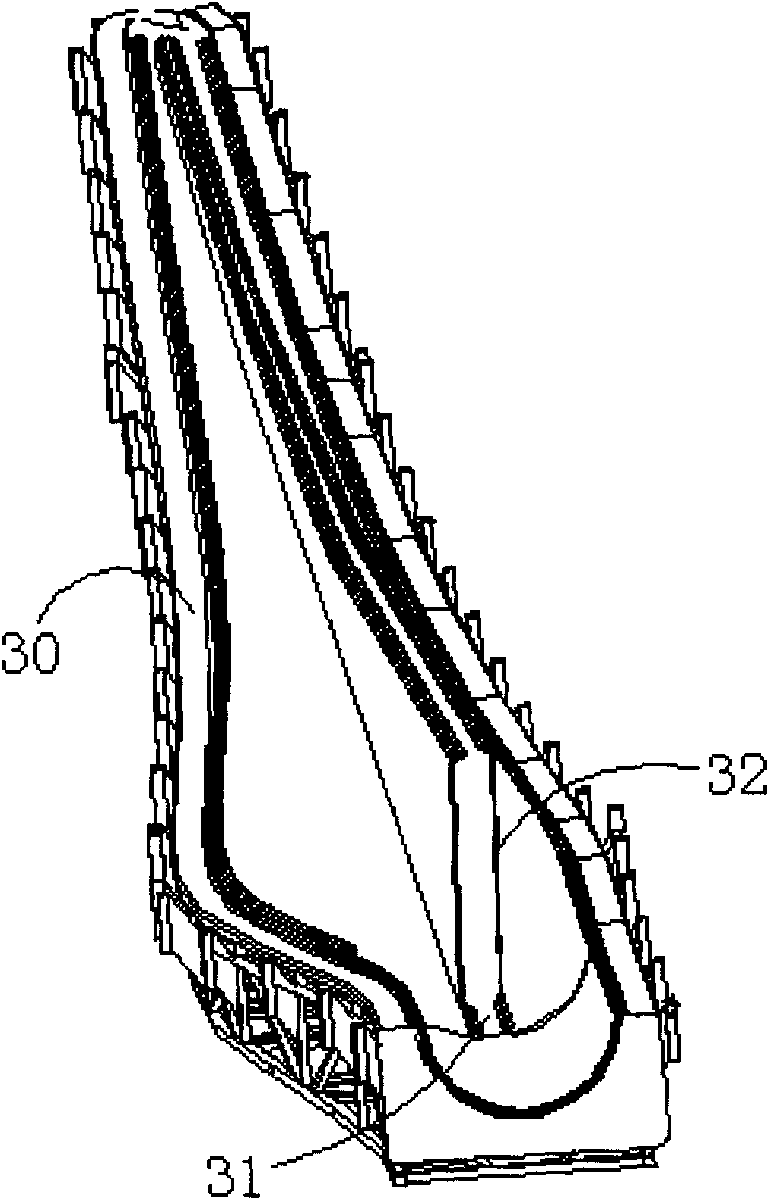

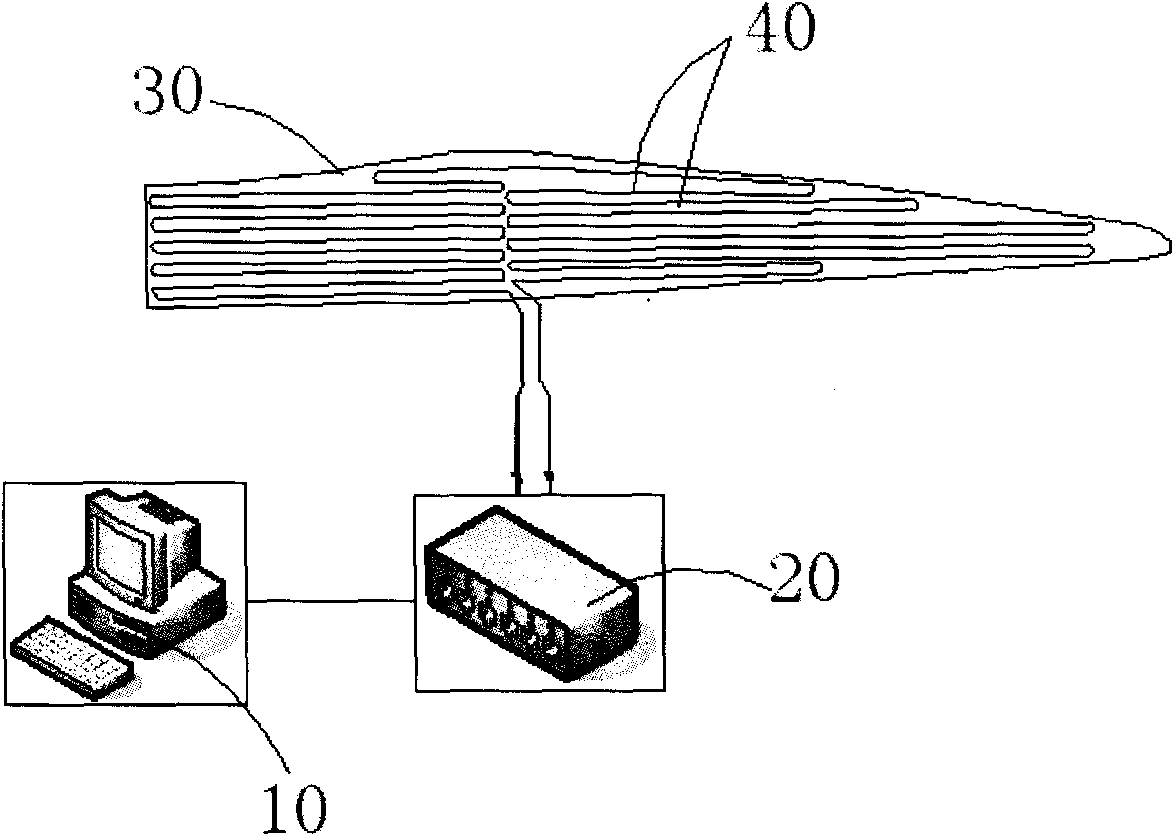

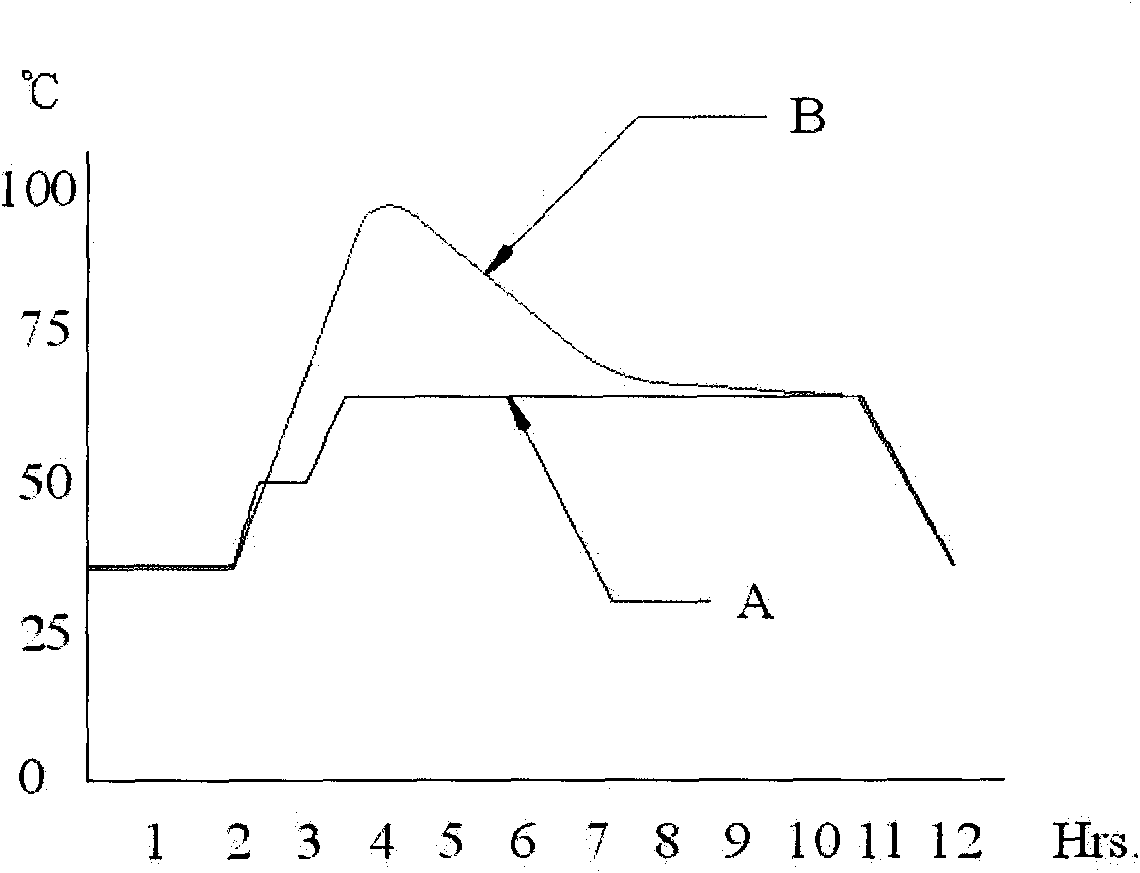

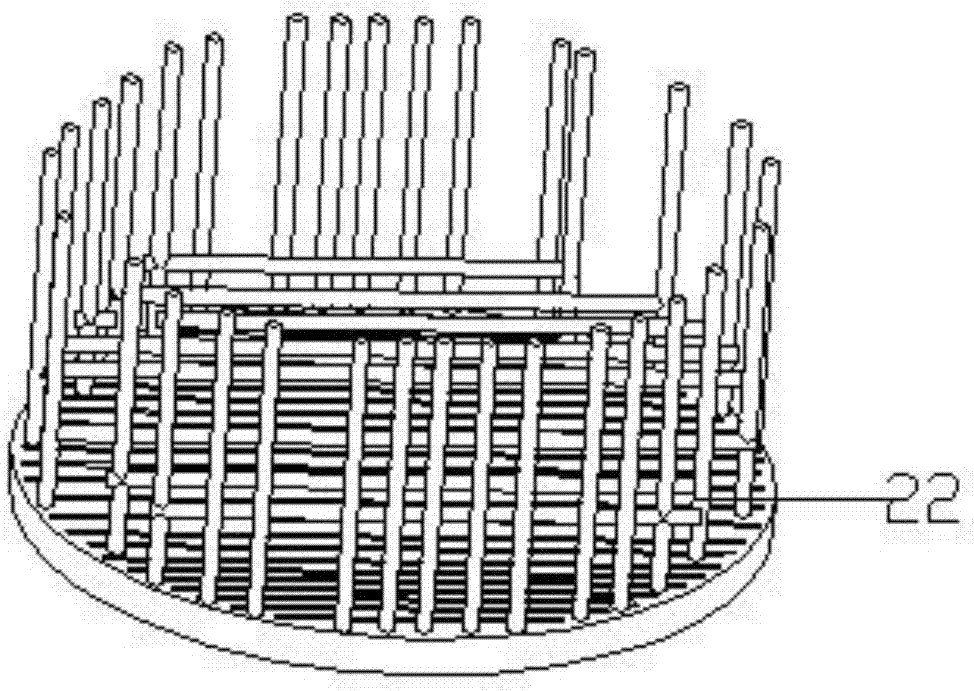

Intelligent segmental temperature control system of wind power blade die

The invention relates to an intelligent segmental temperature control system of a wind power blade die, which is provided based on the technical theory that segmental temperature control is bound to be carried out based on the differences on the formed region thickness of a designed blade structure and the energy-saving purpose can be achieved by lowering the dependence on external heating in a curing manufacturing procedure by utilizing the reaction exothermic character of a matrix material. To achieve the purpose, the invention adopts the technical measures of the construction of a die segmental temperature control pipeline, which ensures that each temperature segment can be heated or cooled independently based on requirements on thermal energy in the curing manufacturing procedure; the establishment of an intelligent temperature control system, wherein temperature and hardness data of the die and a blade shell can be captured to judge whether heating setting, exothermic peak initiating temperature and the states of completion degree, gel curing degree and the like are completed or conform to design values; and antecedent technical measures, wherein energy consumption is saved by utilizing the reaction heat of materials per se to heat and reaction and temperature control are combined to match the design of a temperature curve, which are helpful for obtaining the blades with uniform curing and excellent quality and can improve the production efficiency as a characteristic.

Owner:上海力仓实业有限公司

Method for recycling copper from waste circuit board

InactiveCN101270411AEfficient separationEfficient recyclingProcess efficiency improvementCopper foilFilm material

The invention belongs to recycling of waste printed circuit board, in particular to recycling method of copper metal including copper foil and copper wire from the waste printed circuit board. Firstly a copper metal with the surface of polymer film material, which is separated from the waste printed circuit board, is soaked in a swelling agent, and the copper metal matrix material and the polymer film material on the surface are separated by providing the good swelling environment and controlling the temperature change; The polymer film material and the copper metal are recycled in classification by utilizing the difference of specific gravity between the copper metal and the polymer film material. The method of the invention can carry out the effective and complete separation of the copper metal and the polymer film material on surface of the waste printed circuit board and the swelling agent can be repeatedly used; The recycling method of copper metal of the invention has the advantages of the simple and feasible process without pollution and having the good social efficiency, economical efficiency and environmental efficiency.

Owner:北京正康创智科技发展有限公司

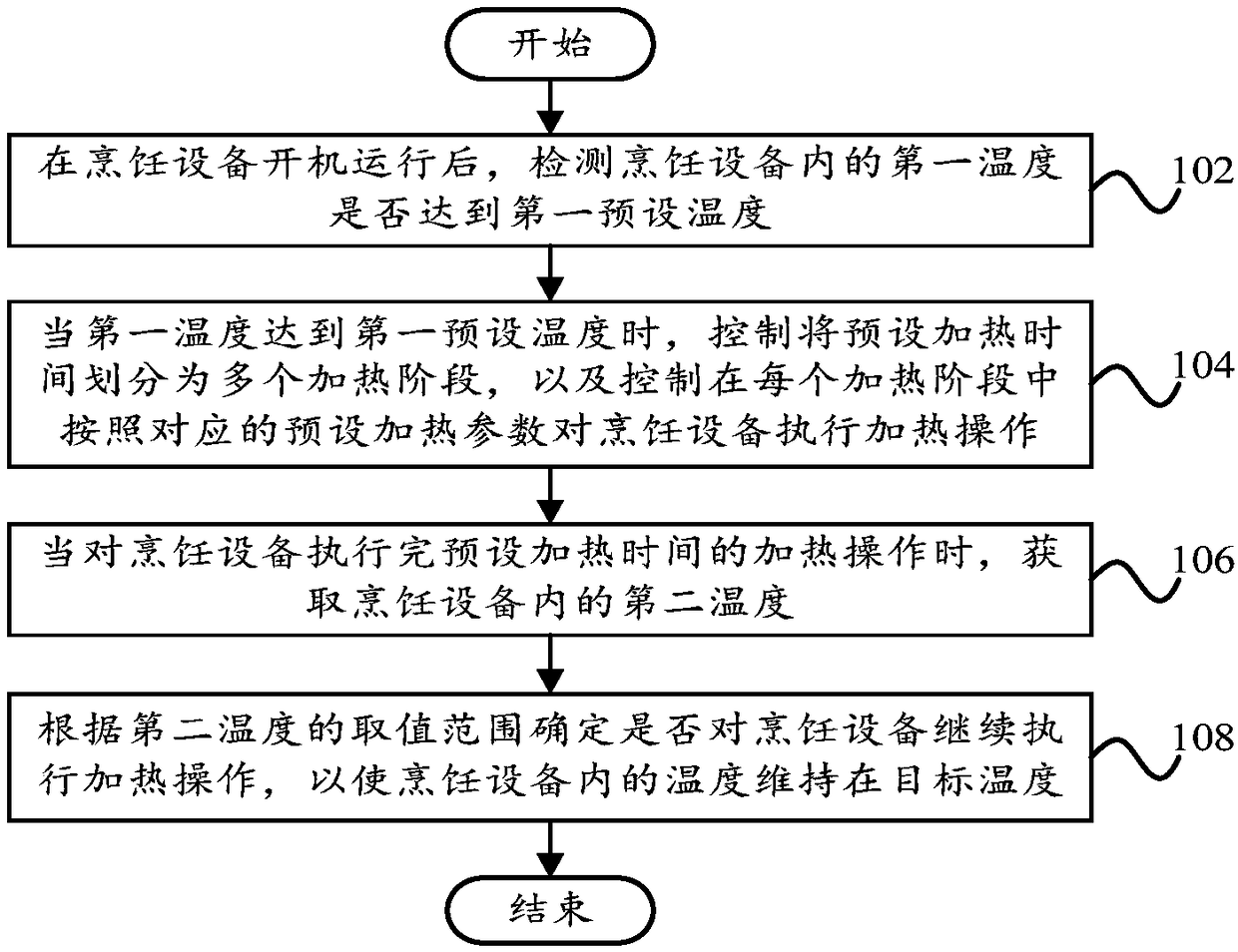

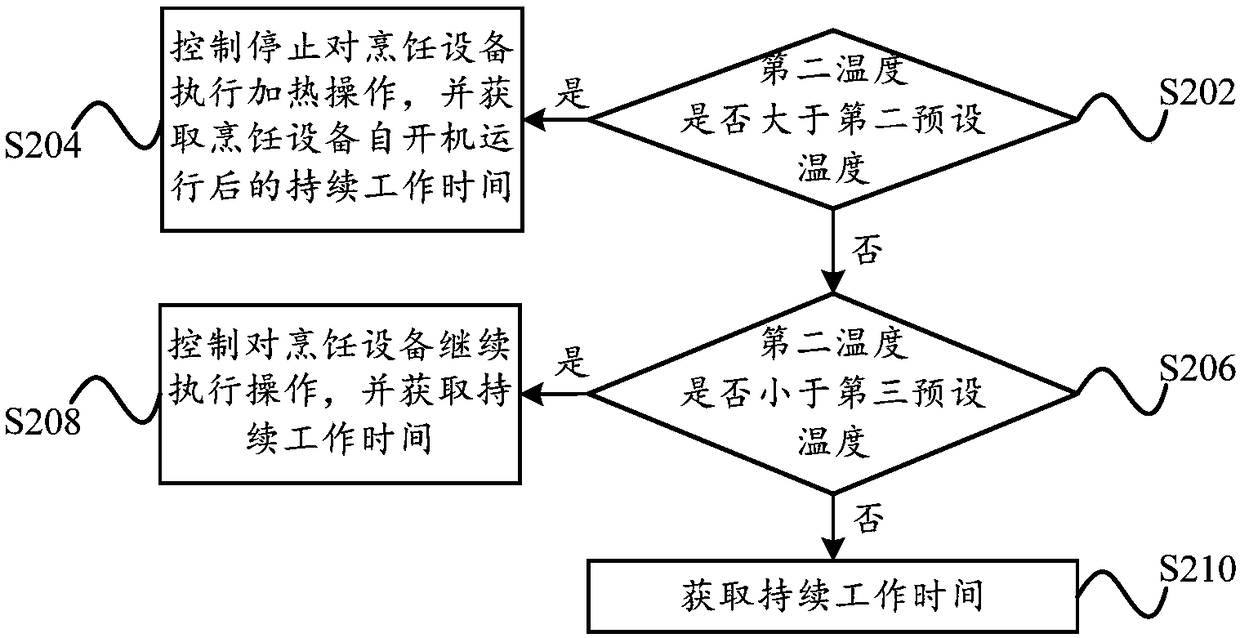

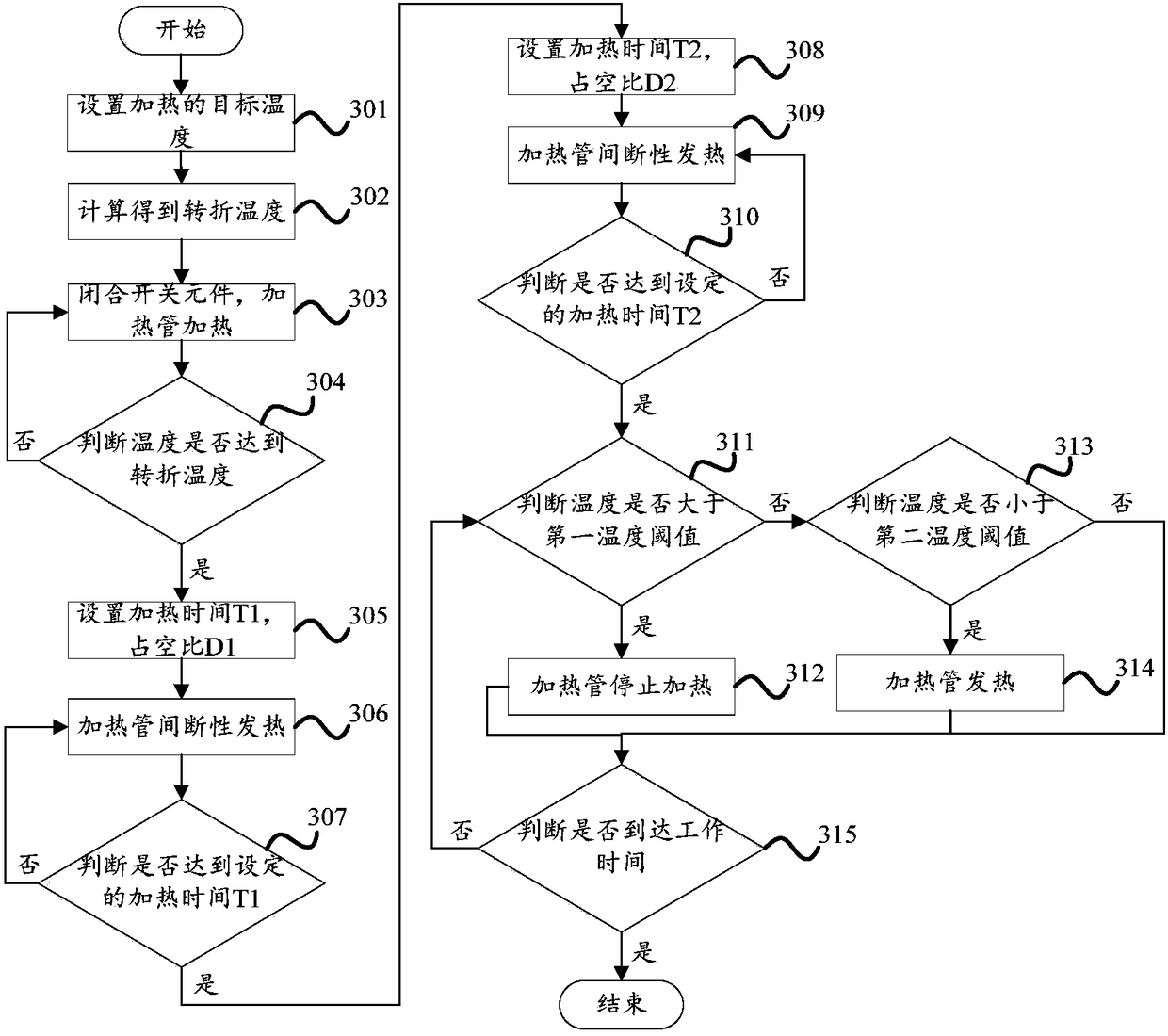

Cooking control method and cooking control device, and cooking equipment

ActiveCN108354440AControl temperature changesGuarantee the safety of useWarming devicesVessels with intergral heatingHeating timeProcess engineering

The invention provides a cooking control method, which comprises the following steps: detecting whether a first temperature in cooking equipment reaches a first preset temperature or not when the cooking equipment is started up; controlling and dividing a preset heating time into a plurality of heating stages when the first temperature reaches the first preset temperature, and implementing a heating operation on the cooking equipment under control in each heating stage in accordance with preset heating parameters; acquiring a second temperature in the cooking equipment after executing the heating operation on the cooking equipment by the preset heating time; and confirming whether it needs to continue the heating operation on the cooking equipment or not in accordance with a valuing rangeof the second temperature, so that temperature in the cooking equipment is kept at a target temperature. Correspondingly, the invention also provides a cooking control device and the cooking equipment. According to the technical scheme, temperature changes in the cooking equipment can be effectively controlled in a mode of piecewise control of heating; and production equipment of the cooking equipment can be reduced, and service life can be prolonged.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Rubber friction experiment machine and experiment method

InactiveCN107449732AContinuous Dynamic Friction RealizationEffective detection of temperatureUsing mechanical meansMaterial analysisExperimental methodsEngineering

The invention discloses a rubber friction experiment machine and an experiment method. Problems that the existing abrasion test machine can not conduct the rubber friction research under the conditions of high temperature, high pressure and humidity are solved. The rubber friction experiment machine comprises a base, a rubber fixing device, a rubber movement amplitude detecting device, a rubber pressure loading device, a rubber friction loading device and a signal collecting and processing device, wherein the rubber fixing device is fixed on the base, the rubber movement amplitude detecting device is directly or indirectly fixed on the base, the rubber pressure loading device, the rubber friction loading device are fixed on a shell body, the shell body is fixed on the base, the signal collecting and processing device is connected with a control circuit of the rubber fixing device, the rubber movement amplitude detecting device, the rubber pressure loading device and the rubber friction loading device. The rubber friction experiment machine has the advantages of reasonable structure design, wide test range, anti-damage and accurate measurement of experimental data.

Owner:ANYANG INST OF TECH

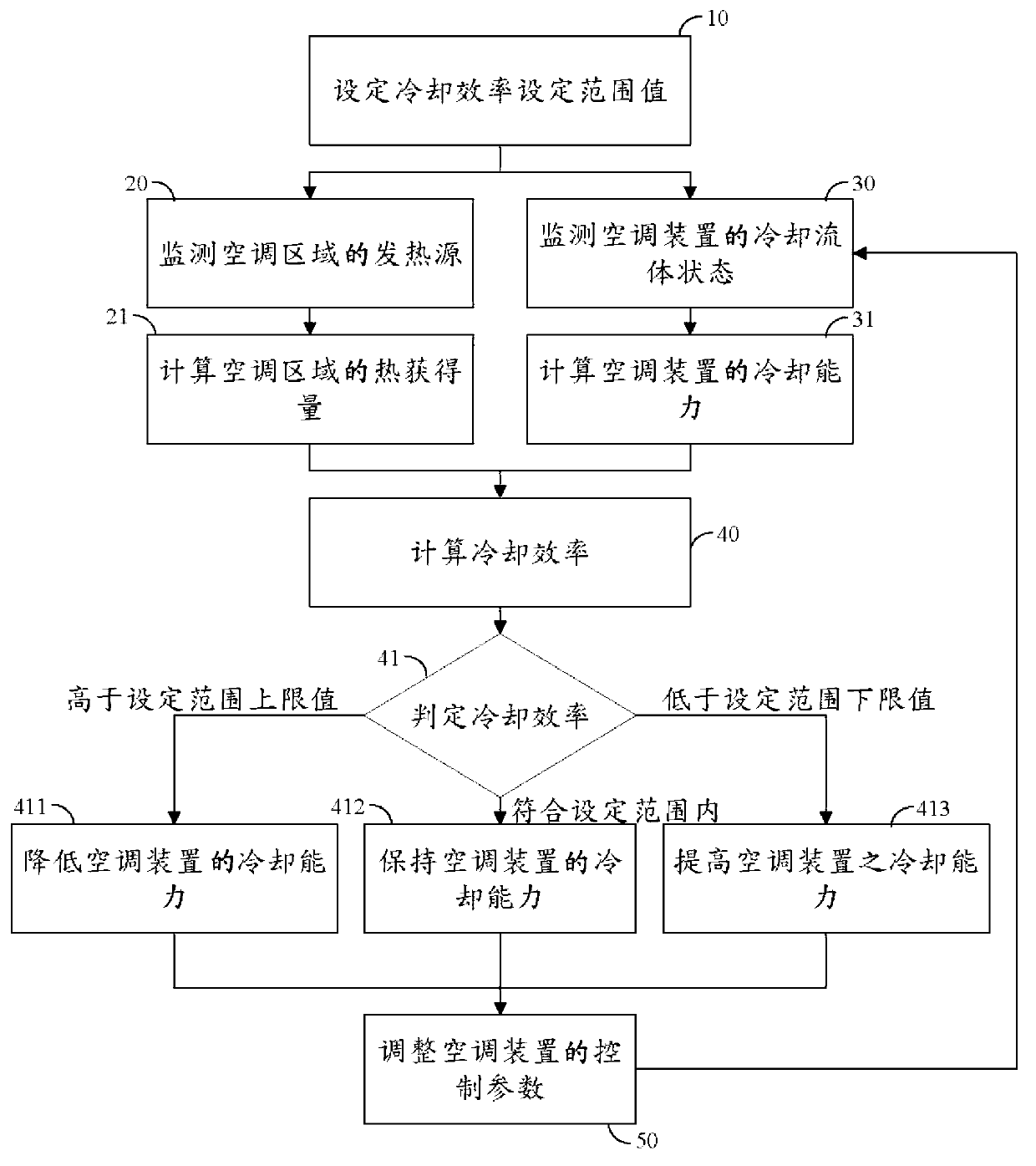

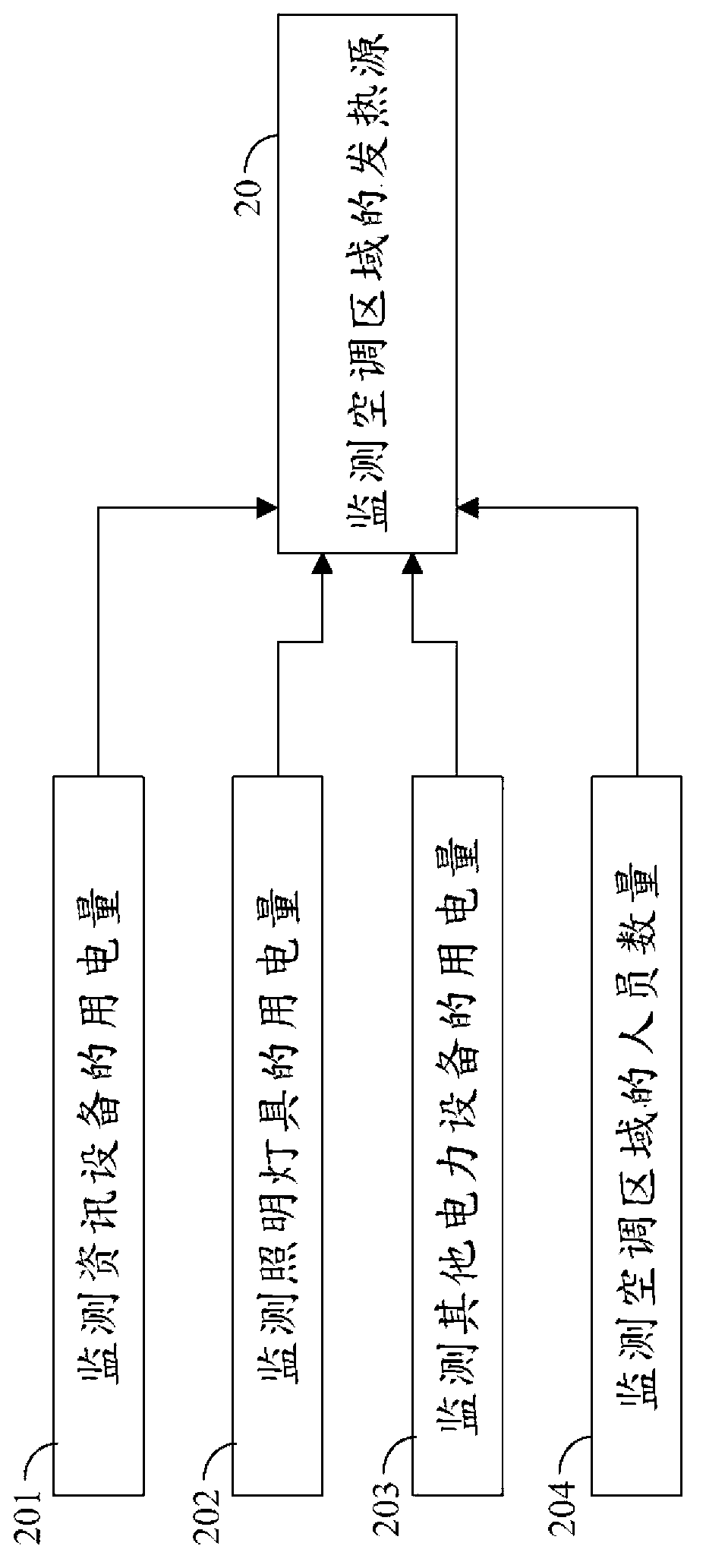

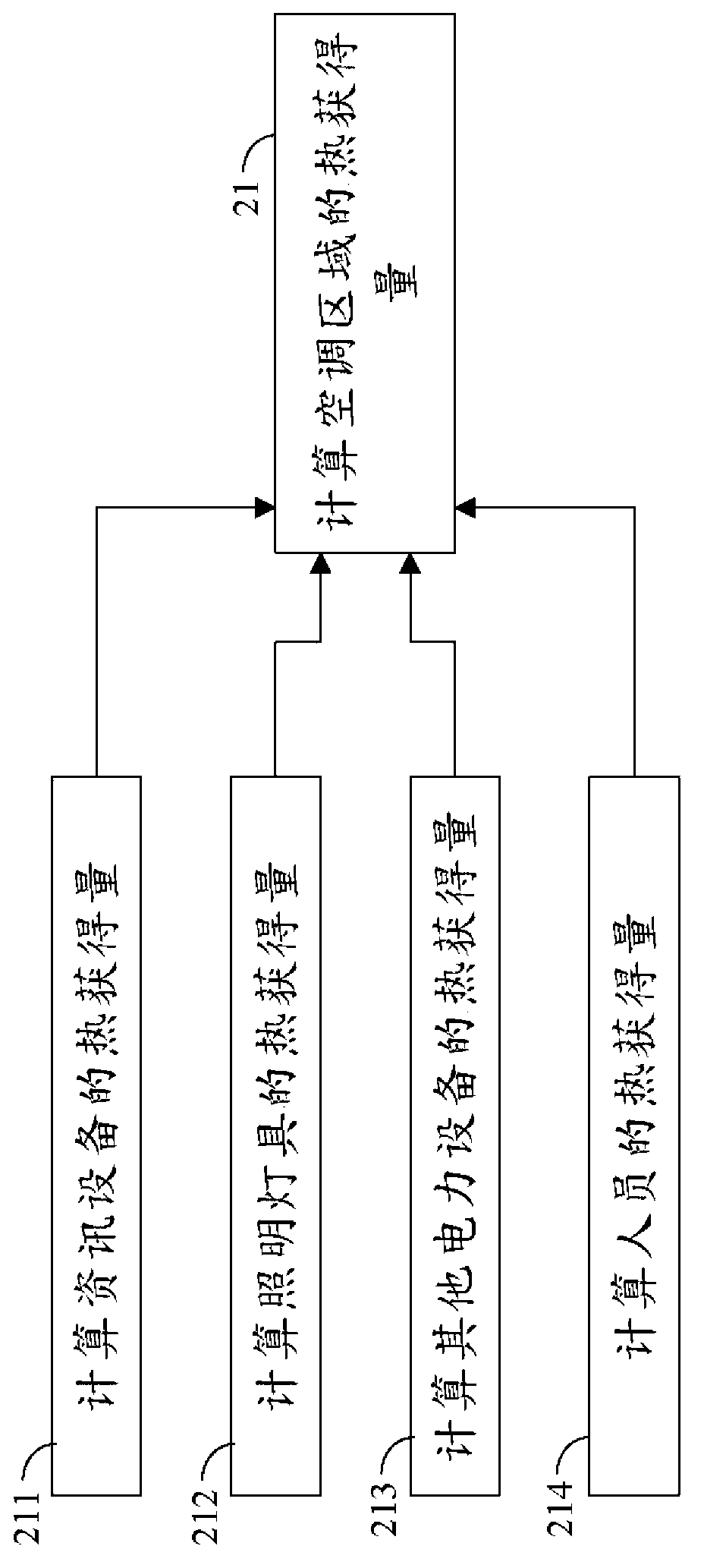

Control method for air conditioner

InactiveCN102865643AWith automatic adjustment of cooling capacityControl the number of start and stop unitsSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlEngineering

The present invention discloses a control method for an air conditioner, comprising the steps calculating cooling efficiency according to the cooling capability value of the air conditioner and the obtained heat by an air conditioning area, dynamically adjusting the control parameters of the air conditioner, such as starting and closing, flow or temperature control processes of the air conditioner, and enabling the air conditioner to have a minimum cooling capability for automatically adjusting air temperature to be in accord with the required temperature of the air conditioning area, thereby increasing the comprehensive operation efficiency of the air conditioner system and achieving the purpose of saving energy.

Owner:CHUNGHWA TELECOM CO LTD

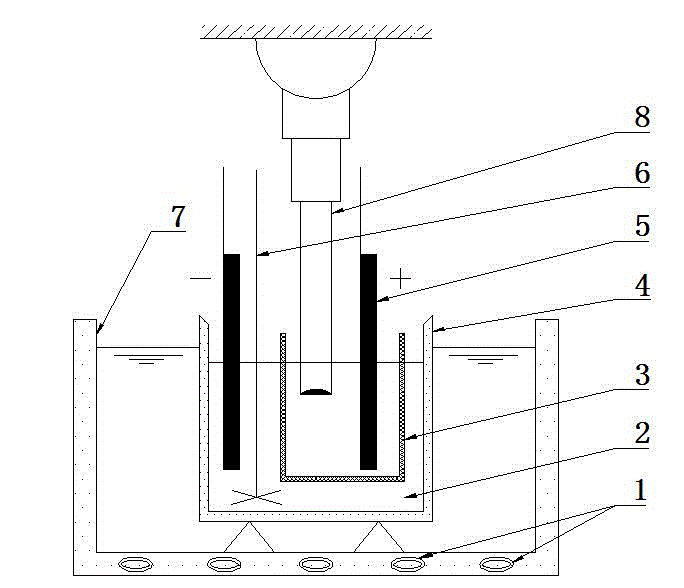

Ultrasonic-assisted pulp electrolysis method for tailing sand

InactiveCN105297078AControl temperature changesPhotography auxillary processesUltrasound - actionHydrometallurgy

The invention discloses an ultrasonic-assisted pulp electrolysis method for tailing sand. The hydrometallurgy process is greatly simplified by applying the pulp electrolysis technology. The method can effectively overcome the defects that the hydrometallurgy process is long, and energy consumption is high, and is suitable for a mineral which is not very high in processing amount but complex in component and high in additional value. By means of the pulp electrolysis technology, mineral powder leaching, leaching agent purifying, target metal electrolytic deposition, impurity component separating and other processes are combined in a pulp electrolytic cell to proceed. According to the technical purposes, the leaching rate of the mineral powder can be increased through the assisting function of ultrasonic waves, the leaching rate of the target metal in the mineral is improved to more than 90%, and time is shorter. By means of ultrasonic waves, metal ions can be promoted to be evenly scattered in an electrolyte, the phenomenon of cathode passivation of cations is eliminated, the current efficiency and the purity of precipitated metal are improved, and the purity of metal precipitated on a cathode reaches more than 98%. The ultrasonic technology is free of pollution, easy to operate and low in cost, the pulp electrolysis efficiency is improved, and the environment protection effect is obvious.

Owner:SUN YAT SEN UNIV +2

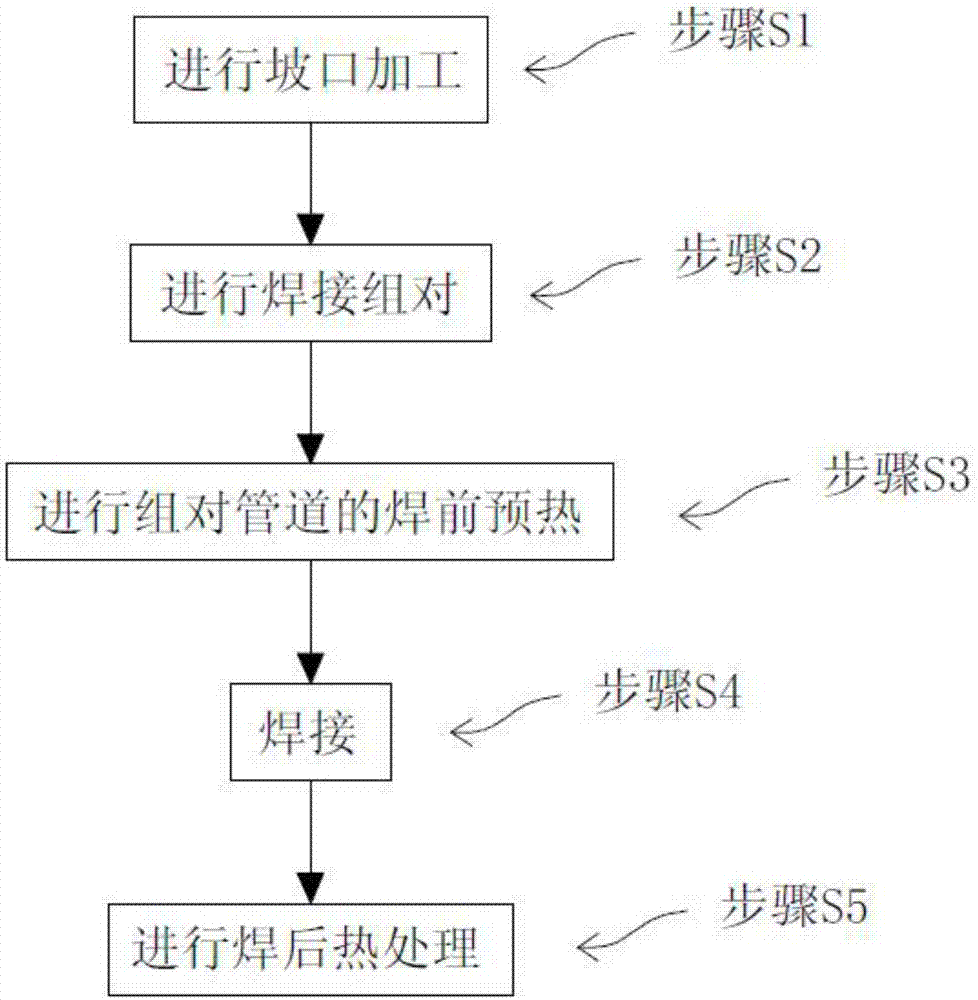

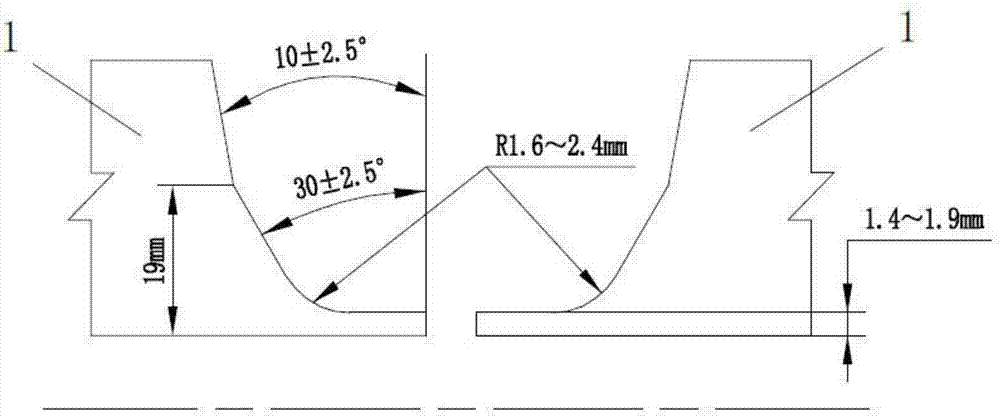

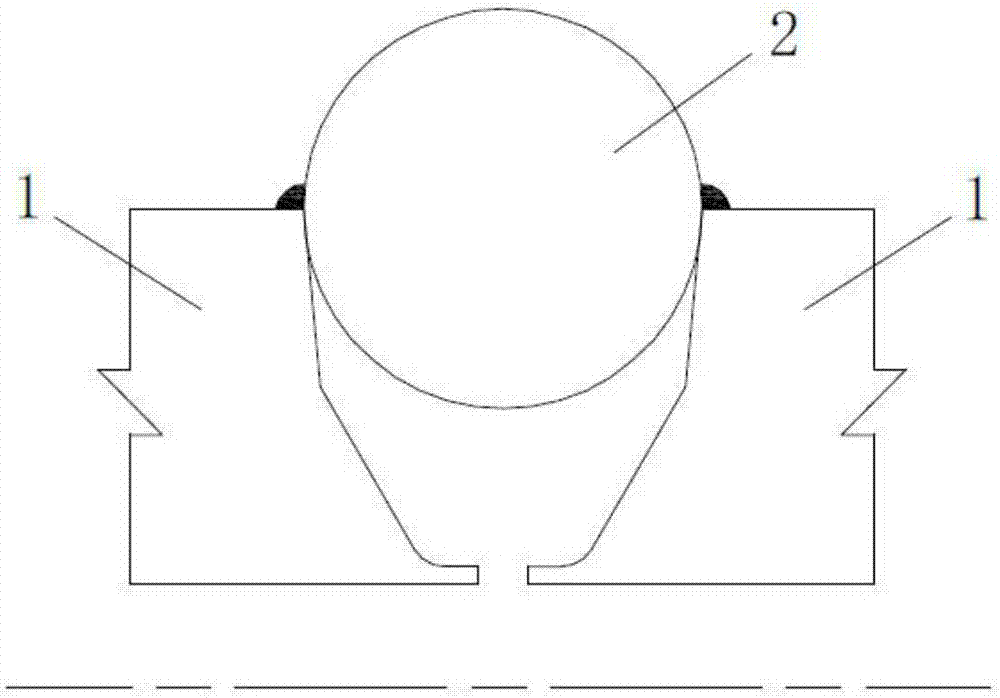

AP1000 main steam pipeline welding method

InactiveCN107457473AAvoid indentation defectsPrevent collapseArc welding apparatusNuclear powerShielding gas

The invention belongs to the technical field of AP1000 nuclear power, and particularly relates to an AP1000 main steam pipeline welding method. In order to solve the problems that an air filling protection device is difficult to install and potential safety hazards exist in the good health of operators when a conventional air filling protection device is used for auxiliary welding of an AP1000 main steam pipeline, the AP1000 main steam pipeline welding method is disclosed. The welding method particularly includes the following several steps of S1, chamfering; S2, welding assembly; S3, weld preheating; S4, welded connection; and S5, postweld heat treatment. When the welding method is used for welding the AP1000 main steam pipeline, through adjustment matching of the groove dimensions and welding parameters, welded joints formed in the welding process can still achieve a continuous and uniform forming effect without the supporting action of backing gas, and therefore installation of the air filling protection device is omitted and the influence on the good health of the operators by protective gas is avoided.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

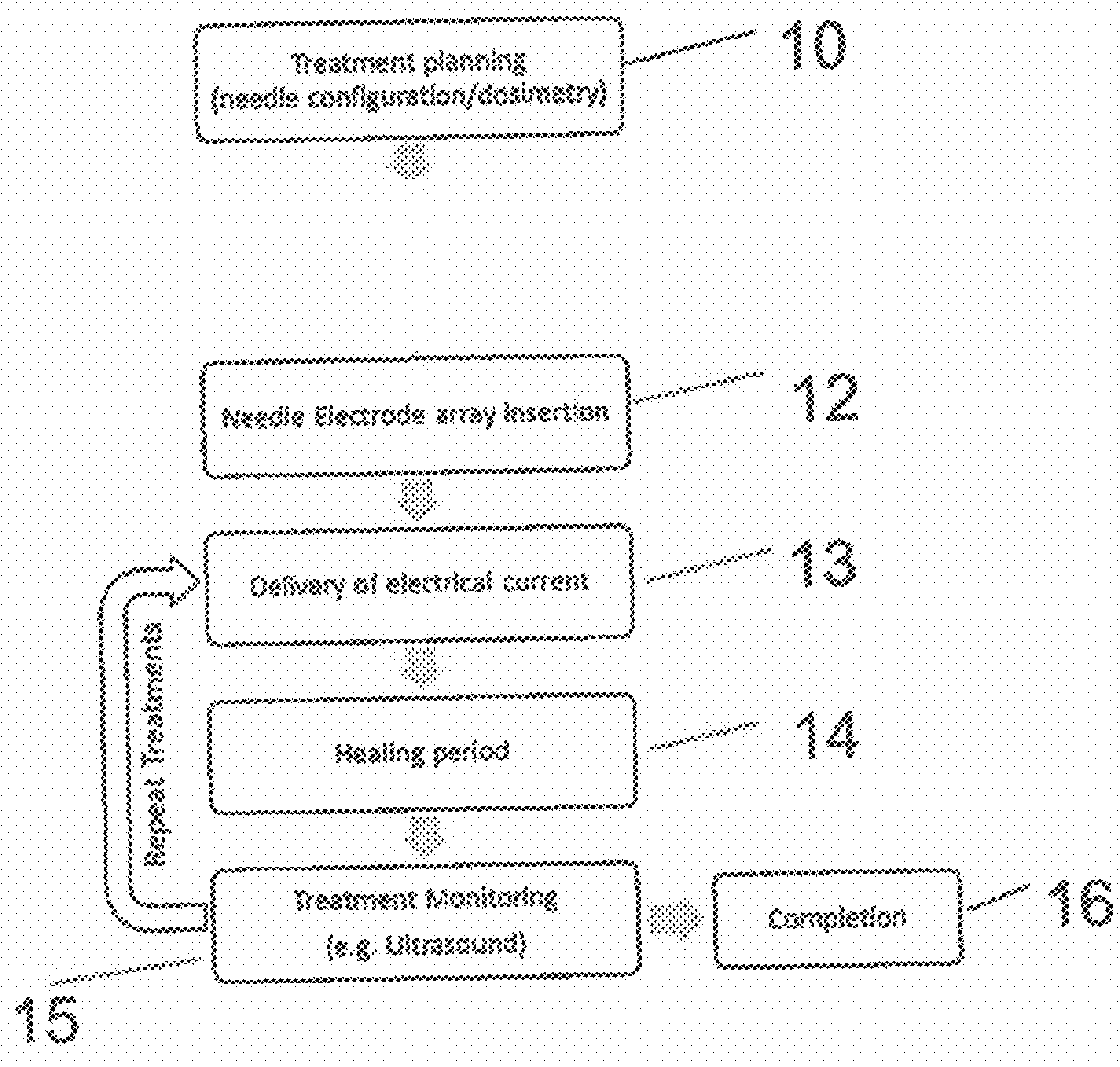

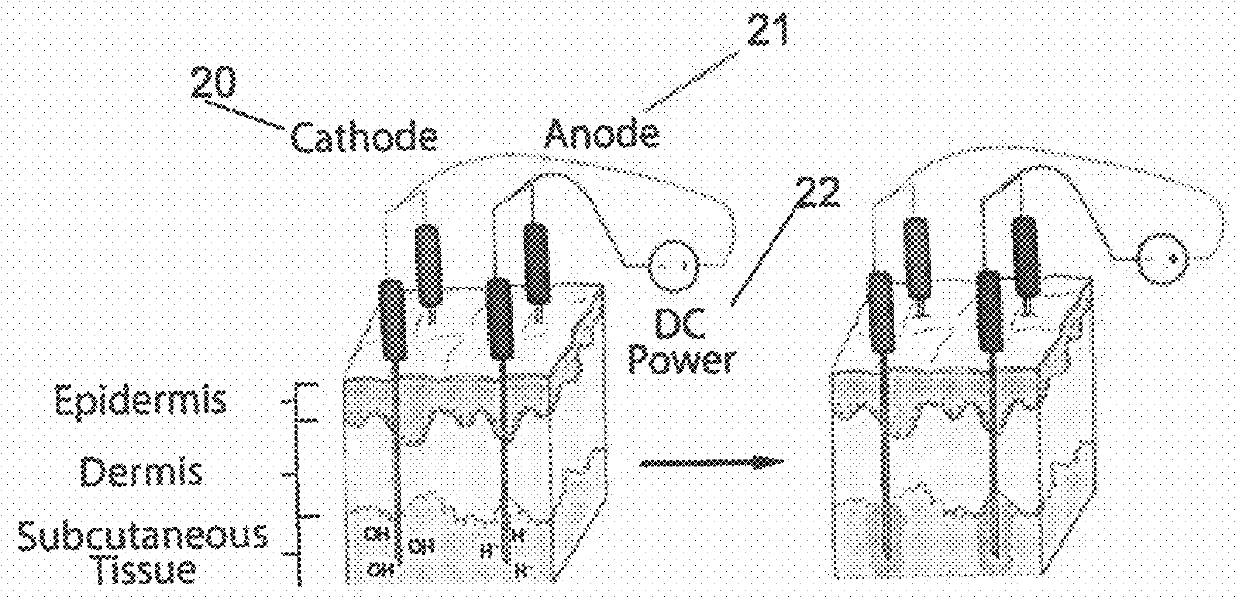

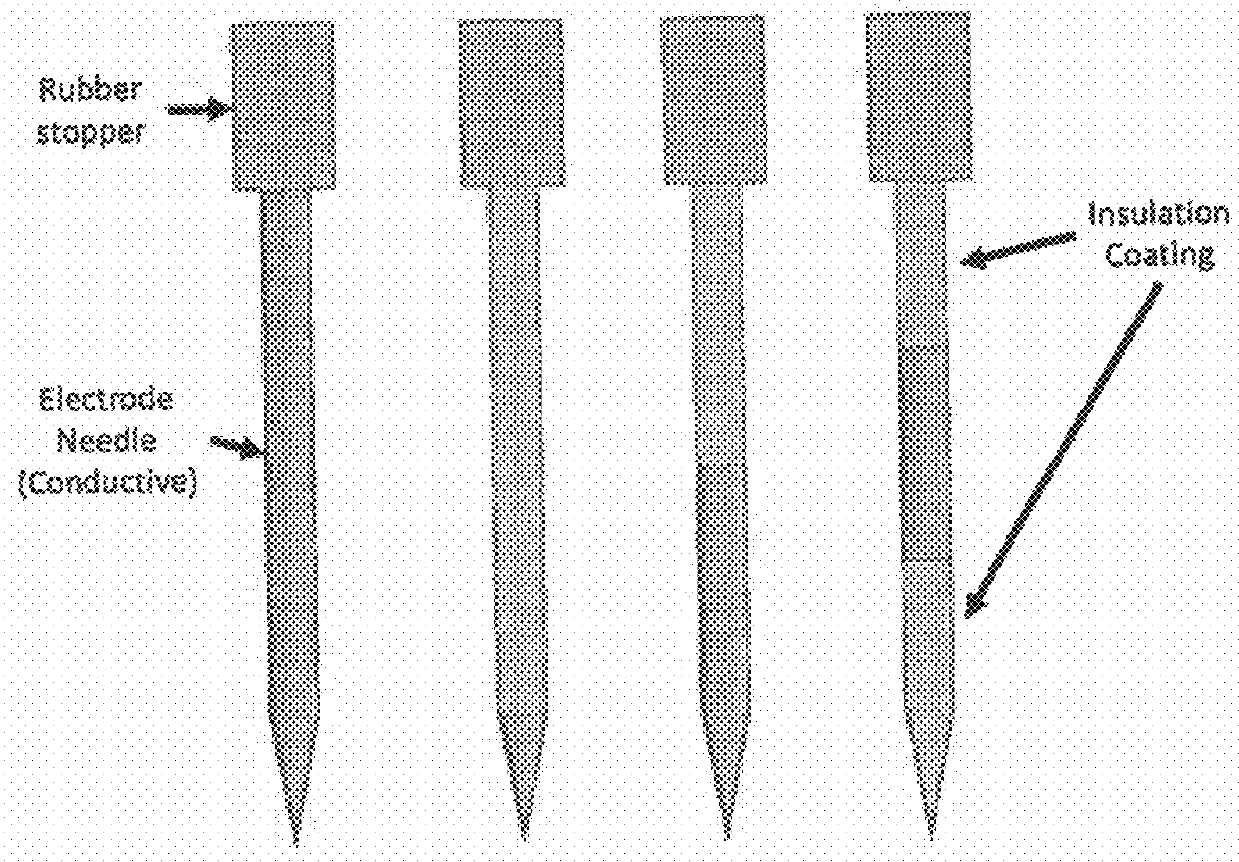

Method and device for electrochemical therapy of skin and related soft tissues

ActiveUS20180177543A1Avoid heat damageLimiting change in temperatureSurgical needlesSurgical instruments for heatingElectrochemical responseSkin tissue

A method of altering skin tissue includes creating an electrochemical reaction in the tissue, wherein the electrochemical reaction occurs while avoiding electro-thermal damage to the tissue.

Owner:RGT UNIV OF CALIFORNIA

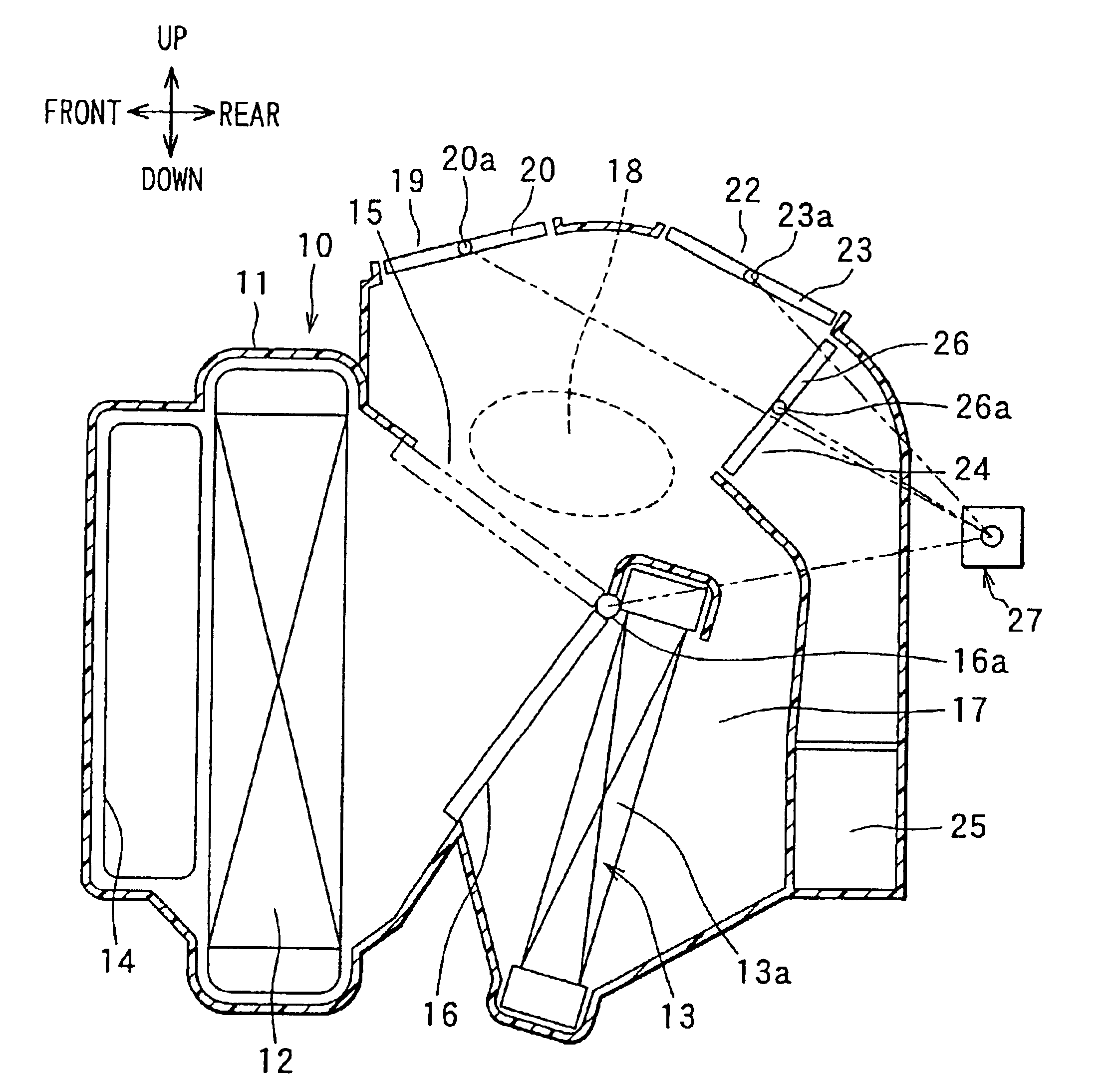

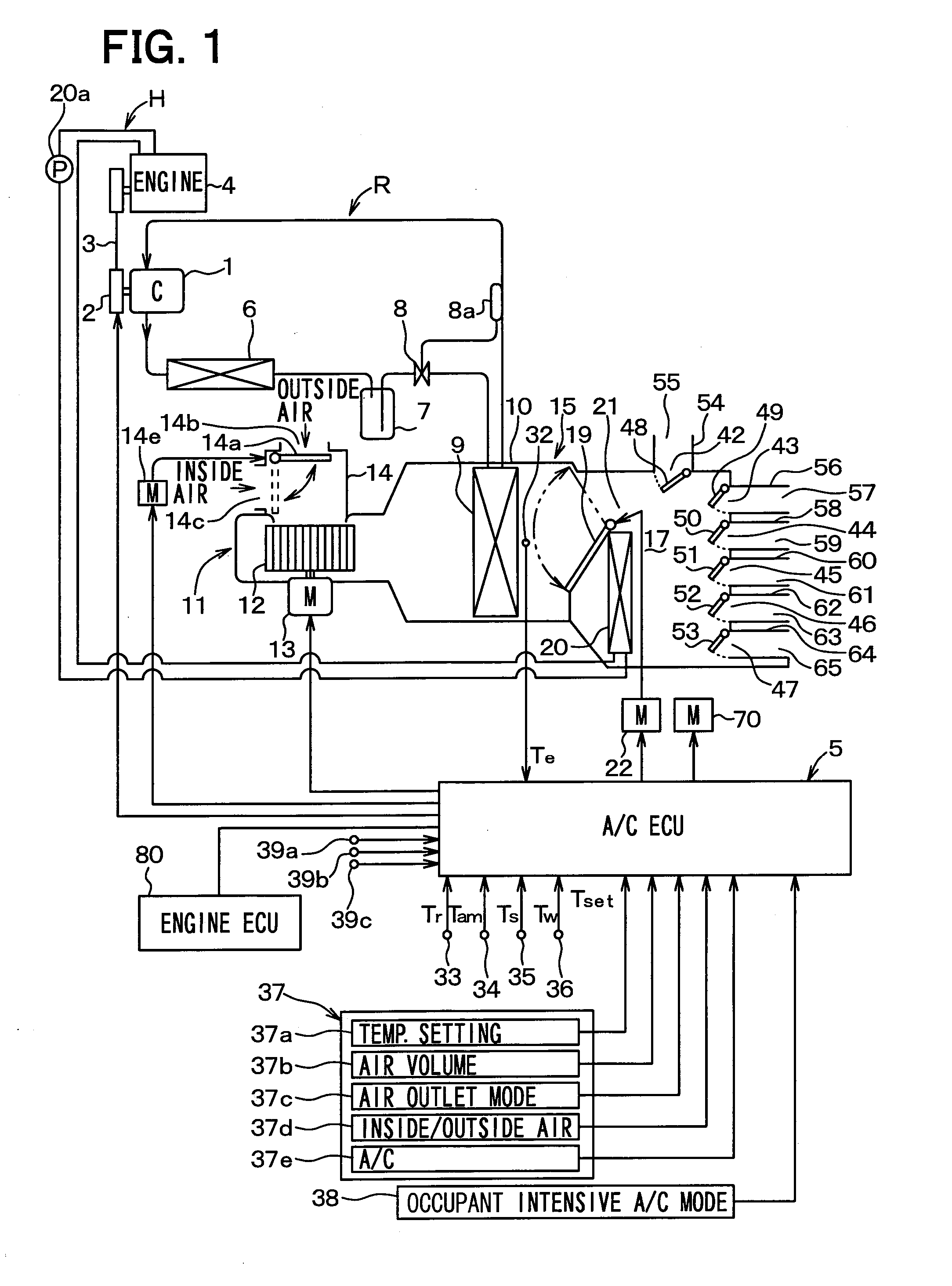

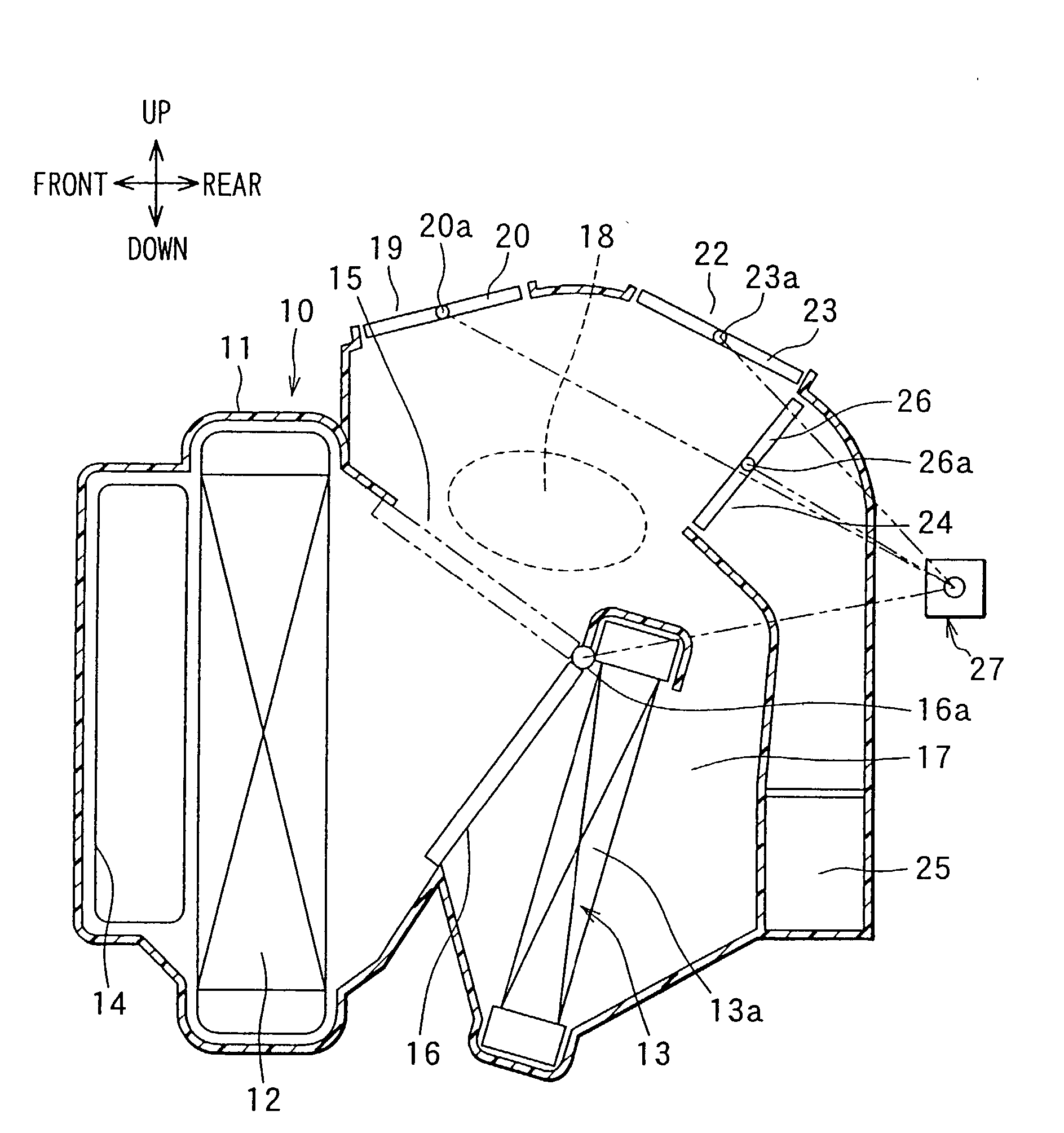

Vehicle air conditioner with mode switching pattern

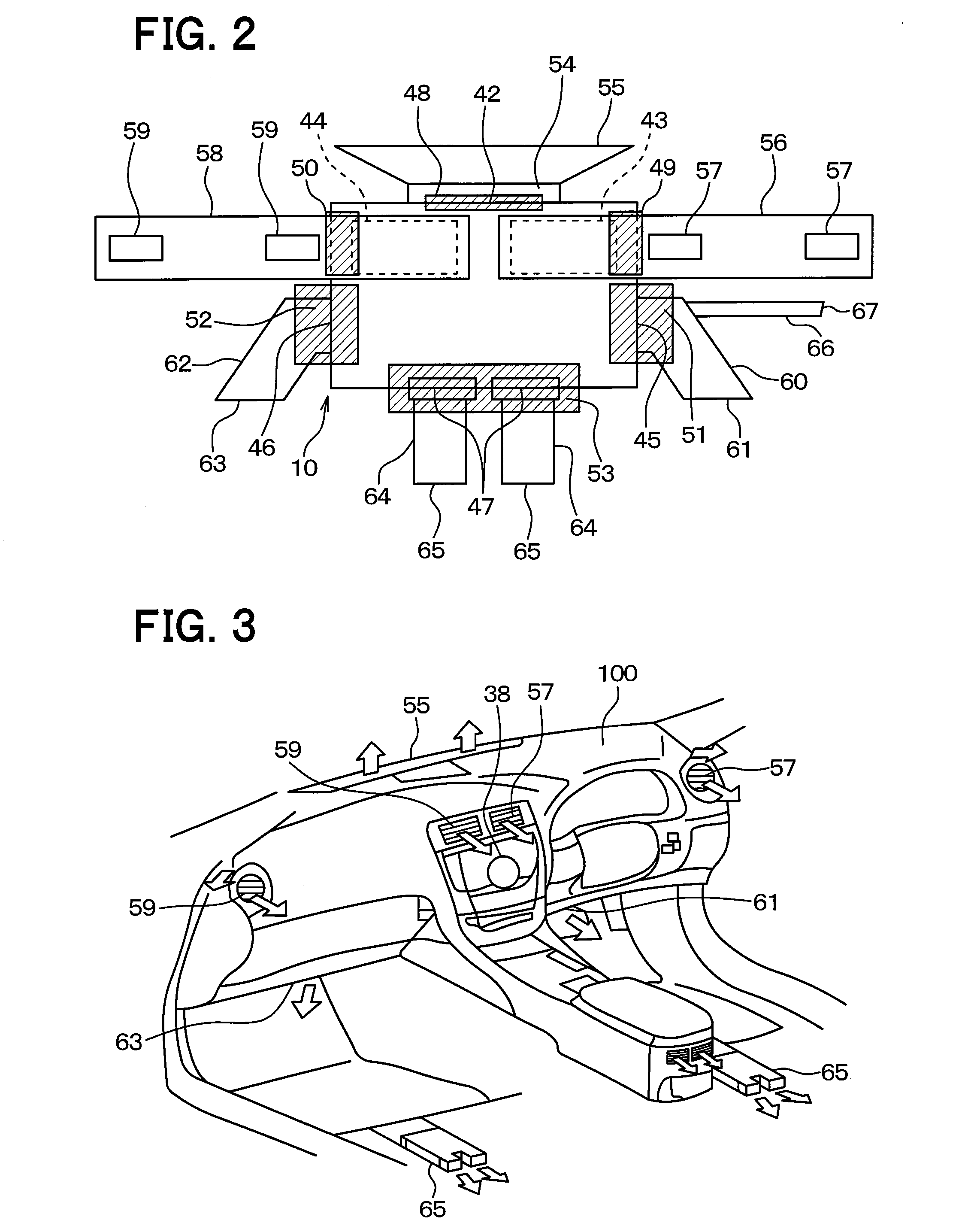

InactiveUS6761214B2Control temperature changesSmall range of anglesAir-treating devicesRailway heating/coolingActuatorControl theory

A vehicle air conditioner has an actuator for driving an air mixing door and various mode switching doors. An automatic range and a manual range are set in different operating angle ranges of the actuator. In the automatic range, an air outlet mode is automatically switched in accordance with an opening degree of the air mixing door. On the other hand, in the manual range, a multi-mode or a defroster mode is manually set, regardless of the opening degree of the air mixing door. In the manual range, air is simultaneously blown from all openings such as a face opening, a foot opening and a defroster opening in the multi-mode, and air is blown from the defroster opening in the defroster mode.

Owner:DENSO CORP

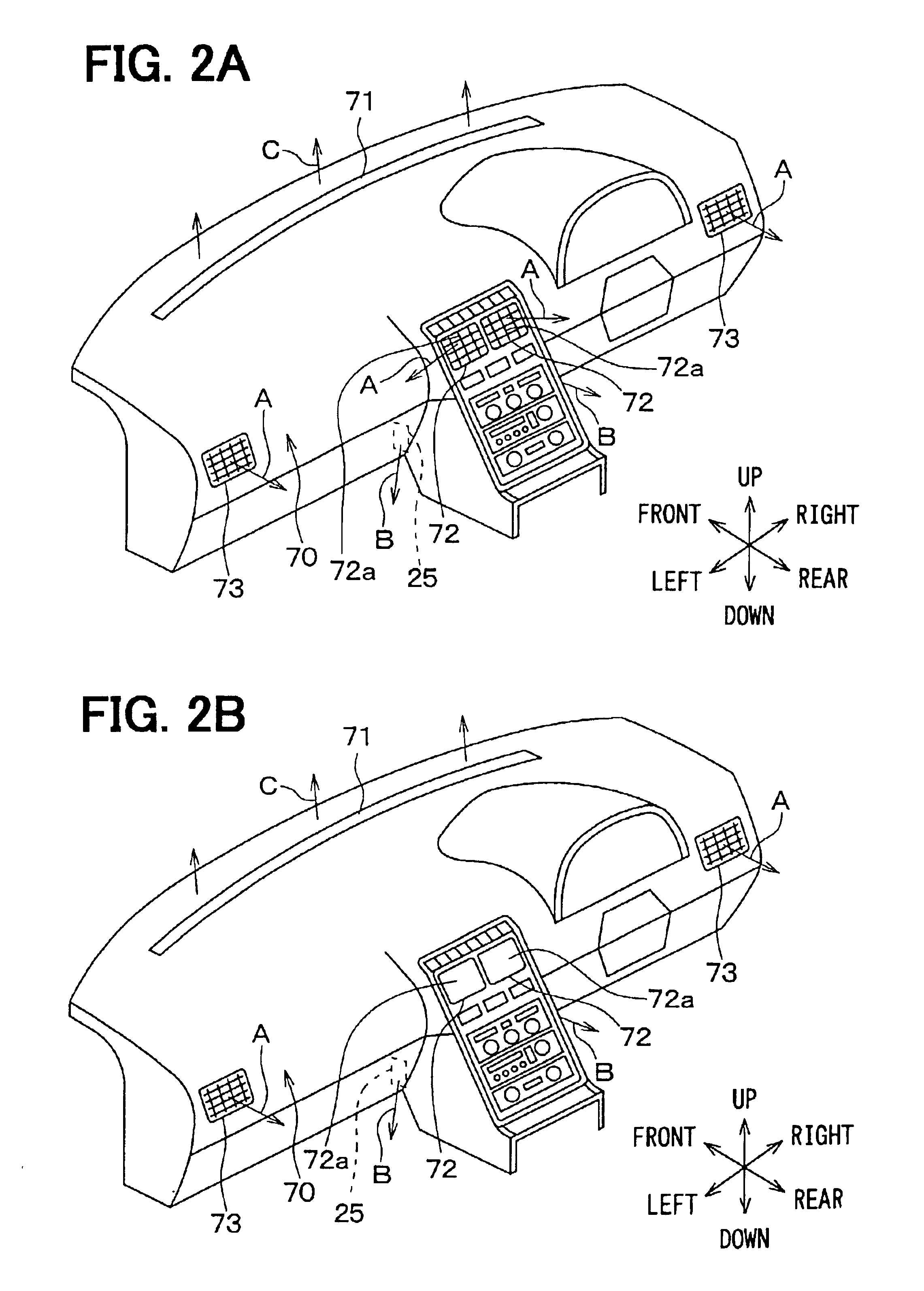

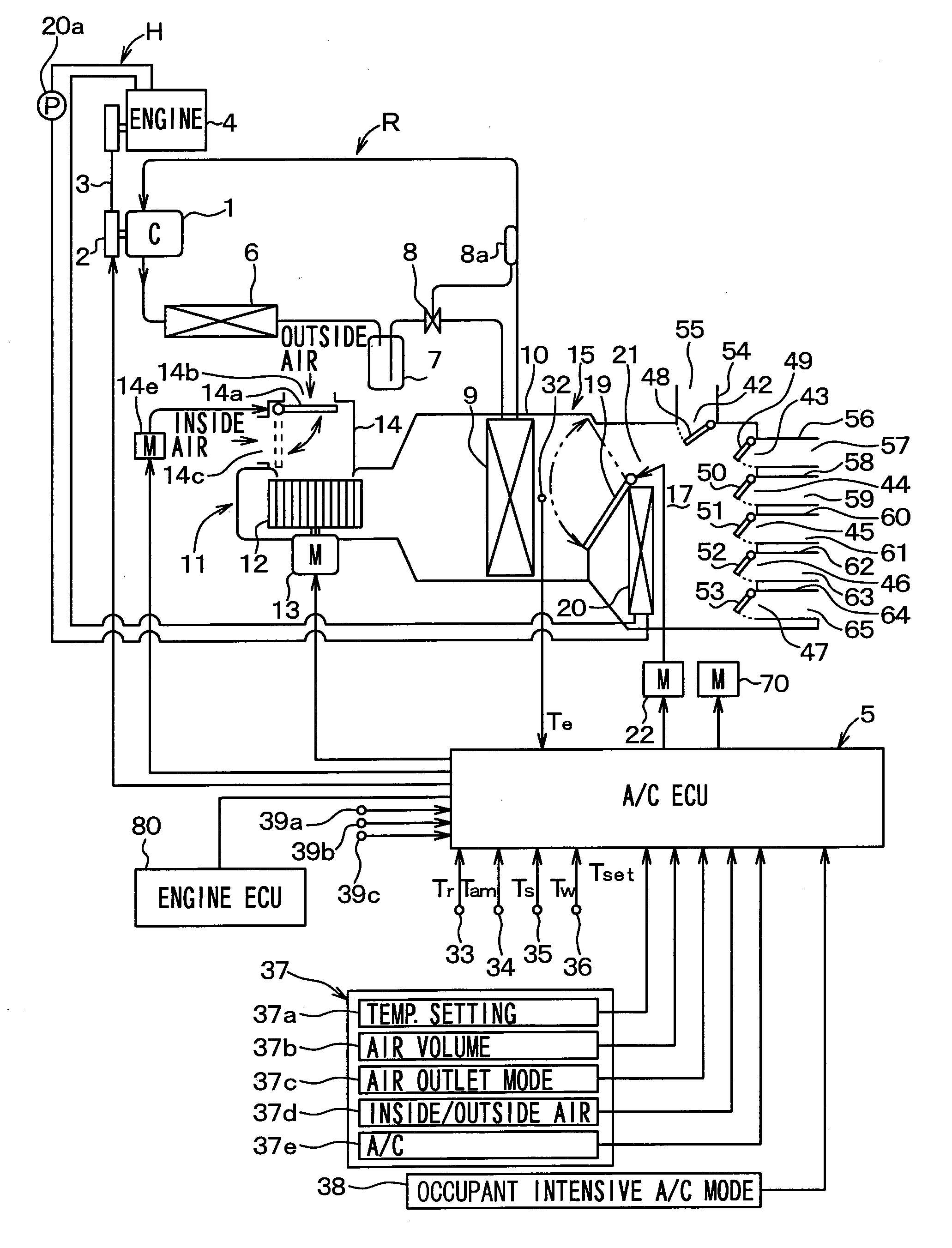

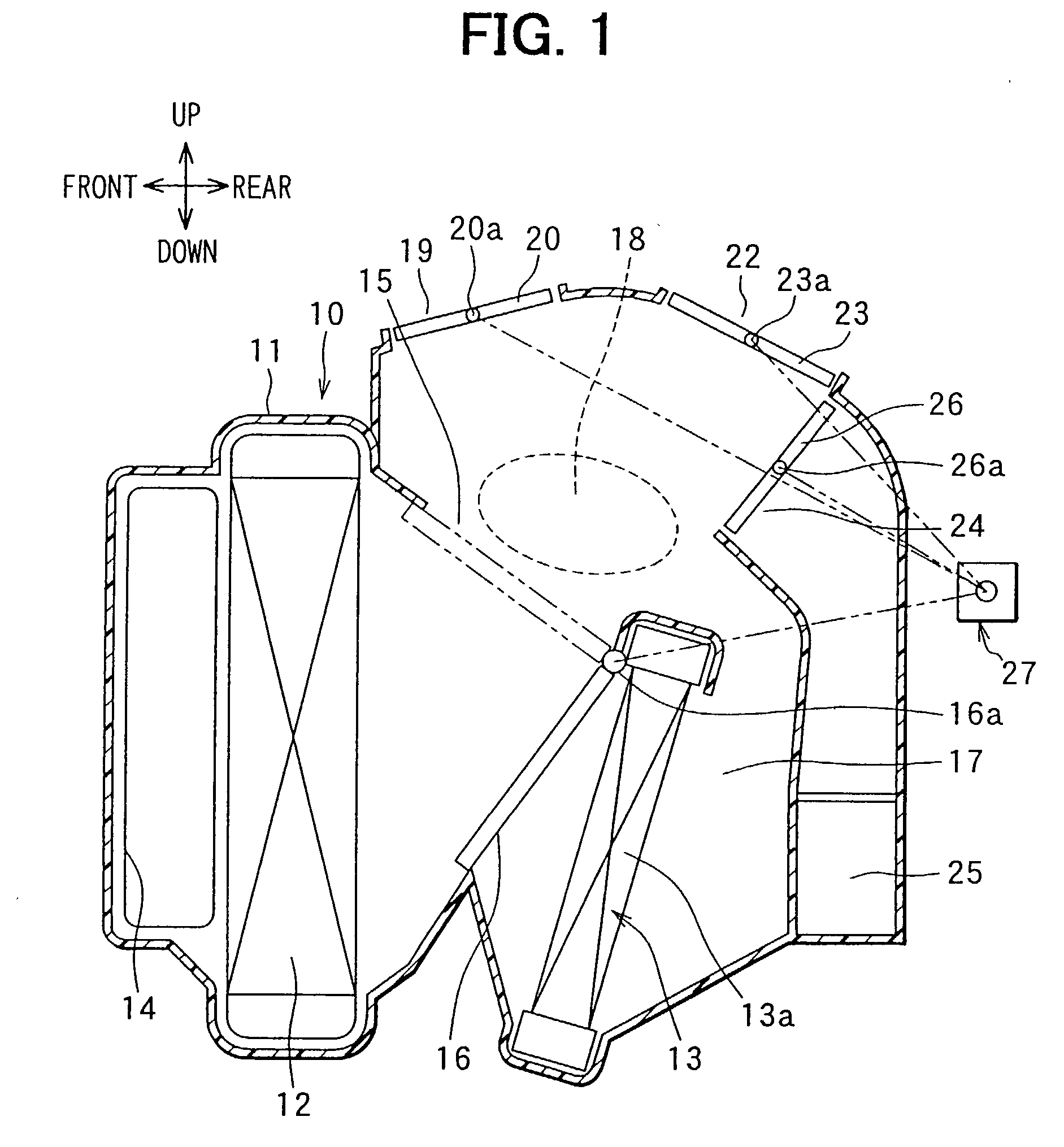

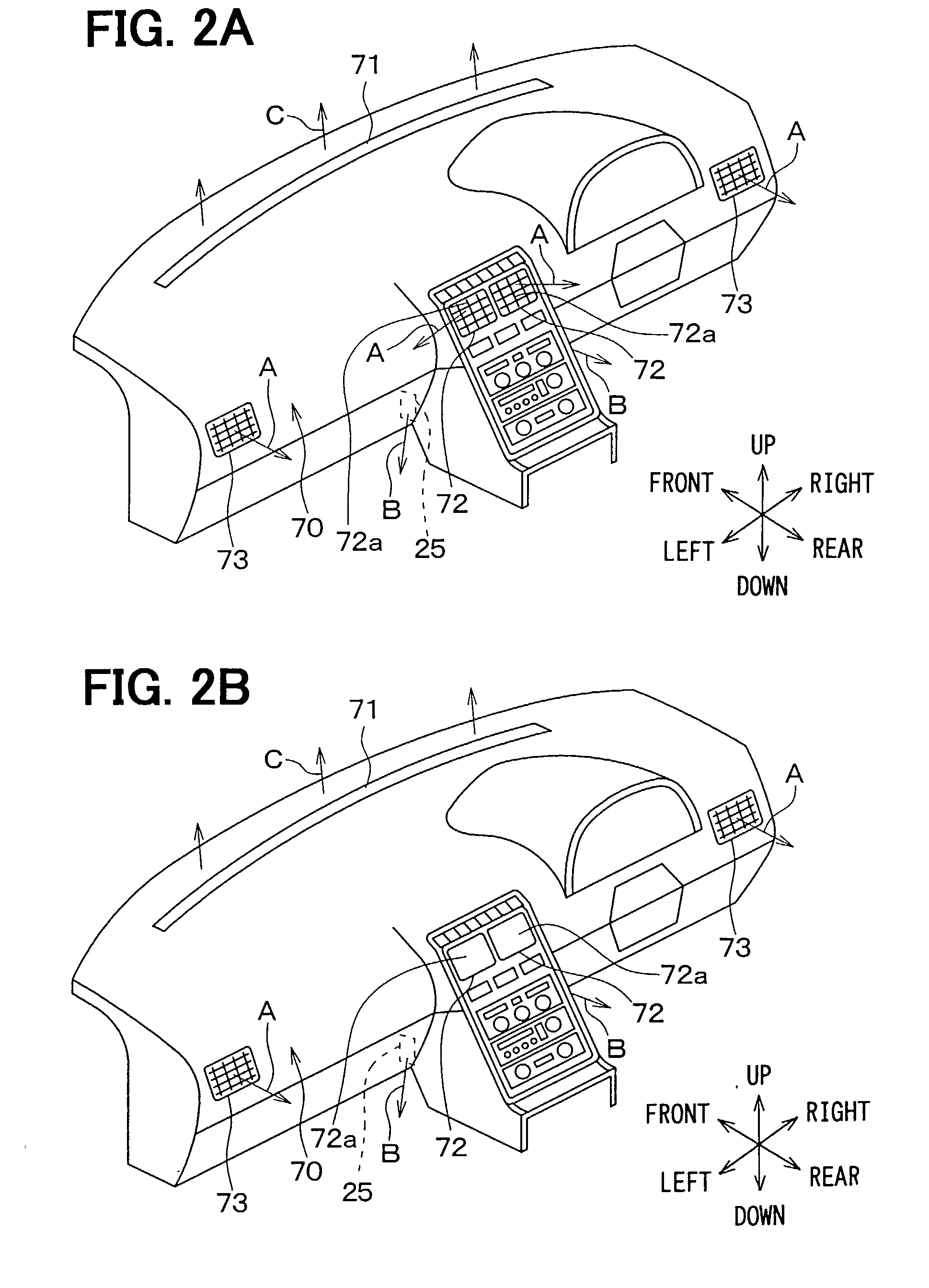

Vehicle air conditioner

ActiveUS20150114016A1Extended maintenance periodControl temperature changesAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

When an air conditioning ECU determines that it is immediately before idling stop, the air conditioning ECU implements a front seat air conditioning mode even if the air conditioning ECU determines that an occupant intensive air-conditioning mode can be implemented. Accordingly, the air conditioning ECU controls opening and closing mechanisms so as to blow a conditioned air from driver's seat side outlet ports, and also blow the conditioned air from a passenger's seat side foot outlet port. Hence, in cooling operation, since a temperature increase of air drawn into an inside air inlet port is limited when the idling stop is carried out, temperature increase of air blown into the vehicle interior from the outlet port can be restricted. In other words, a temperature change in the vehicle interior can be limited when a travel engine stops due to the idling stop.

Owner:DENSO CORP

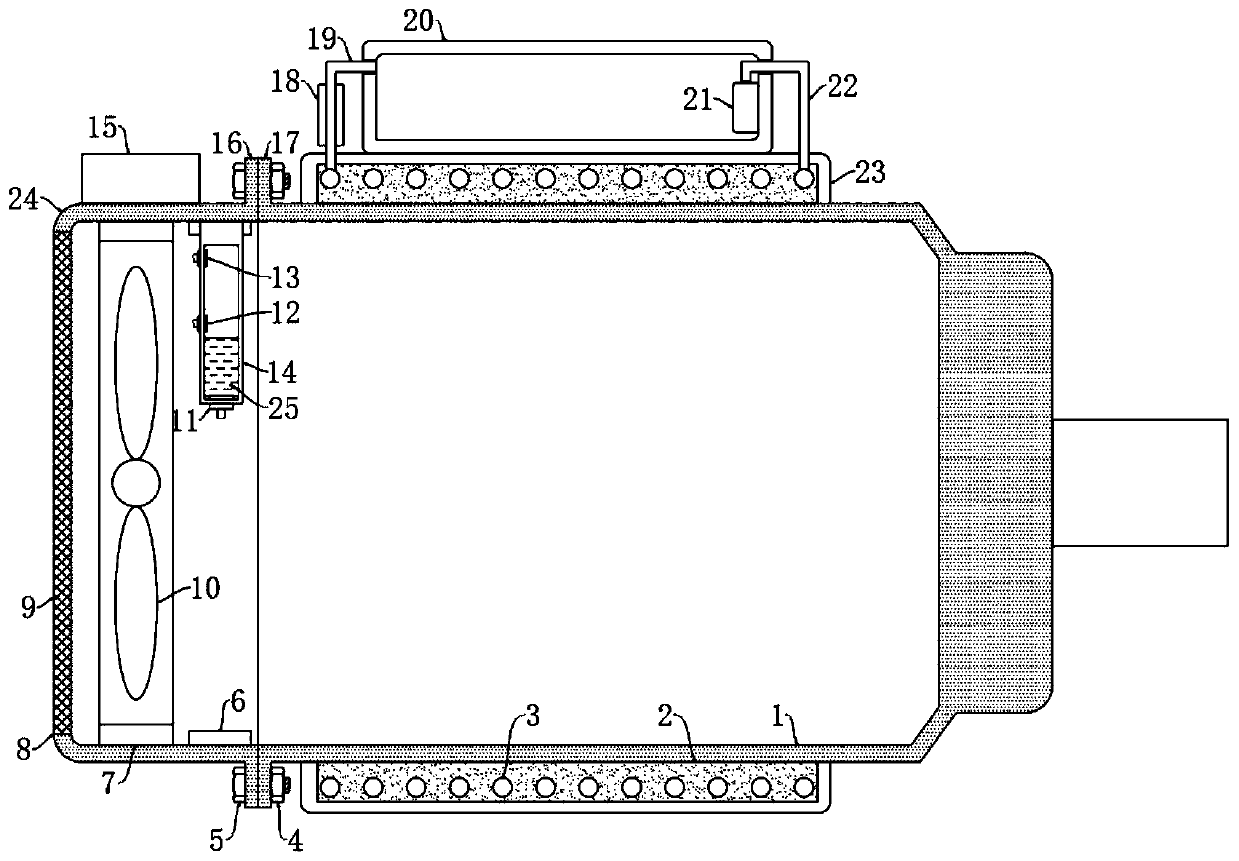

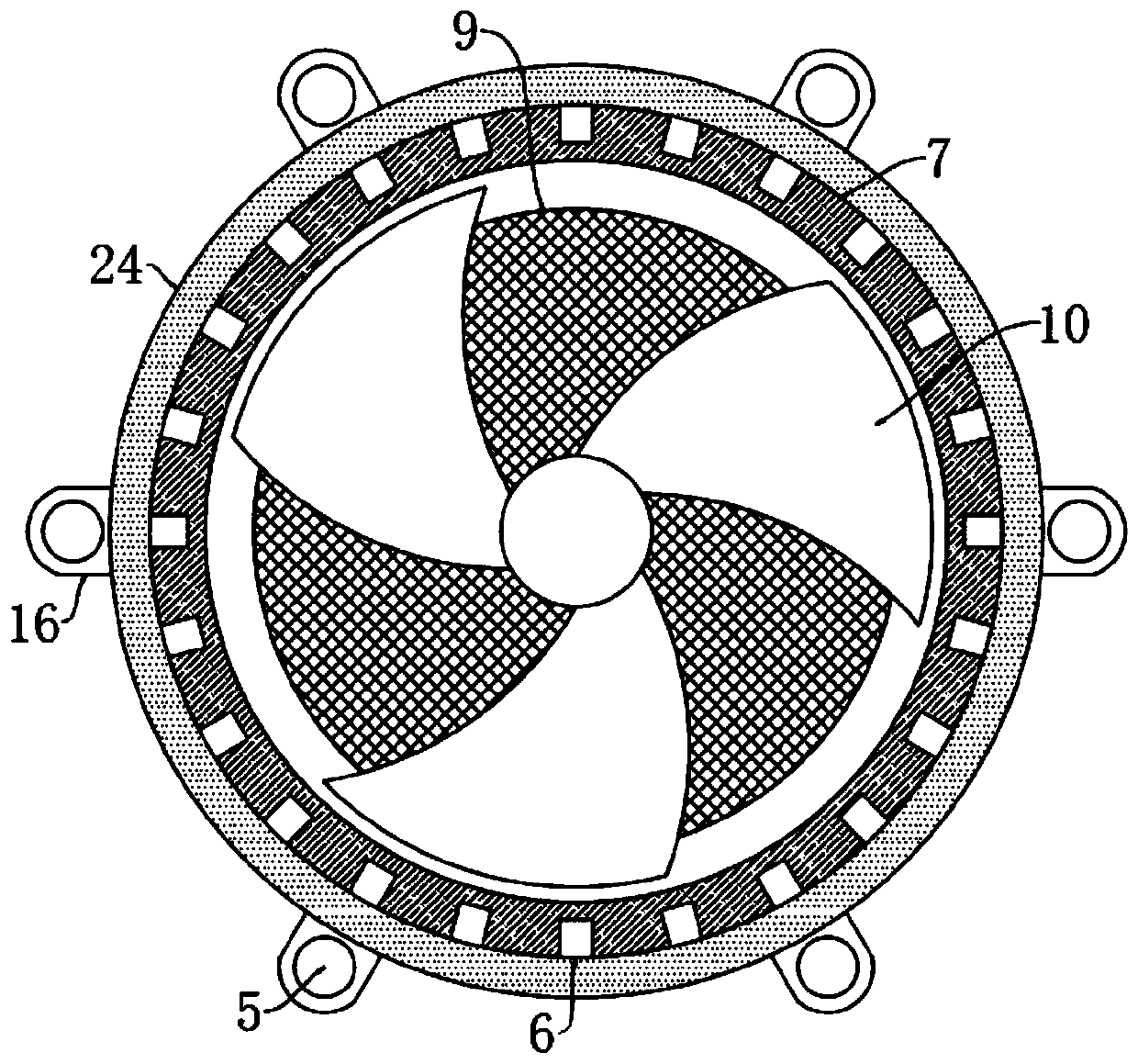

Self-heat-dissipation system for switched reluctance motor

InactiveCN111478499AConvenient heat conduction and coolingExtension of timeCooling/ventillation arrangementSupports/enclosures/casingsElectric machineryEngineering

The invention discloses a self-heat-dissipation system for a switched reluctance motor. The self-heat-dissipation system comprises a switch reluctance motor shell, the switch reluctance motor shell issleeved with a fixing plate., the fixed plate is fixedly connected with the switched reluctance motor shell, a heat conduction plate is fixedly connected to the inner side of the fixed plate, a cooling pipeline is arranged in the heat conduction plate, a circulating water cooling mechanism communicated with the cooling pipeline is arranged on the outer side of the fixing plate, a rear cover shellis arranged at the rear end of the switched reluctance motor shell, the switched reluctance motor shell is detachably connected with the rear cover shell through a mounting mechanism, and a heat dissipation mechanism is arranged in the rear cover shell. The self-heat-dissipation system is reasonable in structural design, the purpose of circuit conduction is achieved through mercury rising along with temperature rising of the switched reluctance motor, the good heat dissipation effect of air cooling heat dissipation and water cooling heat dissipation is achieved, the temperature in the switched reluctance motor shell is prevented from being too high, and operation of the switched reluctance motor is facilitated.

Owner:山东翔讯科技有限公司

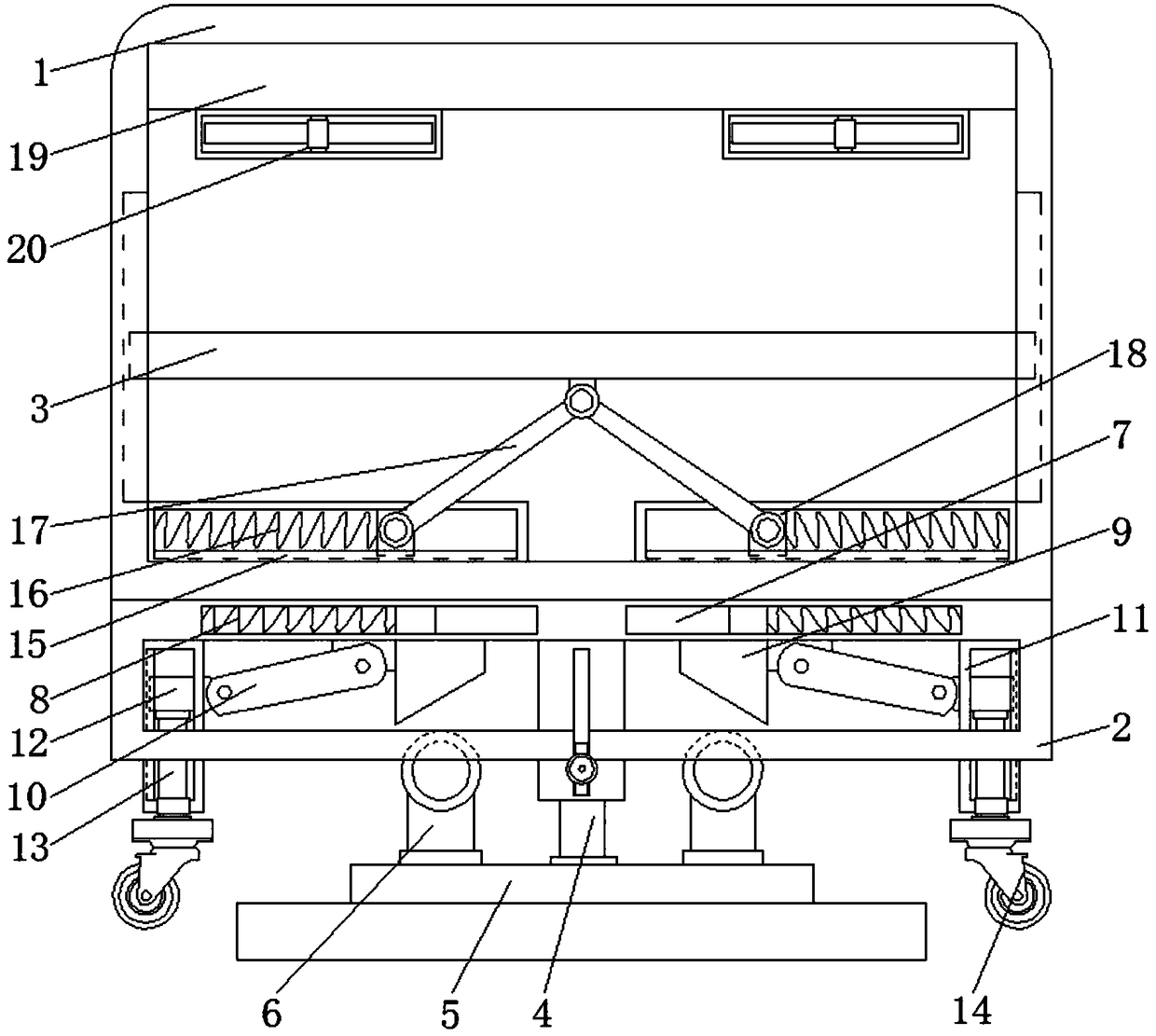

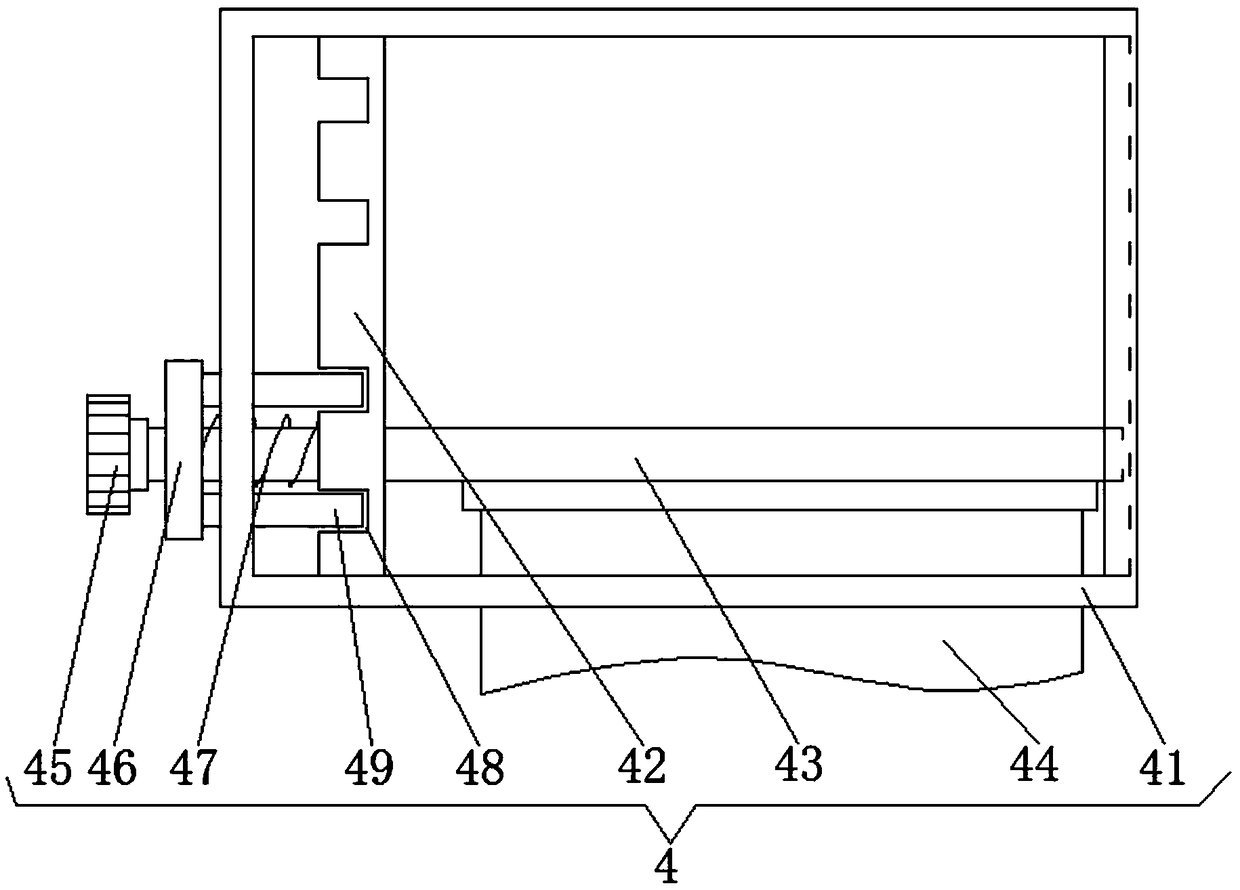

Transport case convenient to use

ActiveCN108128532AEasy to useReduce the burden onShock-sensitive articlesContainers to prevent mechanical damageEngineering

Owner:河北拓发通信电力器材制造有限公司

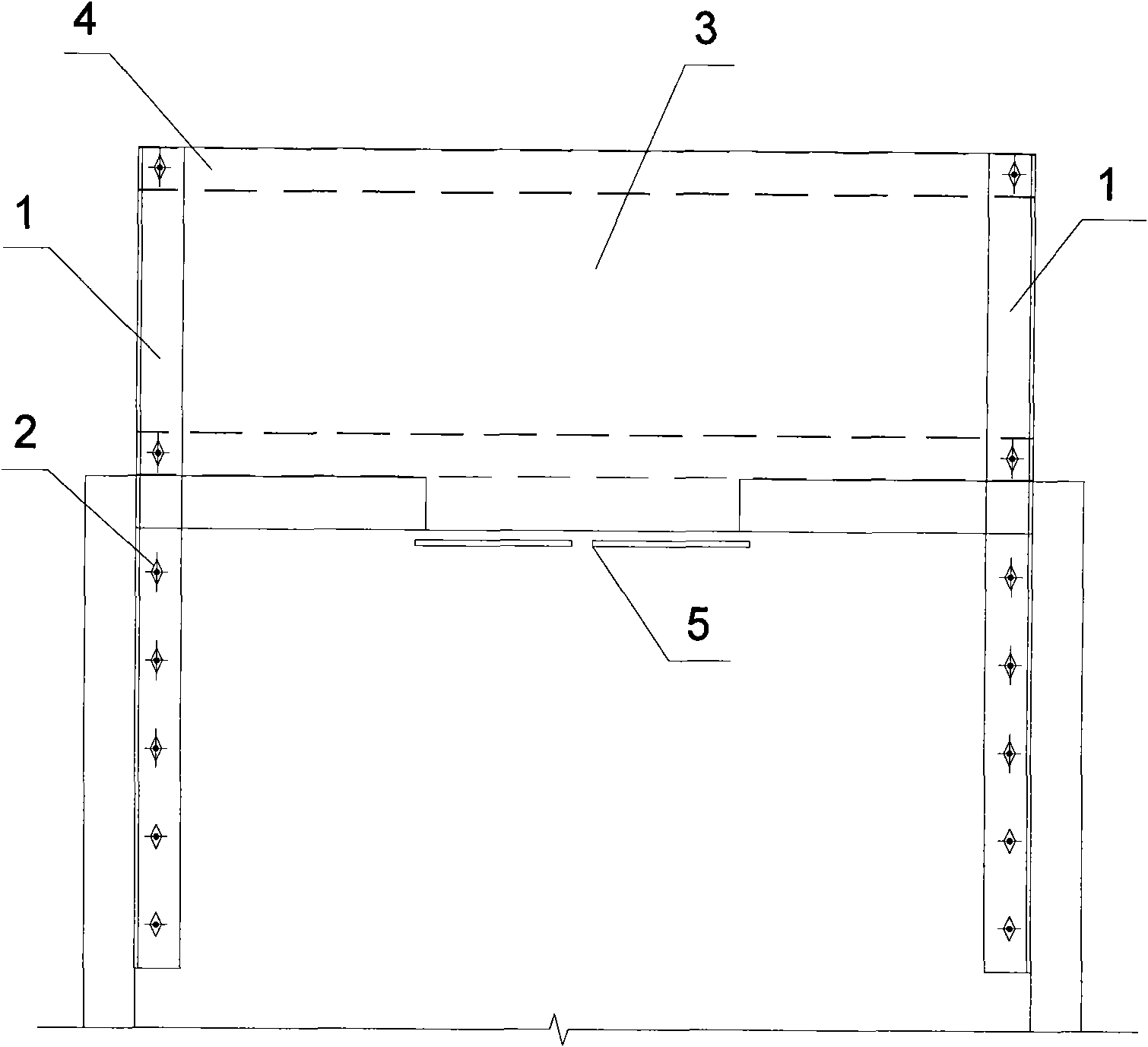

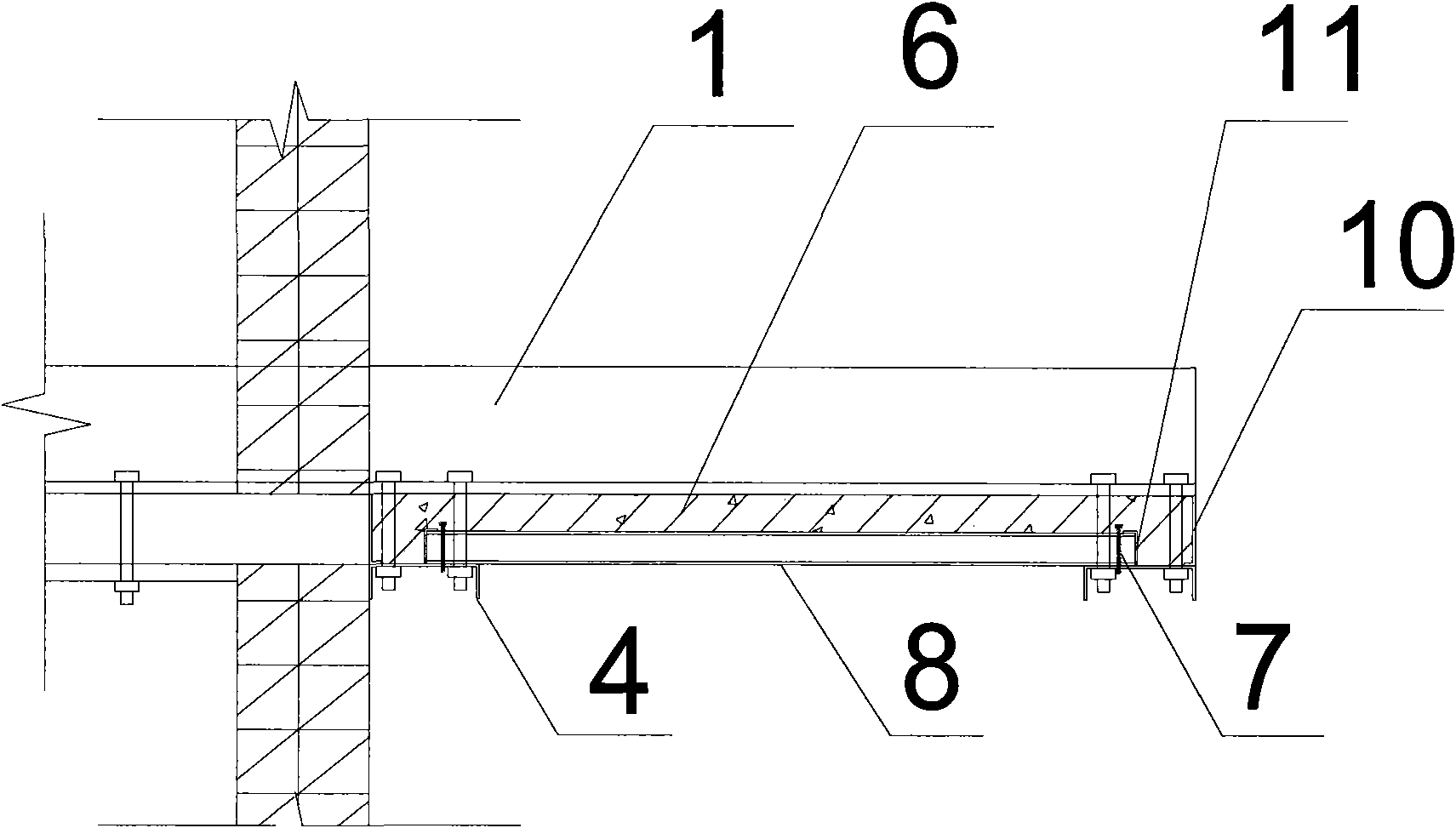

Current building renovation external energy-saving balcony structure system

The invention discloses a current building renovation external energy-saving balcony structure system. The structure comprises stressed steel angles anchored on a building floor and a profiled steel sheet-concrete combined building floor plate, wherein the different models of steel angles are directly anchored on the current building floor by a plurality of bolts according to the span of a balcony, while the other ends of the steel angels are suspended outside a room to bear the load of the balcony; the profiled steel sheet-concrete combined building floor plate serves as a balcony plate, and plastic doors and windows serve as the building envelope of the balcony; and isolating door and windows are arranged between the balcony and the inside of the room to reduce the heat exchange between the inside of the room and the balcony receiving direct sunlight. The structure system has the advantages of light weight, convenient and simple construction, high construction speed and good energy-saving effect. The structure system can be used for energy-saving renovation of various industrial and civil building structures such as brickwork and framework structures and framework-shear wall structures.

Owner:ZHEJIANG UNIV

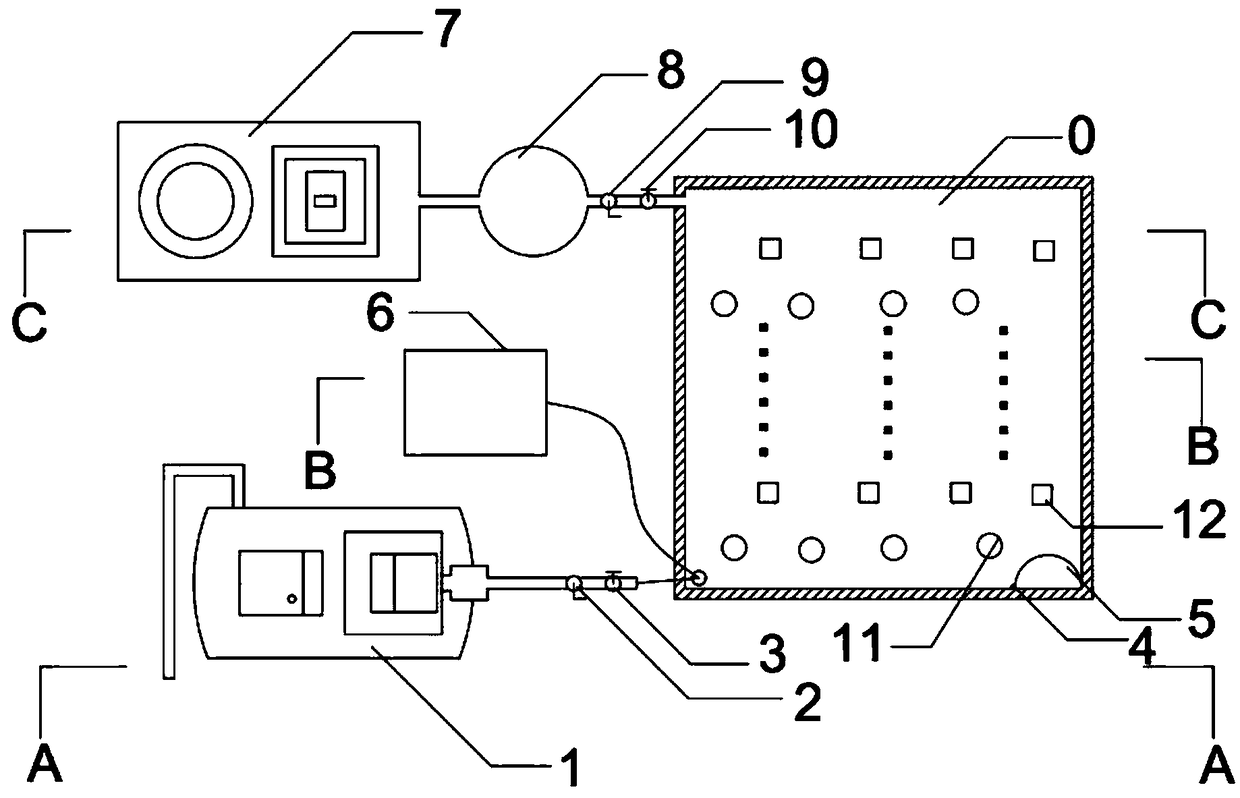

Test device for model of sand well wall static liquefaction induced by hydrate depressurization mining

PendingCN108760575ASimulation of static liquefaction instabilityControl temperature changesFlow propertiesData acquisitionInstability

The invention relates to a geotechnical engineering model test device, in particular to a test device for a model of sand well wall static liquefaction induced by hydrate depressurization mining. Thetest device comprises a sealed box with glass on the front side, a hydraulic control assembly, an inflation control assembly, a temperature control assembly, a volume loss control assembly and a dataacquisition assembly, wherein the model box is filled with water, clay and sand from top to bottom, and a mining well is buried on the side close to the glass; the hydraulic control assembly is used for controlling pressure of water in the sealed box; the inflation control assembly is used for supplementing gas for sand to simulate the process of changing saturated sand into gas-bearing sand, andthe temperature control assembly is used for controlling the temperature of the sand in the sealed box; the volume loss control assembly is used for simulating the volume loss when static liquefactionoccurs; the data acquisition assembly is used for acquiring data needed for the test. The device can simulate the static liquefaction instability behavior of the sand well wall in the depressurization mining process of the natural gas hydrate, and has the characteristics of being convenient to operate, simple in structure, accurate in control and the like.

Owner:TONGJI UNIV

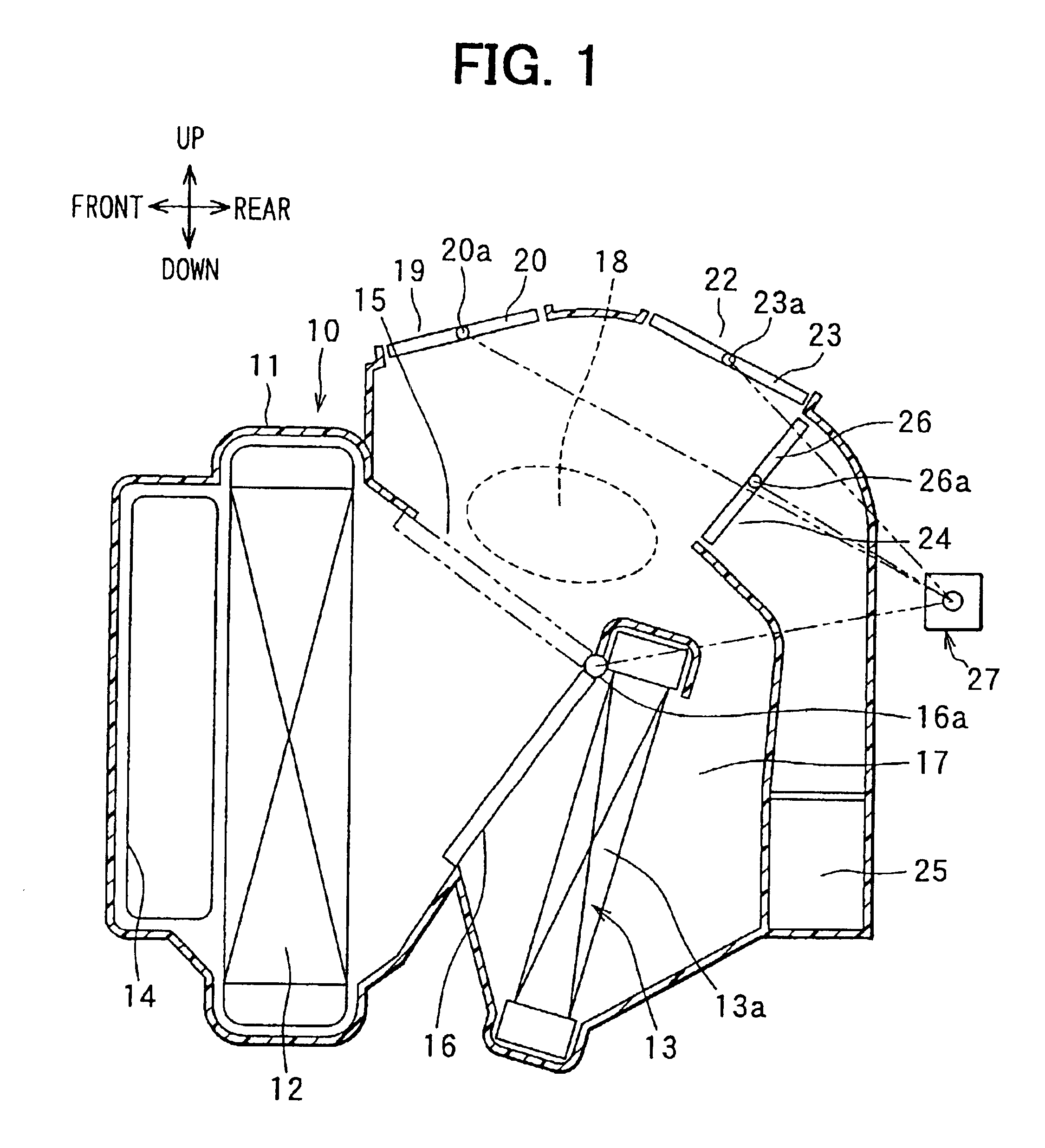

Vehicle air conditioner with mode switching pattern

InactiveUS20030029609A1Control temperature changesSmall range of anglesAir-treating devicesRailway heating/coolingActuatorControl theory

In a vehicle air conditioner having an actuator for driving an air mixing door and mode switching doors, an automatic range and a manual range are set in different operation angle ranges of an operation angle of the actuator. In the automatic range, an air outlet mode is automatically switched in accordance with an opening degree of the air mixing door. On the other hand, in the manual range, a multi-mode or a defroster mode is manually set, regardless of the opening degree of the air mixing door. In the manual range, air is simultaneously blown from all openings such as a face opening, a foot opening and a defroster opening in the multi-mode, and air is blown from the defroster opening in the defroster mode.

Owner:DENSO CORP

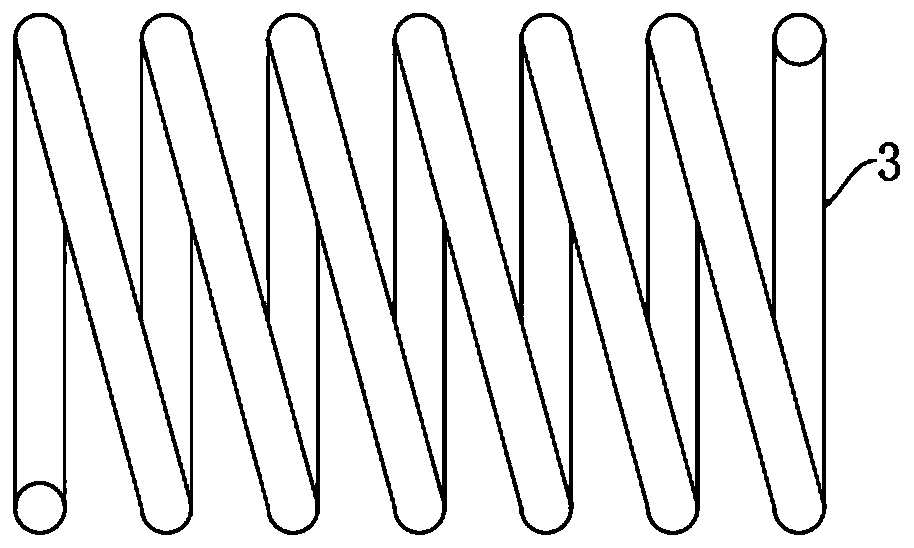

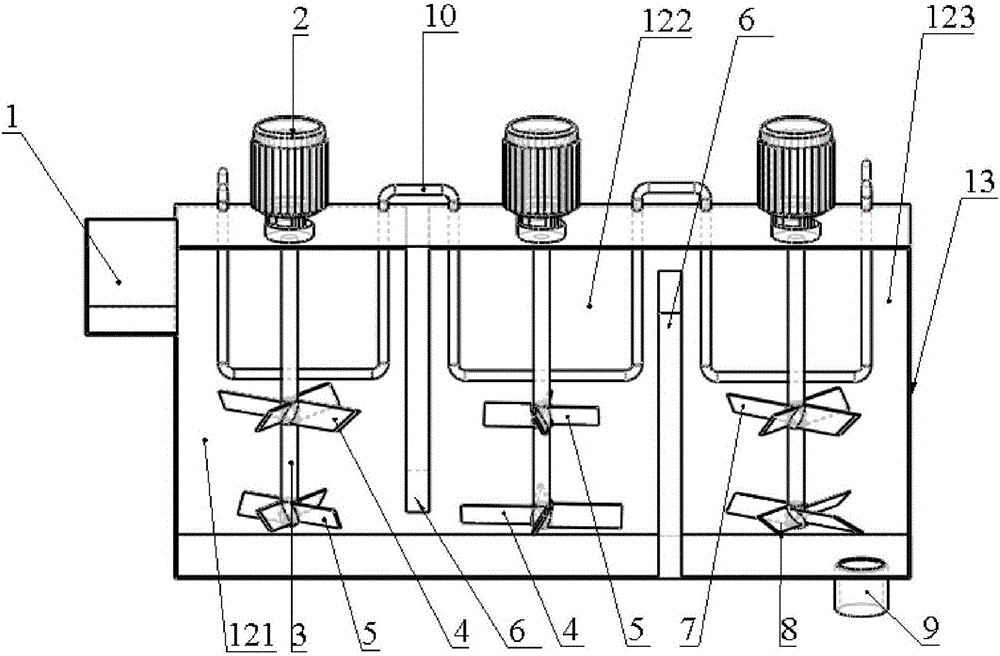

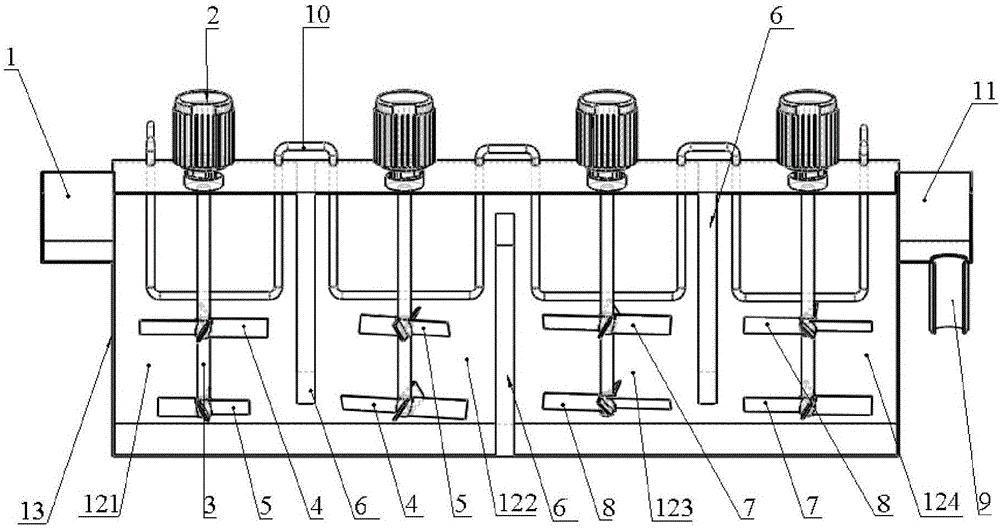

Quicklime slaking apparatus and method used for coke oven flue gas desulphurization

PendingCN106582422AImprove digestibilityIncrease the flow distanceGas treatmentTransportation and packagingFlueProcess engineering

The invention relates to a quicklime slaking apparatus and method used for coke oven flue gas desulphurization. The apparatus comprises a slaking tank, a motor, stirring shafts, blades, a temperature control device and separator plates, the separator plates are arranged in the slaking tank to separate the inner cavity of the slaking tank into a plurality of areas, one stirring shaft is arranged in every separated area, every stirring shaft is provided with two groups of blades, the groups of the blades have opposite tilting directions, the diameter / propeller pitch angle of one group of the blades is more than that of the remaining group, and the temperature control device is also arranged in the slaking tank. The temperature change of a liquid in the tank is controlled in the invention, so the quicklime slaking rate is improved. Arrangement of the flow of a lime slurry in the tank is helpful for proceeding a slaking reaction and enhances solid and liquid mixing. A guiding flow flows according to a required path, so deposition at the bottom of the tank is reduced, the stirring capacity is enhanced, the particle size of the solid is refined, the slaking reaction is promoted, pipeline obstruction is reduced, and the desulphurization technology effect is improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

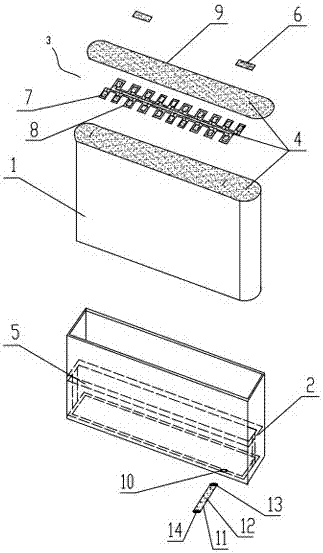

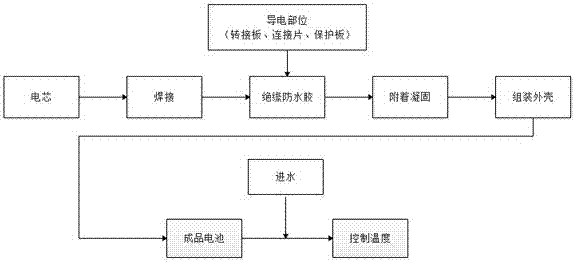

Passive waterproof system of lithium battery, fabrication and waterproof methods of passive waterproof system and electromobile

ActiveCN106981618AEffective control of temperature changesControl temperature changesBattery isolationSecondary cellsLiquid cooling systemEngineering

The invention discloses a passive waterproof system of a lithium battery. The passive waterproof system comprises the lithium battery and a shell, wherein a conductive part is arranged on the lithium battery, a layer of insulation waterproof glue is plated and coated on a surface of the conductive part by immersion, and a circulation water way is arranged between the lithium battery and the shell. The invention also discloses a fabrication method and waterproof method of the passive waterproof system of the lithium battery and an electromobile. By the passive waterproof system of the lithium battery, waterproof treatment is fundamentally performed, and the insulation of a conductor is achieved; water is effectively utilized after the water enters the battery, the water entering the battery shell forms a simple liquid cooling system, the temperature change of the battery can be effectively controlled, and overhigh temperature of the battery during the application process is prevented; and moreover, the waterproof system is convenient to fabricate, the effect and the structure of the battery are not affected, and the method for water prevention by the waterproof system and temperature reduction by effectively using water is good in effect.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

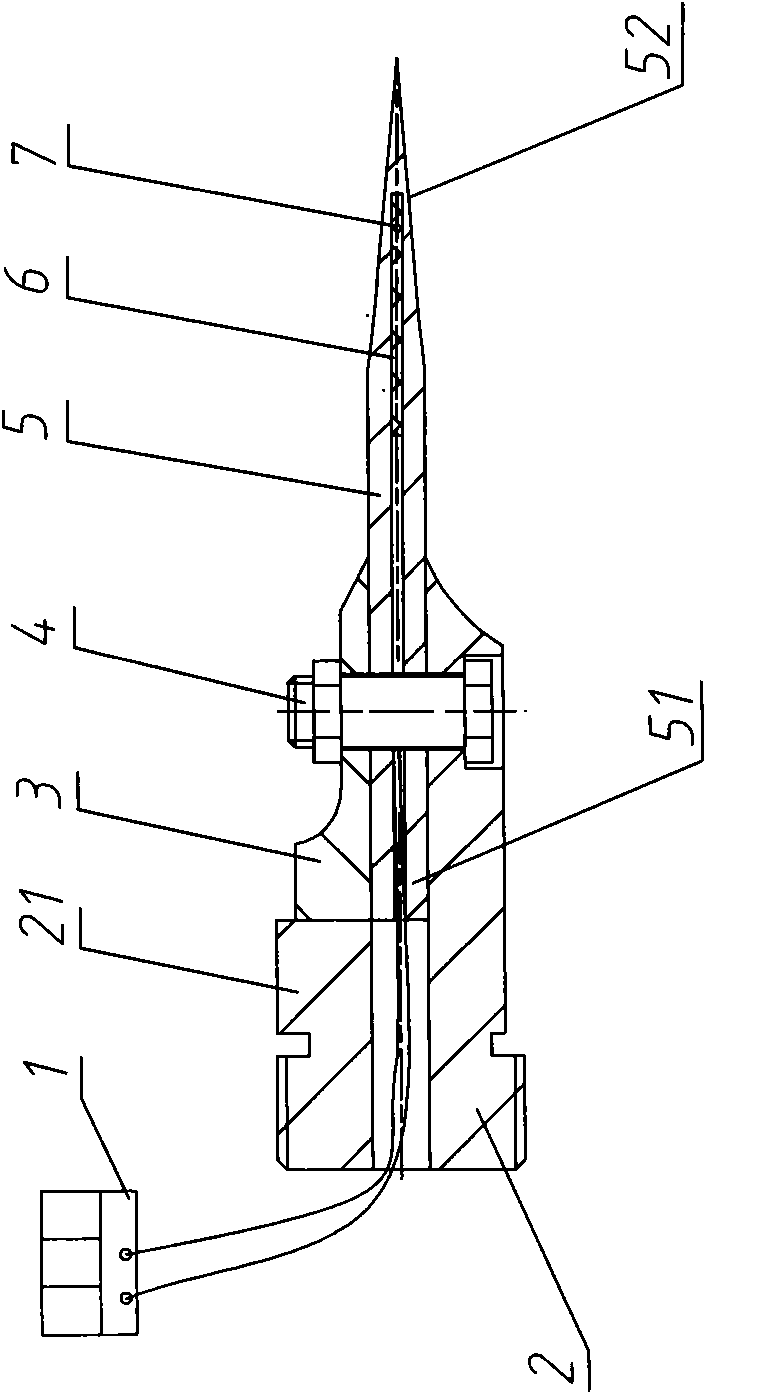

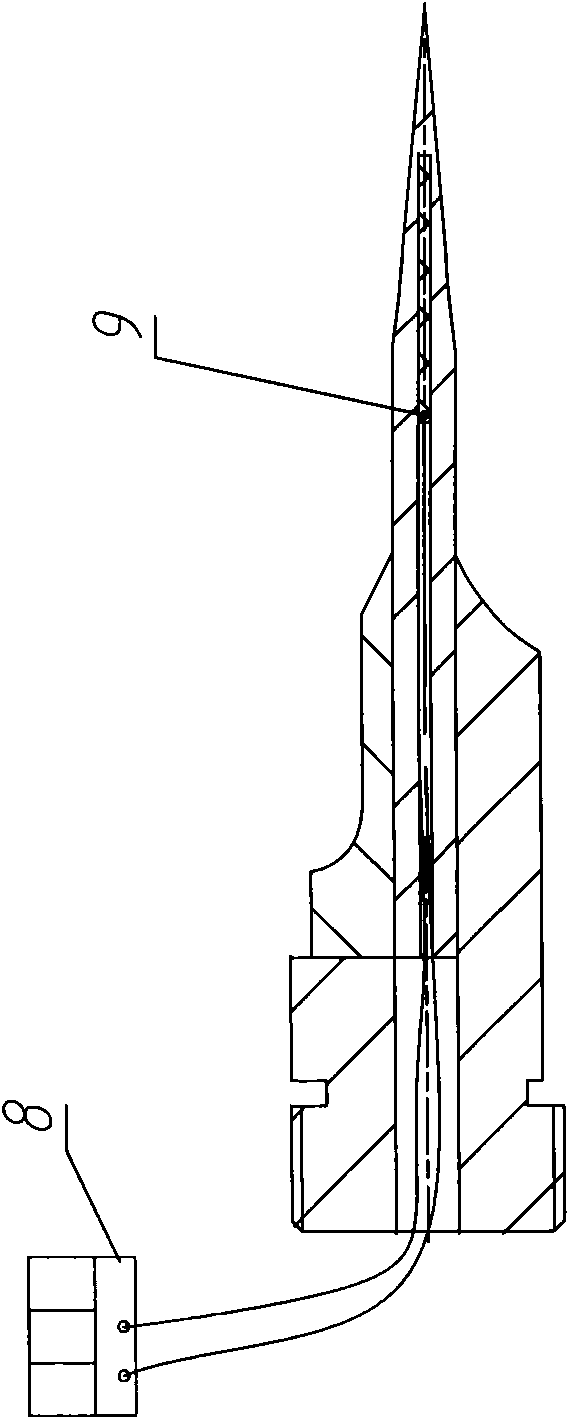

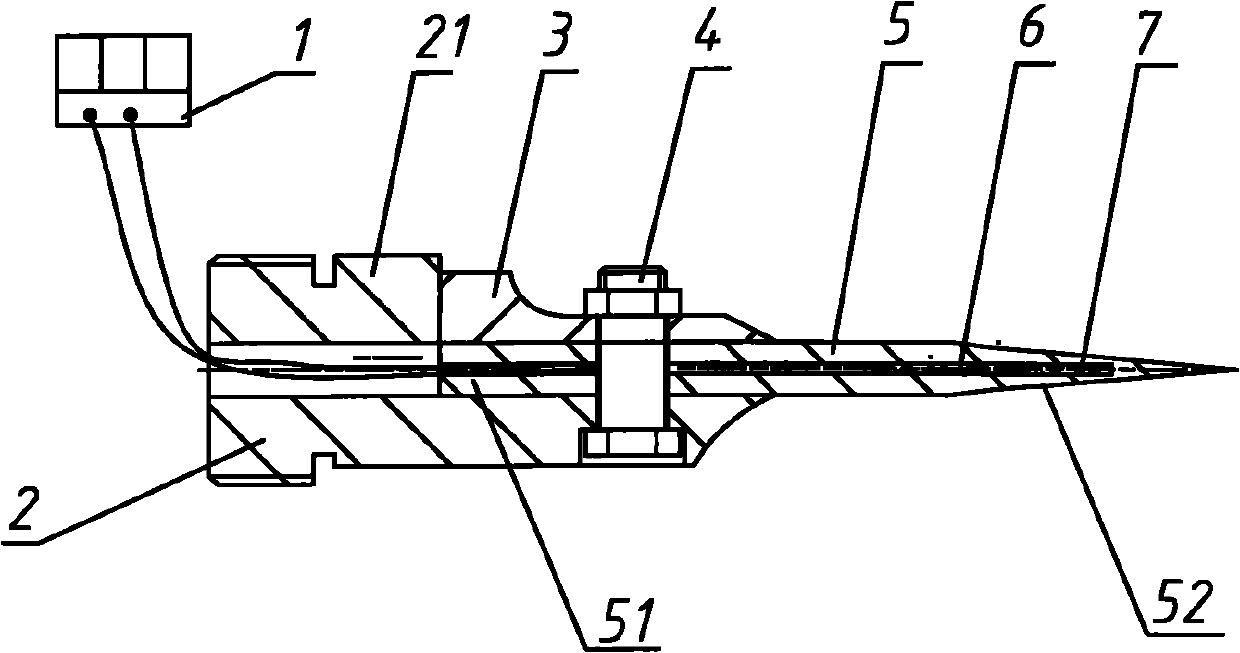

Internally conductive hot cut-off knife and method thereof

InactiveCN102476393AHeating up fastAccurate perception fastMetal working apparatusTemperature controlHeat transmission

The invention provides an internally conductive hot cut-off knife and a method thereof. A heat supply element and a temperature sensor are installed in the interior of a knife edge part of a knife body so that produced heat energy is acted on a knife edge directly and cutting operation is performed while hot melting is performed on the surface of a sizing material; and the heat source is installed on the knife edge part for performing the cutting operation directly, obvious heat loss is avoided without long distance heat transmission, thereby saving energy effectively. The internally conductive hot cut-off knife comprises a lower fixture body, an upper fixture body and the knife body, wherein the knife body comprises a base part clamped and fixed between the lower fixture body and the upper fixture body and the knife edge part for cutting on the surface of the sizing material; and the heat supply element for directly acting the heat energy on the knife edge and the temperature sensor which is used for connecting with an external power supply and a temperature control instrument and detecting work temperature on the surface of the knife edge are installed in the knife edge part.

Owner:MESNAC

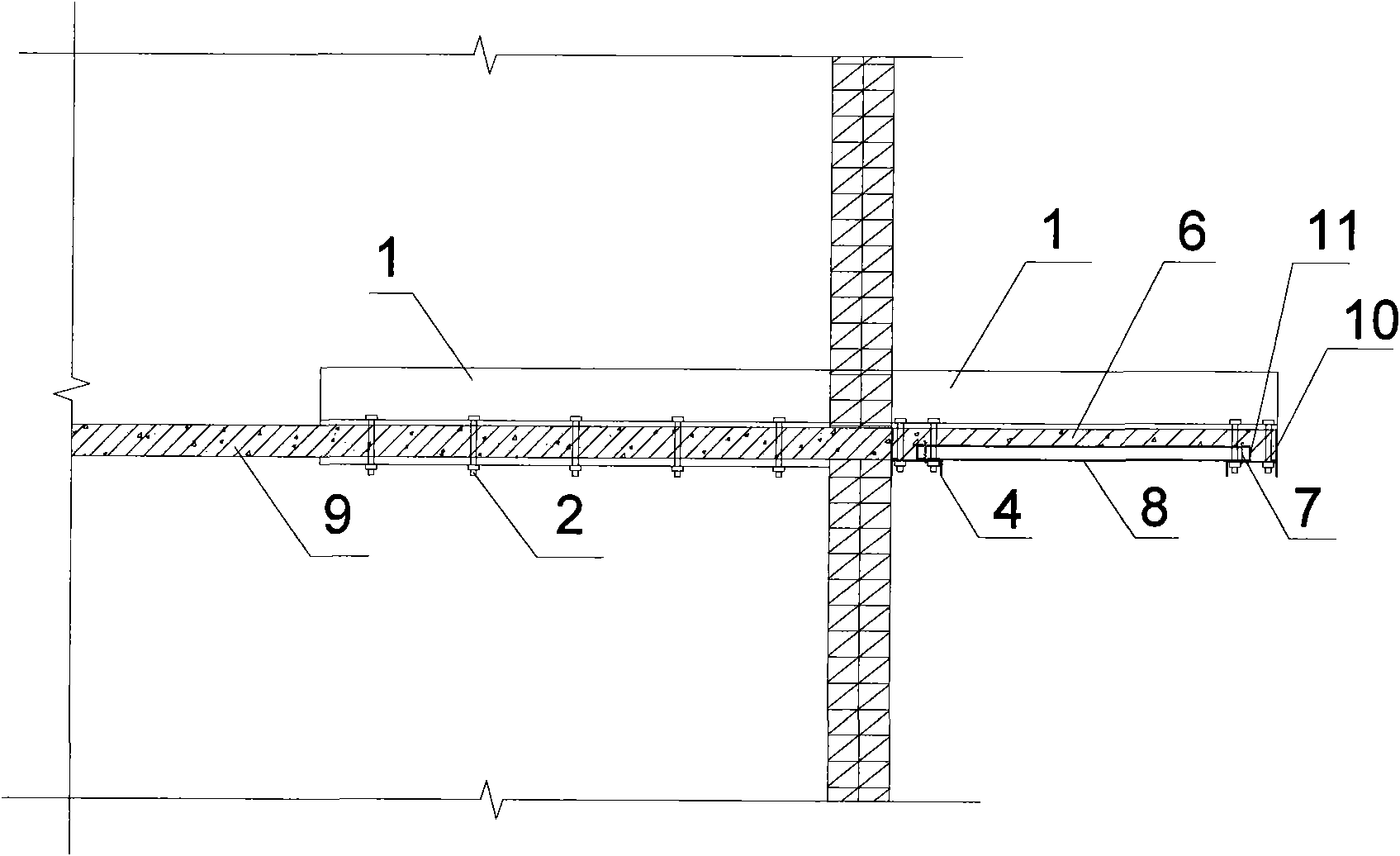

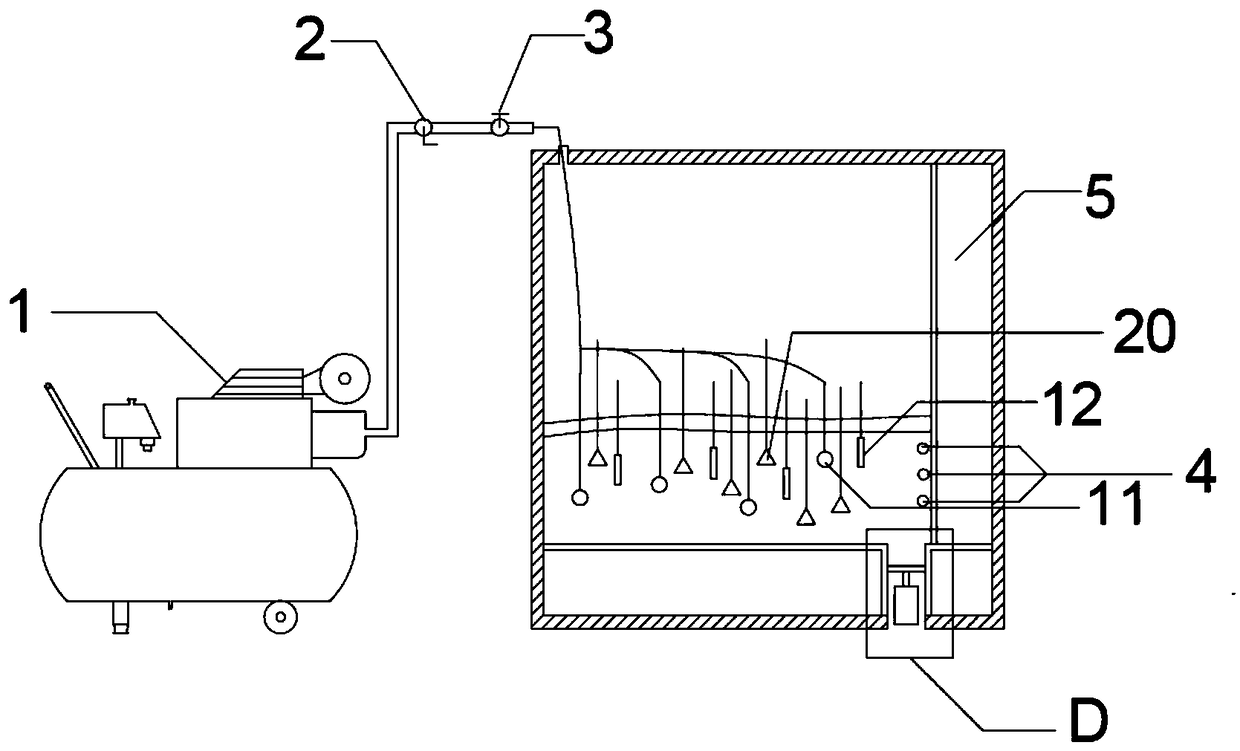

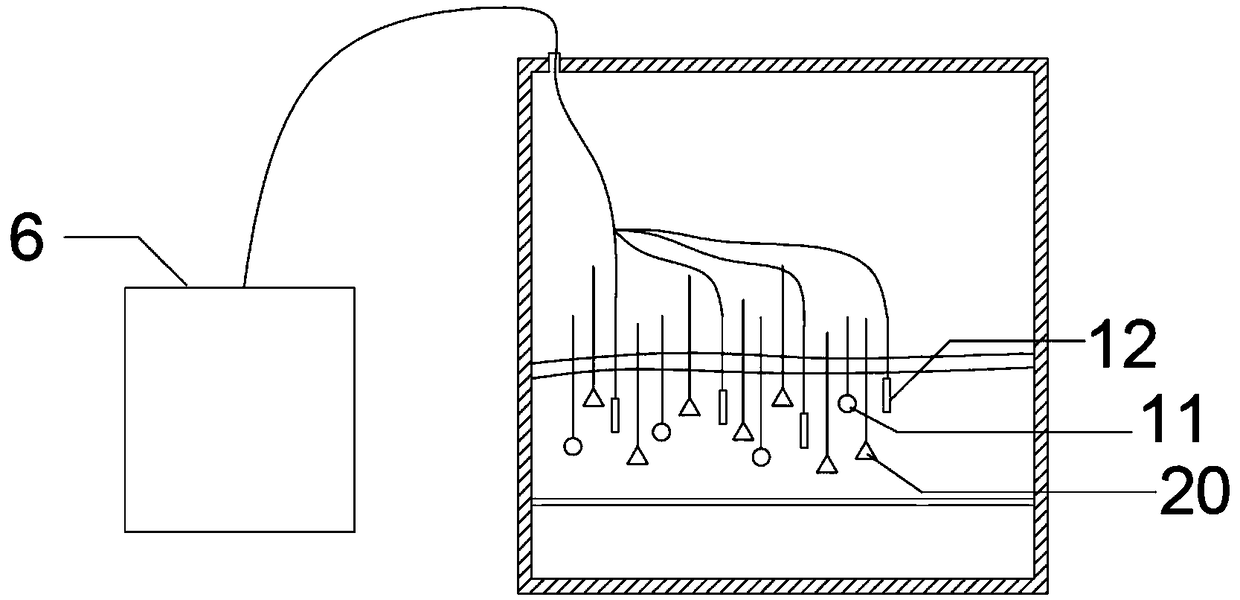

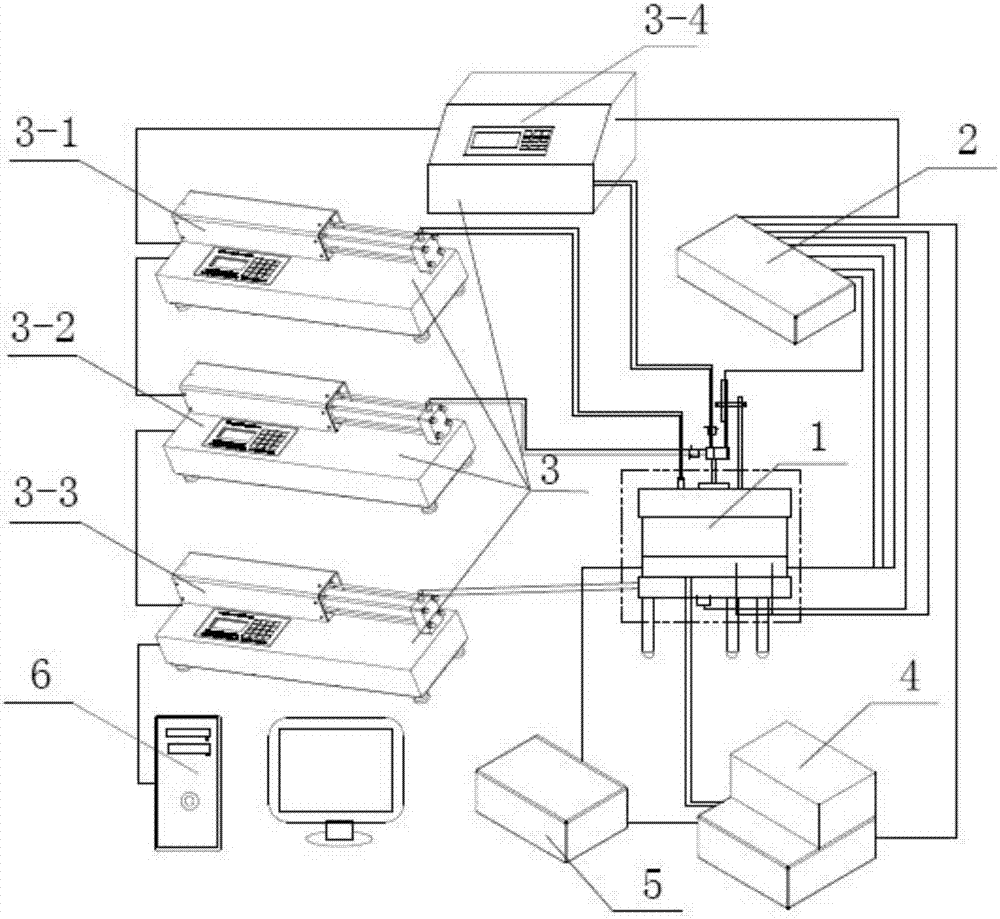

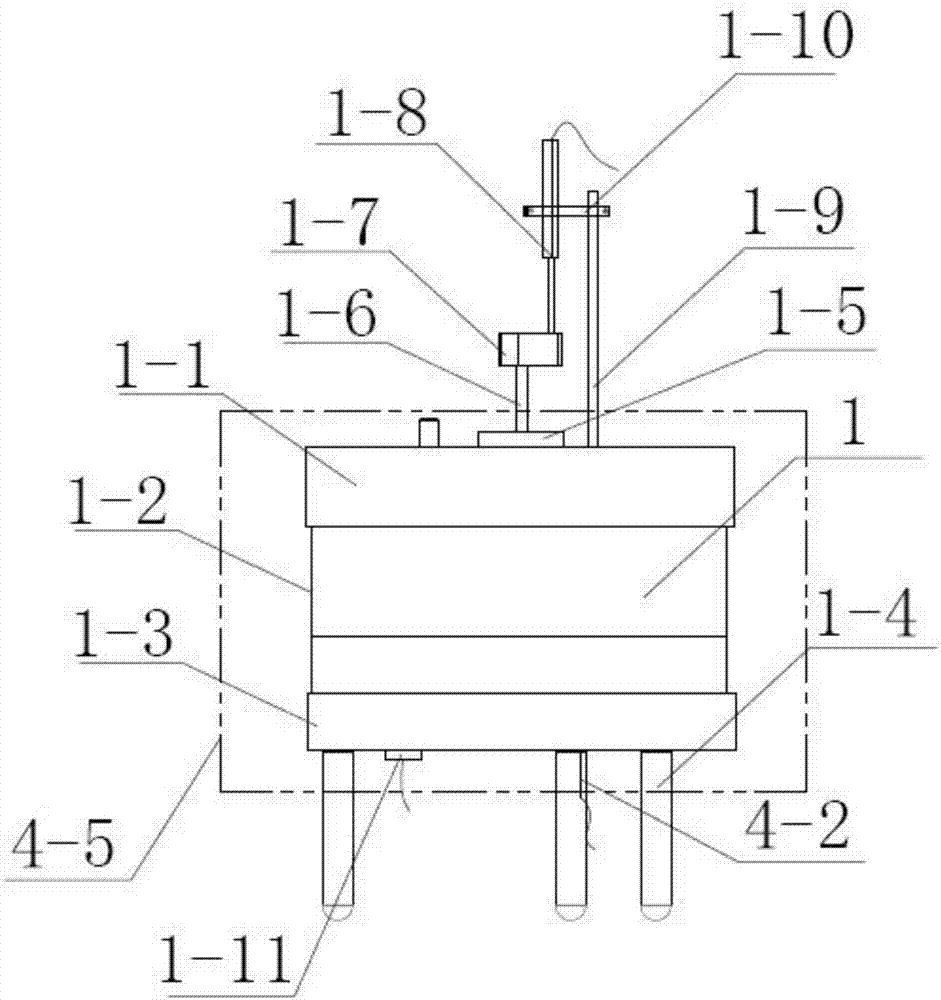

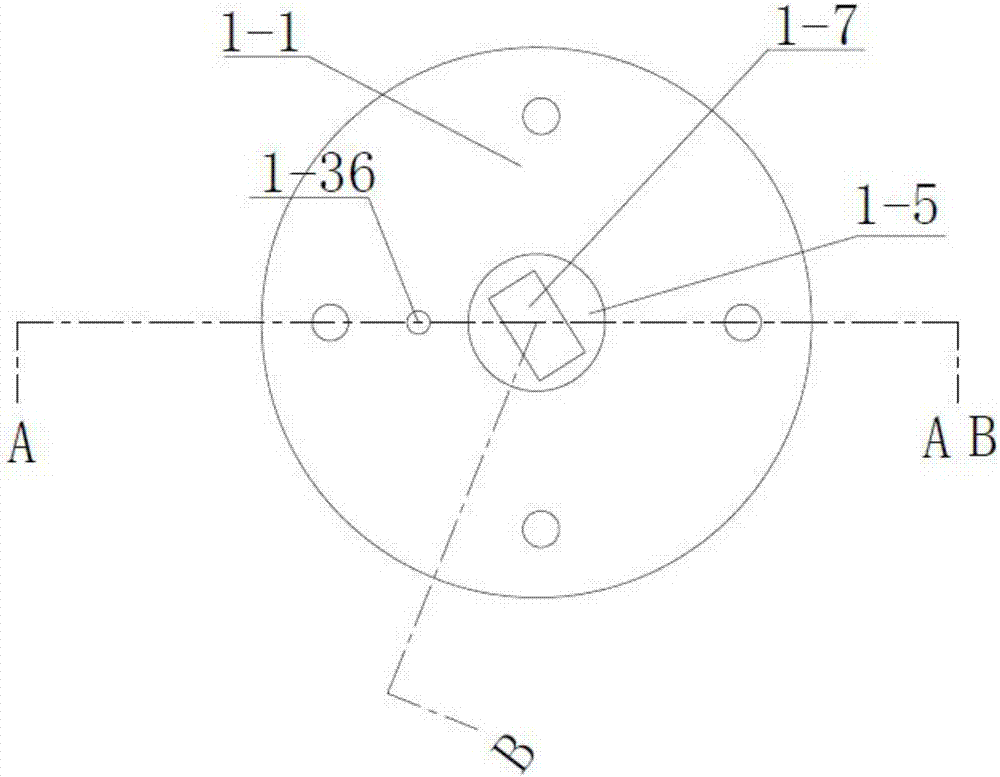

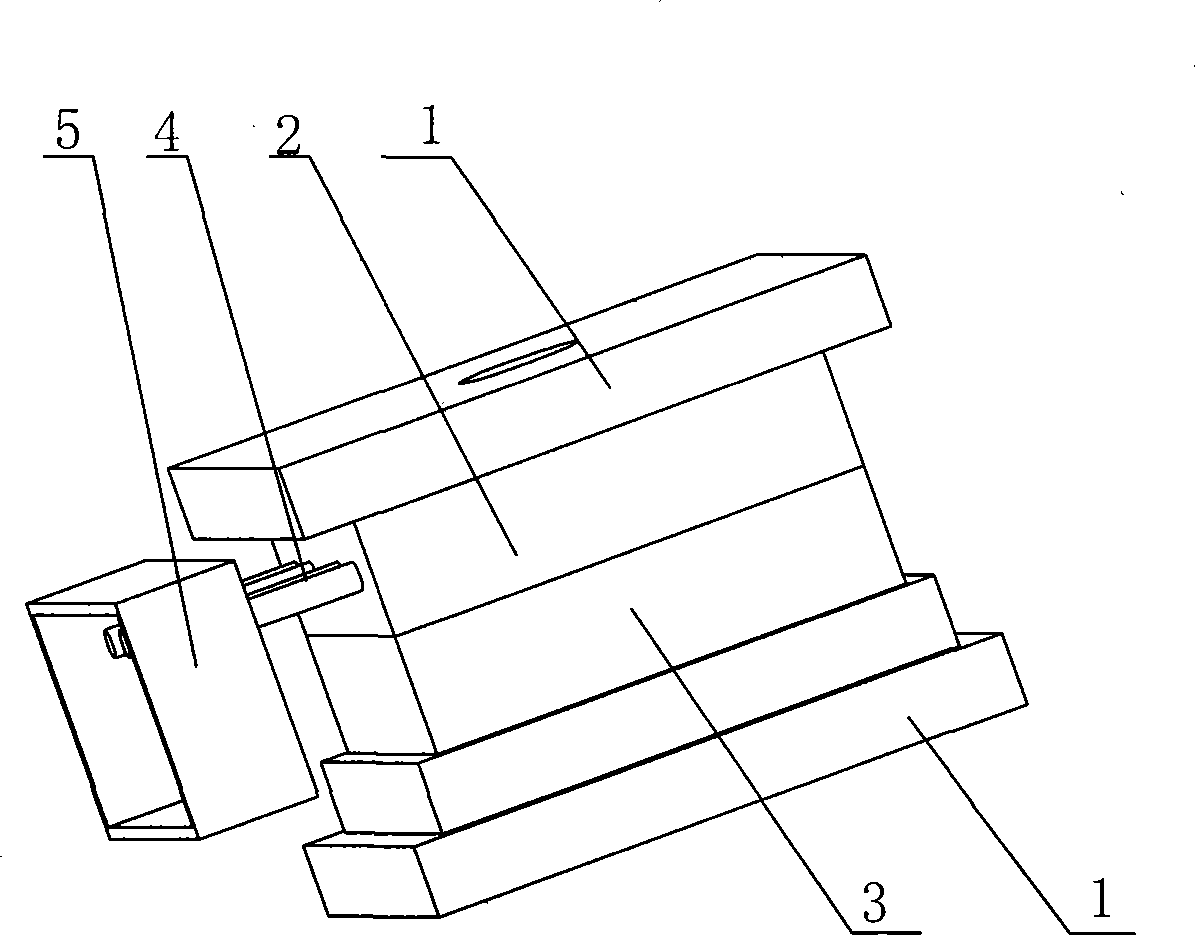

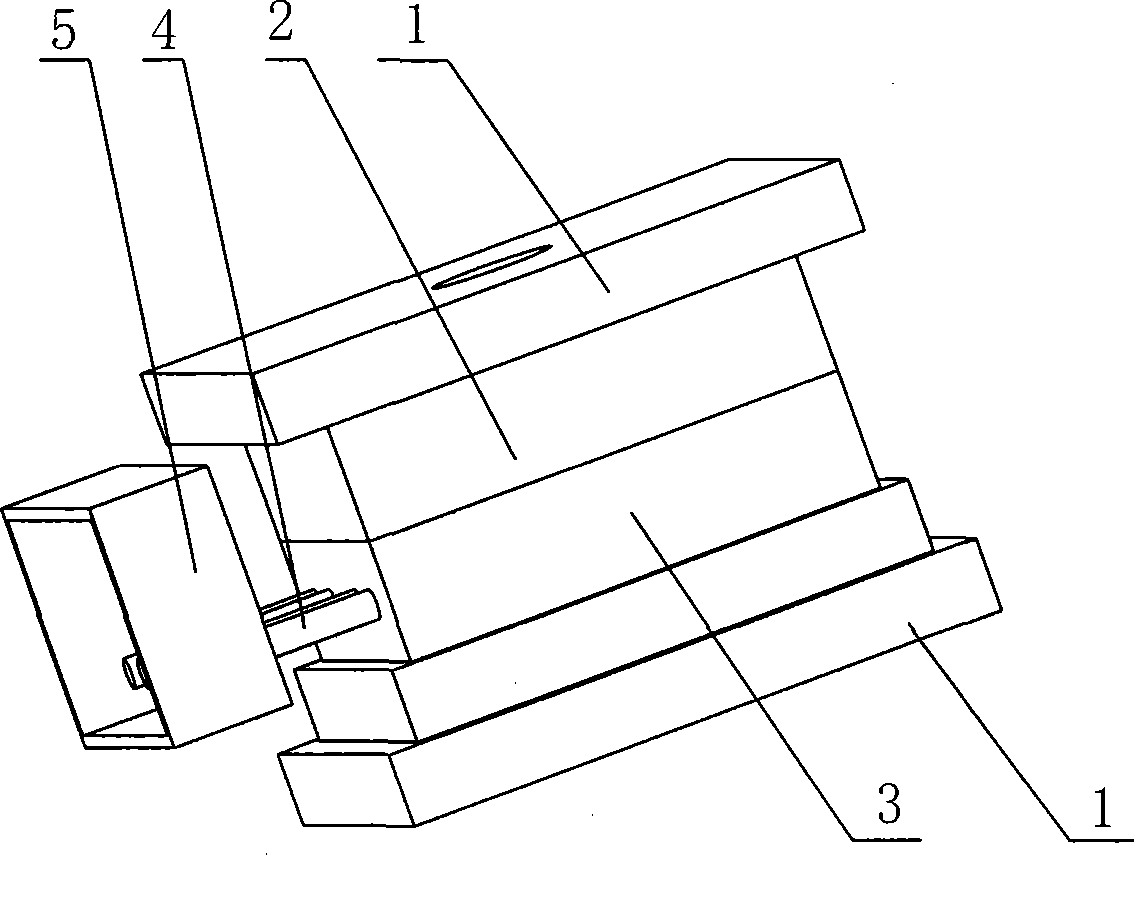

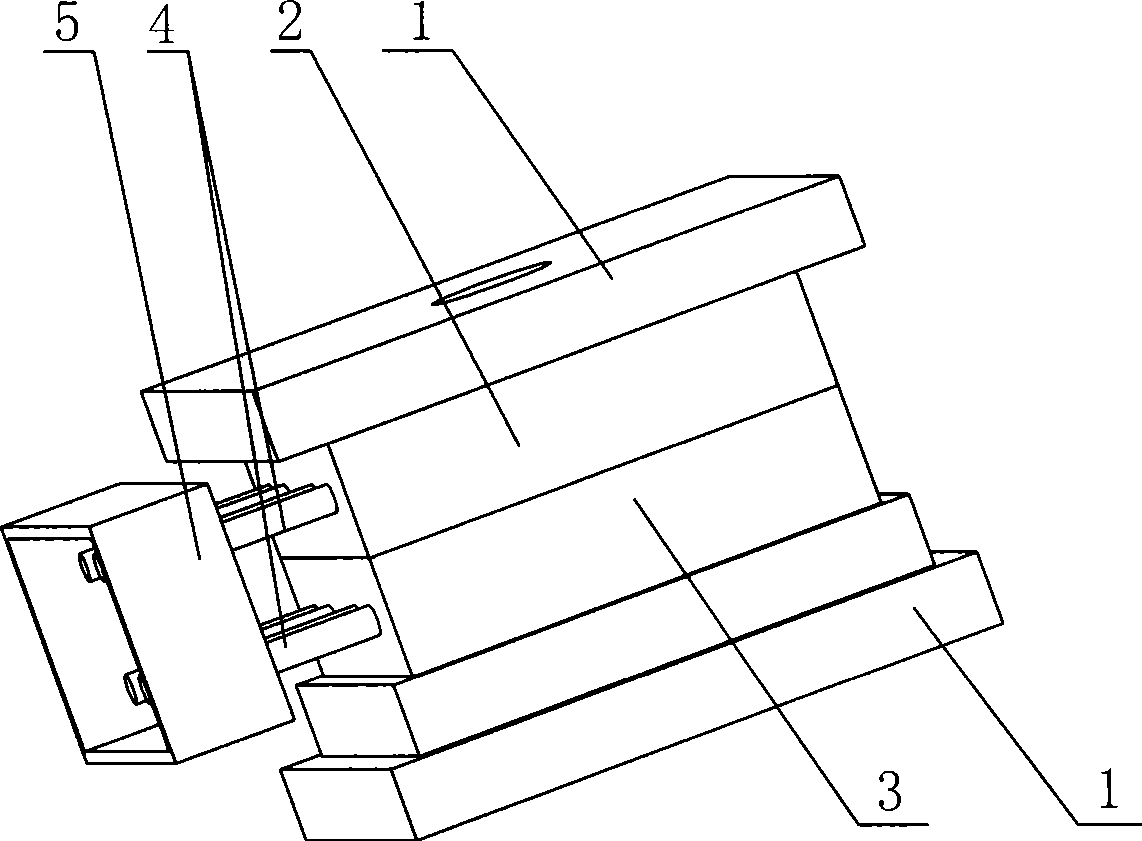

Temperature-suction force-infiltration-stress coupled multifunctional consolidation system and operating method thereof

PendingCN106885893AHigh measurement accuracyRealize multi-field couplingEarth material testingEngineeringMultiple function

The invention discloses a temperature-suction force-infiltration-stress coupled multifunctional consolidation system and an operating method thereof. The system comprises a consolidation device (1), a data acquisition device (2), a pressure control device (3), a temperature controlling and monitoring device (4), a shearing wave sending and receiving device (5) and a computer (6) which are sequentially connected, wherein the computer (6) or control panels of all devices can be used for carrying out operation control on the system and recording test data in real time. According to the system and the operating method thereof, the structural design is reasonable, the operation is simple, the range of application is wide, the degree of automation is high, temperature, suction force, infiltration and stress random-coupled geotechnical engineering test research can be achieved, the accuracy of measurement results is higher, the working efficiency is higher, and the range of application is more extensive.

Owner:南京泰克奥科技有限公司

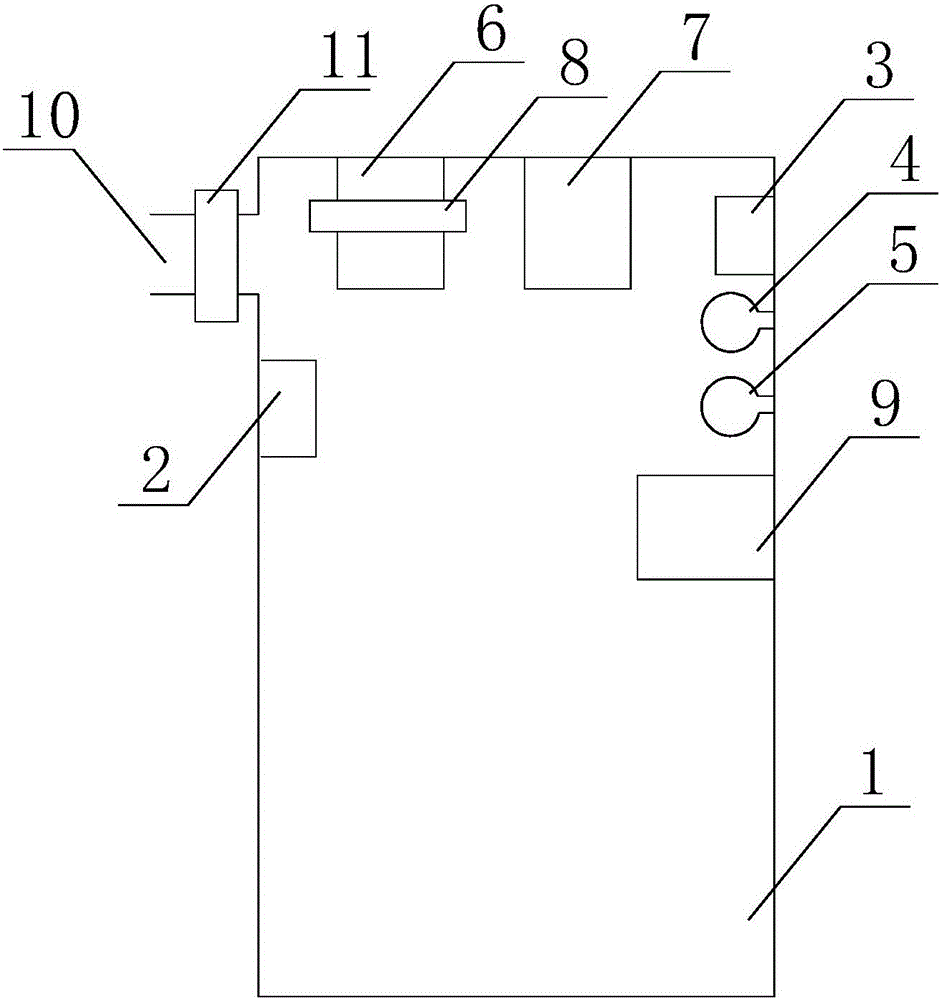

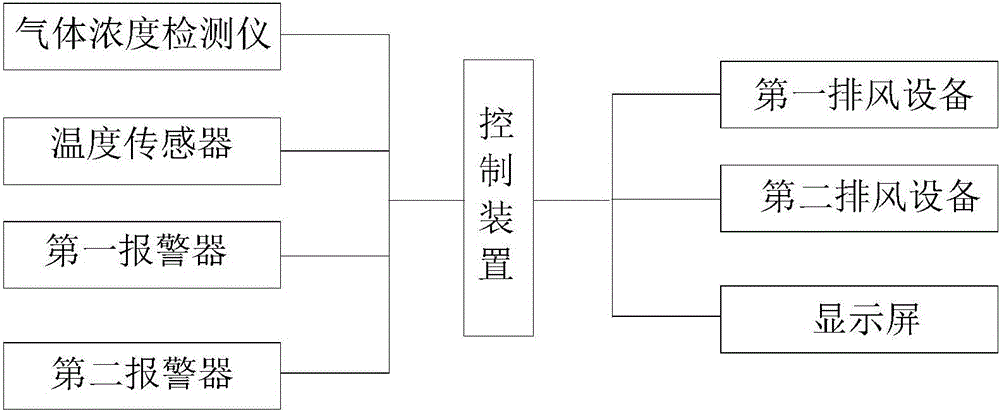

Automatic temperature control ventilation cabinet

The invention discloses an automatic temperature control ventilation cabinet. The automatic temperature control ventilation cabinet comprises a cabinet body, an exhaust device, a warning device and a control device; a gas concentration detector for detecting the concentration of poisonous and harmful gas and a temperature sensor for detecting the internal temperature of the cabinet body are arranged on the inner side of the cabinet body; the warning device works according to instructions of the control device; the exhaust device includes first exhaust equipment and second exhaust equipment; the first exhaust equipment is provided with an electromagnetic valve, and includes three exhaust modes; the electromagnetic valve is different in openness under different exhaust modes; the second exhaust equipment includes three exhaust grades, and is different in working power under different exhaust grades; the control device dynamically controls the first exhaust equipment to work in different exhaust modes according to different gas concentration values in the cabinet body; and the control device dynamically controls the second exhaust equipment to work in different exhaust grades according to the temperature in the cabinet body.

Owner:ANHUI YUAN LAB EQUIP

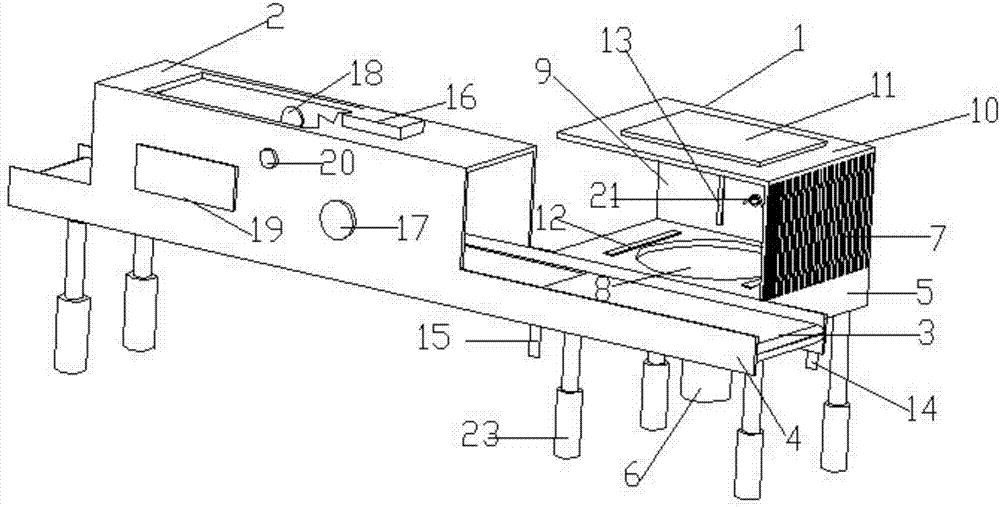

Washing and drying device

InactiveCN107411673AImprove convenienceControl temperature changesTableware washing/rinsing machine detailsEngineeringElectric motor

The invention discloses a washing and drying device, which comprises: a dishwasher main body, a dryer main body, a conveyor belt and a bracket; the dishwasher main body includes an exchange box, a curtain, a motor, a side baffle and an upper top plate; The main body of the dryer includes a heating device, a blower, a camera, a display screen and a controller; the main body of the dishwasher and the main body of the dryer are connected by a conveyor belt; brackets are arranged on both sides of the conveyor belt; the main body of the dishwasher It is arranged on one side of the bracket; the main body of the dryer is arranged on the upper end of the conveyor belt and fixed on the bracket; the four corners of the lower end of the exchange box and the lower end of the conveyor belt are respectively provided with supporting legs. The invention has the advantages of simple structure, reasonable design, convenient installation and convenient use by workers.

Owner:SUZHOU LANGRUIJIE AUTOMATION TECH CO LTD

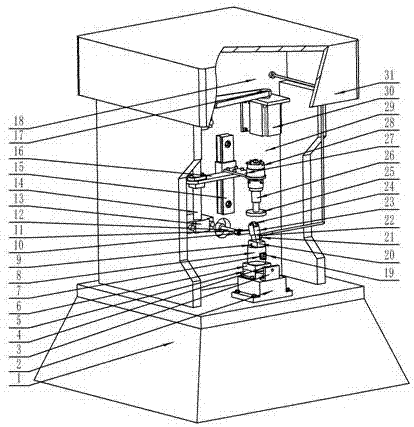

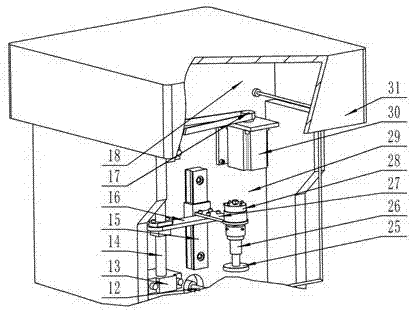

Method for quickly keeping heat displacement of spindle constant

ActiveCN109015107AControl temperature changesEnsure high precision operationMaintainance and safety accessoriesControl systemEngineering

The invention discloses a method for quickly keeping the heat displacement of a spindle constant. The method comprises the following steps that through a temperature sensor, the temperature of the spindle is detected and a temperature signal is output to a control system; through the control system, an electromagnetic valve is controlled to act according to the temperature signal, so that the spindle is in the circulating cooling state or the cooling stop state; furthermore, the rotating speed of the spindle is changed through the control system, so that the auxiliary cooling operation at a lower rotating speed can be achieved when the spindle is cooled; the cooling operation can be stopped when the spindle is heated, and the auxiliary heating operation at a higher rotating speed can be achieved; and the cooling operation is stopped from continuing when the spindle is shut down, the long-time temperature constancy is kept, and the auxiliary heating of the spindle is achieved, so that under the circumstance that the structure of the spindle is kept unchanged, the temperature variations of the spindle can be quickly and effectively controlled before the spindle is started up, duringthe running process of the spindle, and after the spindle is stopped, no extra time for waiting for the heat displacement of the spindle is needed, the heat displacement of the spindle can be stabilized and kept constant for a long time within a shorter time, the high-precision running of the spindle can be ensured, and the processing efficiency of a machine tool can be greatly improved.

Owner:昆山市玉山镇新光威精密机械厂

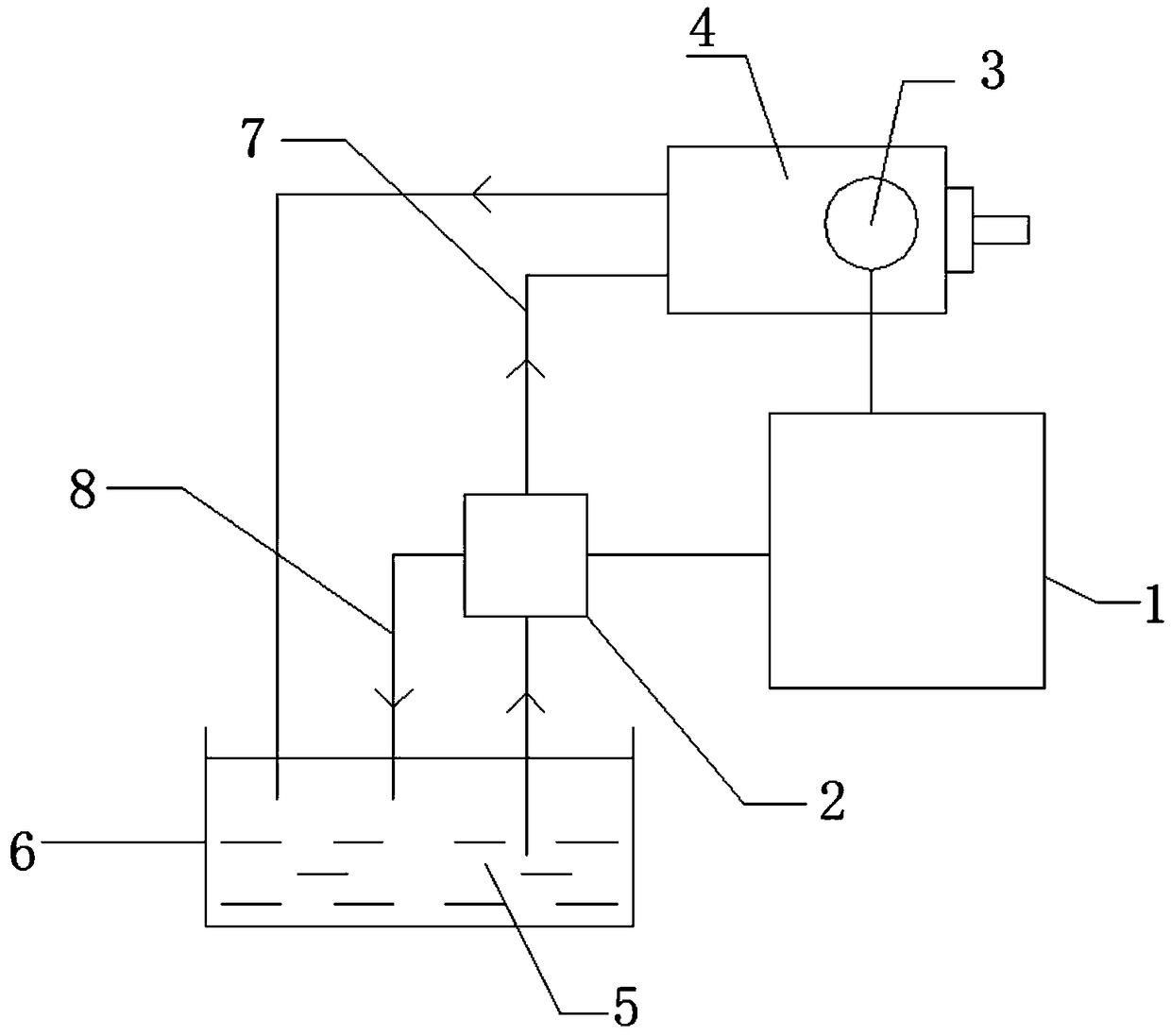

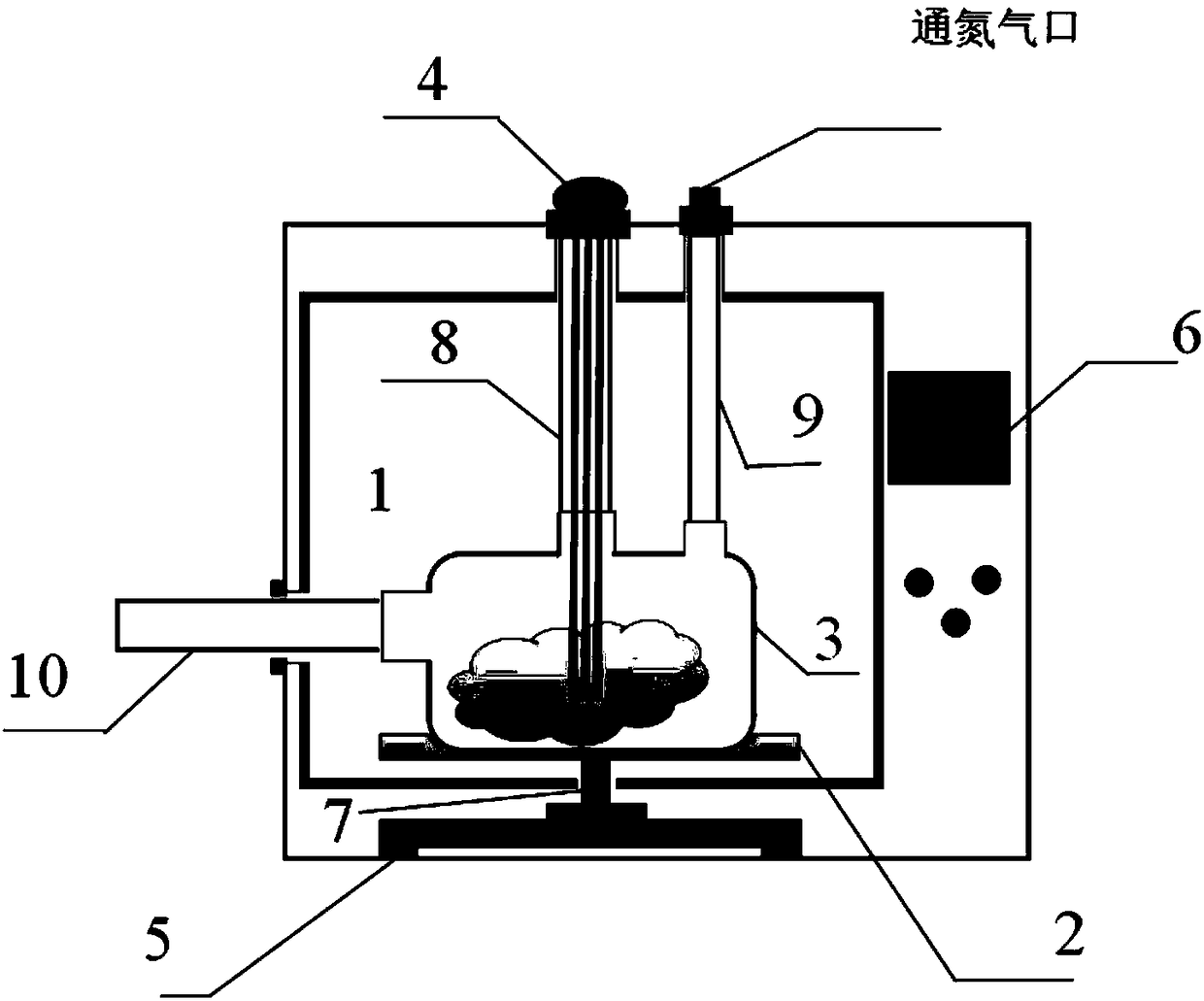

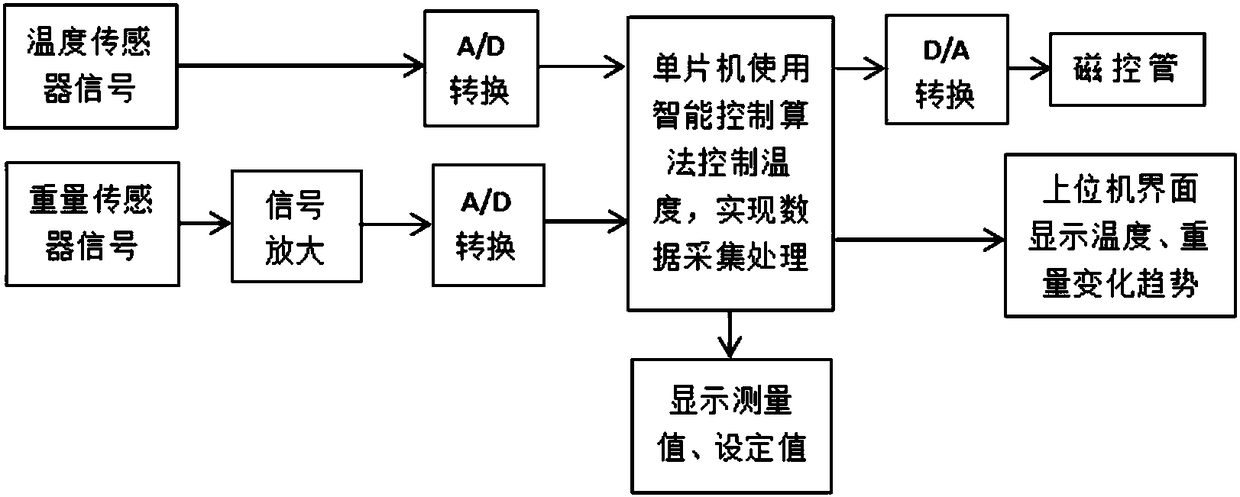

Microwave thermogravimetric analysis system

PendingCN108489853AControl temperature changesQuick responseWeighing by removing componentPreparing sample for investigationChemical reactionMicrowave pyrolysis

The invention relates to the technical field of microwave pyrolysis , and especially relates to a microwave thermogravimetric analysis system. The analysis system includes a thermocouple temperature sensor, a gravity sensor, a control circuit, a display module, a chemical reaction system material pyrolysis part, a subsidiary part, a magnetron and a computer. The microwave power in the invention isadjustable, reaction temperature and weight change data in the microwave pyrolysis process of a material are highly precisely measured, thermogravimetric analysis and reaction kinetics analysis of the microwave pyrolysis reaction of the material are performed, a chemical reaction module is externally connected to realize the condensation separation of a product and catalyst refining and upgrading, and other analytical instruments also can be externally connected to achieve the mechanism analysis of the pyrolysis reaction of the material.

Owner:JIANGSU UNIV

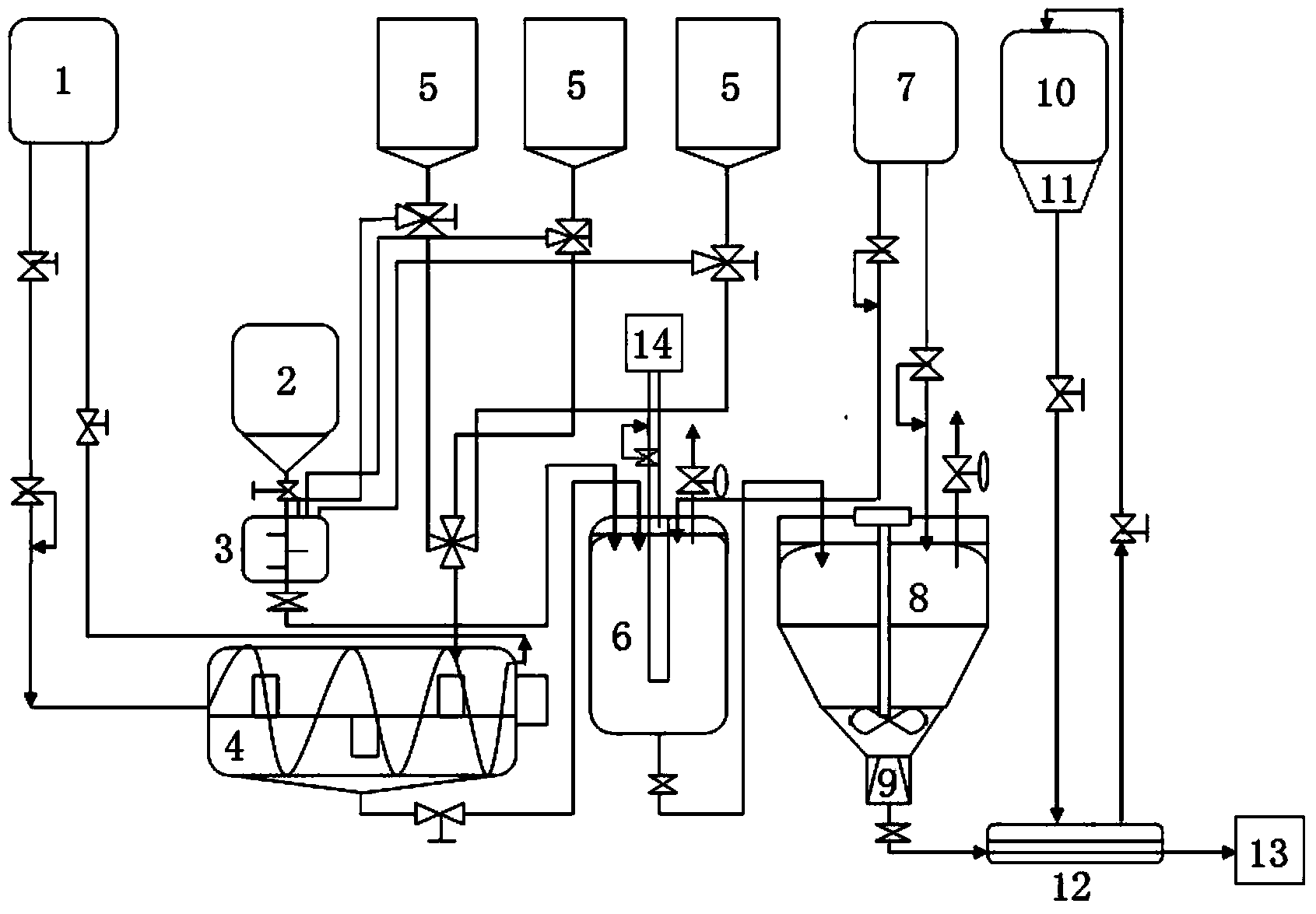

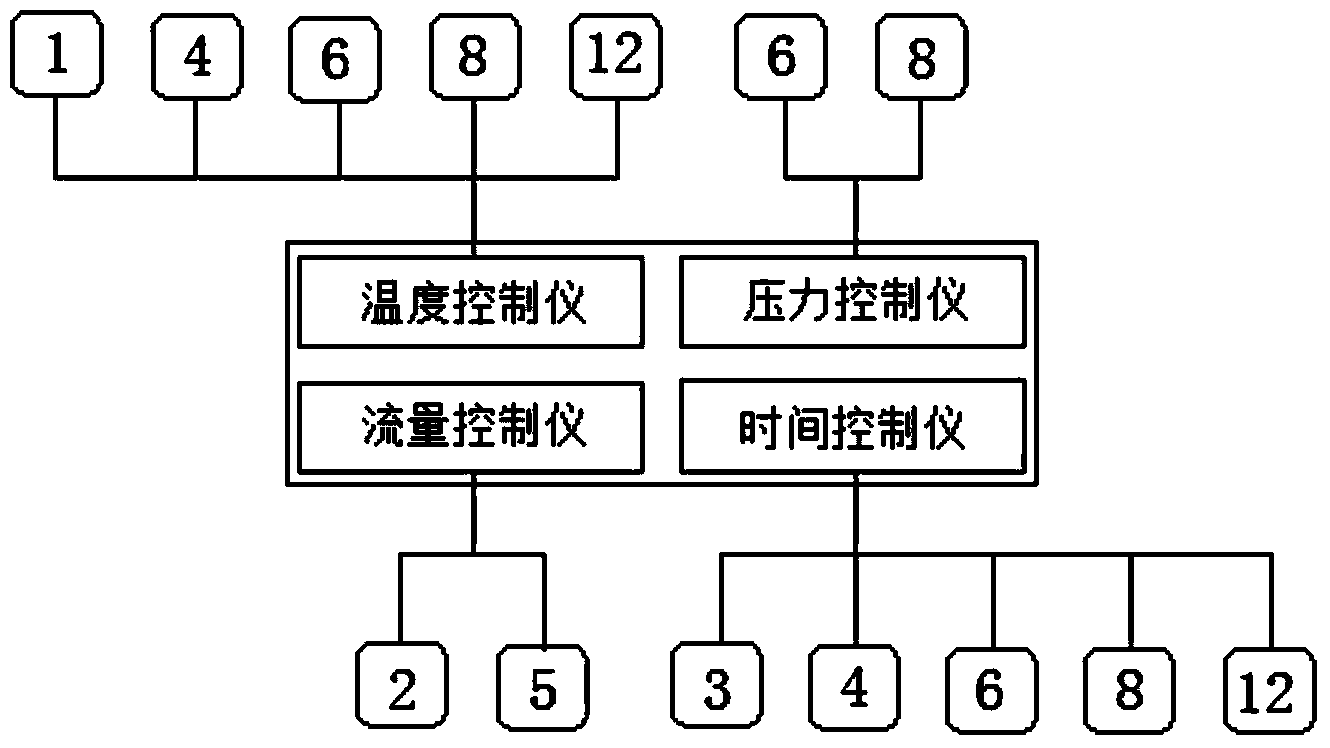

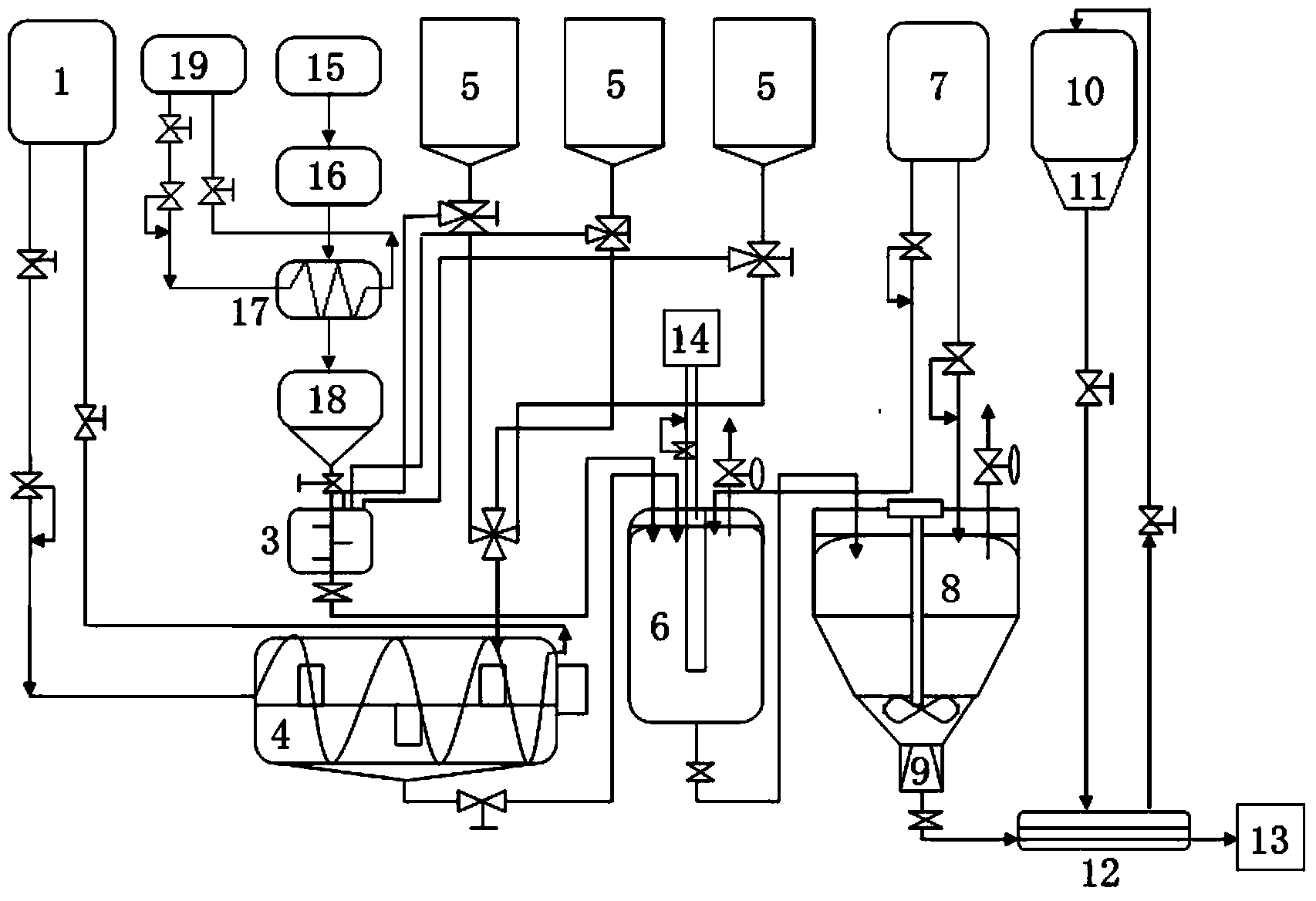

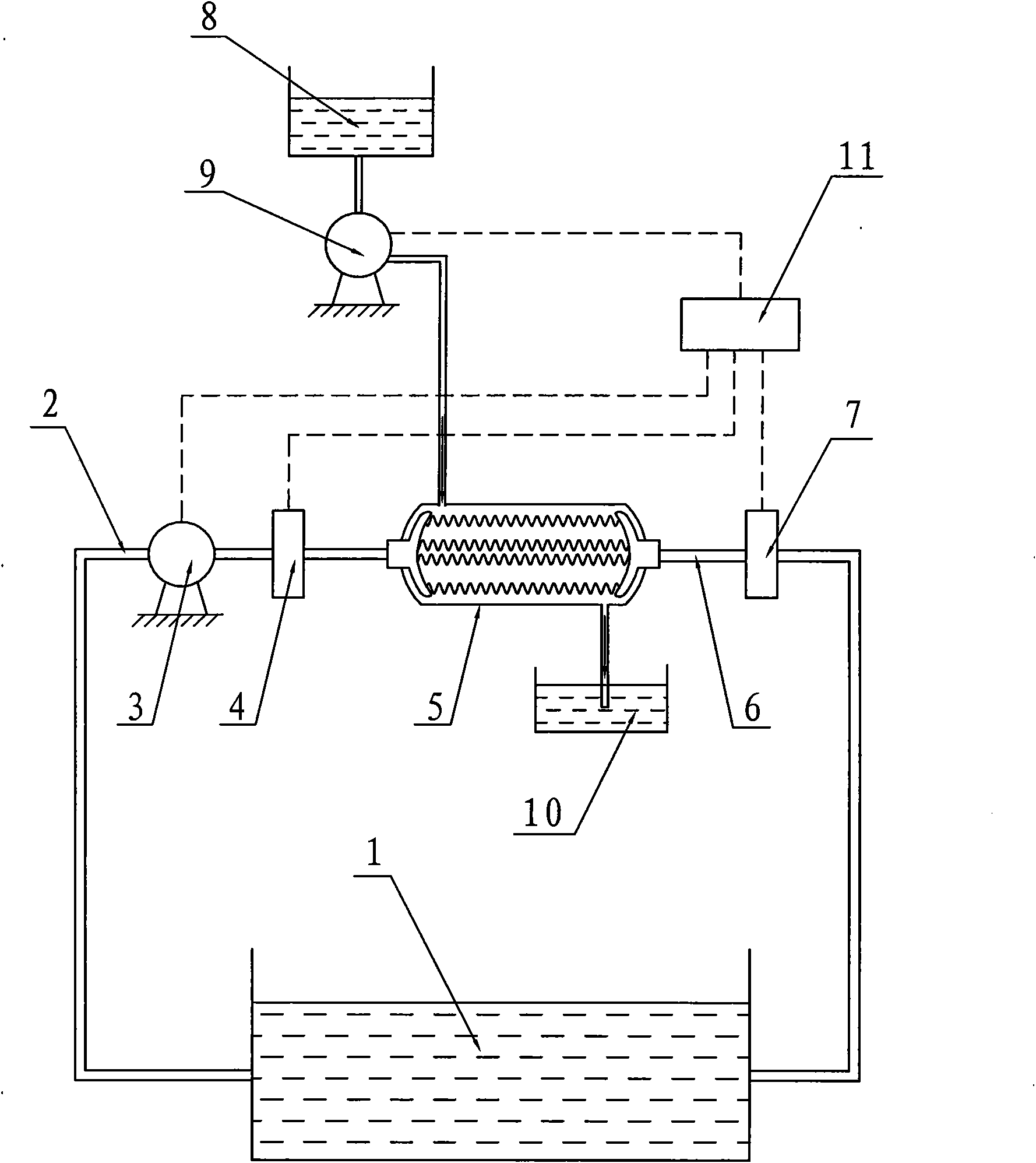

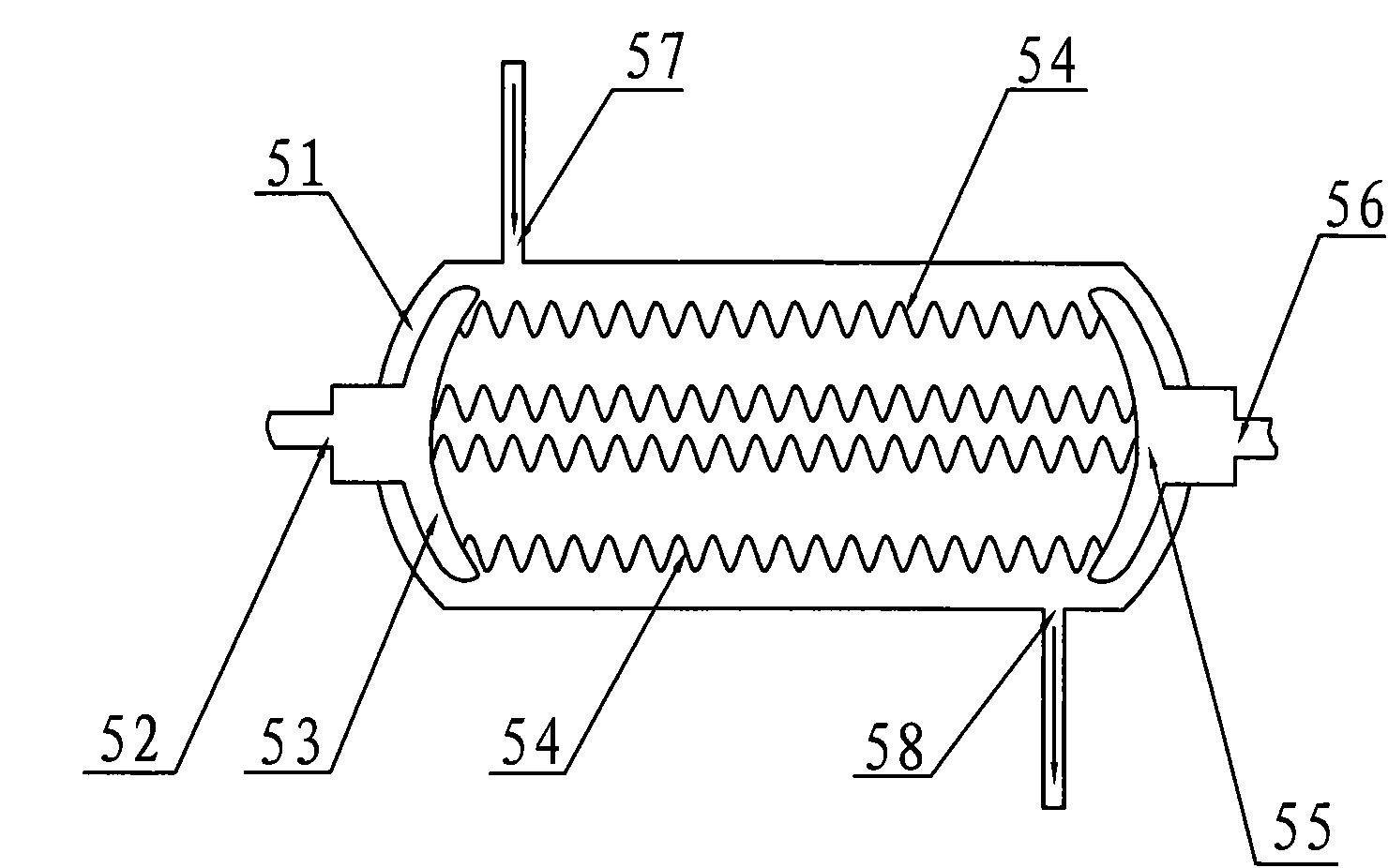

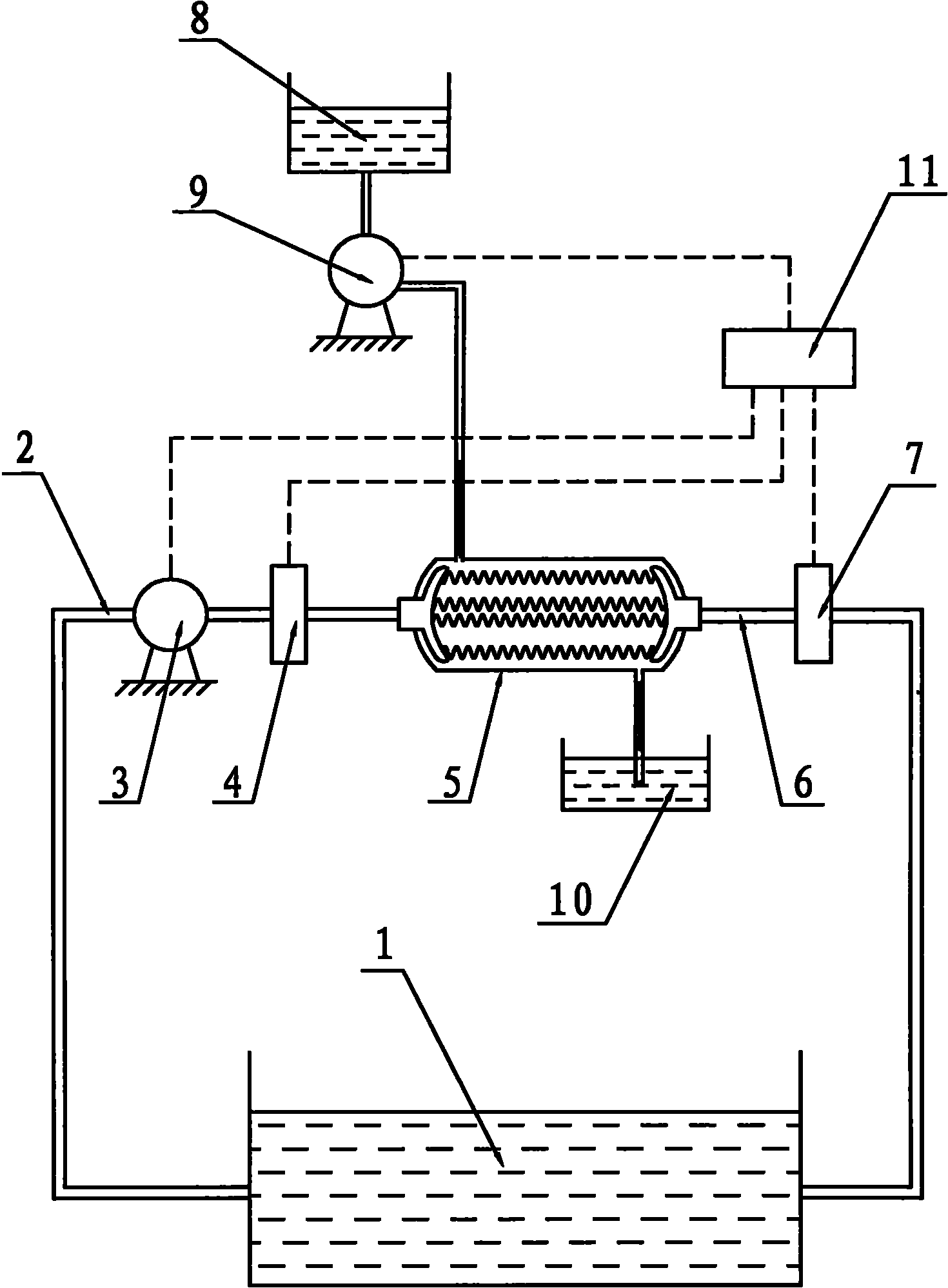

Temperature control system of stirring kettle for material mixing

InactiveCN104441294ASolve the influence of temperature controlControl temperature changesTransportation and packagingChemical/physical processesTemperature controlControl system

The invention discloses a temperature control system of a stirring kettle for material mixing. The temperature control system comprises the stirring kettle for material mixing and at least one raw material storage tank, wherein the raw material storage tank is connected with the stirring kettle for material mixing by a first conveying pipeline, a cooling jacket for cooling mixture inside the stirring kettle for material mixing is arranged outside the stirring kettle for material mixing, and a heat exchange device is arranged outside each of the raw material storage tank and the first conveying pipeline. According to the temperature control system of the stirring kettle for material mixing, the temperature control system can be applied to the stirring kettle for material mixing, temperature variation can be well controlled in a stirring process, the influences of poor thermal conductivity of the material and environment temperature variation on the temperature control effect of the stirring kettle can be effectively overcome, and the temperature control to PVC (polyvinyl chloride) paste can be realized indirectly by a raw material temperature control method.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

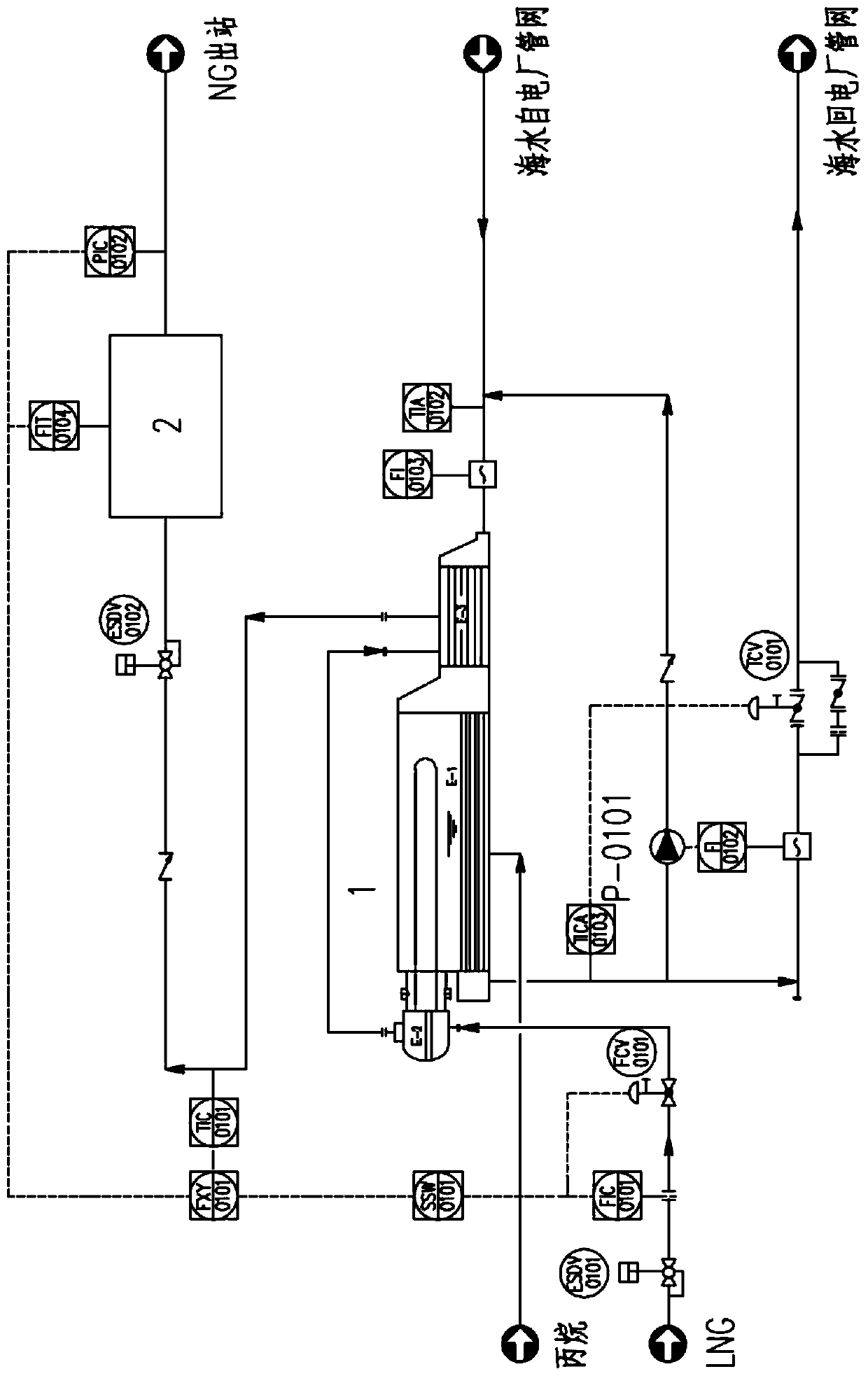

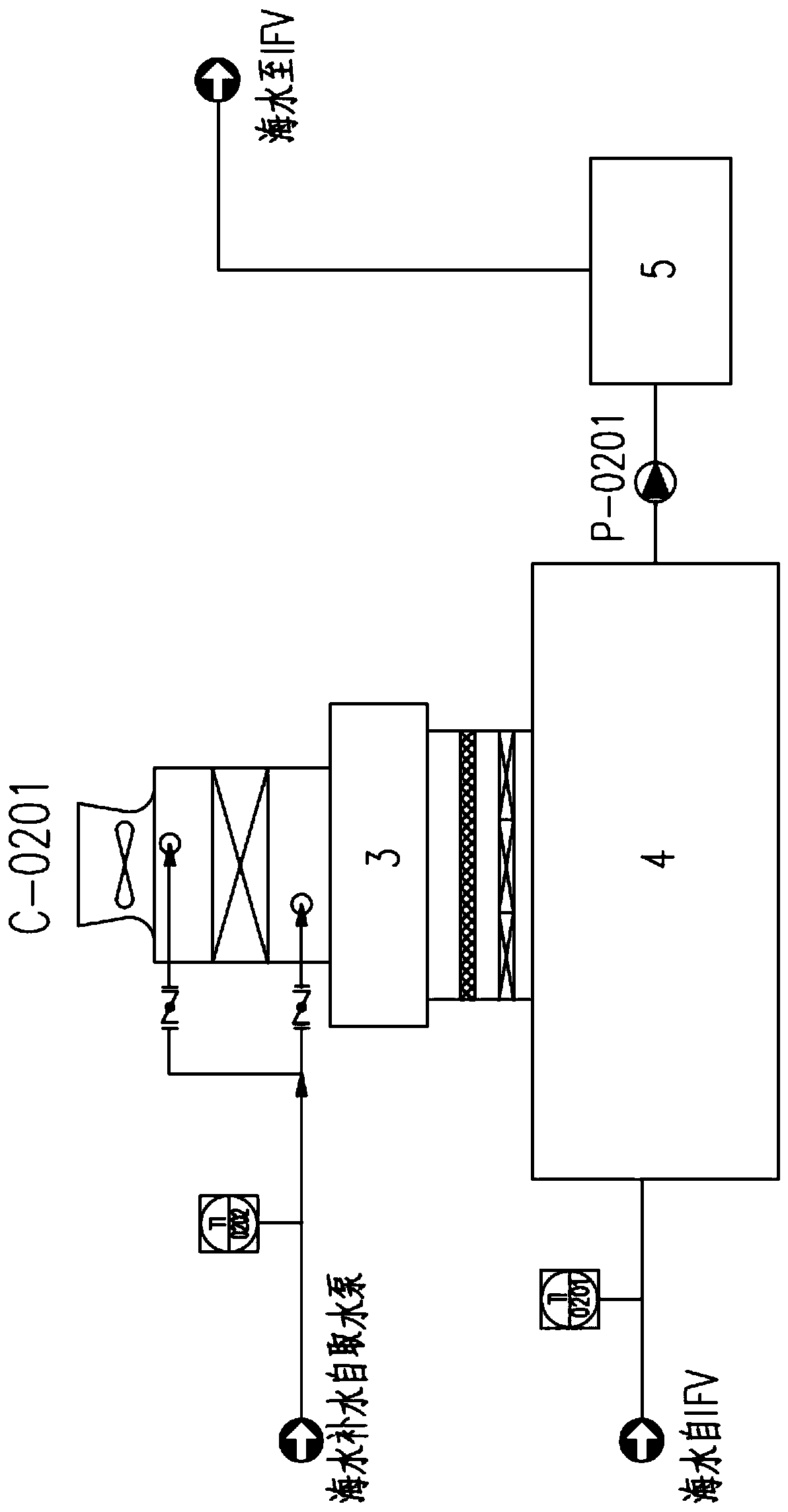

LNG receiving station gasification device and power plant circulating water combined use system

The invention relates to an LNG receiving station gasification device and power plant circulating water combined use system. The system comprises an IFV gasifier, a seawater circulation pump and a power plant circulating water system, and the power plant circulating water system comprises a circulating water cooling tower, a tower discharging pool, a water sucking pool, a water taking pump and power plant cooling water using equipment which are connected in sequence. LNG uses circulating backwater of a power plant circulating water field as a heat source, the LNG receives heat to be vaporizedinto NG, meanwhile, the cooled circulating backwater is sent back to the power plant circulating water device to serve as cooling cycle supply water for a power plant condenser and a heat exchanger, and energy cascade utilization is achieved. The opening degree of a temperature control TCV valve is set by an outlet of the IFV gasifier, and it is ensured that the temperature of the water supplied to a power plant is within a lower range. Through control interlocking, the overall control process is achieved through temperature and flow transmitters arranged on a pipe line of the water discharging side of the IFV gasifier and a PLC rigid line.

Owner:XINDI ENERGY ENG TECH

Production method and production system for health-protection lycopene oil

The invention discloses a production method and a production system for health-protection lycopene oil, belonging to the field of edible oil production. The production method comprises the following steps of (1) preheating part of raw oil, and preliminarily mixing the rest raw oil and lycopene powder or a lycopene extract; (2) mixing the preheated raw oil and the preliminarily mixed mixture again, and performing pressure vibration and pressure stirring; (3) extracting the mixture; (4) separating the extracted mixture to obtain the health-protection lycopene oil; (5) cooling the obtained health-protection lycopene oil and conveying the health-protection lycopene oil into a filling line. The invention also discloses the production system for the lycopene health-protection oil. The production method and the production system are simple in technology, high in production efficiency, safe and reliable; the physical characteristics that the lycopene is easy to oxidize, needs to be kept in a dark place and is low in heat stability are fully considered, so that the loss of the lycopene during processing is reduced to the maximum extent.

Owner:华康能仁(天津)生物科技有限公司

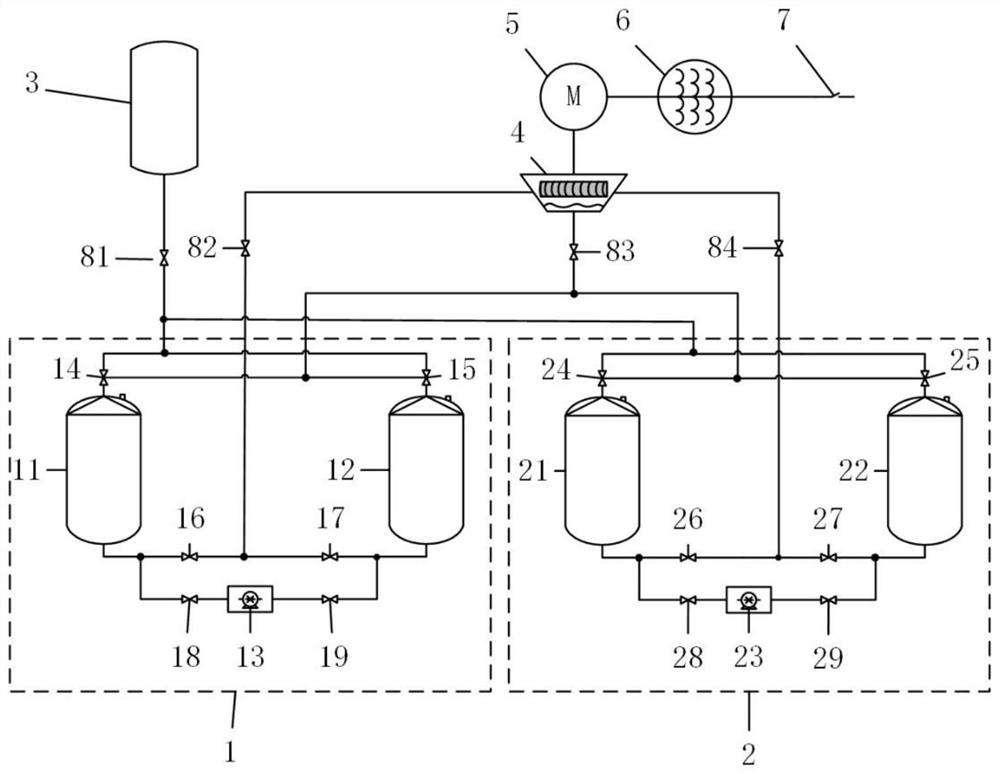

Isothermal compressed air energy storage system with primary frequency modulation capability and operation method thereof

ActiveCN112952871AShort adjustment timeStable output powerElectrical storage systemSingle network parallel feeding arrangementsWater turbineControl theory

The invention discloses an isothermal compressed air energy storage system with primary frequency modulation capability and an operation method thereof. The system comprises a high-pressure air storage cavity, an impulse turbine, a synchronous power generator and at least two working units, wherein the working units are connected in parallel, the top ends of the working units communicate with the high-pressure air storage cavity and the tail water pipeline of the impulse turbine, the bottom ends of the working units arecommunicated with the water inlet of the impulse turbine through a pipeline, the working unit comprises two compression tanks, a top outlet formed by connecting the two compression tanks in parallel serves as the top end of the working unit, two pipelines are arranged at the bottom ends of the two compression tanks, the first pipeline is used for connecting the two compression tanks in parallel and serves as the bottom end of the working unit, the second pipeline is communicated with the two compression tanks, a water pump system is arranged on the second pipeline, and a nozzle with an adjustable opening degree is adopted in the impulse turbine. According to the invention, long-time constant-power output can be achieved, the purpose of stable overall output power is achieved through phase-shifting superposition of the multiple independent working units, the opening degree adjusting time of the nozzle is short, and throttling loss is small.

Owner:XI AN JIAOTONG UNIV

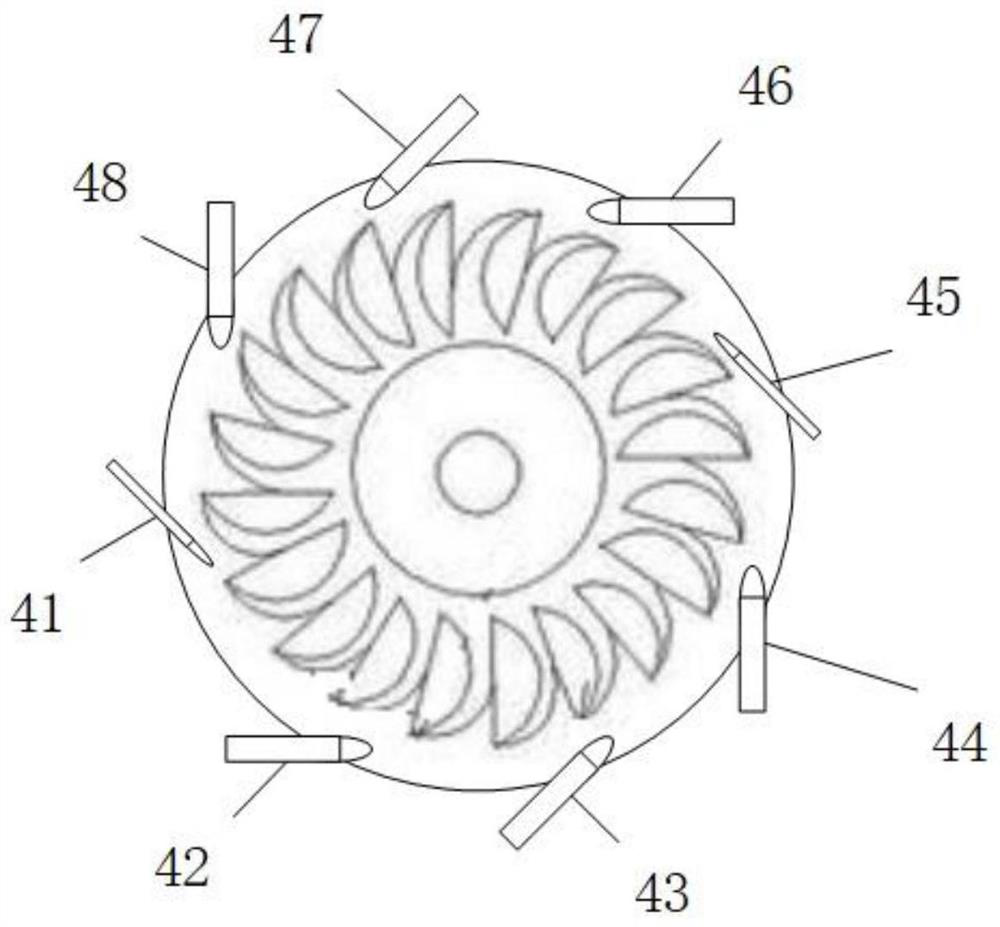

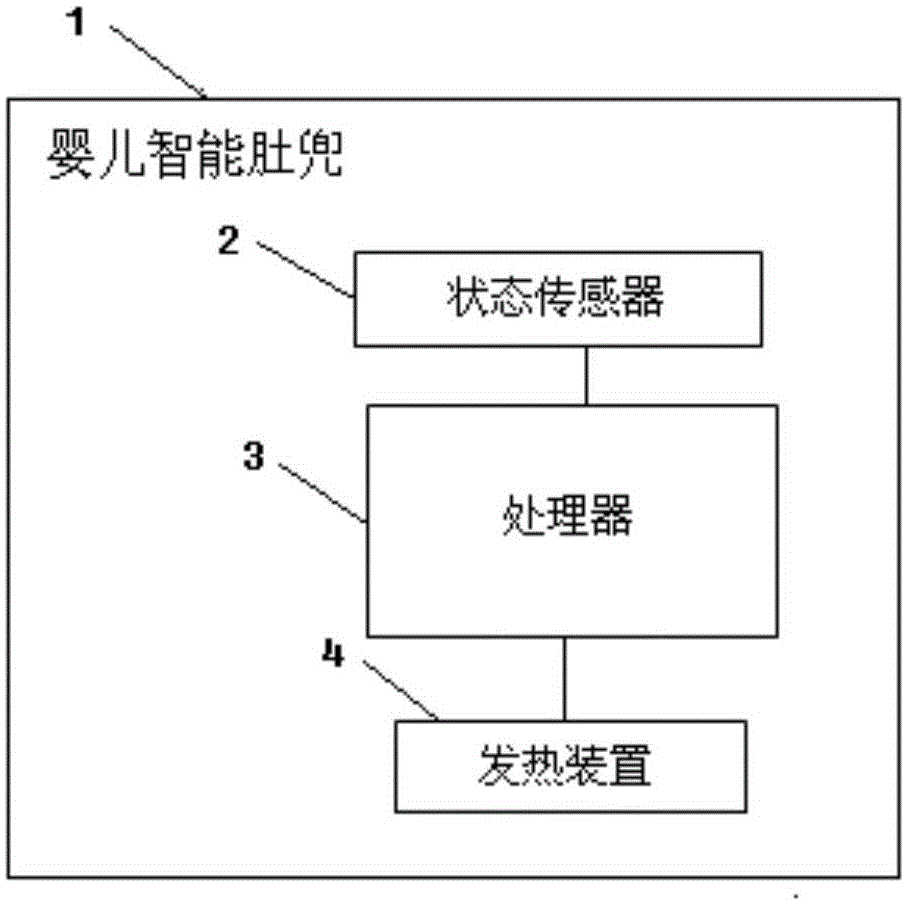

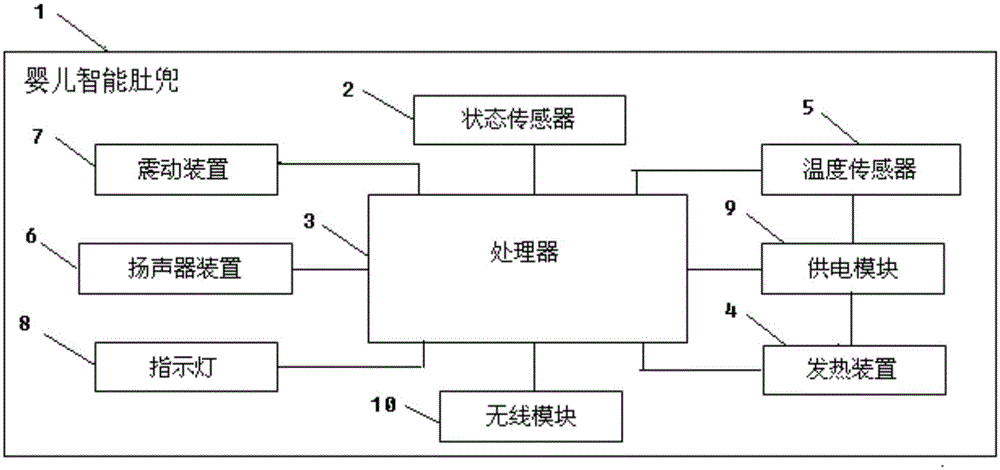

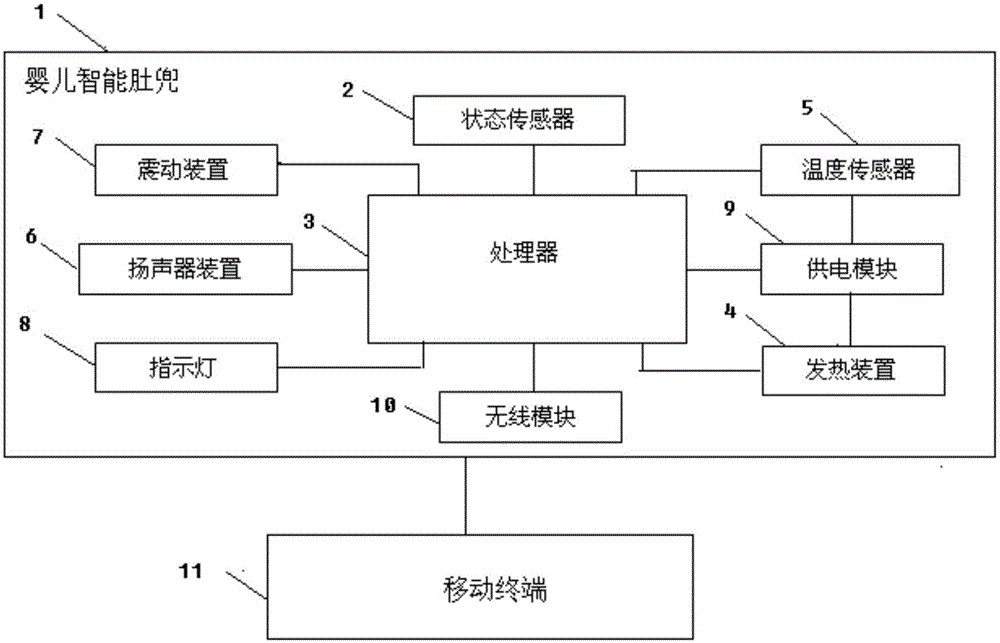

Intelligent baby stomacher and baby sleep monitoring system

ActiveCN105160812AImplement Music InterventionStimulate intellectual growthAlarmsSleep stateMonitoring system

The invention discloses an intelligent baby stomacher and a baby sleep monitoring system. The intelligent baby stomacher comprises a stomacher body, and a state sensor, a processor and a heating device which are arranged on the stomacher. The state sensor is used for collecting state data of a baby. The processor is used for judging the state of the baby according to the state data and controlling the heating device to generate heat according to the state of the baby. The intelligent baby stomacher is capable of intelligently detecting whether the baby is in an awake state or a sleep state and intelligently controlling the temperature change of the stomacher according to whether the baby is awake or sleeping, so that the belly of the baby is kept warm, and the heat preservation effect is realized; a music intervention effect on the baby is also realized, and the intellectual growth of the baby is excited; in addition, the intelligent baby stomacher is internally provided with a shock device, so that a shocking calming sleep effect is realized when the baby falls asleep.

Owner:湖州丰源农业装备制造有限公司

Polysilicon channel type wool making and cooling device

InactiveCN101967682AReduce the temperatureControl temperature changesAfter-treatment detailsEngineeringElectric control

The invention relates to a polysilicon channel type wool making and cooling device which comprises a wool making channel, a corrosive liquid input pipe, a circulating pump, an inlet temperature sensor, a heat exchanger, a corrosive liquid output pipe, an outlet temperature sensor, a cooling liquid pool, a variable pump, a recovery pool and an electric control component, wherein corrosive liquid in the wool making channel is sucked through the circulating pump and enters a hot liquid branch pipe in the heat exchanger through a corrosive liquid inlet pipe; cooled corrosive liquid flows back to the wool making channel from the corrosive liquid output pipe; the inlet temperature sensor and the outlet temperature sensor are respectively arranged on the corrosive liquid input pipe and the corrosive liquid output pipe; the electric control component is used for controlling the variable pump according to signals of the corrosive liquid input pipe and the corrosive liquid output pipe; and the cooling speed is regulated through changing the flow of the cooling liquid. Because the polysilicon wool making channel is subjected to circulating cooling treatment, the temperature change of the corrosive liquid in the wool making channel can be effectively controlled to ensure that the temperature difference value is controlled within a preset process requirement range, thereby the defects in the prior art are overcome, and the temperature control requirement of a polysilicon wool making process on the corrosive liquid is met.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Plastic mold with mold heat conduction device

InactiveCN101474836AControl temperature changesImprove heat transfer efficiencyHeat transmissionHeat conducting

The present invention discloses a mold heat transmission plastic mold which comprises a mold base and a mold kernel. The mold heat transmission plastic mold is provided with a heat conductor which is prepared by heat conducting solid. One end of heat conductor is installed in the mold kernel, and the other end extends out of the mold kernel. The mold heat transmission plastic mold of the invention can quickly increase the temperature of mold excellently and has the advantages of quick heat transmission speed and safe use.

Owner:杨东佐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com