Internally conductive hot cut-off knife and method thereof

A technology of hot cutting knife and knife body, which is applied in metal processing and other directions, can solve the problems of unfavorable heat preservation and accurate temperature control, component damage service life, large energy waste, etc., to achieve protection from damage and service life, easy installation and Effect of dismantling and reducing energy consumption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

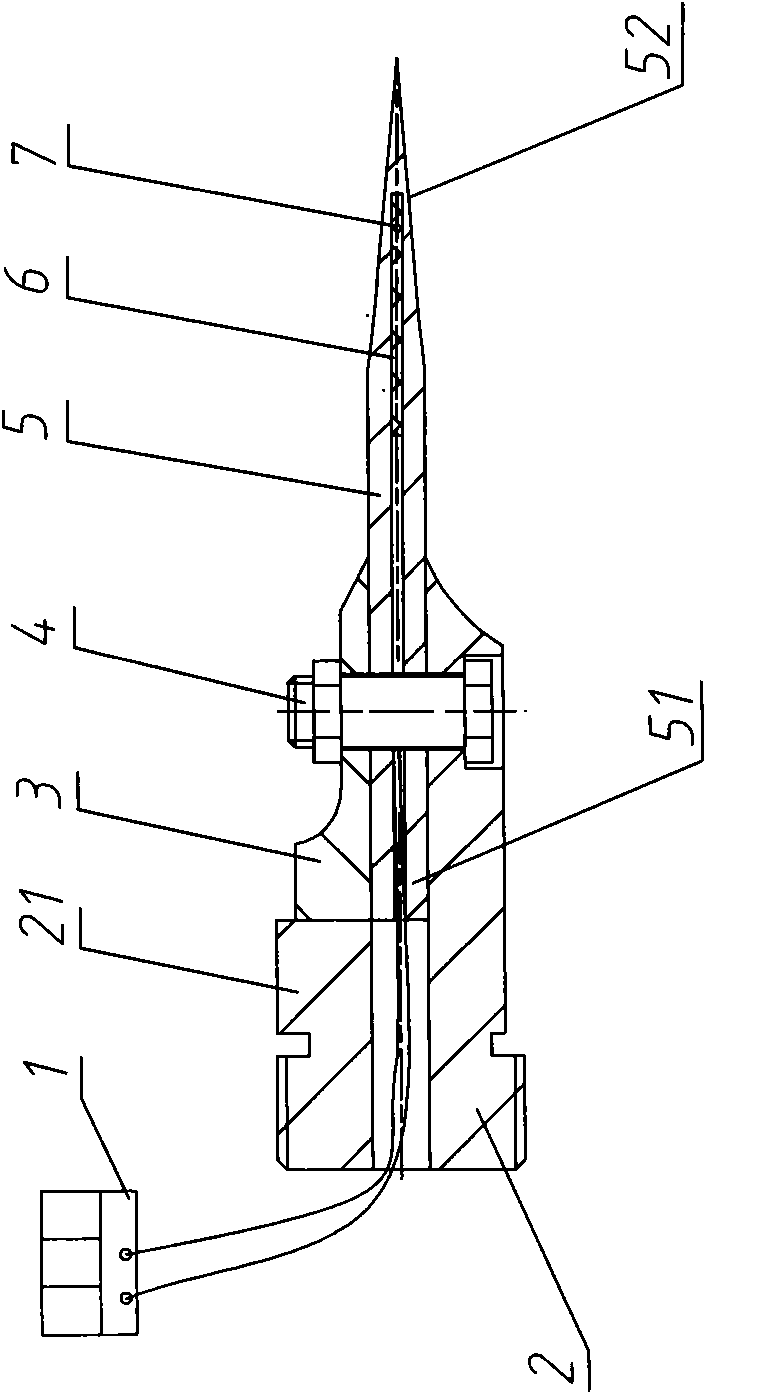

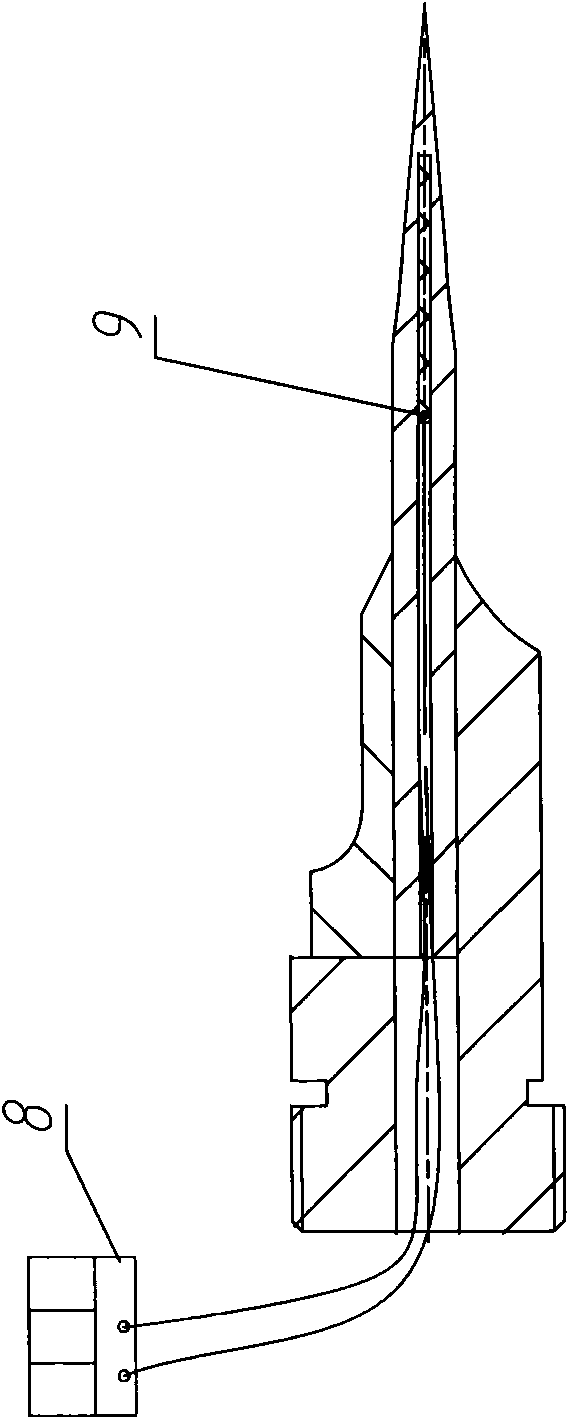

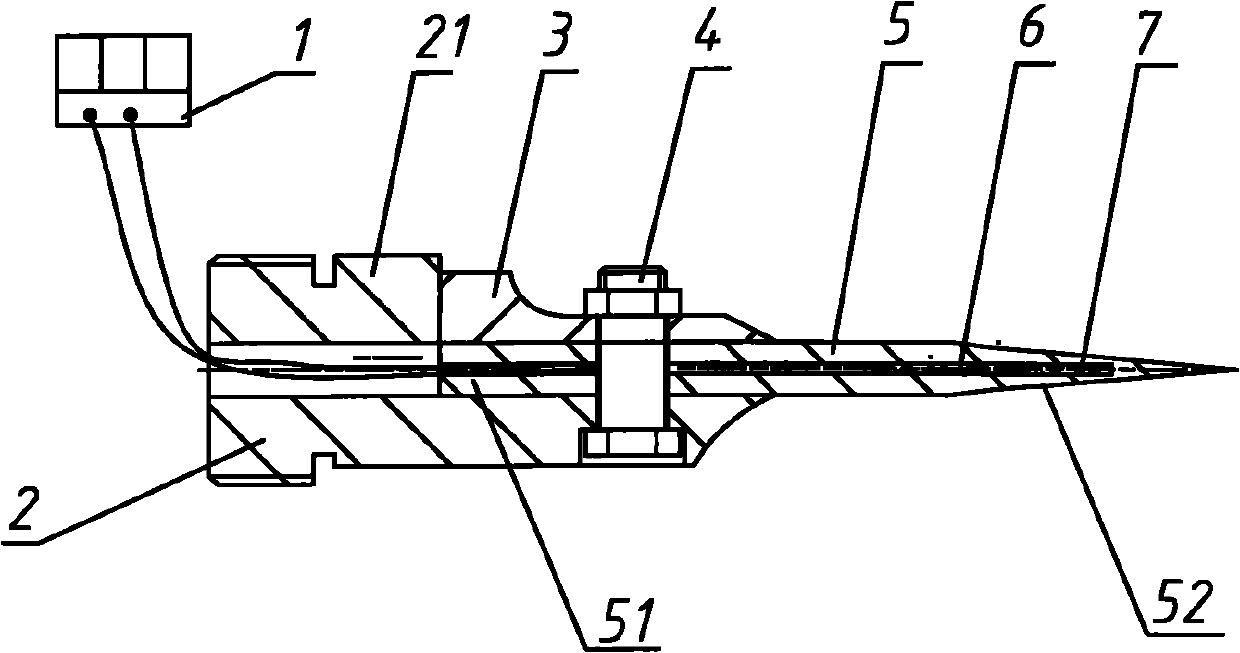

[0041] Example 1, such as figure 1 and figure 2 As shown, the internal heat conduction type hot cutter is applied to polymer material processing machinery, such as rubber tire manufacturing process.

[0042] The internal heat conduction thermal cutter includes a lower clamp body 2, an upper clamp body 3 and a cutter body 5, and the HRC hardness value of the cutter body 5 is greater than 60.

[0043] The cutter body 5 includes a base portion 51 clamped and fixed between the lower clamping body 2 and the upper clamping body 3 , and a blade portion 52 for cutting on the rubber surface.

[0044] The upper clamp body 3 and the cutter body 5 abut against the front surface of the mounting boss 21 at the rear of the lower clamp body 2 respectively.

[0045] The lower clamping body 2 , the upper clamping body 3 and the cutter body 5 are respectively provided with screw holes for vertical installation through connecting bolts 4 .

[0046] Inside the blade portion 52 are provided a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com