Patents

Literature

185results about How to "Lower energy consumption levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic two-gear transformer for pure electric automobile

InactiveCN104595450ACompact structureLight in massElectric propulsion mountingToothed gearingsElectricityAutomatic transmission

An automatic two-gear transformer for a pure electric automobile comprises an input shaft, a first middle shaft, a second middle shaft, a third middle shaft, a first cylindrical gear pair, a second cylindrical gear pair, a third cylindrical gear pair, a first torque transmission device, a second torque transmission device and a differential assembly; rotation center lines of the input shaft, the third middle shaft and the differential assembly are mutually parallel. According to the automatic two-gear transformer for the pure electric automobile, automatic two-gear speed change is adopted, the transmission ratio range is expanded, the performance requirement on a drive motor can be reduced greatly, an efficient and light drive motor is allowed to be used, and the total size, the total mass and the total cost of an electric drive system of the pure electric automobile are further reduced.

Owner:BEIHANG UNIV

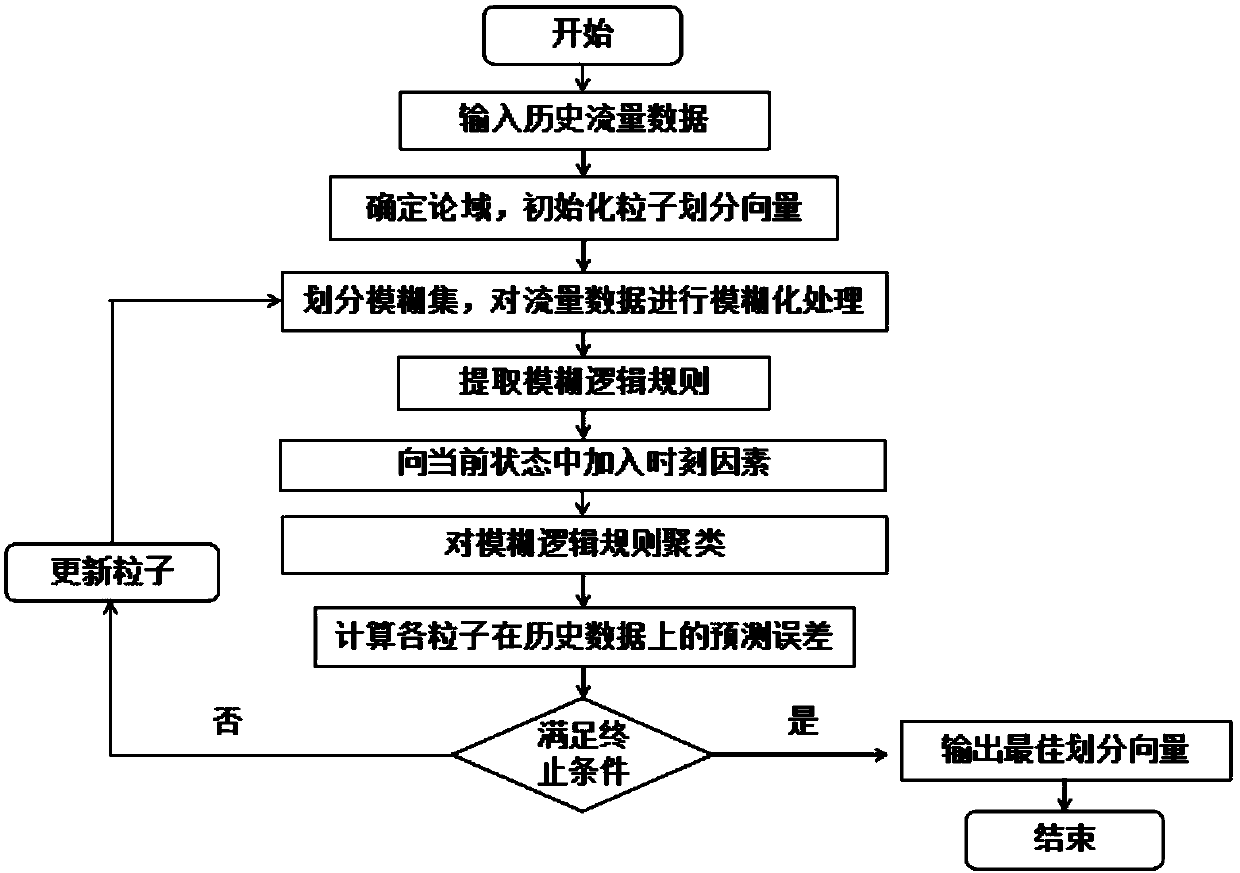

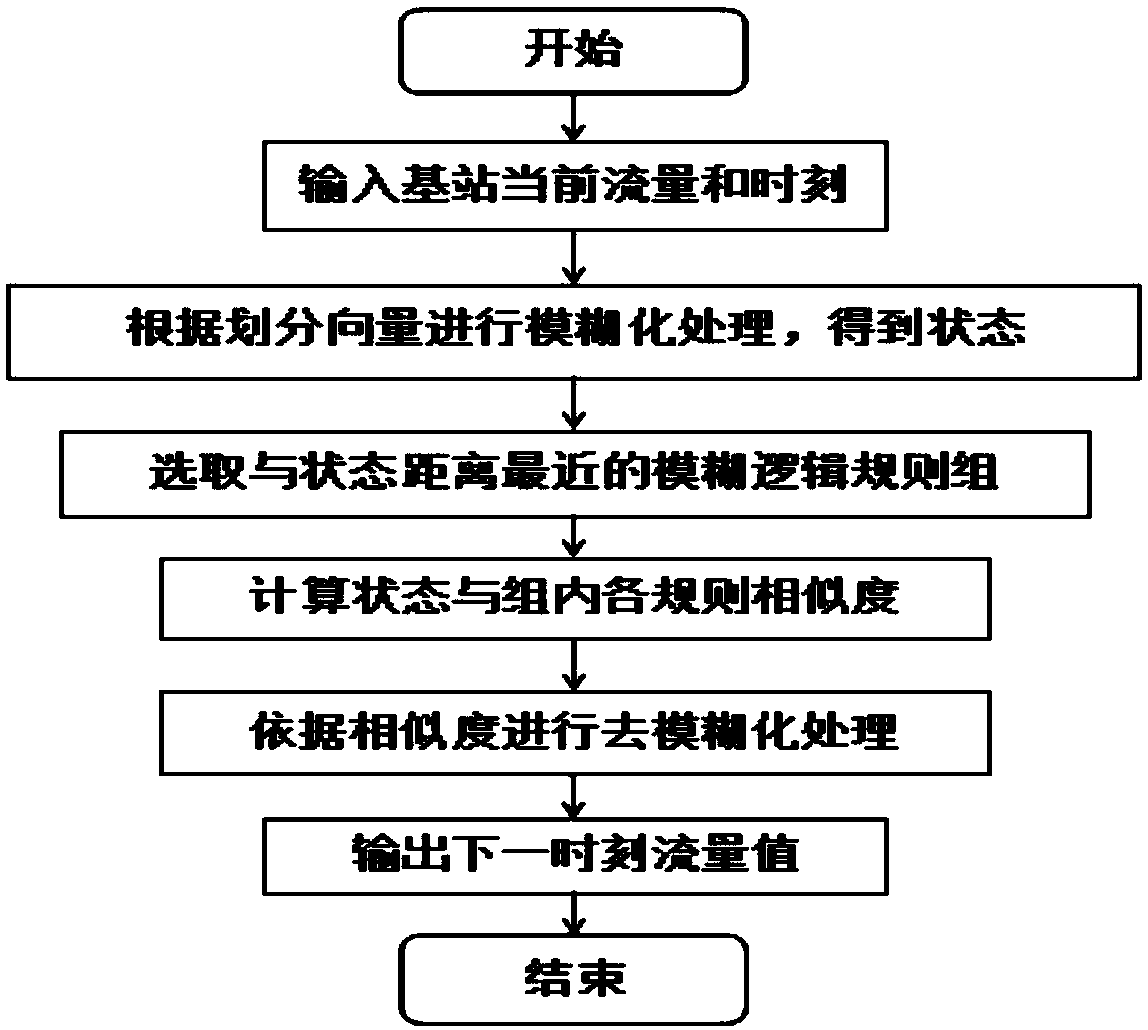

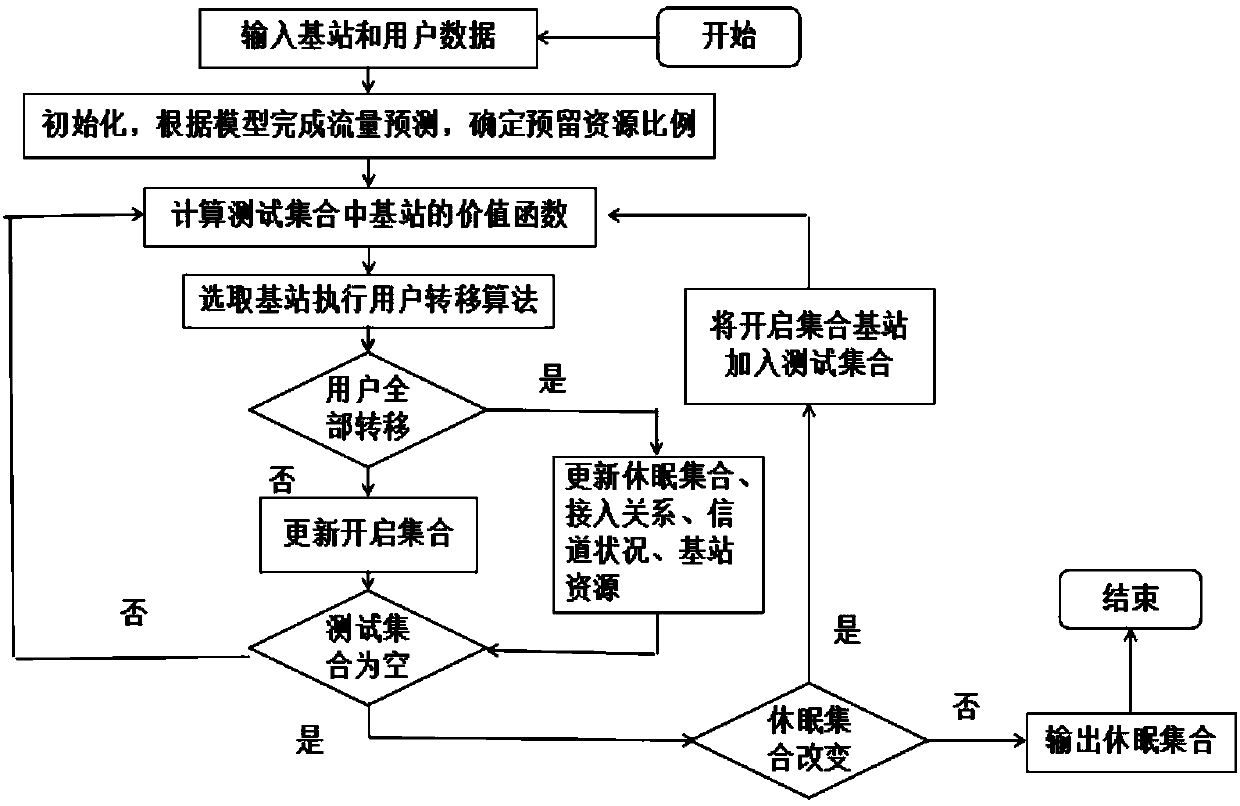

Base station dormancy method based on traffic prediction and base station state

ActiveCN108848520AReduce the number of work state switchingRobustPower managementHigh level techniquesFuzzy predictionWork status

The invention discloses a base station dormancy method based on traffic prediction and base station state. The method predicts the future traffic load of each base station in the cellular network by introducing a fuzzy prediction model, which has better robustness and may obtain more accurate predicting result. By introducing traffic prediction in the sleep mode of the base station, the proportionof reserved resources of each base station may be reasonably set to improve the utilization of network resources, so that more base stations may switch to the sleep state so as to reduce the networkenergy consumption. Adding state factors of the base station to the value function may reduce the number of times of switching the working state of the base station and improve the stability of the base station state. By introducing a fuzzy prediction model, the invention predicts the future traffic of the base station, dynamically sets the reserved resources of the base station according to the prediction result, performs pre-sorting of the dormancy test on each base station by using the value function, and finally determines the dormant base station in the cellular network, thereby reducingthe network energy consumption.

Owner:XI AN JIAOTONG UNIV

Synergistic gas-liquid-solid pollutant treatment system based on power plant wastewater zero-discharge technology

InactiveCN105967420AImprove economyImprove operational efficiencyElectrostatic separationDispersed particle separationDevice failureEconomizer

The invention provides a synergistic gas-liquid-solid pollutant treatment system based on a power plant wastewater zero-discharge technology and belongs to the technical field of coal-fired boiler pollutant control. The synergistic gas-liquid-solid pollutant treatment system includes a desulfurized wastewater zero-discharge treatment system, an SNCR + SCR united denitration system and a high-temperature electric dust removal system, wherein the desulfurized wastewater zero-discharge treatment system performs desulfurized wastewater pretreatment and pre-concentration, the SNCR + SCR united denitration system absorbs dissolved ammonia or urea of the treated desulfurized wastewater, uses the dissolved ammonia or urea as a reducing agent to be sprayed into an outlet of a boiler and a flue behind a coal economizer to complete denitration reaction, and the high-temperature electric dust removal system is arranged behind the coal economizer to collect and remove evaporated crystal substances of the wastewater. The synergistic gas-liquid-solid pollutant treatment system has excellent properties, is stable in process operation, achieves zero discharge of wastewater while achieving synergistic and coupled gas-liquid-solid pollutant treatment, reduces equipment investment by 10%-50% and the operation costs by 75%-90%, greatly reduces the equipment failure rate and maintains the working amount.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

Straw rubbing process

The invention provides a straw rubbing process, which comprises the following operating steps: 1) carding raw material straws, removing sundries, such as broken pieces and the like, and cutting fringe pulling ends away; 2) rolling the straws with a continuous roll squeezer; 3) softening the straws with vapor; 4) drying the straws and controlling water content; 5) rubbing the straws with a straw rubbing machine to obtain straw threads and removing dust during the rubbing process; and 6) screening the straw threads to extract the straw threads with lengths not less than 5cm and diameters of 1 to 3mm. The process has the advantages of simple operation, easy implementation, low cost, high efficiency, no pollution to the environment, relatively longer silky fibers and high mechanical strength, and is mainly used for manufacturing products, such as a vegetation carpet, a green pad and the like.

Owner:SICHUAN UNIV

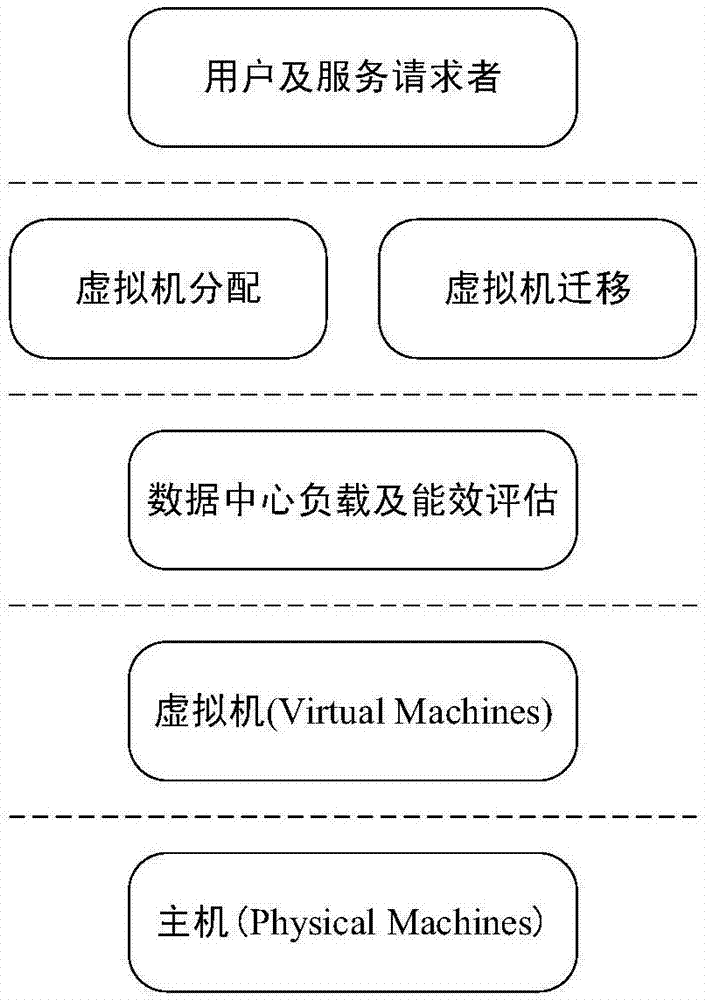

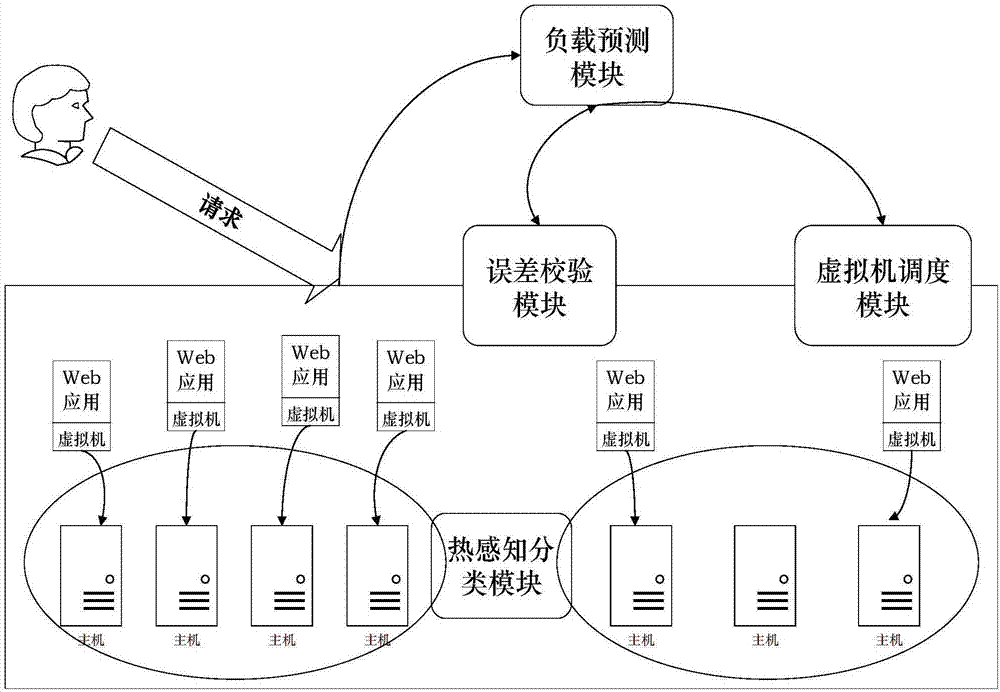

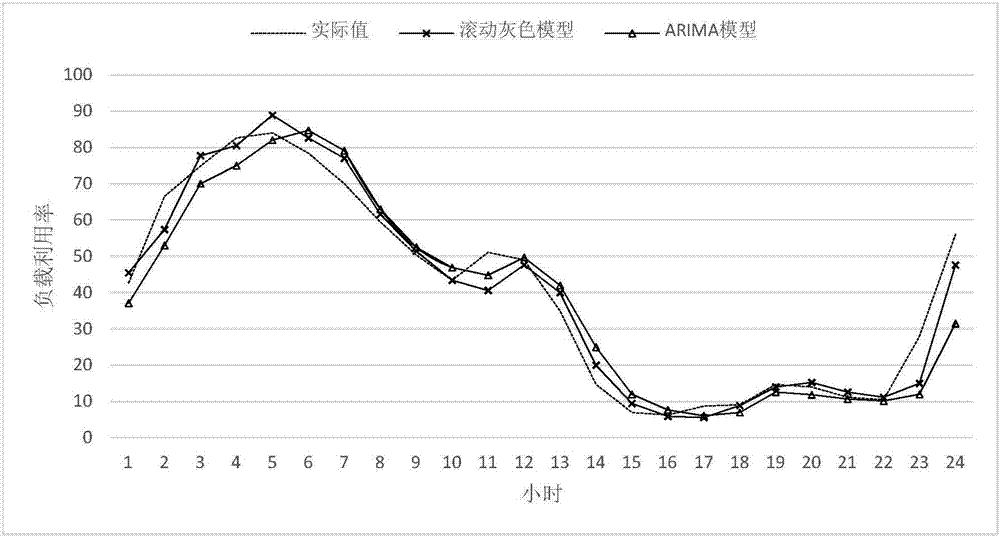

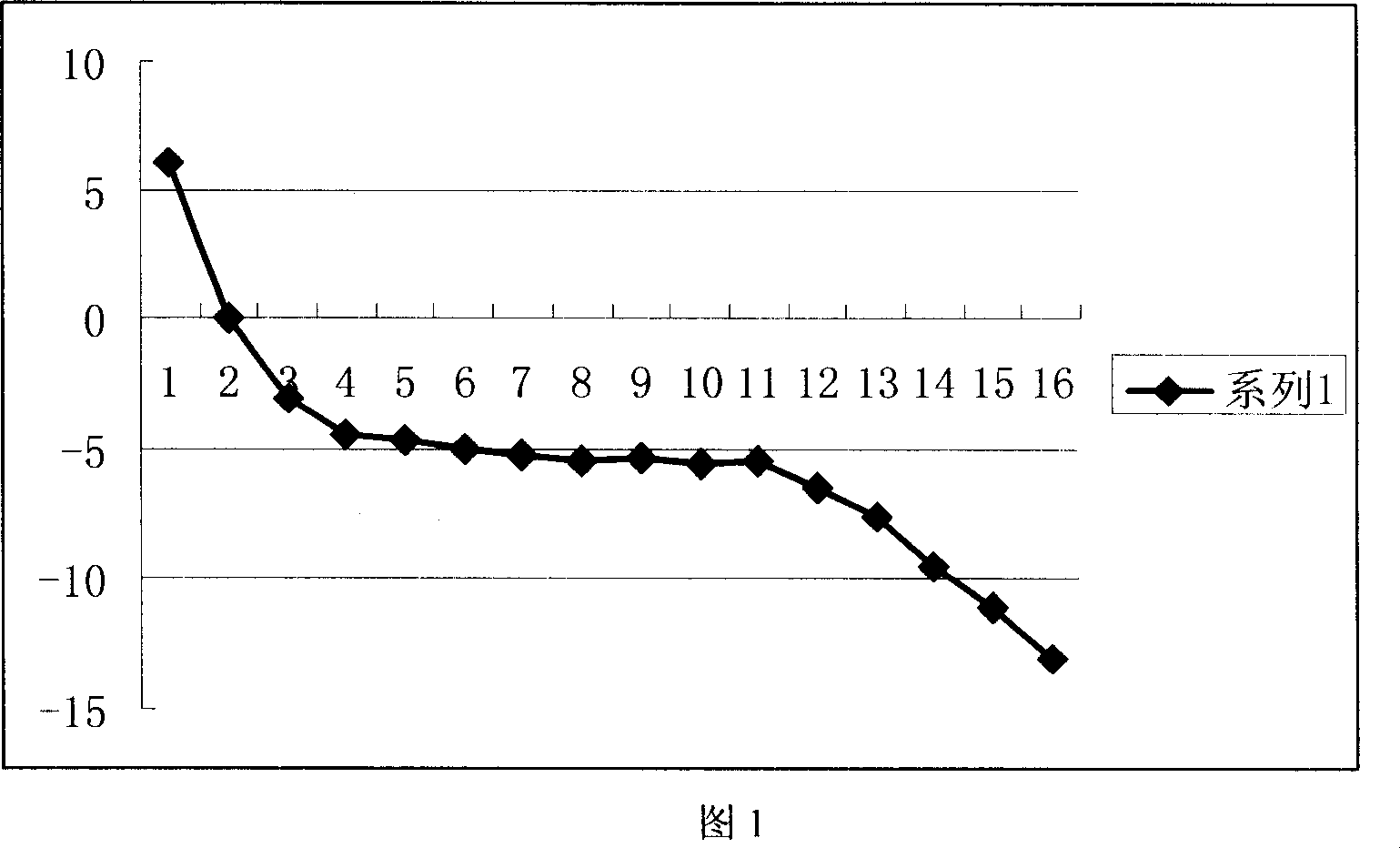

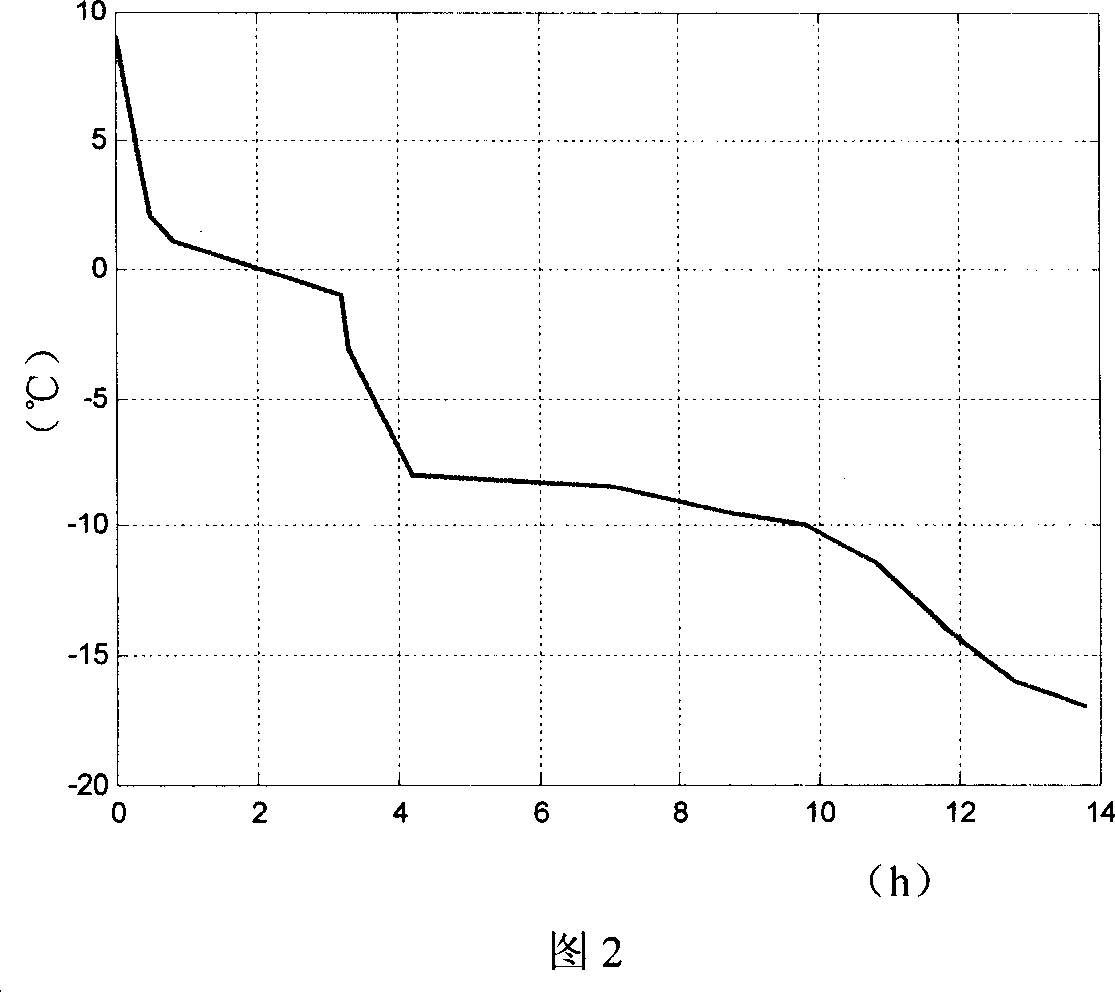

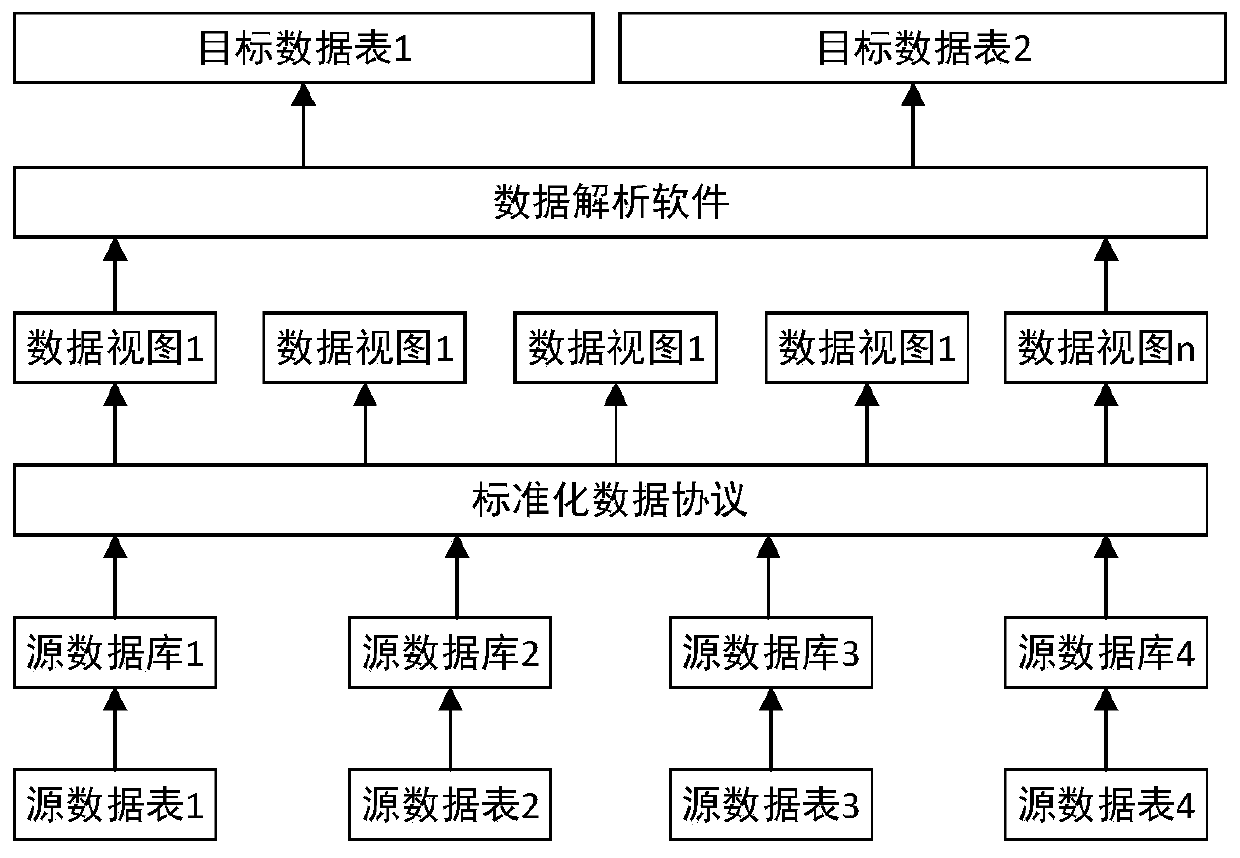

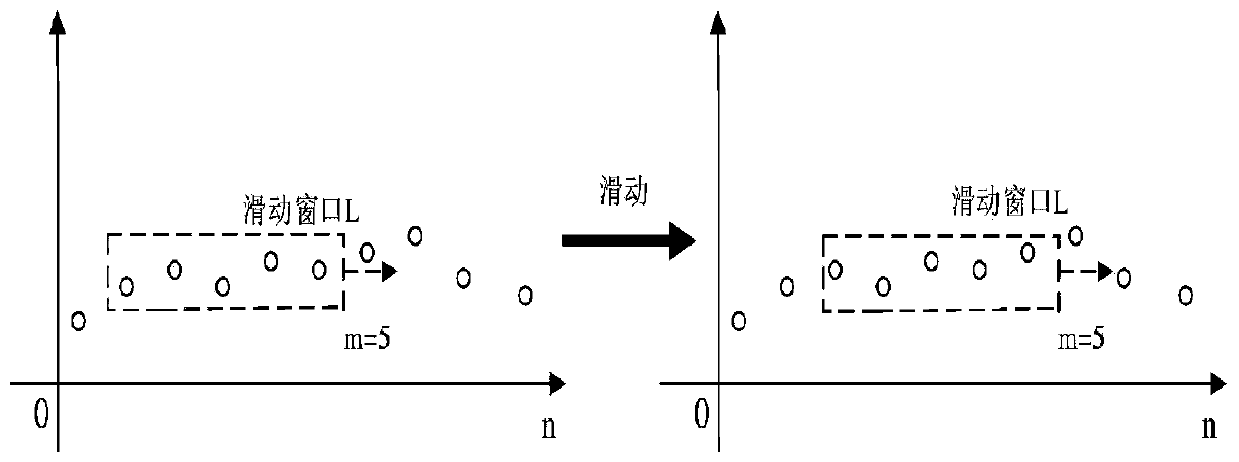

Cloud data center energy-saving scheduling implementation method based on rolling grey prediction model

ActiveCN106899660AAvoid overloading or no-loadingLower energy consumption levelsSubstation remote connection/disconnectionHigh level techniquesVirtual machine schedulingError checking

The invention discloses a cloud data center energy-saving scheduling implementation method based on a rolling grey prediction model. According to the method, the energy-saving process of the cloud data center is abstracted to a load prediction module, an error checking module, a thermal perception classification module and a virtual machine scheduling module, wherein the load prediction module is used for predicting the workload of the data center at the next moment to obtain the load utilization rate of each host; the thermal perception classification module divides the thermal states of all hosts according to the prediction values of the load utilization rate of the hosts, and determines that the utilization rate of the hosts in a higher thermal state is at a higher level, and the utilization rate of the hosts in a cooler state is at a lower level; and in order to maintain that most of the hosts are in a relatively mild thermal state, the virtual machine scheduling module carries out migration, integration and other operations to the virtual machines on each host according to the classification results of the thermal state to finally achieve the purposes of guaranteeing the service quality of the data center and reducing the energy consumption of the data center. According to the energy-saving scheduling implementation method disclosed by the invention, the problem that a traditional grey model has the difficulty of low precision due to partial value deficiency can be solved.

Owner:SOUTH CHINA UNIV OF TECH

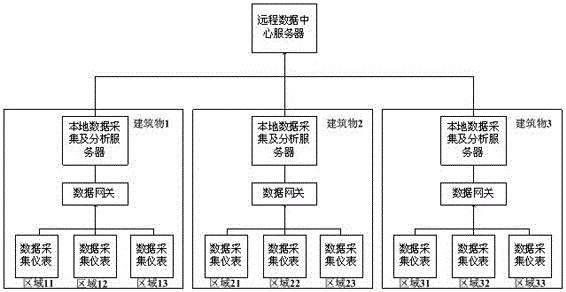

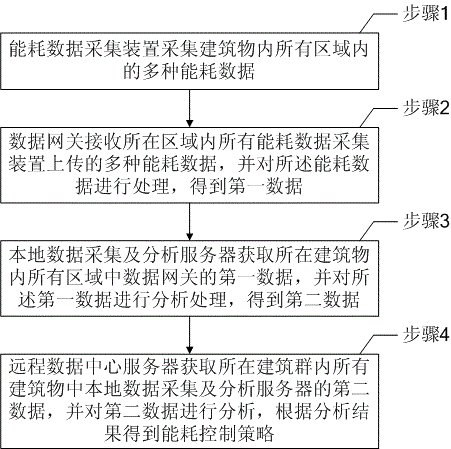

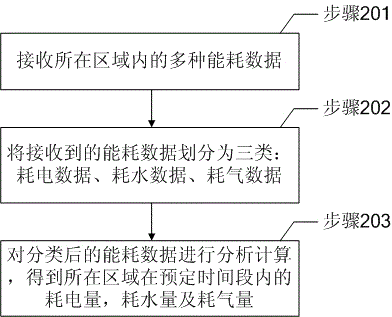

Building energy consumption management system and method based on Internet of things

The invention discloses a building energy consumption management system and method based on Internet of things. The system comprises energy consumption data acquisition devices used for acquiring multiple energy consumption data in areas where buildings are located; data gateways used for receiving the multiple energy consumption data uploaded by the energy consumption data acquisition devices in the areas and obtaining first data through processing the energy consumption data; local data acquisition and analysis servers used for obtaining the first data of the data gateways in all the areas where the buildings are located and obtaining second data through performing analysis processing on the first data; and a remote data center server used for obtaining the second data of the local data acquisition and analysis servers in all the buildings in a building group, analyzing the second data and obtaining energy consumption control strategies according to an analysis result.

Owner:武汉烽火富华电气有限责任公司

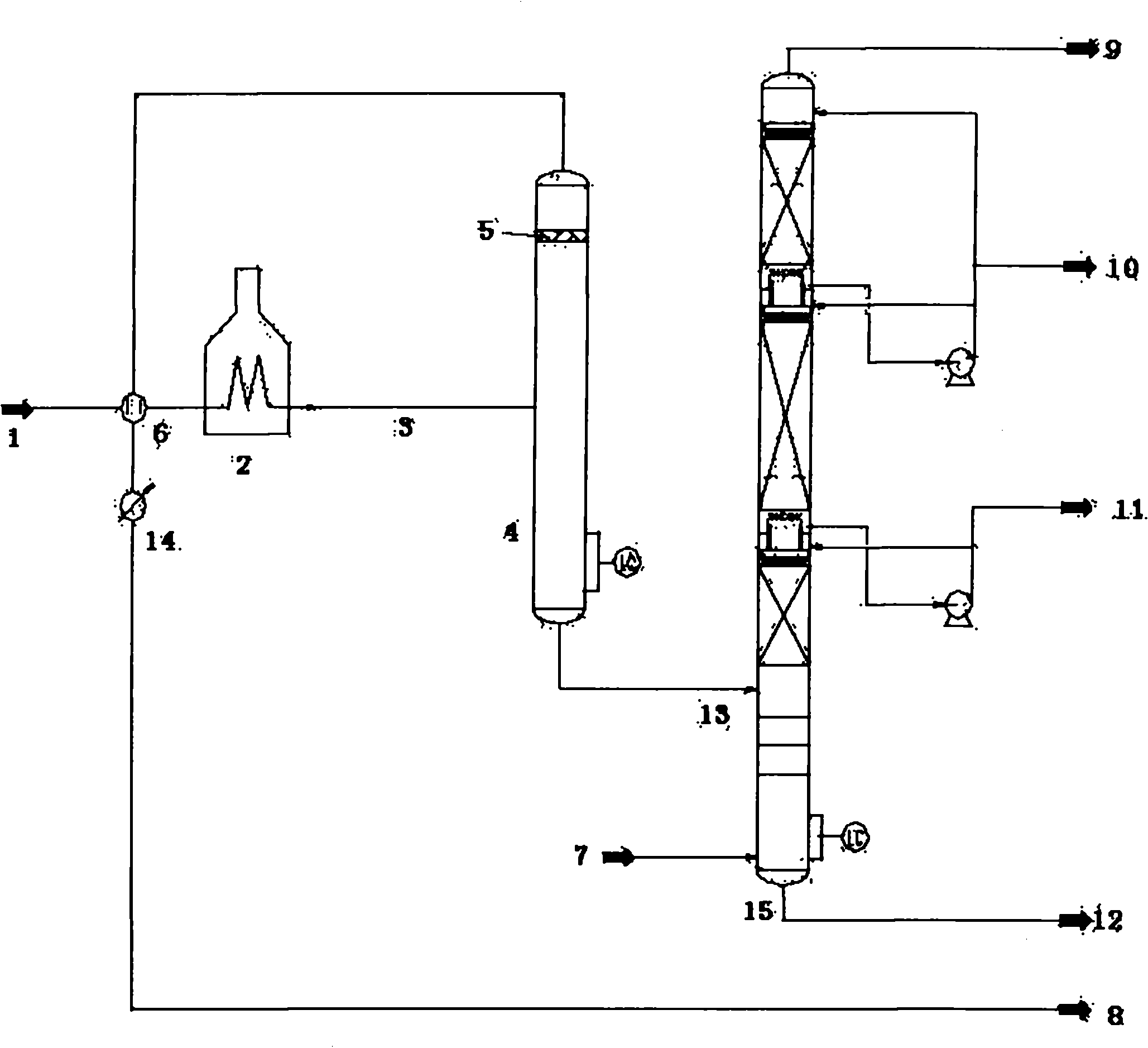

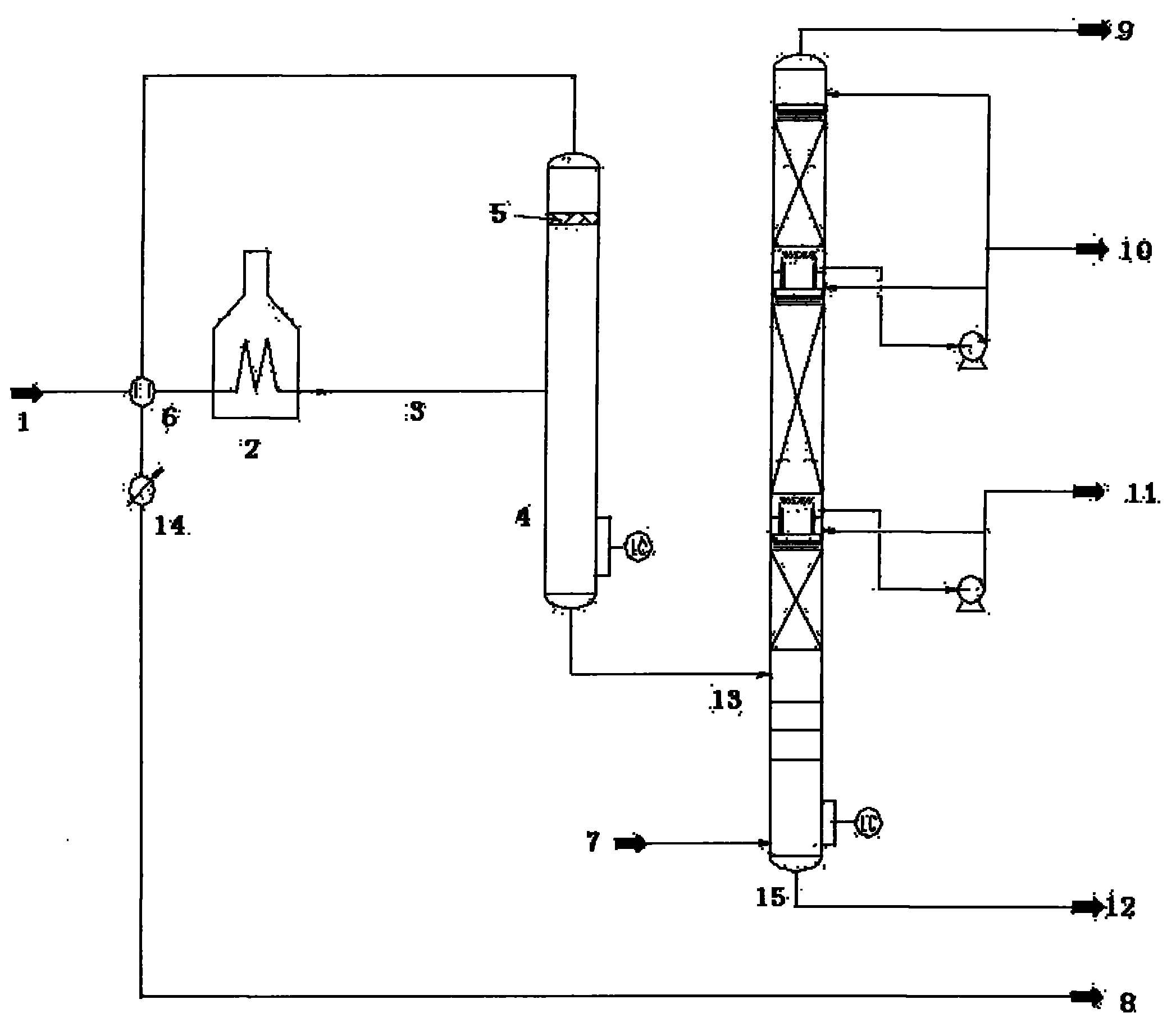

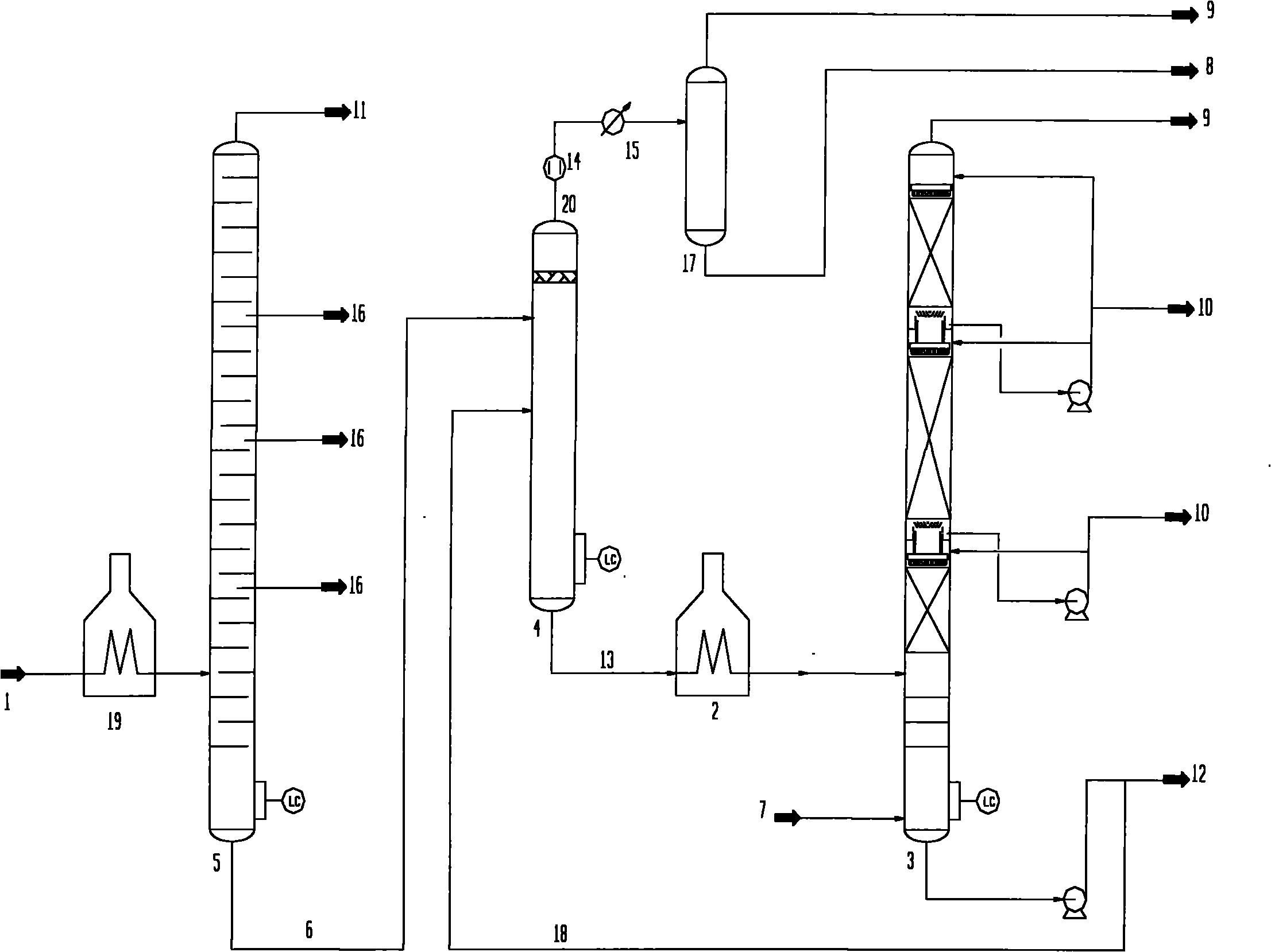

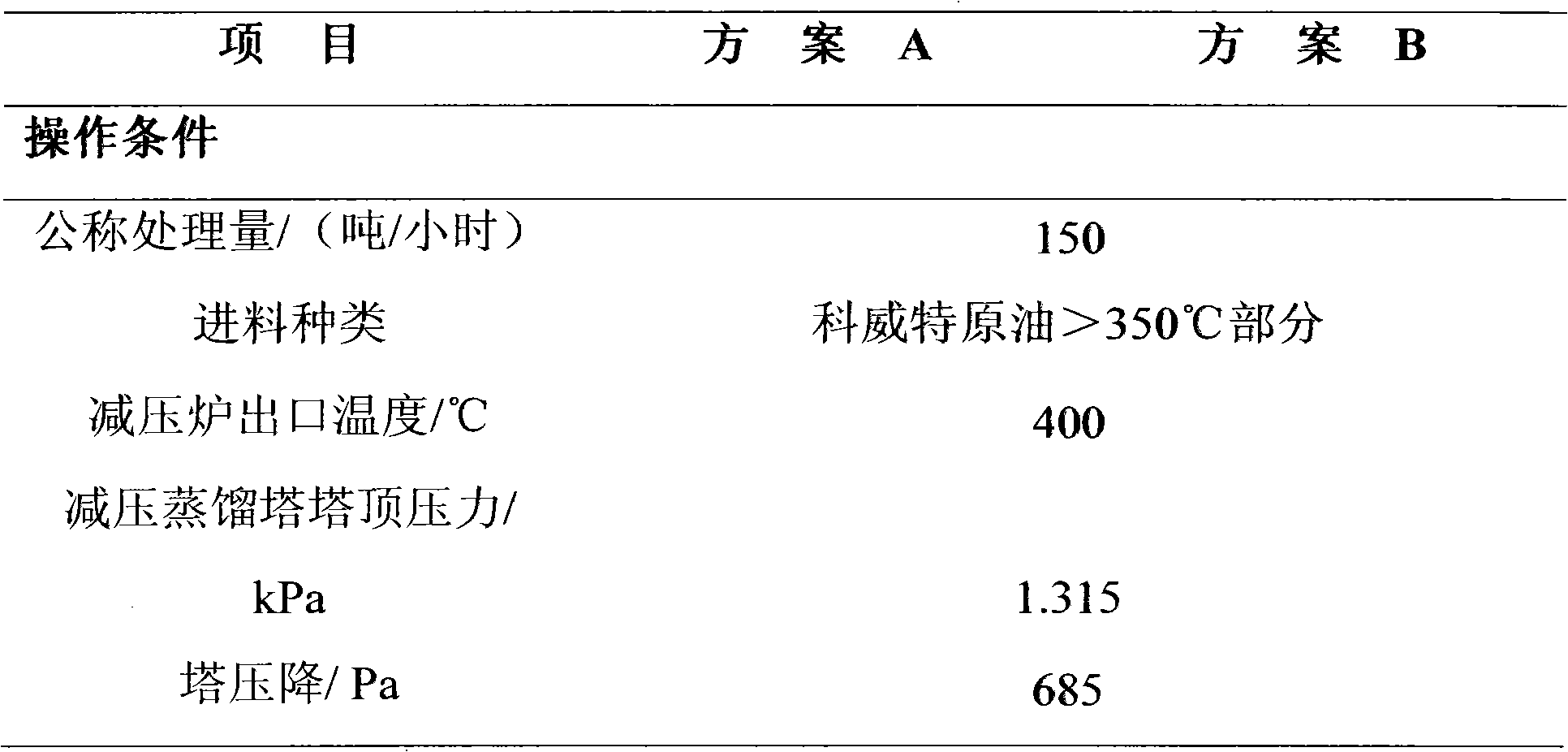

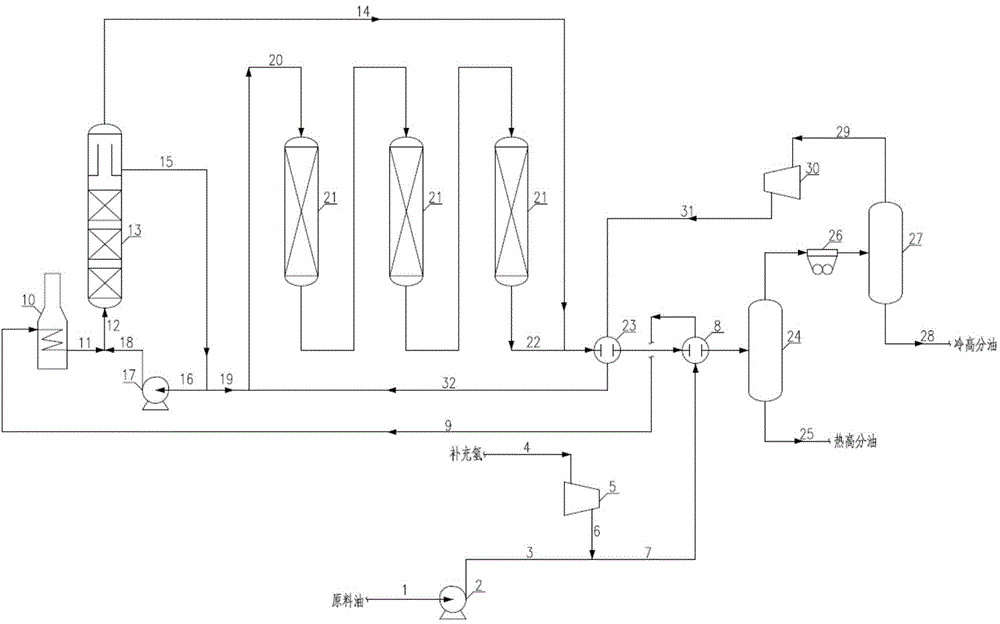

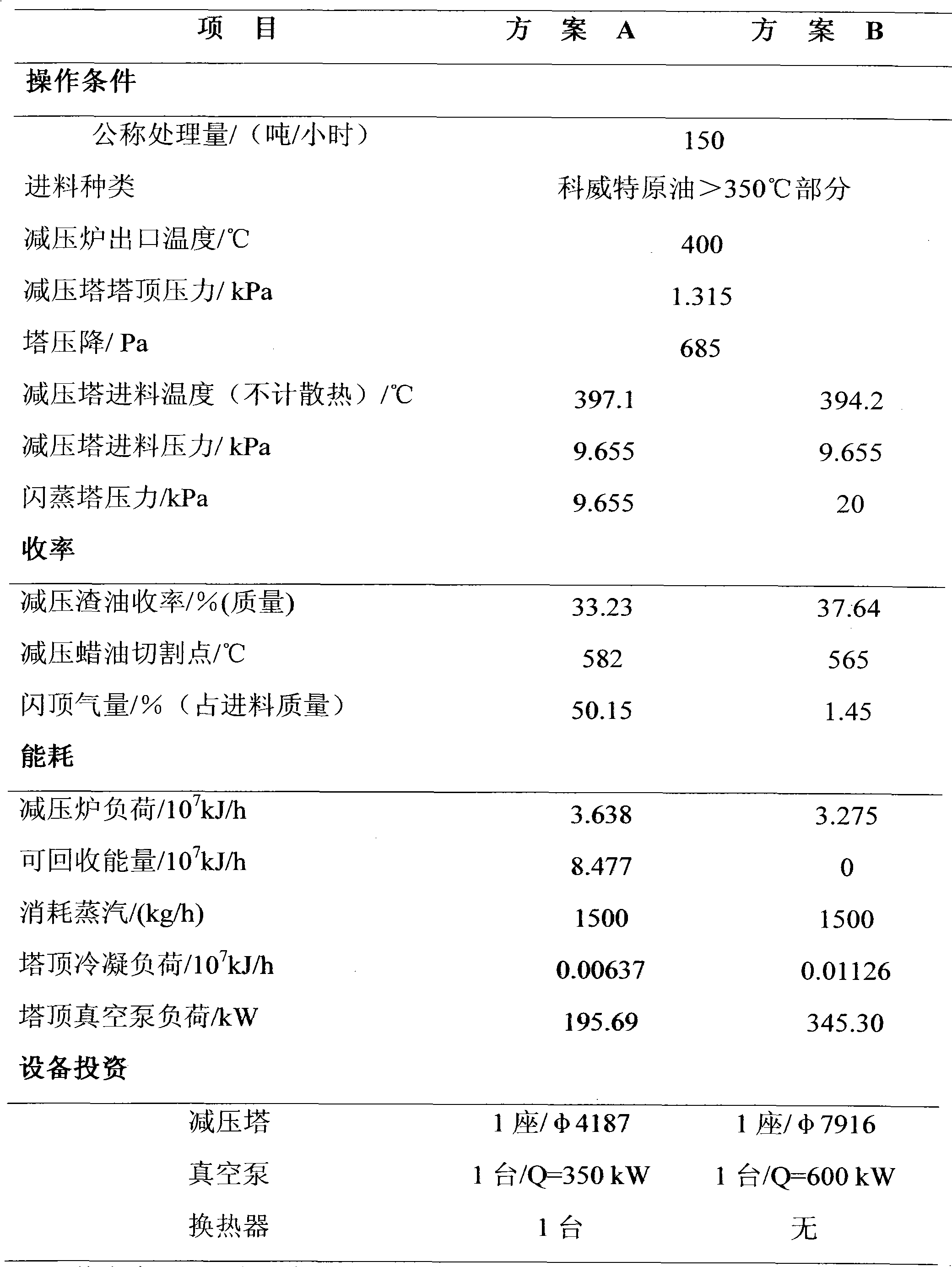

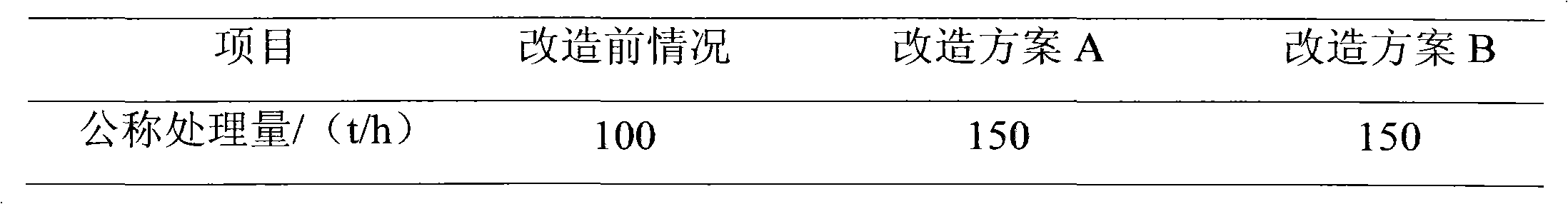

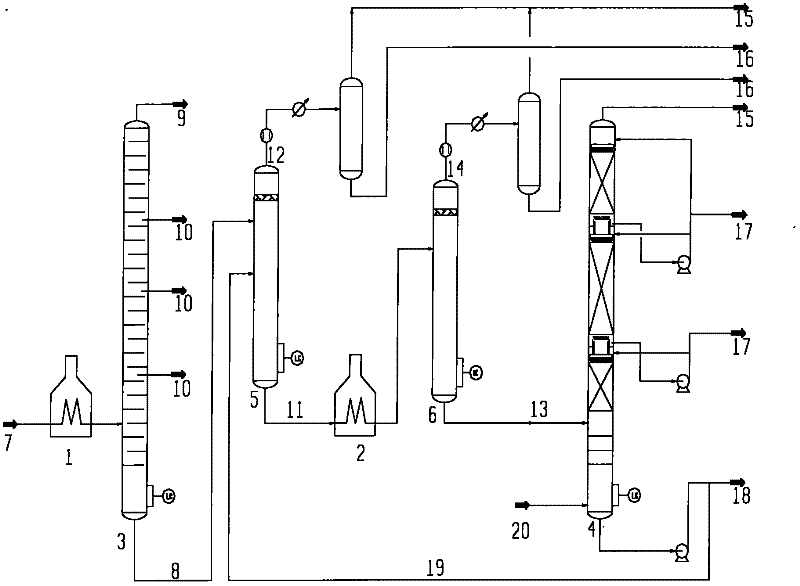

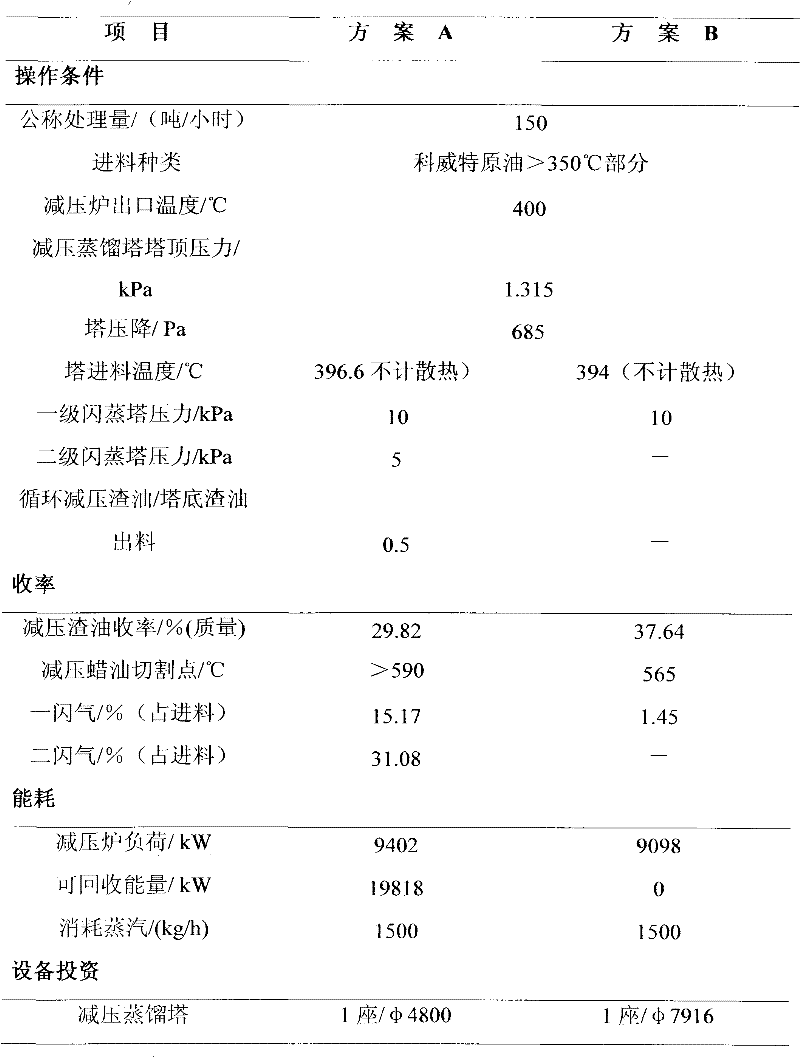

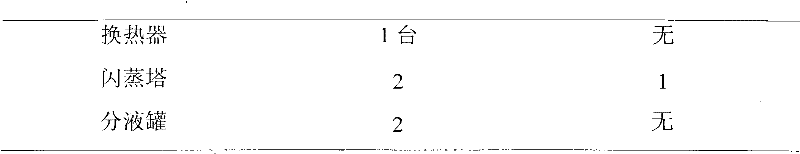

Distillate yield improving vacuum distillation method and device

ActiveCN102311772AAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

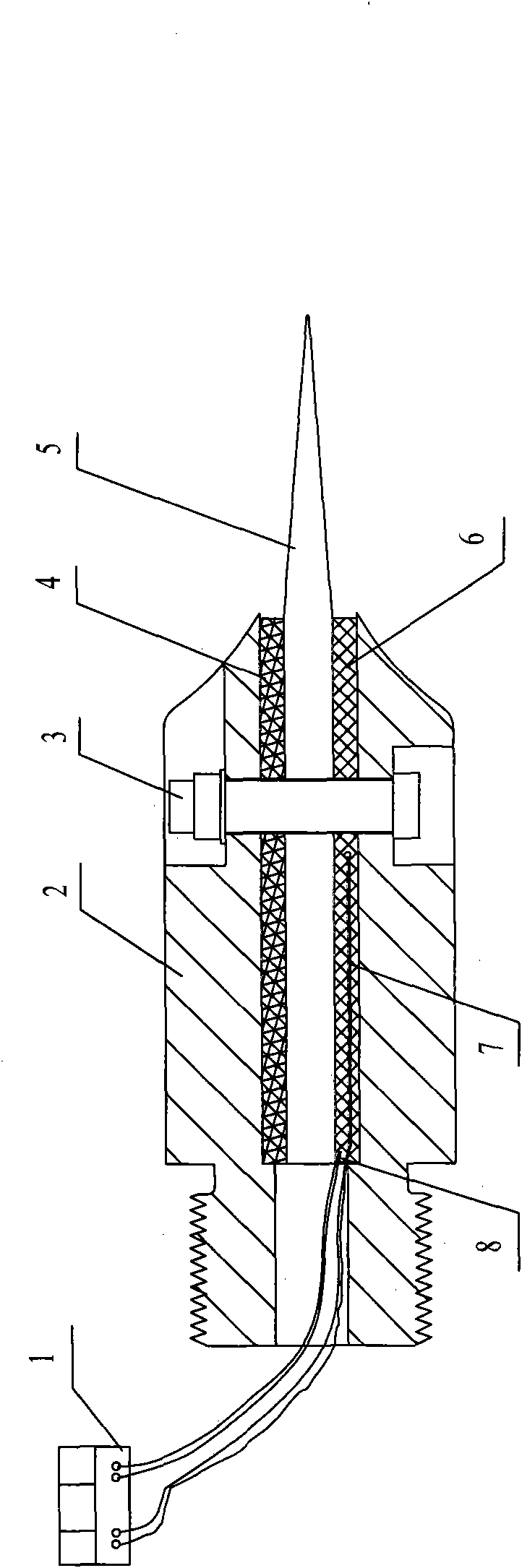

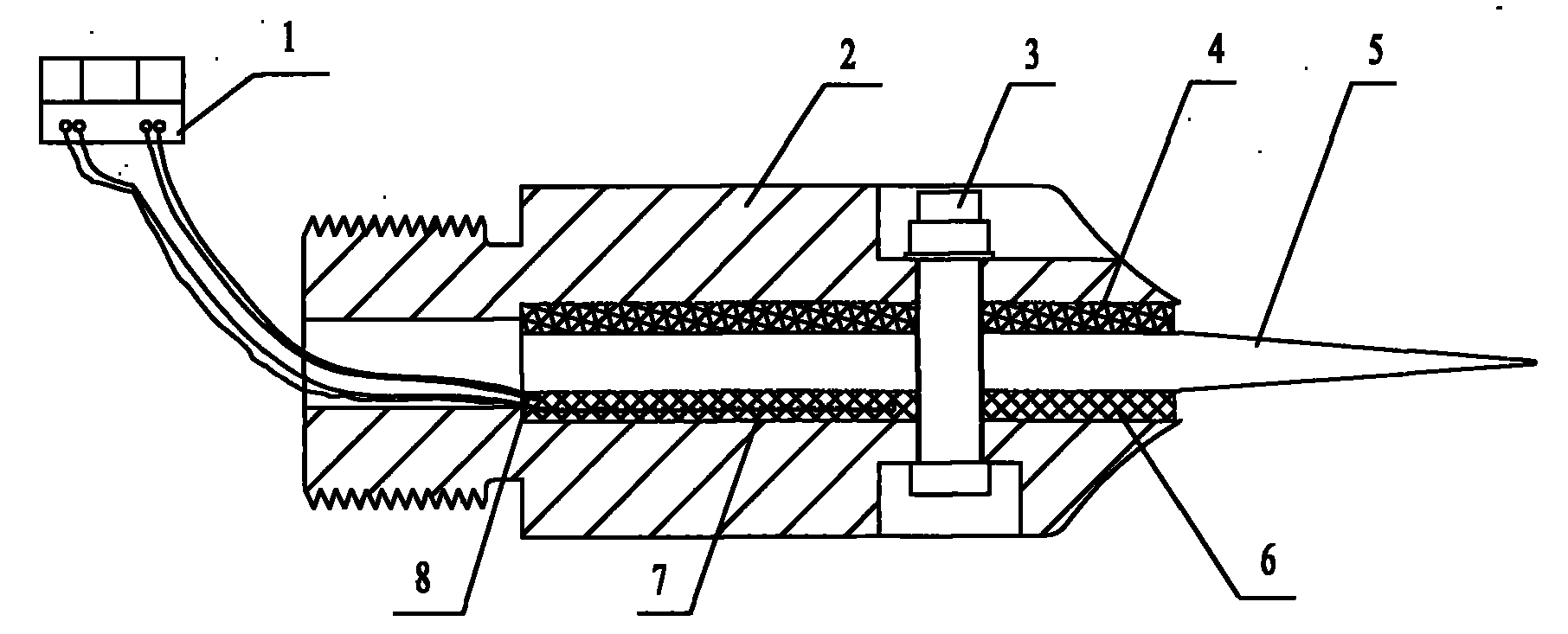

Thermal cutting shear and cutting method thereof

InactiveCN101992473ATemperature is directly measured and controlledTemperature measurement and controlMetal working apparatusRubber materialTemperature control

The invention relates to a thermal cutting shear and a cutting method thereof, and a flat arrangement type heating mode in fixture bodies is adopted to enhance the heating efficiency and the heat transfer speed and effectively control the operating temperature when the front end of a cutting edge carries out the cutting so as to enhance the cutting quality of the rubber material, and the quality of the joint and the stitching among various materials. The cutting shear comprises a group of the fixture bodies and shear bodies clamped and fixed among the fixture bodies, wherein at least one flat plate type heating plate is lined among the fixture bodies and the bases of the shear bodies; a heat source temperature sensor is arranged in the heating plate and is connected with an external power supply and a temperature control meter through a power supply wire; and a shear body temperature sensor is arranged in the cutting edge part of the shear bodies.

Owner:MESNAC

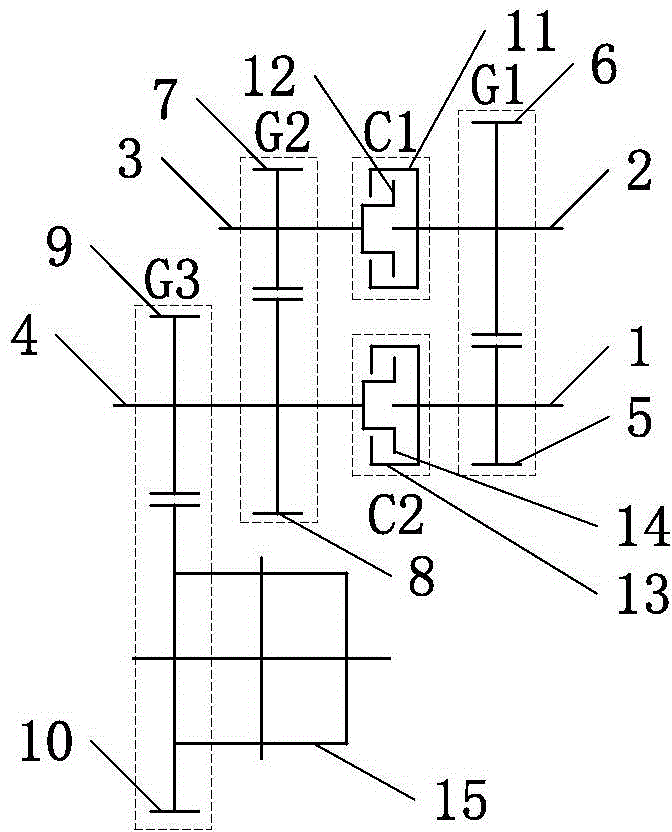

Two-gear automatic gearbox for pure electric vehicle

ActiveCN104565226ACompact structureLight in massElectric propulsion mountingToothed gearingsElectricityAutomatic transmission

The invention relates to a two-gear automatic gearbox for a pure electric vehicle. The two-gear automatic gearbox comprises an input shaft, a first middle shaft, a second middle shaft, a first cylinder gear pair, a second cylinder gear pair, a third cylinder gear pair, a first torque transferring device, a second torque transferring device and a differential mechanism assembly, wherein the rotating central lines of the input shaft, the second middle shaft and the differential mechanism assembly are parallel to one another. The two-gear automatic transmission is adopted by the two-gear automatic gearbox, so that the driving ratio scope is widened, the performance demand on a driving motor is greatly reduced, the high-efficiency and light driving motor is allowed to be adopted, and the total volume, the total mass and the total cost of the two-gear automatic gearbox for the pure electric vehicle are further reduced.

Owner:绿传(北京)汽车科技股份有限公司

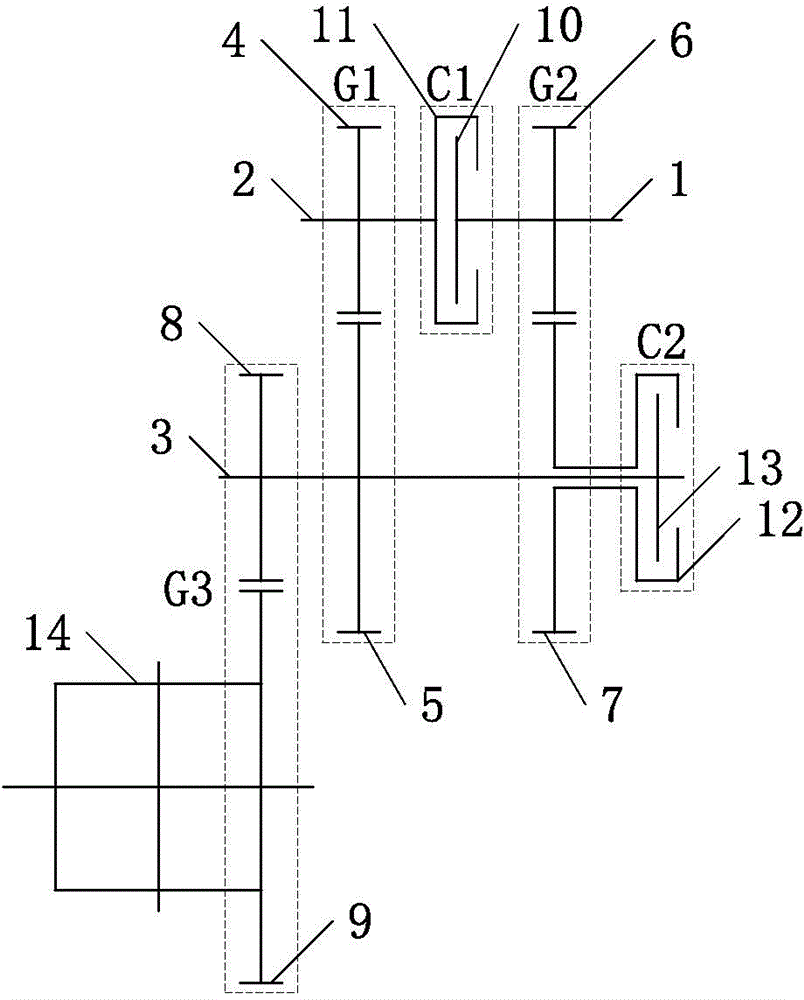

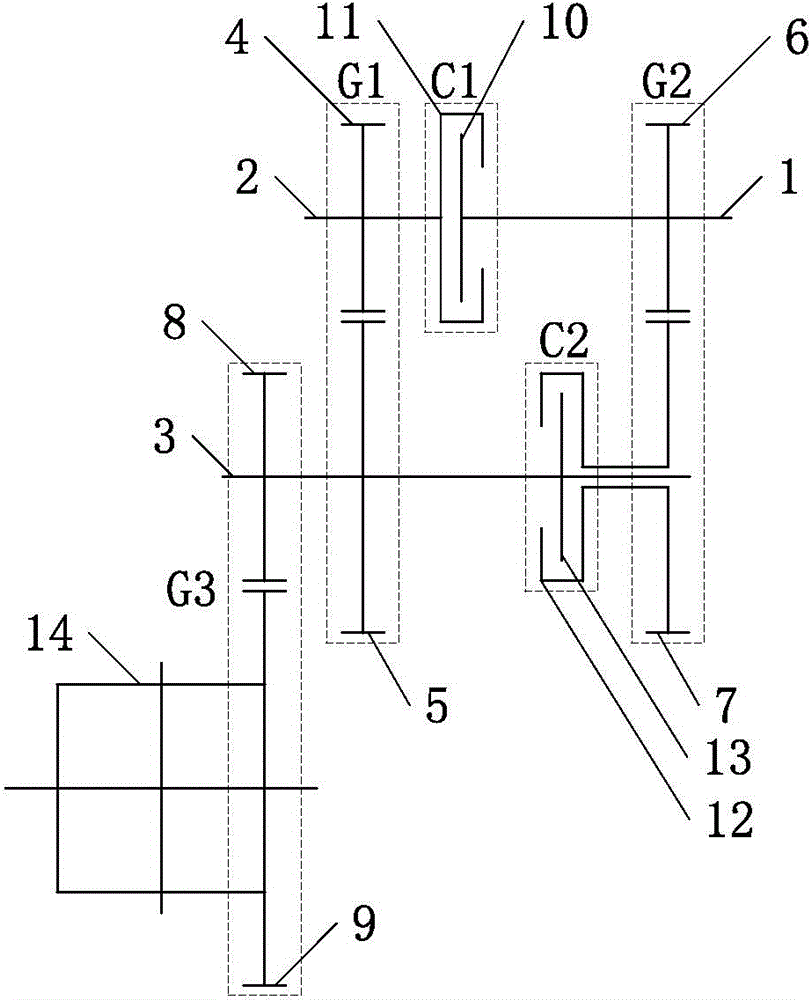

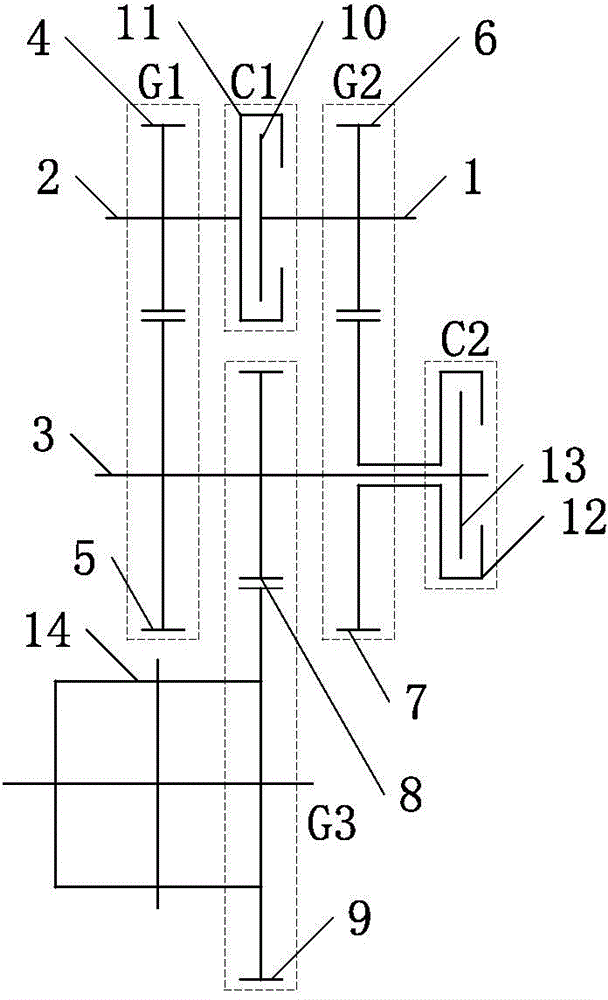

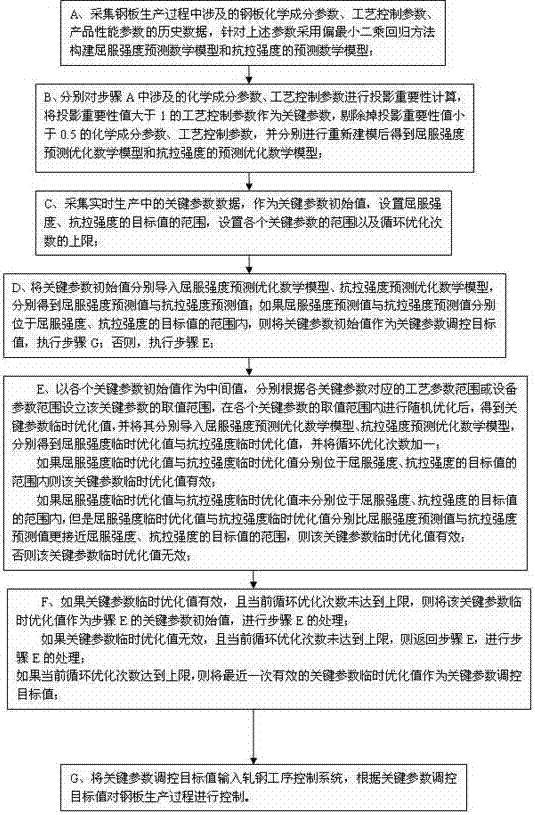

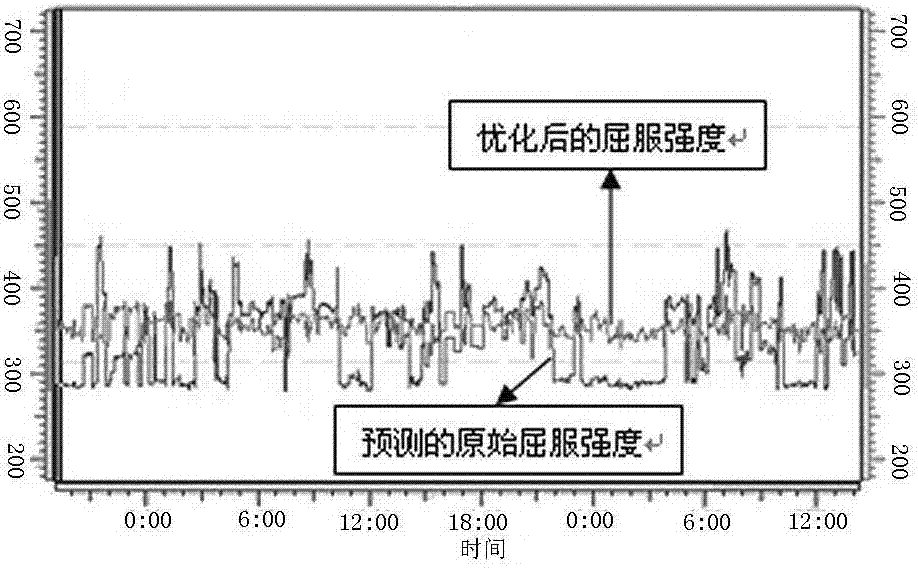

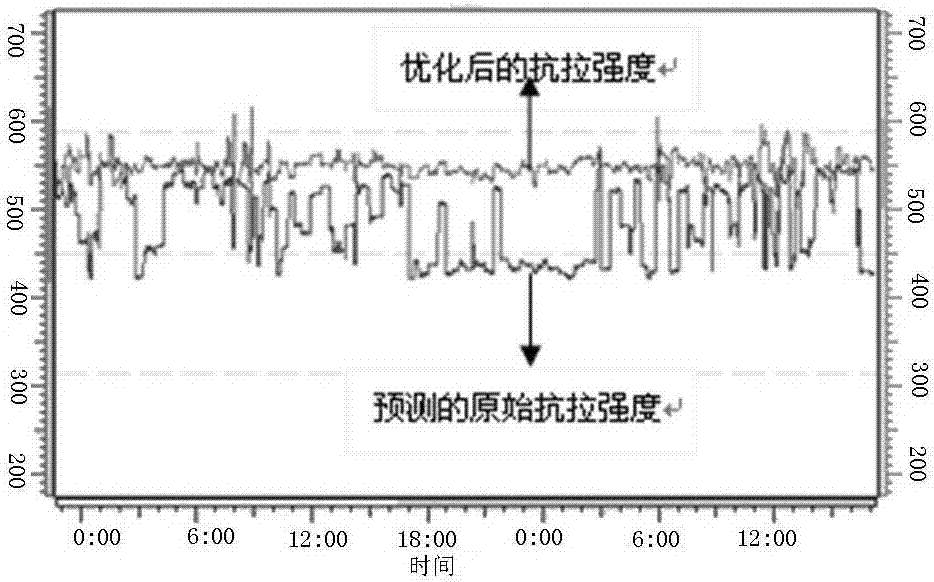

Control method for steel plate performance optimization

InactiveCN106991242ALow costImprove performanceDesign optimisation/simulationMulti-objective optimisationTheoretical computer scienceLoop optimization

The invention aims at providing a control method for steel plate performance optimization. The control method includes the steps that A, historical data of parameters involved in the steel plate production process is acquired, and a prediction mathematical model of yield strength and tensile strength is established; B, projection importance values of respective variables are calculated, and key parameters are determined; C, key parameter data in real-time production is acquired to serve as key parameter initial values; D, the key parameter initial values are introduced into the prediction mathematical model of yield strength and tensile strength, if predicted values are within the range of target values, key parameter regulation and control target values are obtained, and the step G is executed; or else, the step E is executed; E, after being randomly optimized, the key parameter initial values are introduced into the prediction mathematical model; F, loop optimization is continuously carried out till the key parameter regulation and control target values are obtained; G, the steel rolling procedure process is controlled through the key parameter regulation and control target values. The method overcomes the defects that the existing technology is complex in calculation, poor in precision and the like, and has the advantages of being simple in calculation and high in control precision.

Owner:柳州市同维达豪科技有限公司 +1

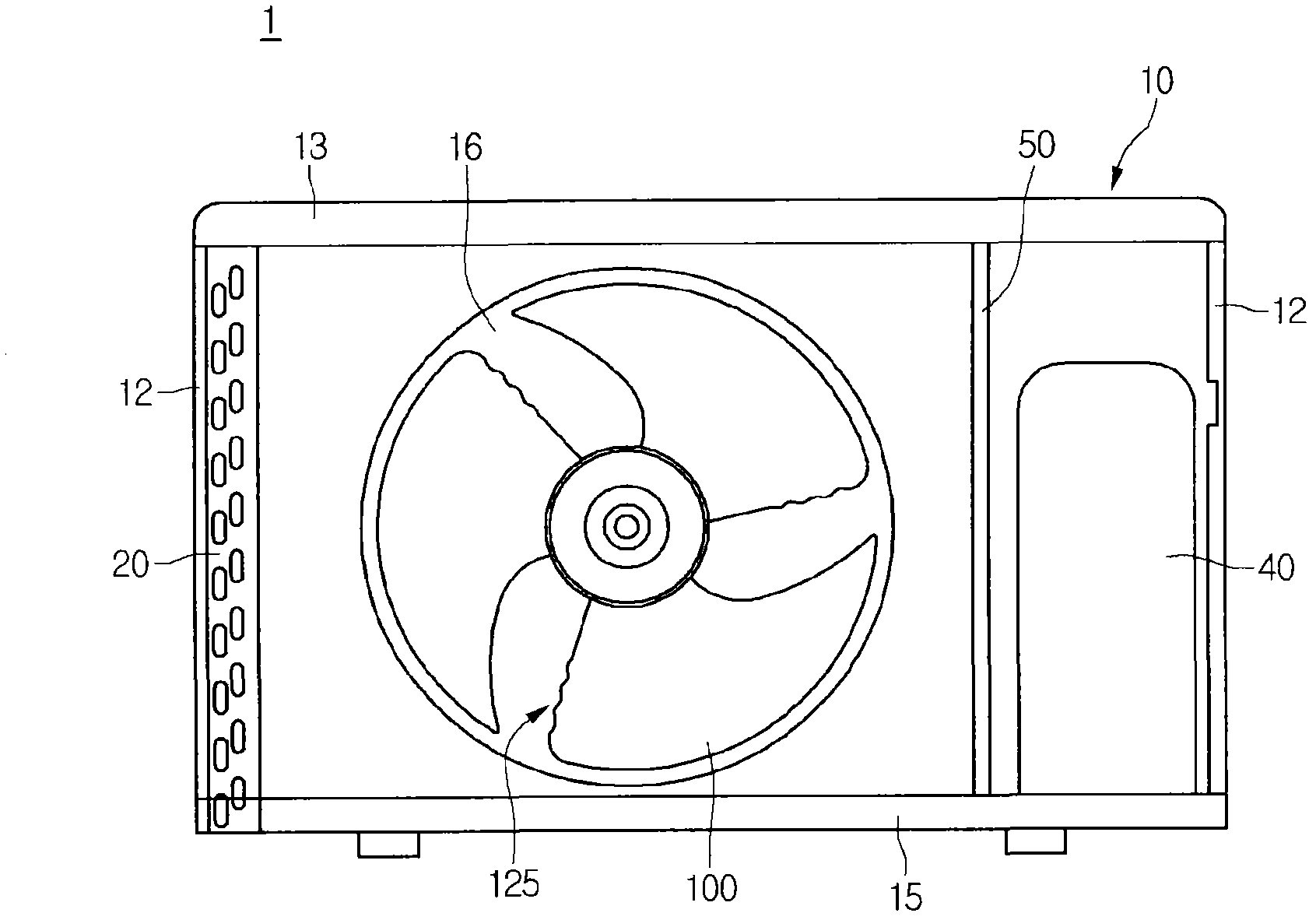

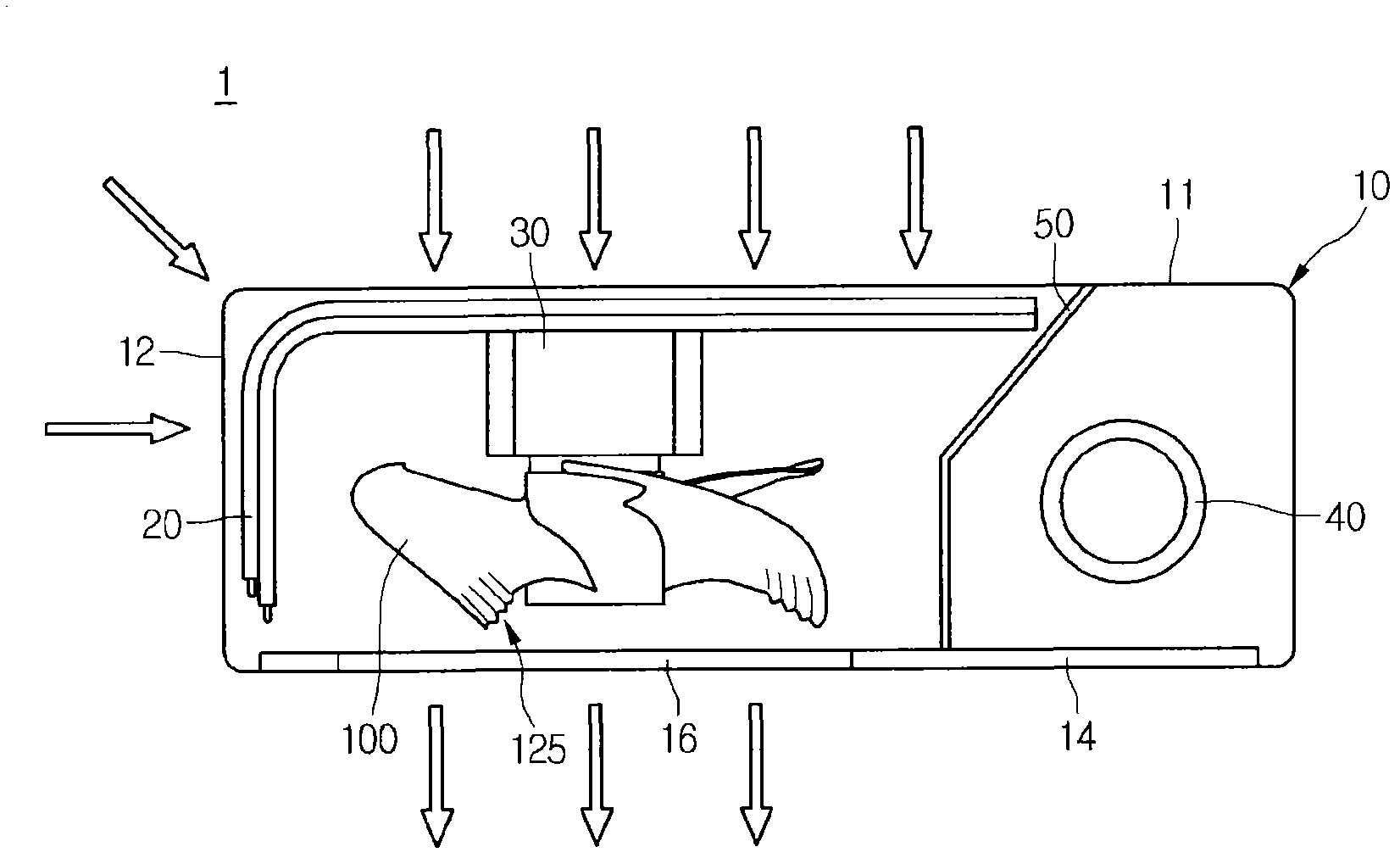

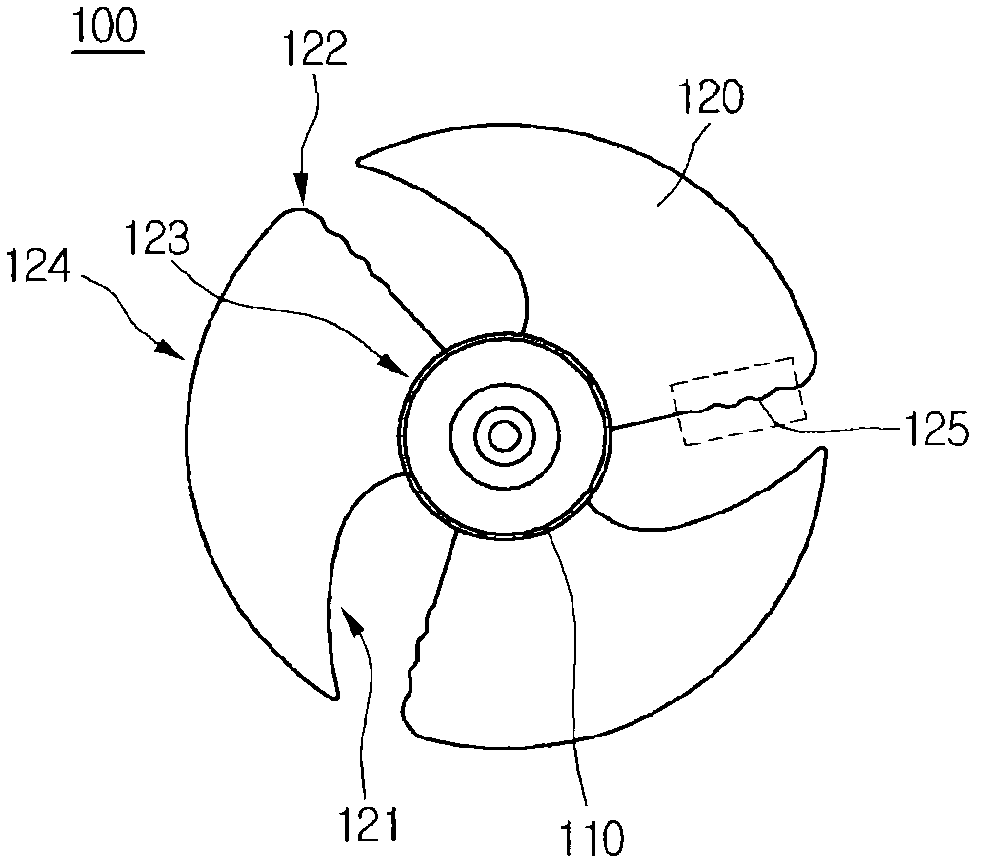

Axial flow fan and air conditioner

InactiveCN103047180ASatisfied with useIncrease flow ratePump componentsLighting and heating apparatusEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

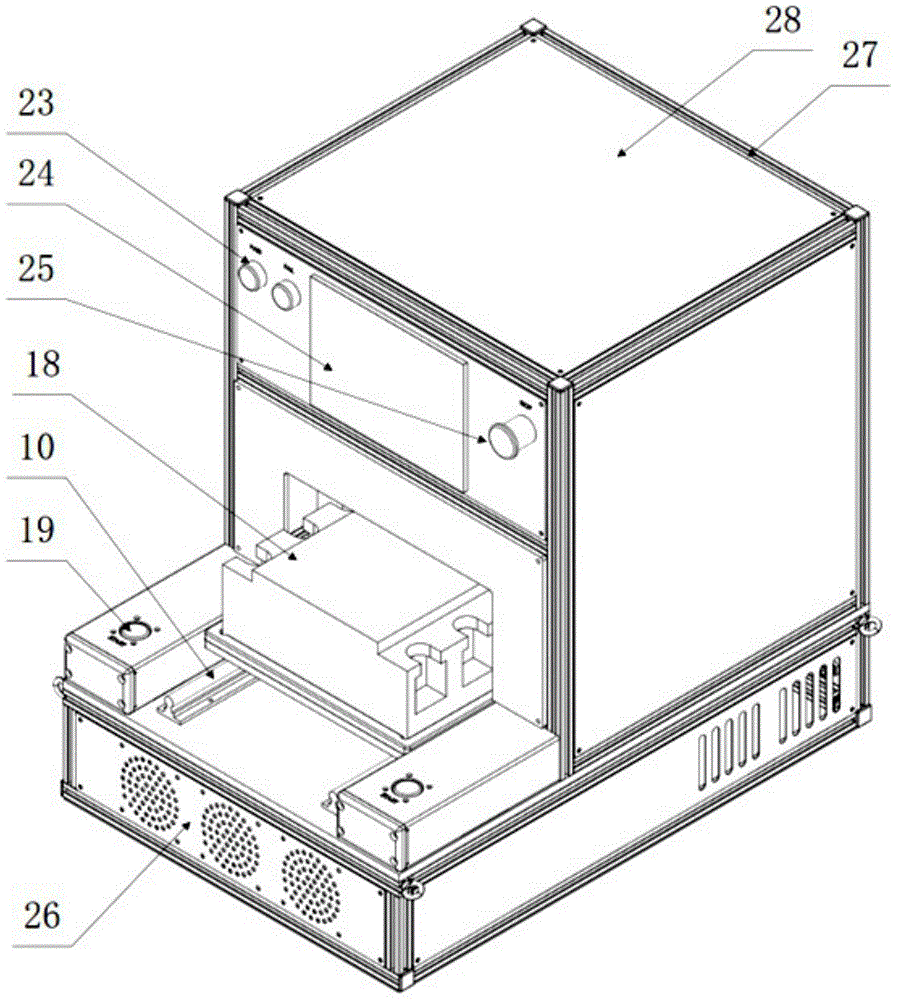

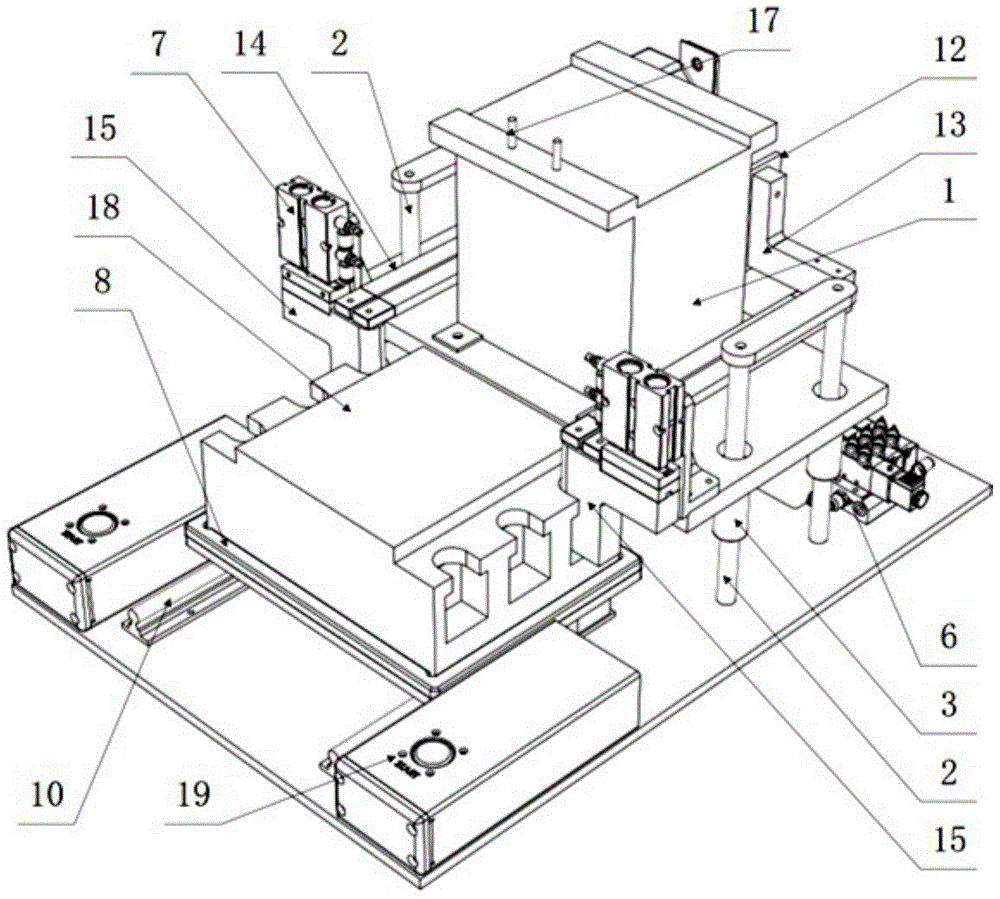

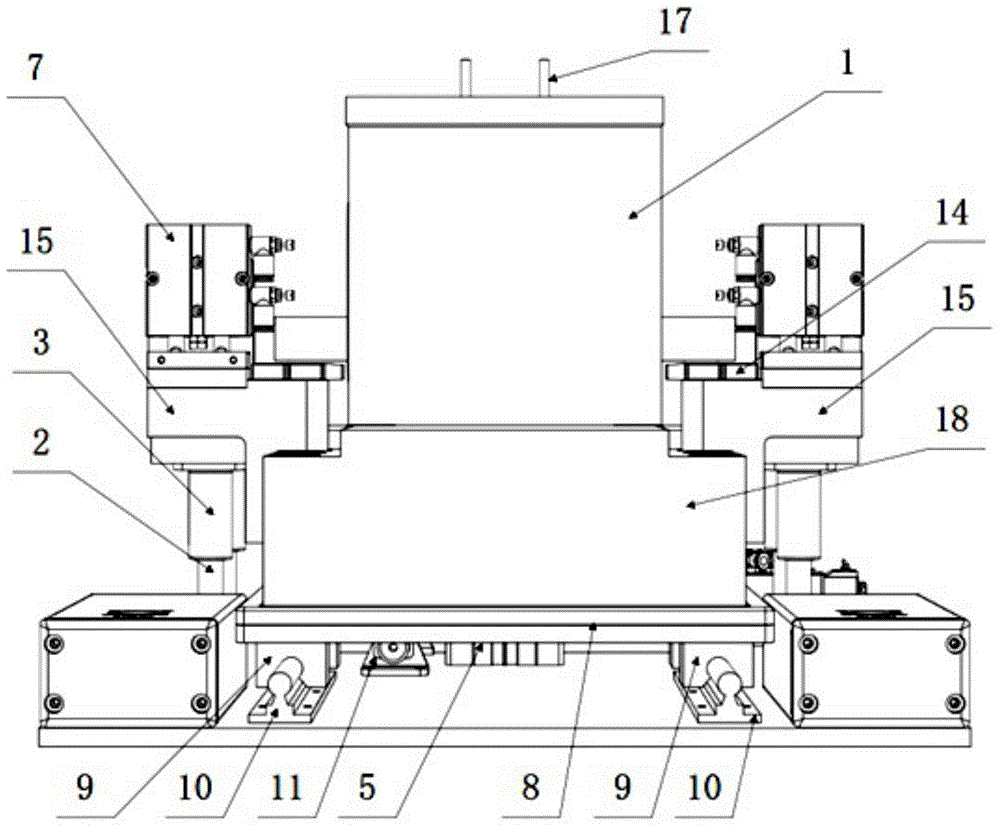

Integrated device for large-scale low-voltage breaker high-current tests

ActiveCN104898053ALower impedanceLower energy consumption levelsMeasurement instrument housingCircuit interrupters testingHuman–machine interfaceLow voltage

The invention relates to the technology of low-voltage breaker detecting tests and aims to provide and integrated device for large-scale low-voltage breaker high-current tests. The device comprises a transformer, a detecting power source, a vertical compression connecting mechanism, an auxiliary compression connecting mechanism, a horizontal positioning mechanism, a loop bus bar, a man-machine interface and a central controller, wherein the horizontal positioning mechanism, the auxiliary compression connecting mechanism and the vertical compression connecting mechanism are arranged on a mounting plate; the man-machine interface is respectively connected to electronic switch equipment through the central controller. The integrated device has the advantages that current loop length in high-current tests is reduced, transformer secondary-side high-current loop impedance is reduced, and high-current test equipment power consumption is lowered; the integrated device is small in equipment size, convenient and fast in compression connection, long in equipment service life, easy to popularize in factory automatic production lines and convenient to popularize in departments such as detecting institutions with limited sites; the integrated device can continuously detect the multiple electrodes of a three-phase breaker and is high in automation level.

Owner:中华人民共和国上海浦江出入境检验检疫局

Crude oil processing method

The invention discloses a crude oil processing method, which comprises normal-pressure distillation and reduced-pressure distillation, wherein the heavy oil at the bottom of a normal-pressure distillation tower, namely normal bottom oil, is mixed with part of circular reduced-pressure residual oil at the bottom of a reduced-pressure distillation tower, the mixture enters a flash tower, and a top gas phase, namely flash top gas, of the flash tower undergoes heat exchange and is condensed into a liquid phase to be discharged out of the device as a product; and bottom oil, namely flash bottom oil, of the flash tower, is heated in a reduced-pressure furnace to 390 to 420 DEG C, the heated bottom oil is intruded into a flash section of the reduced-pressure distillation tower from a reduced-pressure oil transfer line for reduced-pressure distillation, proper distillate product is drawn from a side line of the reduced-pressure distillation tower, part of reduced-pressure residual oil drawn out from the bottom of the reduced-pressure distillation tower is circulated, and another part of the reduced-pressure residual oil is discharged of the device. Compared with the prior art, the method can effectively improve the drawing rate of a reduced-pressure distillation process and can reduce the load of the reduced-pressure furnace and the reduced-pressure distillation tower at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

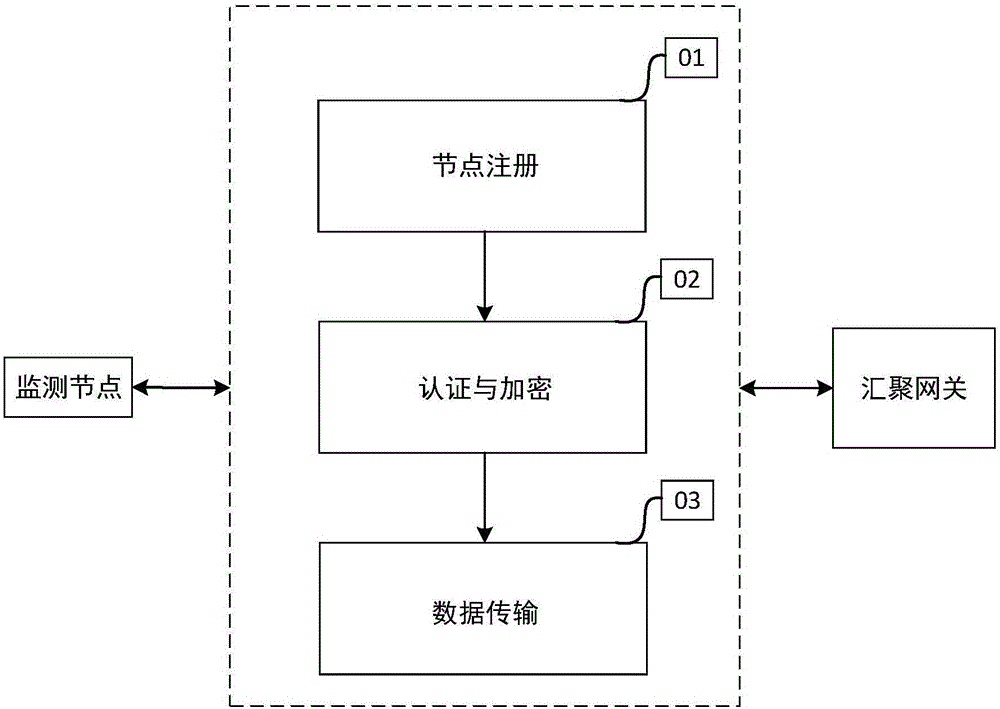

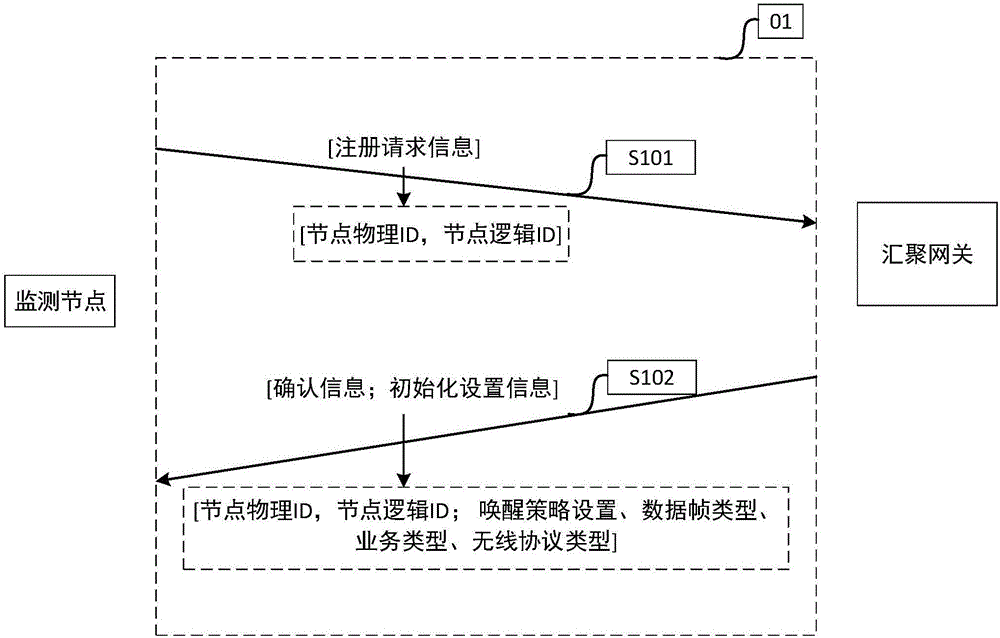

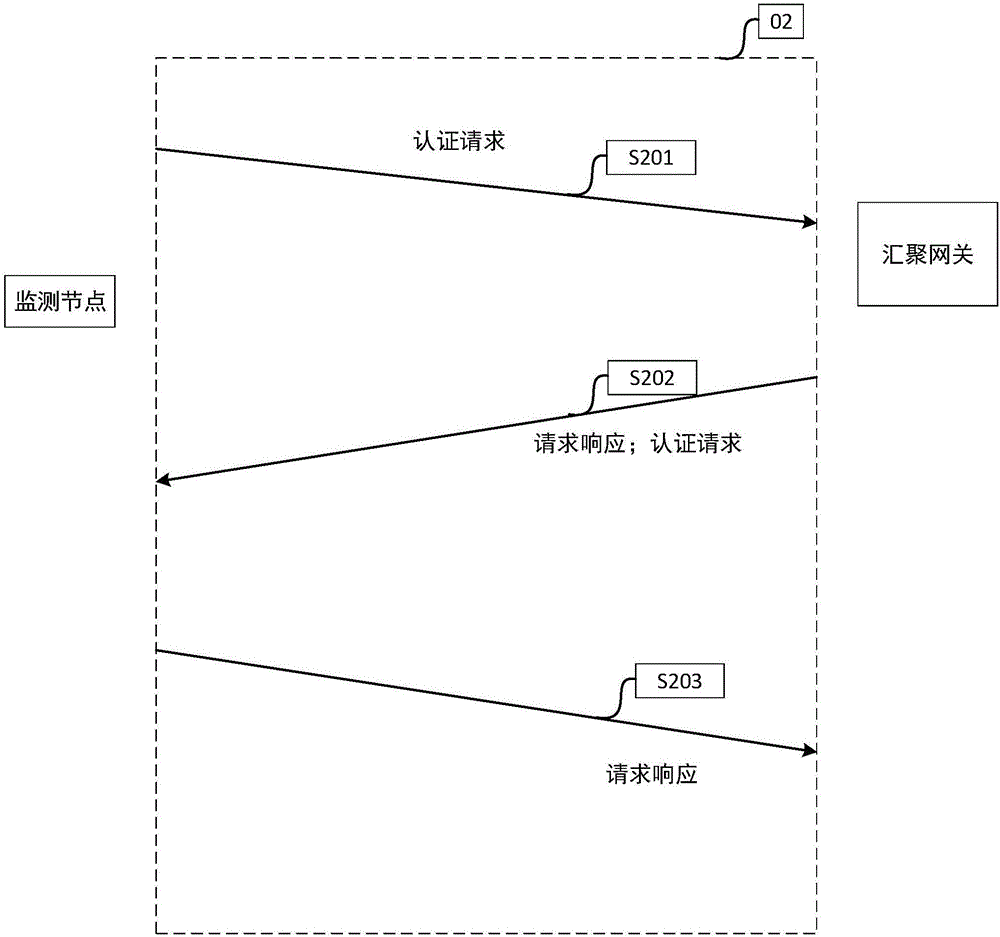

Method of low-power consumption wireless communication between monitoring node and convergence gateway

ActiveCN106230645ALower energy consumption levelsConvenient power supplyData switching networksActivity timeRadio frequency

The invention discloses a method of low-power consumption wireless communication between a monitoring node and a convergence gateway. The method at least comprises three stages of monitoring node registration, authentication and encryption and data transmission. In the data transmission stage, the monitoring node organizes and stores acquired sensor data in a data grouping mode. In order to improve the transmission efficiency and reduce the power consumption, grouped sensor data are firstly segmented or merged to adapt to the characteristics of monitoring business; and then, wireless transmission protocol adaptation is carried out on business data frames to select the best wireless transmission protocol, and the best transmission performance and the energy-saving efficiency are thus acquired. In order to acquire better energy-saving efficiency, the monitoring node continuously learns and improves a sleep awakening control strategy of a node radio frequency unit according to safety assessment and energy consumption assessment results to reduce the activity time of the radio frequency unit. The sleep awakening control with a learning ability can better adapt to various different intelligent security application scenes, and the energy consumption efficiency and the system performance are thus maximized.

Owner:陕西哥莱信息科技有限公司

Phase change cold storage agent for air conditioner and its producing method

InactiveCN1944566ASimple configurationShorten ice making timeHeat-exchange elementsHeat conductingPotassium

The present invention discloses one kind of phase change cold accumulating agent for air conditioner and its production process. The phase change cold accumulating agent consists of potassium chloride 1-4 wt%, nucleator 0.1-0.5 wt%, surfactant 0.05-0.5 wt%, titania grain as heat conducting enhancer 0.01-1 wt% and pure water for the rest, and has phase change temperature region of -1 deg.c to -8 deg.c. The phase change cold accumulating agent has the advantages of simple recipe, low cost, long cold releasing time, etc; and using the phase change cold accumulating agent in air conditioner can reach the aims of 'removing peak to fill the valley', raising efficiency and saving energy.

Owner:DONGGUAN GUANGDA REFRIGERATION

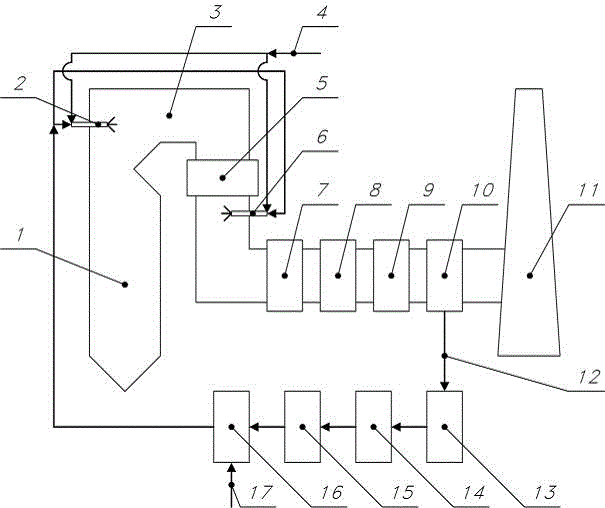

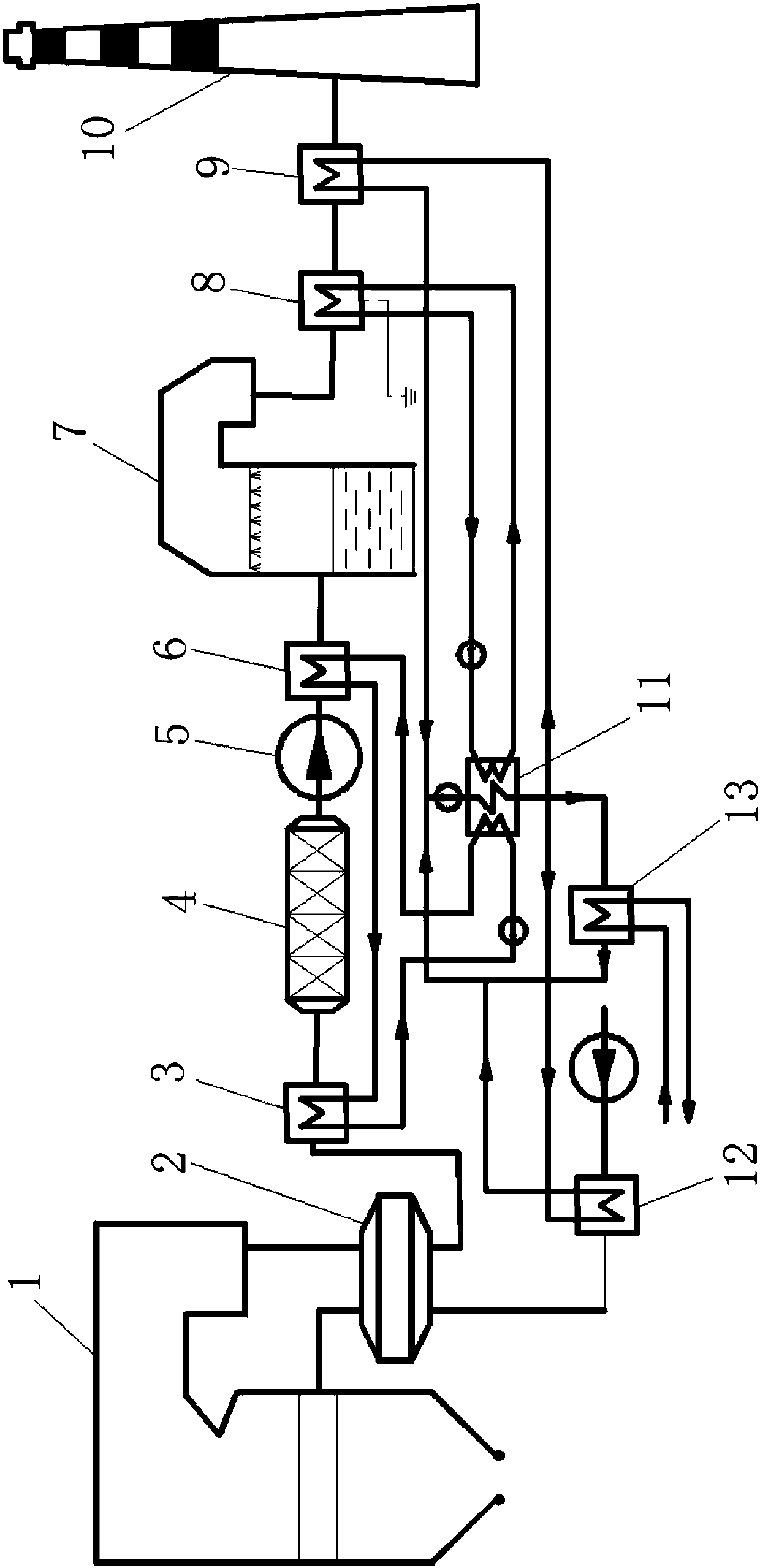

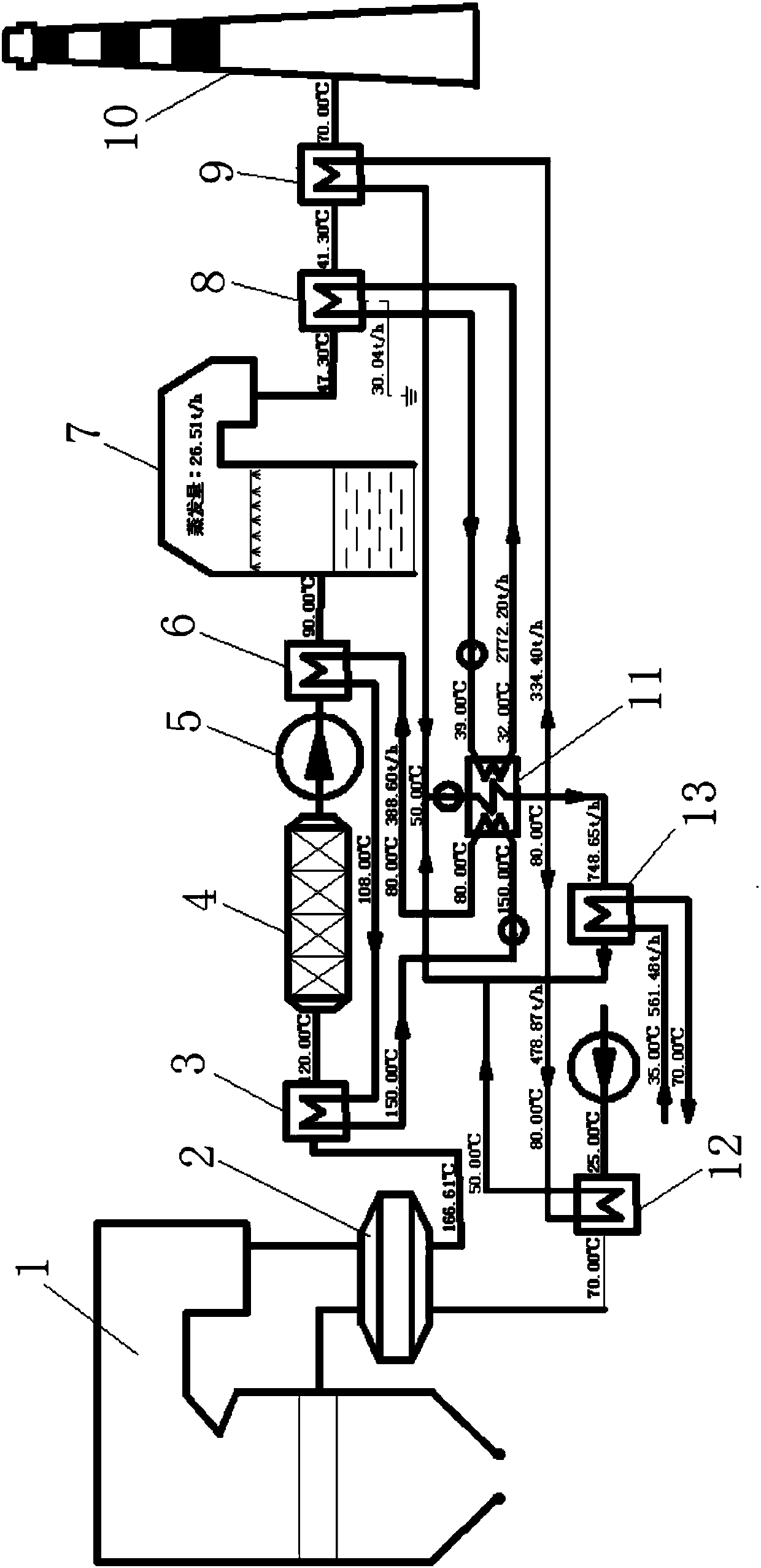

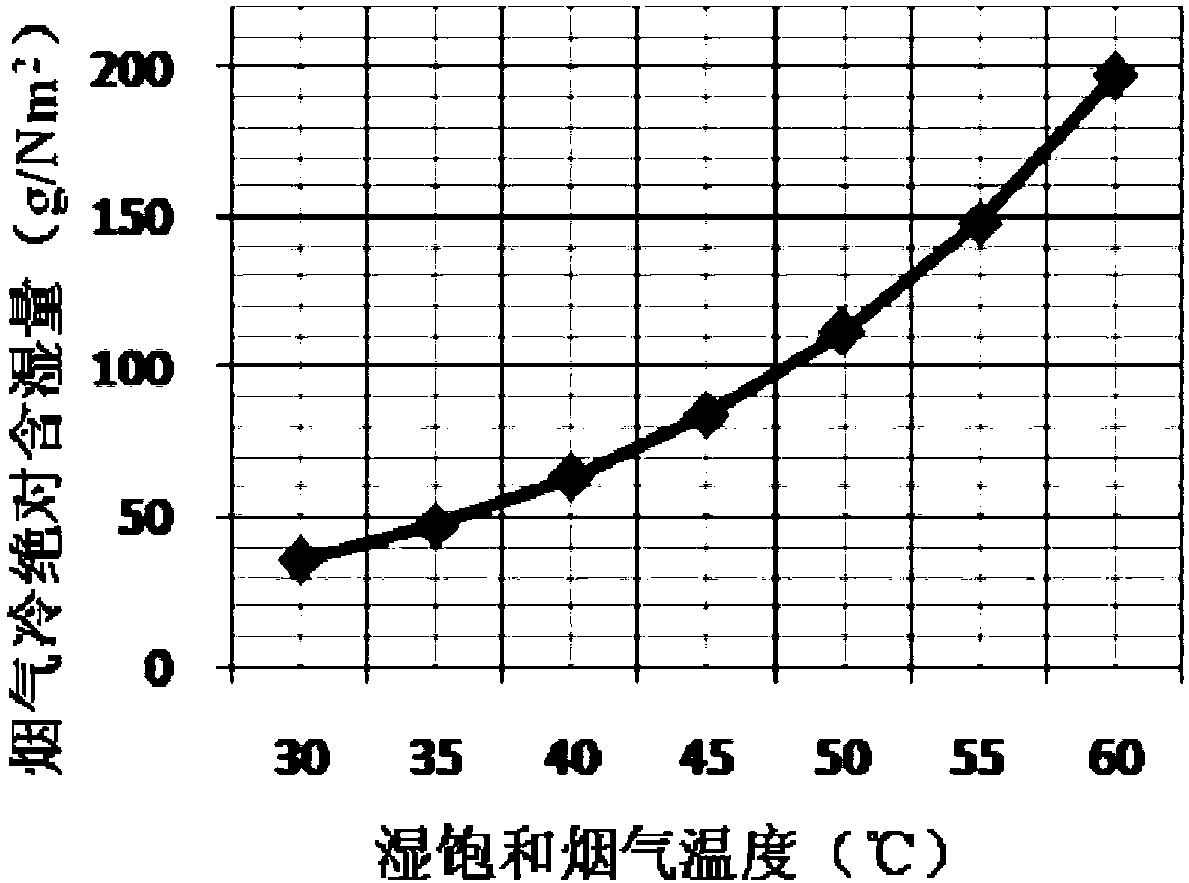

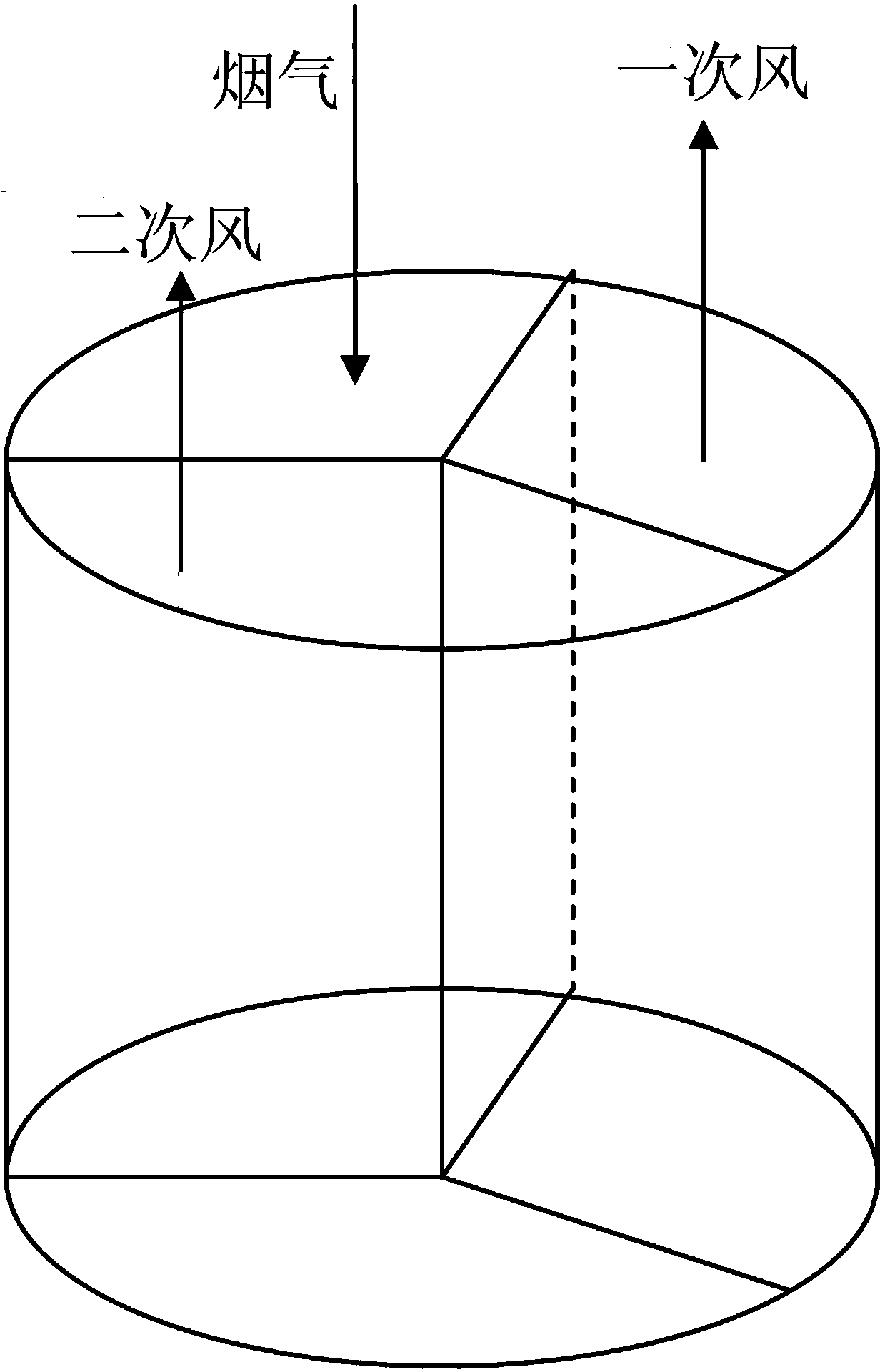

Wet flue gas advanced comprehensive treatment system and method for energy and water saving-type coal-fired boiler

PendingCN107860153ARealize zero water consumption operationReduce consumptionHeat pumpsEnergy efficient heating/coolingEconomizerCoal fired

The invention discloses a wet flue gas advanced comprehensive treatment system for an energy and water saving-type coal-fired boiler. The wet flue gas advanced comprehensive treatment system comprisesan absorption heat pump, an air pre-heater, a coal economizer, an electric dust remover, an induced draft fan, a gas cooler, a desulfurization absorption tower, a flue gas condenser and a flue gas reheater, wherein the air pre-heater, the coal economizer, the electric dust remover, the induced draft fan, the gas cooler, the desulfurization absorption tower, the flue gas condenser and the flue gasreheater are sequentially communicated between a flue gas outlet of the tail portion of the boiler and a flue gas inlet of a chimney. A water outlet of the flue gas condenser communicates with a water inlet of the coal economizer. The absorption heat pump communicates with the coal economizer, the gas cooler, the flue gas condenser and the flue gas reheater. The invention further discloses a wetflue gas advanced comprehensive treatment method for the energy and water saving-type coal-fired boiler. By adoption of the method, recycled boiler flue gas waste heat is used for driving the absorption heat pump, and the saturated wet flue gas waste heat of a desulfurization absorption tower outlet is recycled; and meanwhile water vapor in the saturated wet flue gas of the desulfurization absorption tower outlet is condensed and recycled and zero-water-replenishing operation of the desulfurization system is realized. Meanwhile, multiple sorts of pollutants can be removed, and 'gypsum rain' and 'misty rain' nearby a chimney outlet can be treated.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST

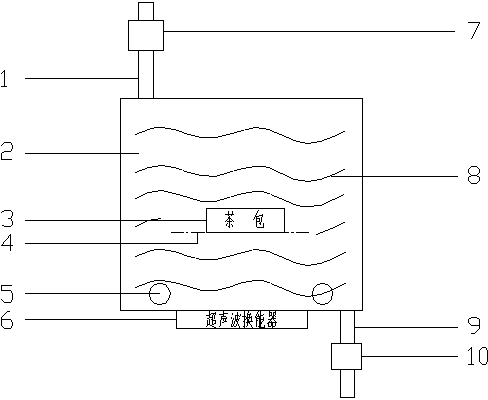

Method and device for making tea for machine

InactiveCN103720351AStrong penetrating powerLower energy consumption levelsBeverage vesselsUltrasonic sensorElectronic control system

The invention discloses a method and device for making tea for a machine. The method comprises the steps that tea leaves are fed, water is injected, the water is heated, heat is preserved, and the tea is made, wherein in the heating process, an electric heater and an ultrasonic wave generation device in a tea making tank are started at the same time, so that the water is heated to a set temperature; in the heat preservation process, the water is kept at the set temperature continuously for 80 to 150 seconds. The device comprises the electric heater, an ultrasonic transducer, an electronic control system and the like. The electric heater is installed at the bottom inside the tea making tank. The ultrasonic transducer is installed at the bottom outside the tea making tank. A tea making tank cover is provided with a steam outlet and a water inlet connector. The water inlet connector is connected with a water inlet pump. A filter screen is arranged in the tea making tank. A water outlet connector is arranged at the bottom at the side face of the tea making tank and connected with a tea faucet through a tea outlet tube. The electronic control system is respectively connected with the water inlet pump, the electric heater and the ultrasonic transducer. According to the method and device, beneficial ingredients in the tea leaves can be rapidly extracted and dissolved, the tea making time is shortened, the tea making efficiency is improved by over one time, the energy consumption level is reduced, the extraction efficiency is high, and the tea making cost is reduced.

Owner:JIANGXI KEYI TEA IND CO LTD

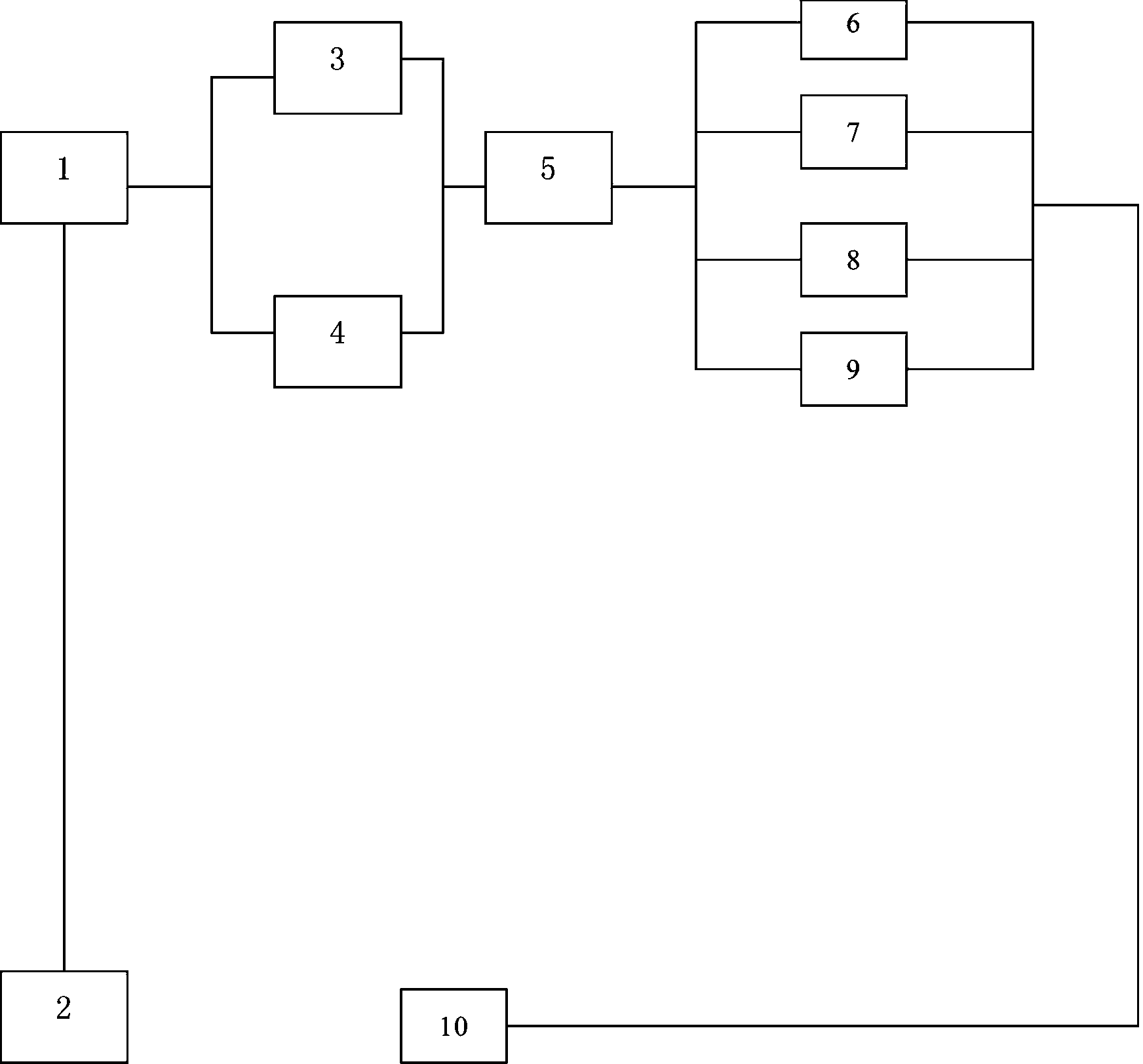

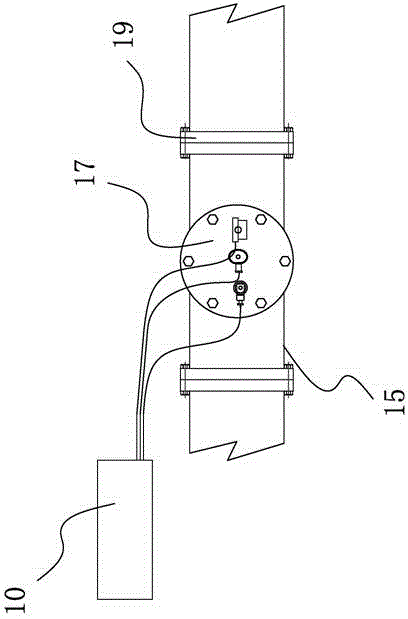

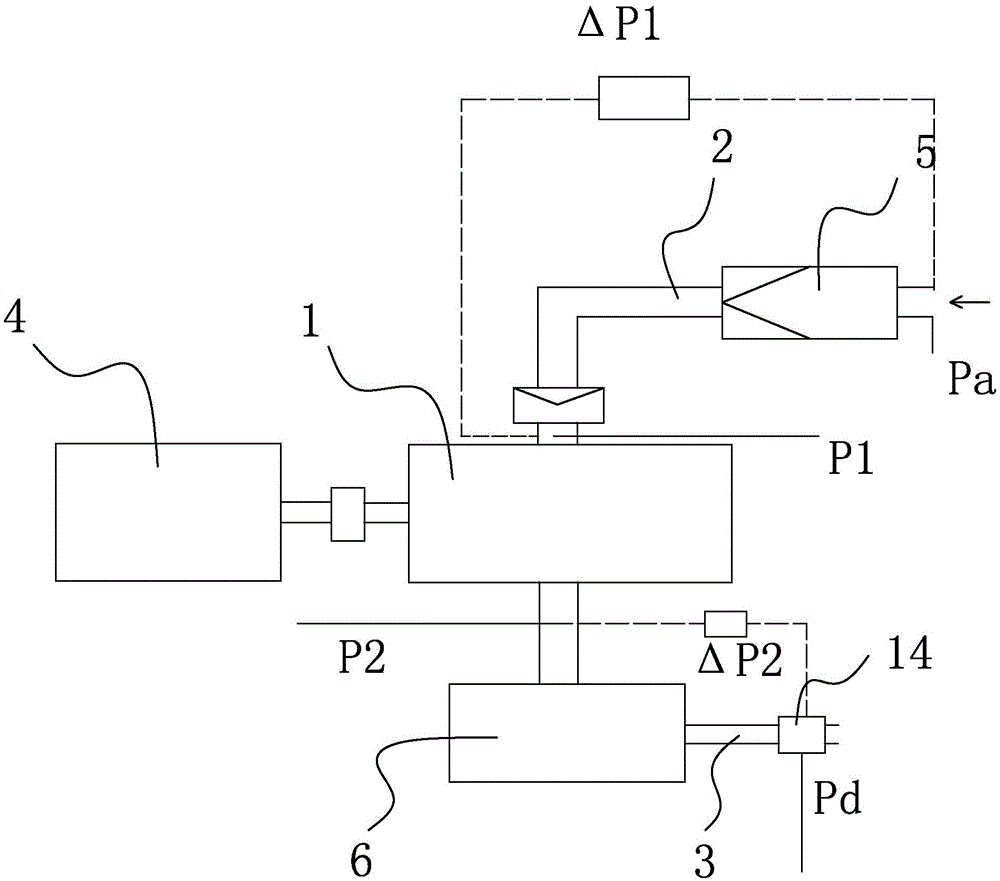

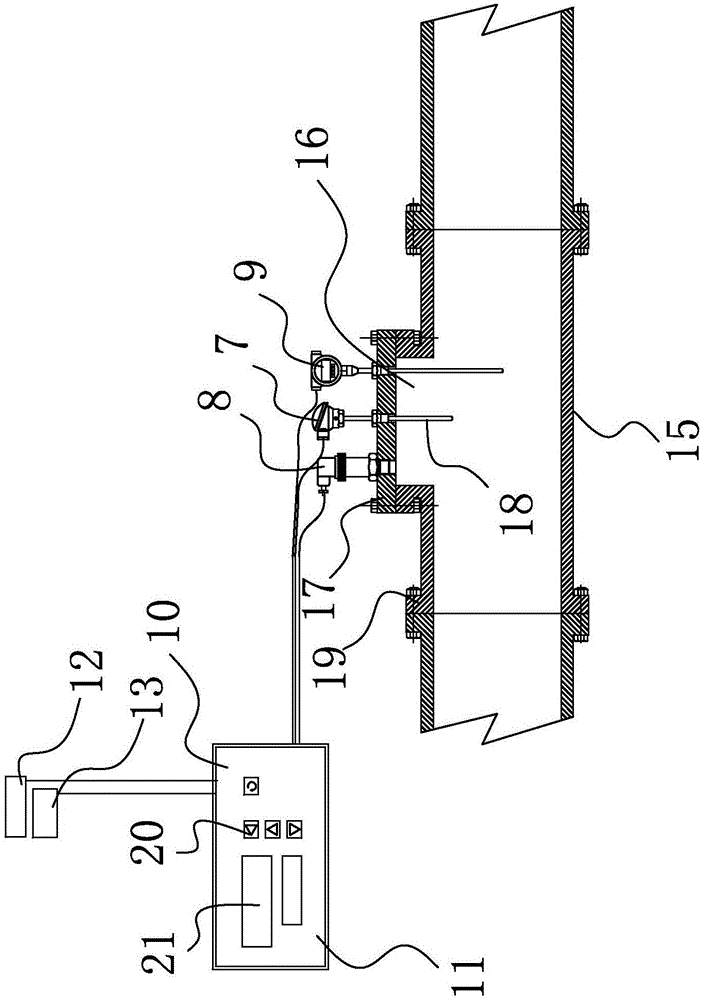

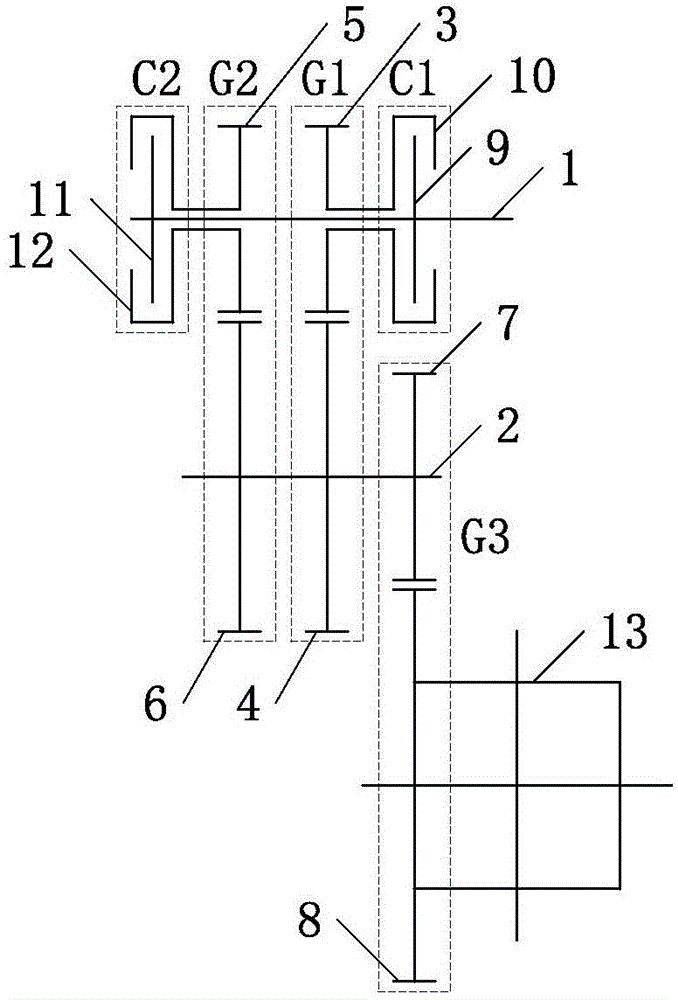

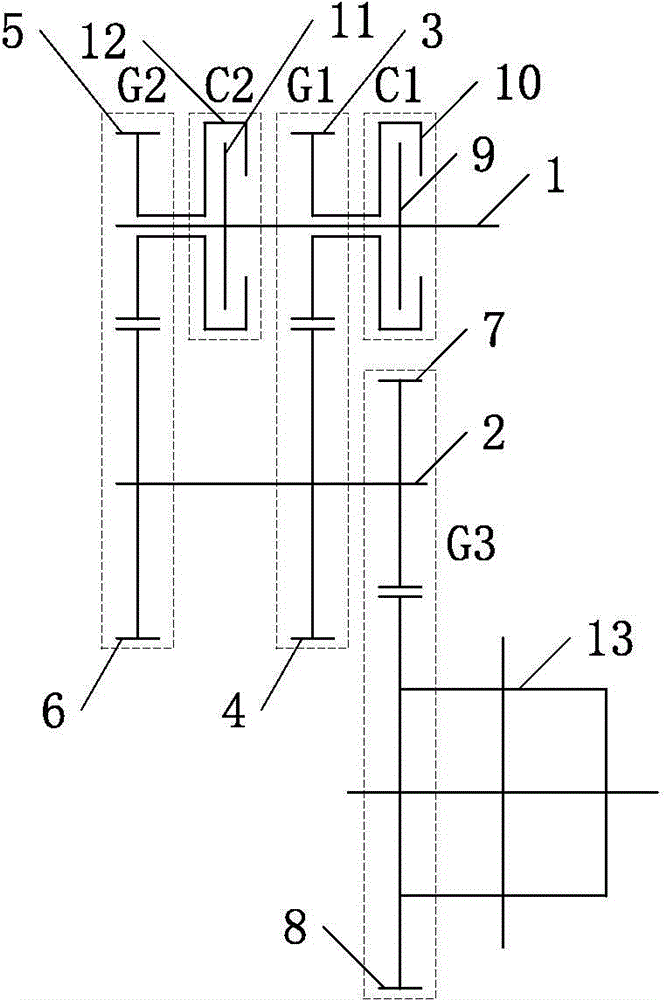

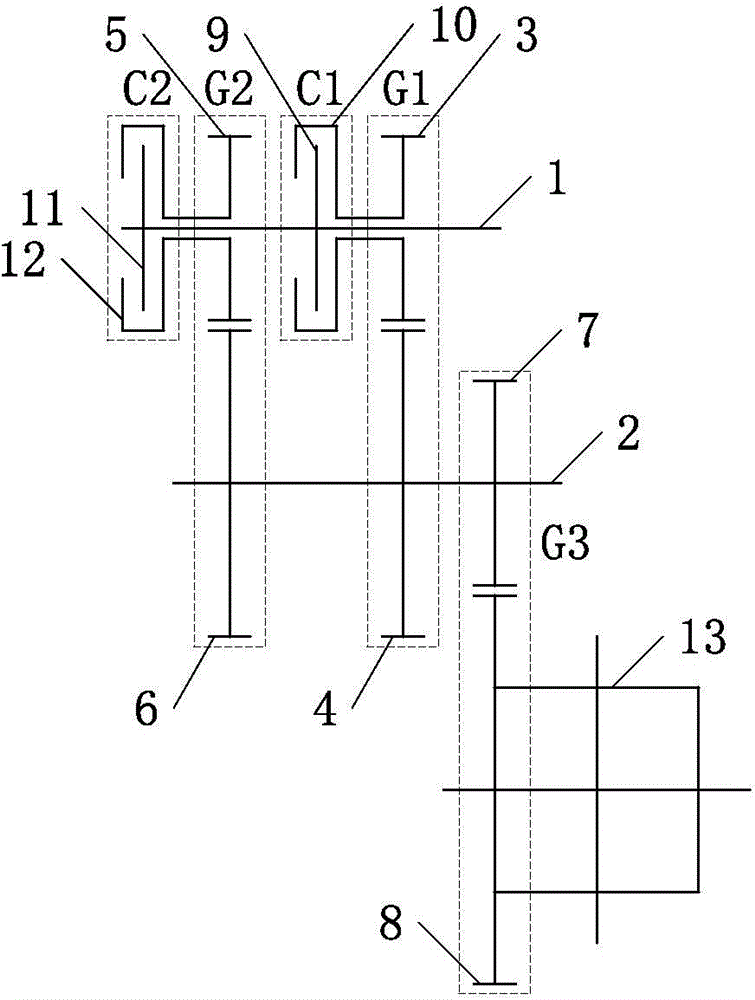

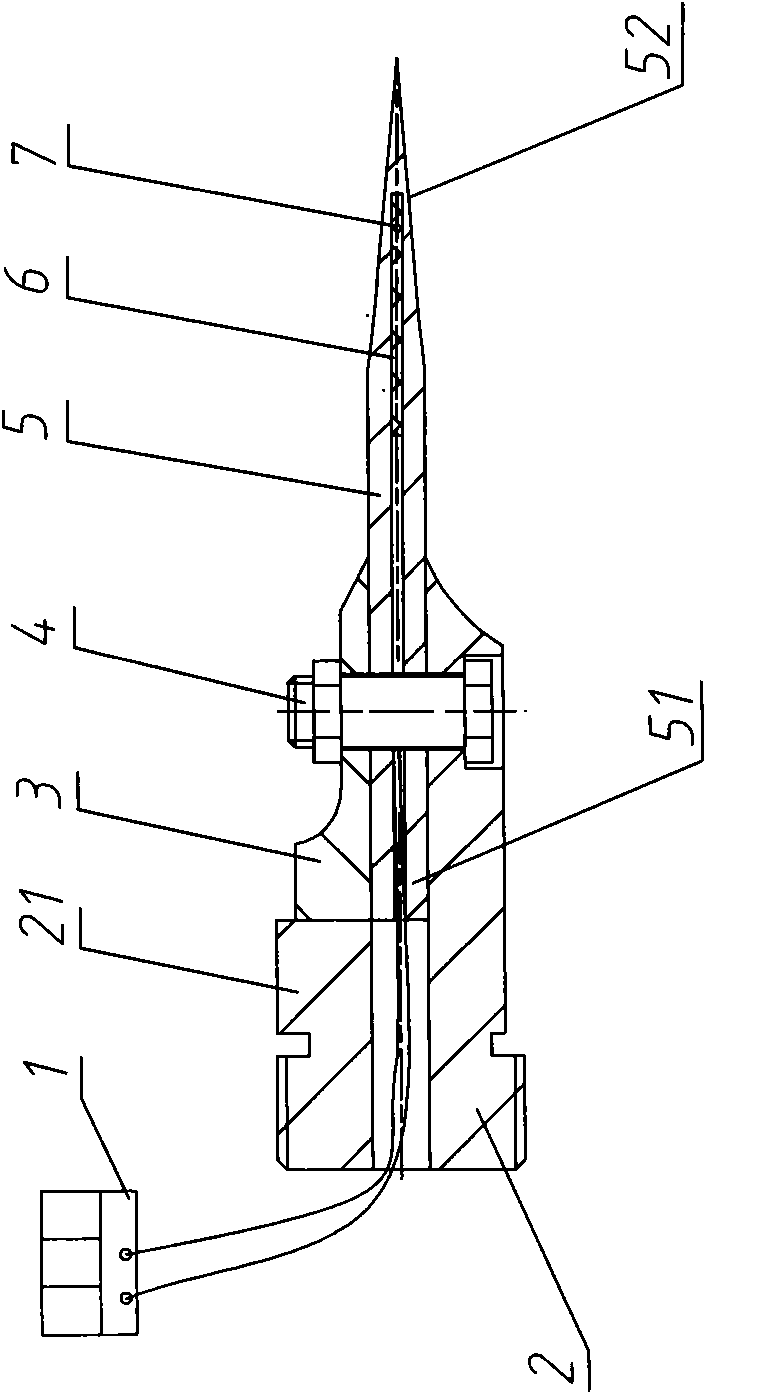

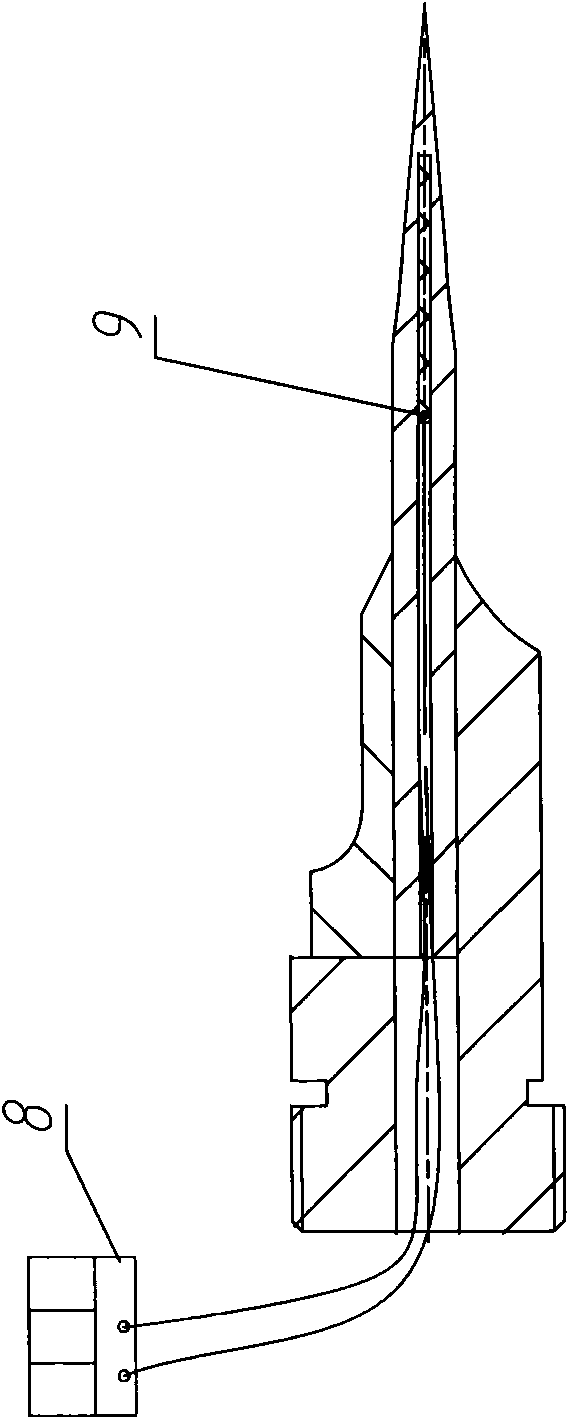

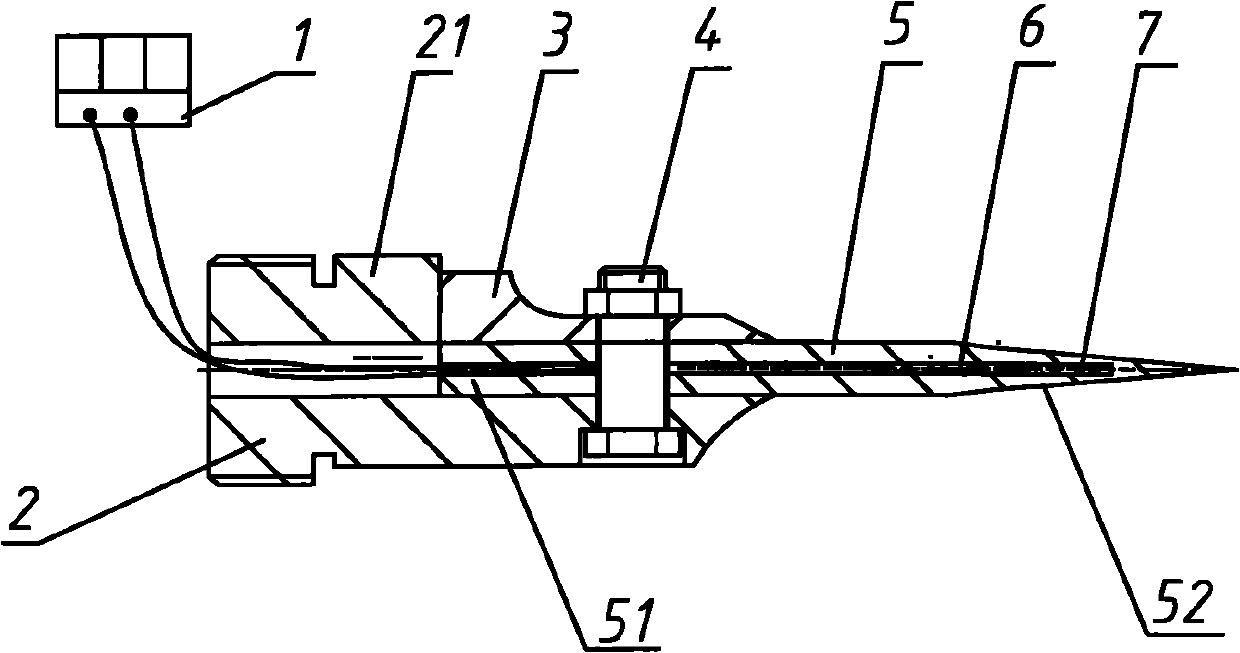

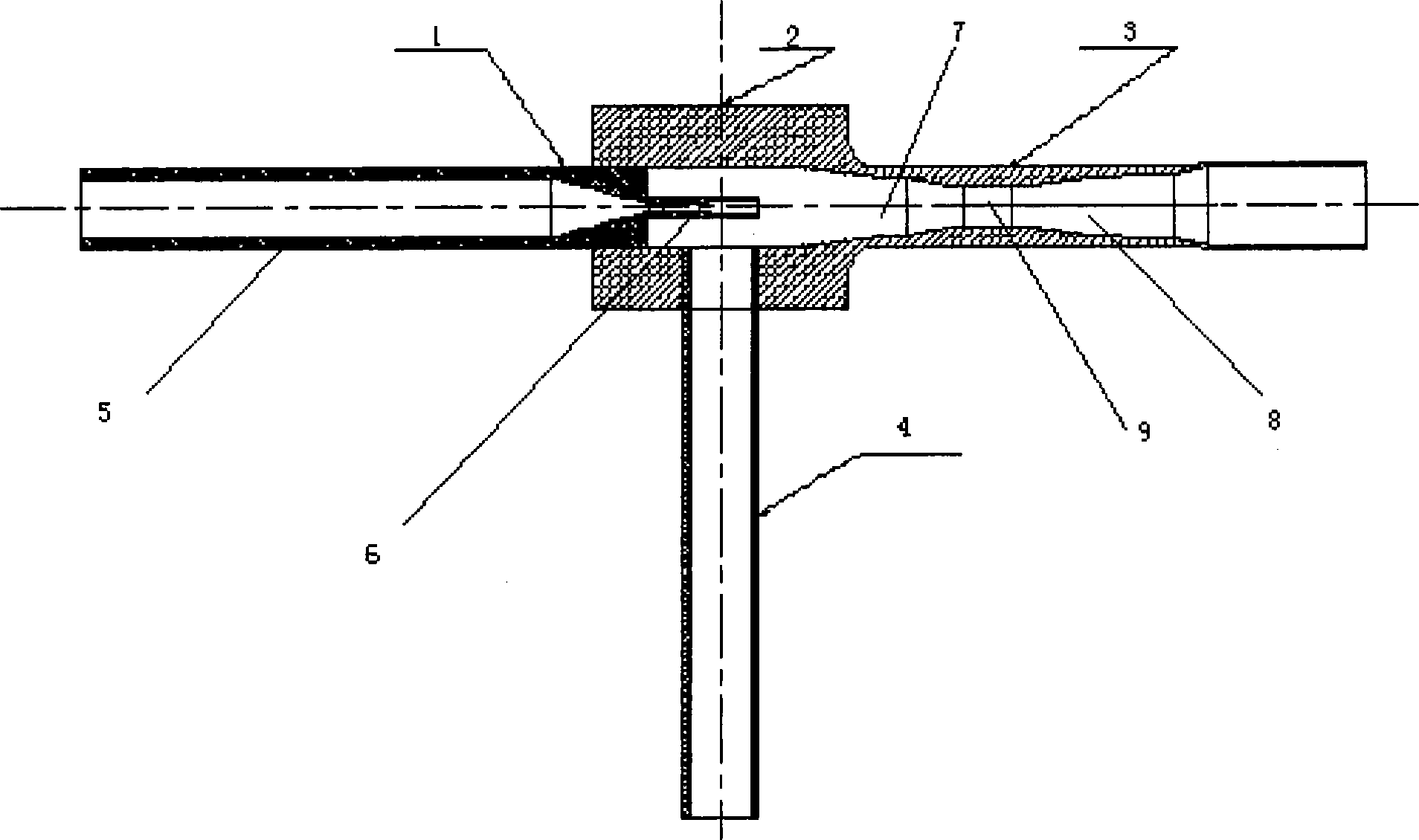

On-line performance diagnostic system and method for rotary air pre-heater

InactiveCN103914063AGuaranteed uptimeLower energy consumption levelsElectric testing/monitoringAir volumeClosed loop

The invention relates to an on-line performance diagnostic system and method for a rotary air pre-heater. The system comprises a computer platform (1) and an operation and overhaul department control device (2). A data processing module (3) and a manual handling unit (4) are arranged in the computer platform (1). Information of the data processing module (3) and the manual handling unit (4) comes from a performance diagnostic technological theory module (5). The performance diagnostic technological theory module (5) comprises a diagnostic module (6) for diagnosing whether the cooling air amount reaches a designed value, a corrosive dust accumulation diagnostic module (7), a heat storage element damage diagnostic module (8) and a cold end air leakage diagnostic module (9) and is used for detecting the performance of the air pre-heater. In addition, the air pre-heater performance diagnostic technological theory module, all sub-modules and an operation and overhaul department control platform are connected through a closed-loop management module (10), so that performance abnormity of the air pre-heater is found and eliminated in time, it is ensured that the air pre-heater is always in an efficient running state, and the energy consumption level of a unit is effectively reduced.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD

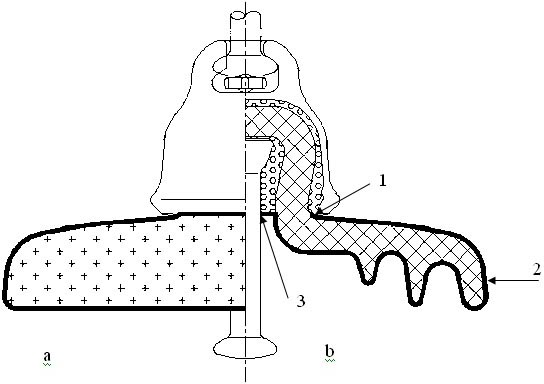

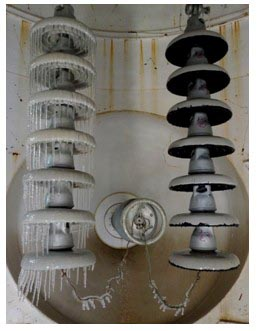

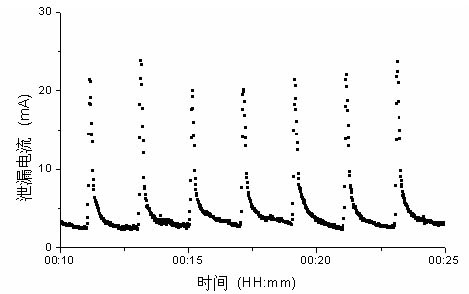

Insulator and transmission line

ActiveCN102511065AWith self-shutdown effectIncrease surface temperatureRubber insulatorsPower cables for overhead applicationConductive coatingEngineering

The present invention discloses an insulator comprising an insulation surface, wherein one part of the insulation surface is coated with conductive coating having special resistivity,the conducting coating area of the special resistivity and the uncondutive coating area are arranged in a discontinuous conduting channel between an upper armour clamp and a lower armour clamp of the insulator under a dry environment,and the conductive coating area of the special resistivity makes the leakage current value caused on the insulation surface reach to the temperature for preventing ice coating under ice coating weather conditions. The utility model also discloses a transmission device using the insulator. under the ice coating weather conditions, the conductive coating can improve the leakage current value of the surface of the insulator so as to prevent ice coating.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

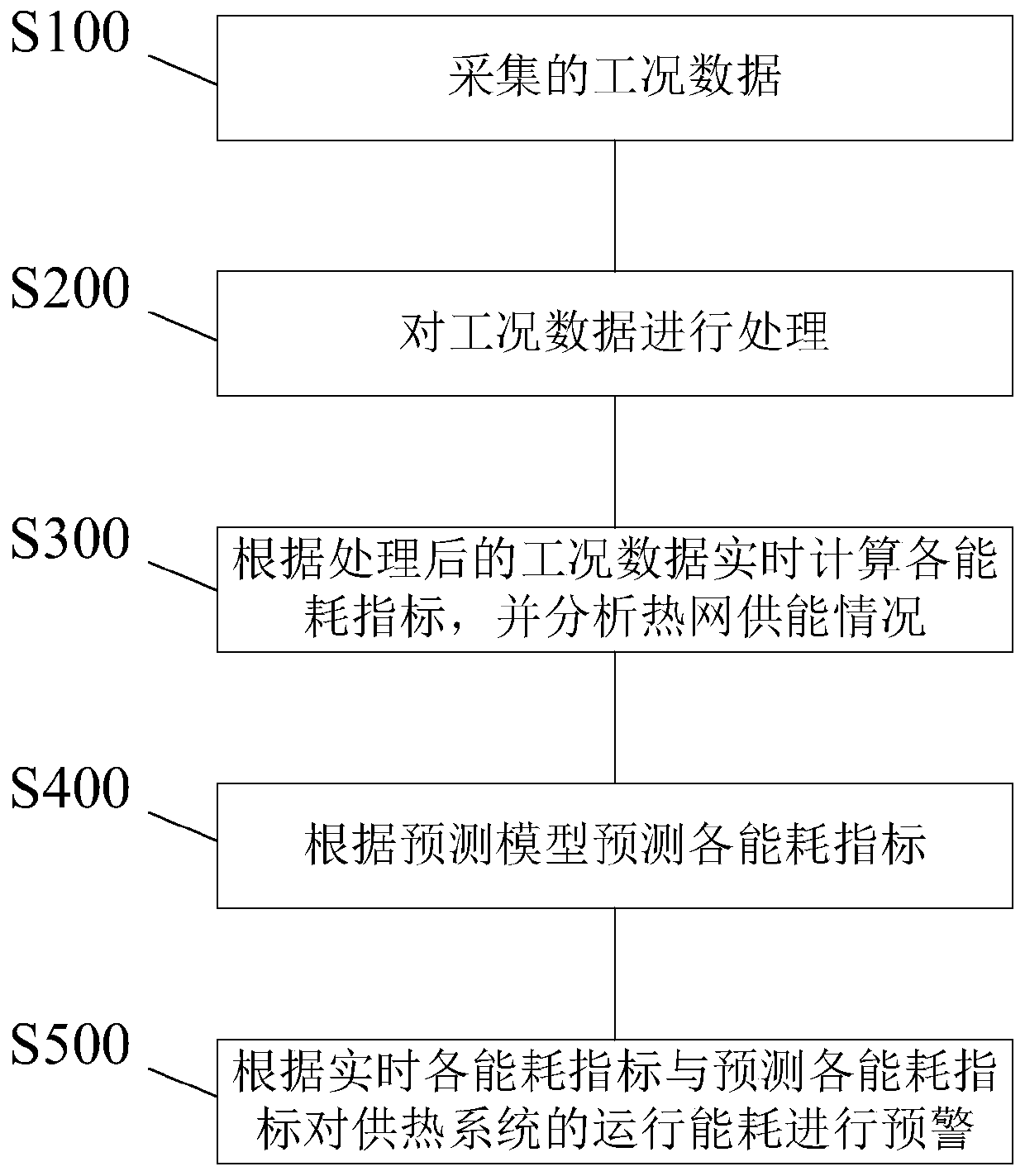

Method and system of heat network energy consumption index analysis and early warning based on BP neural network

ActiveCN110332605ALower energy consumption levelsImprove the degree of refinementLighting and heating apparatusSpace heating and ventilation detailsOperation schedulingEnergy supply

The invention relates to the field of energy consumption analysis and prediction of a heat supply system, and particularly relates to a method and system of heat network energy consumption index analysis and early warning based on a BP neural network. The method of the heat network energy consumption index analysis and early warning based on the BP neural network comprises the following steps thatthe working condition data is collected; the working condition data is processed; energy consumption indexes in real time are calculated according to the processed working condition data, and the energy supply situation of the heat network is analyzed; the energy consumption indexes are predicted according to a prediction model; and early warning is carried out on the operation energy consumptionof the heat supply system according to the real-time energy consumption indexes and the predicted energy consumption indexes, and online analysis and comparison are performed on the energy consumption indexes, the energy consumption level of the operation of the heat supply system can be calculated on line in real time, and energy consumption early warning can be achieved based on a prediction result, an operation scheduling strategy is adjusted, the improvement of the fine degree of operation regulation and control of the heat supply system is facilitated, and the operation energy consumption level of a hot net is reduced.

Owner:CHANGZHOU ENGIPOWER TECH

Method for hydrogenating residual oil

ActiveCN105316037AIncrease hydrogen partial pressureExtend your lifeTreatment with hydrotreatment processesHydrogenGas phase

The invention provides a method for hydrogenating residual oil. The method comprises the steps of firstly carrying out hydrogenating protection reaction on the raw material residual oil in a hydrogenating protection device so as to obtain hydrogenating protection products, then, carrying out hydrotreating reaction on the hydrogenating protection products in a hydrotreater so as to obtain hydrotreating products, and finally, carrying out separation on the hydrotreating products in a separating unit, thereby obtaining recycle hydrogen and a product. The method is characterized in that the hydrogenating protection products are divided into gas-phase and liquid-phase products, the gas-phase product is directly mixed with the hydrotreating products, then, separation is carried out, part of the liquid-phase product is mixed with a mixed hydrogen raw material, the hydrogenating protection reaction is carried out, and the other part of the liquid-phase product is fed to a hydrotreating reactor for hydrotreating reaction. Compared with the prior art, the method provided by the invention has the advantages that the lives of a hydrotreating catalyst and a hydrogenating protection catalyst can be prolonged, and the selectivity of a target product of the hydrogenating protection reaction is improved.

Owner:SINOPEC ENG +1

Crude oil pressure-reduced distillation method and device

InactiveCN102311754AEasy to separateGood stripping effectVacuum distillation separationVacuum distillationHydrogenGas phase

The invention discloses a crude oil pressure-reduced distillation method and a crude oil pressure-reduced distillation device. A flash tower is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, an oil transfer line is eliminated, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and directly enter the flash tower, a small amount of stripping gas is introduced into the flash tower, and the liquid phase, namely flash bottom oil, obtained by gas-liquid separation in the flash tower is introduced into the reduced-pressure distillation tower; and a gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into a liquid phase to be led out of the device. A high-temperature hydrogen or inert gas is introduced into the bottom of the flash tower. When the pressure-reduced distillation method and the pressure-reduced distillation device, in which the flash tower for high-temperature hydrogen or inert gas stripping flash tower is arranged behind the reduced-pressure furnace, are used, the yield of a reduced-pressure fraction oil is increased, the conventional reduced-pressure oil transfer line is not used, the operation load of the reduced-pressure furnace is lowered, and the tower diameter of the reduced-pressure tower can be reduced properly; therefore, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Air compressor efficacy instrument and efficacy calculating method thereof

ActiveCN105090003AEasy to adjustAdjust in timePump testingPositive-displacement liquid enginesEngineeringAir compressor

The invention belongs to the technical field of energy conservation and emission reduction and relates to air compressor detection, in particular to an air compressor efficacy instrument and an efficacy calculating method thereof. The technical problem that the design in the prior art is not reasonable enough and the like is solved. The efficacy instrument comprises a temperature sensor, a pressure sensor and a flow sensor, wherein the temperature sensor, the pressure sensor and the flow sensor are respectively connected with a central processor used for calculating the efficacy of the air compressor, and an input device used for inputting parameters is connected to the central processor. The air compressor efficacy instrument and the efficacy calculating method thereof have the advantages that the design is reasonable, and the structure is simple; and the efficacy of the air compressor can be conveniently, rapidly and visually obtained so as to timely regulate the air compressor, thereby effectively saving energy consumption and promoting the air compressor to lie in the optimum work state.

Owner:浙江联核动力科技有限公司

Crude oil distillation method

The invention discloses a crude oil distillation method. A primary flash distillation tower is arranged between a normal pressure distillation tower and a pressure reduction furnace, a pressure reduction oil line from an outlet of the pressure reduction furnace to a pressure reduction distillation tower is omitted, a secondary flash distillation tower is arranged between the pressure reduction furnace and the pressure reduction distillation tower, tower bottom heavy oil of the normal pressure distillation tower, i.e. normal bottom oil enters the primary flash distillation tower after being mixed with cyclic pressure reduction slag oil, the tower top gas phase of the primary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the primary flash distillation tower enters the secondary flash distillation tower through being heated by the pressure reduction furnace, the tower top gas phase of the secondary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, and bottom oil of the secondary flash distillation tower is introduced into a flash distillation section of the pressure reduction distillation tower for pressure reduction distillation. Compared with the prior art, the method has the advantages that on one hand, the yield of the pressure reduction slag oil is reduced, and the economic benefits of devices are improved; and on the other hand, the load of the pressure reduction furnace and the pressure reduction distillation tower is reduced, the device investment is saved, and the energy consumption of the devices is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reduced pressure distillation method with low energy consumption and deep total distillation rate

ActiveCN103242896AIncrease gasification rateReduce pressure drop lossTreatment with plural serial refining stagesThermodynamicsEconomic benefits

The invention discloses a reduced pressure distillation method with low energy consumption and deep total distillation rate. By arranging a reduced pressure flashing tower behind a reduced pressure heating furnace, light fractions vaporized by heat are separated out, load of a reduced pressure distillation tower is reduced and energy consumption of an apparatus is reduced; by arranging a reduced pressure flashing tank behind the reduced pressure distillation tower, relatively light fractions in reduced pressure residues can be further flashed under a vacuum degree higher than that of the bottom of a reduced pressure distillation tower, yield of reduced pressure distillate oil is increased, and thus a reduced pressure distillation operation with low energy consumption and deep total drawing rate can be realized. With the reduced pressure distillation method, the content of fractions with a temperature lower than 500 DEG C in the reduced pressure residues can be reduced to the minimum, so that the distillation rate of the reduced pressure distillation is increased and economic benefits of the apparatus can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

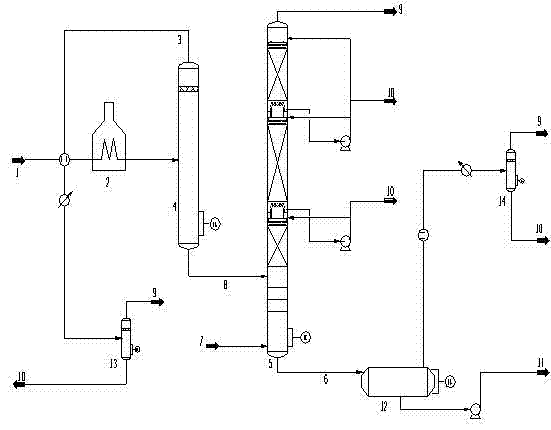

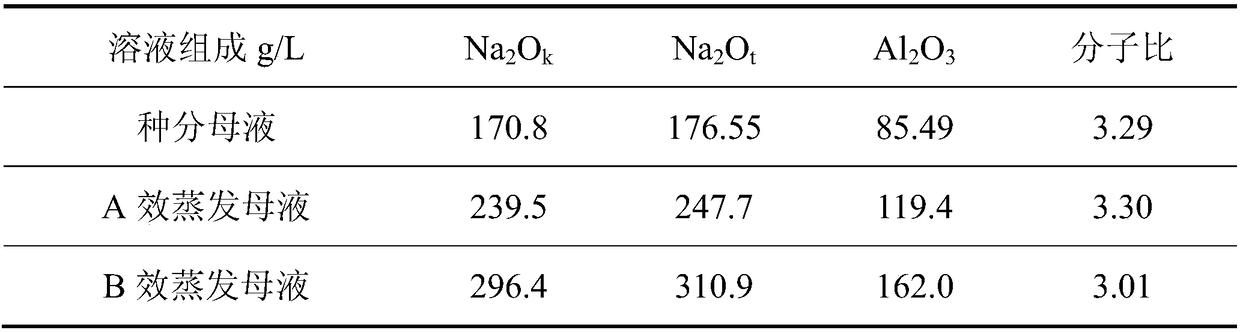

Method for improving production efficiency of aluminium oxide produced with Bayer process

InactiveCN108658111ASave big investmentImprove medium circulation efficiencyAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationChemistryMother liquor

The invention relates to a method for improving production efficiency of aluminium oxide produced with the Bayer process. According to the method, caustic soda flakes required to be supplemented for an aluminium oxide plant are subjected to a reaction with Bayer-process seeded precipitation spent liquor or evaporation mother liquor, a sodium aluminate solution with high alkali and high molecular ratio is formed, and carbon alkali removal and causticizing of Bayer mother liquor can be realized without forced effect evaporation and other processes; by means of efficient crystallization of sodiumaluminate hydrate as an intermediate product, circulating efficiency of dissolution media and production capacity of the conventional equipment can be improved. Synchronous salt elimination and causticizing and improvement of medium circulating efficiency can be realized on the premise that other substances or energy are or is not input; the newly added sodium aluminate hydrate crystallization process is mild in condition, equipment investment is low, industrial controllability is high, and economic benefit is obvious. The aluminium oxide product prepared with the method is identical to thatof the aluminium oxide product produced with the Bayer process, no new waste gas, waste liquor or solid waste is produced, and energy conservation and environmental protection are realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Two-gear automatic transmission for battery electric vehicle

InactiveCN104633015ACompact structureLight in massElectric propulsion mountingToothed gearingsManufacturing cost reductionAutomatic transmission

A two-gear automatic transmission for a battery electric vehicle comprises an input shaft, an intermediate shaft, a first cylindrical gear pair, a second cylindrical gear pair, a third cylindrical gear pair, a first torque transfer device, a second torque transfer device and a differential assembly. The rotating central lines of the input shaft, the intermediate shaft and the differential assembly are mutually parallel. A driving motor, an automatic transmission and a driving bridge are integrated to form a whole, a transmission ratio range is widened, the performance requirement of the driving motor is remarkably reduced, the two-gear automatic transmission is simple and compact in structure, light in weight, stable in transmission and wide in transmission ratio range and has very high power transfer efficiency, energy consumption level is reduced, the power performance and economical efficiency of the whole vehicle are improved, and manufacturing cost is remarkably reduced.

Owner:BEIHANG UNIV

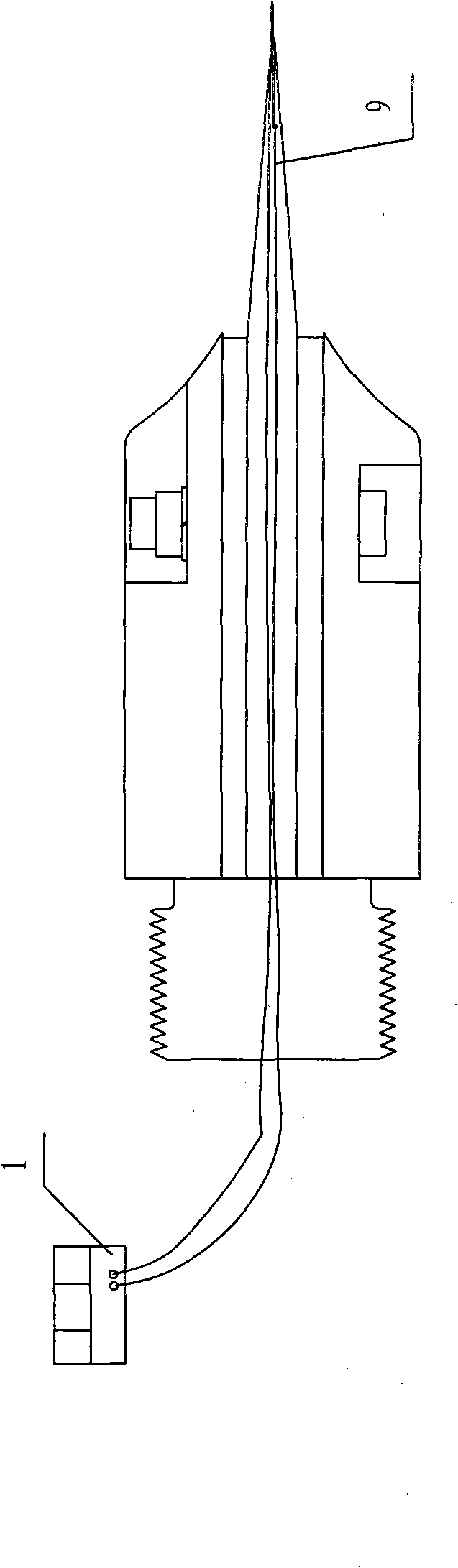

Internally conductive hot cut-off knife and method thereof

InactiveCN102476393AHeating up fastAccurate perception fastMetal working apparatusTemperature controlHeat transmission

The invention provides an internally conductive hot cut-off knife and a method thereof. A heat supply element and a temperature sensor are installed in the interior of a knife edge part of a knife body so that produced heat energy is acted on a knife edge directly and cutting operation is performed while hot melting is performed on the surface of a sizing material; and the heat source is installed on the knife edge part for performing the cutting operation directly, obvious heat loss is avoided without long distance heat transmission, thereby saving energy effectively. The internally conductive hot cut-off knife comprises a lower fixture body, an upper fixture body and the knife body, wherein the knife body comprises a base part clamped and fixed between the lower fixture body and the upper fixture body and the knife edge part for cutting on the surface of the sizing material; and the heat supply element for directly acting the heat energy on the knife edge and the temperature sensor which is used for connecting with an external power supply and a temperature control instrument and detecting work temperature on the surface of the knife edge are installed in the knife edge part.

Owner:MESNAC

Compressing and injecting mixed cycle refrigerating method and device for electric refrigerator

InactiveCN101109595AImprove cooling effectLower energy consumption levelsFluid circulation arrangementRefrigeration devicesTemperature differenceEngineering

The invention provides a method for compression-jetting mixed circulation refrigeration for a refrigerator and the arrangement for the circulation refrigeration. Wherein, an injector is connected between the outlets of two evaporimeters of the refrigerating chamber and the freezing chamber of the refrigerator and an air-return pipe of the compressor, so as to mix the refrigerant of different pressures generated by the two evaporimeters of the refrigerating chamber and the freezing chamber, hence form a mixed flow of moderate pressure, which enters into the air-return pipe of the compressor, this will increase the pressure of the returned air of the compressor, and reduce the pressure ratio, and improve the refrigerating performance of the compressor. The invention is of simple structure, easy to manufacture, low cost, and runs reliably, is applicable for connecting with pipelines of different refrigerator systems to improve the evenness and controllability of the temperature in the refrigerating chambers, and reduce the loss in useable energy due to too high temperature difference in the refrigerating chambers, hence to save energy for refrigerators. The invention is applicable for industrial production.

Owner:CENT SOUTH UNIV +1

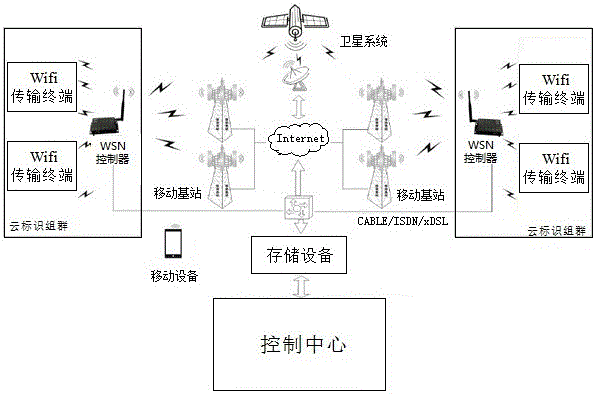

Smart city Wifi information transmission system

InactiveCN105916159AOverall safety is goodRealize cross-level transferNetwork planningOn columnInformation transmission

The invention discloses a smart city Wifi information transmission system which comprises a cloud identification group composed of a plurality of Wifi transmission terminals, a satellite system, mobile base stations, a storage device and a control center. Information is emitted to the satellite system through the Wifi transmission terminals, then is forwarded to each mobile base station for conversion processing and enhancement and finally is transmitted to the storage device, the control center and each processing terminal. The Wifi transmission terminals are installed on column tops of each city name guiding identification system, and the city area is completely covered by means of a point array layout. According to the invention, a wireless sending mode is adopted, the integral safety of the system is good, information is transmitted by a three-dimensional space, a multi-level matrix structure formed by the transmission terminals, the satellite system, the mobile base stations and the control center is formed, information cross-level transmission can be realized, and the system is high in response degree, flexible in operation and control and not liable to be damaged by the external world.

Owner:GREEN PHIL INTELLIGENT TECH JIANGSU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com