Method and device for making tea for machine

A tea and black tea technology, applied in the field of tea art, can solve the problems of insufficient utilization of active ingredients, unsatisfactory dissolution efficiency of beneficial ingredients, and increased tea making cost, so as to improve tea making efficiency and tea utilization rate, and reduce brewing efficiency. The level of tea energy consumption and the effect of reducing the cost of making tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

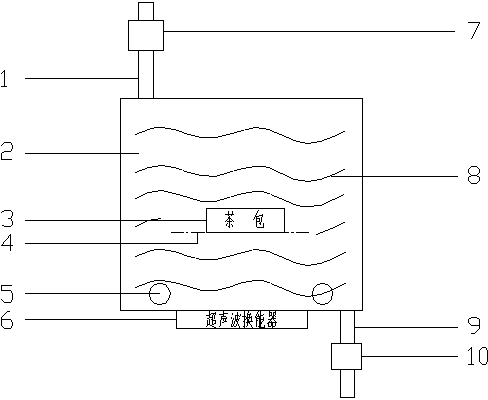

[0036] The tea making device of this embodiment includes a water inlet pipe 1, a tea making tank 2, a filter screen 4, an electric heater 5 with temperature control, an ultrasonic transducer 6, a water inlet pump 7, a tea outlet pipe 9, a tea faucet 10, an electric control system. The electric heater 5 with temperature control is installed at the bottom inside the tea making tank 2; the ultrasonic transducer 6 is installed at the bottom outside the tea making tank 2; The water pumps 7 are connected; the cover of the tea-making tank 2 is also provided with a steam outlet, which is used to discharge the steam generated when the water is heated in the tea-making tank; a filter screen 4 is provided in the tea-making tank 2, which is used to hold tea leaves or tea bags 3 , to prevent tea or other solids from being discharged with the tea; the bottom of the side of the tea making tank 2 is provided with a water outlet joint, which is connected to the tea faucet 10 through the tea ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com