Integrated device for large-scale low-voltage breaker high-current tests

A low-voltage circuit breaker and high-current technology, which is applied in the field of integrated test devices for high-current detection of low-voltage circuit breakers, can solve the problems of reducing the production efficiency of enterprises, long detection time, high electric energy, etc., so as to improve production efficiency and equipment reliability. , The crimping process is convenient and fast, and the effect of reducing the power consumption of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the structural features and functions of the patent of the present invention more clearly, the patent of the present invention will be described in detail below in conjunction with the accompanying drawings of specific embodiments. The implementation case is a specific description of the technical solution of the patent of the present invention, but it is not a limitation of the scope of protection of the patent of the present invention.

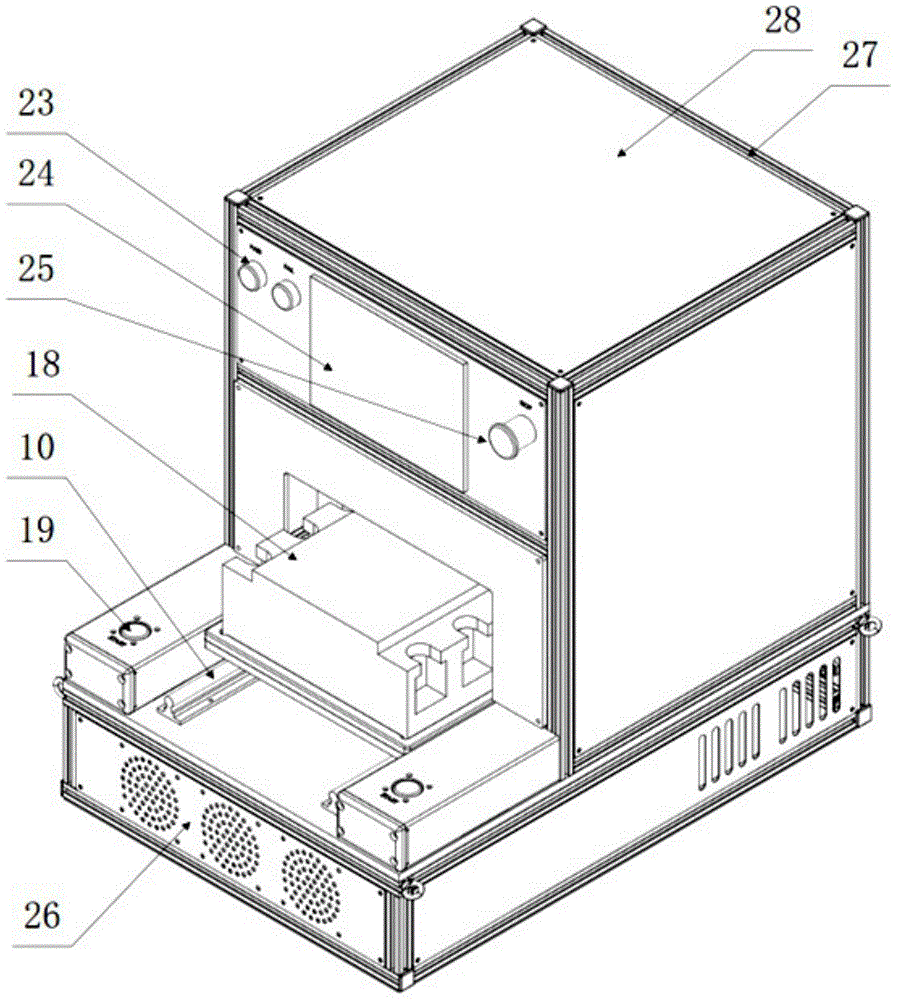

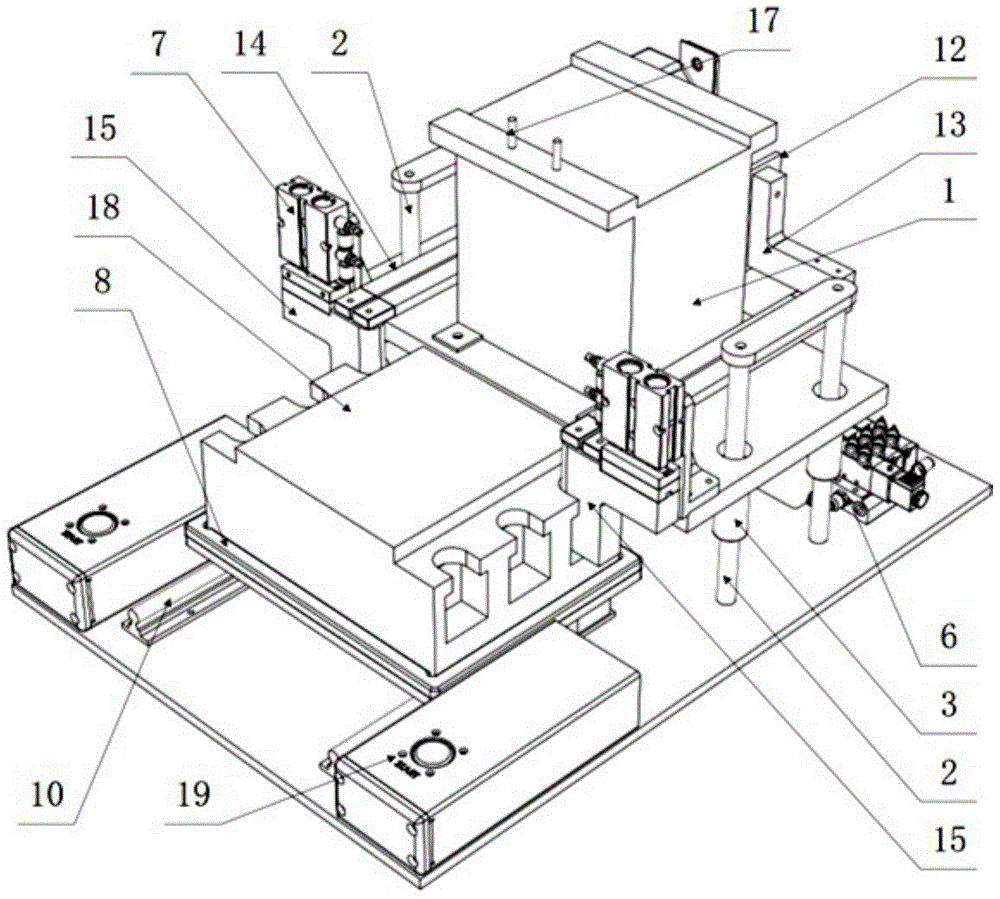

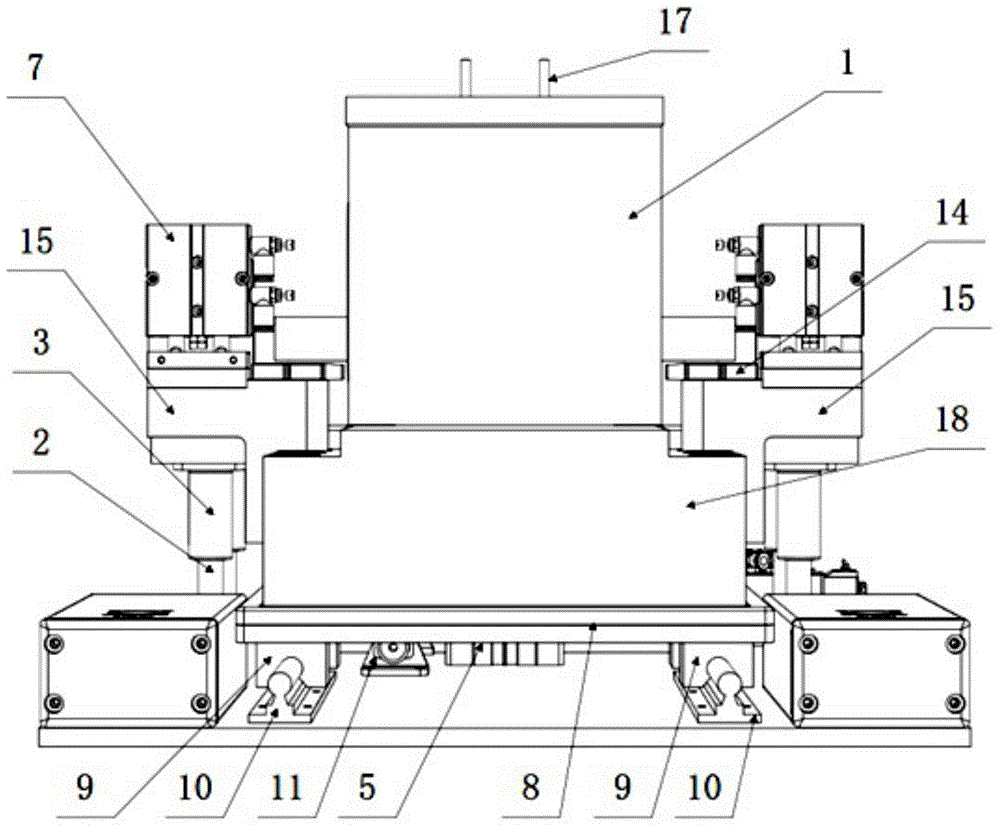

[0035] The integrated device for large-scale low-voltage circuit breaker high-current test in the present invention includes a detection power supply 29 using a three-phase power supply, a vertical crimping mechanism, an auxiliary crimping mechanism, a horizontal positioning mechanism, a return busbar, a transformer 1, and a man-machine interface With the central controller; the horizontal positioning mechanism, the auxiliary crimping mechanism and the vertical crimping mechanism are arranged on the mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com