Compressing and injecting mixed cycle refrigerating method and device for electric refrigerator

A technology of jet mixing and refrigeration device, applied in household refrigeration devices, cooling fluid circulation devices, refrigerators, etc., can solve problems such as loss of available energy, and achieve the effect of reducing pressure ratio, long-term reliable operation, and reducing overall energy consumption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

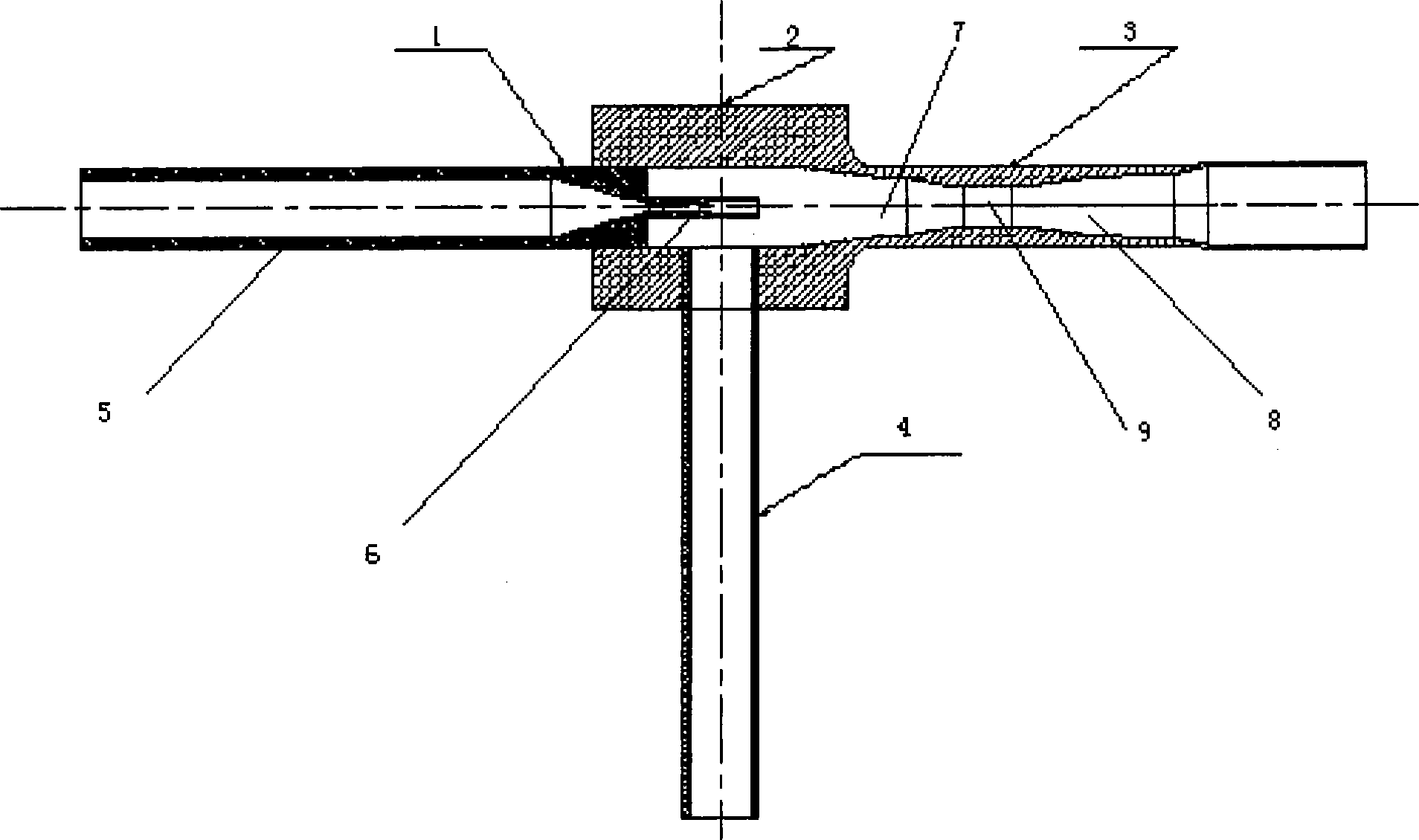

[0015] Referring to the accompanying drawings, the present invention---refrigerator compression / jet hybrid cycle refrigeration device is to connect an ejector between the two evaporator outlets of the refrigerator and the freezer and the return air pipe of the compressor, and the ejector It consists of four parts: working nozzle 1, absorption chamber 2, injection pipe 4 and diffuser pipe 3. The absorption chamber 2 is a three-way pipe, and one end of the through hole in the axial direction of the three-way pipe is connected to the working nozzle 1, and the other end is connected to There is a diffuser pipe 3, and an ejector pipe 4 is connected to the third through hole of the tee pipe; the working nozzle 1 is composed of a nozzle body 5 and a nozzle throat 6, and the nozzle body 5 and nozzle throat 6 Conical through-holes are arranged in the axial direction, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com