Synergistic gas-liquid-solid pollutant treatment system based on power plant wastewater zero-discharge technology

A power plant wastewater and collaborative treatment technology, applied in the direction of heating water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of system integration and coupling to be further improved, and achieve economical improvement Performance indicators and overall operating efficiency, improving integration, and optimizing the effect of operating status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A coal-fired power plant is equipped with two 330MW coal-fired generating units. Under the operating condition of the two units running at the same time, and the average power generation load of the whole plant is close to 70% of the rated load, the average desulfurization wastewater discharged from the desulfurization system is 8.4t / h, boiler outlet NO x The average concentration is 600mg / m 3 (Standard state, dry basis, 6% oxygen), the SCR denitrification system is equipped with 3 layers of catalysts.

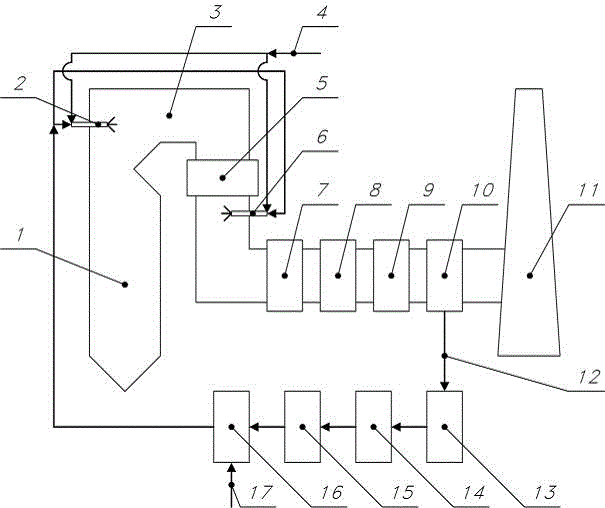

[0041] This embodiment system refers to figure 1 , will not be repeated, wherein, the SNCR nozzle 2 of each unit is a 3-layer spray gun, and each layer is provided with 9 spray guns, and the SCR nozzle 6 is a single-layer spray gun, and each unit is provided with 2 spray guns. In the specific operation process, most of the time only SNCR nozzle 2 works, while SCR nozzle 6 does not work, only when the NO x When the concentration rises rapidly, the SCR nozzle 6 is put...

Embodiment 2

[0048] A coal-fired power plant is equipped with two 350MW coal-fired generating units. Under the operating condition of the two units running at the same time, and the average power generation load of the whole plant is close to 75% of the rated load, the average desulfurization wastewater discharged from the desulfurization system is 10t / h, boiler outlet NO x The average concentration is 650mg / m 3 (Standard state, dry basis, 6% oxygen), the SCR denitrification system is equipped with 3 layers of catalysts.

[0049] This embodiment system refers to figure 1 , will not be repeated, wherein, the SNCR nozzle 2 of each unit is a 3-layer spray gun, and each layer is provided with 9 spray guns, and the SCR nozzle 6 is a single-layer spray gun, and each unit is provided with 2 spray guns. In the specific operation process, most of the time only SNCR nozzle 2 works, while SCR nozzle 6 does not work, only when the NO x When the concentration rises rapidly, the SCR nozzle 6 is put ...

Embodiment 3

[0056] A coal-fired power plant has two 660MW ultra-supercritical coal-fired units installed. When the two units are running at the same time and the average power generation load of the whole plant is close to 80% of the rated load, the average desulfurization wastewater discharged from the desulfurization system is 14t / h, boiler outlet NO x The average concentration is 550mg / m 3 (Standard state, dry basis, 6% oxygen), the SCR denitrification system only has 2 layers of catalysts.

[0057] This embodiment system refers to figure 1 , No need to repeat, wherein, the SNCR nozzle 2 of each unit is a 3-layer spray gun, and each layer is provided with 15 spray guns, and the SCR nozzle 6 is a single-layer spray gun, and each unit is provided with 4 spray guns. In the specific operation process, most of the time only SNCR nozzle 2 works, while SCR nozzle 6 does not work, only when the NO x When the concentration rises rapidly, the SCR nozzle 6 is put into operation as a supplement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com