Method for hydrogenating residual oil

A technology for residual oil hydrogenation and residual oil, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, and can solve the internal layout of the undisclosed hydrogenation protection reactor, the increase of the average flow rate of the mixed phase, and the increase of the circulating hydrogen system Problems such as pressure drop, to achieve the effect of prolonging life, reducing total temperature rise, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

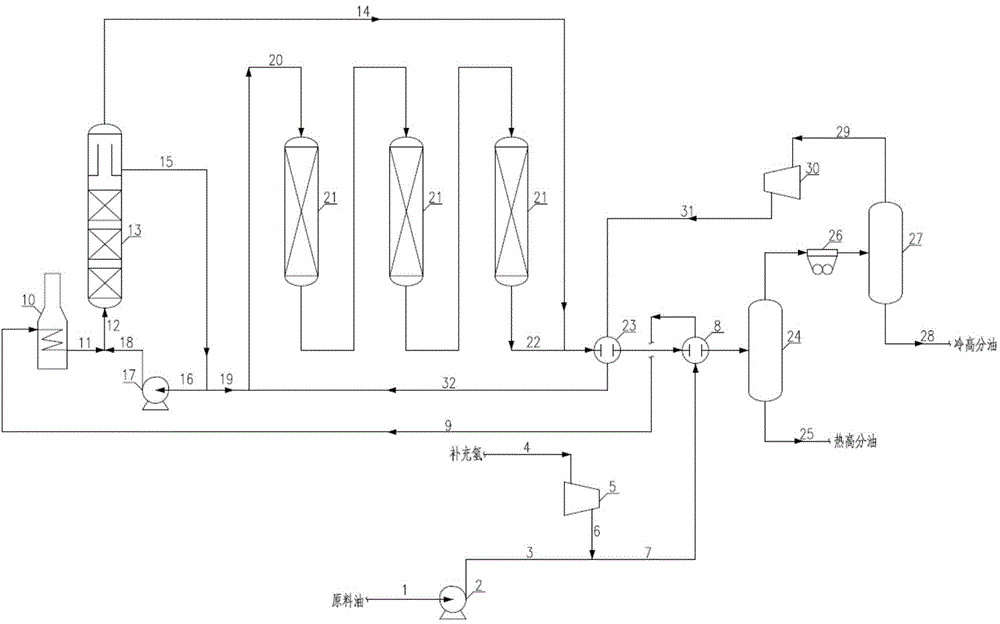

[0073] This embodiment will further describe a specific implementation manner of the present invention with reference to the accompanying drawings.

[0074] see figure 1 , after the raw material residual oil 1 is boosted by the feed pump 2, it is first mixed with the supplementary hydrogen 6 boosted by the supplementary hydrogen compressor 5. The mixture is a gas-liquid two-phase hydrogen-mixed raw material 7, and then the 8 heat exchange, then sent to the heating furnace 10 entrance. The hydrogen-mixed raw material oil is heated to the temperature required by the reaction in the heating furnace, and then mixed with the booster circulating oil 18, and then enters the upward hydrogenation protection reaction separator 13 from the bottom. Under the action of the catalyst, the hydrogen-mixed raw material undergoes hydrogenation reaction in the reaction zone of the upward hydrogenation protection reaction separator, and most of the heavy metals, calcium, sodium, iron, and solid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com