Patents

Literature

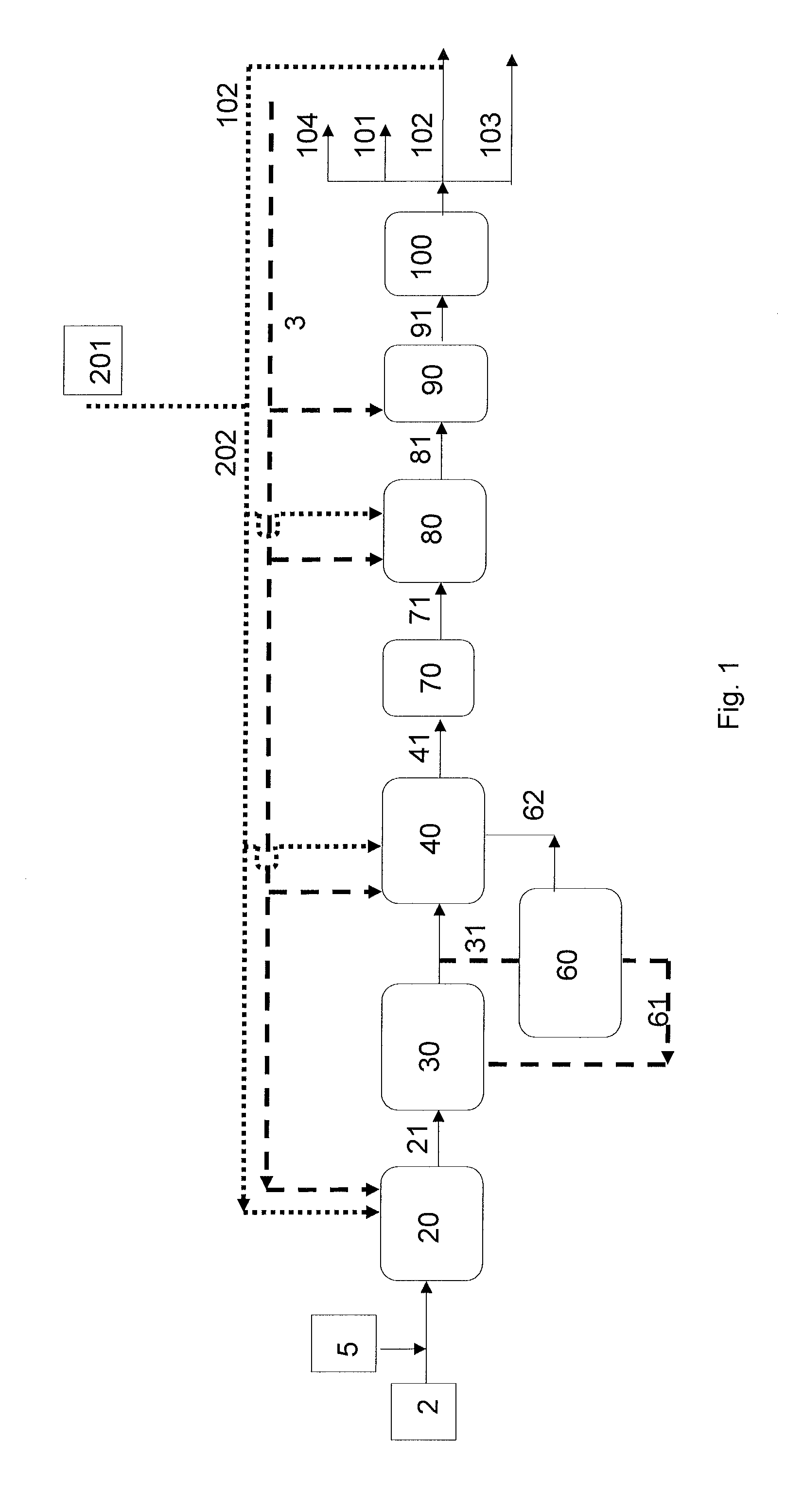

82results about How to "Increase hydrogen partial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing a branched hydrocarbon component

InactiveUS20070135316A1Reduce carbon dioxide emissionsImprove stabilityOrganic compound preparationCatalytic naphtha reformingIsomerizationHydrodeoxygenation

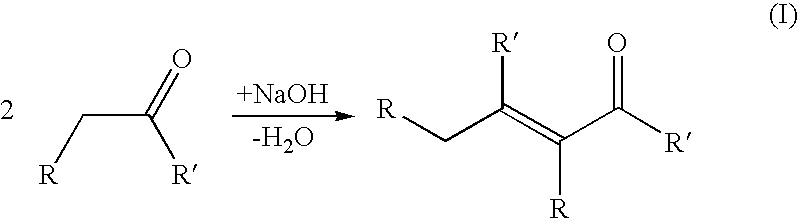

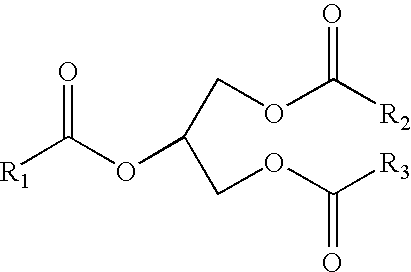

The invention relates to a process for producing high-quality hydrocarbon base oil particularly of biological origin. The process of the invention comprises aldol condensation, hydrodeoxygenation, and isomerization steps. Aldehydes and / or ketones, preferably of biological origin are used as the feedstock.

Owner:NESTE OIL OY

Process for producing acetic acid

ActiveUS7476761B2Decrease in reaction rate can be inhibitedIncrease hydrogen partial pressurePreparation from carboxylic acid saltsOrganic compound preparationCarbon numberReaction rate

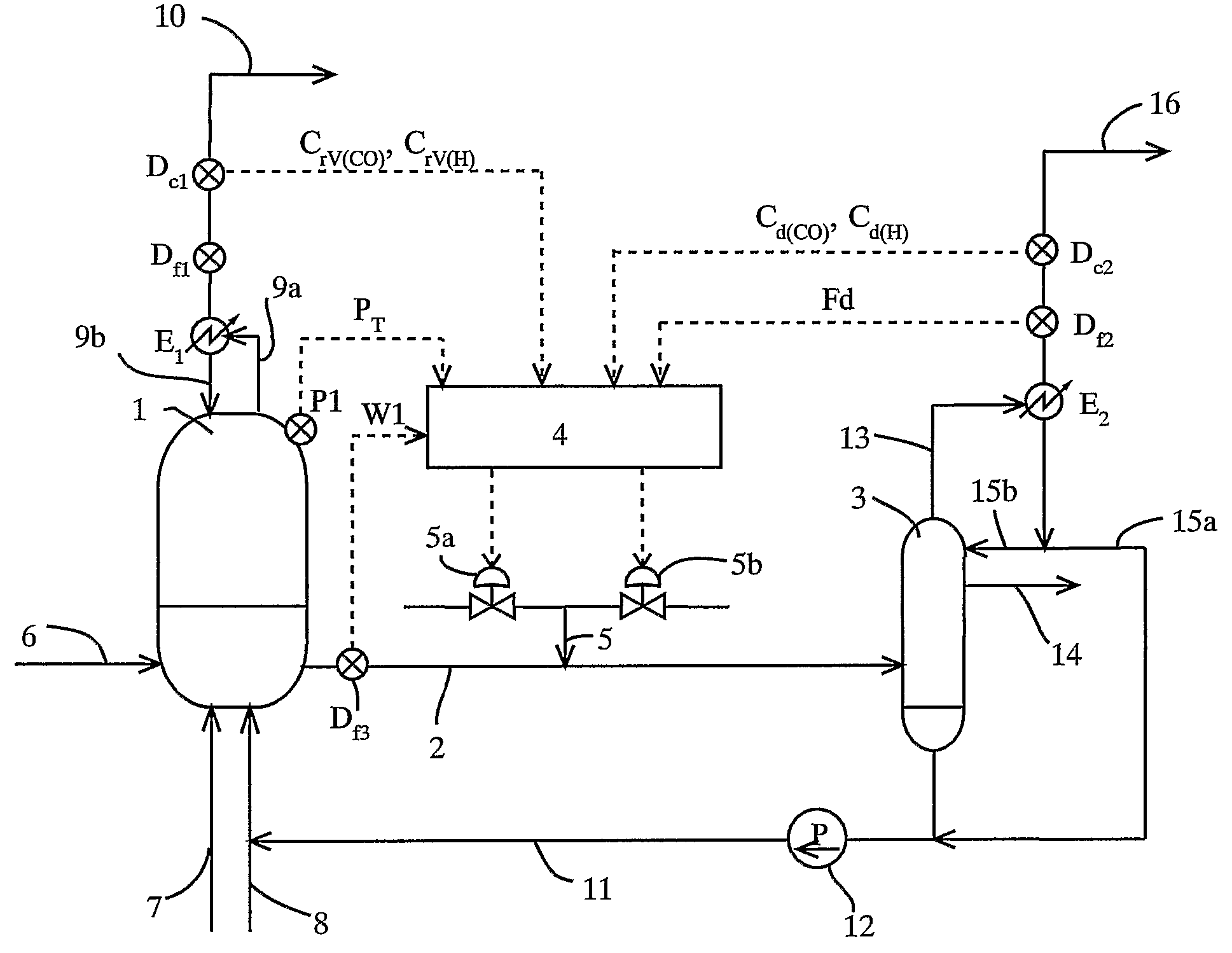

A process for producing a carboxylic acid comprises allowing an alcohol having a carbon number of “n” to continuously react with carbon monoxide in the presence of a carbonylation catalyst system, and a limited amount of water, continuously withdrawing the reaction mixture from the reaction system 1, introducing the withdrawn reaction mixture into a distillation step (distillation columns 3a and 3b), and separating a higher-boiling component and a lower-boiling component containing a carboxylic acid having a carbon number of “n+1”, respectively. In the process, the amount of carbon monoxide and / or hydrogen contained in a liquid phase of the reaction system is adjusted to at least one of the following conditions (i) and (ii): (i) the amount of carbon monoxide relative to 1 kilogram of the liquid phase by weight is at least 2 mmol per 1 MPa of carbon monoxide partial pressure of the reaction system, and (ii) the amount of hydrogen relative to 1 kilogram of the liquid phase by weight is at least 50 mmol per 1 MPa of hydrogen partial pressure of the reaction system. Such a process inhibits deactivation of a metal catalyst and deterioration in a reaction rate, and decreases formation of by-products in producing a carboxylic acid under a low water content.

Owner:DAICEL CHEM IND LTD

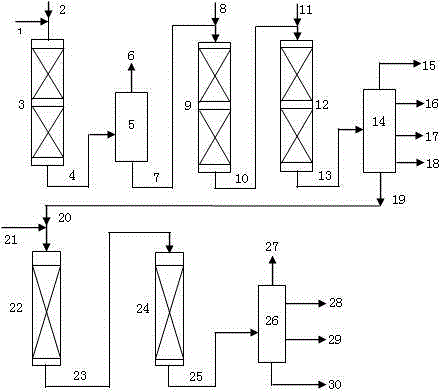

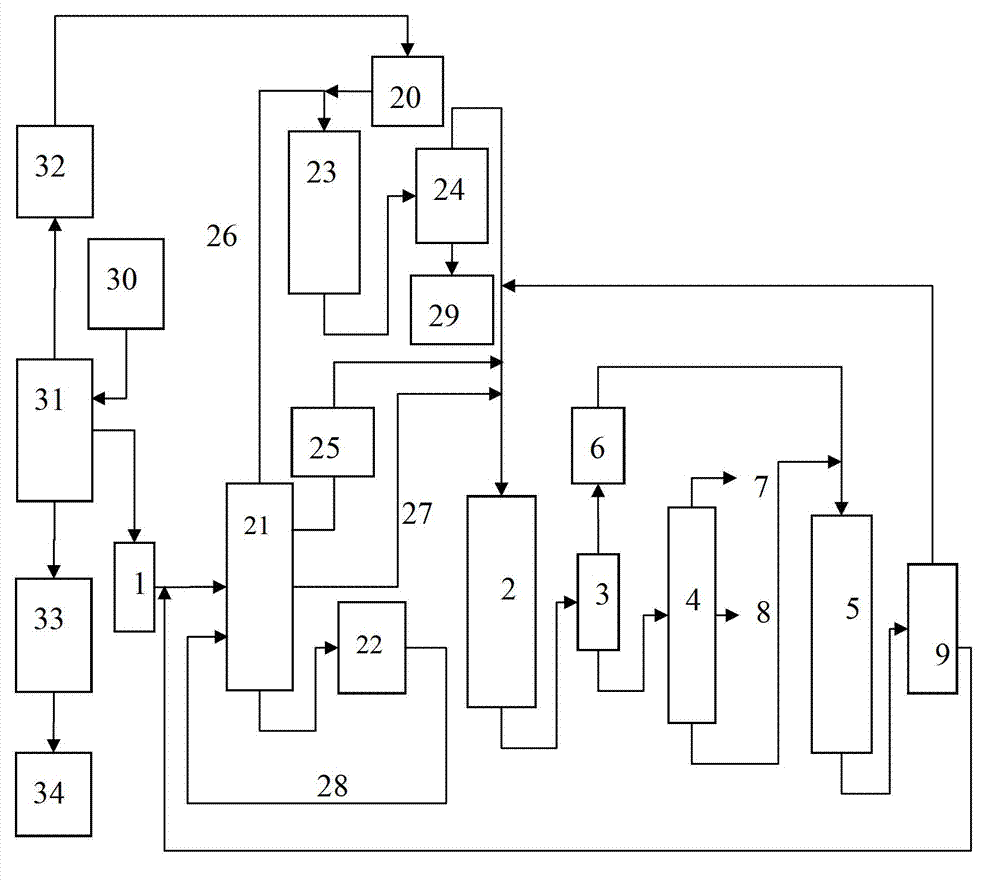

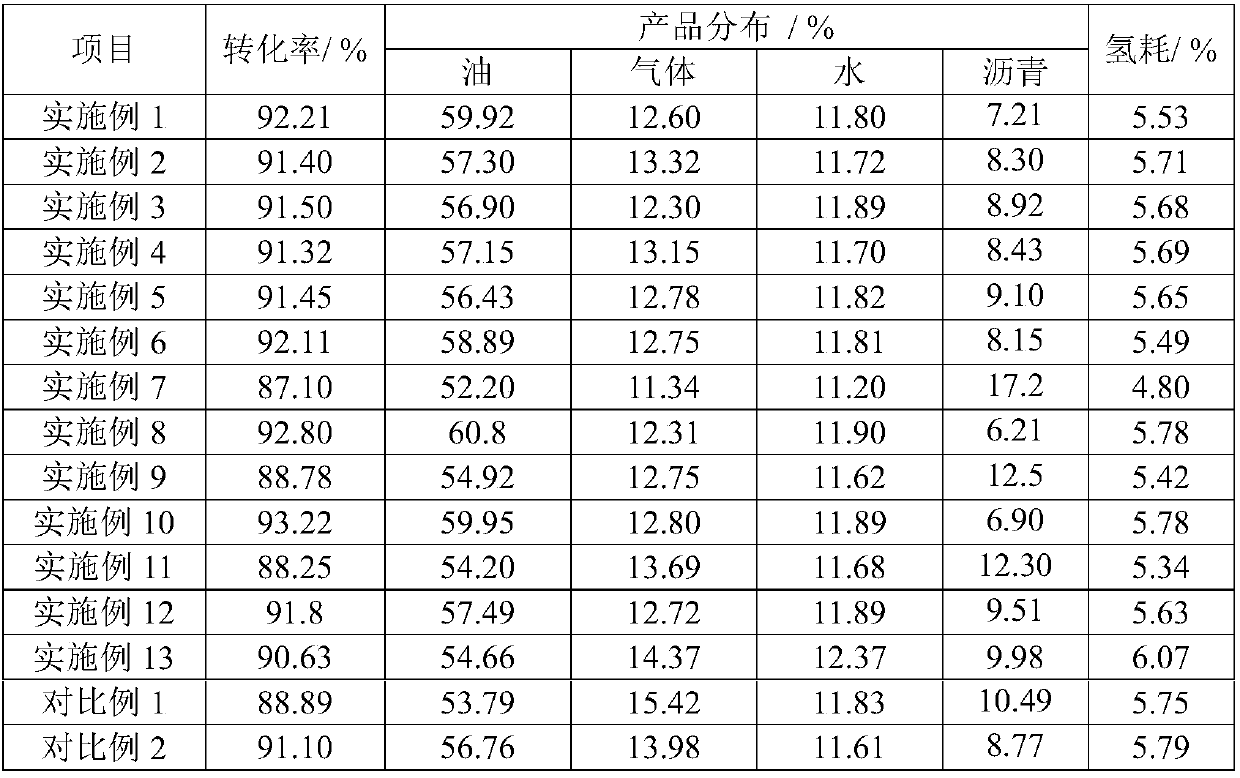

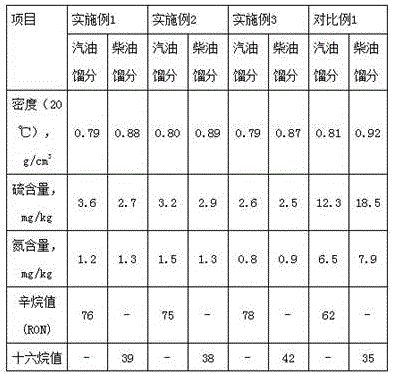

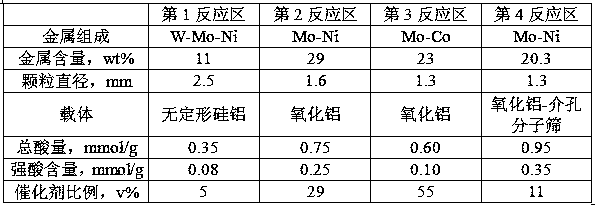

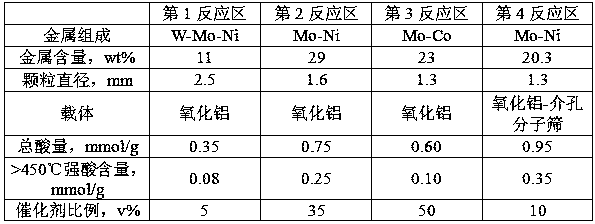

Two-stage hydrocracking method for high-nitrogen raw material

InactiveCN103102957AEffectively play an active roleReduce ammonia contentTreatment with hydrotreatment processesPtru catalystProcess engineering

The invention relates to a two-stage hydrocracking method for a high-nitrogen raw material. According to the method, high-nitrogen heavy distillate oil is used as a raw material, and two-stage process flow is employed; under hydrorefining conditions, the raw material heavy distillate oil and hydrogen are mixed and enter into a first-stage reaction zone which uses a hydrorefining catalyst, and an effluent of the first-stage reaction zone enters into a separation system; a separated liquid phase of the effluent of the first-stage reaction zone enters into a second-stage reaction zone with hydrogen, the hydrorefining catalyst and a hydrocracking catalyst are successively utilized along a flow direction of reaction materials in the second-stage reaction zone, and an effluent of the second-stage reaction zone enters into the separation system so as to obtain a hydrocracking reaction product. Compared with conventional two-stage hydrocracking technology, the method provided by the invention has the following advantages: process flow is more flexible, and more inferior raw materials can be processed. Compared with conventional one-stage tandem hydrocracking technology, the method can substantially improve processing capability of an apparatus. Moreover, the method can be carried out at mild conditions, which is favorable for increasing a running period of a hydrogenation apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

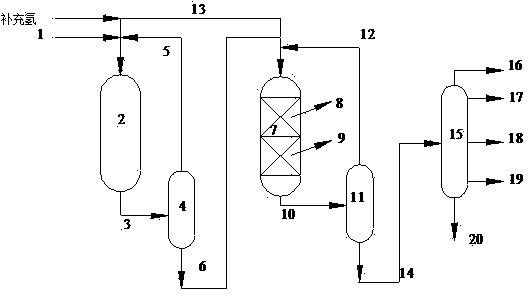

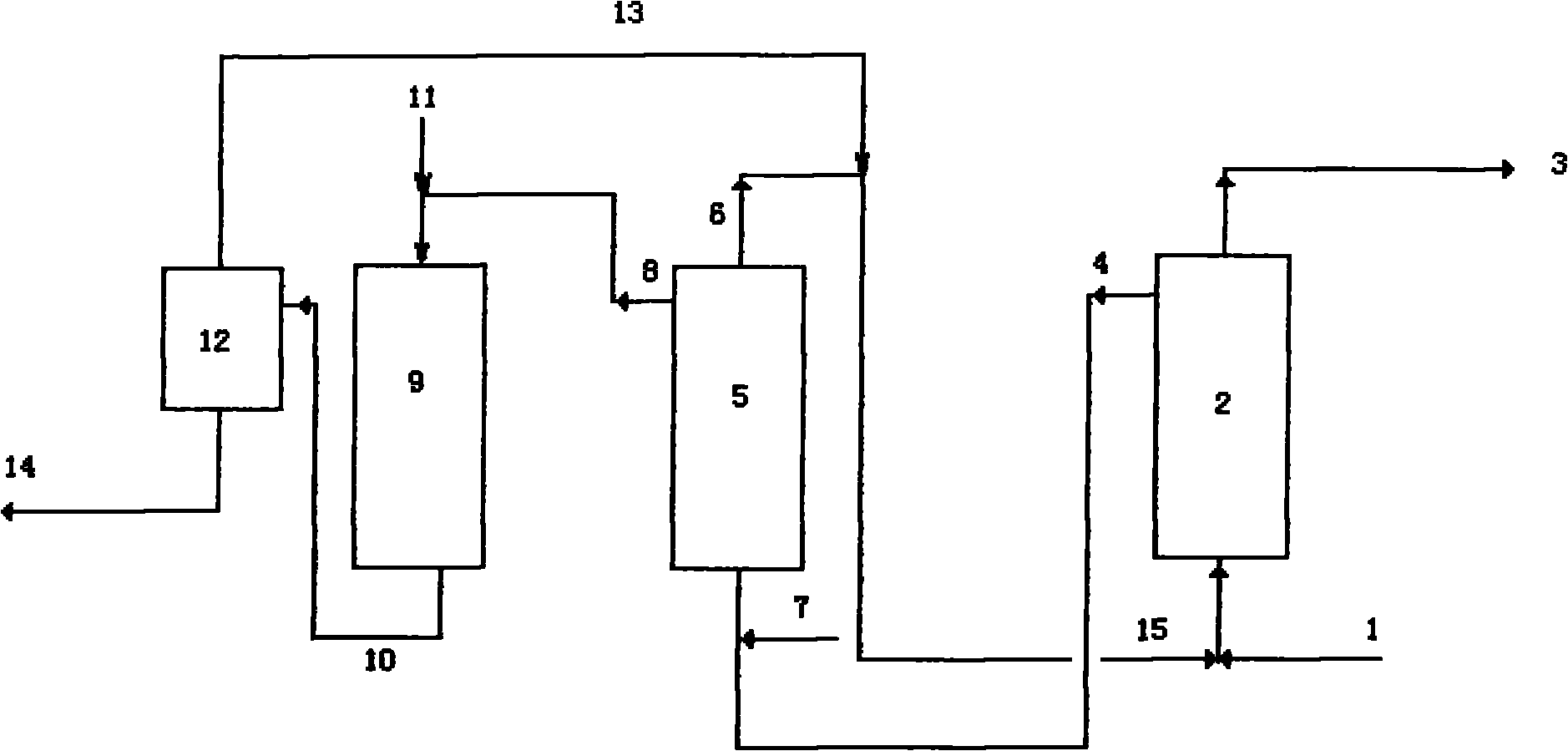

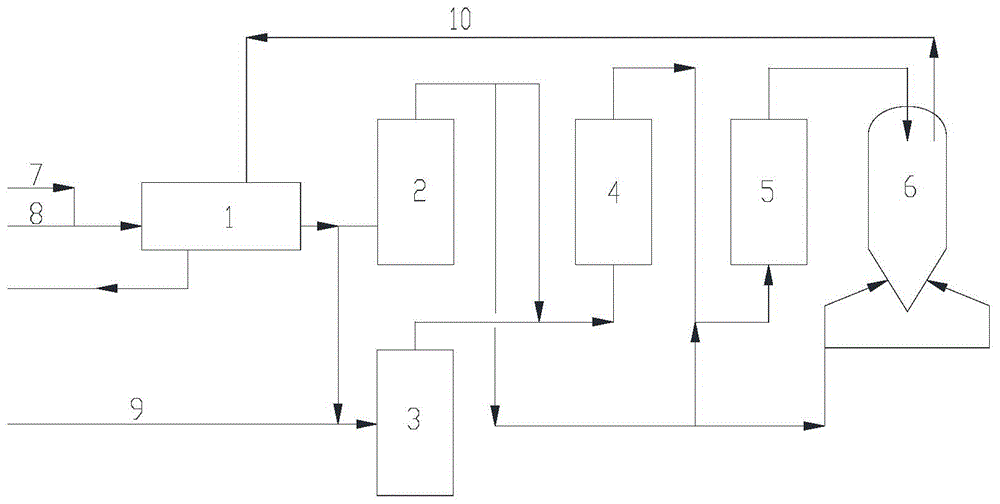

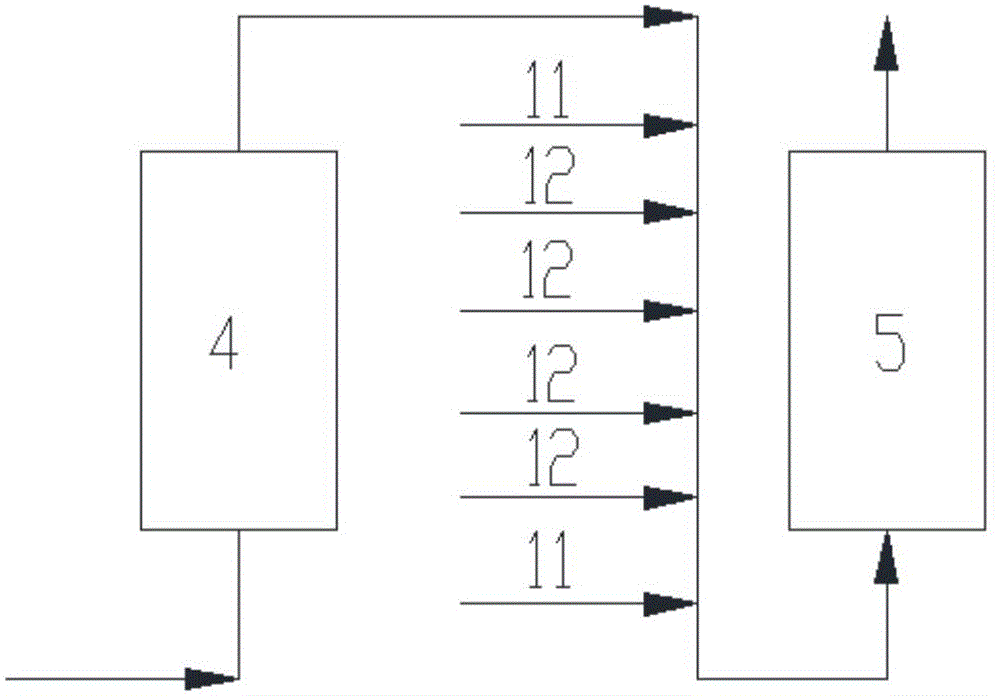

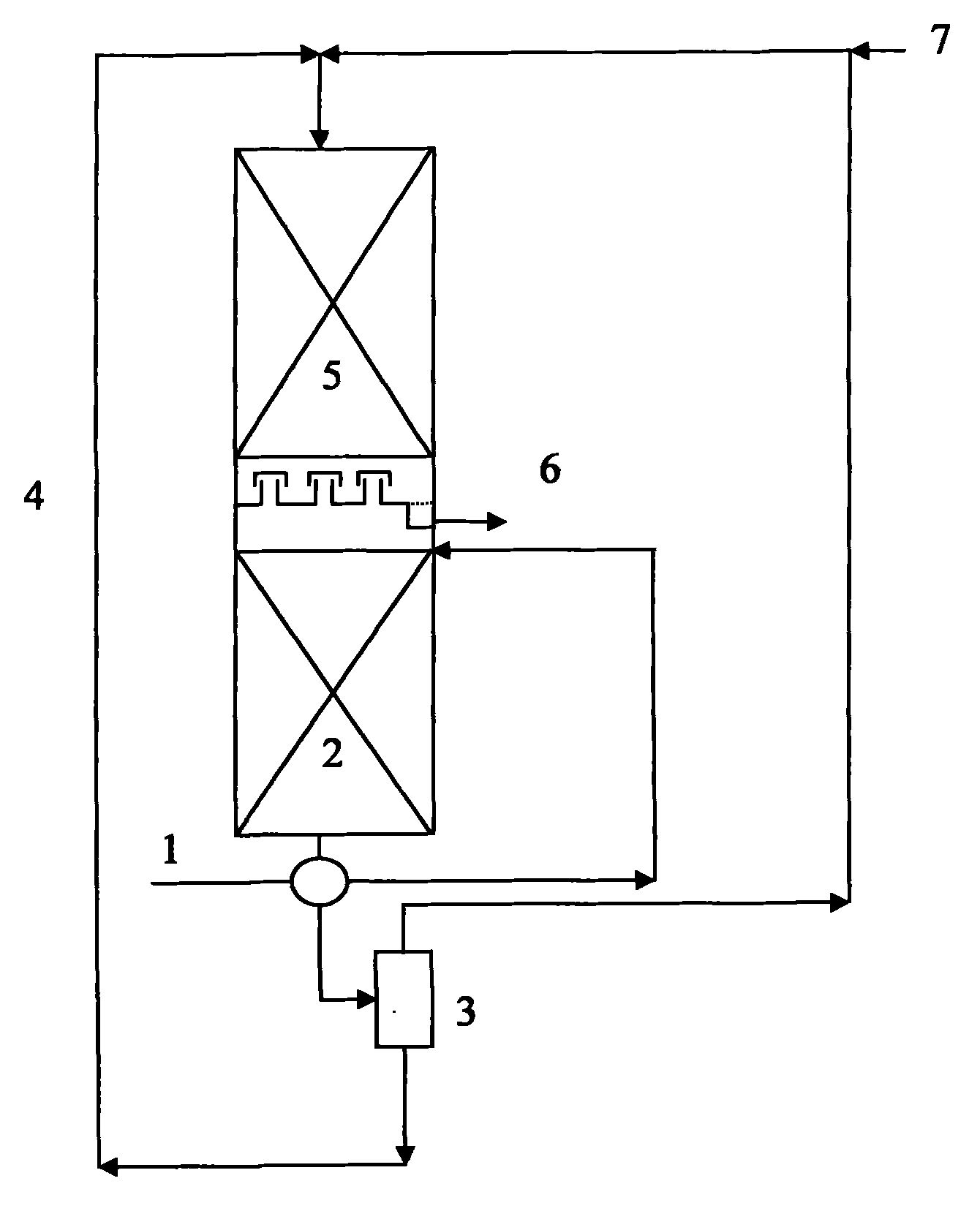

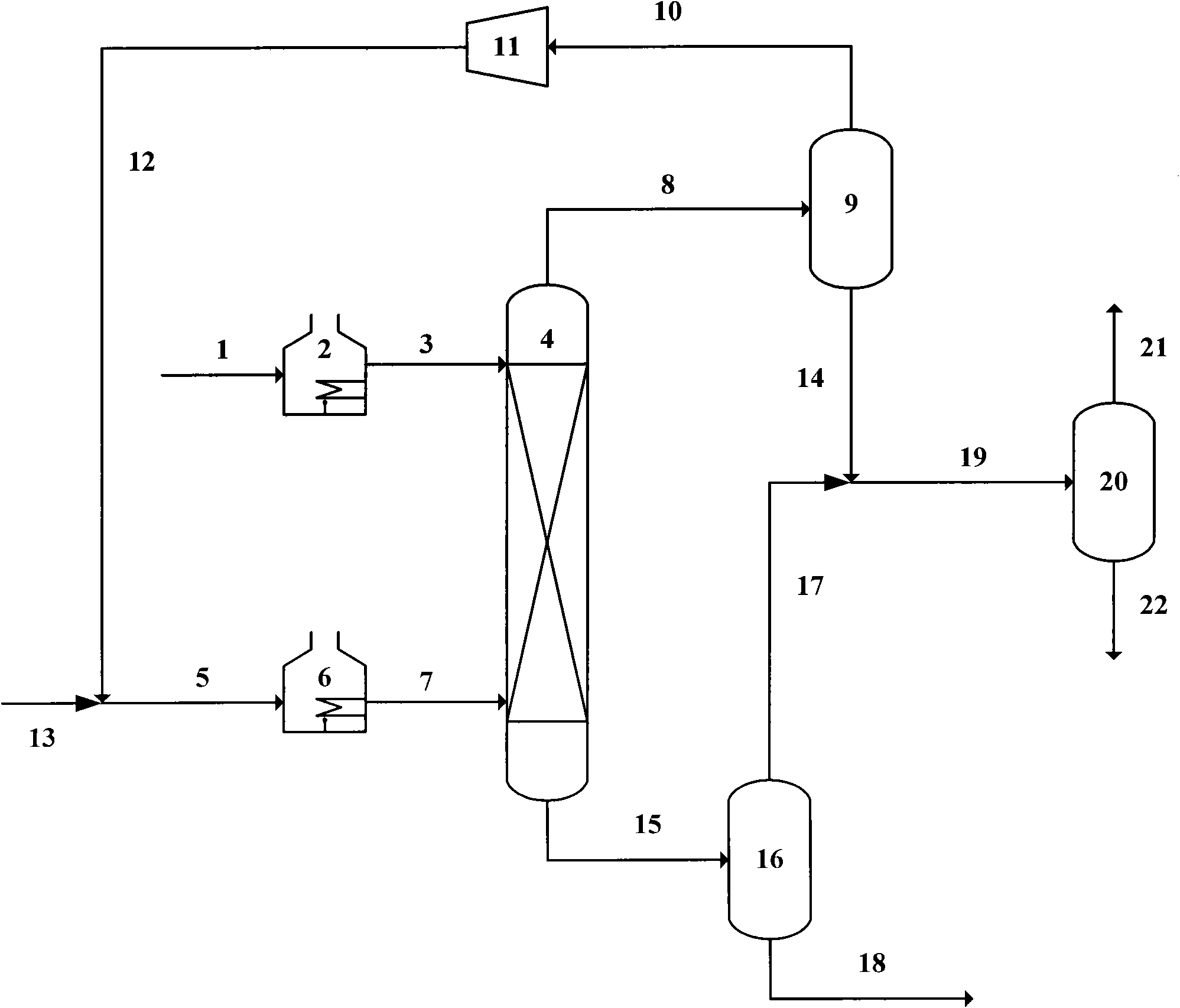

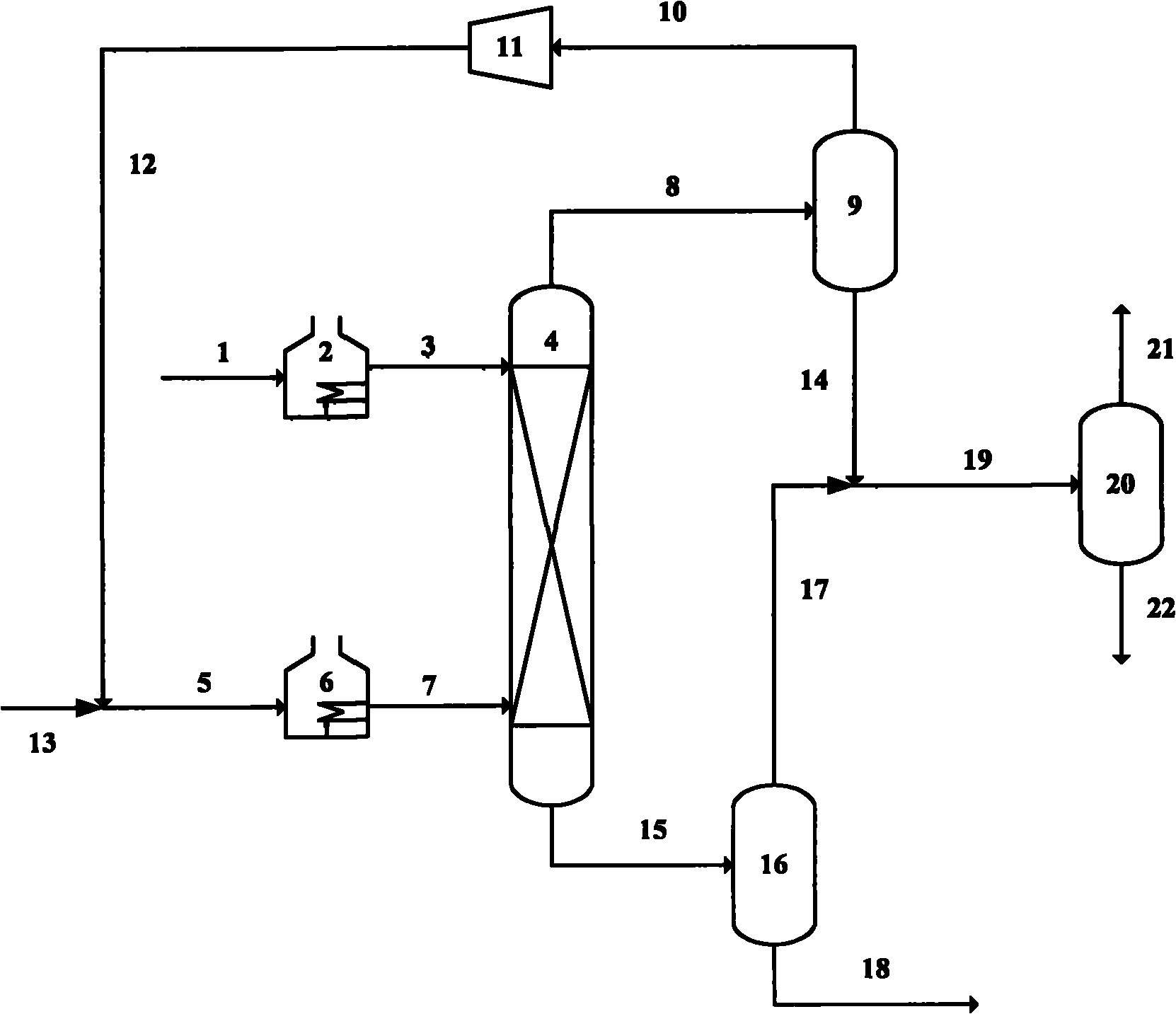

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453AReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseFuel oil

The invention discloses a hydrogenation method of a heavy hydrocarbon multi-segment fluidized bed. The technical process comprises the steps of: mixing thick heavy hydrocarbon raw materials with gas phase material flow which is discharged from a fluidized bed hydrogenation-desulfuration reactor and a hydrogenation-denitrification reactor to enter into a hydrogenation-demetalization reactor; cooling and purifying reacted gas phase material flow to be taken as recycle hydrogen; mixing the demetallized liquid phase material flow with hydrogen to enter into the fluidized bed hydrogenation-desulfuration reactor; mixing the desulfurated liquid phase material flow with hydrogen to enter into the hydrogenation-desulfuration reactor; and leading the denitrified liquid phase material flow to enter into a separating device. The technology adopts a new reactor assembly mode to machine heavy oil raw materials with high viscosity and bad quality, can provide a new flexible, high-efficiency and energy-saving operation mode, organically combines the performances of the raw materials with the characteristic of each hydrogenation reaction, makes full use of reaction heating on the premise that a device is guaranteed to be stably operated, provides a product with good quality, and can flexibly adjust the operation process according to the requirement of a refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

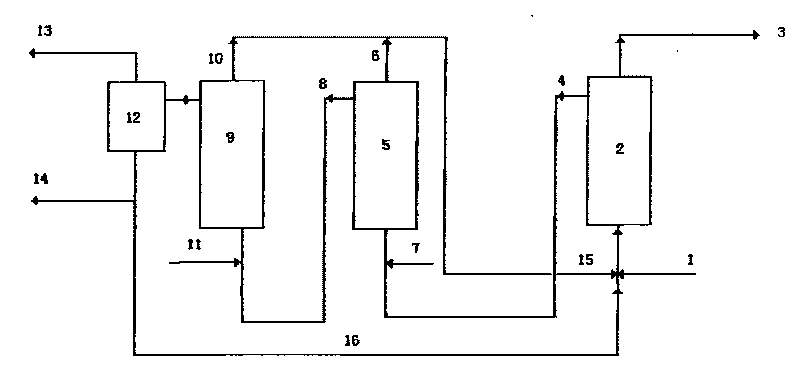

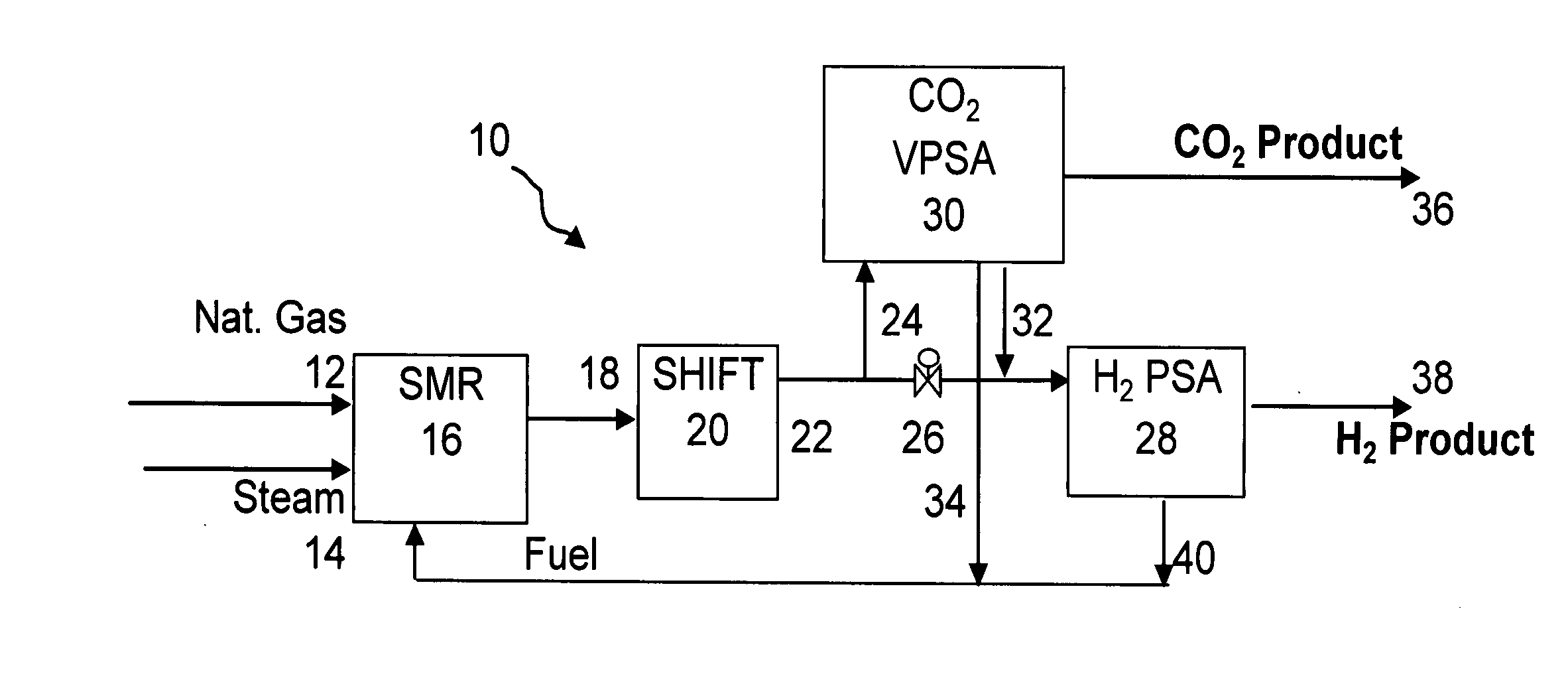

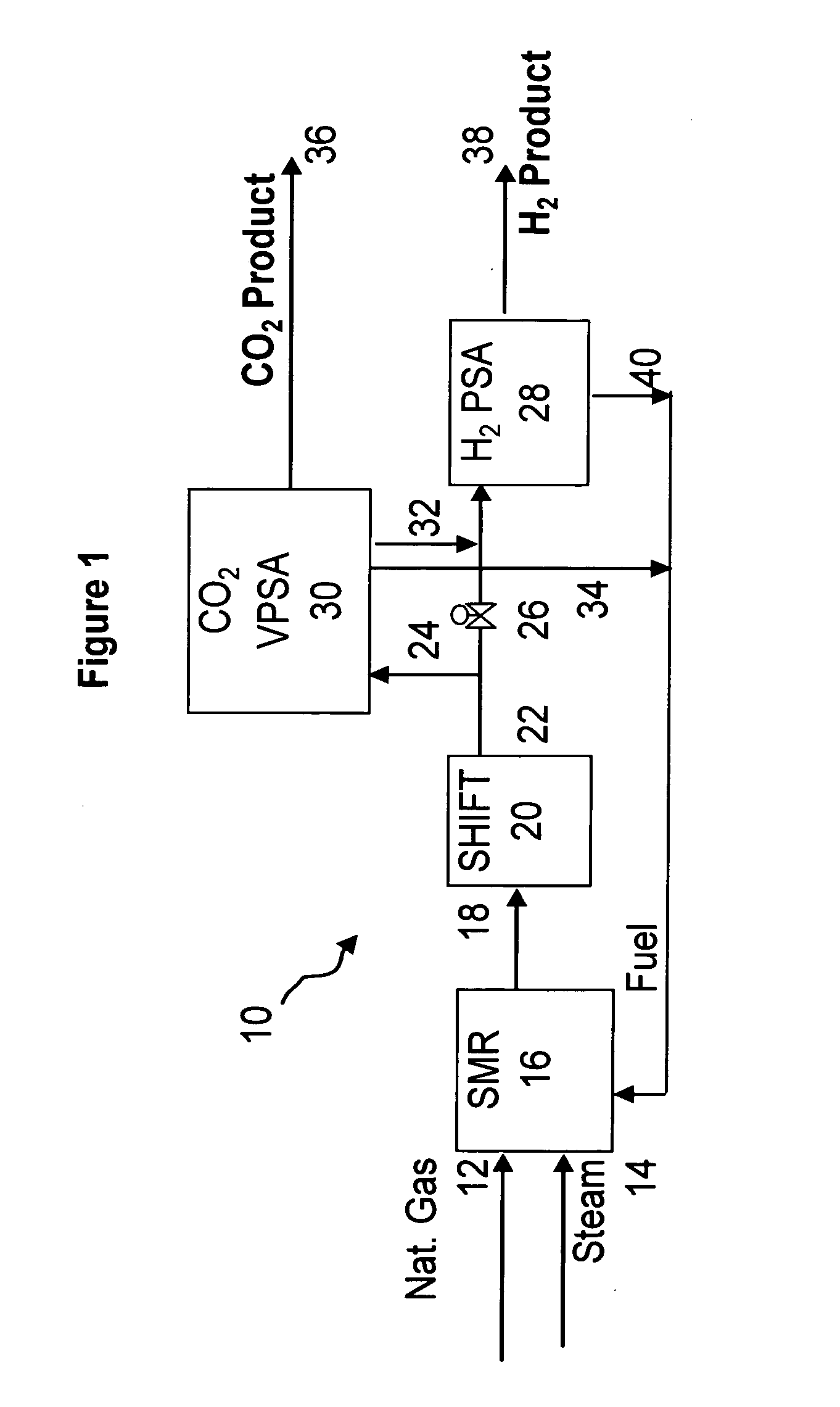

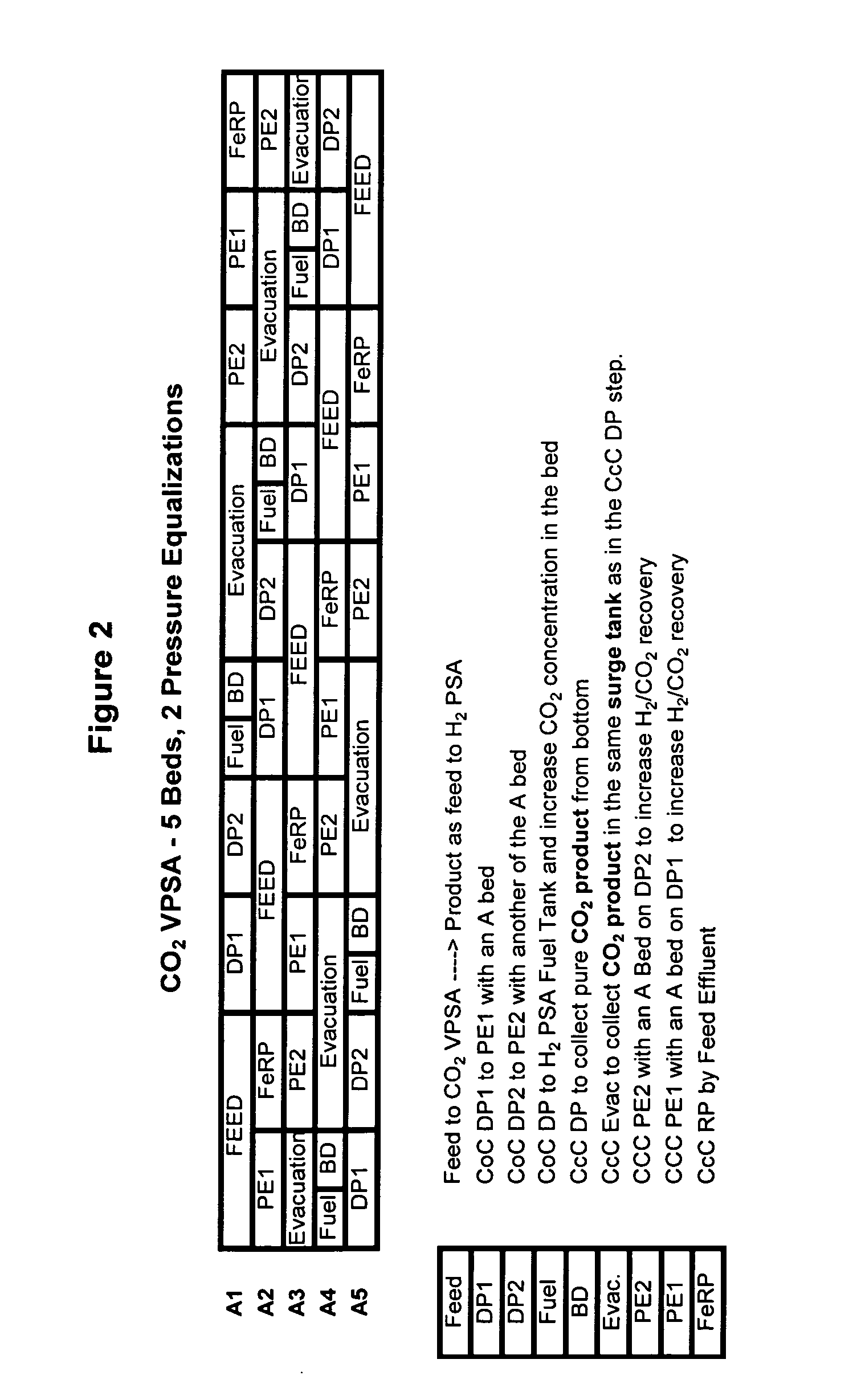

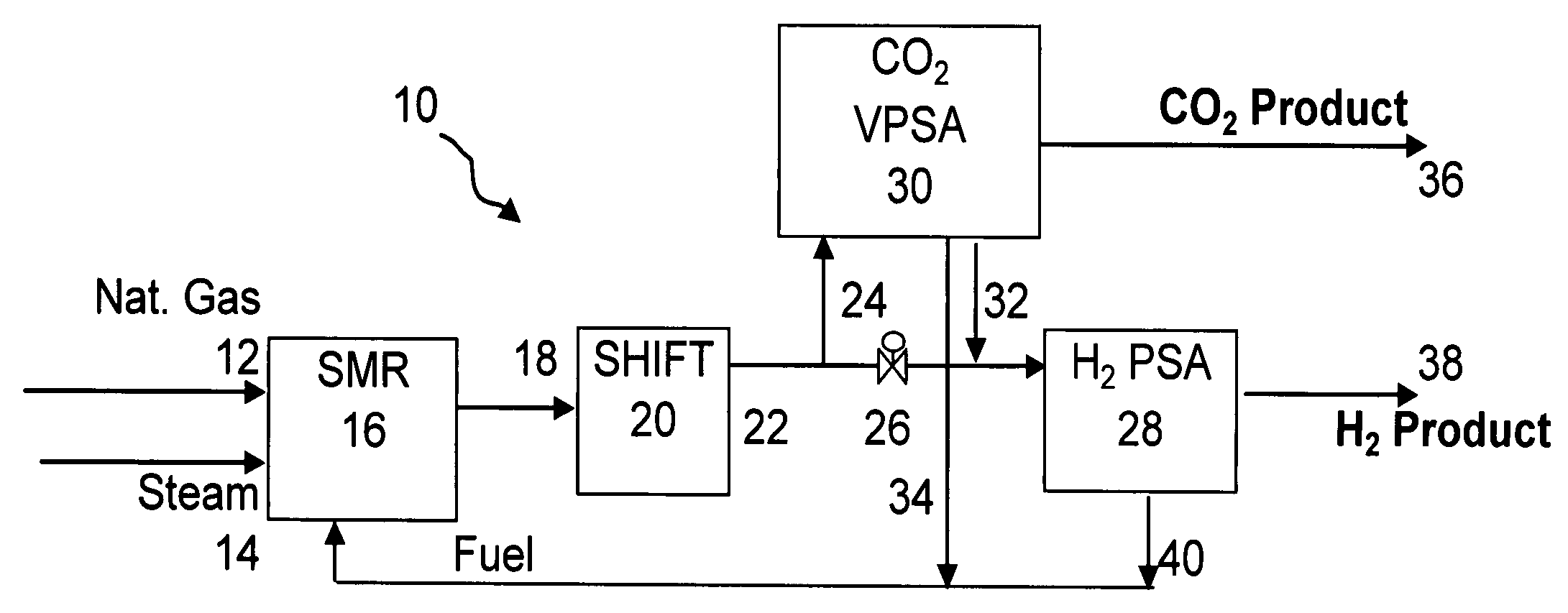

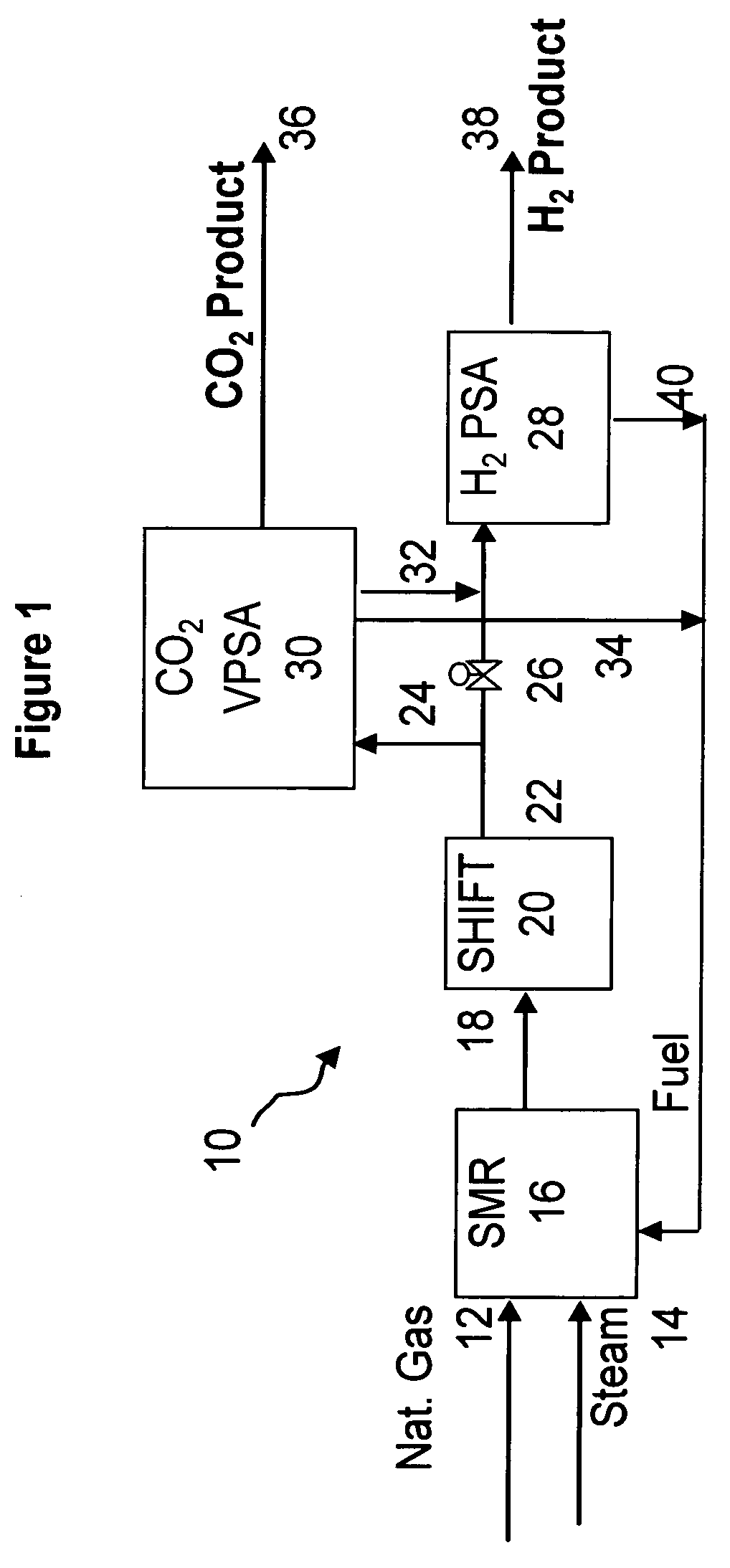

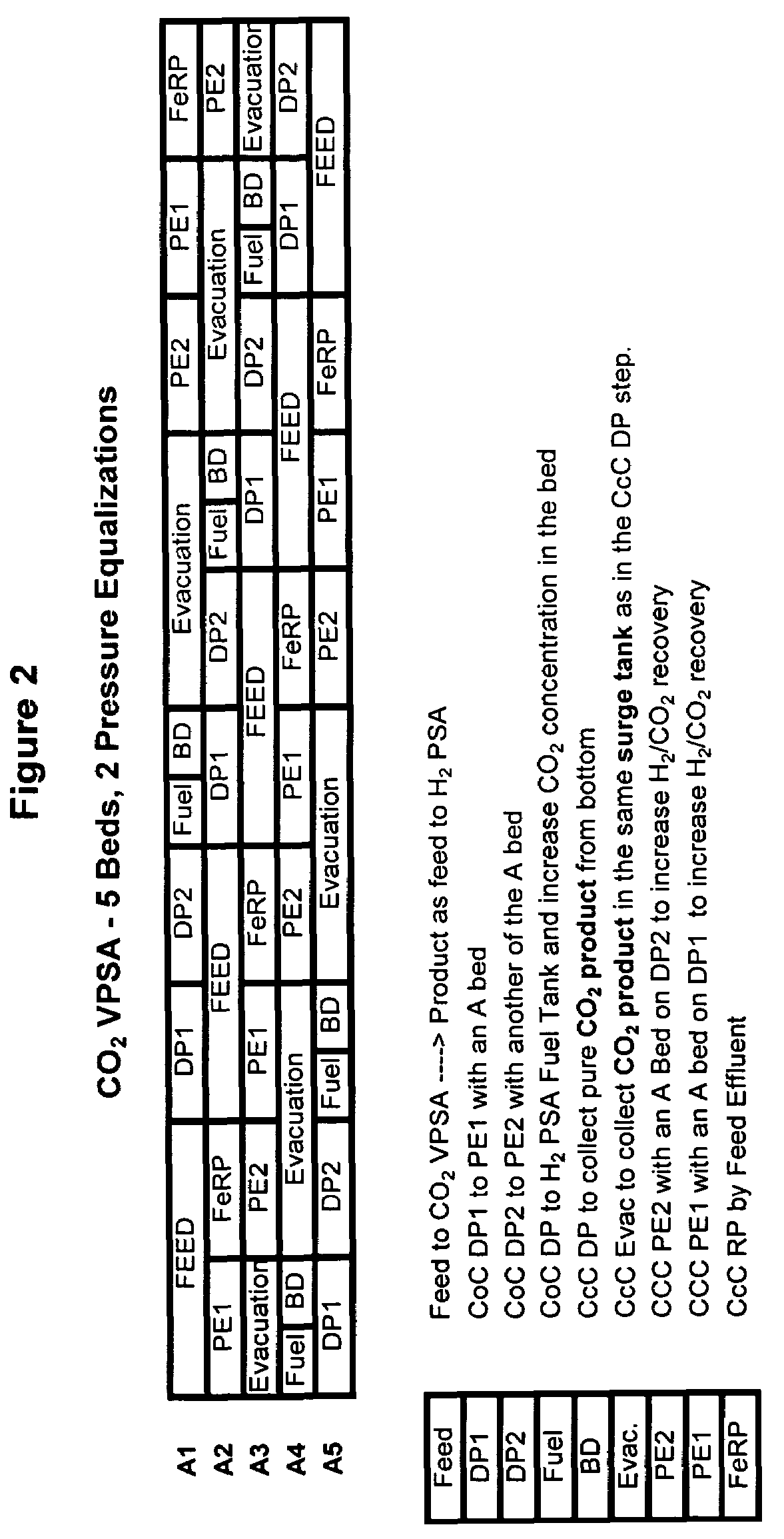

Process and apparatus to recover high purity carbon dioxide

The present invention generally relates to vacuum pressure swing adsorption (VPSA) processes and apparatus to recover carbon dioxide having a purity of approximately ≧90 mole % from streams containing at least carbon dioxide and hydrogen (e.g., syngas). The feed to the CO2 VPSA unit can be at super ambient pressure. The CO2 VPSA unit produces three streams, a H2-enriched stream, a H2-depleted stream and a CO2 product stream. When the CO2 VPSA unit is installed between an SMR / shift reactor and a H2 PSA unit, hydrogen recovery is expected to be increased by extracting CO2, thereby increasing hydrogen partial pressure in the H2 PSA feed. The recovered CO2 can be further upgraded, sequestered or used in applications such as enhanced oil recovery (EOR).

Owner:PRAXAIR TECH INC

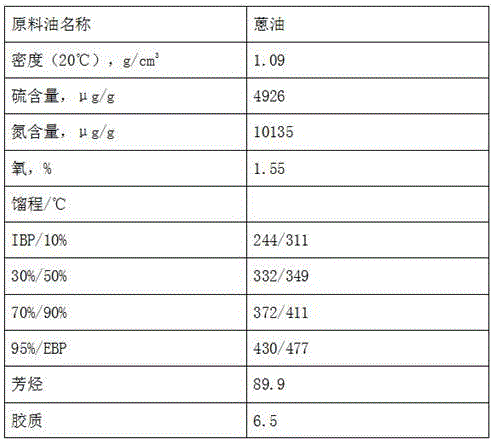

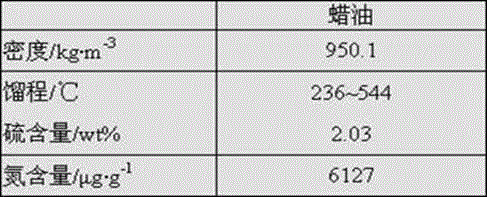

Hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil

ActiveCN104611037AEffectively play an active roleBroaden sources of raw materialsTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenNitrogen

The present invention discloses a hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil. According to the method, poor-quality heavy distillate oil and hydrogen gas enter a first-stage reaction zone to carry out a hydrorefining reaction, the reaction effluent is separated, the obtained liquid enters a second-stage reaction zone to carry out a hydrorefining reaction, the second-stage reaction effluent enters a third-stage reaction zone to carry out a hydrocracking reaction, the hydrocracking effluent is separated, and at least part of the tail oil and new hydrogen are mixed and then are subjected to an isomerizing dewaxing and finishing reaction to obtain various lubricating oil base oils. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the lubricating oil base oil raw material source is broadened; and the hydrorefining temperature is substantially reduced so as to increase the operation period of the device and process the poor-quality raw material, or increase the processing capacity of the device in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

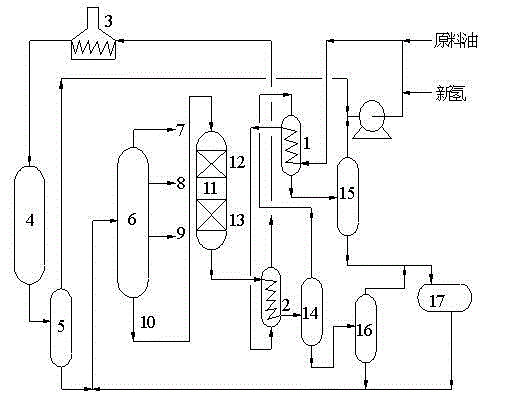

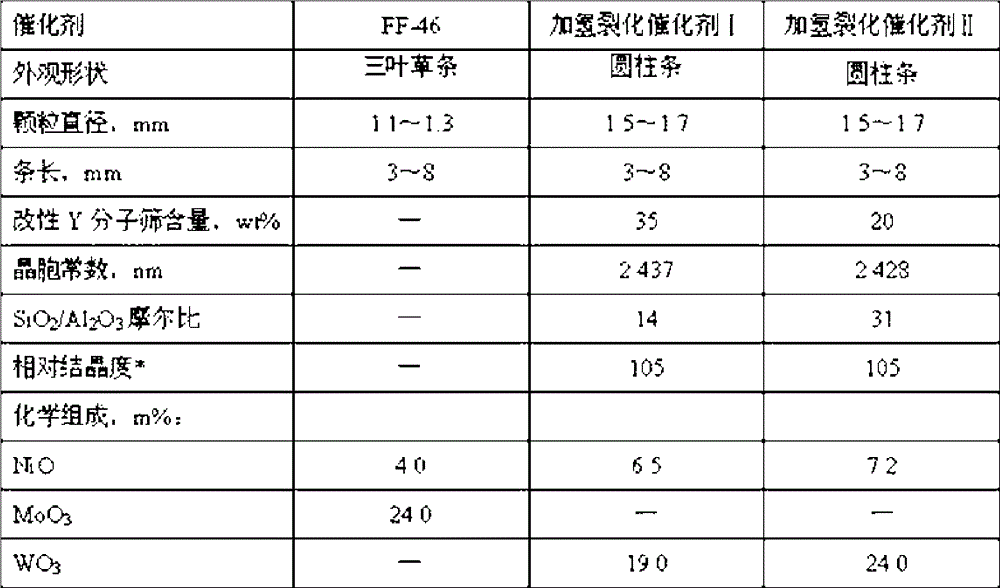

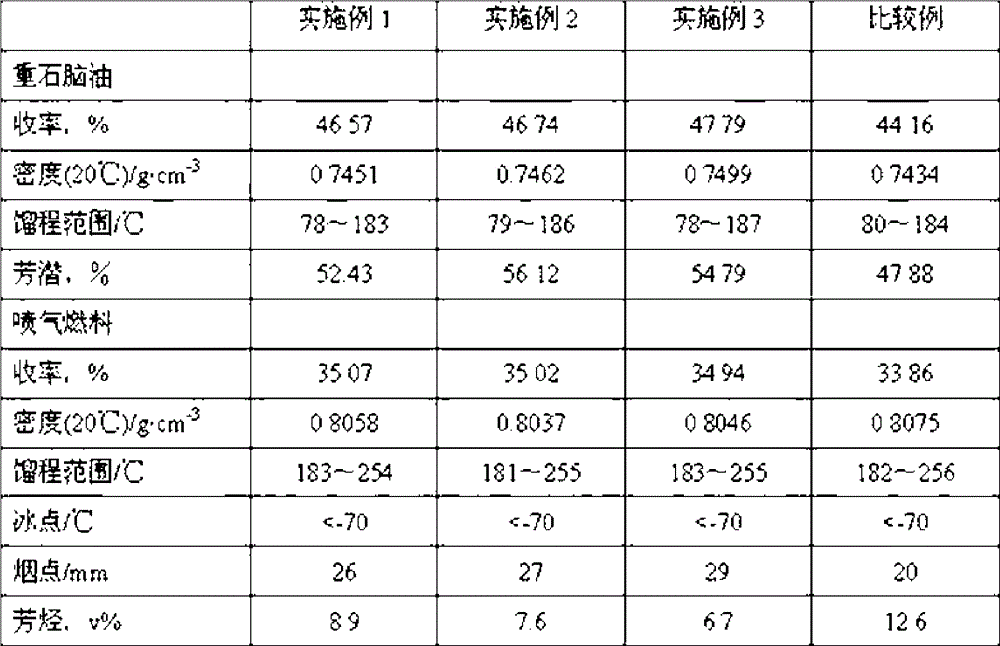

Two-stage hydrocracking method

ActiveCN103773463AIncrease hydrogen partial pressureImprove conversion abilityTreatment with hydrotreatment processesMolecular sieveAlkane

The invention discloses a two-stage hydrocracking method. The two-stage hydrocracking method comprises following steps: (1) inferior raw oil is mixed with hydrogen for hydrofinishing; (2) a hydrofinishing effluent is subjected to gas-liquid separation so as to obtain a gas material and a liquid material; (3) the liquid material is delivered into a hydrocracking reaction zone for hydrocracking, wherein the hydrocracking reaction zone comprises a hydrocracking catalyst I and a hydrocracking catalyst II with different molecular sieve contents; and (4) a hydrocracking effluent is subjected to separation and fractionation so as to obtain needed products. According to the two-stage hydrocracking method, the hydrocracking catalyst I possesses relatively high aromatic hydrocarbon transformation ability, and is capable of transforming aromatic hydrocarbons in raw material heavier components into smaller molecules, and distributing the small molecules into naphtha and jet fuel fractions; the hydrocracking catalyst II possesses relatively high hydrocarbon alkyl cracking ability; synergistic effect of the two catalysts is capable of improving quality of hydrocracking products obviously, and especially increasing smoke point of jet fuel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process and apparatus to recover high purity carbon dioxide

InactiveUS7550030B2Hydrogen recoveryIncrease hydrogen partial pressureProductsGas treatmentSyngasVacuum pressure

Owner:PRAXAIR TECH INC

Two-stage hydrocracking method used for producing high-quality chemical raw materials

ActiveCN103773462AReduce the impactIncrease hydrogen partial pressureTreatment with hydrotreatment processesMolecular sieveLiquid product

The invention discloses a two-stage hydrocracking method used for producing high-quality chemical raw materials. The two-stage hydrocracking method comprises following steps: (1) raw material oil is mixed with hydrogen, and an obtained mixture is subjected to hydrofinishing reaction; (2) a refining reaction product is subjected to gas-liquid separation; (3) an obtained liquid product and hydrogen are subjected to hydrocracking reaction, and are contacted with a catalyst I and a catalyst II successively, wherein molecular sieve content of the catalyst I and molecular sieve content of the catalyst II are different; and (4) a hydrocracking effluent is subjected to separation and fractionation so as to obtain a plurality of hydrocracking products. The molecular sieve content of the hydrocracking catalyst I is higher, acid center of the hydrocracking catalyst I matches hydrogenation center, and the hydrocracking catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw material oil into smaller molecules so as to distribute in heavy petroleum fractions. The two hydrocracking catalysts with different molecular sieve contents are combined, so that aromatic hydrocarbon potential content of heavy naphtha is increased, and tail oil BMCI value is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

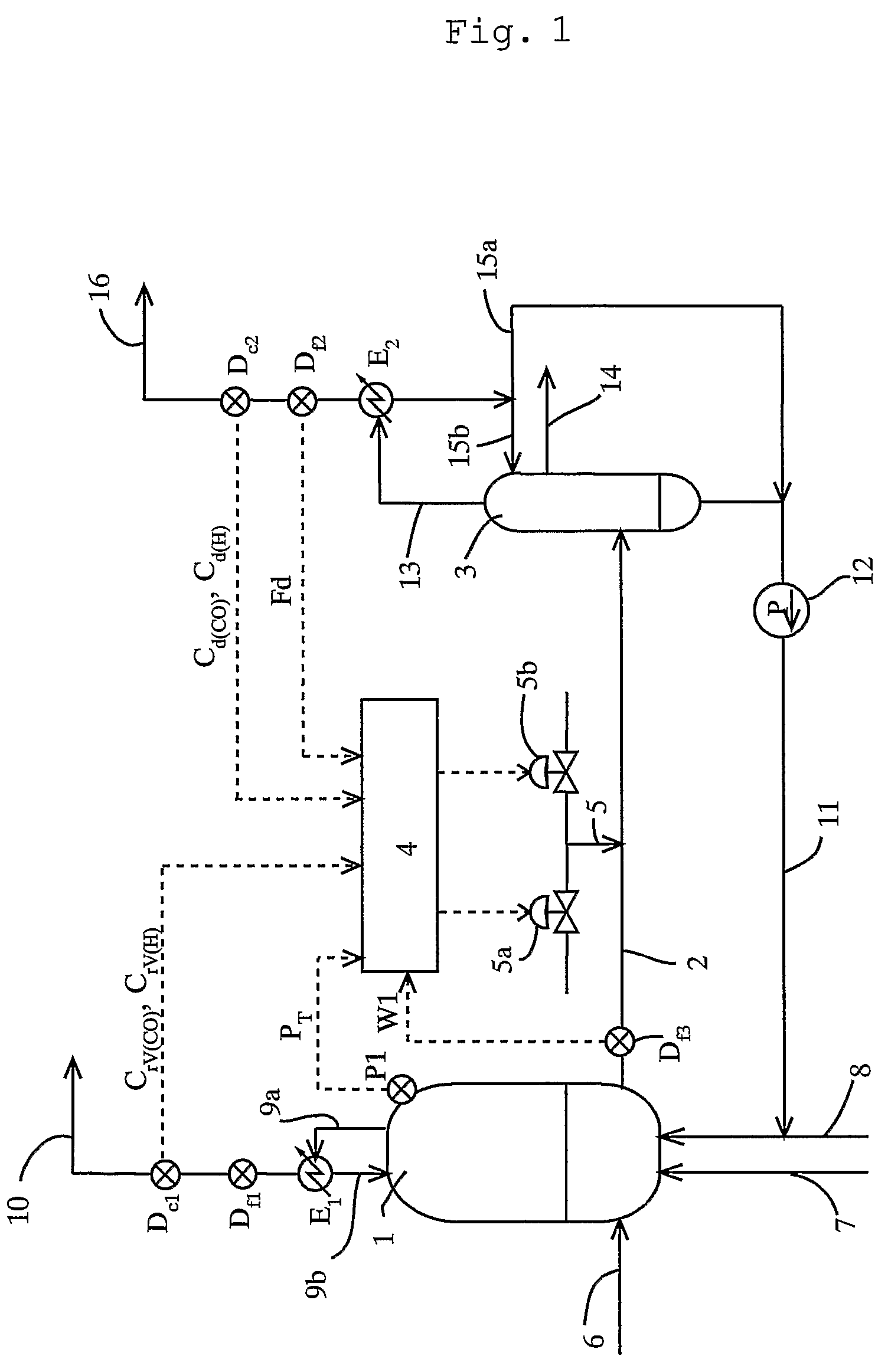

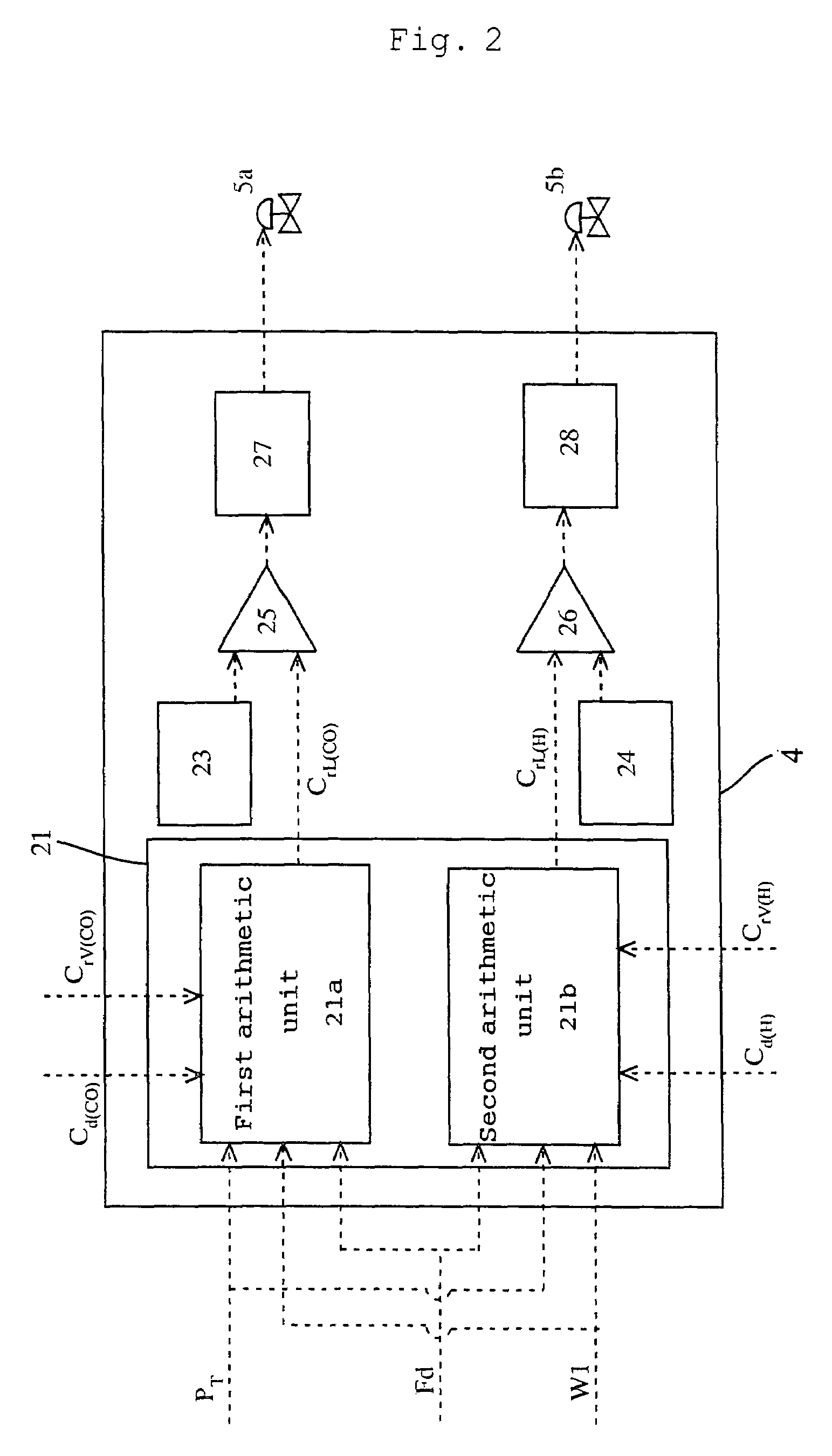

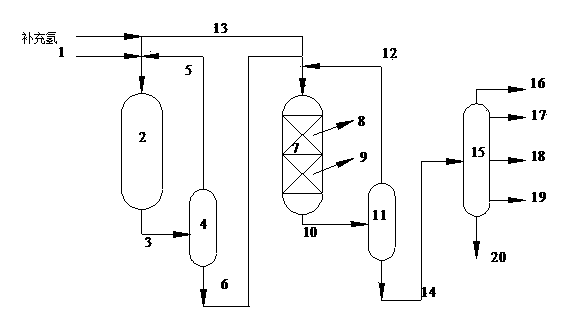

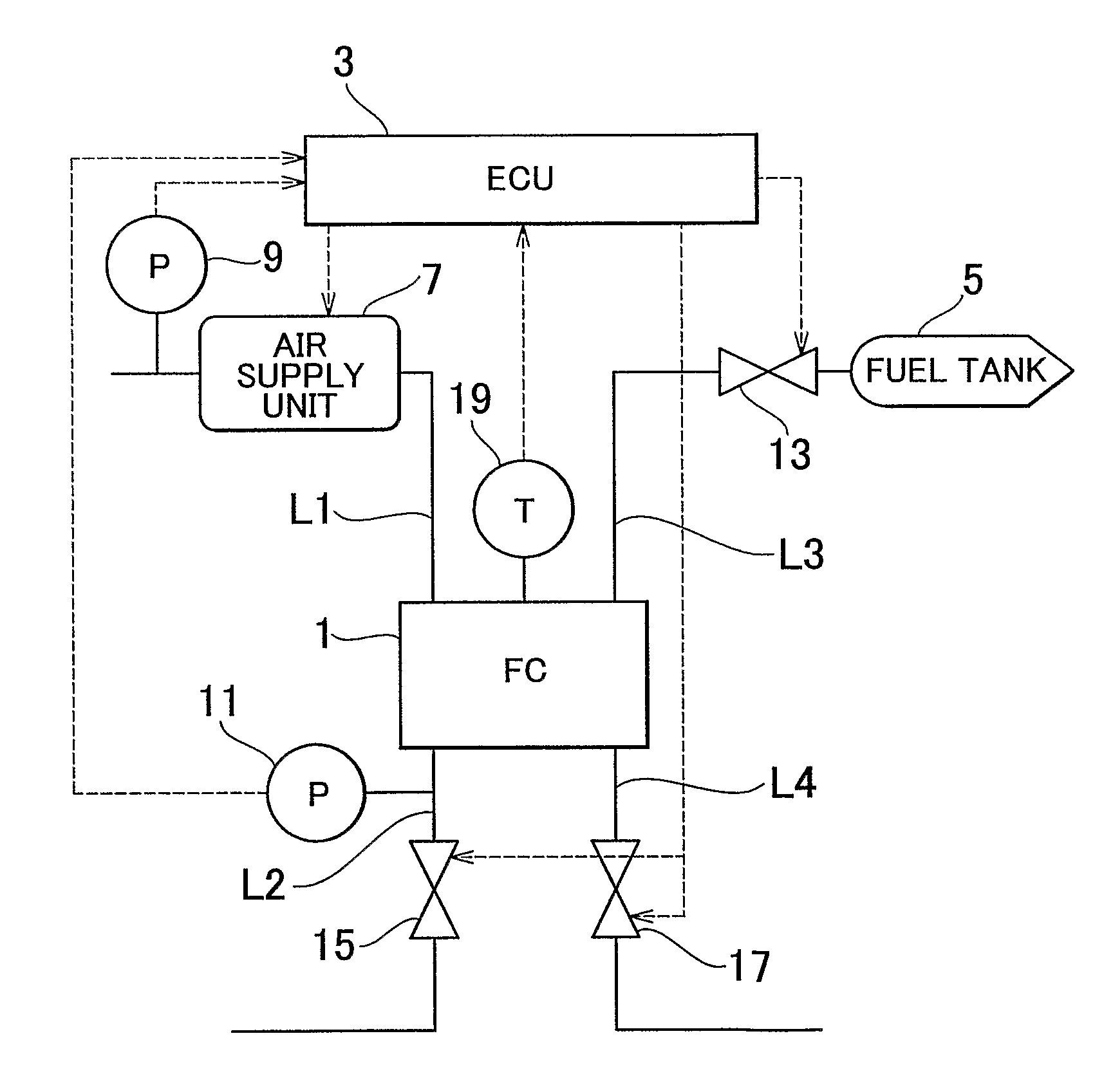

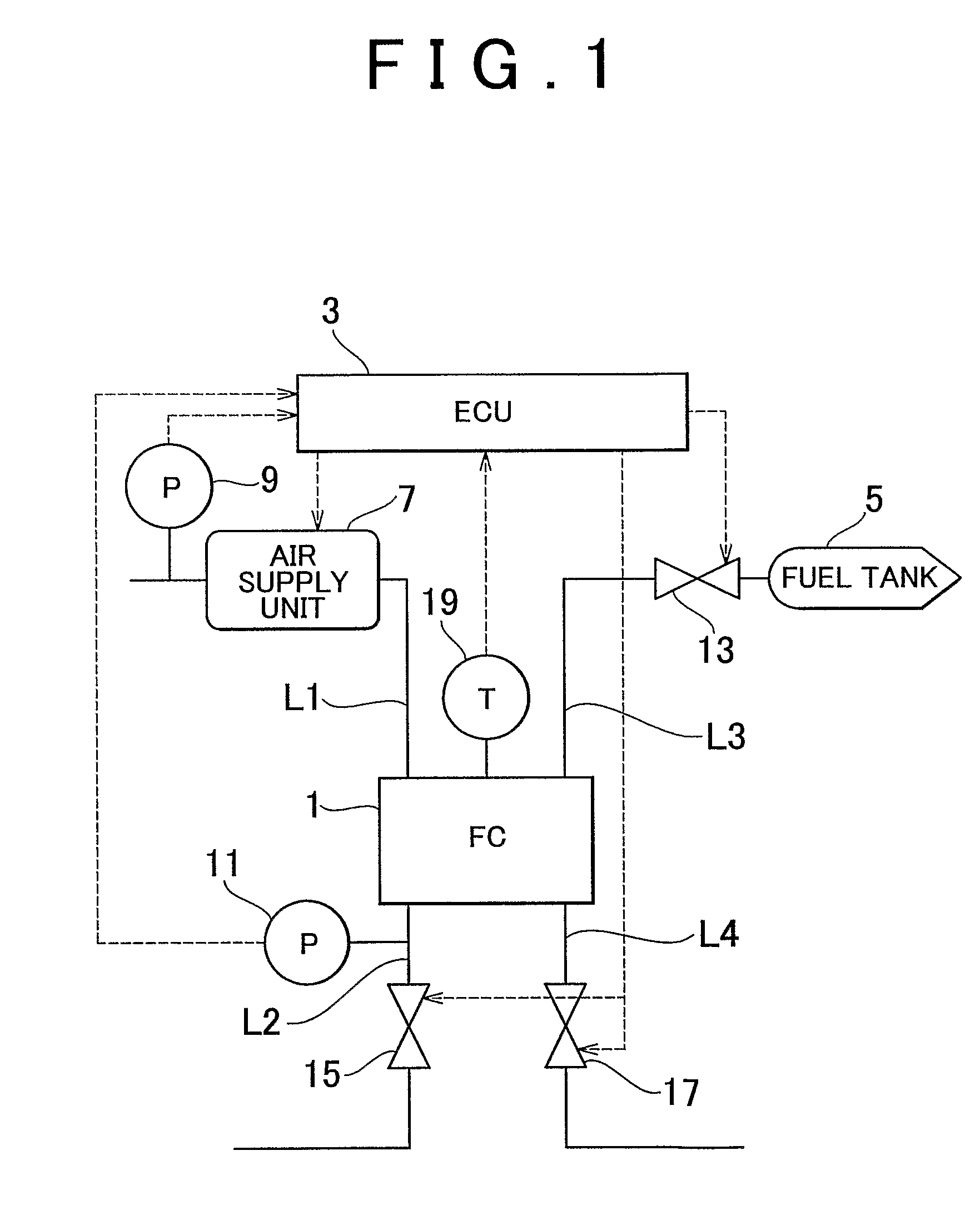

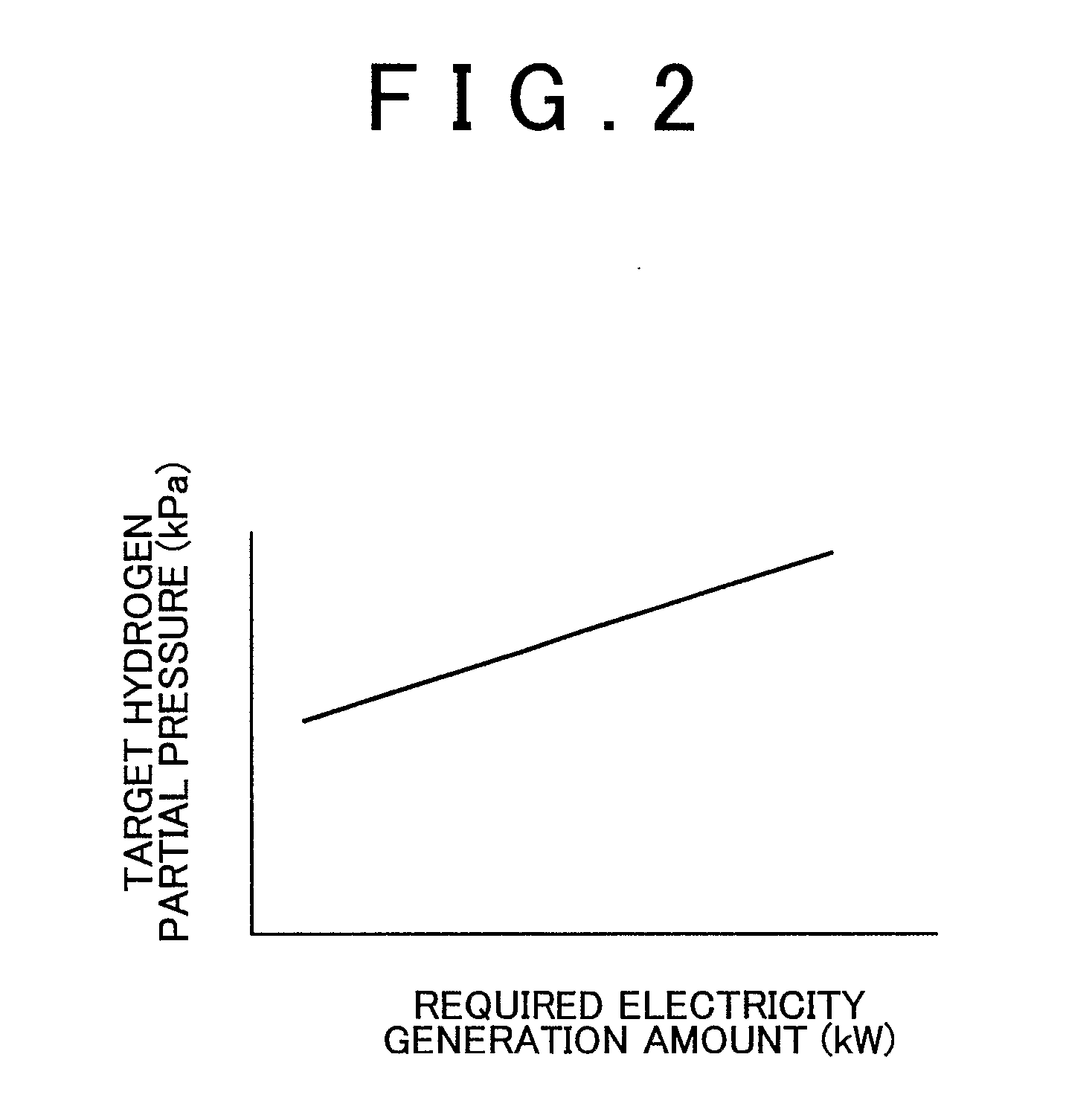

Control apparatus and control method for fuel cell

ActiveUS20070184318A1Increase hydrogen partial pressureFuel cell heat exchangeHydrogen pressureHydrogen supply

A control apparatus for a fuel cell, including oxidizing gas supplying means for supplying oxidizing gas to a cathode via an oxidizing gas supply line; cathode-side gas pressure detecting means for detecting a gas pressure within the oxidizing gas supply line or the cathode; hydrogen supplying means for supplying hydrogen to an anode via a hydrogen supply line; target hydrogen partial pressure determining means for determining a hydrogen pressure among a gas pressure within the hydrogen supply line or the anode; hydrogen supply pressure calculating means for calculating a hydrogen supply pressure of hydrogen to be supplied to the fuel cell, based upon the target hydrogen partial pressure and the gas pressure detected by the cathode-side gas pressure detecting means; and hydrogen supply control means for supplying hydrogen from the hydrogen supplying means to the fuel cell at the hydrogen supply pressure, and the method thereof.

Owner:TOYOTA JIDOSHA KK

Two-stage hydrocracking method used for producing high-quality jet fuel

ActiveCN103773473AReduce the impactIncrease hydrogen partial pressureTreatment with hydrotreatment processesAlkaneMolecular sieve

The invention discloses a hydrocracking method used for producing high-quality jet fuel from inferior raw materials. The hydrocracking method comprises following steps: (1) inferior raw material oil is subjected to hydrofinishing reaction; (2) a hydrofinishing effluent is subjected to gas-liquid separation, and an obtained liquid material is subjected to fractionation; (3) tail oil obtained via fractionation is subjected to hydrocracking reaction, wherein a hydrocracking reaction zone comprises a hydrocracking catalyst I and a hydrocracking catalyst II with different molecular sieve contents; and (4) a hydrocracking effluent is subjected to separation, and an obtained liquid product is subjected to fractionation so as to obtain corresponding products. The upper part of the hydrocracking reaction zone is filled with the hydrocracking catalyst I; the hydrocracking catalyst I possesses relatively high aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw materials into smaller molecules, and distributing the smaller molecules into heavy petroleum and jet fuel fractions; the lower part of the hydrocracking reaction zone is filled with the hydrocracking catalyst II; and the hydrocracking catalyst II possesses relatively high hydrocarbon alkyl cracking capacity. The two catalysts are combined, so thathydrocracking product quality is improved obviously, and especially, smoke point of jet fuel fractions is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

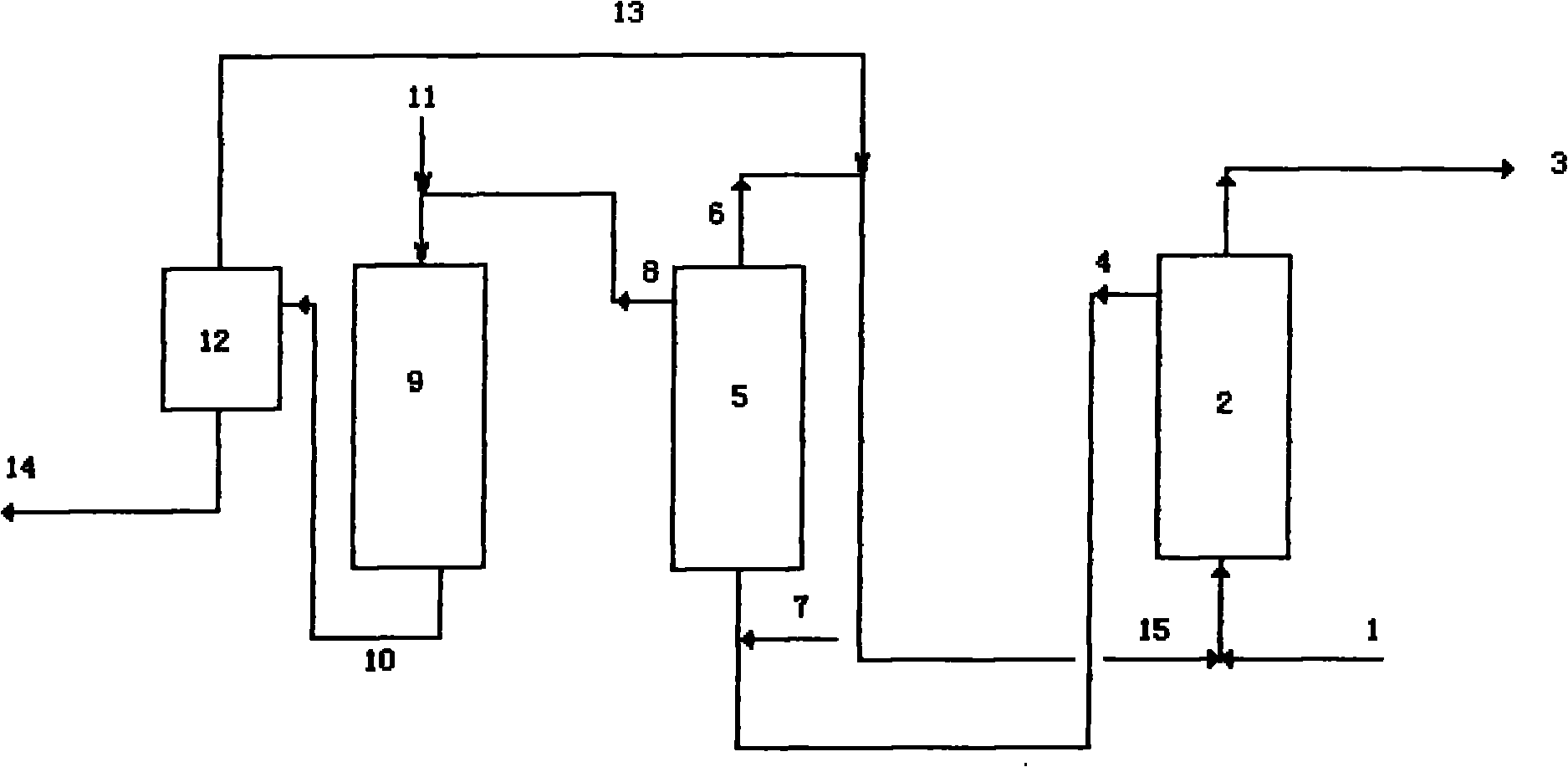

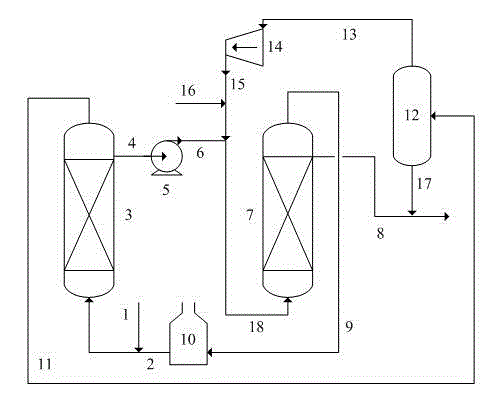

Multistage hydrogenation method for heavy hydrocarbon

ActiveCN102071059AWide applicability of raw materialsImprove product qualityTreatment with hydrotreatment processesHydrogenation reactionGas phase

The invention discloses a multistage hydrogenation method for heavy hydrocarbon. The method comprises the following technical steps of: mixing a condensed heavy hydrocarbon raw material and a gas phase material flow discharged from a hydrogenation desulfurization reactor and a hydrogenation denitrification reactor, and putting the mixture into a boiling bed hydrogenation demetalization reactor; cooling and purifying the reacted gas phase material flow and taking the cooled and purified reacted gas phase material flow as recycled hydrogen; mixing a liquid phase material flow subjected to the boiling bed demetalization reaction and the hydrogen, and putting the mixture into the hydrogenation desulfurization reactor; mixing the liquid phase material flow subjected to the desulfurization reaction with the hydrogen, and putting the mixture into the hydrogenation denitrification reactor, wherein at least one of the hydrogenation desulfurization reactor and the hydrogenation denitrification reactor is a fixed bed reactor. Compared with the prior art, the method provides a novel flexible, efficient and energy-saving operating mode for treating inferior heavy and residual oil raw materials; the property of the raw materials is organically combined with characteristics of the hydrogenation reactions, so the reaction released heat is fully used, the quality of the product is perfect and the operation process can be flexibly adjusted as required on the premise of guaranteeing the stable operation of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

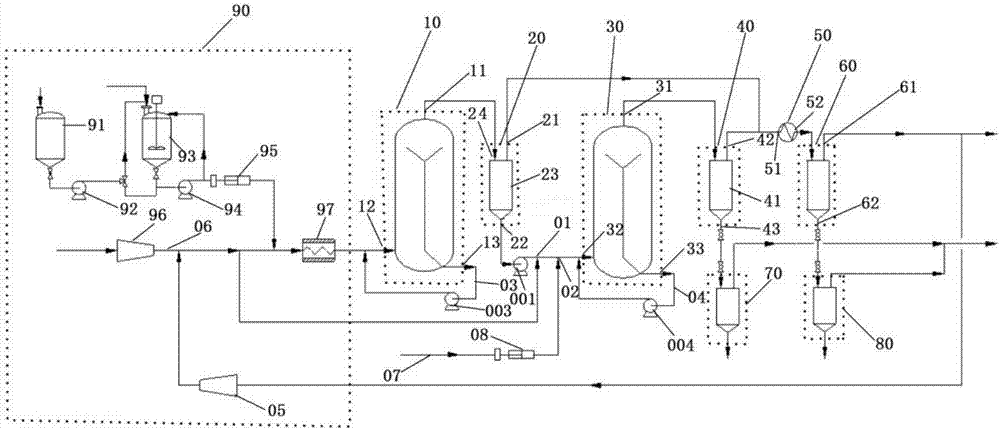

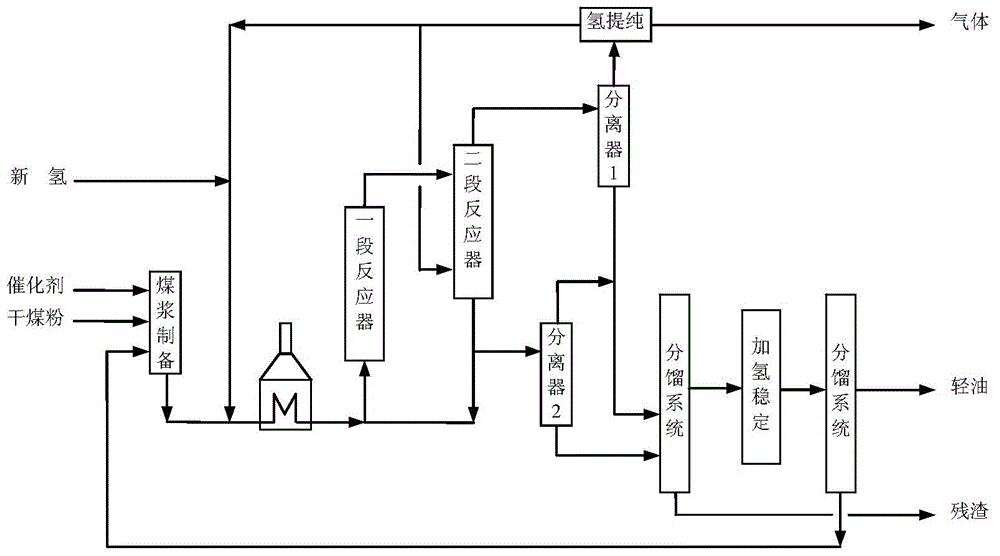

Coal liquefaction method and device

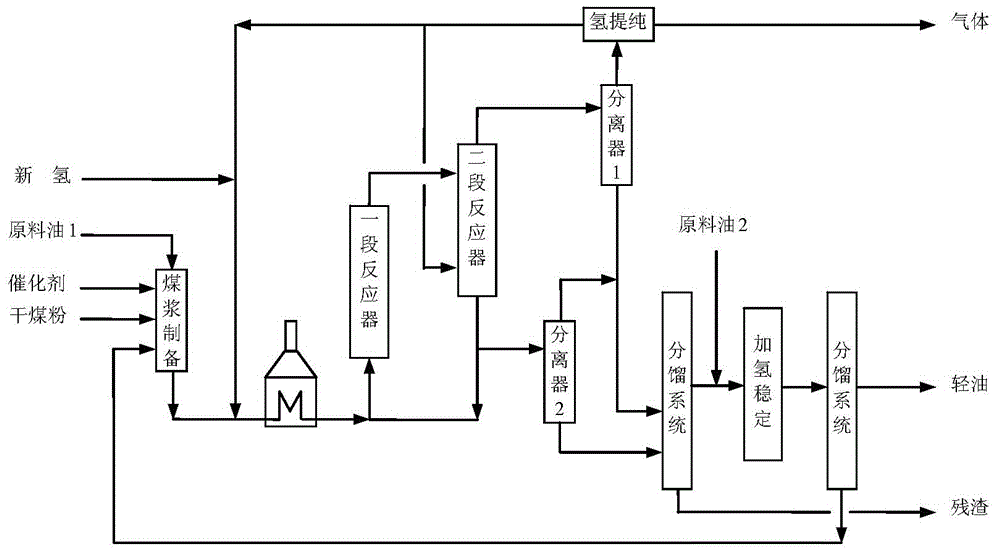

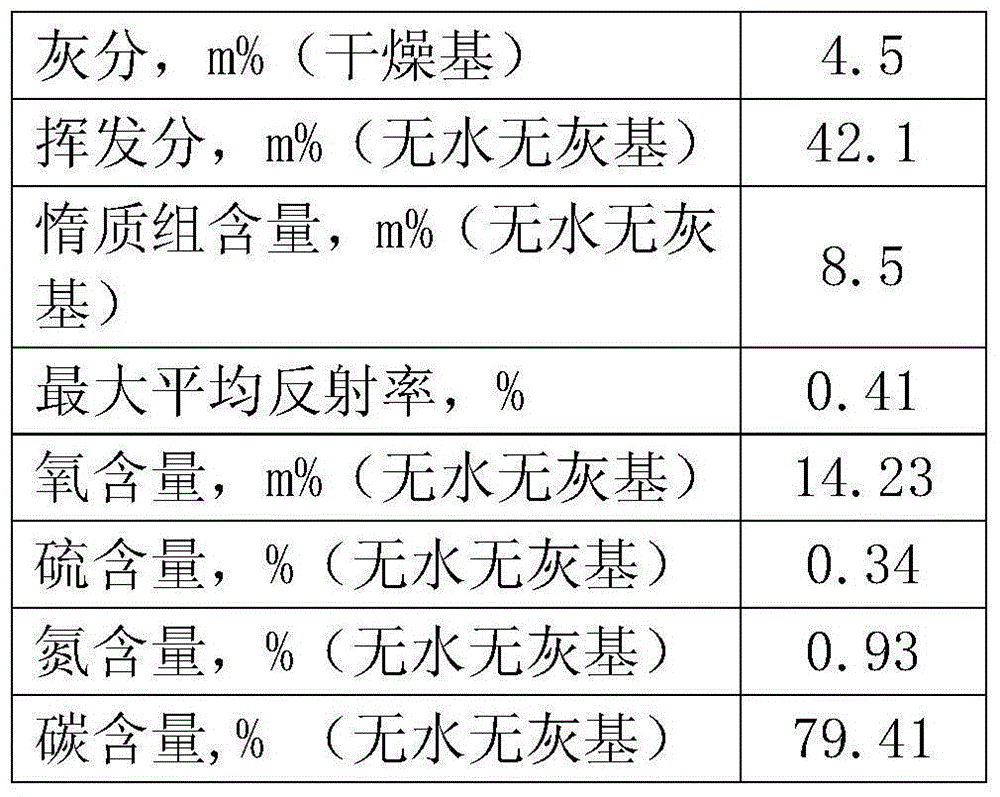

InactiveCN107057742APromotes deep liquefactionAchieve deep conversionLiquid hydrocarbon mixture productionProcess engineeringCoal slurry

The invention provides a coal liquefaction method and device. The coal liquefaction method comprises the steps as follows: first liquefaction reaction is carried out on coal slurry and hydrogen to obtain a first liquefied product, wherein the first liquefied product comprises a first gas mixture and a first heavy product and the first gas mixture comprises a first liquefied light oil and a first gas product; a first heavy product in the first liquefied product is separated and second liquefaction reaction is carried out on the first heavy product and the hydrogen to obtain a second liquefied product; and before or during the second liquefaction reaction, the method also comprises the step of adding a first hydrogenation catalyst to the first heavy product. Through the method and the device provided by the invention, the conversion rate and the oil yield of coal can be improved, and meanwhile, the hydrogen consumption and the gas yield are reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

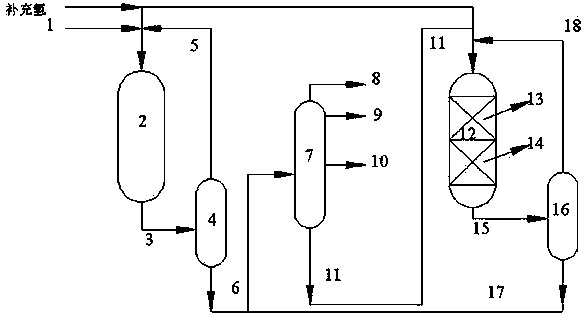

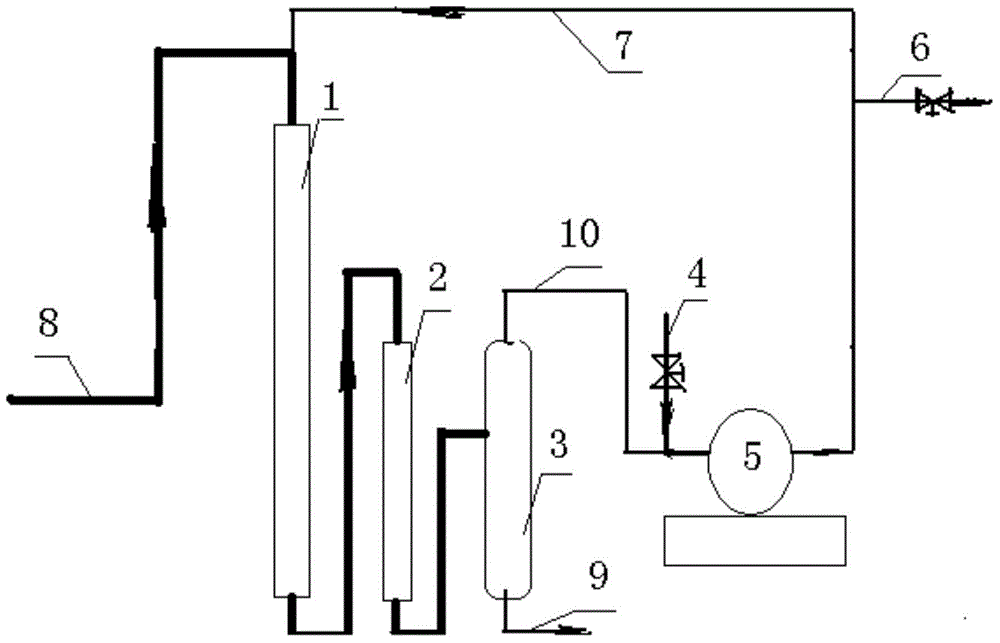

Method for hydrogenating residual oil

ActiveCN105316037AIncrease hydrogen partial pressureExtend your lifeTreatment with hydrotreatment processesHydrogenGas phase

The invention provides a method for hydrogenating residual oil. The method comprises the steps of firstly carrying out hydrogenating protection reaction on the raw material residual oil in a hydrogenating protection device so as to obtain hydrogenating protection products, then, carrying out hydrotreating reaction on the hydrogenating protection products in a hydrotreater so as to obtain hydrotreating products, and finally, carrying out separation on the hydrotreating products in a separating unit, thereby obtaining recycle hydrogen and a product. The method is characterized in that the hydrogenating protection products are divided into gas-phase and liquid-phase products, the gas-phase product is directly mixed with the hydrotreating products, then, separation is carried out, part of the liquid-phase product is mixed with a mixed hydrogen raw material, the hydrogenating protection reaction is carried out, and the other part of the liquid-phase product is fed to a hydrotreating reactor for hydrotreating reaction. Compared with the prior art, the method provided by the invention has the advantages that the lives of a hydrotreating catalyst and a hydrogenating protection catalyst can be prolonged, and the selectivity of a target product of the hydrogenating protection reaction is improved.

Owner:SINOPEC ENG +1

Process method for producing lubricating oil base oil through poor-quality raw material

ActiveCN104611047AFully activeExpand sourceTreatment with hydrotreatment processesLubricant compositionCounter flowHydrogenation reaction

The present invention discloses a process method for producing lubricating oil base oil through a poor-quality raw material. According to the process method of the present invention, a poor-quality raw material firstly enters a first-stage reaction zone to carry out a hydrorefining reaction, a co-current flow process and a counter flow process are concurrently adopted in the first stage, the generated oil obtained in the first stage enters a second-stage reaction zone to carry out a deep hydrogenation reaction, and the second-stage reaction effluent is subjected to hydrocracking; and the cracking tail oils are subjected to cutting pre-fractionation to obtain the suitable tail oil distillate, and the suitable tail oil distillate is subjected to an isomerizing dewaxing and finishing reaction to obtain the lubricating oil base oil distillate. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the lubricating oil base oil raw material source is broadened; and the operation period of the device can be increased and the poor-quality raw material can be processed, or the processing capacity of the device can be increased in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep processing method of non-caking coal or feebly caking coal

The invention discloses a deep processing method of non-caking coal or feebly caking coal, which comprises the following steps: performing medium-and-low-temperature carbonization reaction on non-caking coal or feebly caking coal to generate coal gas, semicoke and coal tar; treating the coal tar as follows: inputting the coal tar material, oil gas obtained through delayed coking reaction and a hydrocracking liquid-phase product into a distillation tower, and distilling out naphtha fractions, carbolic-oil-containing fractions, wax oil fractions and tower bottom oil; mixing the naphtha fractions with hydrogen, and inputting into a naphtha hydrofining reaction section; dephenolizing the carbolic-oil-containing fractions to obtain dephenolized oil, mixing with the wax oil fractions, and inputting into a hydrotreating reaction section; fractionating the hydrotreating reaction liquid phase into light fractions and heavy fractions, and performing hydrocracking on the heavy fractions; and inputting the tower bottom oil obtained through distillation into a delayed coker. Compared with the prior art, the method disclosed by the invention performs sufficient deep processing on coal, improves the yield of light fuel oil produced from coal tar, and simultaneously prolongs the service life of a catalyst in a hydrogenation device.

Owner:中铝能源有限公司

Method for directly liquefying coal

ActiveCN104560098AIncreased purity and hydrogen partial pressureSave construction investmentLiquid hydrocarbon mixture productionHydrocarbon oils treatmentChemistryStream flow

The invention relates to a method for directly liquefying coal, which comprises the following steps: coal slurry, hydrogen gas and a catalyst enter a first reaction region, and the mixture stream flows upwards in the first reaction region and reacts under the direct liquefying condition of slurry bed coal; after flowing out of the first reaction region, the mixture stream is subjected to gas-liquid separation into a gas-phase stream and a liquid-phase stream; the liquid-phase stream enters a second reaction region and flows downwards, performs countercurrent contact with the upward-flowing hydrogen gas in the second reaction region, and reacts under the direct liquefying condition of slurry bed coal; and the liquid-phase stream flowing out of the second reaction region partially or completely enters a separation system to perform separation. The method can lower the gas separation rate in the reactor and further enhance the direct liquefying effect of coal.

Owner:BLOOMING BEIJING TECH

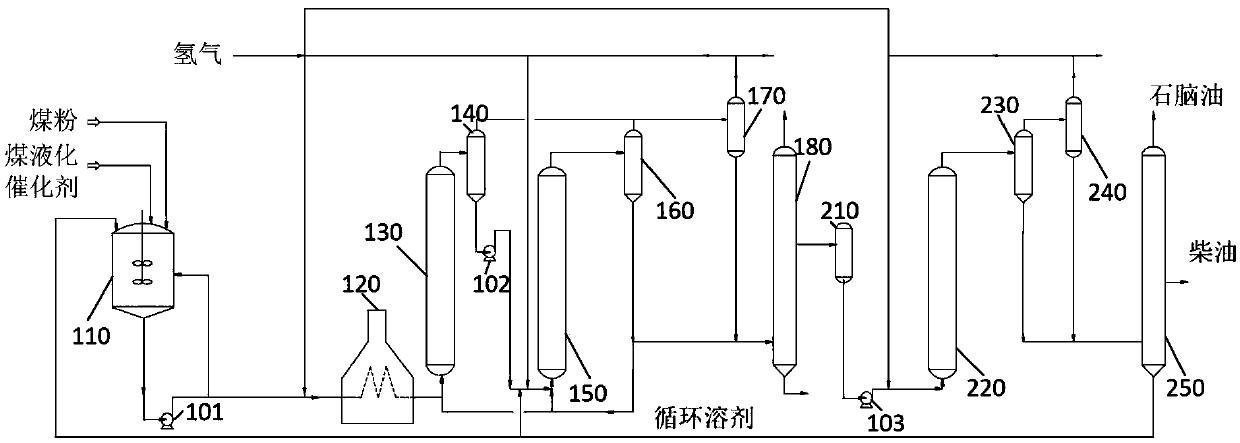

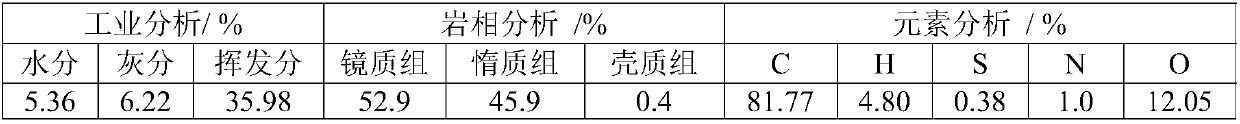

Method and device for coal direction liquefaction

ActiveCN108048121AImprove liquefaction conversionExtended stayLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsLiquid productHydrogen

The invention provides a method and device for coal direction liquefaction. The method for the coal direct liquefaction includes the following steps of: S1, performing a first liquefaction reaction ona first raw material which includes coal slurry and hydrogen so as to obtain first liquefied products, and performing oil-gas separation on the first liquefied products to obtain a first liquid-phaseproduct; S2, performing a second liquefaction reaction on a second raw material which comprises the first liquid-phase product, hydrogen and a solvent so as to obtain second liquefied products, and performing oil-gas separation on the second liquefied products to obtain a second liquid-phase product; S3, performing distillation and catalytic hydrogenation treatment on a part of the second liquid-phase product so as to obtain a coal liquefaction product; and S4, performing the steps of S1-S3 repeatedly, wherein the first raw materials and / or the second raw materials also include the rest of the second liquid-phase product during the repeated operation. Through the method for the coal direct liquefaction, the liquefaction conversion rate and liquid product yield of coal can be improved, andthe resource utilization rate can be improved significantly.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

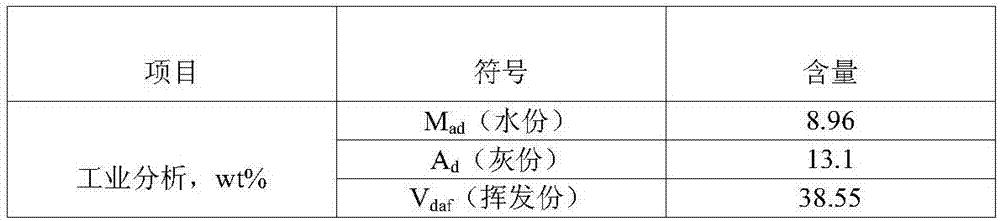

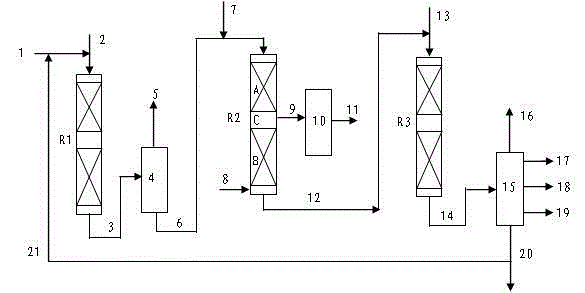

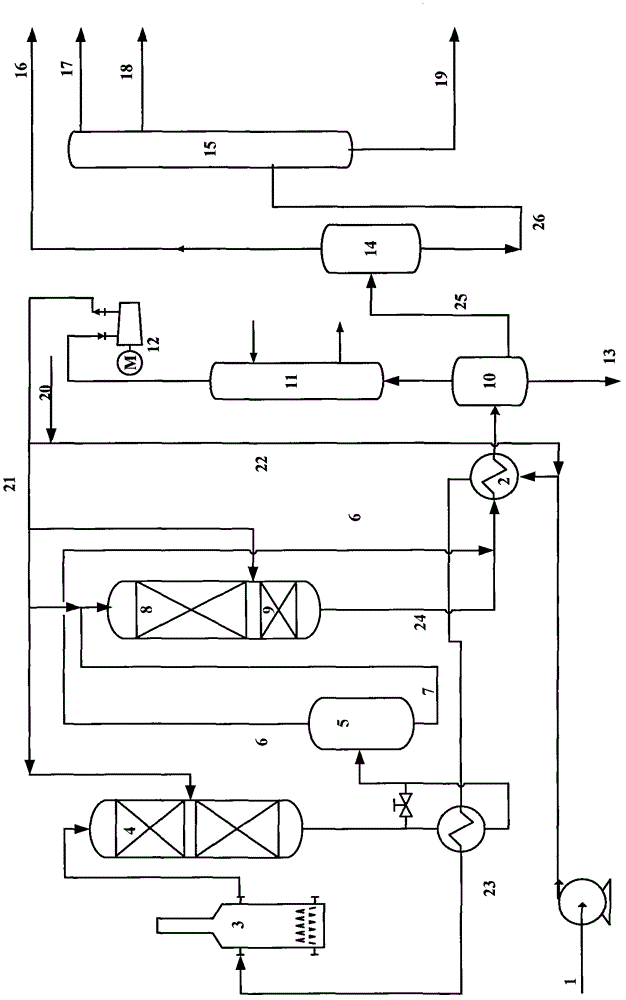

Two-stage hydrocracking method for low energy consumption production of high-quality jet fuels

ActiveCN105001909AReduce consumptionSave engineering investmentHydrocarbon oil crackingTreatment with hydrotreatment processesFractionationHigh pressure

The invention discloses a two-stage hydrocracking method for low energy consumption production of high-quality jet fuels. The method comprises the following steps: mixing a raw material with hydrogen, carrying out two-time heat exchange, allowing the obtained material to go through a heating furnace, and carrying out a hydrofining reaction; carrying out gas-liquid separation and fractionation on a refining effluent; allowing obtained tail oil to enter a hydrocracking reaction zone, wherein the cracking reaction zone comprises at least two cracking catalysts, the upstream is a catalyst I, the downstream is a catalyst II, the catalyst I contains 15-50wt% of modified Y molecular sieve, the catalyst II contains 3-30wt% of the modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-25% higher than the content of the modified Y molecular sieve in the catalyst II; and separating and fractioning a hydrocracking effluent to obtain various products. The method organically combines a high temperature and high pressure countercurrent heat transfer technology with a hydrocracking catalyst grading technology, comprehensively utilizes hydrocracking reaction heat, maintains the catalyst selectivity, improves the quality of target products, and reduces the engineering investment and the operation energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Temperature control method for slurry bed reactor, design method and application thereof

InactiveCN104888666AImprove running stabilityStable temperatureTemperature control using electric meansChemical/physical processesAutomatic controlHydrodesulfurization

The invention provides a temperature control method for a slurry bed reactor, a design method and the application thereof. The method comprises the step of injecting a coolant in pipes in front of the inlets of a reactors at all levels. The pipes are connected with at least one coolant pipeline to realize the temperature control. The coolant is composed of cold hydrogen and cold oil. According to the method, the method can be applied to reactors during the heavy oil hydrodesulfurization process, the direct coal liquefaction process and the oil-coal mixing process. Through adjusting the number of coolant pipelines and the flow of the coolant, the reaction temperature of the reactor can be controlled. The method is easy to realize during the project implementation process, and facilitates the automatic control. Meanwhile, the operation stability of the reactor is improved. Cold hydrogen and cold oil are necessary raw materials for the reaction, and the forestage reaction heat of the reactor is fully utilized. Therefore, the efficient utilization of heat is realized. The method is especially suitable for second-stage reactors and third-stage reactors. For first-stage reactors, the temperature control effect can still be realized through respectively heating two ways of hydrogen and then mixing up the two ways of hydrogen.

Owner:CATECH TECH

Poor-quality raw material hydrocracking method

ActiveCN104611016AEffectively play an active roleReduce ammonia contentTreatment with hydrotreatment processesHydrogenCounter flow

The present invention discloses a poor-quality raw material hydrocracking method. According to the method, a poor-quality raw material is firstly subjected to a first-stage hydrorefining reaction, and the reaction effluent is separated; and the liquid enters a second-stage refining stage to carry out a deep denitrogenation and aromatic hydrocarbon saturation reaction, a gas-liquid co-current flow process and a gas-liquid counter flow process are concurrently adopted in the second stage, the refining generated oil obtained in the second stage and hydrogen gas are mixed and then enter a third-stage reaction zone to carry out a hydrocracking reaction. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the hydrocracking raw material source is broadened; and the hydrorefining temperature is substantially reduced so as to increase the operation period of the device and process the poor-quality raw material, or increase the processing capacity of the device in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

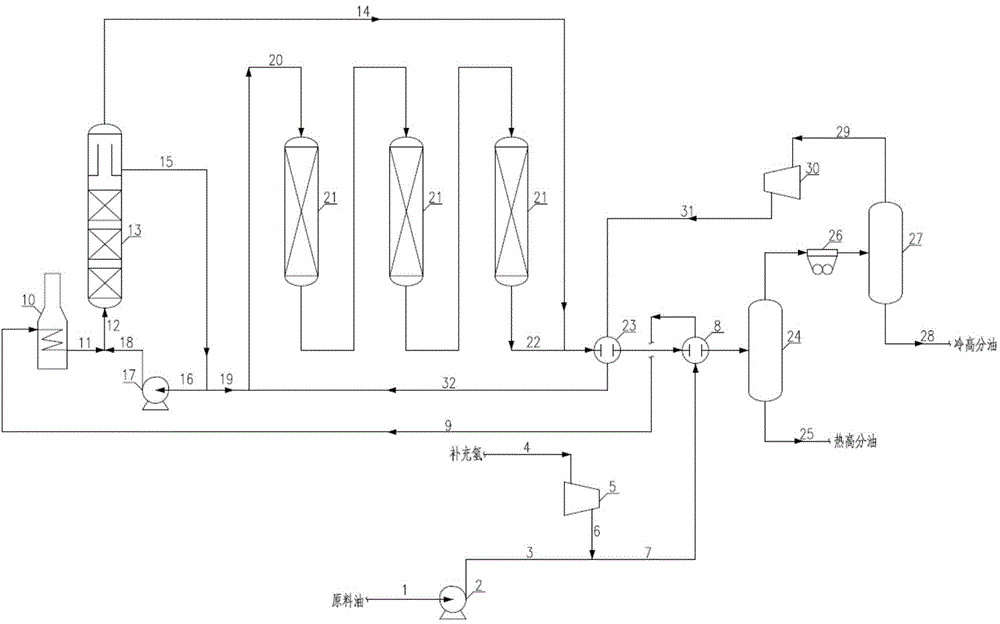

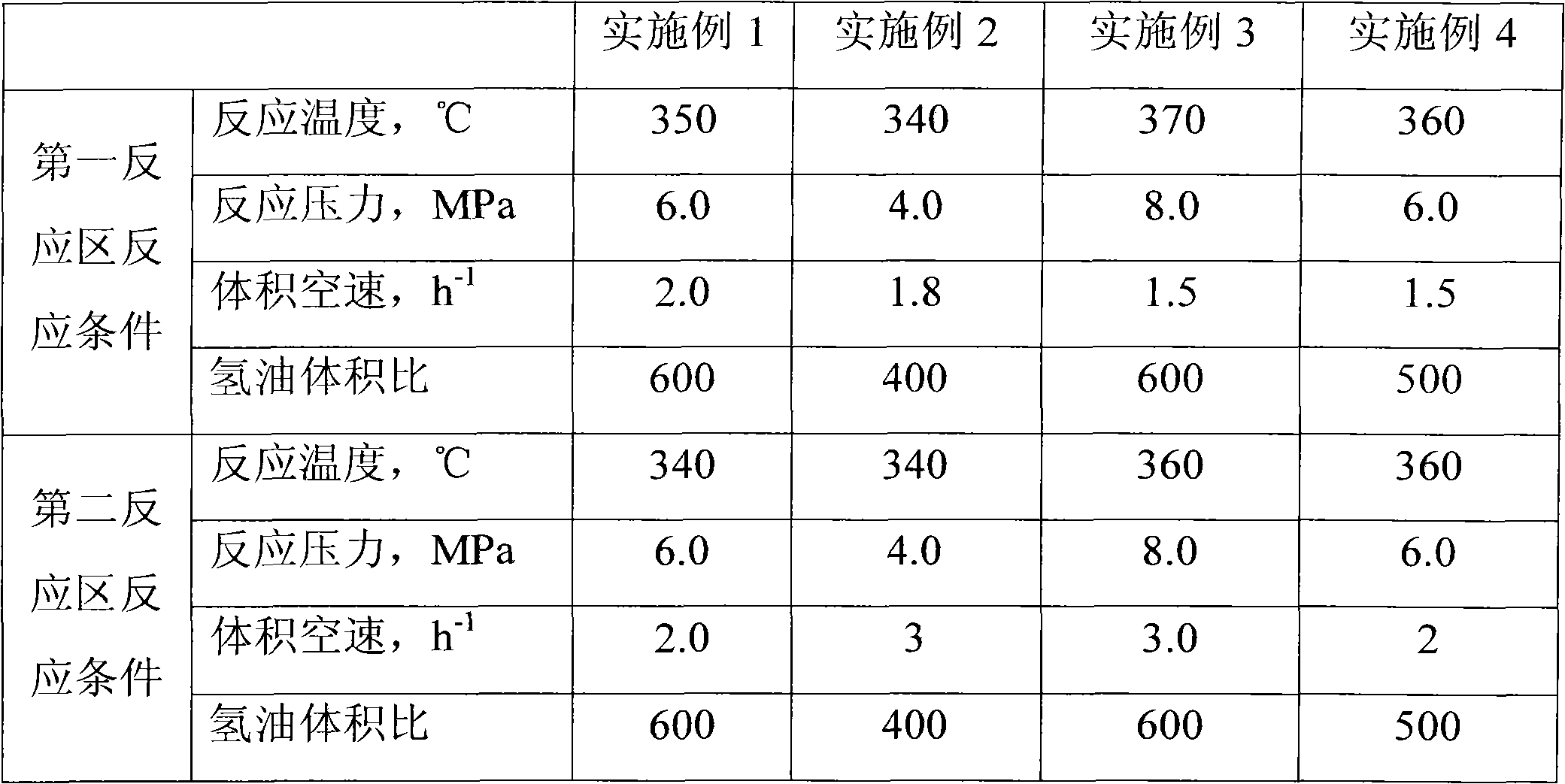

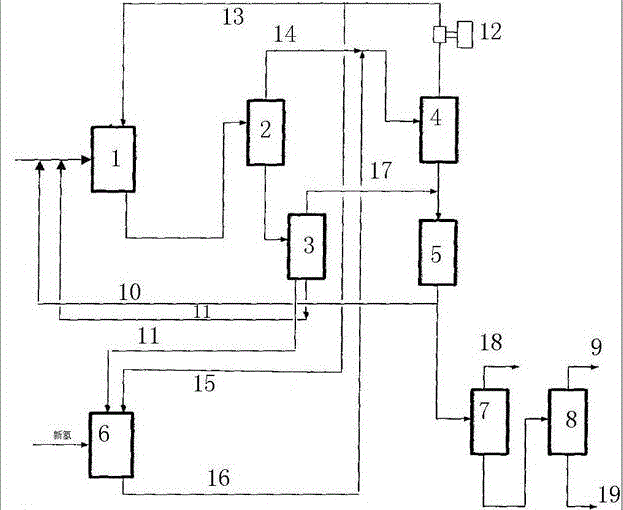

Semi-regenerative catalytic reforming method

ActiveCN104560131AReduce carbon depositionExtended service lifeCatalytic naphtha reformingHydrocarbon oils treatmentCatalytic reformingNaphtha

The invention discloses a semi-regenerative catalytic reforming method, comprising the following steps: starting a compressor to carry out gas circulation, feeding naphtha to a semi-regenerative reforming reactor, heating to 400-550 DEG C, and reacting under 0.2-3.0MPa; introducing high-purity hydrogen at the inlet of the compressor, and mixing with reforming cycle hydrogen, wherein the volume flow per hour of the introduced high-purity hydrogen is 10-1000 times volume of the catalyst. The method is low in operation cost and simple and convenient to operate; carbon deposit of a catalyst in the reaction process can be reduced; and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

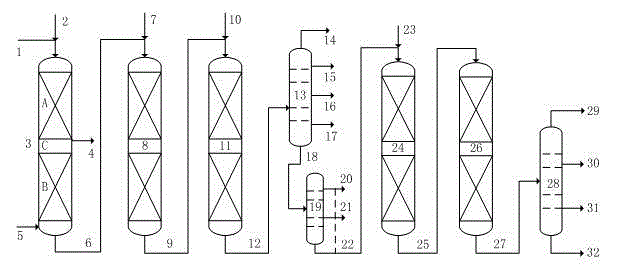

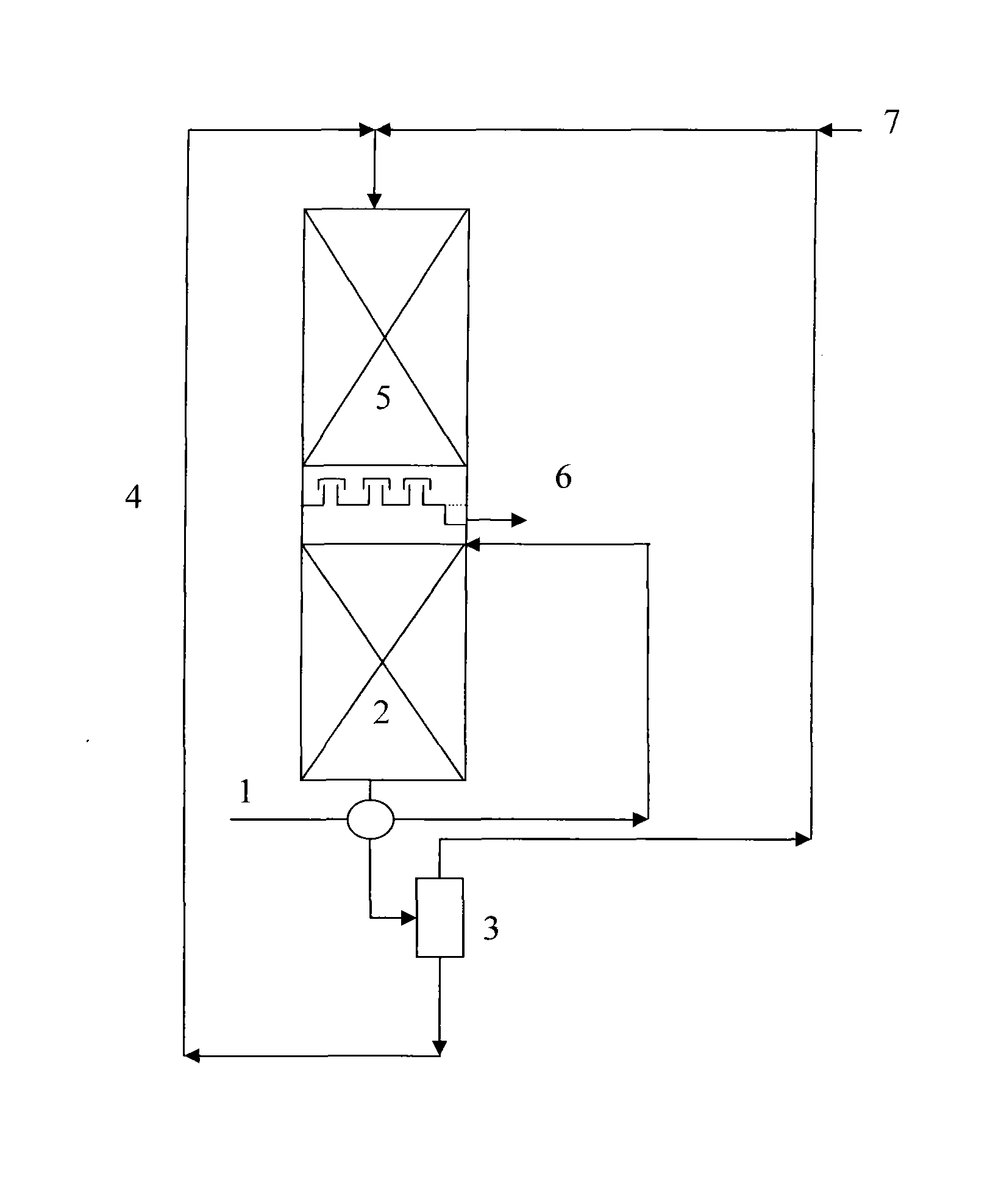

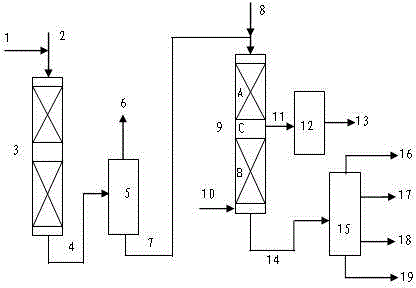

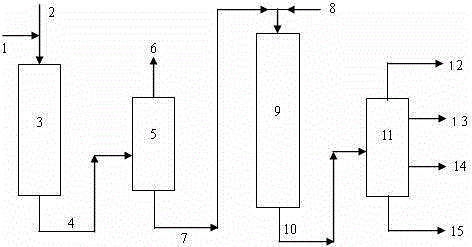

Diesel hydrogenation process method

ActiveCN102041072AUniform temperature distributionImprove the reaction environmentTreatment with hydrotreatment processesGas phaseHydrogenation reaction

The invention discloses a diesel hydrogenation process method. The upper part in a hydrofining reactor is provided with a first reaction zone, and the lower part in the hydrofining reactor is provided with a second reaction zone; a liquid collecting and discharging part is arranged between the two reaction zones and is used for collecting liquid of reaction effluent in the first reaction zone and discharging the liquid out of the reactor; a gas phase of the reaction effluent in the first reaction zone enters the second reaction zone through a bubble cap of the liquid collecting and discharging part; a diesel raw material enters the second reaction zone and is mixed with the gas phase inflowing from the first reaction zone to be subjected to hydrofining reaction under the hydrofining condition; reaction effluent in the second reaction zone is subjected to gas-liquid separation to form a gas phase; the gas phase from which hydrogen sulfide is removed is mixed with a liquid phase to enter the first reaction zone so as to be subjected to hydrogenation reaction; and the hydrogenated product is obtained after the liquid phase of the reaction effluent in the first reaction zone is discharged by the liquid collecting and discharging part. Compared with the prior art, the method has the advantages that: reaction heat is fully utilized; a large amount of cold hydrogen is not needed; meanwhile, the reaction environments of different reaction zones are optimized, and the whole reaction performance is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coking full-distillate oil hydrocracking method

ActiveCN104611028AAddress uneven distributionRealize separation operationTreatment with hydrotreatment processesHydrocarbon oils treatment productsGas phaseFractionation

The present invention discloses a coking full-distillate oil hydrocracking method. According to the method, coking full-distillate and a hydrocracking gas phase heated by a heating furnace are mixed and then enter an upflow type reactor, and the hydrorefining product is separated on the upper portion of the reactor to obtain a gas phase and a liquid phase; the gas phase enters a separator to separate to obtain gas and a liquid phase; the pressure-increasing hydrorefining liquid and hydrogen gas are mixed and then enter a hydrocracking reactor from the bottom portion of the reactor, and the cracking reaction product is separated in the reactor; the obtained cracking gas phase is heated and then is mixed with raw material oil; and the obtained cracking liquid phase is mixed with the liquid phase obtained through the separator, and then fractionation is performed to obtain the hydrocracking product. With the method of the present invention, the problem of the non-uniform material distribution is well solved, the problem that the direct mixing heat exchange of the raw material oil and the hydrocracking gas phase heated by the heating furnace at the low temperature causes the sharply-increased pressure drop due to the coking deposition of the unsaturated hydrocarbon in the equipment is solved, the operating period is effectively prolonged, and the energy consumption of the equipment is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing low freezing point diesel oil by coked gasoline and diesel oil

ActiveCN103059943ALowering the freezing pointHigh distillate yieldTreatment with hydrotreatment processesGas phaseFractionation

The invention relates to a method for producing a low freezing point diesel oil by coked gasoline and diesel oil, which is characterized in that coked gasoline and diesel oil is contacted in a first reaction zone with a Hydrobon catalyst I for reaction, an effluent is performed with flash evaporation in a hot high-pressure separator, the obtained liquid phase material flow is introduced in a second reaction zone and is contacted with a hydrogenation modified pour point depression catalyst for a hydrogenation modified pour point depression reaction, a reaction effluent is mixed with the gas phase material flow obtained in the hot high-pressure separator and is introduced in a separating system and a fractionation system, and the gas, a naphtha fraction and a low freezing point diesel oil fraction can be separated. According to the invention, the optimal hydrogenation modified heterogeneous pour point depression reaction is employed, the freezing point of the diesel oil fraction can be obviously reduced, and the high product diesel oil fraction yield can be simultaneously kept. The method can directly produce the number -10--35 low freezing point diesel oil, the sulfur content, nitrogen content and aromatic hydrocarbons content of the product can be reduced, and the cetane number is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anthracene oil hydrogenation method

InactiveCN106221792ALow aromatic contentHigh purity hydrogenTreatment with hydrotreatment processesHydrocarbon oils treatment productsAnthraceneGasoline

The invention belongs to the technical field of coalification industry and particularly relates to an anthracene oil hydrogenation method. The anthracene oil hydrogenation method comprises the following steps that after anthracene oil hydrofining, separation is performed through a hot high-pressure separator, a liquid-phase product enters a hot low-pressure separator, and hot low-fraction oil is partially circulated to a hydrofining reactor; the residual hot low-fraction oil enters a hydrocracking reactor to obtain a hydrocracking product, the hydrocracking product and gas separated from the hot high-pressure separator enter a cold high-pressure separator, the liquid separated from the hot high-pressure separator and gas separated from the hot low-pressure separator enter a cold low-pressure separator for further gas-liquid separation, cold low-fraction oil separated from the cold low-pressure separator is partially circulated to the hydrofining reactor; fractionation is conducted on the residual cold low-fraction oil to obtain various products and tail oil. The method is small in temperature rise at a refining stage and stable in operation, can not only used for production of light gasoline and diesel products through anthracene oil hydrogenation, makes the devices safe and stable in operation and prolongs the operating cycle of the devices.

Owner:山东恒信科技发展有限公司

Two-stage hydrotreating method of poor-quality raw material

ActiveCN104611014AEffectively play an active roleExpand sourceTreatment with hydrotreatment processesHydrocarbon oils treatment productsCounter flowNitrogen

The present invention discloses a two-stage hydrotreating method of a poor-quality raw material. According to the method, a poor-quality raw material firstly enters a first stage to carry out a hydrorefining reaction, and the reaction effluent is separated; and the obtained liquid enters a second-stage refining stage to carry out a deep denitrogenation and aromatic hydrocarbon saturation reaction, and a gas-liquid co-current flow process and a gas-liquid counter flow process are concurrently adopted in the second stage. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the catalytic cracking raw material requirement, such that the hydrotreating raw material source is broadened; and the hydrorefining temperature is substantially reduced so as to increase the operation period of the device and process the poor-quality raw material, or increase the processing capacity of the device in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

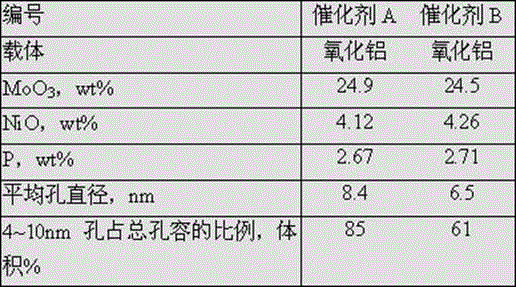

Ultra-deep desulfurization and dearomatization method for diesel oil

ActiveCN111073683AIncrease hydrogen partial pressureHigh purity hydrogenHydrocarbon oils treatmentRefining to eliminate hetero atomsThermodynamicsPtru catalyst

The invention discloses an ultra-deep desulfurization and dearomatization method for diesel oil. The method comprises the following steps that under a hydrogenation reaction condition, raw oil sequentially passes through a region I, a region II, a region III and a region IV filled with a hydrogenation catalyst in a reactor from top to bottom, and is subjected to a hydrogenation reaction with the catalyst in each region and hydrogen from bottom to top, and a hydrogenation reaction product flows out from the bottom of the reactor, wherein the reaction temperatures of the region I, the region IIand the region III are gradually increased, and the reaction temperature of the region IV is 51-100 DEG C lower than the reaction temperature of the region III. According to the method, different catalysts are reasonably graded, process parameters corresponding to the catalysts are adjusted, and the method is used for the hydrogenation reaction of diesel oil and can meet the requirements for producing low-sulfur and low-aromatic hydrocarbon diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Poor-quality heavy distillate oil hydrotreating method

ActiveCN104611009AEffectively play an active roleExpand sourceTreatment with hydrotreatment processesHydrogenReaction zone

The present invention relates to a poor-quality heavy distillate oil hydrotreating method. According to the method, under a hydrorefining condition, a heavy distillate oil raw material and hydrogen gas are mixed and enter a first-stage reaction zone to carry out a hydrotreating reaction, the first-stage reaction zone effluent is subjected to gas-liquid separation to obtain a liquid phase, the liquid phase enters a second-stage reaction zone to carry out a hydrotreating reaction, and the second-stage reaction zone reaction effluent is separated to obtain the hydrotreating reaction product. Compared with the existing hydrotreating technology in the prior art, the method of the present invention has the following advantages that: the product quality and the processing capability of the device can be substantially improved, or the operating pressure can be reduced and the operating cost can be reduced under the same product quality and processing capability condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Counter flow hydrogenation method of catalytic-cracked heavy oil

ActiveCN102373082AGood for saturation reactionIncrease hydrogen partial pressureTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonCounter flow

The invention relates to a counter flow hydrogenation method of catalytic-cracked heavy oil. According to the method, catalytic-cracked heavy oil is heated by using a catalytic-cracked heavy oil heating furnace, and is delivered into a hydrogenation reactor from the top of the reactor; the catalytic-cracked heavy oil contacts a hydrogenation catalyst with a down-flow manner; hydrogen is heated by using a hydrogen heating furnace, and is delivered into the hydrogenation reactor from the bottom of the reactor; the hydrogen passed through a hydrogenation catalyst bed with an up-flow manner; two phases which are the catalytic-cracked heavy oil and hydrogen are subject to counter flow contact, such that the hydrogenation reaction is completed; a liquid flow is discharged from the bottom of the hydrogenation reactor after the reaction is finished, and a gas phase glow is discharged from the top of the hydrogenation reactor; and with the controlling over an outlet temperature of the hydrogen heating furnace, the temperature in the lower part of the hydrogenation reactor is lower than that in the upper part of the hydrogenation reactor. According to the invention, hydrogen and the raw material oil are subject to counter flowing; hydrogen partial pressure at the lower part of the reactor is higher than that at the upper part of the reactor, and the temperature at the lower part of the reactor is lower than that at the upper part of the reactor. The conditions are beneficial for saturated reaction of polycyclic aromatic hydrocarbon. With the method, relatively high hydrodesulfurization rate, hydrodenitrogenation rate, and polycyclic aromatic hydrocarbon saturation rate can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com