Multistage hydrogenation method for heavy hydrocarbon

A technology for heavy hydrocarbons and hydrodesulfurization, which is applied in hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problem of no specific combination, etc., to increase conversion rate, improve hydrogen partial pressure, and wide applicability of raw materials. Effect

Active Publication Date: 2011-05-25

CHINA PETROLEUM & CHEM CORP +1

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The combined process is only based on the liquid feed requirements of different devices for the joint use of devices, without specific combination of the characteristics of various processes, try to maximize the advantages of each process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

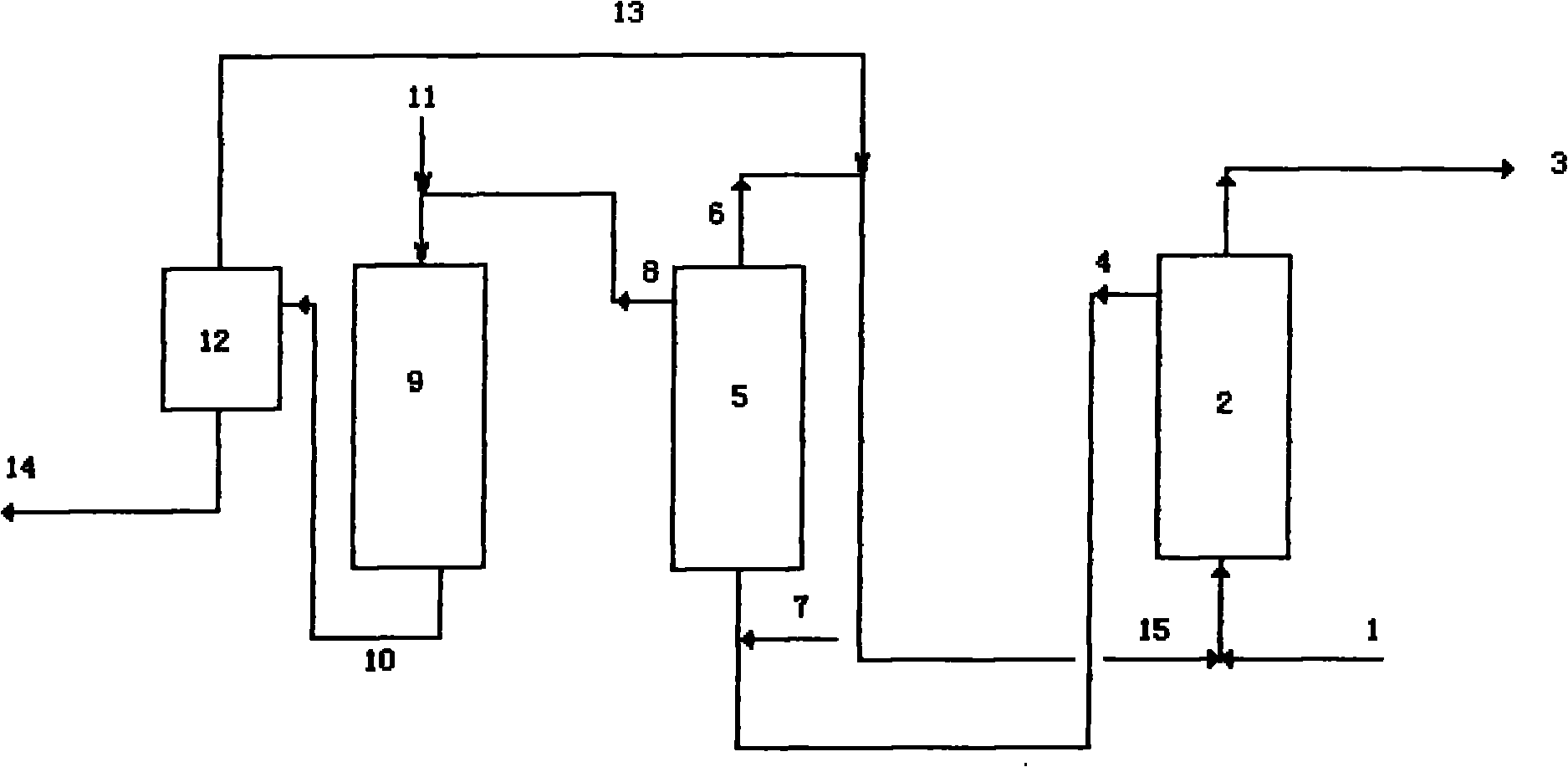

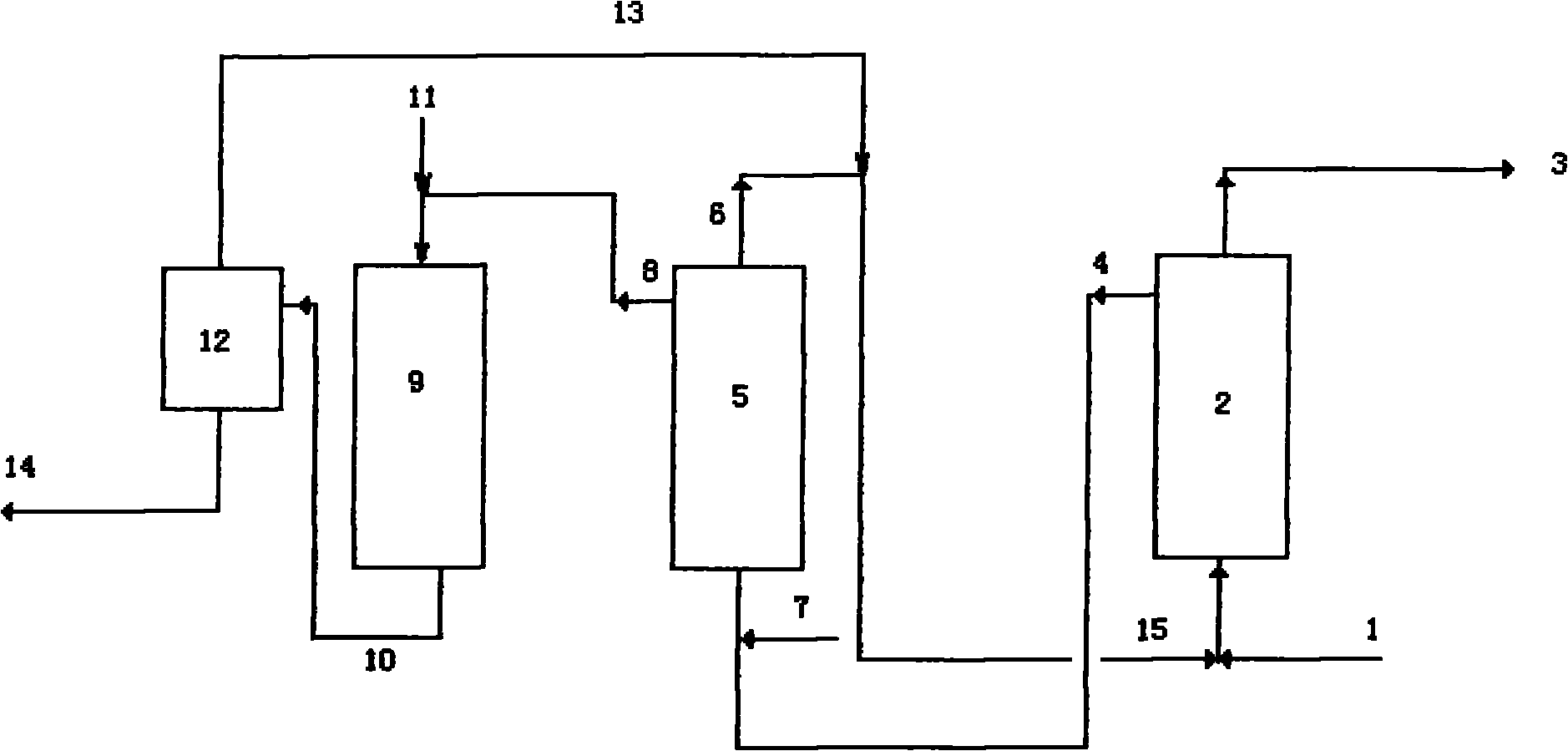

[0034] This example is an embodiment of the ebullating-bed hydrodemetallization, fixed-bed hydrodesulfurization and fixed-bed hydrodenitrogenation processing techniques of the present invention, and the operation flow diagram refers to figure 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a multistage hydrogenation method for heavy hydrocarbon. The method comprises the following technical steps of: mixing a condensed heavy hydrocarbon raw material and a gas phase material flow discharged from a hydrogenation desulfurization reactor and a hydrogenation denitrification reactor, and putting the mixture into a boiling bed hydrogenation demetalization reactor; cooling and purifying the reacted gas phase material flow and taking the cooled and purified reacted gas phase material flow as recycled hydrogen; mixing a liquid phase material flow subjected to the boiling bed demetalization reaction and the hydrogen, and putting the mixture into the hydrogenation desulfurization reactor; mixing the liquid phase material flow subjected to the desulfurization reaction with the hydrogen, and putting the mixture into the hydrogenation denitrification reactor, wherein at least one of the hydrogenation desulfurization reactor and the hydrogenation denitrification reactor is a fixed bed reactor. Compared with the prior art, the method provides a novel flexible, efficient and energy-saving operating mode for treating inferior heavy and residual oil raw materials; the property of the raw materials is organically combined with characteristics of the hydrogenation reactions, so the reaction released heat is fully used, the quality of the product is perfect and the operation process can be flexibly adjusted as required on the premise of guaranteeing the stable operation of a device.

Description

technical field [0001] The invention relates to a multi-stage hydrogenation method for heavy hydrocarbons, in particular to the hydrogenation of heavy hydrocarbon raw materials such as low-quality heavy oil and residual oil, such as hydrodemetallization, hydrodesulfurization, and hydrodenitrogenation, using fluidized bed and fixed bed technologies. process method. Background technique [0002] With the vigorous development of heavy crude oil and the changes in the demand structure of petroleum products worldwide, the market demand for light fuel oil continues to grow rapidly and the demand for heavy fuel oil decreases rapidly. The deep processing technology of heavy oil has become the development of the refining industry. focus. Heavy oil hydrogenation technology is the most effective processing method that can not only meet the current environmental protection requirements, but also maximize the light weight of heavy oil. Heavy oil hydrogenation technology can be divided ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10G67/02

Inventor 贾丽李鹤鸣胡长禄

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com