Novel supported polyacid catalyst and application thereof in furfural preparation

An acid catalyst and supported technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., to achieve the effects of improving catalytic performance, improving reactivity, and wide repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

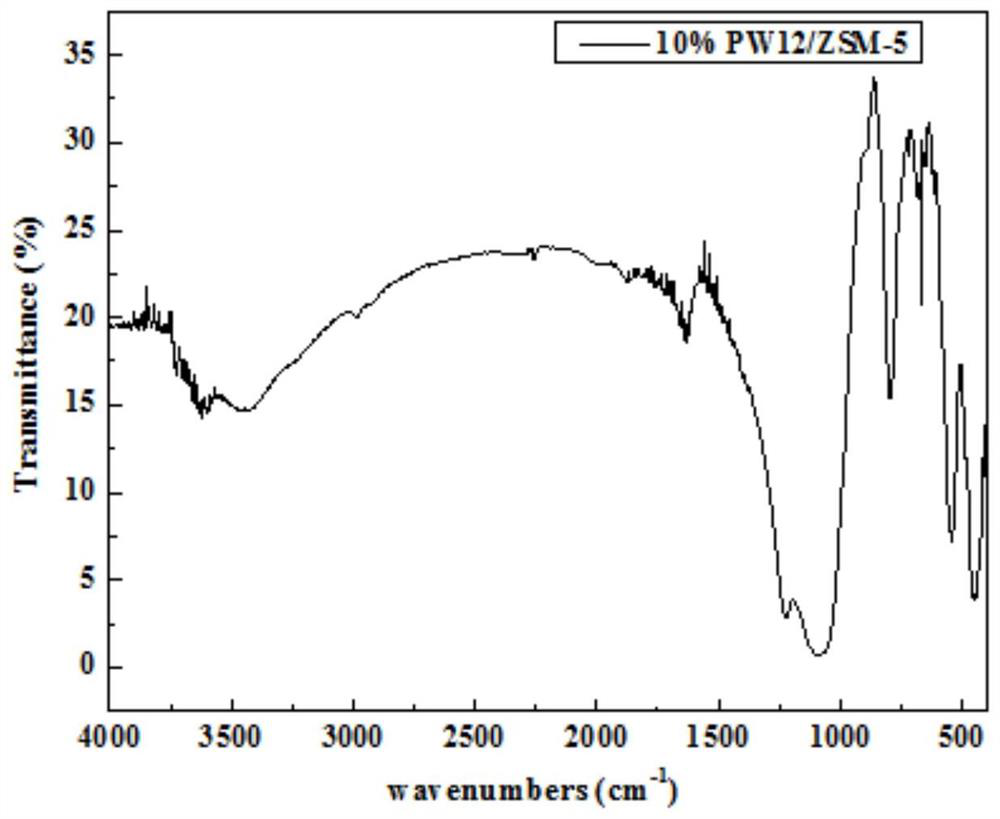

[0035] Weigh molecular sieve ZSM-5(38) and polyacid compound H respectively according to mass ratio 1:0.1 3 PW 12 o 40 ; the polyacid compound H 3 PW 12 o 40 Pour into the reactor, add 2.7ml of water according to the equal-volume impregnation method, stir to dissolve, then add the polyacid solution dropwise to the ZSM-5(38) powder, stir while adding, and stir for 30 minutes after dissolving. The reaction system was left to stand for 24 hours, and a pale yellow solid was precipitated, which was filtered and dried, and the solid was placed in a receptacle furnace and calcined at 250° C. for 4 hours to obtain a polyacid-supported catalyst for preparing furfural.

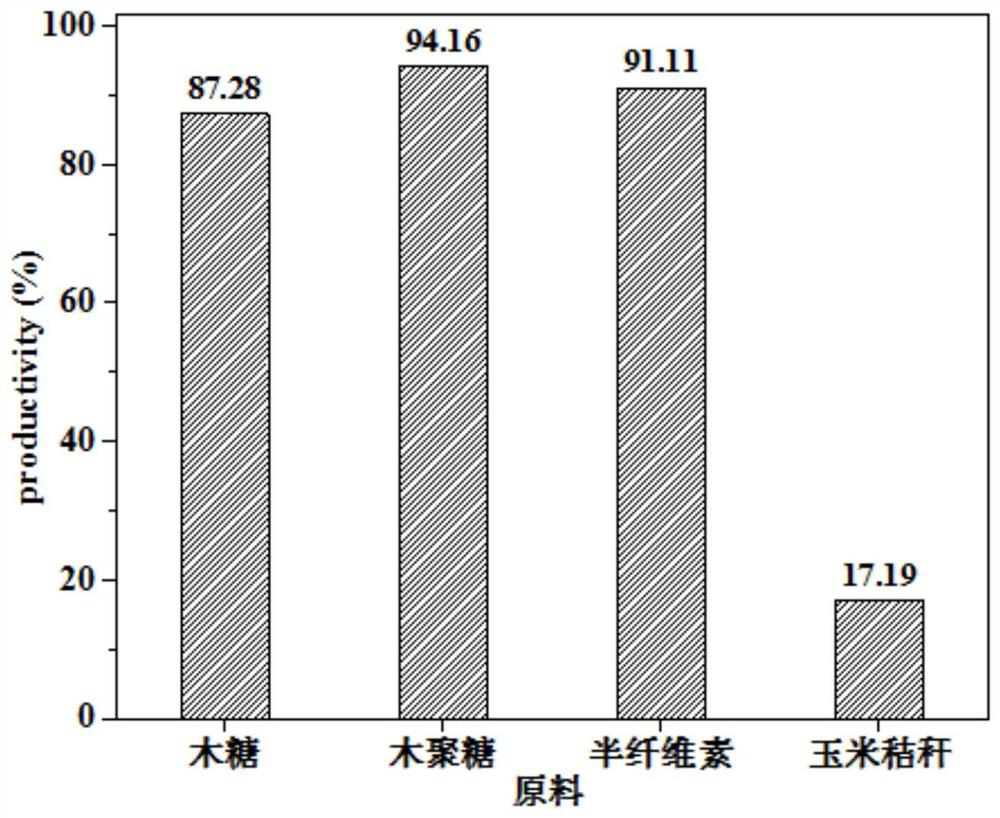

[0036] Xylose powder 0.15g, 0.75mmol10%H 3 PW 12 o 40 Put the catalyst of / ZSM-5 (38) into a thick-walled pressure-resistant bottle, add 6ml of 10% LiBr / water solution, and heat and stir. The reaction temperature is 130° C., and the reaction time is 4 hours. After the reaction is finished, after cooling, the re...

Embodiment 2

[0038] Weigh molecular sieve ZSM-5(38) and polyacid compound H respectively according to mass ratio 1:0.2 3 PW 12 o 40 ; the polyacid compound H 3 PW 12 o 40 Pour into the reactor, add 2.7ml of water according to the equal-volume impregnation method, stir to dissolve, then add the polyacid solution dropwise to the ZSM-5(38) powder, stir while adding, and stir for 30 minutes after dissolving. The reaction system was left to stand for 24 hours, and a light yellow solid was precipitated, which was filtered and dried. The solid was placed in a receptacle furnace and calcined at 300° C. for 4 hours to obtain a polyacid-supported catalyst for preparing furfural.

[0039] xylose powder 0.10g, 0.75mmol10%H 3 PW 12 o 40 Put the catalyst of / ZSM-5 (38) into a thick-walled pressure-resistant bottle, add 6ml of 20% LiBr / water solution, and heat and stir. The reaction temperature is 150°C, and the reaction time is 5h. After the reaction is finished, after cooling, the reaction mix...

Embodiment 3

[0041] Weigh molecular sieve ZSM-5(38) and polyacid compound H respectively according to mass ratio 1:0.3 3 PW 12 o 40 ; the polyacid compound H 3 PW 12 o 40 Pour into the reactor, add 2.7ml of water according to the equal-volume impregnation method, stir to dissolve, then add the polyacid solution dropwise to the ZSM-5(38) powder, stir while adding, and stir for 30 minutes after dissolving. The reaction system was allowed to stand for 24 hours, and a light yellow solid was precipitated, which was filtered and dried. The solid was placed in a mug furnace and calcined at 350° C. for 4 hours to obtain a polyacid-supported catalyst for preparing furfural.

[0042] Xylose powder 0.15g, 0.75mmol10%H 3 PW 12 o 40 Put the catalyst of / ZSM-5 (38) into a thick-walled pressure-resistant bottle, add 6ml of 30% LiBr / water solution, and heat and stir. The reaction temperature is 180°C, and the reaction time is 6h. After the reaction is finished, after cooling, the reaction mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com