Method and device for separating ethylene and propylene from pyrolysis gas and/or dry gas

A cracking gas and dry gas technology, applied in the chemical industry, can solve the problems of complex refrigeration and heat exchange process, large cooling capacity consumption, low ethylene concentration, etc., achieve wide applicability of raw materials, simplify heat exchange process, and reduce refrigeration load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this example, cracked gas produced by steam cracking of light hydrocarbons such as C4, gas fraction propane and liquefied gas in a refinery is used as raw material. The specific composition of the cracked gas is shown in Table 1.

[0063] Table 1

[0064]

[0065]

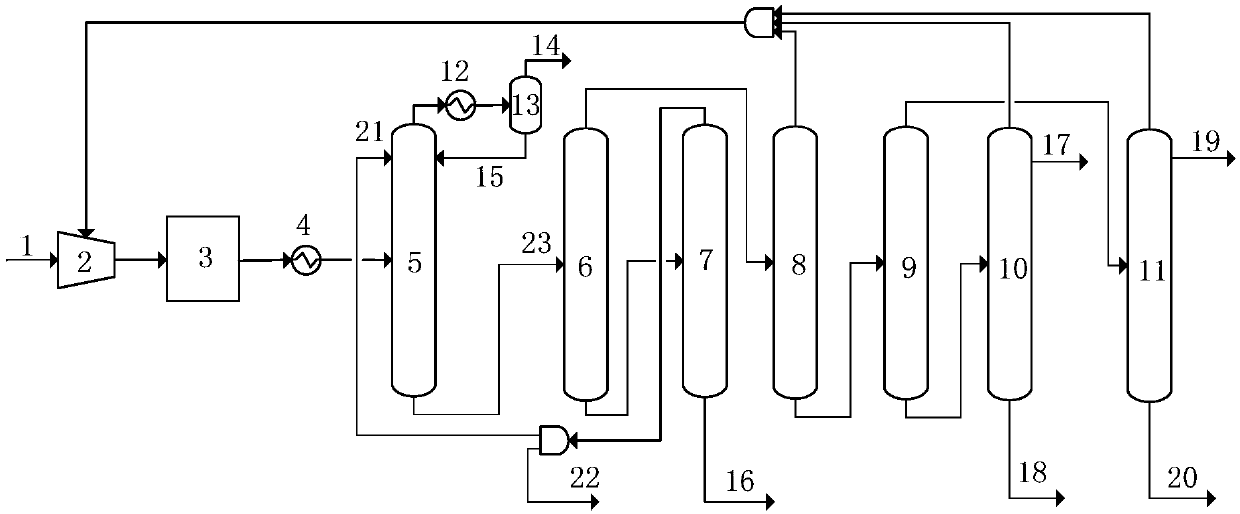

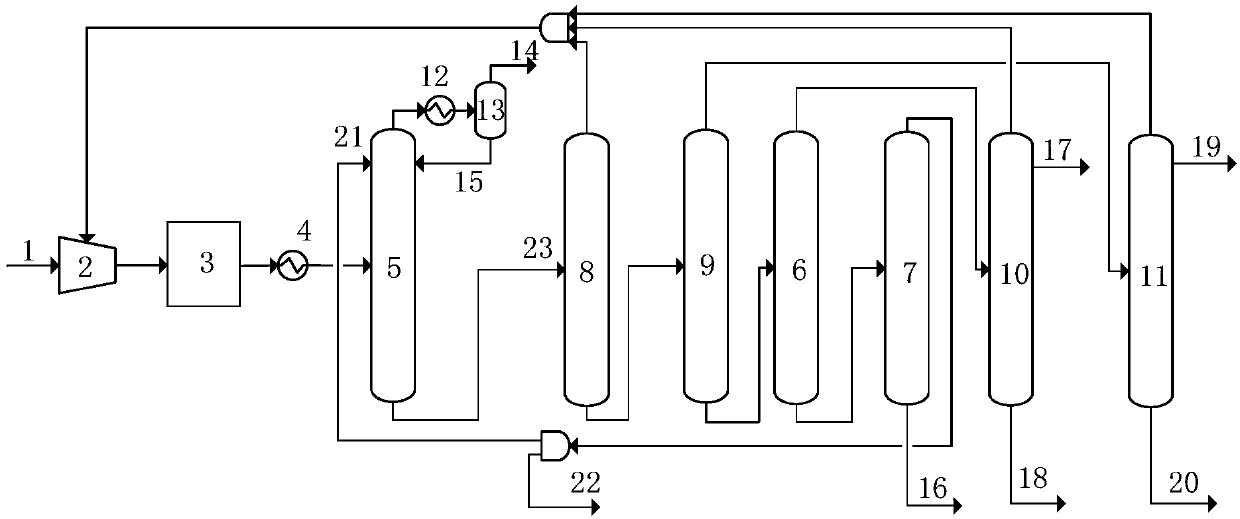

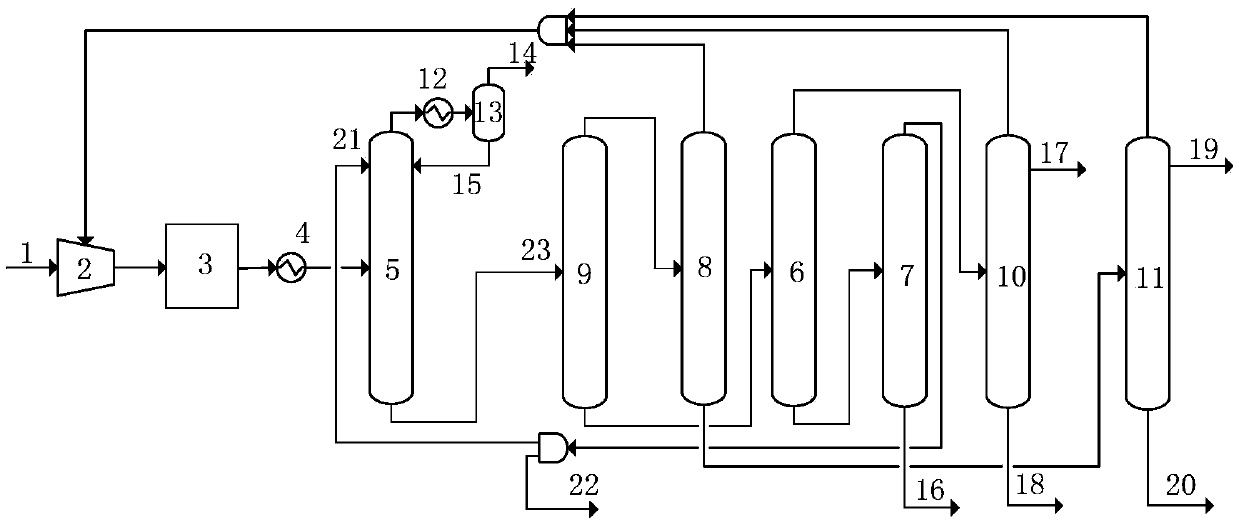

[0066] use as figure 1 Separation flow diagram shown, separation of ethylene and propylene from cracked gas and / or dry gas.

[0067] The separation device includes a compressor 2, a purification unit 3, a cooler 4, an oil absorption tower 5, a light hydrocarbon separation unit, and an olefin rectification unit, wherein the light hydrocarbon separation unit includes a demethanizer 8, a deethanizer 9, a deethanizer The propane tower 6 and the debutanizer 7, the olefin rectification unit includes an ethylene rectification tower 11 and a propylene rectification tower 10.

[0068] The compressor 2 is sequentially connected with the purification unit 3, the cooler 4, and the oil absorption tower 5;

[...

Embodiment 2

[0086] In this example, a stream of FCC dry gas is added to the raw material in Example 1, that is, the cracked gas and FCC dry gas are processed simultaneously, and the FCC dry gas is mixed with the cracked dry gas at the second-stage outlet of the compressor and sent to the compressor together. The third stage: because the FCC dry gas contains oxygen and carbon dioxide, in the purification process 3, the mixed gas is deoxidized, decarburized and dried in sequence. The specific composition of FCC dry gas is shown in Table 3.

[0087] table 3

[0088]

[0089]

[0090] The difference between operating conditions and embodiment 1 is:

[0091] (4) Absorption: The theoretical plate number of the oil absorption tower 5 is 40, the operating pressure is 3MPaG, the tower top temperature is 7.9°C, the tower top condenser outlet temperature is -35°C, and the tower bottom temperature is 92.4°C;

[0092] (5) Depropanization: The theoretical plate number of the depropanization tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com