Patents

Literature

43results about How to "Guaranteed operating cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

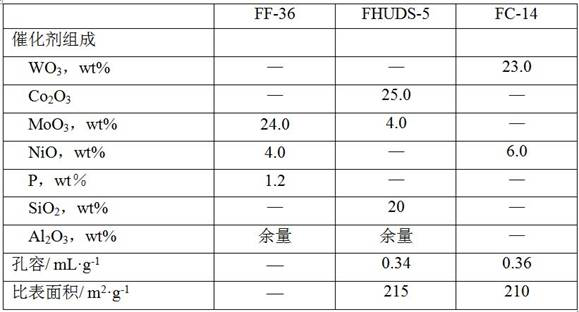

Hydrogenation purification method for siliceous distillate

ActiveCN101343565AIncrease capacityFast inactivationTreatment with hydrotreatment processesPurification methodsHydrogen

The invention relates to a silicon-containing distillate oil hydrofining method, which adopts the method that the silicon-containing distillate oil raw material and hydrogen pass through at least two hydrofining catalyst beds under the hydrofining condition, the silicon-containing distillate oil raw material first passes through a hydrogenising catalyst bed with the silicon catching function, and then passes through a conventional hydrofining catalyst bed; wherein the hydrogenising catalyst with the silicon catching function has a greater pore volume and a specific surface area and a relatively lower metal content. Compared with the prior art, the method has the advantages that the process is simple, the good hydrodesulfurization and hydrodedenitrification performance is kept on the premise of enhancing the silicon-containing ability, and the running period of the device is effectively prolonged. The method can be applied to various silicon-containing distillate oil hydrofining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

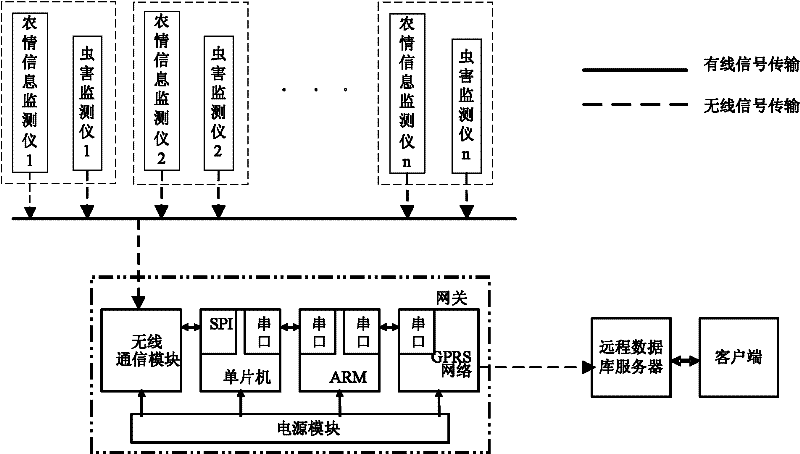

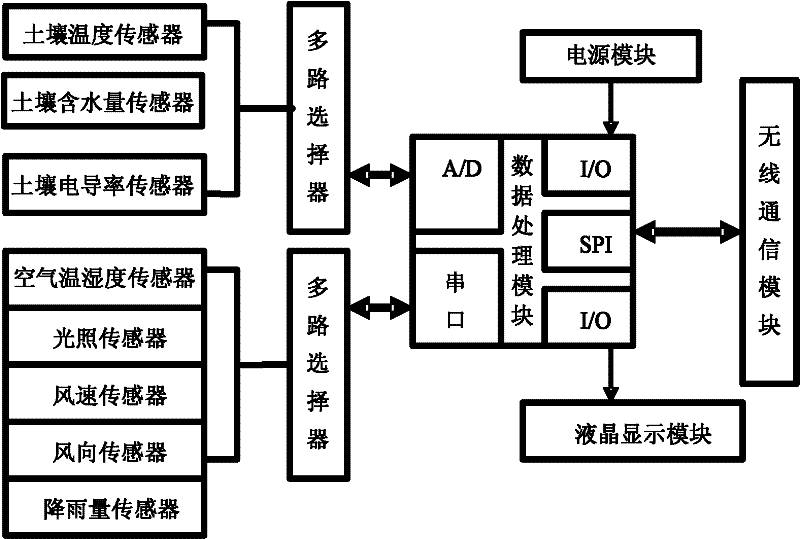

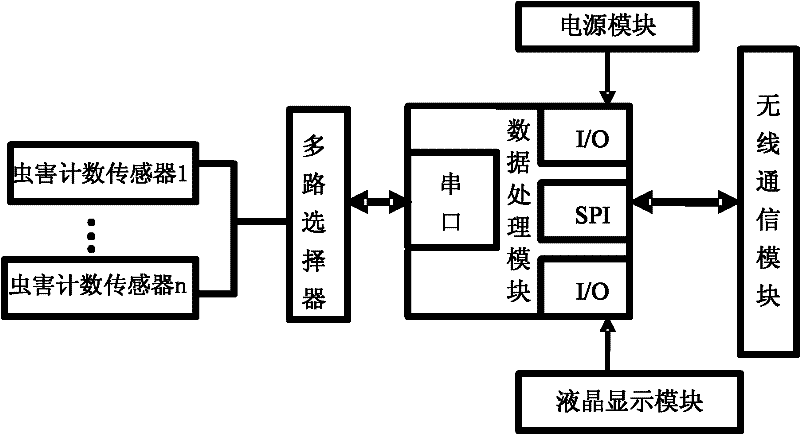

Agricultural condition information real-time monitoring platform based on wireless sensor network

InactiveCN102288222ARealize full coverage monitoringAchieve normalizationMeasurement devicesNetwork topologiesGeneral Packet Radio ServiceLiquid-crystal display

The invention discloses an agricultural condition information real-time monitoring platform based on a wireless sensor network. The platform comprises a plurality of agricultural condition information monitoring sub-systems deployed in a farmland to be tested, a gateway, a remote database server and a client. Each agricultural condition information monitoring sub-system comprises an agricultural condition information monitoring instrument and an insect damage monitoring instrument. Each agricultural condition information monitoring instrument and each insect damage monitoring instrument comprise a data processing module, a wireless communication module, a power supply module, a liquid crystal display module and a plurality of sensors. After being processed through the data processing module, signals collected by the sensors are displayed on the liquid crystal display module and transmitted to the gateway through the wireless communication module; the gateway transmits data to the remote database server through a GPRS (General Packet Radio Service) wireless communication module arranged on the gateway; and finally, the remote database server transmits the data to the client through a network. The platform disclosed by the invention not only can be used for completely monitoring and feeding back agricultural condition information on the spot in real time but also can be used for remotely monitoring the agricultural condition information.

Owner:SOUTH CHINA AGRI UNIV

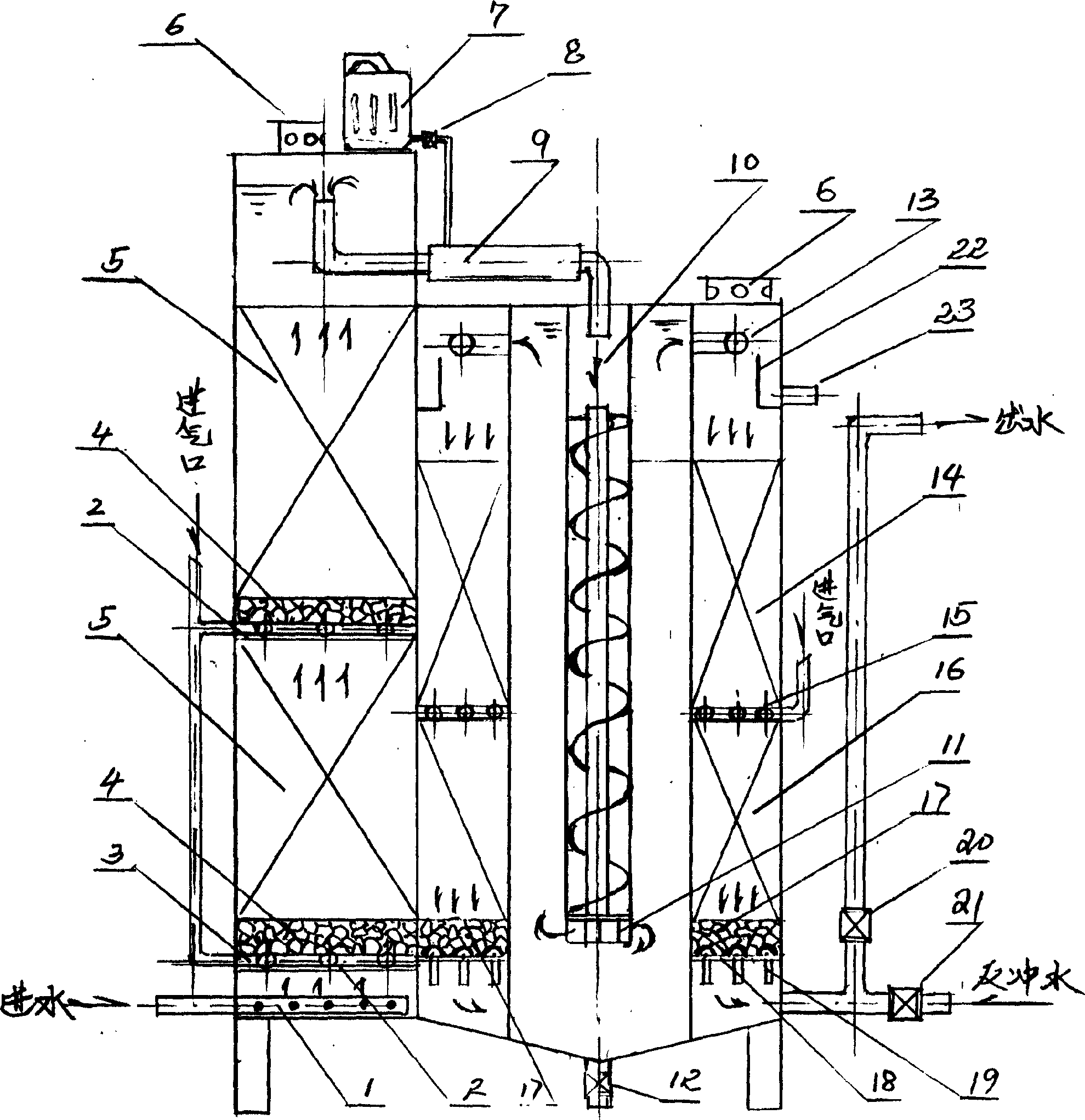

Integrated urban waste water treating apparatus and process

ActiveCN1579967AEasy to removeTo achieve the purpose of phosphorus removalMultistage water/sewage treatmentFlocculationElectrolysis

The invention discloses equipment of processing incorporate urban sewage and its technics. The equipment is made of armor plate. It includes internal electrolysis reaction area, machine-adding mixing system, helix flocculation depressed area and biolobical reaction area. Sewage can reach GB8978-1996 discharging standard through internal electrolysis reaction, flocculating settling (to remove phosphor), aerobic biological reaction, anaerobic reaction and filtration. Adopting incorporate treatment technics, the invention has a little floor space, low investment and a good effect. It adapts to urban subzones, blocks in villages and towns and micromidi companies such as urban diet, food processing and abattoir.

Owner:广西国宏智鸿环保科技集团股份有限公司

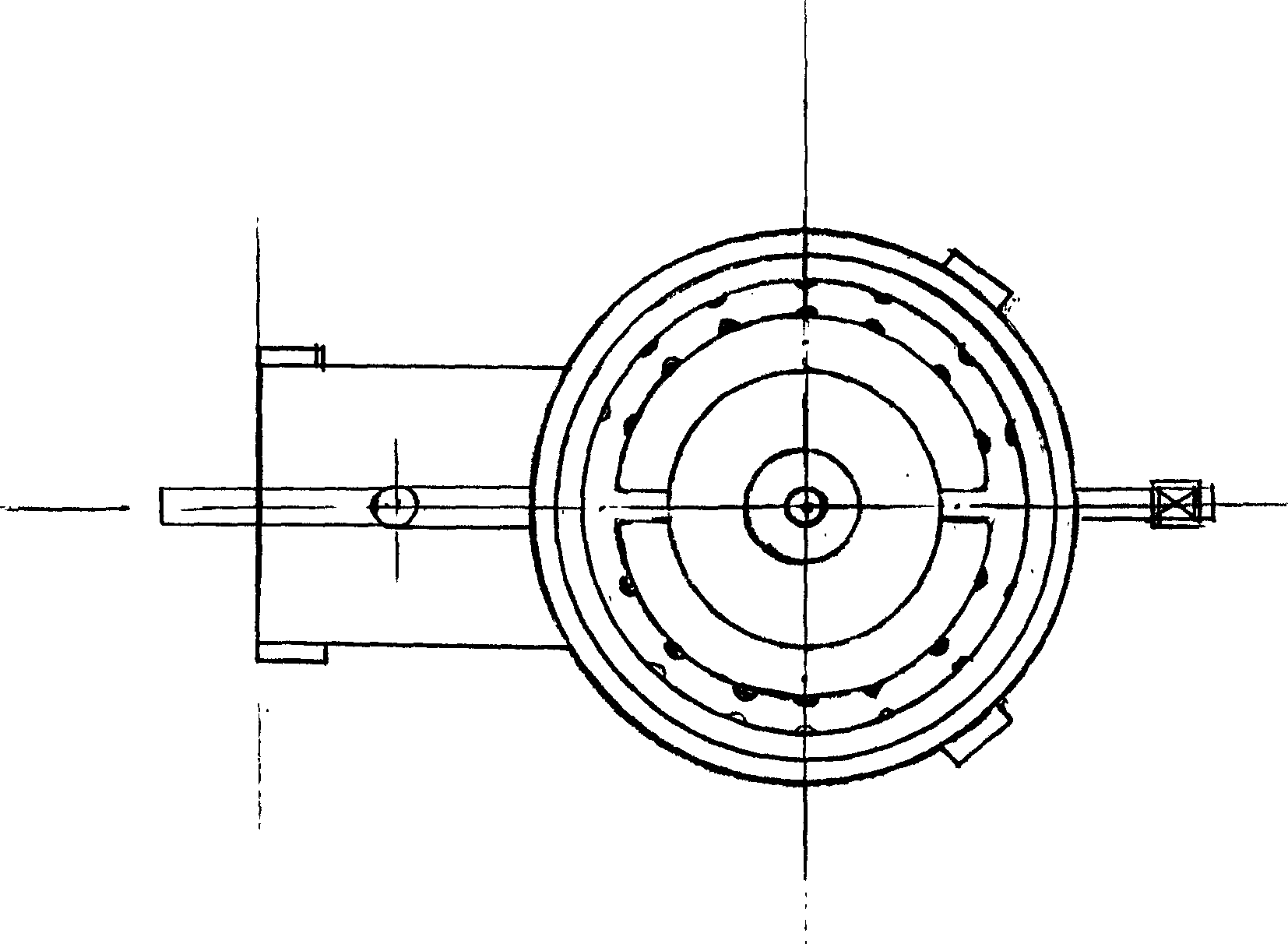

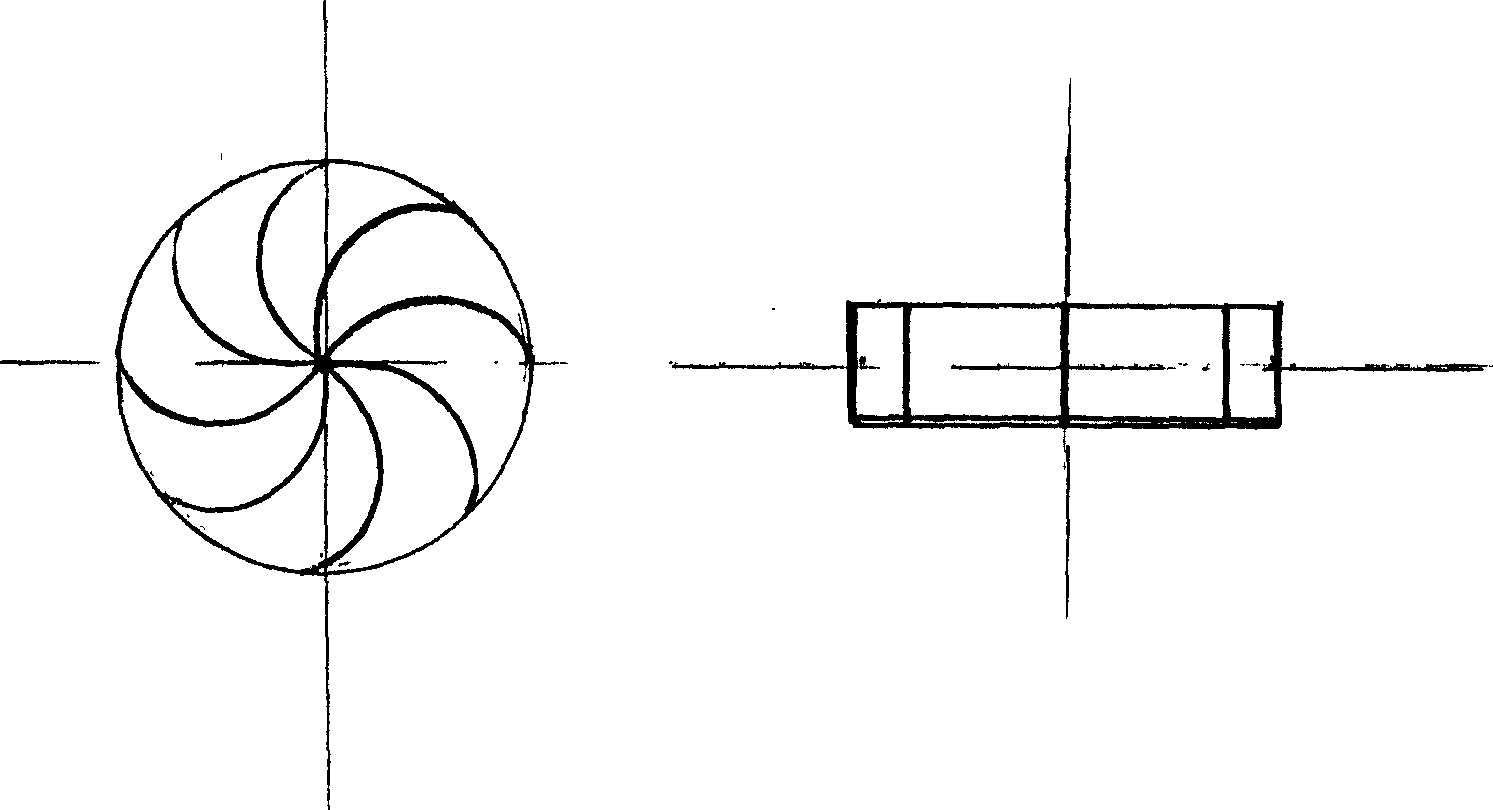

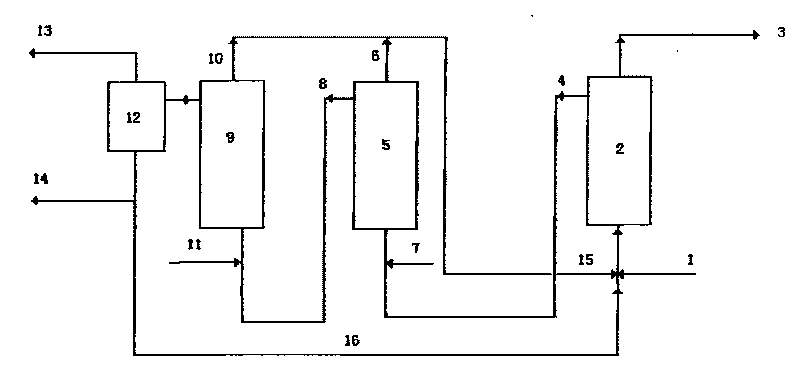

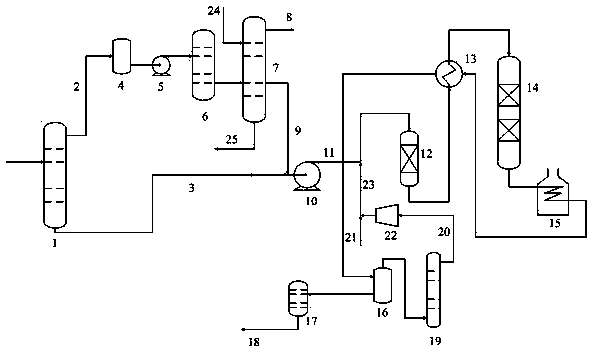

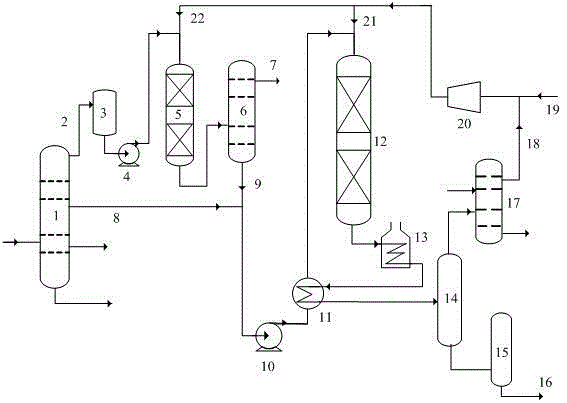

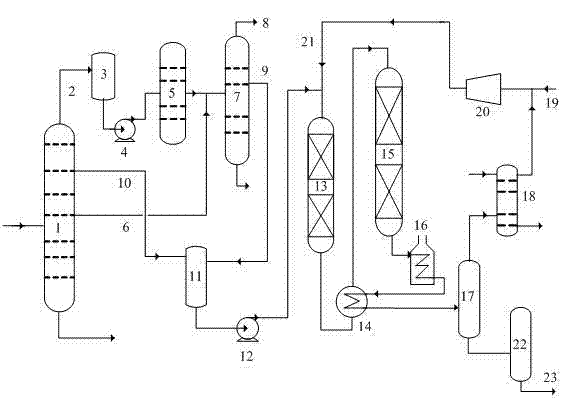

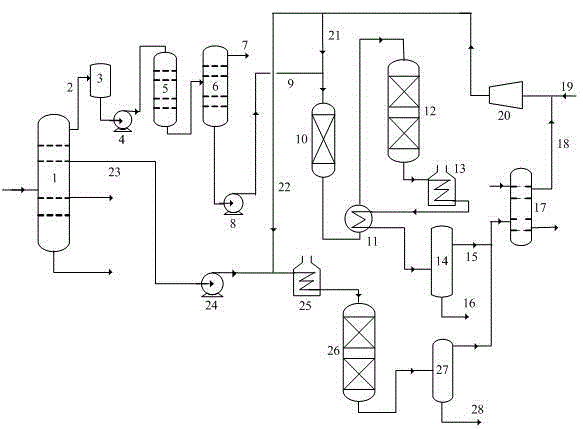

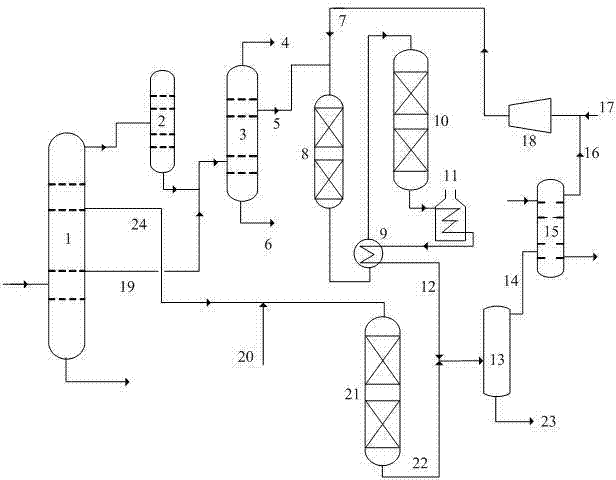

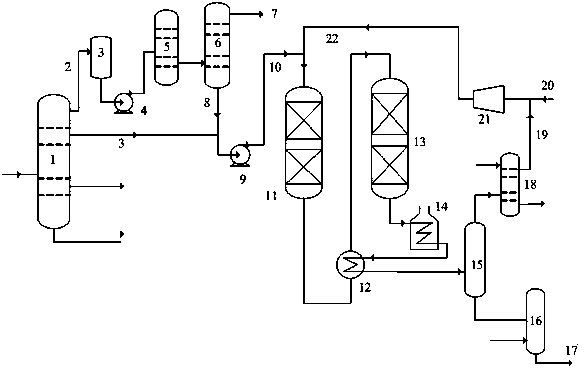

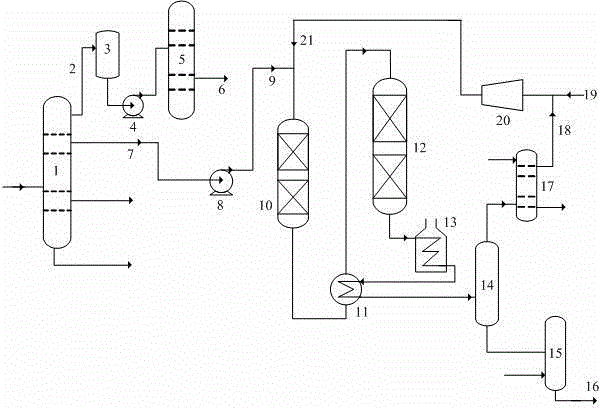

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453AReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseFuel oil

The invention discloses a hydrogenation method of a heavy hydrocarbon multi-segment fluidized bed. The technical process comprises the steps of: mixing thick heavy hydrocarbon raw materials with gas phase material flow which is discharged from a fluidized bed hydrogenation-desulfuration reactor and a hydrogenation-denitrification reactor to enter into a hydrogenation-demetalization reactor; cooling and purifying reacted gas phase material flow to be taken as recycle hydrogen; mixing the demetallized liquid phase material flow with hydrogen to enter into the fluidized bed hydrogenation-desulfuration reactor; mixing the desulfurated liquid phase material flow with hydrogen to enter into the hydrogenation-desulfuration reactor; and leading the denitrified liquid phase material flow to enter into a separating device. The technology adopts a new reactor assembly mode to machine heavy oil raw materials with high viscosity and bad quality, can provide a new flexible, high-efficiency and energy-saving operation mode, organically combines the performances of the raw materials with the characteristic of each hydrogenation reaction, makes full use of reaction heating on the premise that a device is guaranteed to be stably operated, provides a product with good quality, and can flexibly adjust the operation process according to the requirement of a refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

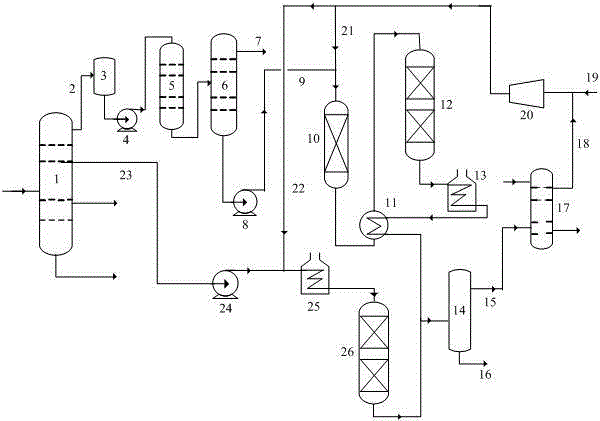

Method used for catalytic gasoline deep hydrodesulfurization

ActiveCN103805269AReduce total sulfur contentFreedom from abnormally rapid rises in pressure dropTreatment with hydrotreatment processesChemistrySulfur content

The invention discloses a method used for catalytic gasoline deep hydrodesulfurization. The method comprises following steps: catalytic gasoline is delivered into a prefrationation tower firstly; an appropriate separation point is adopted, light gasoline fraction and middle gasoline fraction are discharged through the top of the prefrationation tower, and heavy gasoline fraction is discharged through the bottom of the prefrationation tower; the light gasoline fraction and the middle gasoline fraction are subjected to alkali-free deodorization, and are delivered into a hydrogenation prefrationation tower so as to separate light gasoline and middle gasoline, wherein catalytic cracking hot diesel oil extracted from a main fractionate tower side line is also delivered into the hydrogenation prefrationation tower; separated middle gasoline and heavy gasoline are mixed, and are subjected to selective hydrogenation, and an obtained distillate is mixed with light gasoline obtained via alkali-free deodorization so as to obtain clean gasoline products. Compared with existing catalytic gasoline hydrodesulfurization method, the method and equipment of the invention is capable of reducing energy consumption greatly, octane value loss of the gasoline products is less, sulfur content of the gasoline products is less than 10<mu>g / g, and economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

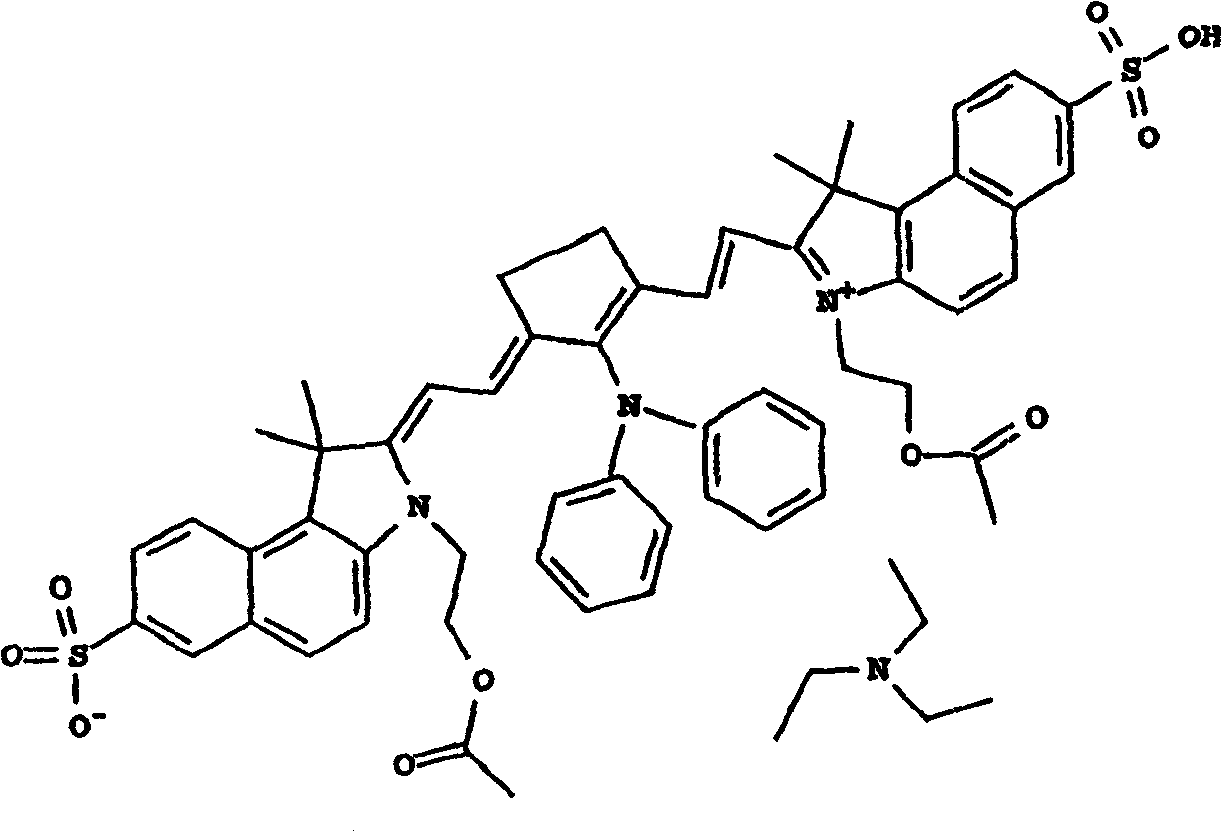

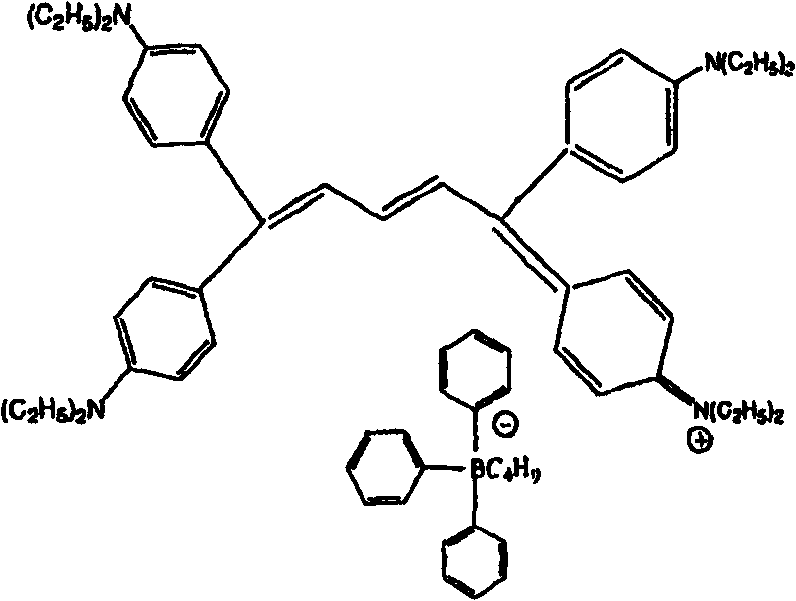

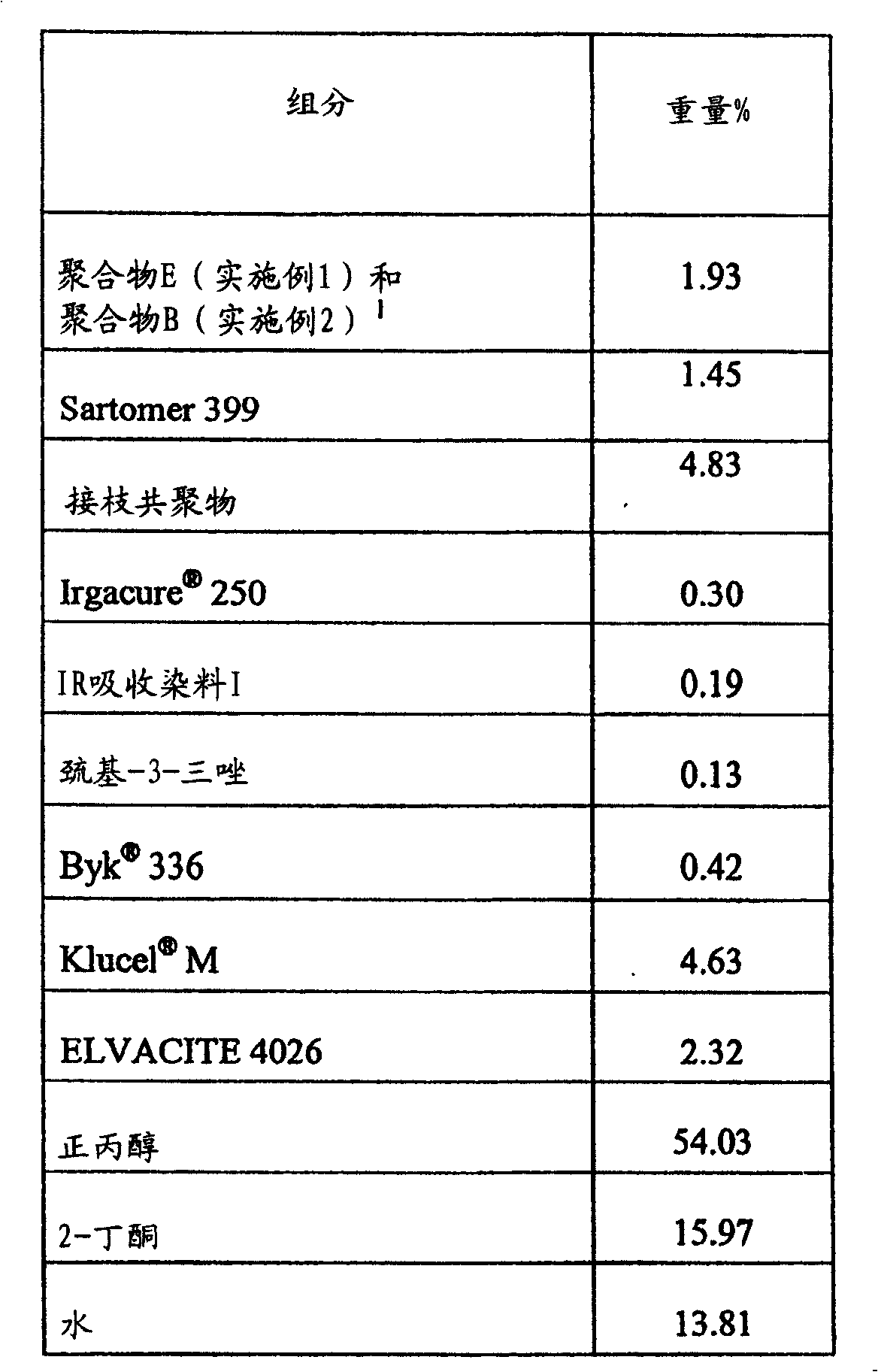

Radiation-sensitive compositions and imageable materials

InactiveCN101283311ANo need to reduce actual coat weightSolve the sticky problemRadiation applicationsPhotomechanical apparatusChemistryRadiation

A radiation-sensitive composition includes a radically polymerizable component that comprises carboxy groups, an initiator composition to generate radicals, and a polymeric binder comprising poly(alkylene oxide) segments and optionally pendant cyano groups. This composition can be used to prepare imageable elements such as negative-working, on-press developable printing plate precursors.

Owner:EASTMAN KODAK CO

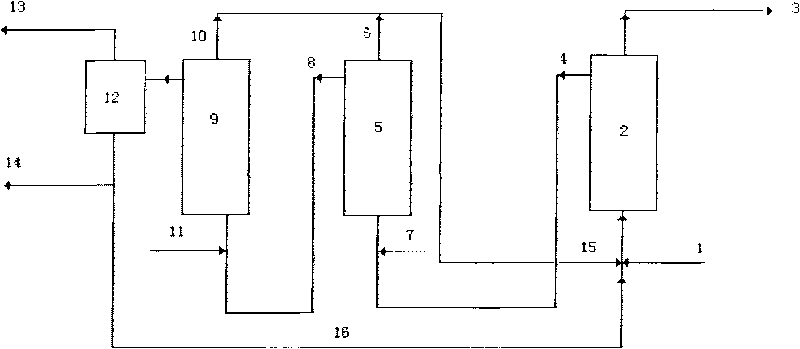

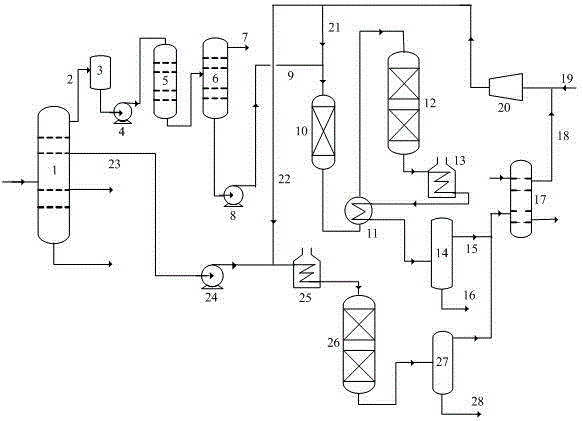

Multistage hydrogenation method for heavy hydrocarbon

ActiveCN102071059AWide applicability of raw materialsImprove product qualityTreatment with hydrotreatment processesHydrogenation reactionGas phase

The invention discloses a multistage hydrogenation method for heavy hydrocarbon. The method comprises the following technical steps of: mixing a condensed heavy hydrocarbon raw material and a gas phase material flow discharged from a hydrogenation desulfurization reactor and a hydrogenation denitrification reactor, and putting the mixture into a boiling bed hydrogenation demetalization reactor; cooling and purifying the reacted gas phase material flow and taking the cooled and purified reacted gas phase material flow as recycled hydrogen; mixing a liquid phase material flow subjected to the boiling bed demetalization reaction and the hydrogen, and putting the mixture into the hydrogenation desulfurization reactor; mixing the liquid phase material flow subjected to the desulfurization reaction with the hydrogen, and putting the mixture into the hydrogenation denitrification reactor, wherein at least one of the hydrogenation desulfurization reactor and the hydrogenation denitrification reactor is a fixed bed reactor. Compared with the prior art, the method provides a novel flexible, efficient and energy-saving operating mode for treating inferior heavy and residual oil raw materials; the property of the raw materials is organically combined with characteristics of the hydrogenation reactions, so the reaction released heat is fully used, the quality of the product is perfect and the operation process can be flexibly adjusted as required on the premise of guaranteeing the stable operation of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing gasoline blend component with high octane value by using cracking gasoline heavy fractions

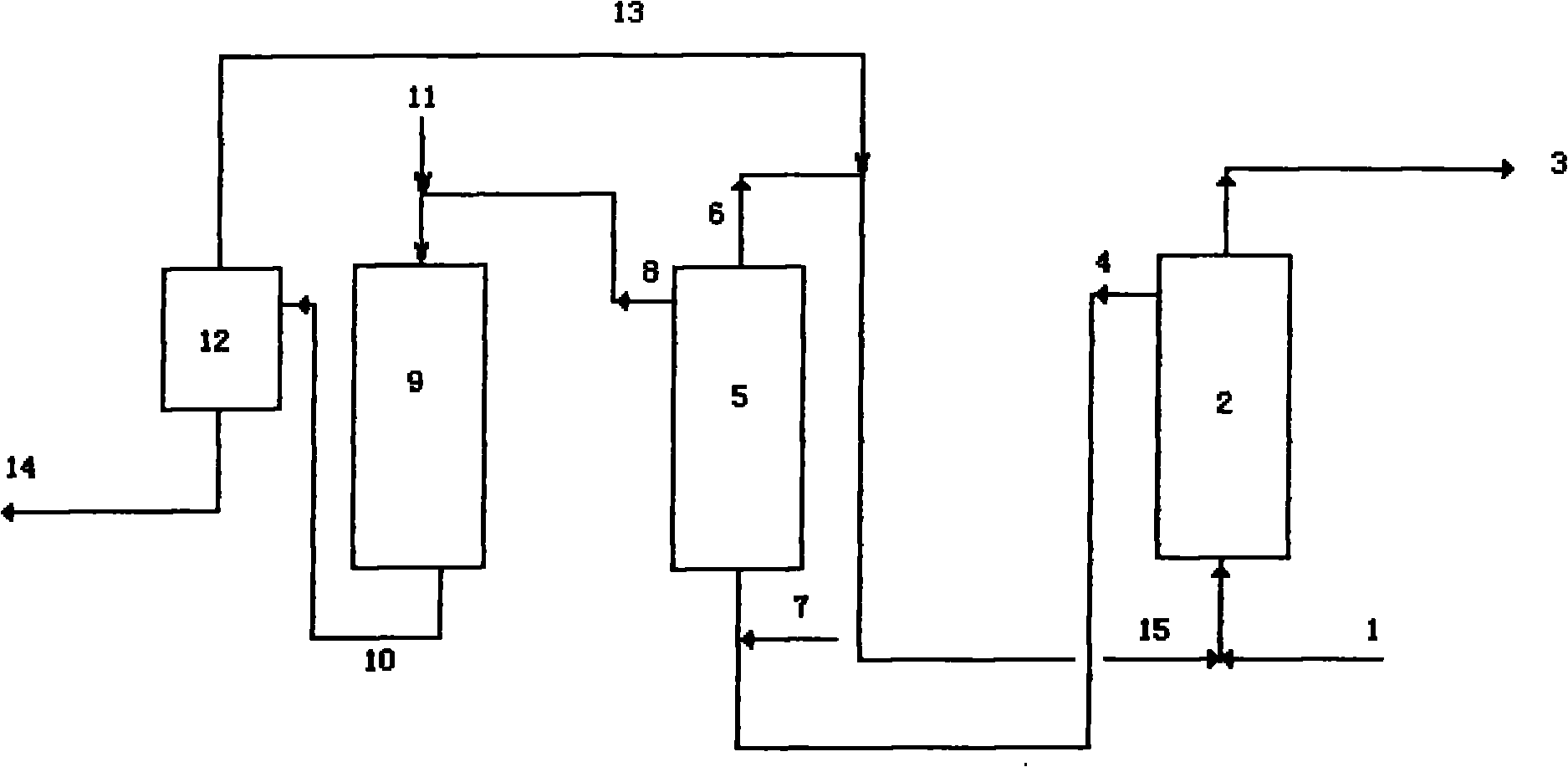

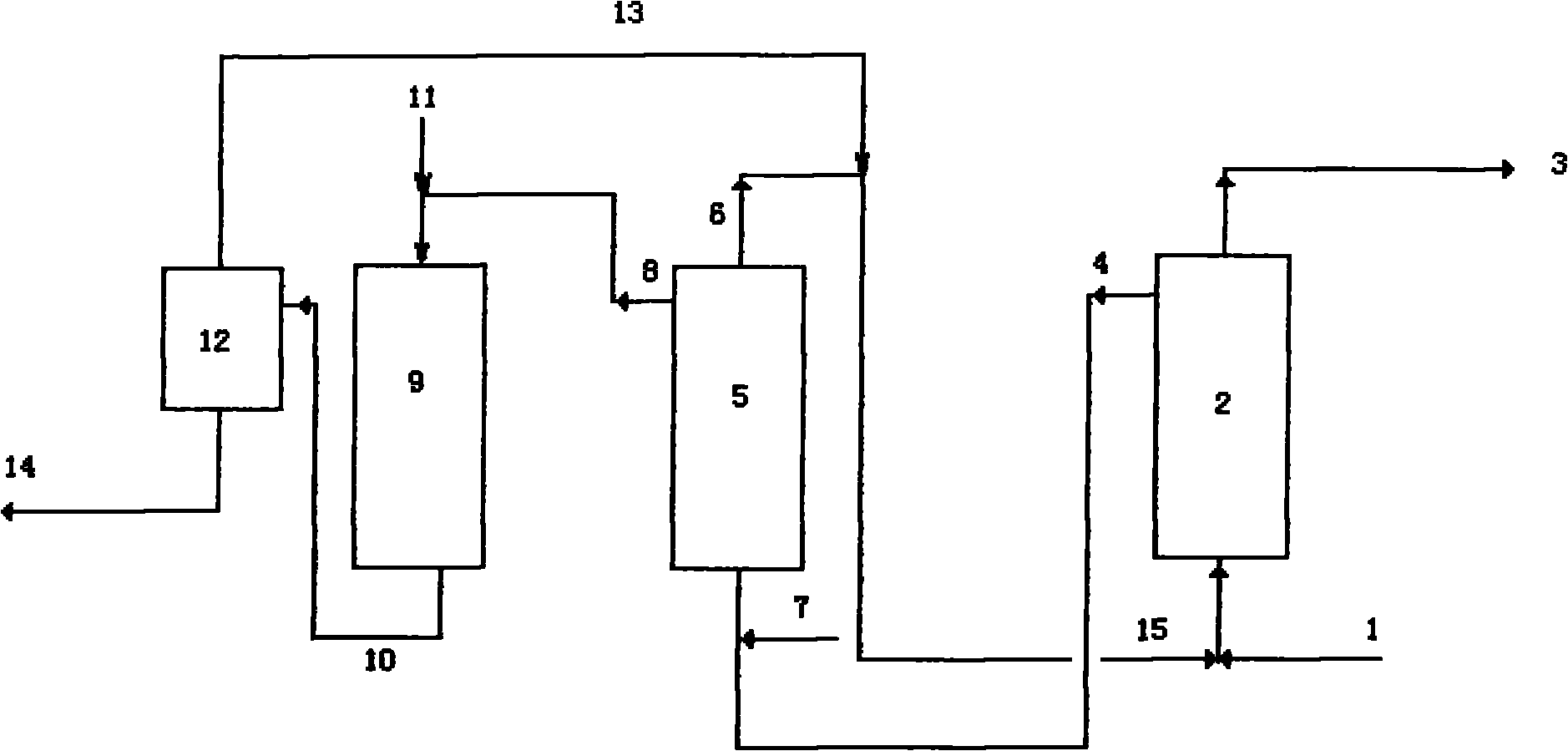

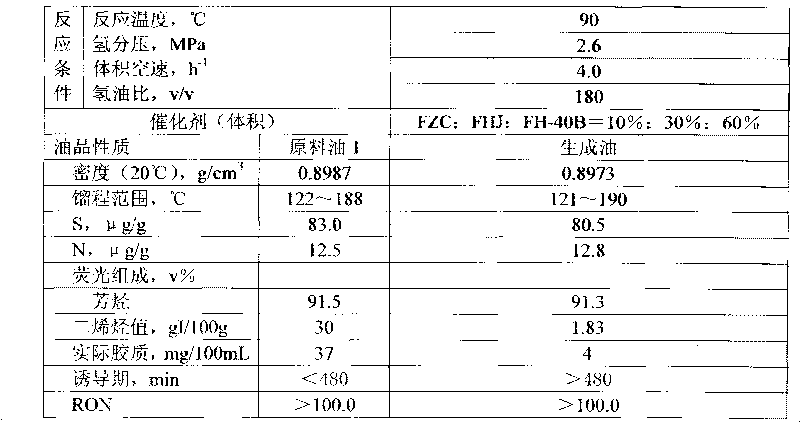

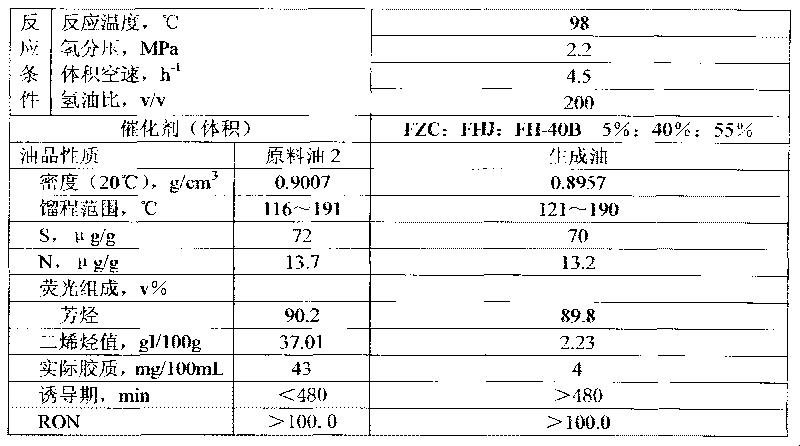

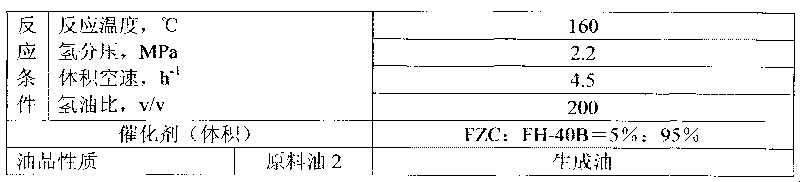

ActiveCN101724447AImprove stabilitySolve the problem of coking too fastHydrocarbon oil crackingLiquid productHydrogen

The invention relates to a method for producing a gasoline blend component with a high octane value by using cracking heavy fractions of gasoline. In the method, a single segment double catalyst matching filling process is adopted, materials of cracking gasoline heavy fractions and hydrogen gas are contacted with two hydrogenation catalysts under a milder process condition, reaction products are separated in a separator, hydrogen enriched gas is recycled, and liquid products are the gasoline blend component with a high octane value. The method aims at the cracking gasoline C9+ fractions difficultly treated by petrochemical processing enterprises; and by the process method, the economic benefits are improved, the process flow is simple, the operation is stable, the product quality is better, the investment and operating costs are lower, and the process method is suitable for new building of a hydrogenation plant as well as modification of the old hydrogenation plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

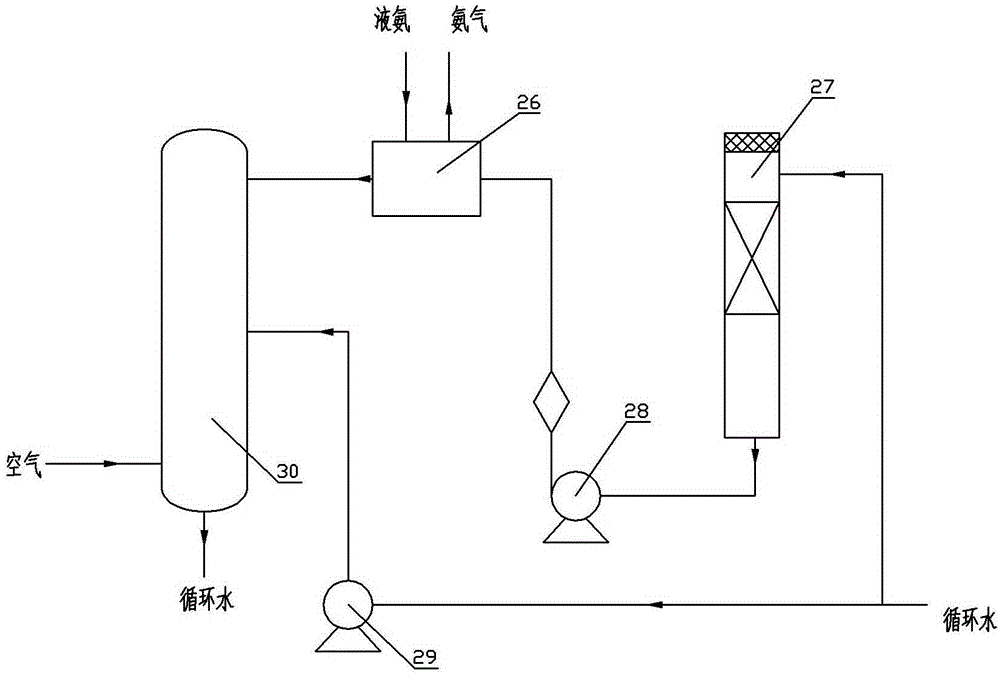

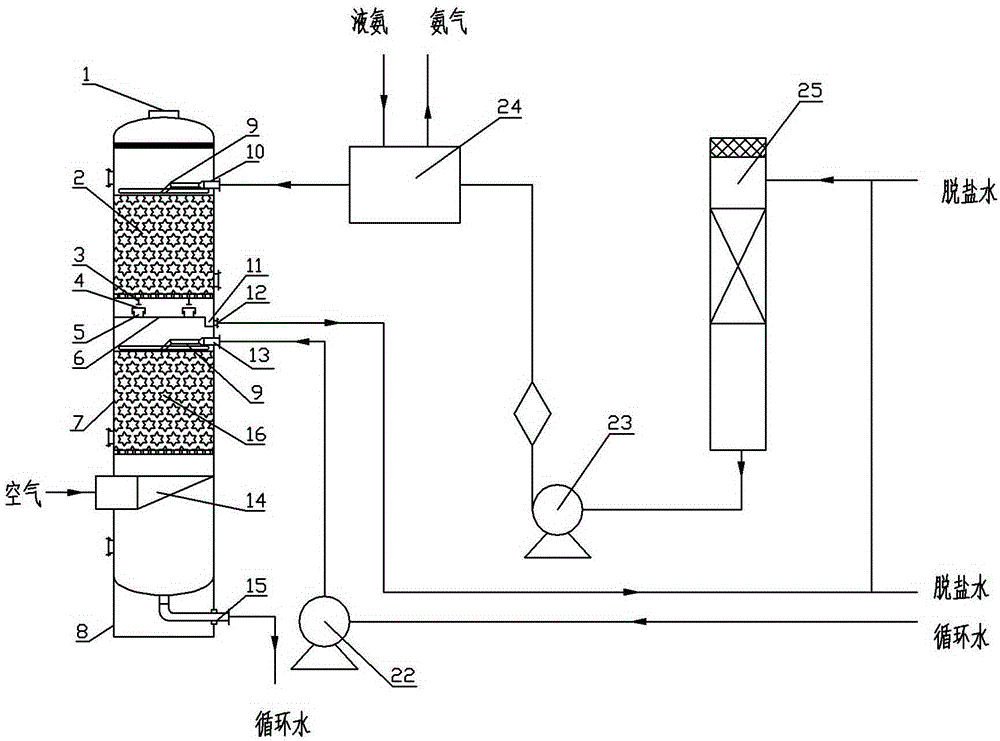

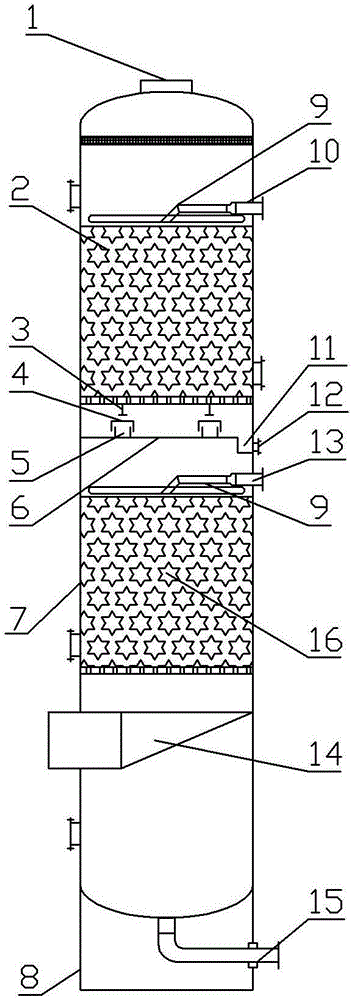

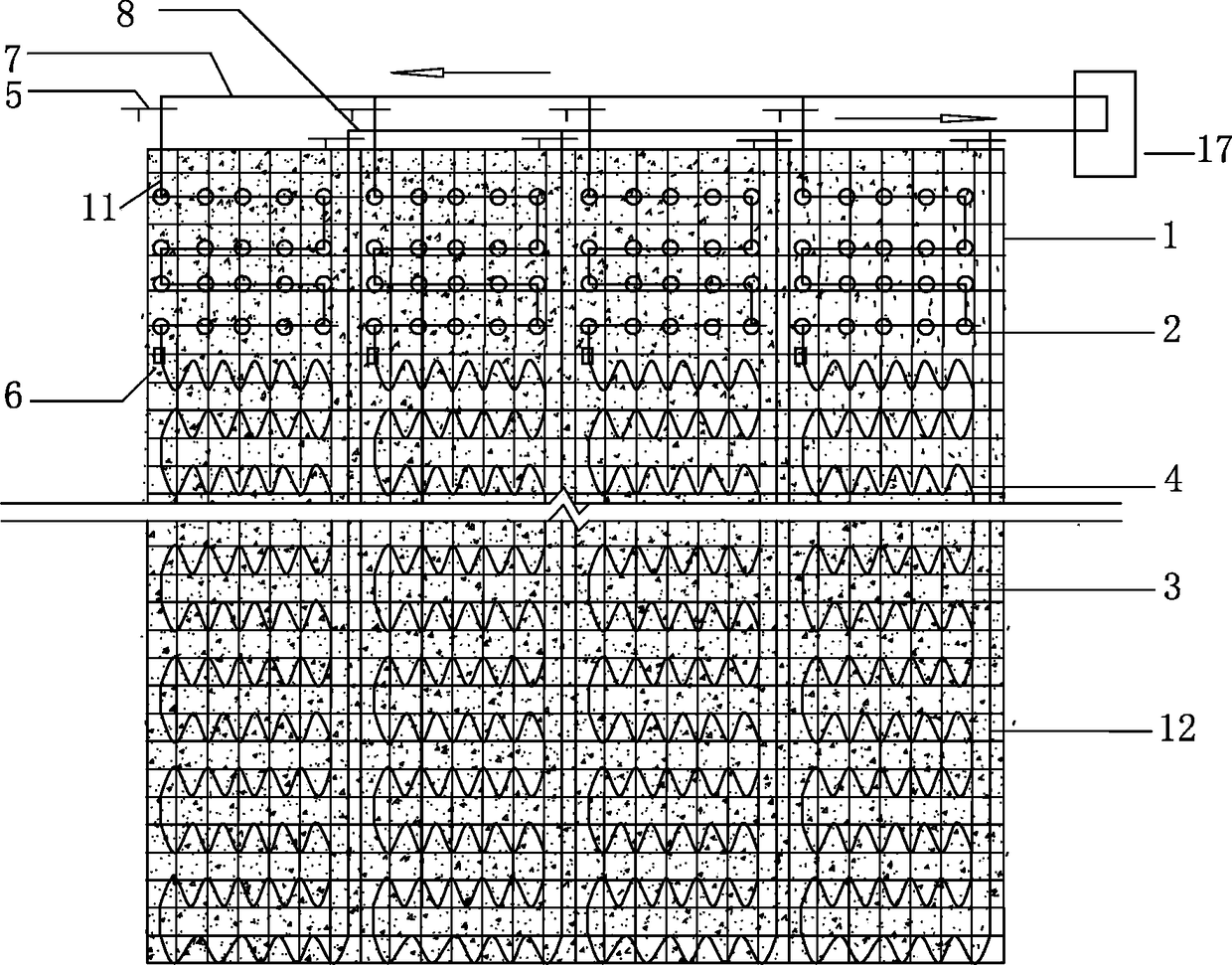

Air separation pre-cooling system

The invention discloses an air separation pre-cooling system and belongs to the field of gas separation. The air separation pre-cooling system comprises a nitrogen water tower, a first pump connected to the bottom of the nitrogen water tower and an ammonia cooling device connected to the first pump. A double-layer air cooling tower is connected to the ammonia cooling device. The double-layer air cooling tower is divided into an upper-layer cooling tower body and a lower-layer pre-cooling tower body. The top of a tower body of the double-layer air cooling tower is provided with an air outlet. The lower portion of the tower body is provided with an air inlet. A desalted water inlet formed in the upper portion of the upper-layer cooling tower body is connected with the ammonia cooling device. A partition plate is arranged between the upper-layer cooling tower body and the lower-layer pre-cooling tower body. The lower portion of the upper-layer cooling tower body is provided with a desalted water outlet. The side wall of the upper portion of the lower-layer pre-cooling tower body is provided with a circulating water inlet. The bottom of the lower-layer pre-cooling tower body is provided with a water discharging opening. The circulating water inlet is connected with a second pump. The desalted water inlet and the circulating water inlet are connected with a water spraying device arranged in the tower body.

Owner:HENAN JINKAI CHEM INVESTMENT HLDG GRP

Low-energy consumption catalytic gasoline hydrodesulfurization method

ActiveCN103059957AAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention discloses a low-energy consumption catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic cracking device fractionating tower, and adopting an appropriate cutting point to perform pre-separation in an FCC (fluid catalytic cracking) fractionating tower so as to obtain light fractions and heavy fractions; subjecting the mercaptan in the light fractions to hydroconversion to form a heavy sulfide, making the treated light fractions enter a hydrogenation prefractionator to fractionate light gasoline and medium gasoline, mixing the medium gasoline with the heavy fractions generated by the FCC fractionating tower, letting the mixture enter a hydrodesulfurization reactor to undergo deep desulfurization, conducting steam stripping on the obtained refined heavy gasoline, and mixing it with the light gasoline, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

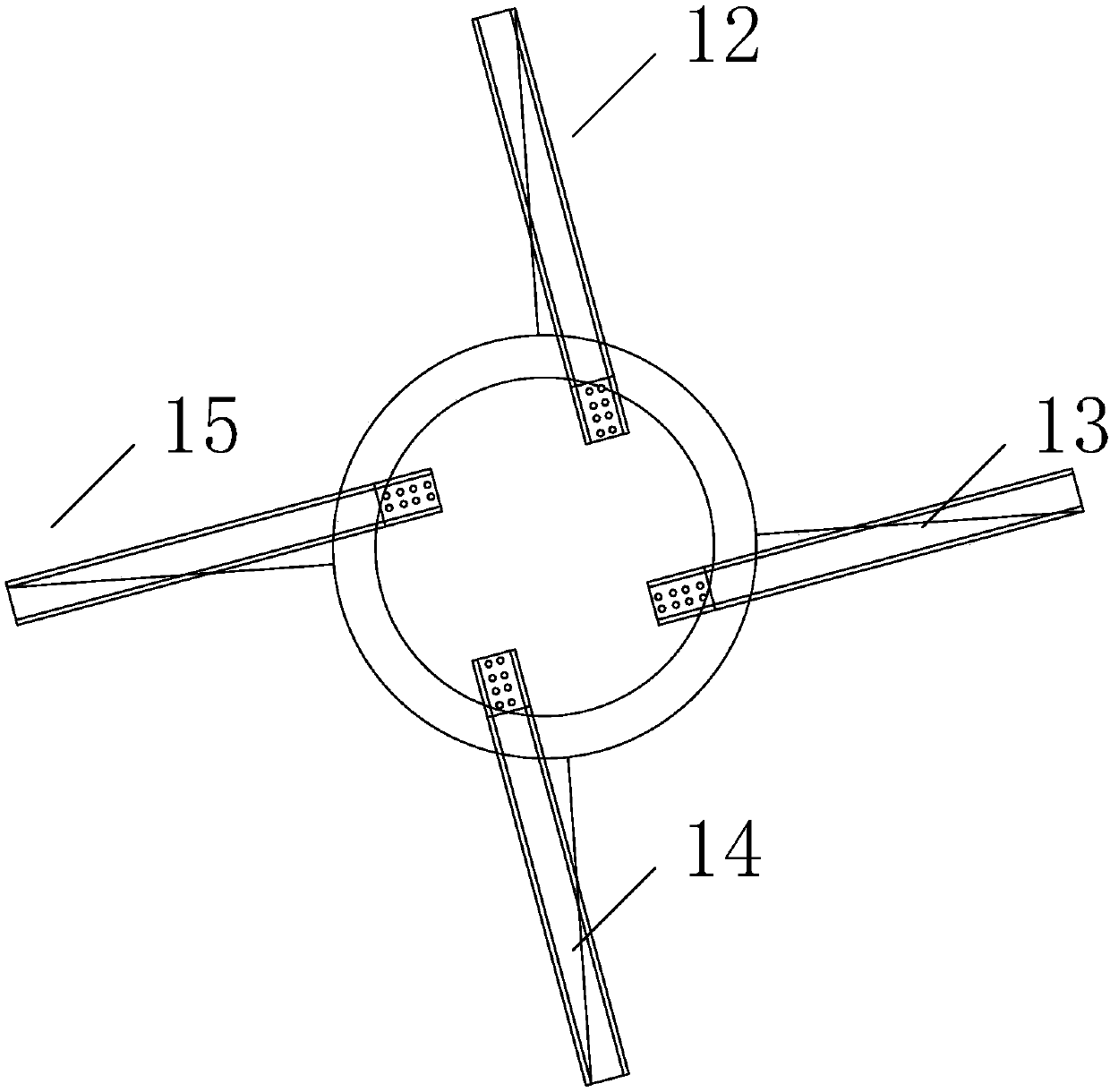

Opposed type solid particle spraying distributor online coke cleaning device

ActiveCN109696079AEnhance gas-solid mixing effectFully diffusedNon-rotary device cleaningSpray nozzleEngineering

The invention relates to an opposed type solid particle spraying distributor online coke cleaning device. The device main solves the problem in the prior art of the hard removing of coke accumulated in gas cooler tubes. The device includes a solid particle storage tank, an ammonia oxidation reaction gas cooler, a solid particle unloading device, a solid particle spraying distributor and gas-solidseparators; the ammonia oxidation reaction gas cooler includes a hollow upper head and a heat exchange section distributed with the tubes; the upper part of the heat exchange section is provided witha protection plate; the solid particle spraying distributor is placed in the upper head along an axial direction; a solid particle distributor is arranged in an opposed manner at least by more than two nozzles which are in opposed arrangement or inclined at a certain angle; the inlet of inert gas communicates with the solid particle spraying distributor after being parallel with the outlet of thesolid particle storage tank; and the outlet of the cooler is provided with at least one gas-solid separator to recycle solid particles. Thus, the problem can be well solved, so that the device can beused for online coke removing industrial devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic gasoline hydrodesulfurization method

ActiveCN103059950AAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationProcess engineering

The invention discloses a catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, conducting cutting at an appropriate cutting temperature so as to obtain light fractions at the tower top and heavy fractions at the lateral line; subjecting the light fractions to an alkali extraction treatment, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrodesulfurization on the medium gasoline, and carrying out deep selective hydrodesulfurization on the heavy gasoline, subjecting the obtained two refined products to gas stripping, and then mixing them with alkali extracted light gasoline, thus obtaining a clean gasoline product. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

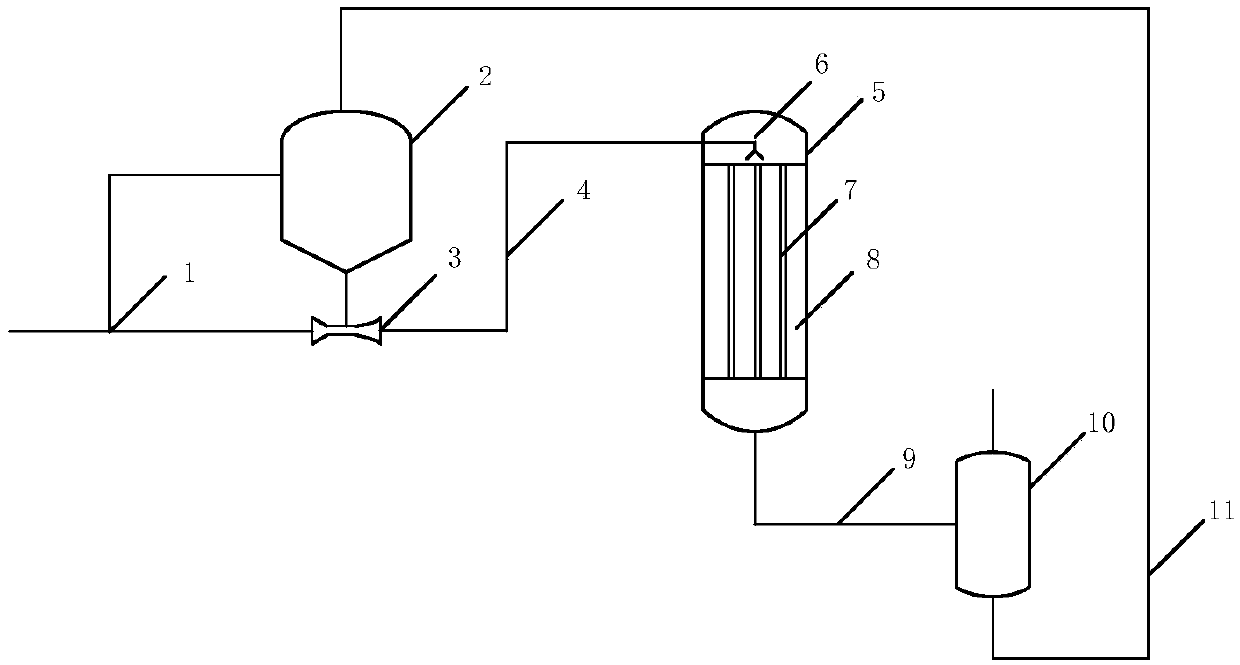

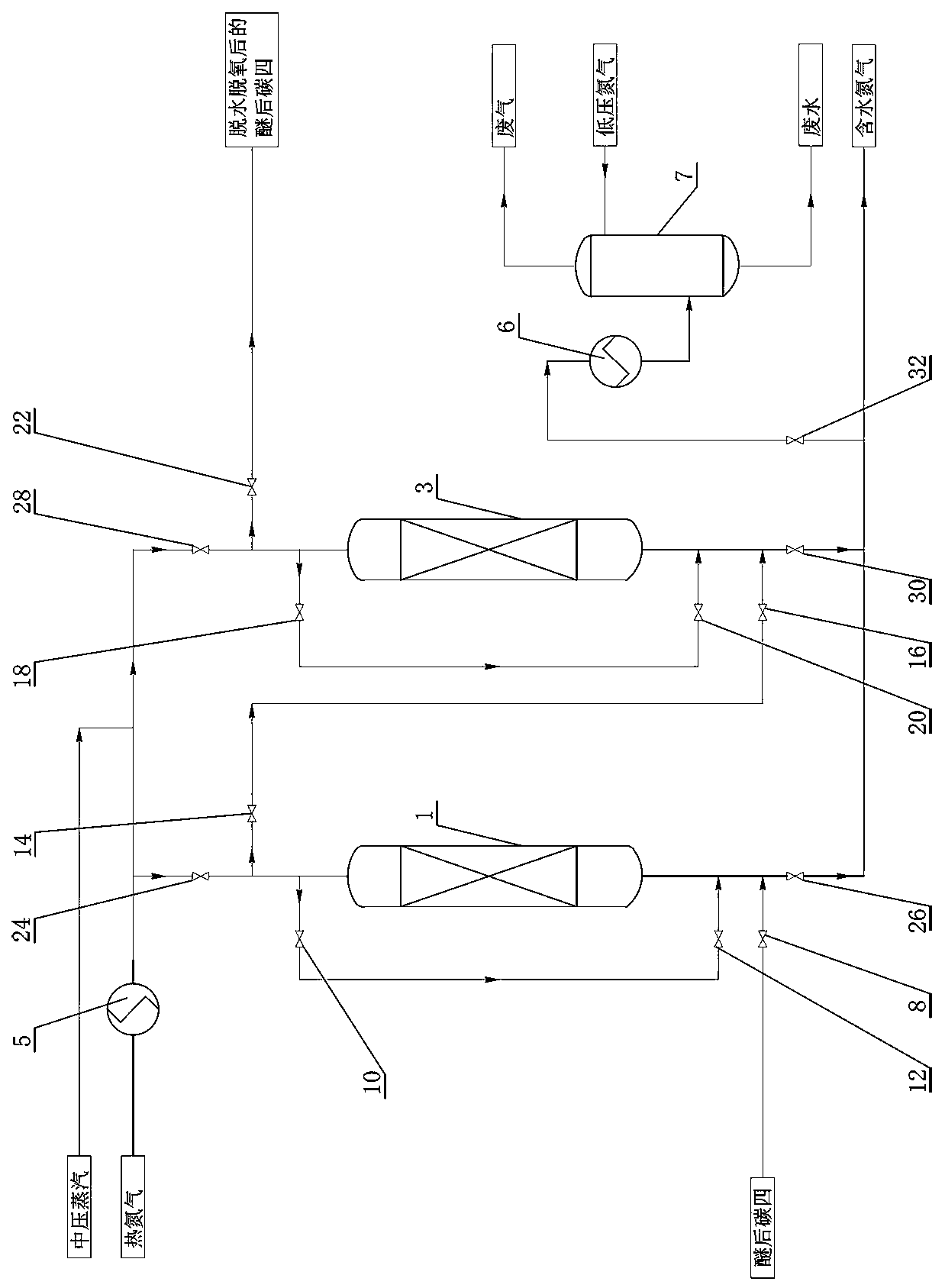

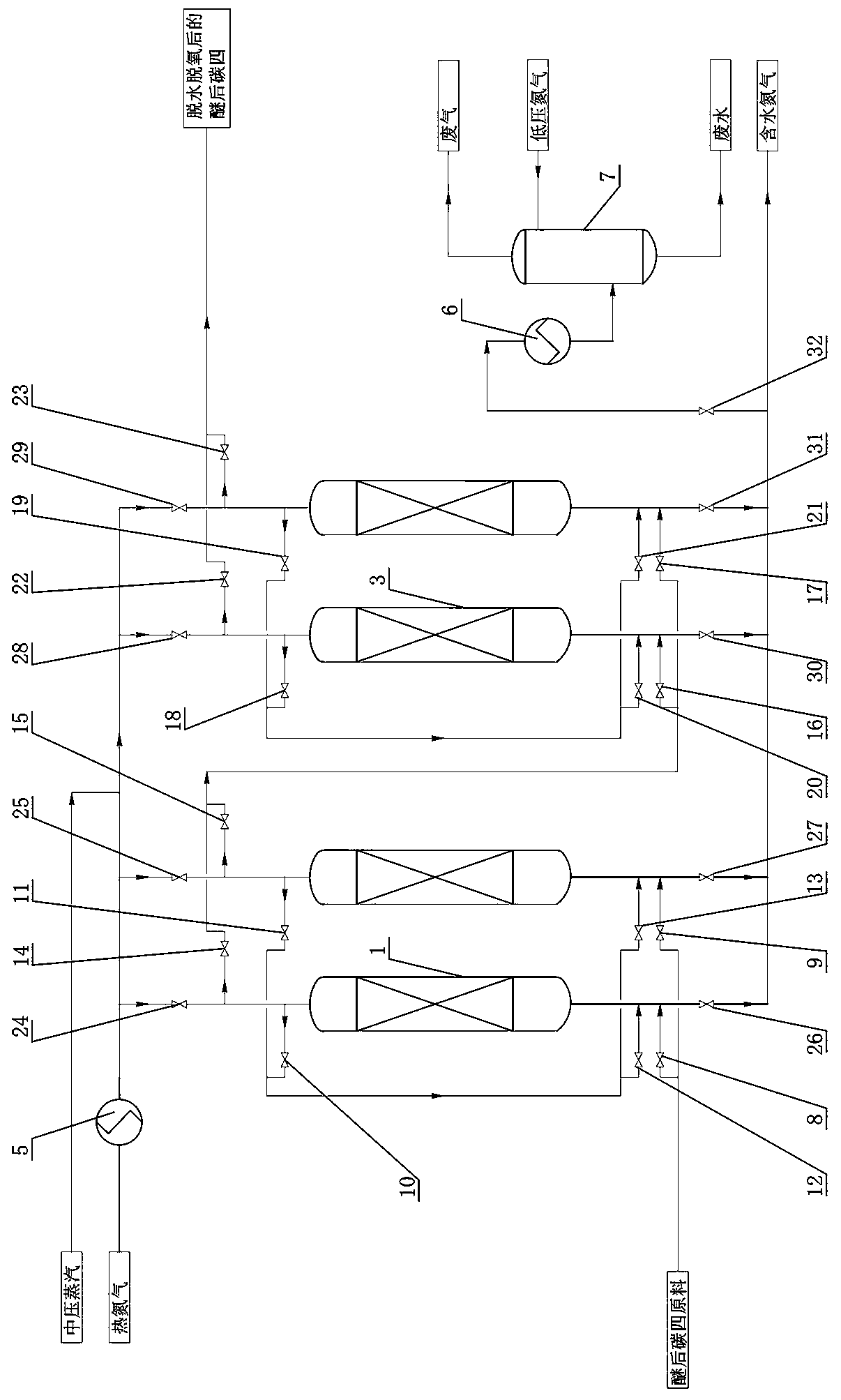

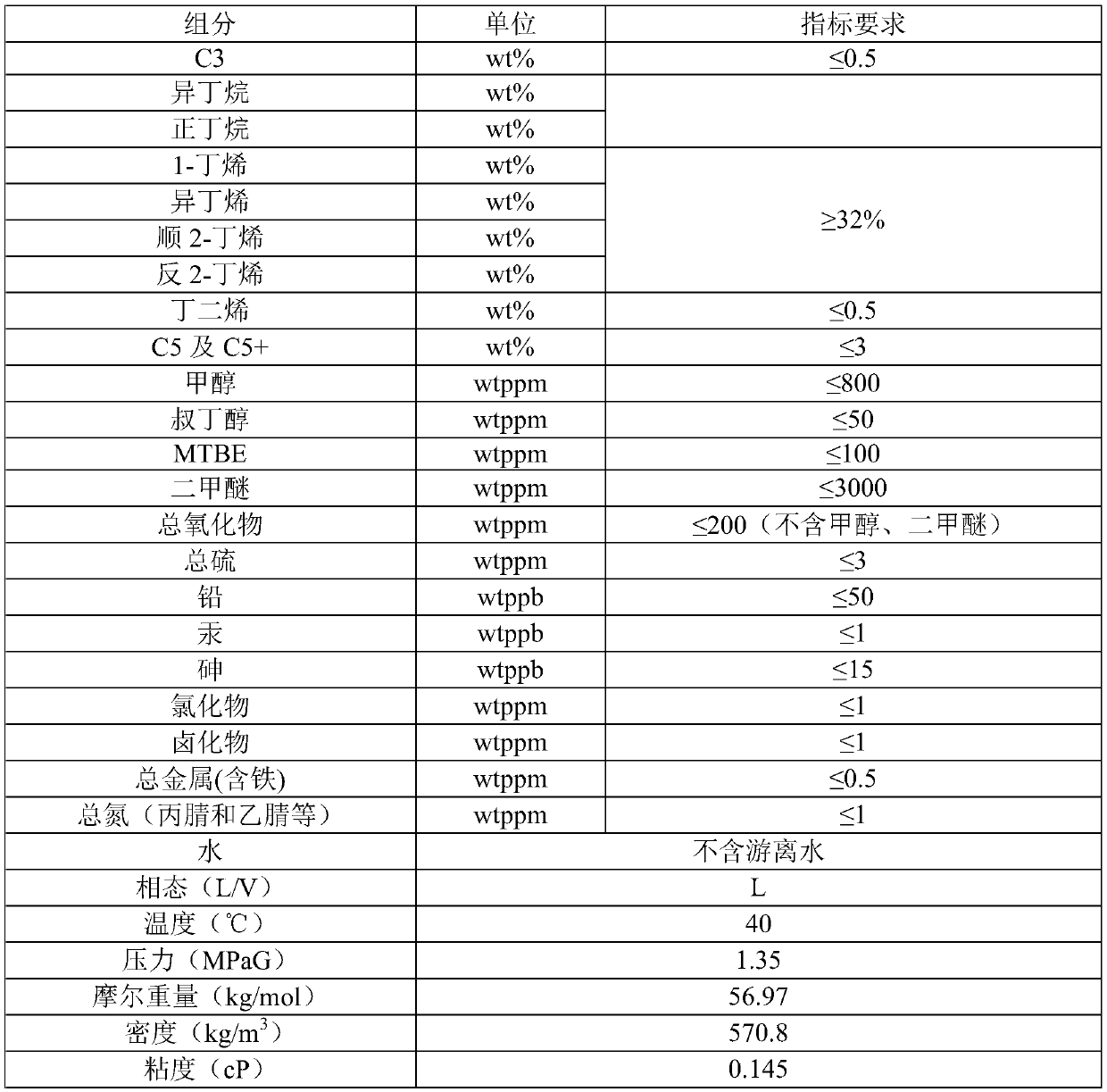

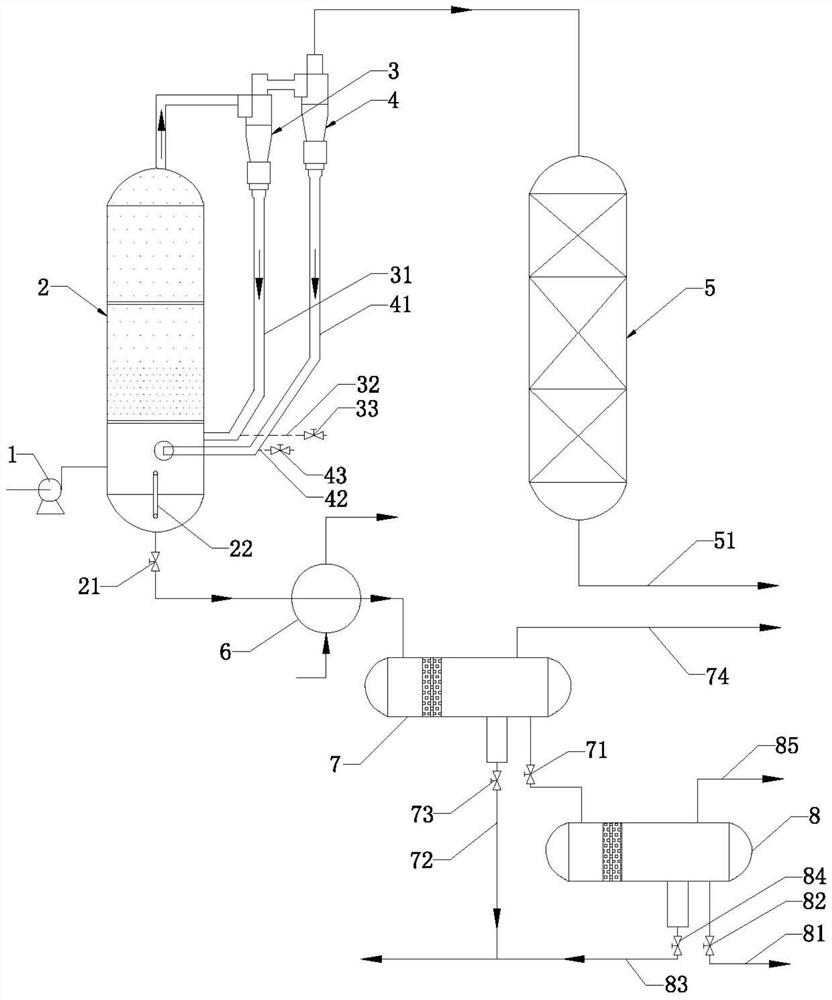

Method and device for pretreating post-etherification C4 raw material

PendingCN110256209AGuaranteed operating cycleFew facilitiesHydrocarbonsAdsorption purification/separationIsomerizationPretreatment method

The invention relates to a method and device for pretreating a post-etherification C4 raw material, belonging to the technical field of treatment of chemical raw materials. The method comprises the following steps: dehydrating the post-etherification C4 raw material; subjecting the dehydrated post-etherification C4 raw material to deoxidation; regenerating a dehydrating agent used in dehydration; and regenerating a deoxidizer used in deoxidation. According to the pretreatment method of the invention, impurities such as micro water, ethers and alcohols in the post-etherification C4 raw material can be removed after dehydration and deoxidation, and the indexes of the pretreated post-etherification C4 raw material reach the requirements of n-butene isomerization units and selective hydrogenation units on the limit values of impurity contents of raw materials, so catalysts in the hydrogenation units and catalysts in the n-butene isomerization units are protected, and the normal operation cycle of the entire MTBE device is ensured; and compared with conventional pretreatment processes for raw materials, the method of the invention reduces investment and operating cost, improves the economic benefits of the industry and has a high promotion value.

Owner:山东东明石化集团有限公司

Catalytic gasoline deep hydrodesulfurization method

ActiveCN103059965AAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic gasoline deep hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, adopting an appropriate cutting point to conduct cutting so as to obtain FCC (fluid catalytic cracking) gasoline light fractions at the tower top and FCC heavy fractions at the lateral line; subjecting FCC gasoline light fractions to alkali-free deodorization, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrogenation on the medium gasoline, performing deep selective hydrogenation on the heavy gasoline, and mixing the obtained two parts of refined distillate oil with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

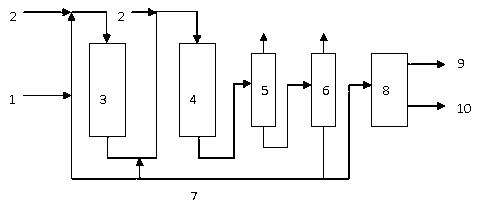

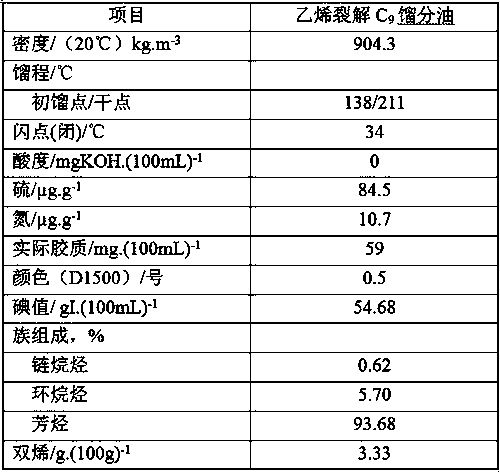

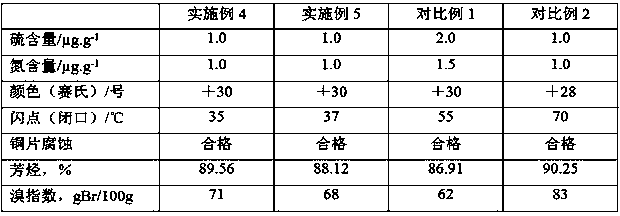

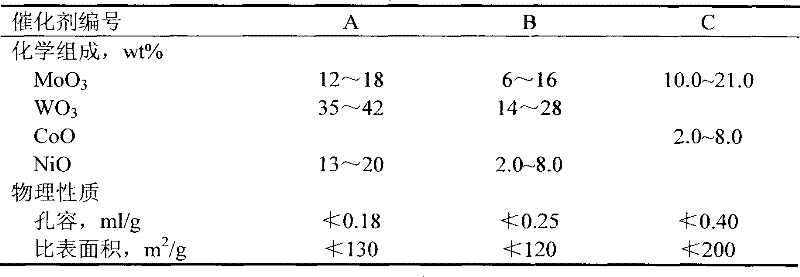

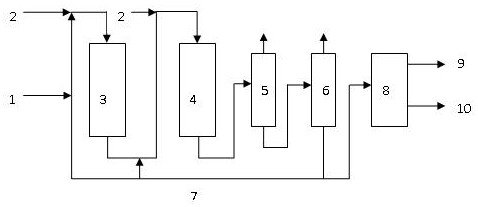

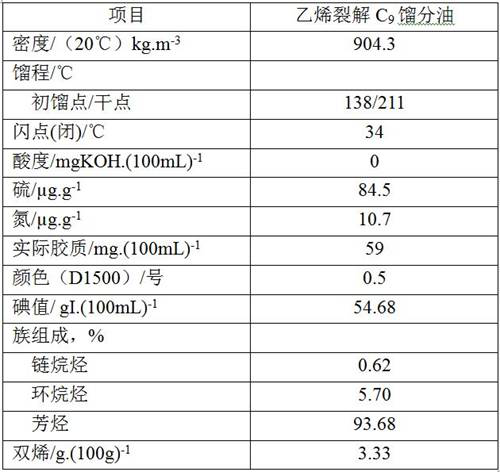

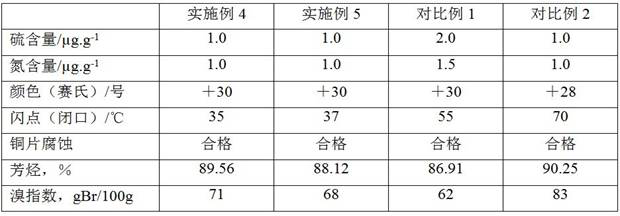

Method for producing aromatic hydrocarbon solvent oil by ethylene cracking C9 aromatic hydrocarbon fraction hydrogenation

ActiveCN111378502AGood hydrogenation activity at low temperatureGuaranteed operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystReaction zone

The invention discloses a method for producing aromatic hydrocarbon solvent oil by ethylene cracking C9 aromatic hydrocarbon fraction liquid-phase cyclic hydrogenation. The method includes mixing theethylene cracking C9 fraction with circulating oil, fully dissolving with hydrogen, feeding into a first hydrofining reaction zone, and carrying out contact reaction with a noble metal hydrofining catalyst; fully dissolving the diene-removed ethylene cracking C9 aromatic hydrocarbon fraction with hydrogen again to enter a second hydrofining reaction zone to be subjected to a hydrofining reactionwith a hydrogenation protection catalyst, a hydrofining catalyst A and a hydrofining catalyst B in sequence, and separating a hydrofining product to obtain the high aromatic hydrocarbon solvent oil. According to the method disclosed by the invention, the high-efficiency utilization of the ethylene cracking C9 aromatic hydrocarbon fraction is realized, and the high-aromatic hydrocarbon solvent oilwith high quality and good stability can be obtained. The invention has the characteristics of low energy consumption and long stable operation period of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

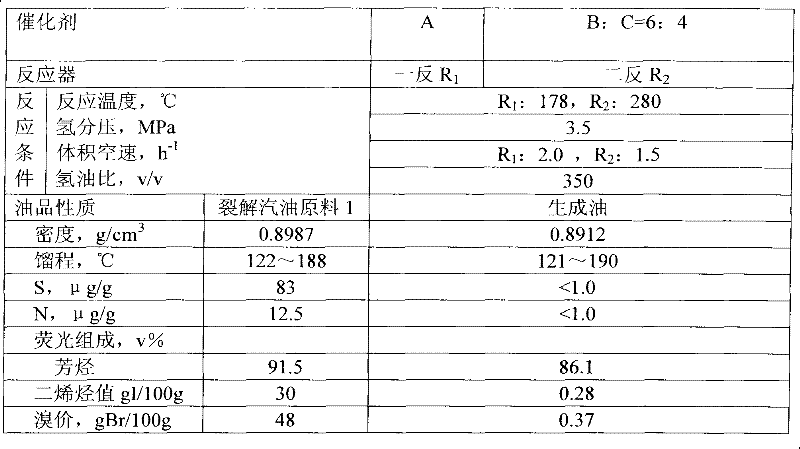

Method for hydrotreatment of heavy fraction of pyrolysis gasoline

ActiveCN101619239BIncrease lossIncrease coking speedTreatment with hydrotreatment processesHydrogenEconomic benefits

The invention relates to a method for hydrotreatment of heavy fraction of pyrolysis gasoline, which adopts the one-section series process flow, and particularly comprises the following steps that: raw materials of the heavy fraction of the pyrolysis gasoline and hydrogen gas are contacted with a first reactor hydrogenation catalyst first under the condition of hydrofining, and the W-Mo-Ni based hydrogenation catalyst with high content of active metal is used in the first reactor; and the product flowed out of the first reactor directly enters a second reactor to be contacted with two hydrogenation catalysts in the second reactor, the reaction materials are contacted with the W-Mo-Ni based hydrogenation catalyst first and then the Mo-Co based hydrogenation catalyst, and the reaction products are subjected to the separating treatment. Aiming at the pyrolysis gasoline C9 to C10 fractions which are difficultly treated by petrochemical enterprises, the economic benefits are improved by adopting the method; moreover, the method also has the advantages of simple process flow, stable operation and good product property, and the hydrogenation device used in the method can be newly built or improved from the old hydrogenation device.

Owner:CHINA PETROLEUM & CHEM CORP +1

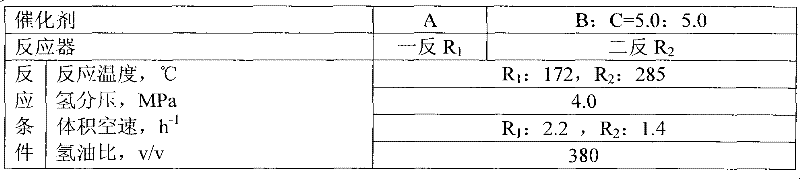

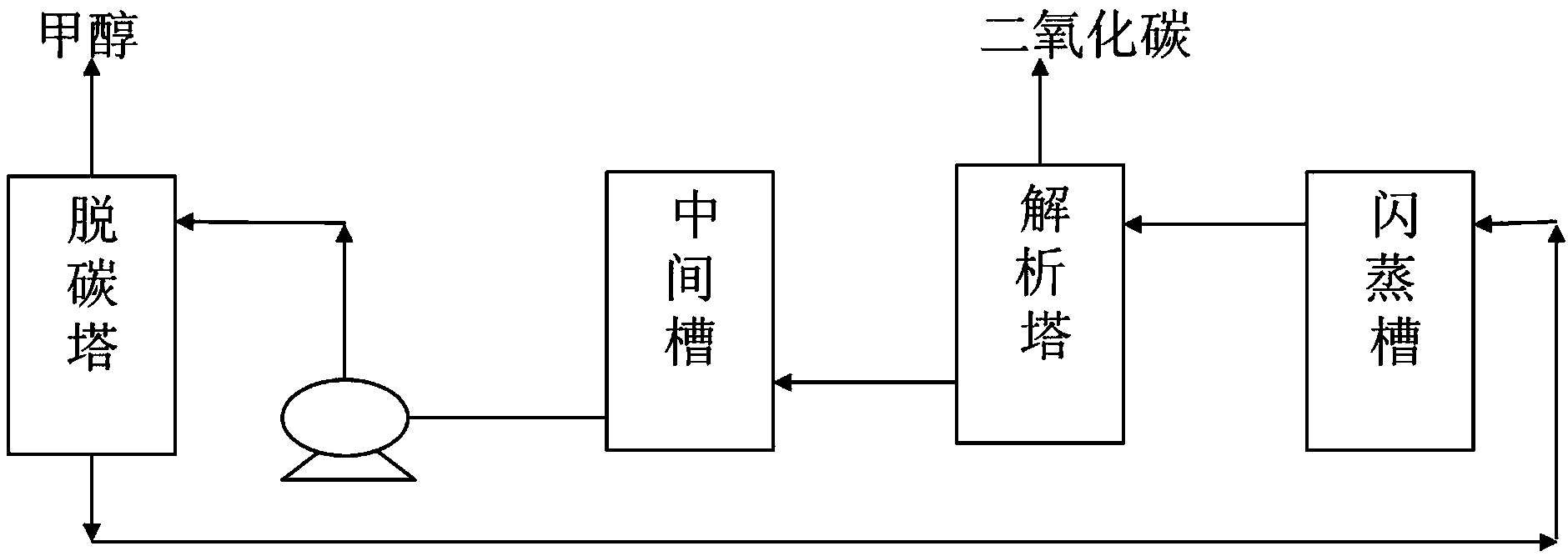

Desulfurization side filtration method in propylene carbonate decarbonization process

InactiveCN104226082AGuaranteed operating cycleEasy to operateDispersed particle separationFiltration circuitsGeosynclineAmmonia production

The invention belongs to the technical field of synthetic ammonia production and relates to a desulfurization side filtration method in a propylene carbonate decarbonization process. The method comprises the following steps: arranging a geosyncline between an intermediate tank and a decarbonization tower, filtering part of liquid in the intermediate tank, and cyclically returning filter liquor after filtration to the intermediate tank to continuously take part in a reaction process. According to the method, the sulfur content of the mother liquid in the intermediate tank can be effectively reduced.

Owner:ANHUI JINGHE IND

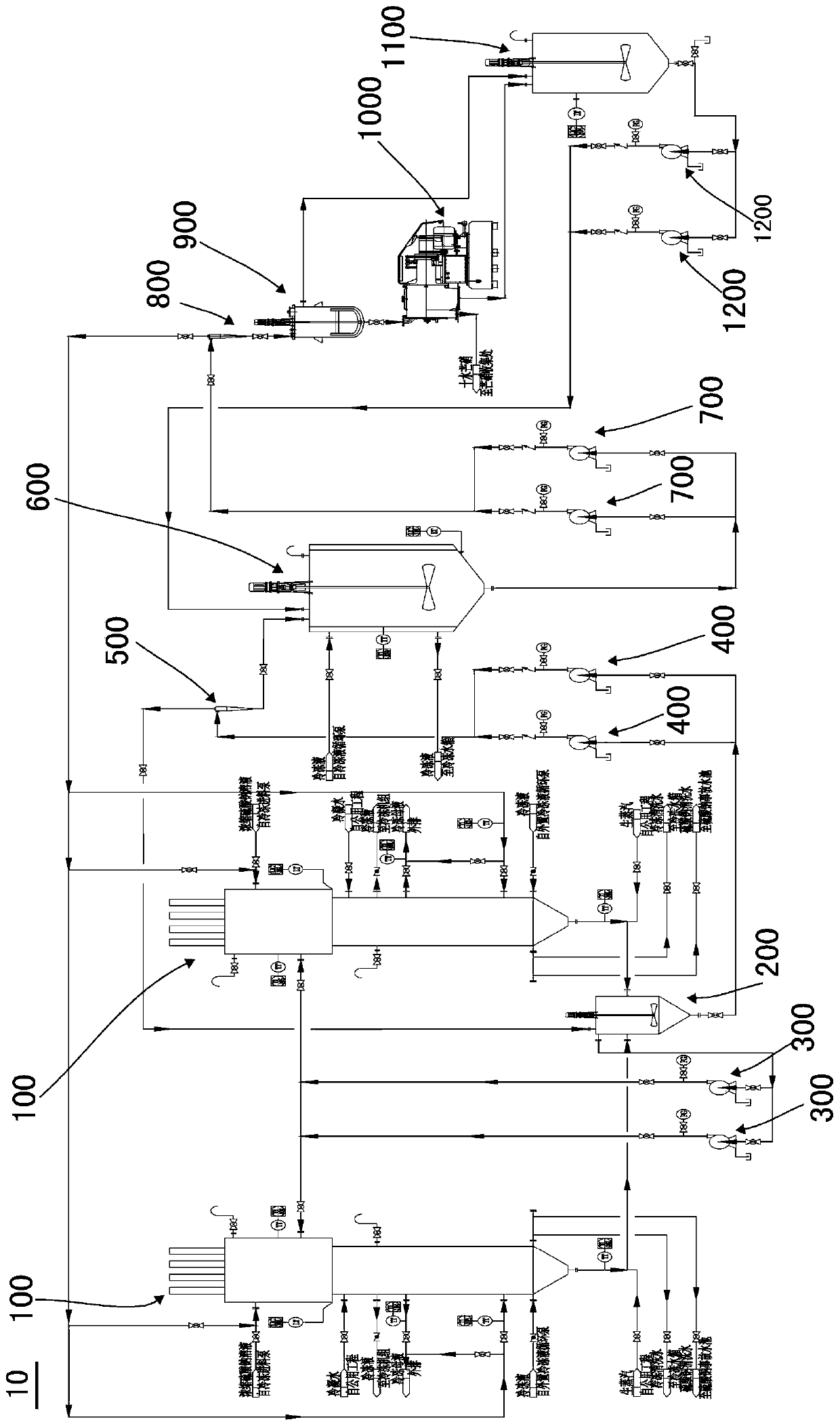

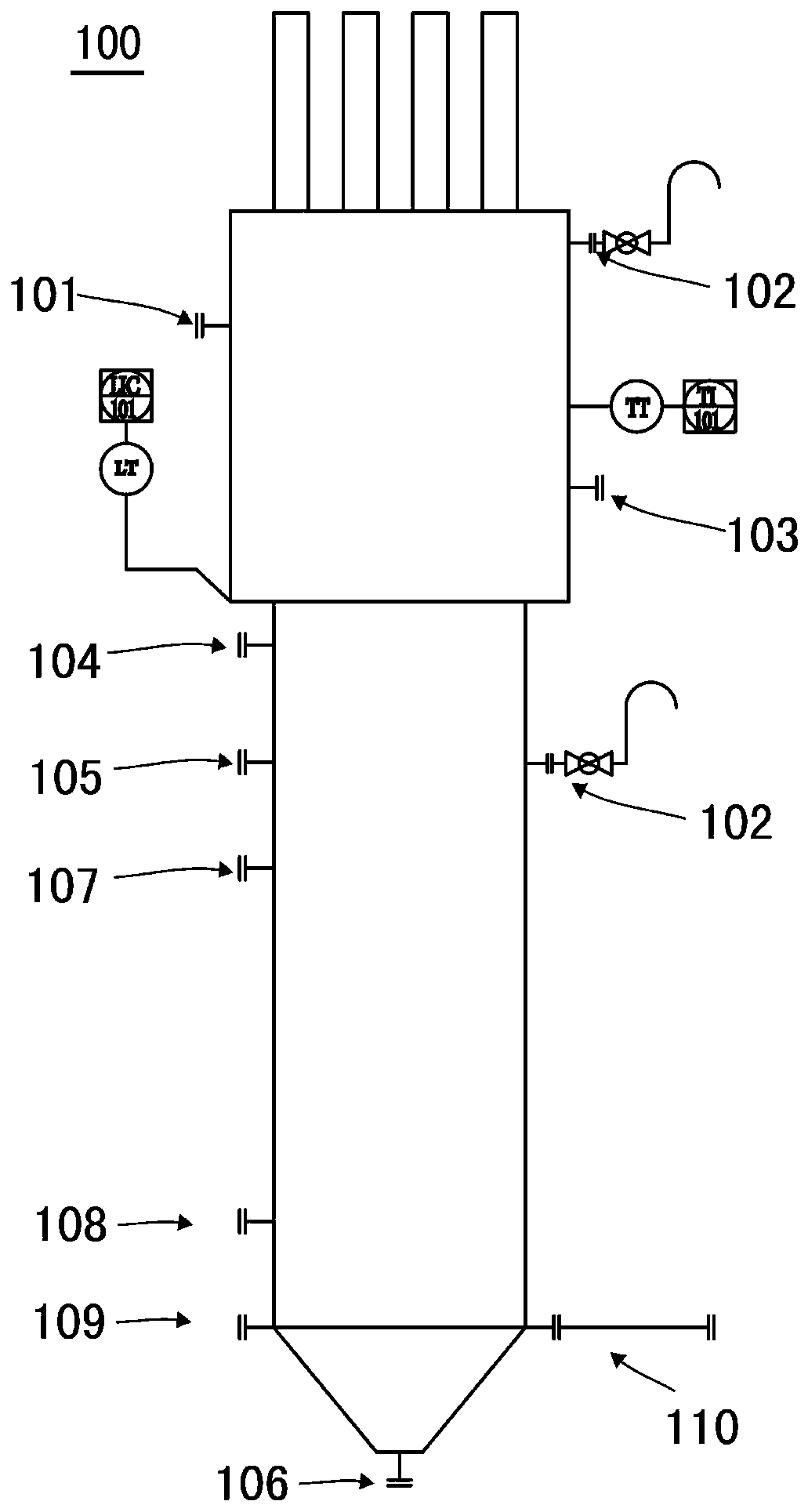

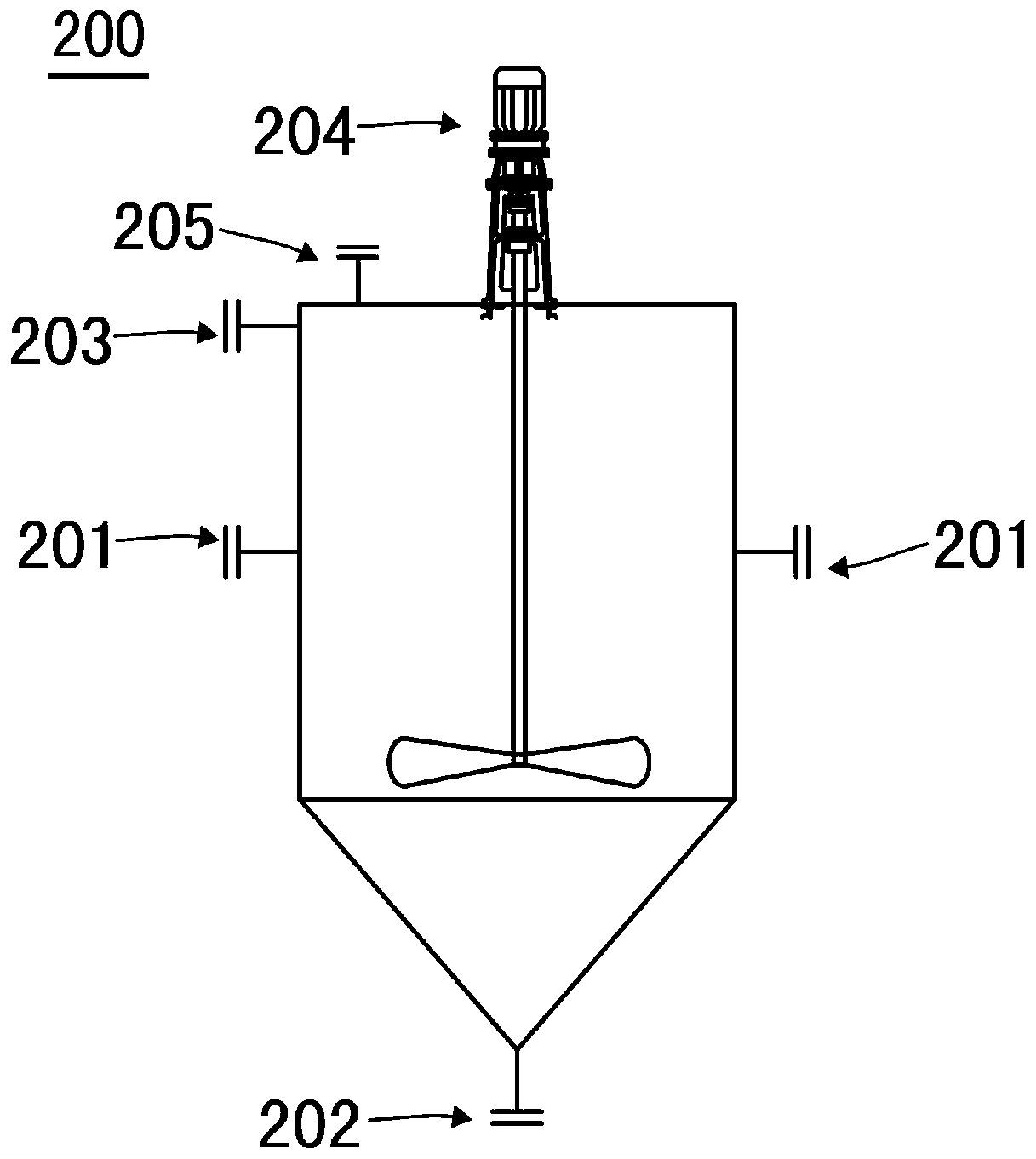

Multistage cooling circulation freezing crystallization system and crystallization process thereof

PendingCN111375221AGuaranteed purityGuaranteed resourcesSolution crystallizationHeat exchange cooling cystallizationBuffer tankCirculating pump

The invention discloses a multistage cooling circulation freezing crystallization system. The multistage cooling circulation freezing crystallization system comprises freezing heat exchangers, a freezing discharging tank, a freezing circulation pump, a freezing crystal mush pump, a first cyclone separator, a freezing crystal growing tank, a freezing discharging pump, a second cyclone separator, afreezing centrifugal buffer tank and a freezing centrifugal machine. The number of the freezing heat exchangers is at least two, and the multiple freezing heat exchangers are arranged in parallel. Thefreezing heat exchanger is communicated with the freezing discharging tank, and the freezing discharging tank, the freezing crystal mush pump, the first cyclone separator, the freezing crystal growing tank, the freezing discharging pump, the second cyclone separator, the freezing centrifugal buffer tank and the freezing centrifugal machine are sequentially communicated; and the freezing discharging tank is also communicated with each freezing heat exchanger through the freezing circulating pump. According to the multistage cooling circulation freezing crystallization system, efficient, stableand long-time operation of freezing crystallization is achieved, and meanwhile the purity and the recycling rate of crystalline salt are guaranteed.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

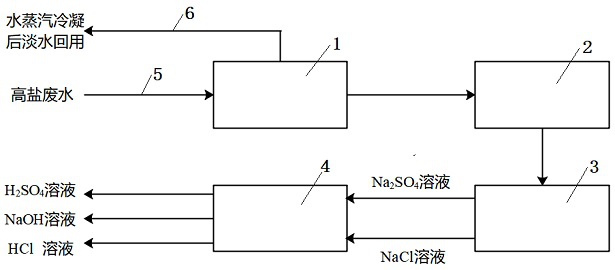

Low-cost concentration reduction and resourceful treatment process for high-salinity wastewater

PendingCN111675406AIncrease profitReduce the amount of treated waterWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFlue gasWastewater

The invention discloses a low-cost concentration reduction and resourceful treatment process for high-salinity wastewater, and solves the problems that in the prior art, the current environmental protection requirement cannot be met, the investment and operation cost is high, and resourceful utilization of a treated product cannot be realized. The process adopts a low-temperature flue gas / hot airheating concentration reduction system, a softening turbidity removal pretreatment system, a nanofiltration salt separation system and a bipolar membrane electrodialysis resourceful treatment system.Through the coupling synergistic effect of multiple systems, a new process is provided for treatment of high-salinity wastewater, the design is reasonable, the national environmental protection requirement is met, the operation cost is low, and the treatment product can be recycled.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Catalytic cracking and catalytic gasoline hydrogenation combined technological method

ActiveCN103059951BLow investment costLow operating costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic cracking and catalytic gasoline hydrogenation combined technological method. The method comprises: adjusting the operating conditions of a FCC (fluid catalytic cracking) device fractionating tower, conducting cutting pre-separation on FCC gasoline in the fractionating tower so as to obtain light fractions and heavy fractions; subjecting the light fractions to alkali-free deodorization, then letting the deodorized light fractions and thermocatalytic diesel oil enter a hydrogenation prefractionator together, thus obtaining light gasoline at the tower top and medium gasoline at a tower middle lateral line, mixing the medium gasoline with the heavy fractions, then passing the mixture through a hydrogenation protection reactor and a hydrodesulfurization reactor in order, and mixing the obtained refined product with the deodorized refined light gasoline so as to obtain a clean gasoline product. With the method provided in the invention, the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, gasoline product quality can meet the quality requirement of a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

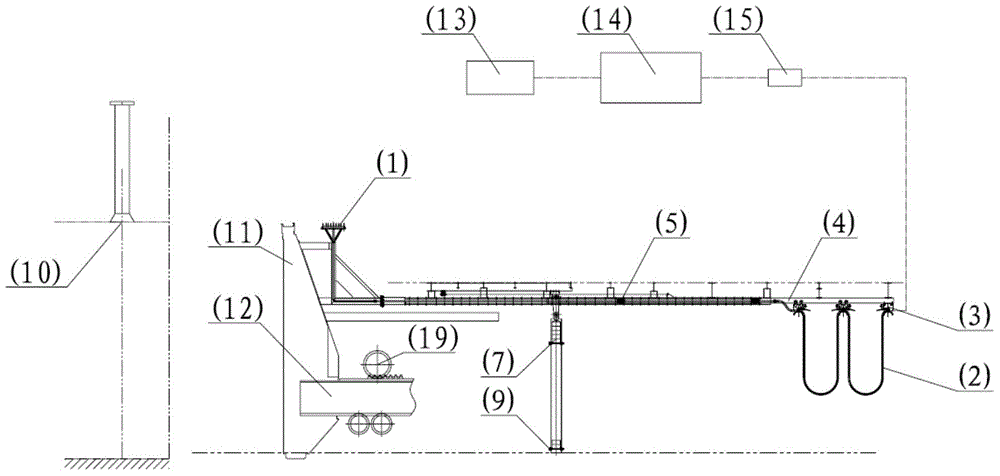

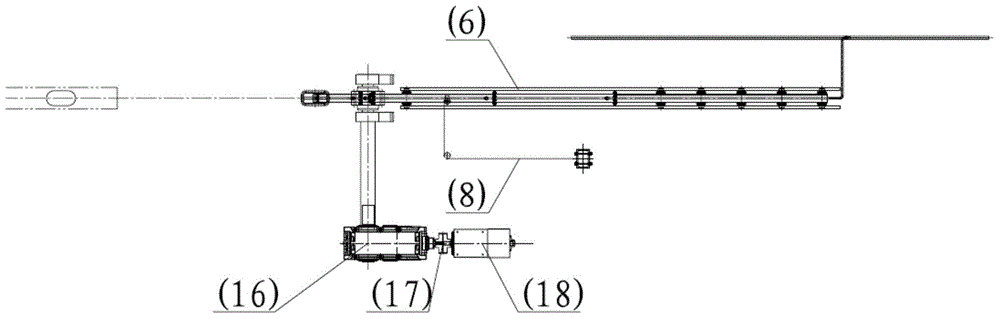

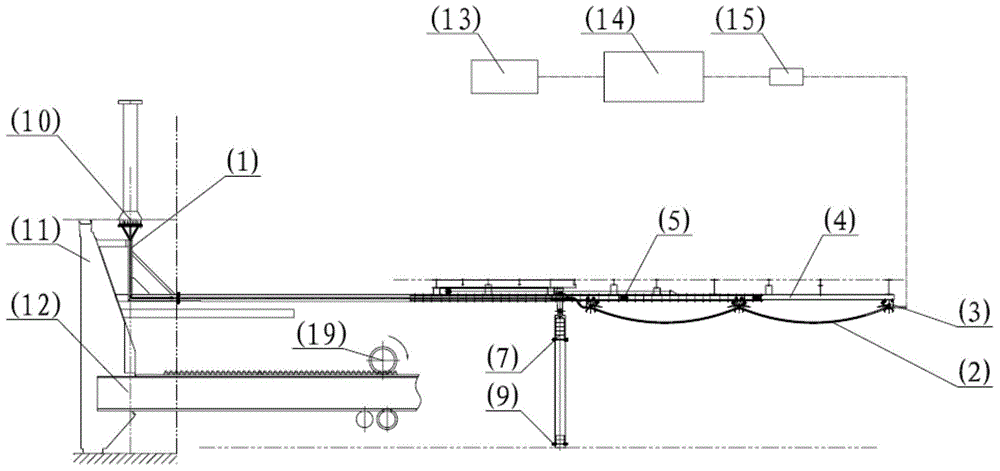

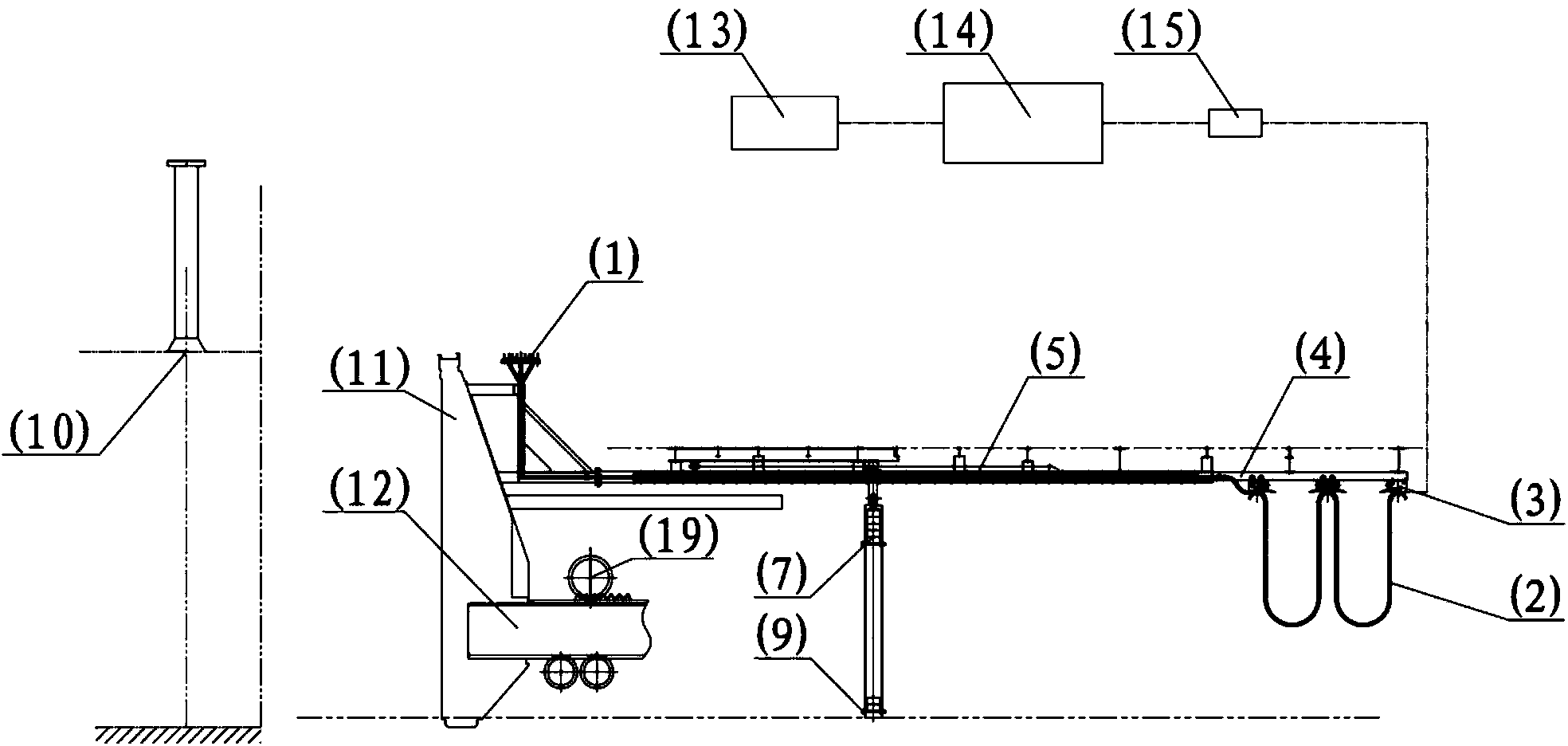

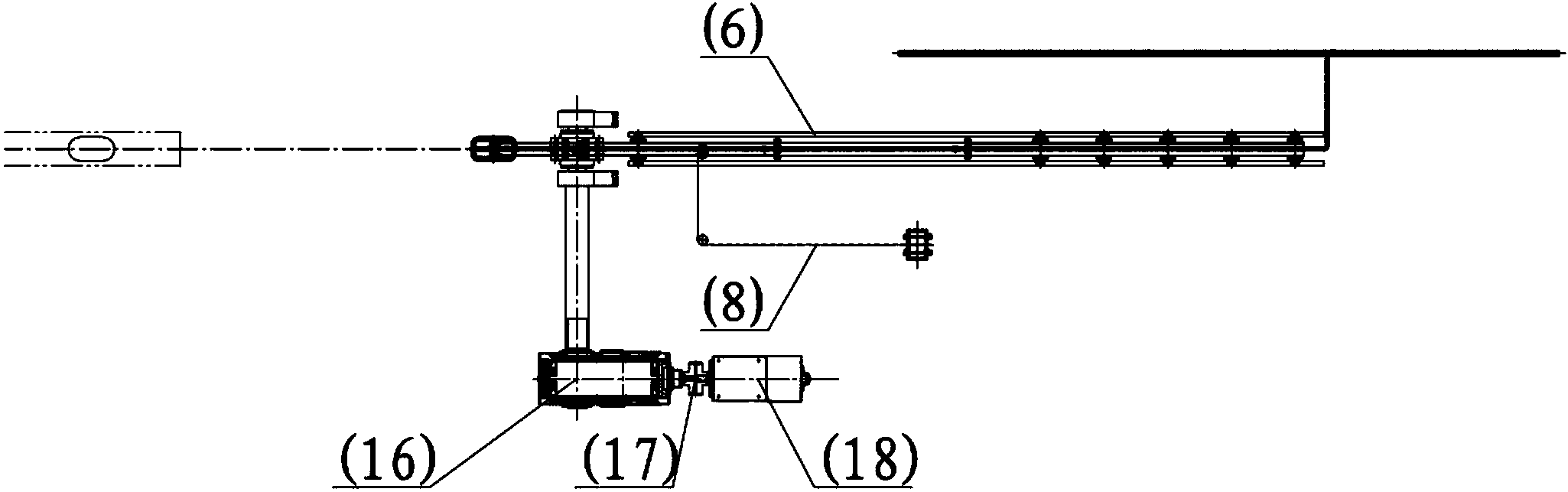

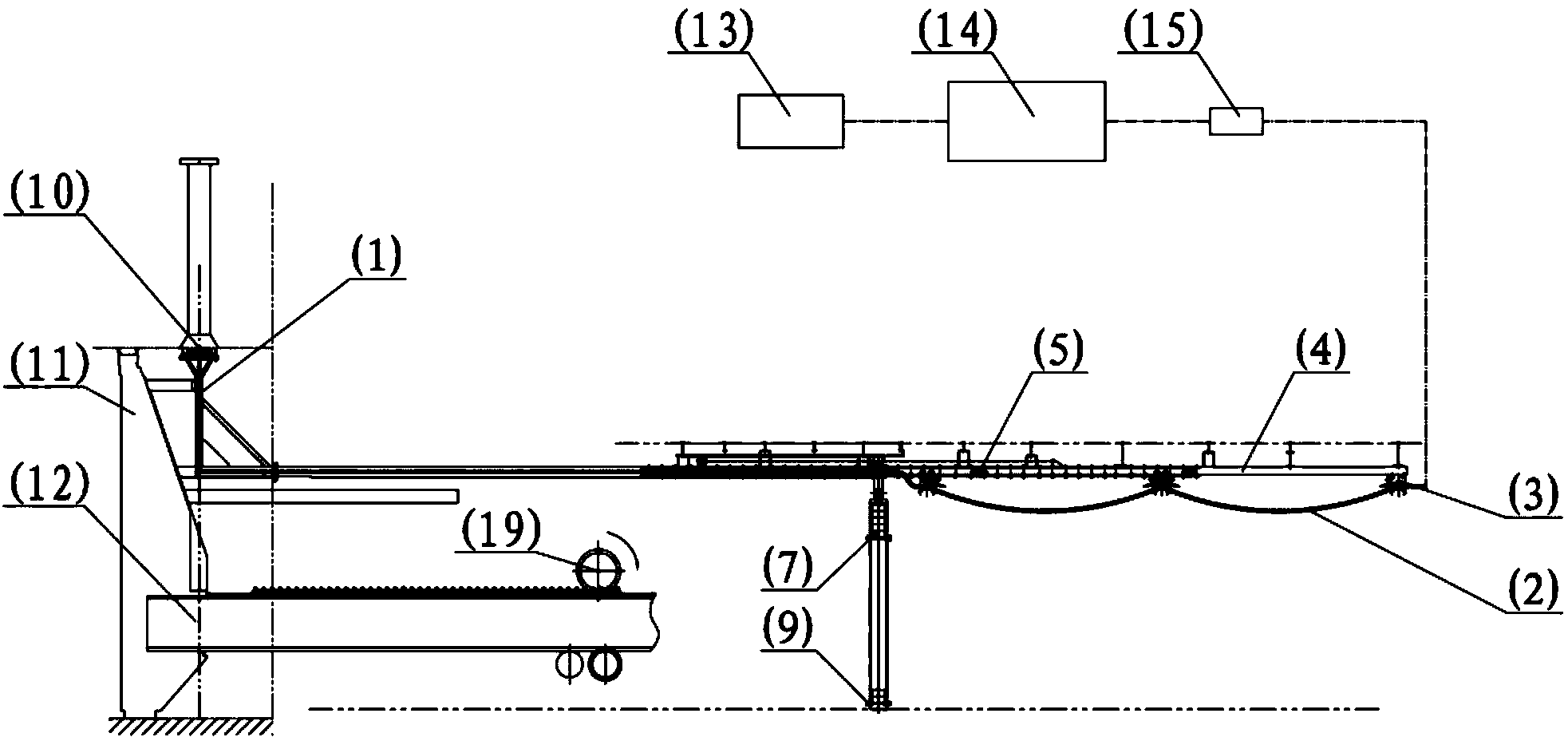

Graphite purging device for root of ascending pipe of coke oven machinery

ActiveCN103509569BGuaranteed operating cycleEfficient removalOven incrustations prevention/removalDischarging devicesMagnetic valveCoke oven

The invention discloses a graphite purging device for the root of an ascending pipe of coke oven machinery. The graphite purging device comprises a coke pushing device and a purging system, wherein the coke pushing device comprises a coke pushing head, a coke pushing rod and a coke pushing transmission gear; the purging system comprises an air compressor, an air bag, a gas circuit magnetic valve, a blowing pipeline, a rubber tube assembly, a cable-supporting pulley, a pulley track beam, a rolling wheel, a slide way and a blowing pipeline driving mechanism; the pulley track beam is fixed above the one side of the coke pushing device; the slide way is fixed right above the coke pushing rod of the coke pushing device; the blowing pipeline is placed on the slide way through the rolling wheel; the front part of the blowing pipeline is propped against the coke pushing head; the rubber tube assembly is placed on the cable-supporting pulley and connected with the rear part of the blowing pipeline; one end of a steel wire rope of the blowing pipeline driving mechanism is connected with the tail part of the blowing pipeline, while the other end is connected with a pulling mechanism; and a backstop is installed on the pulling mechanism. The beneficial effects of the graphite purging device are as follows: the device can ensure the operation period of the coke pushing device, effectively remove the graphite which is at the root of the ascending pipe, improve the production stability of the coke oven body and the operation efficiency of the coke oven machinery, avoid smoke and dust from escaping, and protect environment.

Owner:DALIAN HUARUI HEAVY IND COKE OVEN VEHICLE EQUIP +1

Catalytic gasoline deep hydrodesulfurization method

ActiveCN103059965BAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic gasoline deep hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, adopting an appropriate cutting point to conduct cutting so as to obtain FCC (fluid catalytic cracking) gasoline light fractions at the tower top and FCC heavy fractions at the lateral line; subjecting FCC gasoline light fractions to alkali-free deodorization, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrogenation on the medium gasoline, performing deep selective hydrogenation on the heavy gasoline, and mixing the obtained two parts of refined distillate oil with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

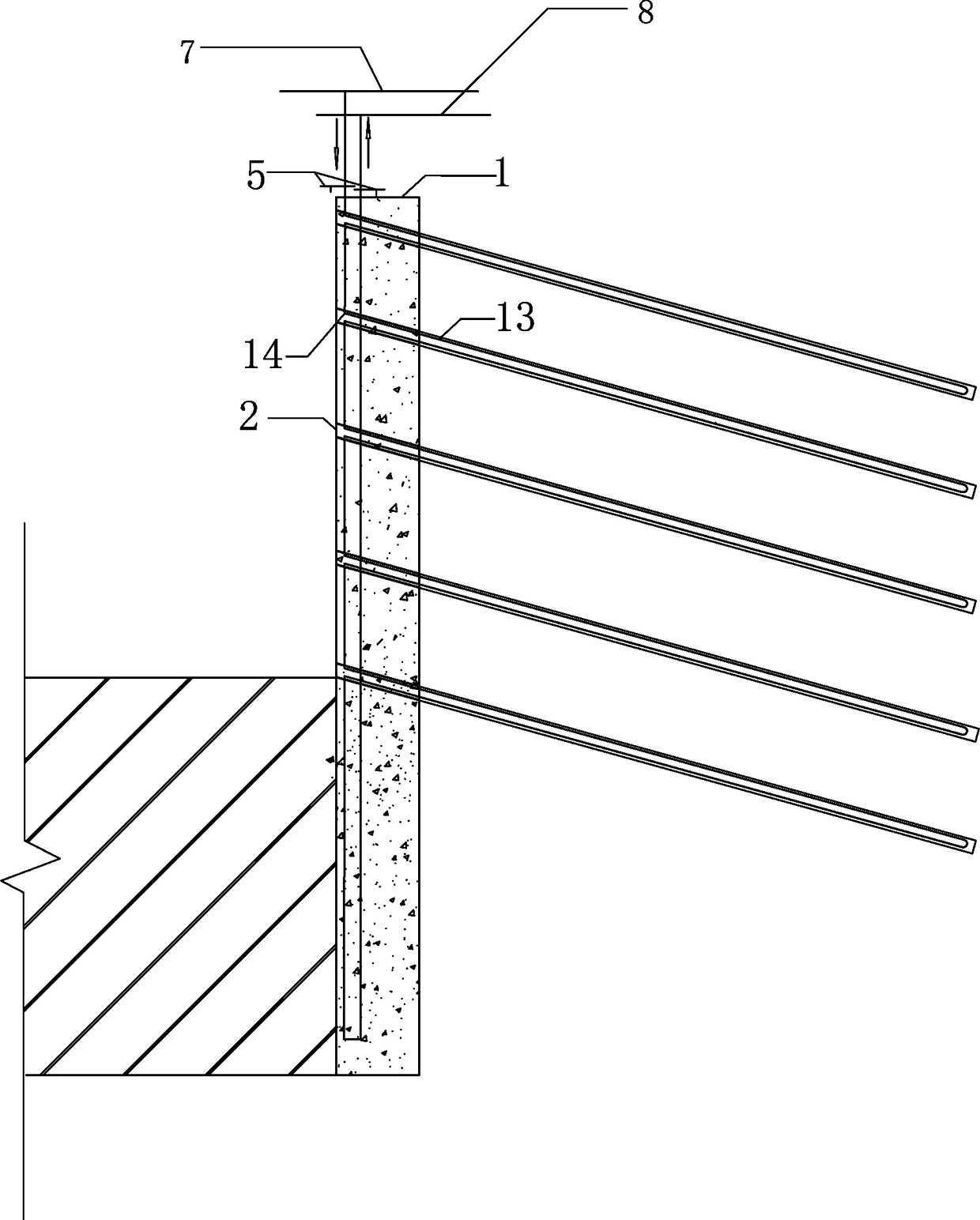

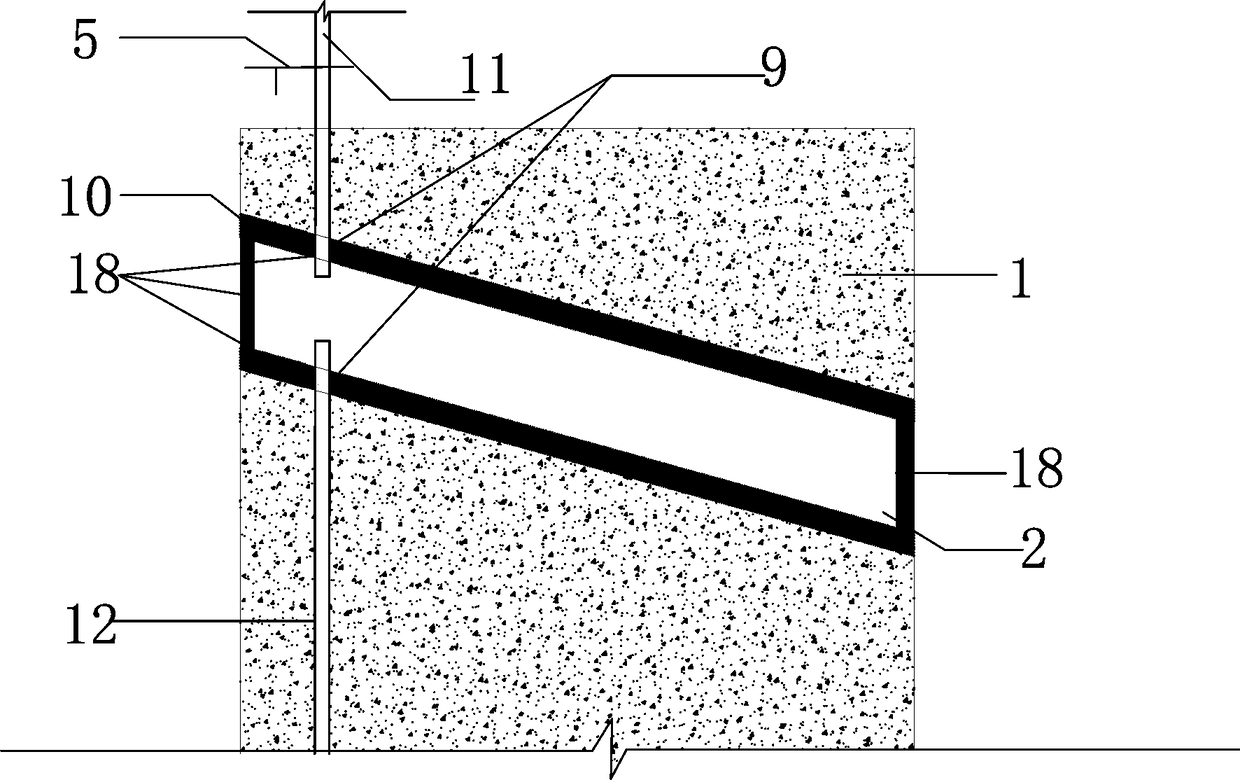

Terrestrial heat collecting device used in underground diaphragm walls

PendingCN108240713AAvoid temperature cyclingImprove heat exchange efficiencyLighting and heating apparatusGeothermal energy generationSlurry wallResource utilization

A terrestrial heat collecting device used in the underground diaphragm walls comprises the underground diaphragm walls, heat conduction pipes, a main water inlet pipe, a main water outlet pipe and anchoring steel pipes. A water inlet branch pipe, a water outlet branch pipe and the corresponding heat conduction pipe are arranged in each underground diaphragm wall, wherein one end of the water inletbranch pipe is connected with the heat conduction pipe, and the other end of the water inlet branch pipe is connected with the main water inlet pipe; and the end, not connected with the water inlet branch pipe, of the heat conduction pipe is connected with one end of the water outlet branch pipe, the other end of the water outlet branch pipe is connected with the main water outlet pipe, and the water inlet branch pipe, the water outlet branch pipe and the heat conduction pipe are connected to form one pipeline loop. The multiple underground diaphragm walls are arranged. The corresponding pipeline loop is arranged in each underground diaphragm wall, the multiple pipeline loops are connected to the same main water inlet pipe and the same main water outlet pipe in parallel, and the main water inlet pipe and the main water outlet pipe are connected with a heat collector. By adoption of the above structure, the land area occupied by the terrestrial heat collecting device can be utilized tothe maximum degree, cost input is reduced, the terrestrial heat resource utilization efficiency can be effectively improved, and meanwhile stability and safety of the underground diaphragm walls areguaranteed.

Owner:CHINA THREE GORGES UNIV

Catalytic cracking and catalytic gasoline hydrogenation combined process

ActiveCN103059958BLow investment costLow operating costTreatment with hydrotreatment processesAlkali freeSulfur

Owner:CHINA PETROLEUM & CHEM CORP +1

Suspended bed external separation system and using method thereof

PendingCN113897210ASmall pressure dropGuaranteed service lifeBiofuelsLiquid hydrocarbon mixture productionReactive separationProcess engineering

The invention relates to the technical field of suspended bed hydrogenation, in particular to a suspended bed external separation system and a using method thereof. The suspended bed external separation system comprises a high-pressure feeding pump, a suspended bed reactor, a primary cyclone separator, a secondary cyclone separator, a fixed bed reactor, a heat exchanger, a cold high-pressure separator and a cold low-pressure separator. The suspended bed external separation system has the following advantages: 1, light and heavy components can be effectively separated through the primary cyclone separator and the secondary cyclone separator, and the heavy components enter the suspended bed reactor again for reaction separation; 2, the operation cycle of the fixed bed reactor at the rear part of the suspended bed reactor is ensured, the pressure drop is reduced, and the service life of a catalyst is ensured; and 3, the heavy oil at the bottom of the suspended bed reactor, which contains more catalyst powder, heavy metals and the like, are discontinuously discharged, so that the load of the suspended bed reactor is reduced.

Owner:山东汇邦新材料有限公司

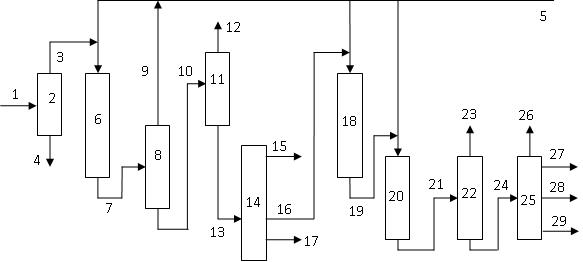

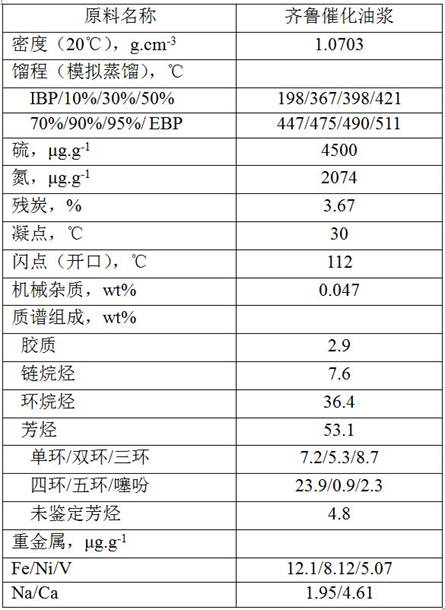

Method for producing special oil product by hydrogenation of catalytic slurry oil

ActiveCN113122324AReduce contentReduce the content of sulfur and nitrogen impuritiesTreatment with hydrotreatment processesBio-feedstockPtru catalystHydrogenation reaction

The invention discloses a method for producing a special oil product by using catalytic slurry oil as a raw material. The catalytic slurry oil is firstly refined by a solvent; raffinate oil is mixed with hydrogen, and the mixture is sequentially in contact with a protective agent, a hydrofining agent and a hydro-upgrading agent for hydrogenation reaction; separating a hydro-upgrading effluent, and enabling an obtained liquid-phase product to enter a fractionating tower; enabling diesel oil fractions obtained through fractionation to enter a pour point depressing reaction zone, using a single-stage hydrocracking catalyst in a hydrogenation pour point depressing reaction zone, and conducting hydrogenation modification and isomerization reaction in the presence of hydrogen; and carrying out hydrofinishing reaction on the hydrodewaxed effluent, and separating the hydrofinishing product to obtain large-specific-gravity aviation kerosene, transformer oil base oil and refrigerating machine oil base oil. The processing method for improving the economical efficiency of the catalytic slurry oil is provided for the catalytic slurry oil with low additional value.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing aromatic hydrocarbon solvent oil by hydrogenation of ethylene cracking C9 aromatic fraction

ActiveCN111378502BGood hydrogenation activity at low temperatureGuaranteed operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrocarbon solventsPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep hydrodesulfurization method for catalytic gasoline

ActiveCN103059956BAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a deep hydrodesulfurization method for catalytic gasoline. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, and adopting an appropriate cutting point to perform cutting so as to obtain light fractions at the tower top and heavy fractions at the lateral line; subjecting the light fractions to alkali-free deodorization, then passing the deodorized light fractions through a hydrogenation prefractionator to separate light gasoline and medium gasoline; and subjecting the separated medium gasoline and the heavy fractions to selective hydrogenation, and mixing the refined product with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Graphite purging device for root of ascending pipe of coke oven machinery

ActiveCN103509569AImprove production stabilityImprove operational efficiencyOven incrustations prevention/removalDischarging devicesSmokeGraphite

The invention discloses a graphite purging device for the root of an ascending pipe of coke oven machinery. The graphite purging device comprises a coke pushing device and a purging system, wherein the coke pushing device comprises a coke pushing head, a coke pushing rod and a coke pushing transmission gear; the purging system comprises an air compressor, an air bag, a gas circuit magnetic valve, a blowing pipeline, a rubber tube assembly, a cable-supporting pulley, a pulley track beam, a rolling wheel, a slide way and a blowing pipeline driving mechanism; the pulley track beam is fixed above the one side of the coke pushing device; the slide way is fixed right above the coke pushing rod of the coke pushing device; the blowing pipeline is placed on the slide way through the rolling wheel; the front part of the blowing pipeline is propped against the coke pushing head; the rubber tube assembly is placed on the cable-supporting pulley and connected with the rear part of the blowing pipeline; one end of a steel wire rope of the blowing pipeline driving mechanism is connected with the tail part of the blowing pipeline, while the other end is connected with a pulling mechanism; and a backstop is installed on the pulling mechanism. The beneficial effects of the graphite purging device are as follows: the device can ensure the operation period of the coke pushing device, effectively remove the graphite which is at the root of the ascending pipe, improve the production stability of the coke oven body and the operation efficiency of the coke oven machinery, avoid smoke and dust from escaping, and protect environment.

Owner:DALIAN HUARUI HEAVY IND COKE OVEN VEHICLE EQUIP +1

A kind of catalytic gasoline hydrodesulfurization method

ActiveCN103059945BAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention discloses a catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, and adopting an appropriate cutting point to perform cutting so as to obtain gasoline light fractions at the tower top and gasoline heavy fractions at the lateral line; subjecting the light fractions to alkali extraction, carrying out selective hydrodesulfurization on the heavy fractions, and mixing the obtained refined oil with the light gasoline generated by alkali extraction, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com