Patents

Literature

35results about How to "Reduce the amount of treated water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

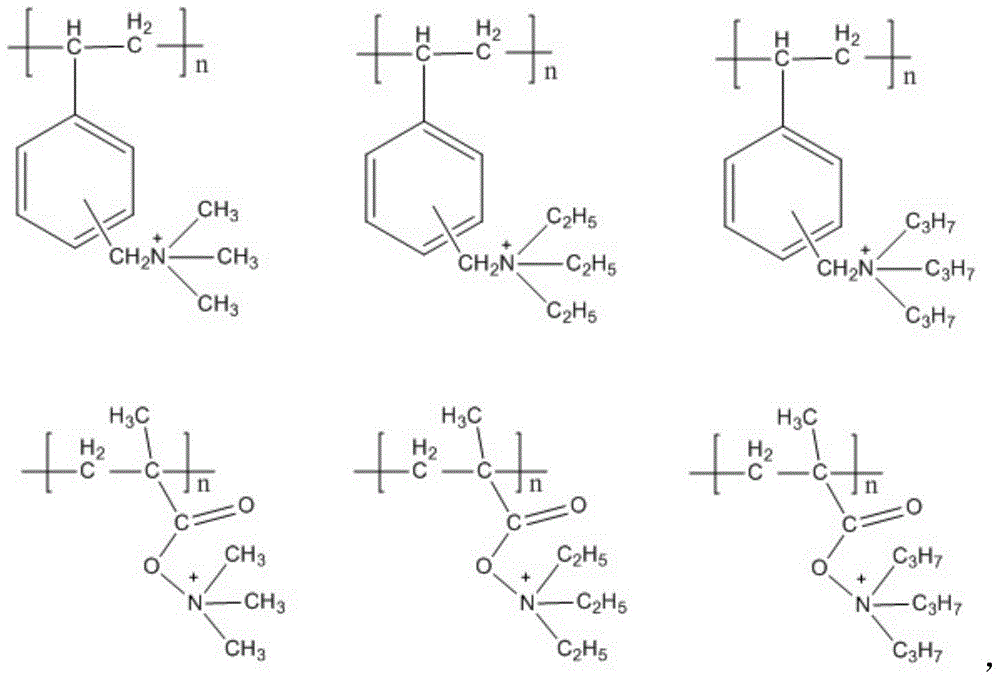

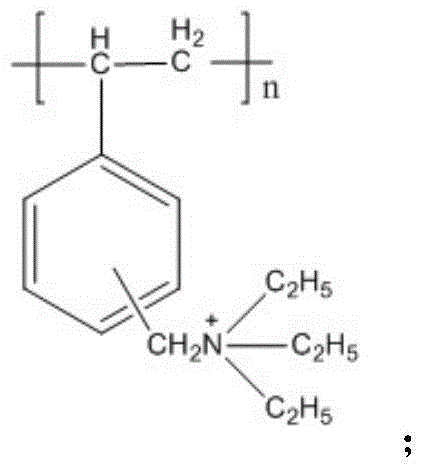

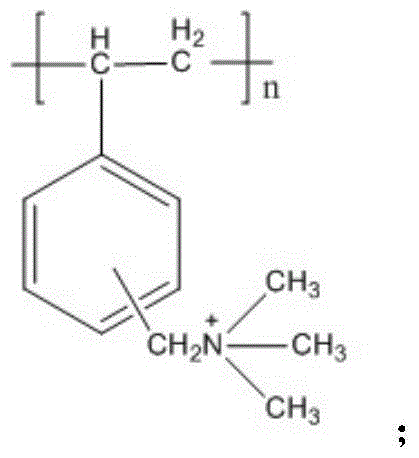

Method for removing nitrate nitrogen in water through ion exchange and denitrification integration

ActiveCN105036495ATemperature and other conditions control cost reductionEfficient removalWater contaminantsMultistage water/sewage treatmentIon exchangeMunicipal sewage

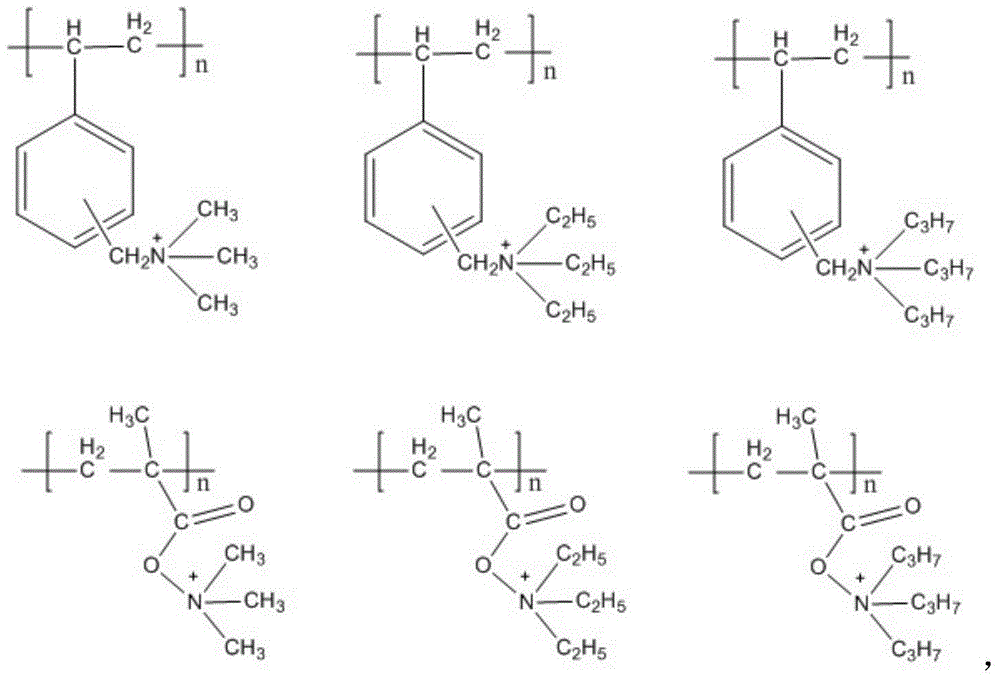

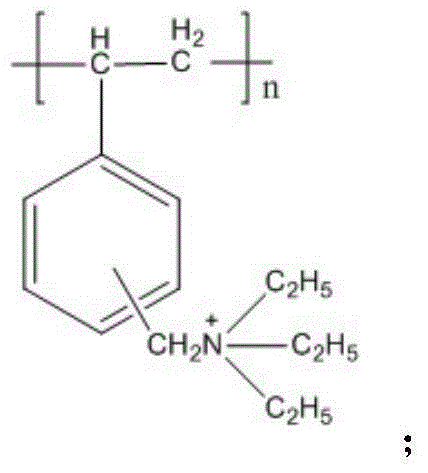

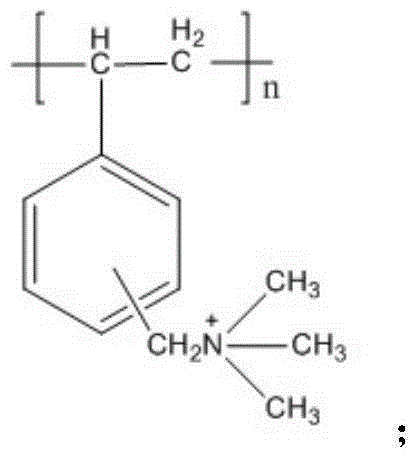

The invention discloses a method for removing nitrate nitrogen in water through ion exchange and denitrification integration to solve the problem that nitrate nitrogen pollution exists in water or waste water at present. The method includes the steps that enrichment of the nitrate nitrogen in the water or waste water is achieved through high-selectivity nitrate ion exchange resin; the ion exchange resin enriched with the nitrate nitrogen is regenerated and recycled under certain conditions directly through the action of biological denitrification; finally, the nitrate nitrogen in the water or the waste water can be effectively removed through the continuous technology. The method can be used for removing nitrate nitrogen in underground water, surface water, municipal sewage, industrial waste water and various kinds of water, and is particularly applicable to natural water body, sewage bio-chemical effluents and water bodies with few carbon sources capable of being used by organisms.

Owner:NANJING UNIV +1

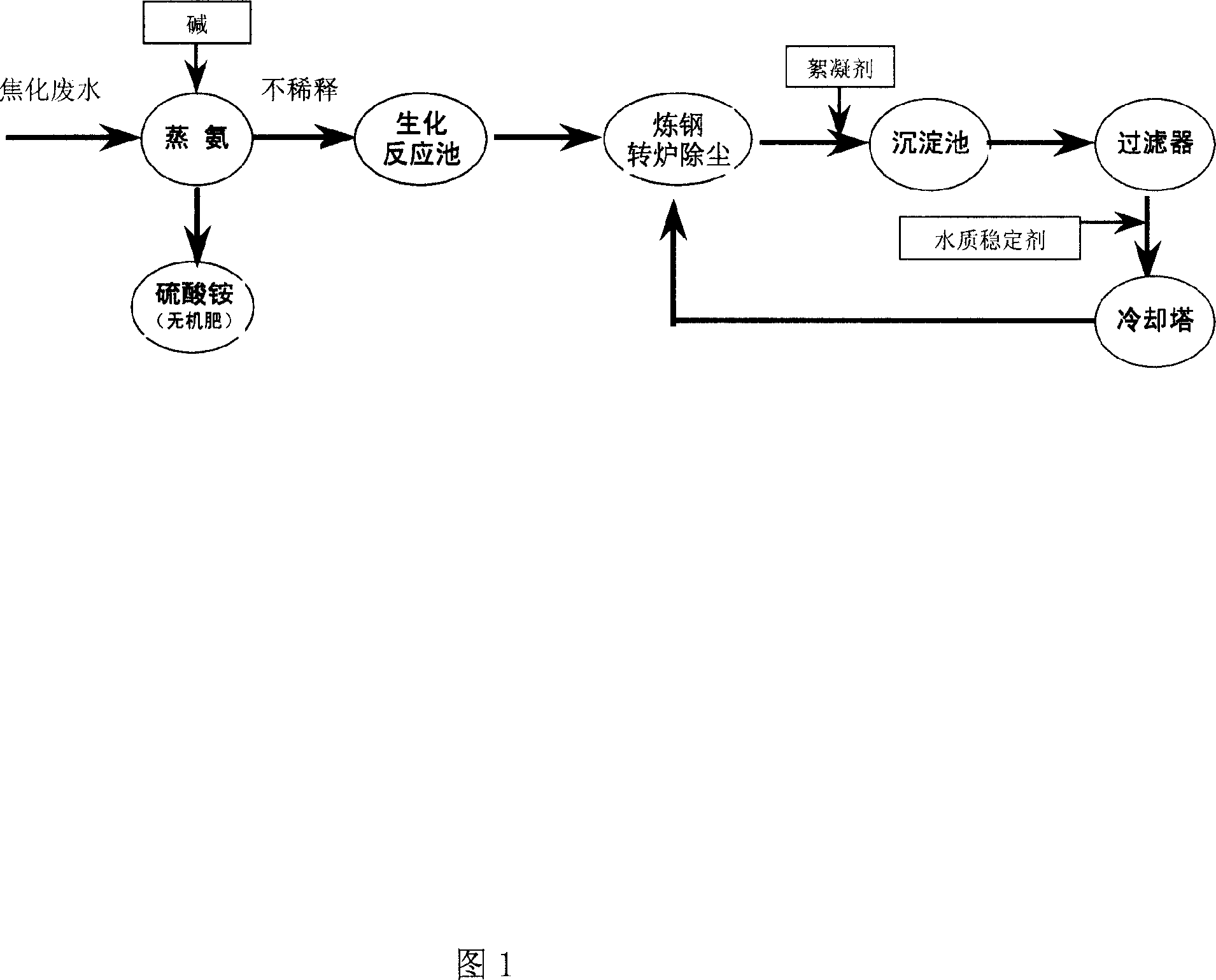

Coking waste water zero discharge treatment process

InactiveCN1948188AAchieving "Zero Emissions"Realize "Zero Emissions"Multistage water/sewage treatmentWater/sewage treatment by degassingDistillationWater quality

The present invention relates to a pyrogenic waste water zero discharge treatment process. It is characterized by that said process includes the following steps: making the pyrogenic waste water undergo the process of primary ammonia distillation treatment, then making biochemical treatment, and making the treated waste water be directly returned into the dust-removing system of steel-smelting converter, utilizing converter smoke dust and flue gas to further degrade the pollutants of amino nitrogen, phenol, cyanogens and COD in the pyrogenic waste water under the high temperature condition, and making the discharged water undergo the processes of flocculating settling, filtering and water quality stabilization so as to attain the discharge requirement.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

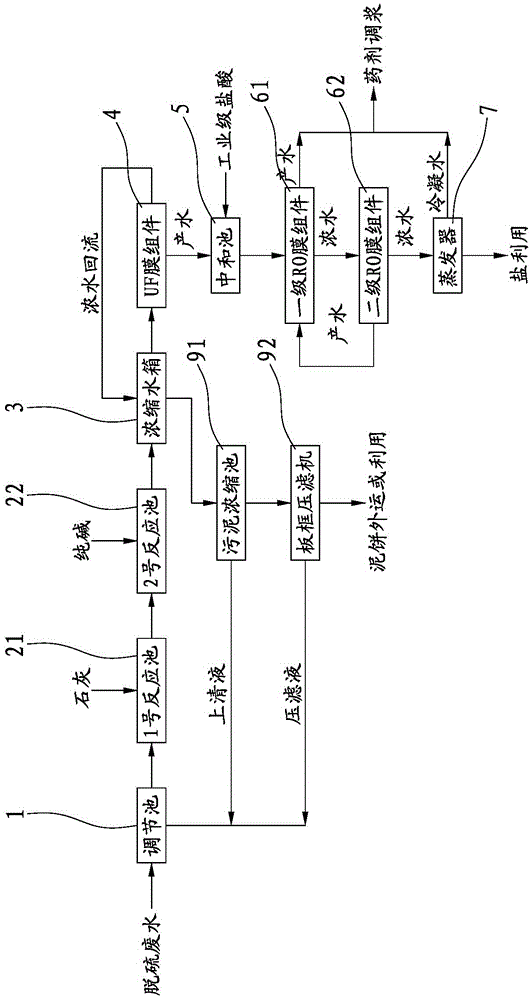

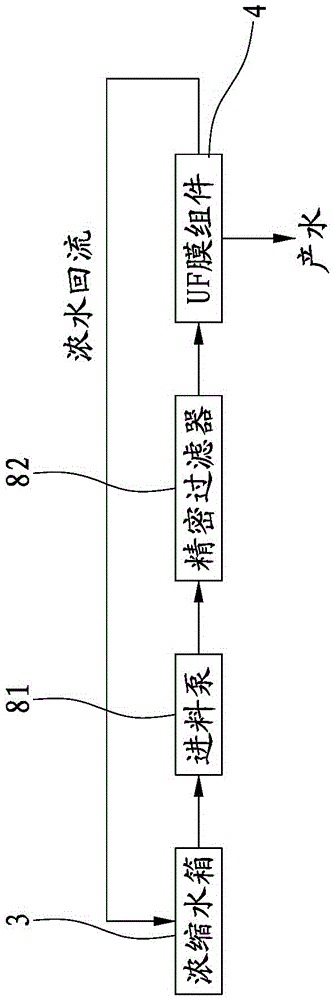

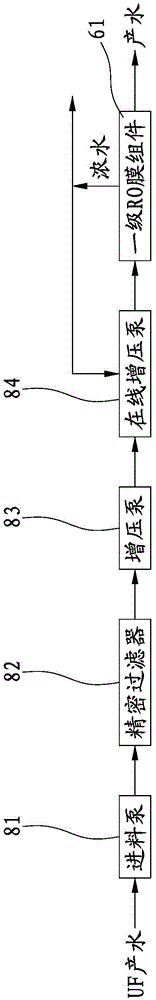

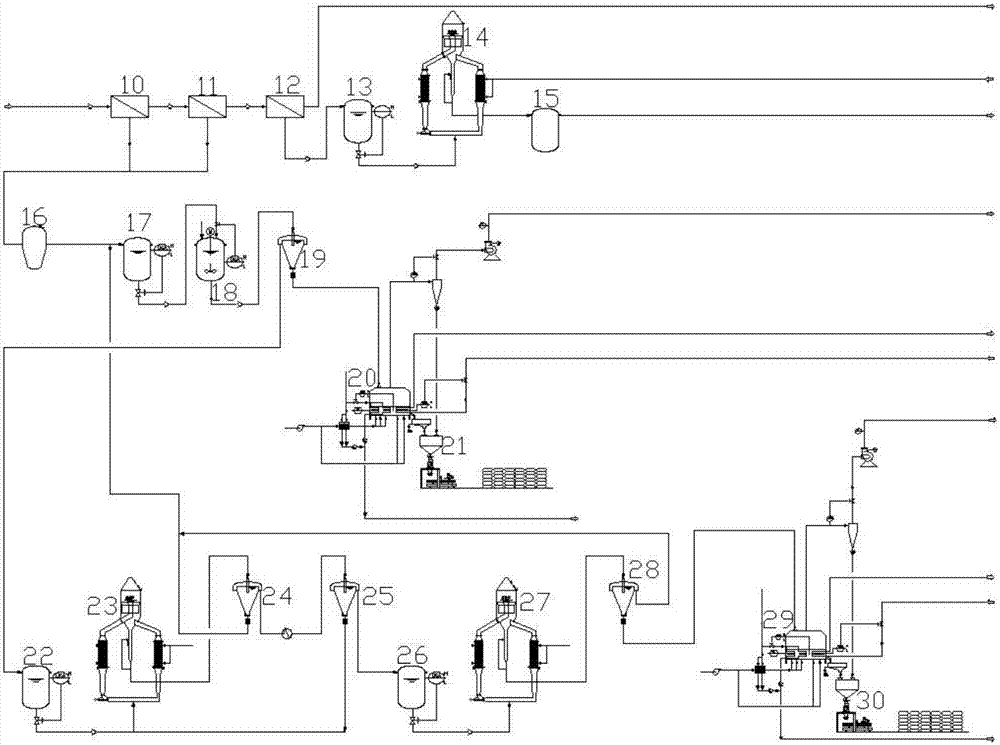

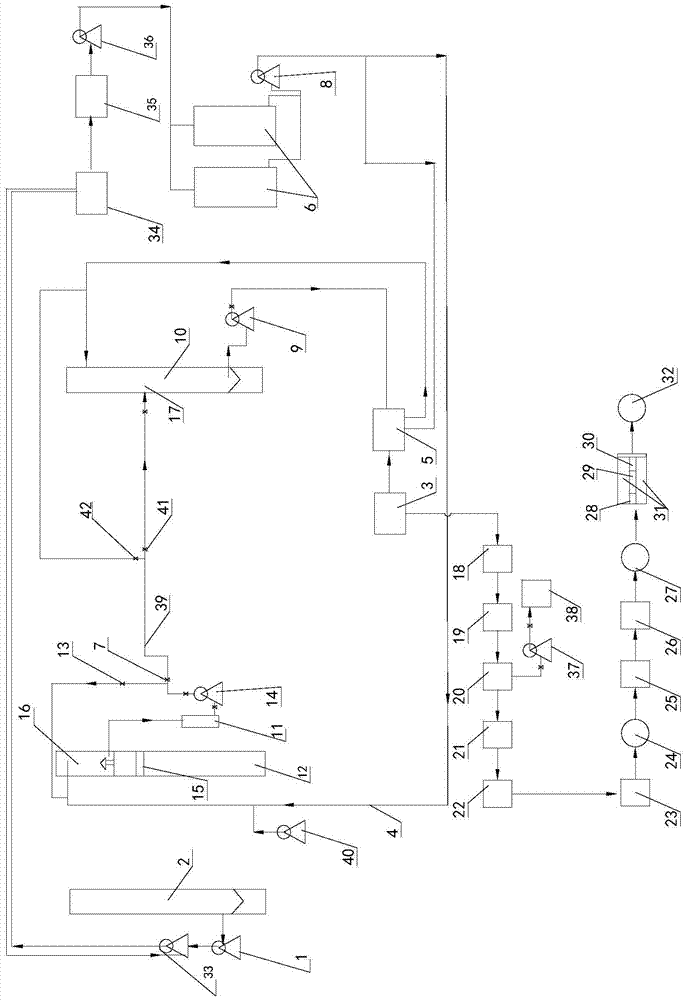

Power plant desulfurization waste water membrane concentrating process and equipment

ActiveCN105461143AHigh precisionHigh hardness removal efficiencyGeneral water supply conservationTreatment involving filtrationProcedure AgentsUltrafiltration

The invention discloses a power plant desulfurization waste water membrane concentrating process. The process comprises the step that water quantity and water quality of desulfurization waste water are adjusted in an adjusting tank, and the adjusted desulfurization waste water is reacted with lime in a first reaction tank, enters a second reaction tank in a coagulation fluid state to be reacted with sodium carbonate and then enters a concentrating water tank in a coagulation fluid state; waste water in the concentrating water tank is lifted to a UF membrane component, filtered contributing water enters a neutralizing tank, the pH value of the contributing water is adjusted through industrial hydrochloric acid, and concentrated water flows back to the concentrating water tank; ultra-filtered contributing water with the pH value adjusted in the neutralizing tank is pumped to a first-stage RO membrane component to be concentrated through a pump, obtained concentrated water is pumped into a second-stage RO membrane component through a pump, concentrated water enters an evaporator, the contributing water of the second-stage RO membrane component flows back to the first-stage RO membrane component to be treated, and the contributing water of the first-stage RO membrane component and evaporator condensate water are recycled for slurry mixing of production process agents. The invention discloses power plant desulfurization waste water membrane concentrating equipment. By means of the power plant desulfurization waste water membrane concentrating process and equipment, the concentrating effect of the desulfurization waste can be improved, the chemical agent and operating cost can be reduced, and the zero-release requirement can be met.

Owner:XIAMEN JIARONG TECH CO LTD

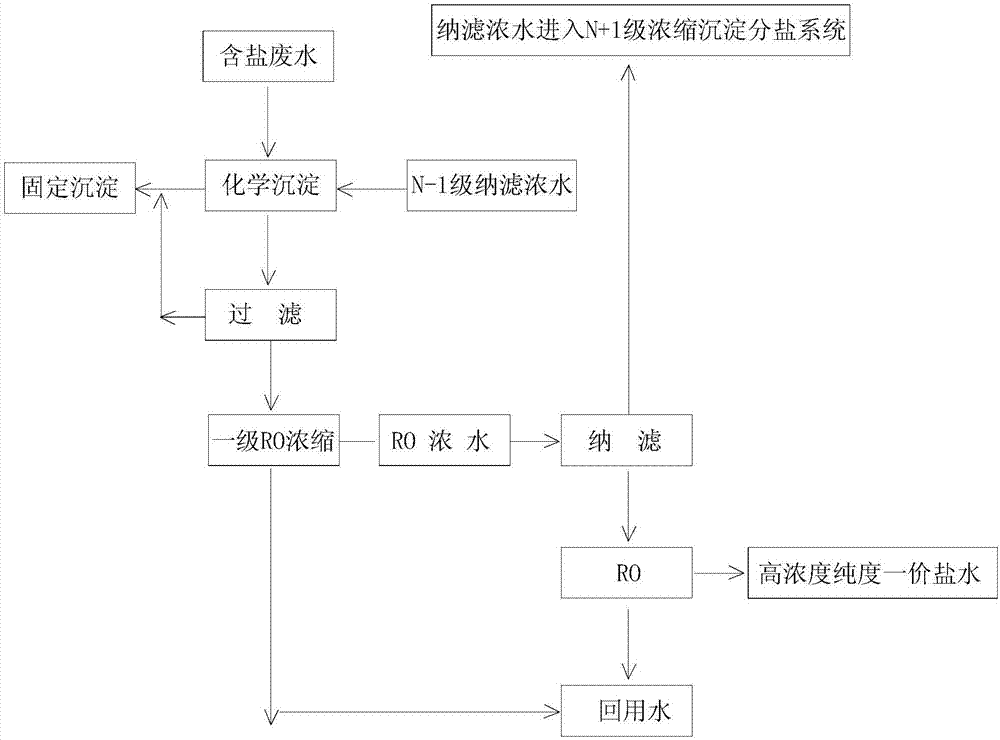

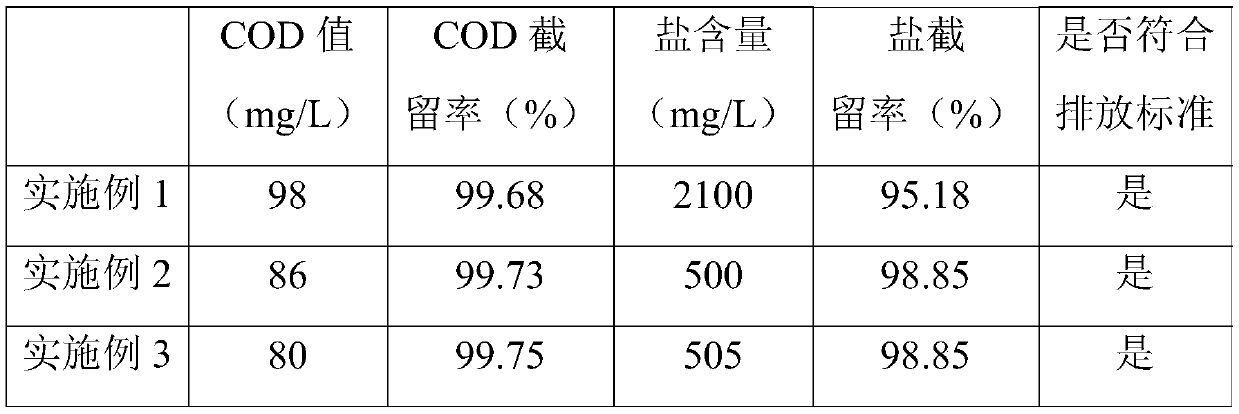

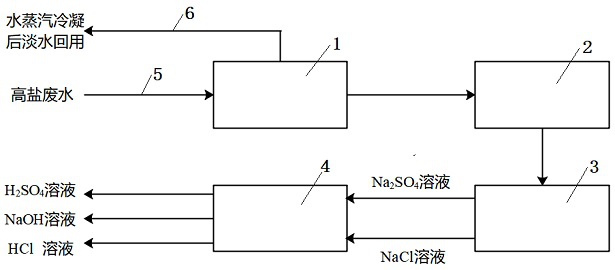

Method for comprehensive treatment of chemical strong brine

InactiveCN106865859AReduce the amount of treated waterReduce energy consumptionWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentSodium bicarbonateEconomic benefits

Belonging to the technical field of resource recycling, the invention discloses a method for comprehensive treatment of chemical strong brine. According to the method, chemical strong brine is separated by a nanofiltration membrane to obtain a sodium chloride solution and a sulfuric acid solution, the sulfuric acid solution is then subjected to nitrate freezing purification in a cold way, then the product reacts with ammonia water and carbon dioxide gas to prepare sodium bicarbonate and ammonium sulfate products. The method provided by the invention solves the problem of difficult treatment of chemical strong brine, realizes recycling of miscellaneous salts in strong brine, and satisfies the requirements of sustainable development. At the same time, compared with salt method for preparation of sodium bicarbonate, the method can reduce the anticorrosion requirement of equipment and save the project investment for preparation of sodium bicarbonate, the byproduct ammonium sulfate has a value higher than ammonium chloride, thus having obvious advantages in economic benefit.

Owner:科莱环保(北京)有限公司

Sewage regeneration and zero discharge method

InactiveCN103193351AReduce the amount of treated waterLow running costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentEnvironmental chemistryNanofiltration

The invention belongs to the technical field of environmental protection, especially belongs to the technical field of water treatment, and relates to a method for respectively removing the pollutants in sewage by using a plurality of membrane separation methods. The method comprises the steps of: 1, carrying out membrane enhanced chemical softening to remove the alkaline deposits in the water in a manner of a deposit (1); 2, filtering by using nanofiltration membrane to obtain organic pollutant concentrated solution (2) and nanofiltration produced water (3), wherein the recovery rate of the nanofiltration membrane is 80-95%; 3, carrying out reverse osmosis concentration on a small part of the nanofiltration produced water (3) to obtain reverse osmosis produced water (4) and dissolving salt concentrated solution (5), wherein the utilization rate of reverse osmosis can be up to 80-97%; 4, evaporating and concentrating the organic pollutant concentrated solution (2), reusing distilled water (6) and combusting organic matter strong liquor (7); and 5, carrying out evaporative crystallization on the dissolving salt concentrated solution (5) and reusing distilled water (8) to obtain solid salt. According to the method, the nanofiltration and the reverse osmosis can be stably carried out under high utilization rate to remarkably decrease the treating water quantity of an evaporative crystallizer, so that the operation cost is reduced, the scaling problem of crystallization equipment is avoided at the same time, the crystallization difficulty of mixture of inorganic salt and organic pollutant is solved and then the crystallizer can stably run in a long term.

Owner:BEIJING GRANT MEMBRANE SEPARATION EQUIP

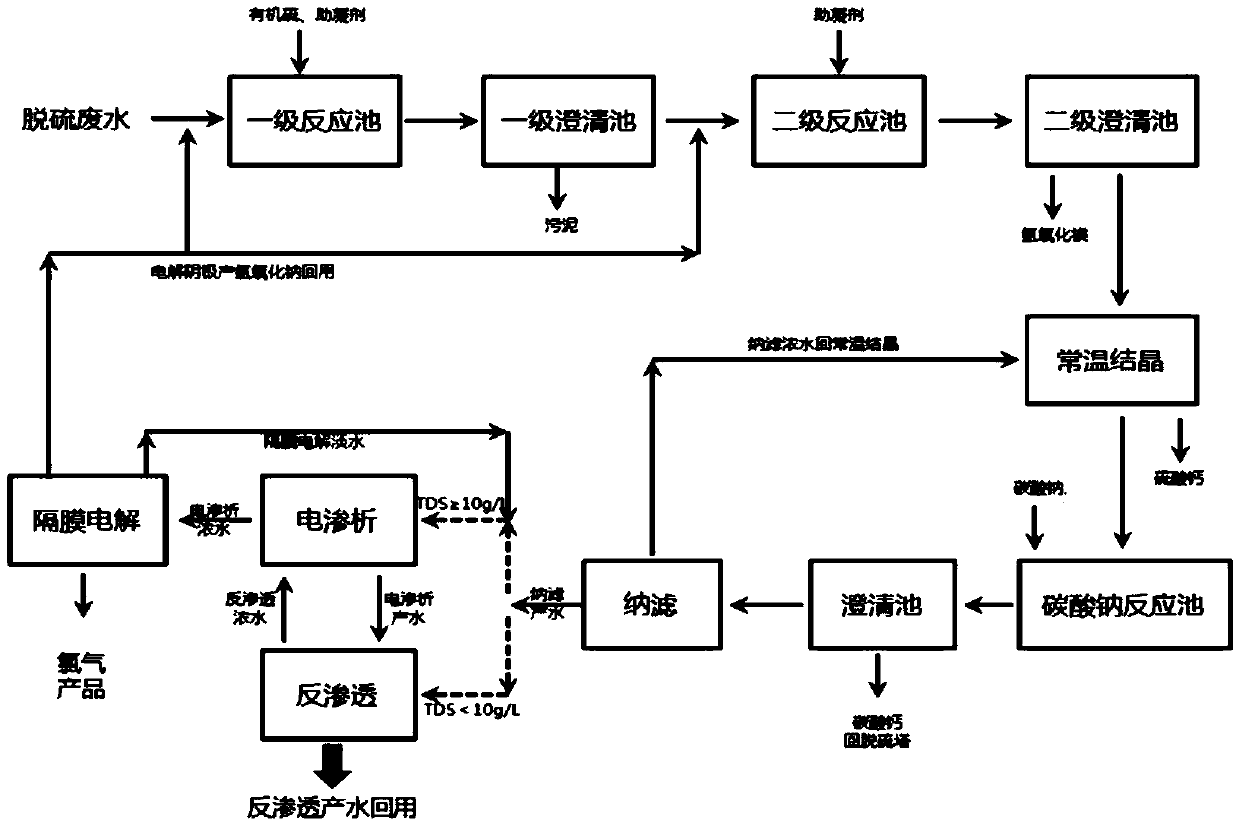

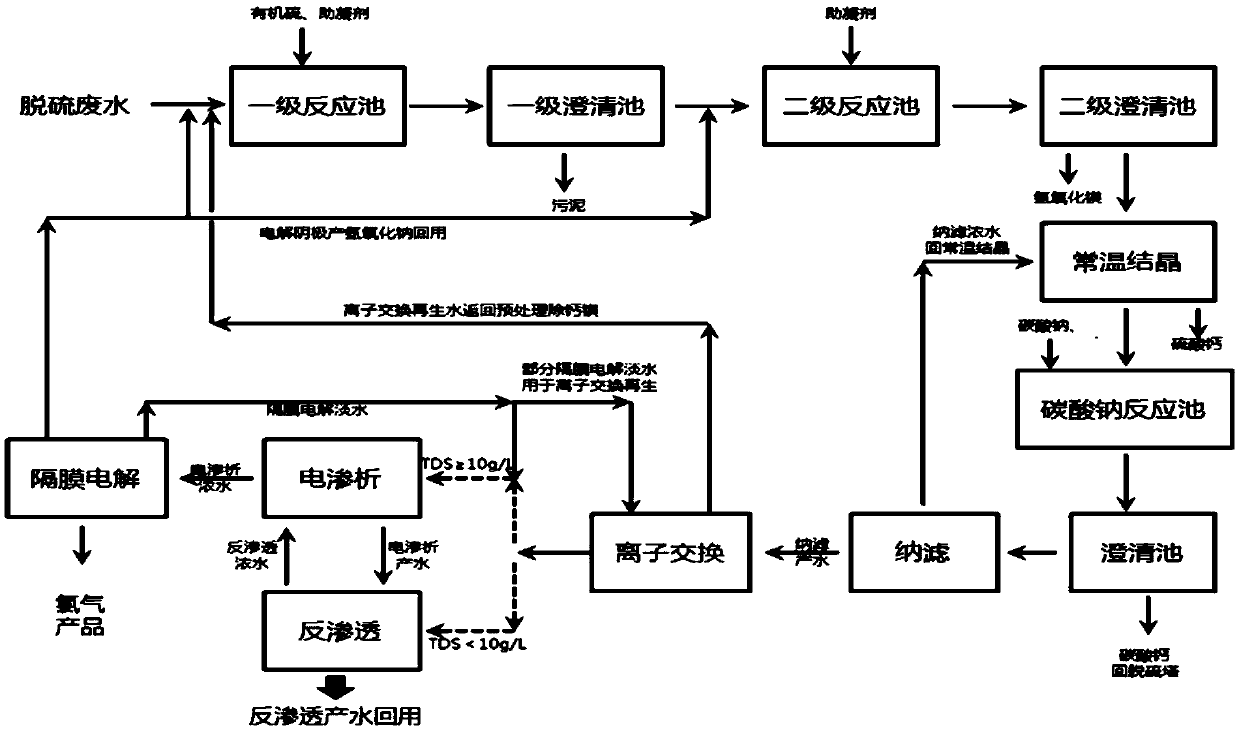

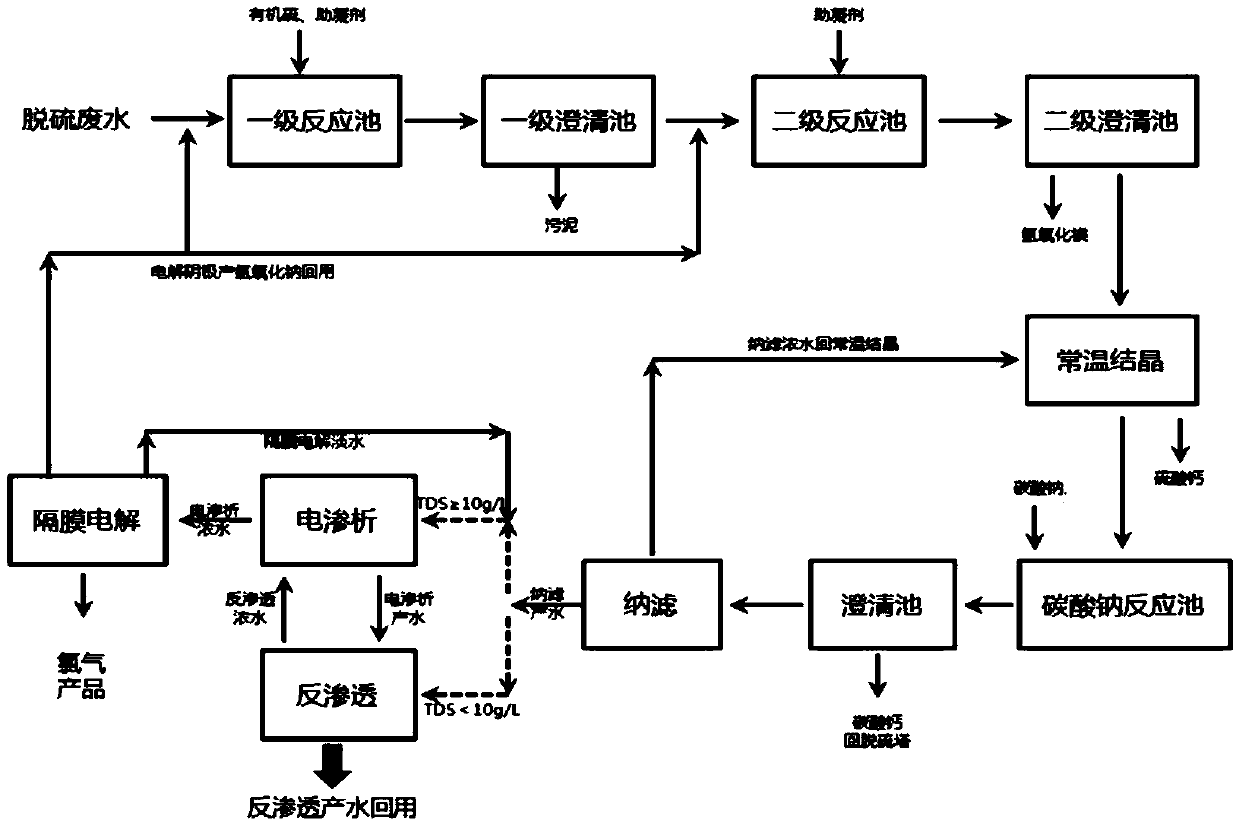

Desulfurization wastewater treatment process and desulfurization wastewater treatment system

InactiveCN111170517AReduce supersaturationReduce dosageCalcium/strontium/barium carbonatesWater treatment parameter controlReverse osmosisNanofiltration

The invention relates to the field of desulfurization wastewater treatment, and discloses a desulfurization wastewater treatment method and a desulfurization wastewater treatment treatment system. Thetreatment method comprises: (1) in the presence of sodium hydroxide, carrying out softening clarification treatment on desulfurization wastewater to obtain softened clarified effluent; (2) adding sodium sulfate into the neutral softened clarified effluent, and carrying out normal-temperature crystallization to obtain normal-temperature crystallized effluent; (3) adding sodium carbonate into the normal-temperature crystallized effluent to obtain hardness regulation effluent and calcium carbonate; (4) carrying out nanofiltration separation treatment on the hardness regulation effluent; (5) carrying out electrodialysis-reverse osmosis coupled concentration treatment on the nanofiltration produced water; and (6) carrying out diaphragm electrolysis on the membrane concentration concentrated water. The treatment method provided by the invention can fully protect the operation of the membrane system, can avoid the addition of additional alkaline agents, and realizes the effective coupling ofself-sufficiency in the system and the whole treatment process.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

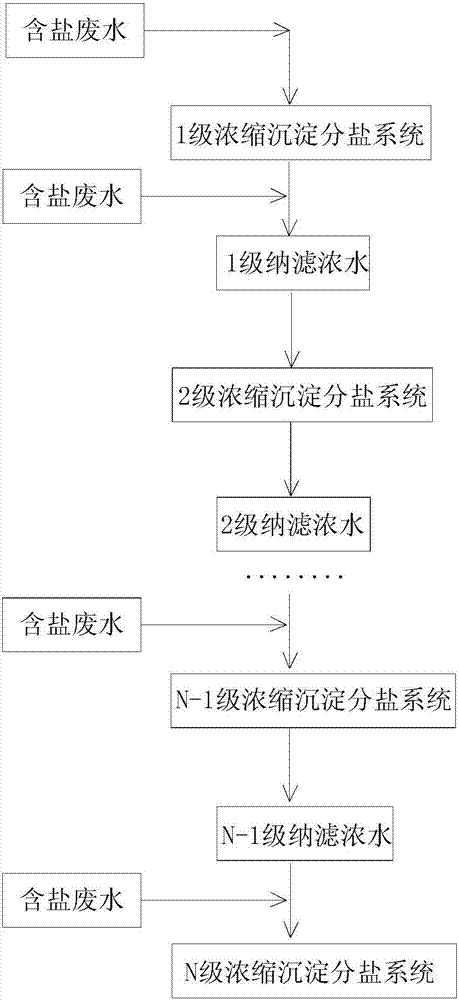

Multistage continuous precipitation and concentration type salt fractionation process method

InactiveCN107055862AIncrease concentrationSufficient precipitationWater/sewage treatment by electrochemical methodsTreatment involving filtrationHigh concentrationInorganic salts

The invention relates to a multistage continuous precipitation and concentration type salt fractionation process method. By utilizing a multistage continuous precipitation and concentration type salt fractionation process, each stage of processing unit can be continuously used, precipitable inorganic salt is removed by virtue of a chemical precipitation method, and monovalence salt and high-valence salt are fractionated by virtue of nanofiltration salt fractionation; by concentrating, the precipitation efficiency and the salt fractionation efficiency can be improved, the concentration of concentrated water can be increased, and recyclable clean water can be obtained; and by treating wastewater by virtue of a first-stage treatment unit, partial recycle water, high-purity and high-concentration monovalence salt, precipitated inorganic salt and nanofiltration concentrated water can be obtained, the nanofiltration concentrated water is mixed with raw water, and mixed water enters a second-stage treatment unit again and is subjected to precipitation, concentration and salt fractionation, so that precipitable substances can be adequately precipitated, and meanwhile, a relatively good separation effect can be achieved through nanofiltration.

Owner:SUZHOU XINER ENVIRONMENTAL TECH CO LTD

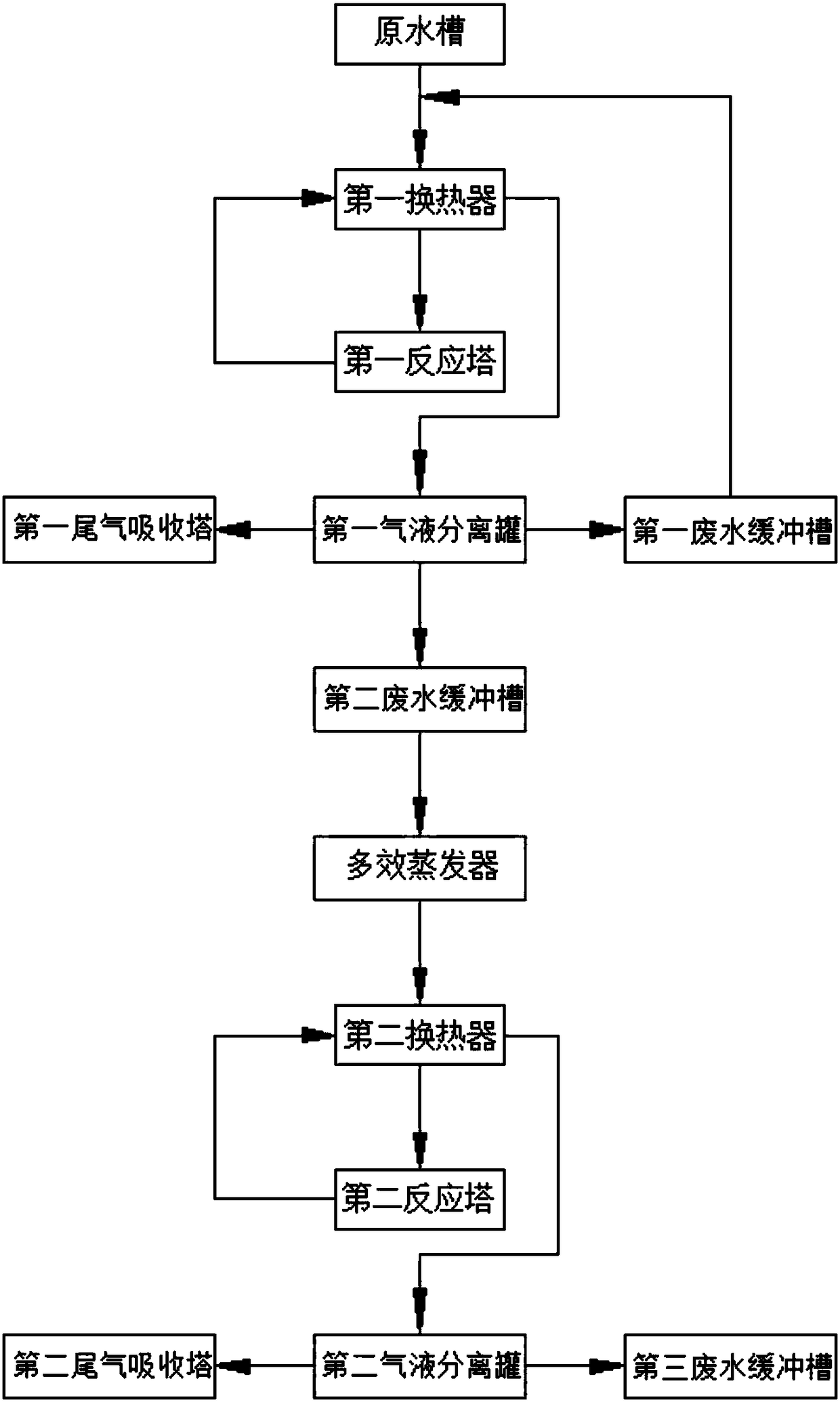

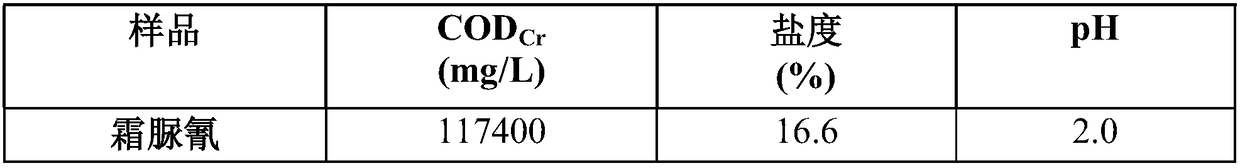

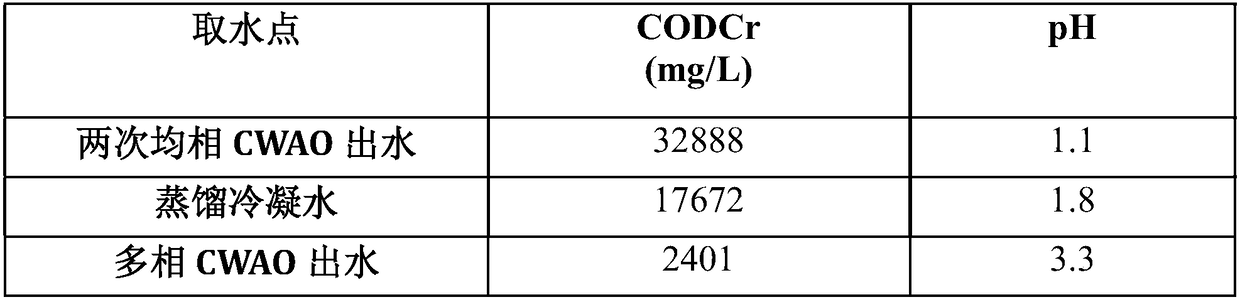

Method for catalytic wet oxidation treatment of high concentration cymoxanil wastewater

PendingCN109399846AReduce the amount of treated waterLess investmentWater contaminantsMultistage water/sewage treatmentHigh concentrationTower

The invention relates to a catalytic wet oxidation method for treating industrial organic wastewater, in particular to a method for treating high concentration cymoxanil wastewater. By adopting a process of treatment by a homogeneous reactor twice and connecting the homogenous reactor to a multiphase reaction tower, high concentration wastewater which is not diluted can be directly treated, so that one tower is multipurpose, the occupied area and the investment are reduced, and both economical benefit and environment benefit are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Spent solution treatment method of silver electrolyte

InactiveCN106048659AReduce outputIncrease production capacityPhotography auxillary processesProcess efficiency improvementElectricitySolution treatment

The invention discloses a spent solution treatment method of a silver electrolyte. A silver electrolyte spent solution, as a silver electro-deposition liquid, is fed into a whirl-flow electro-deposition system to perform primary electro-deposition; and then metal copper is added to a low-silver liquid to replace crude silver powder; a desilverized solution, as a copper electro-deposition mother liquid, is fed into the whirl-flow electro-deposition system to perform secondary electro-deposition; and finally, a part of a low-copper liquid is fed back to a sliver liquid preparing system, while the rest part of the low-copper liquid is sent to an environmental protection workshop for treatment. The spent solution treatment method of the silver electrolyte is simple in processes, convenient to carry out and low in cost, can be used for directly recycling valuable metal, such as silver, copper and the like, in a high-effective, low-cost and high-recovery-rate manner.

Owner:ZIJIN MINING GROUP

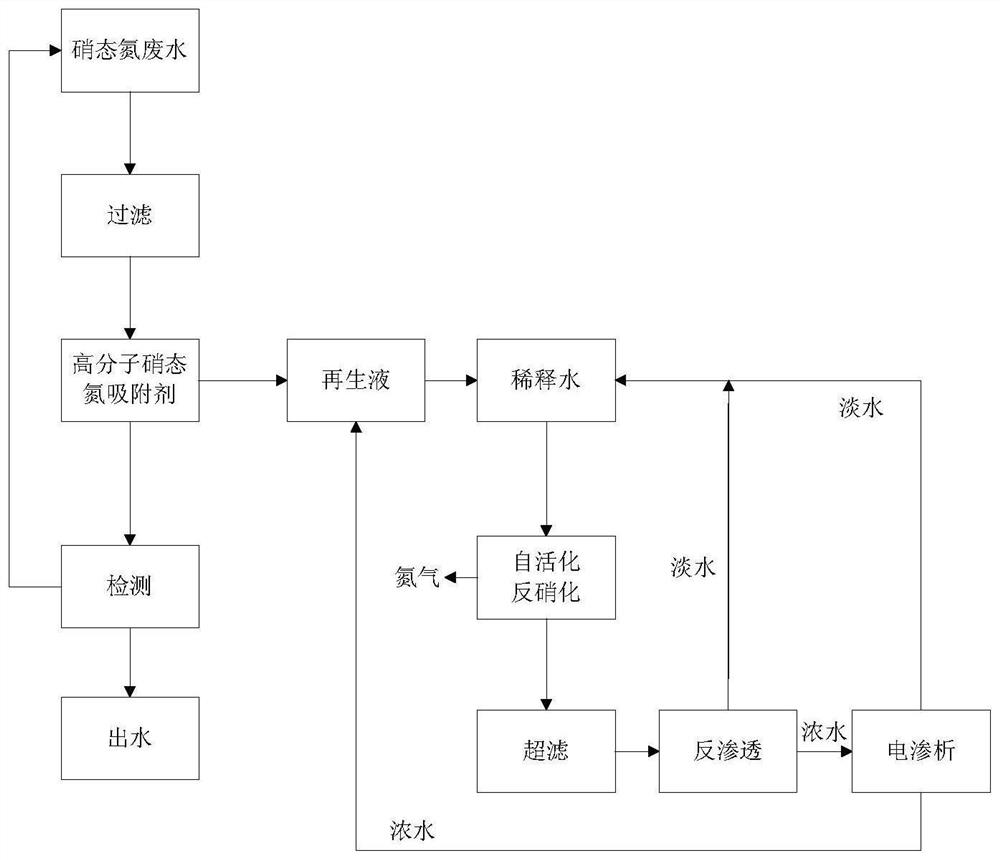

Process method and device for advanced treatment of nitrate nitrogen in water

PendingCN112266050AStrong impact resistanceIncrease frictionSpecific water treatment objectivesWater contaminantsSorbentReverse osmosis

The invention discloses a process method and device for advanced treatment of nitrate nitrogen in water, and belongs to the field of nitrate nitrogen wastewater treatment processes. Nitrate nitrogen wastewater is absorbed through a macromolecular nitrate nitrogen adsorbent to obtain nitrate-removed effluent, and the nitrate-removed effluent is discharged after the nitrate-removed effluent is detected to reach the standard; when the effluent does not reach the standard, a sodium chloride solution with the mass percentage concentration of 35% is added into the macromolecular nitrate nitrogen adsorbent for regeneration, a self-activity denitrification process is conducted after obtained regenerated waste liquid is diluted, and the effluent obtained after the self-activity denitrification process is sequentially subjected to ultrafiltration, reverse osmosis and electrodialysis concentration to serve as fresh regenerated liquid; and both the reverse osmosis fresh water and the electrodialysis fresh water are used as diluents of regenerated waste liquid. The process is high in automation degree, easy to manage, small in equipment investment and low in operation cost. According to the method, the macromolecular nitrate nitrogen adsorbent is adopted to adsorb nitrate nitrogen in the water, the regenerated waste liquid is filtered out through self-activity denitrification, and the method has the advantages that no waste liquid or waste gas is discharged, and the process cleanliness is high.

Owner:艾西姆(辽宁)环境技术有限公司

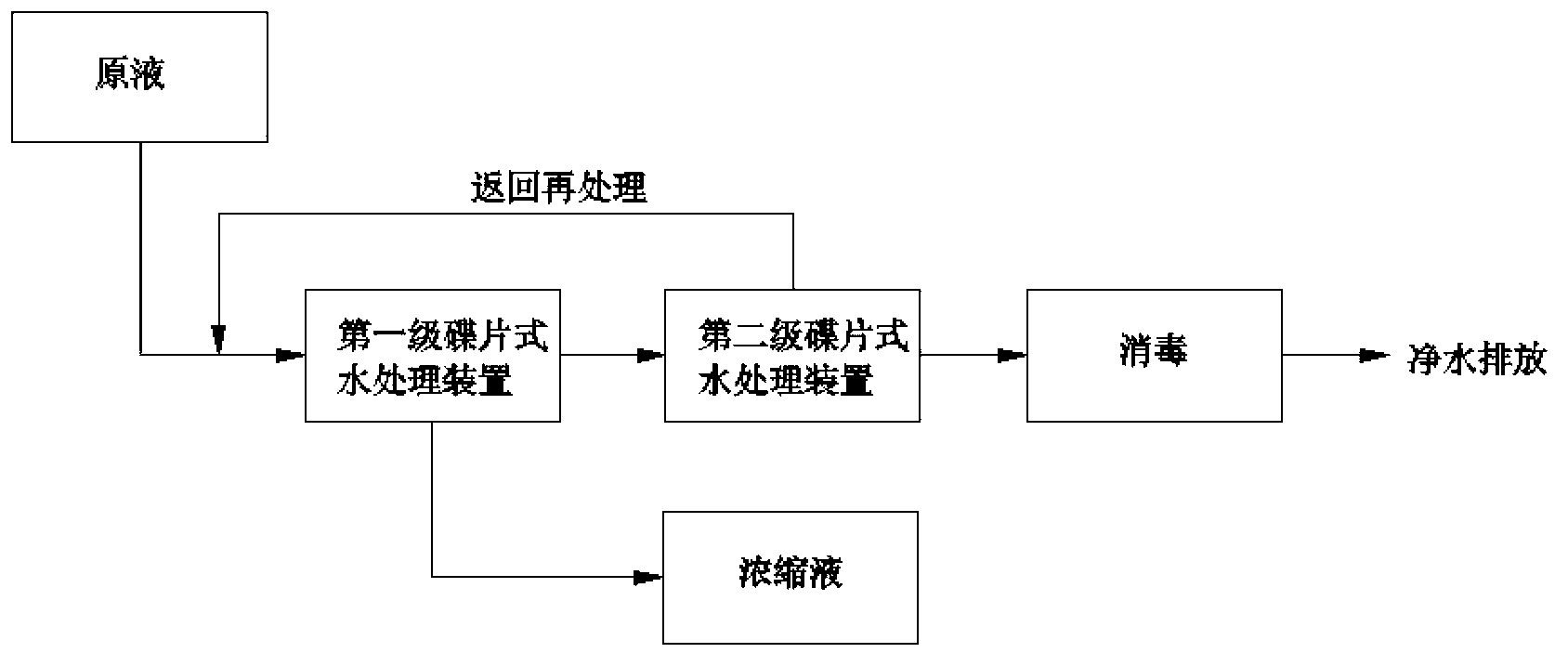

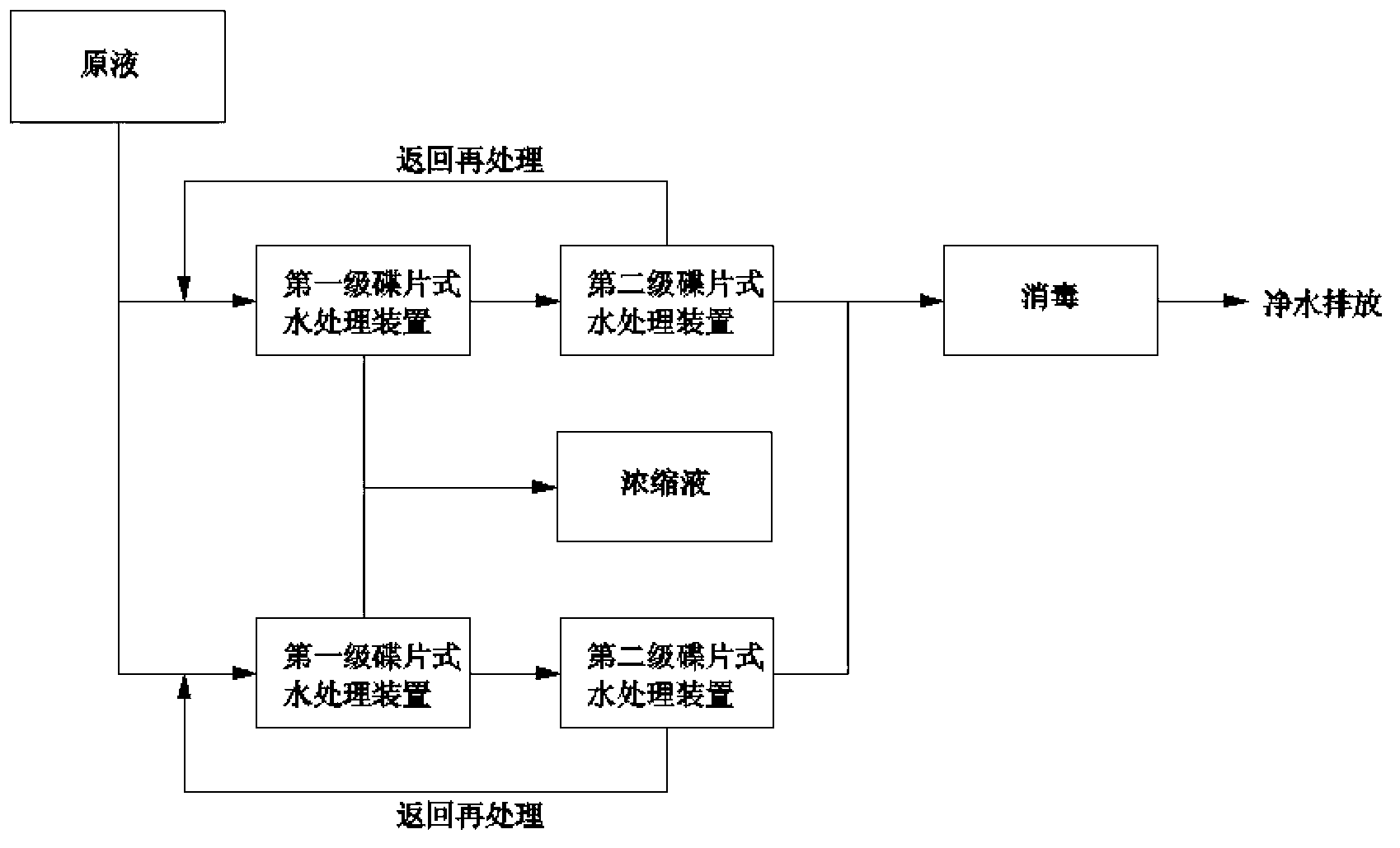

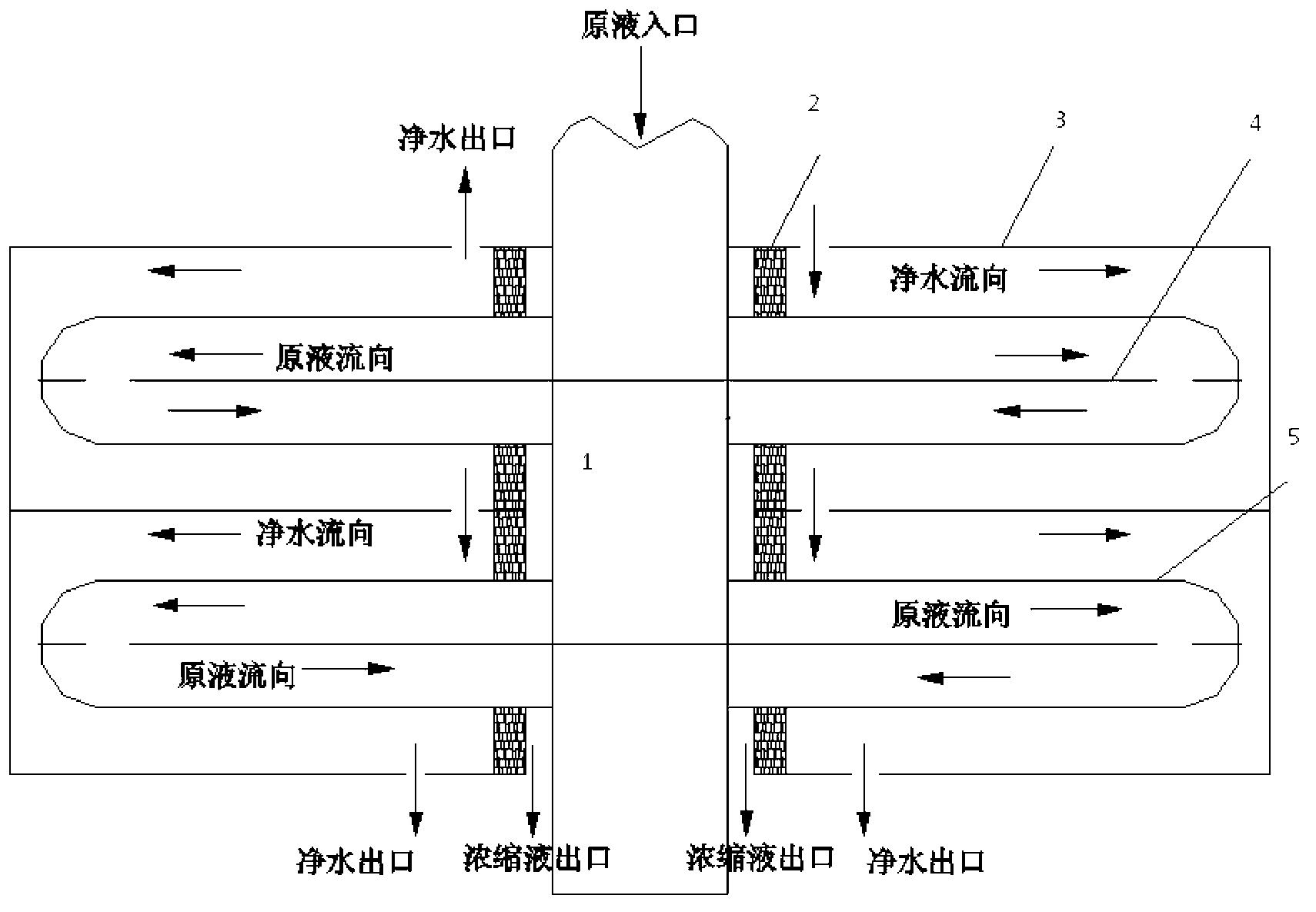

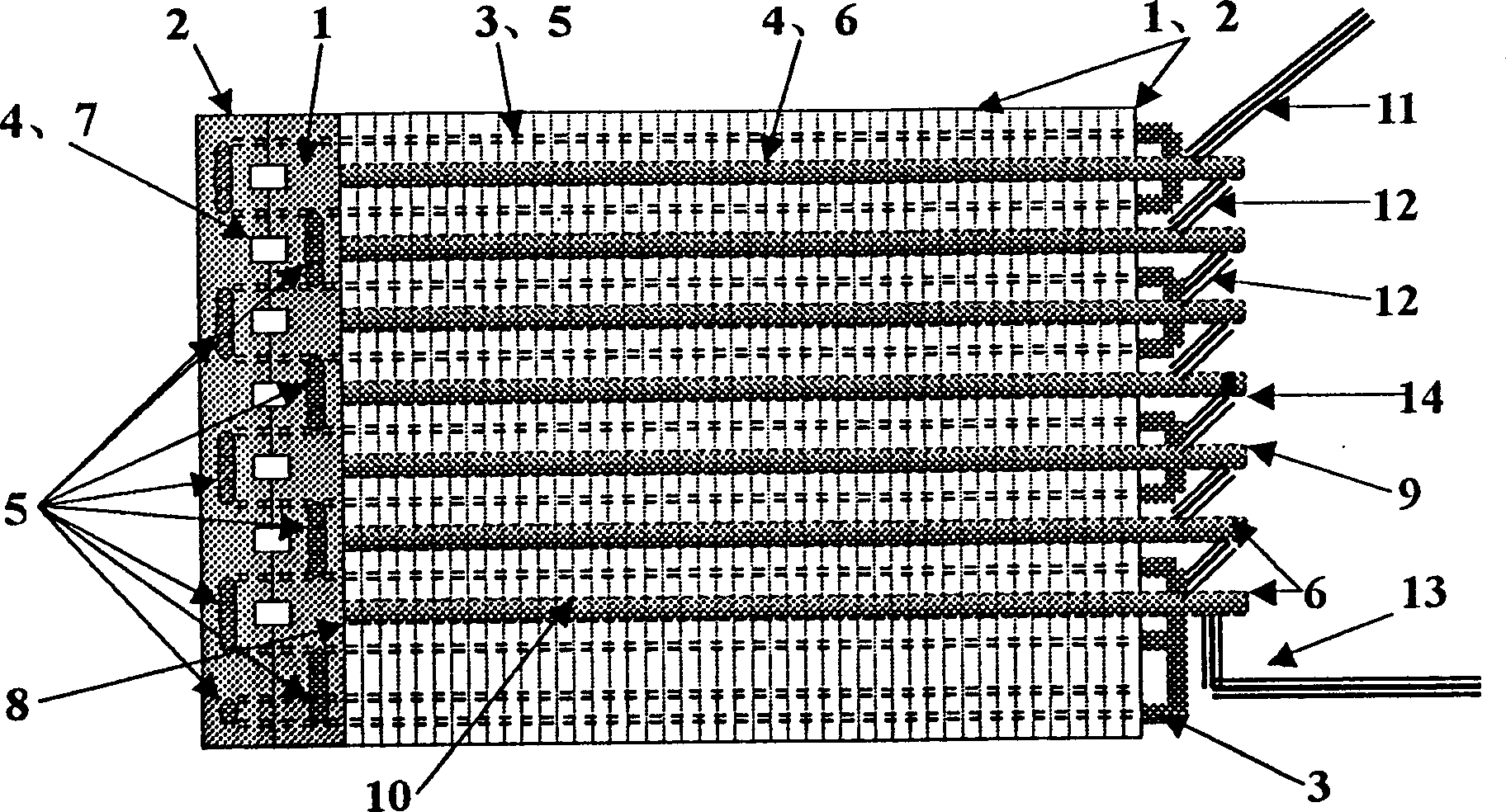

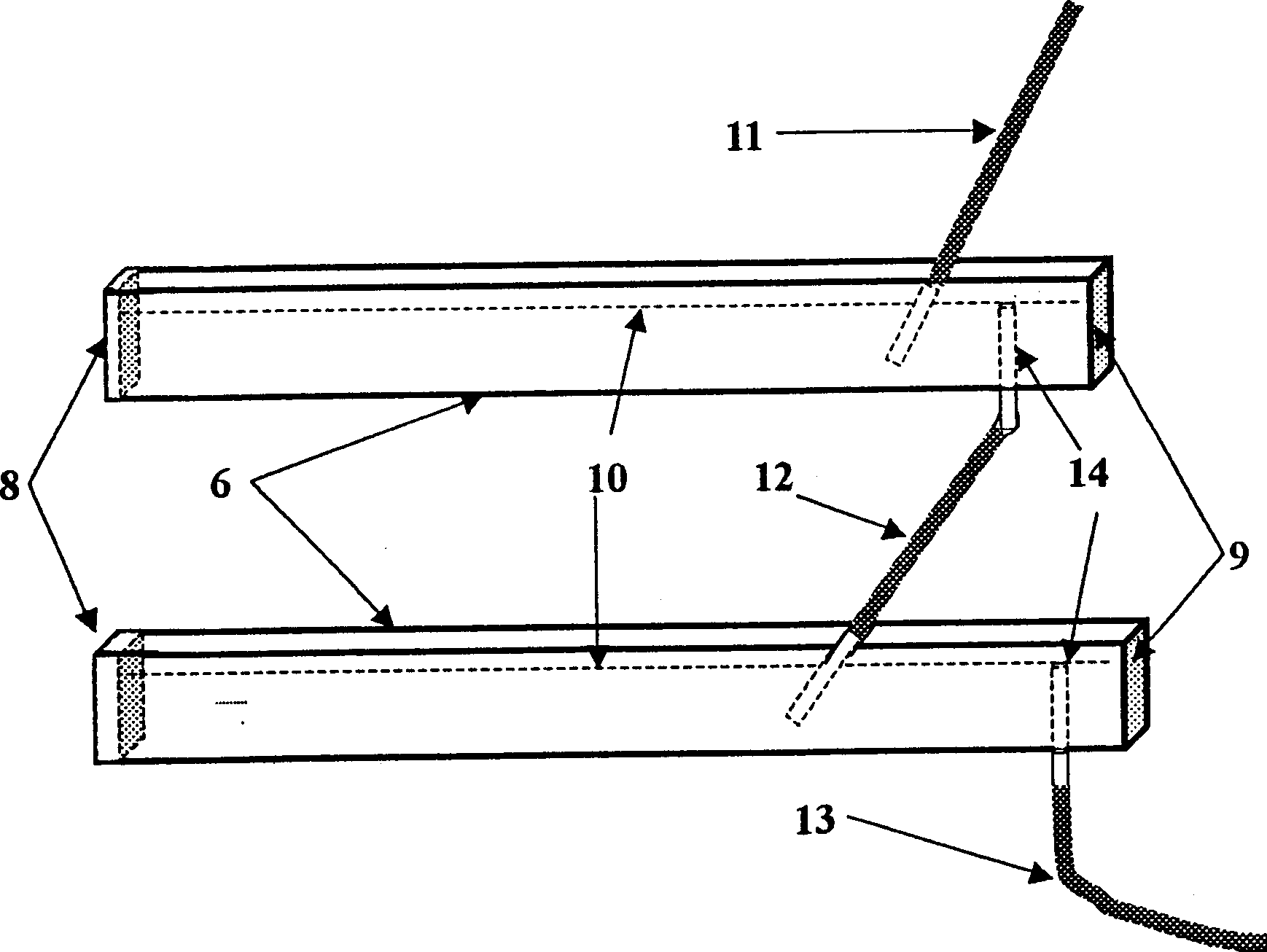

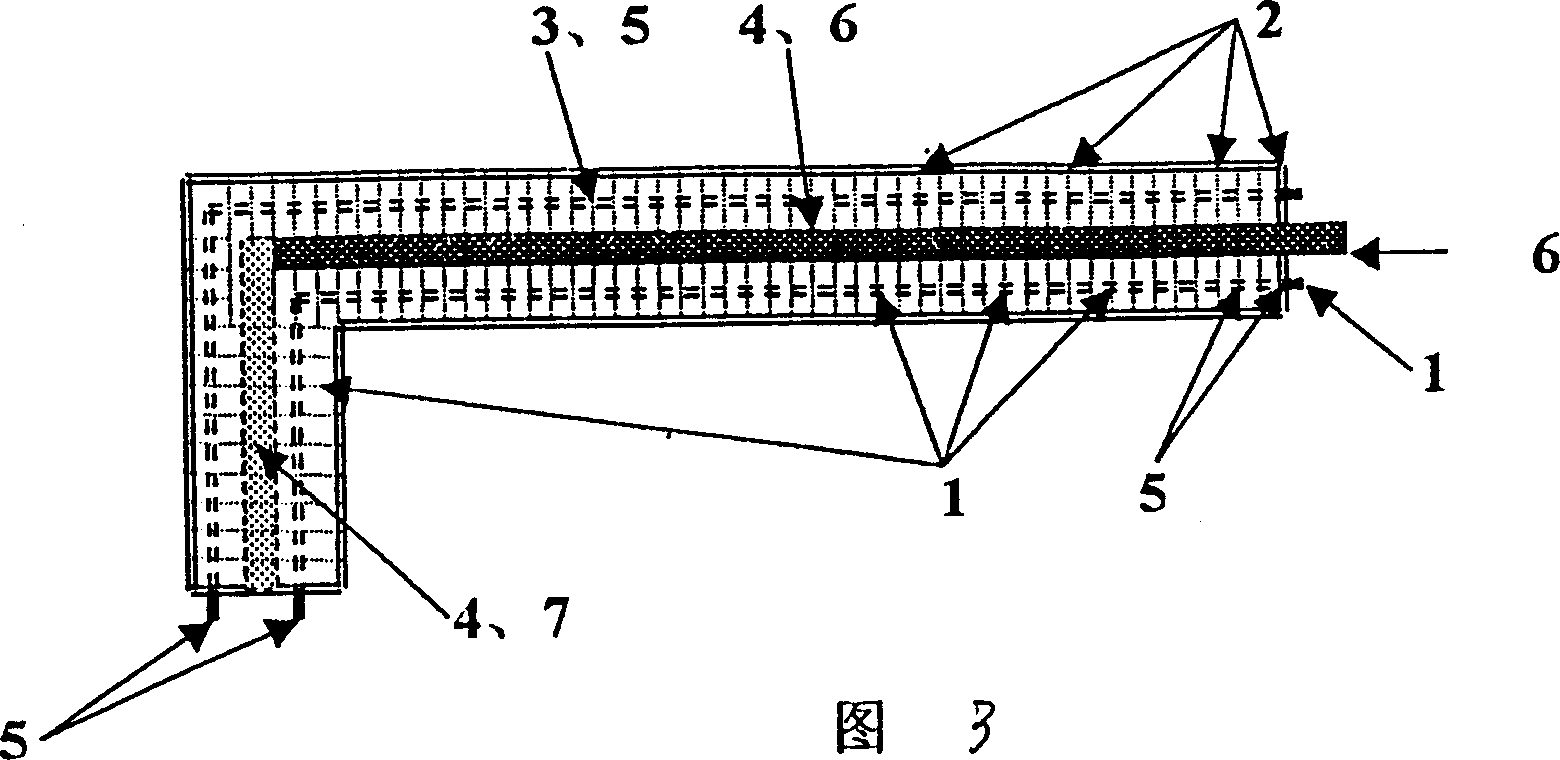

Treatment method of disc type column membrane water and device

ActiveCN103224302AImprove stabilityImprove securityMultistage water/sewage treatmentHigh concentrationDiagnostic Radiology Modality

Treatment method of disc type column membrane water, is the immediate processing of high concentration sewage to achieve the required emission standards, which selects processing options in series, parallel, primary or secondary treatment modalities according to the water quality and emission standards. The treatment method of disc type column membrane water is used in combination with other processes, as the final treatment step before discharge to ensure reliable standards of high concentrations of sewage treatment. The treatment device of disc type column membrane water can be connected in series or parallel alternately with flexible operation mode. Device can be designed to be connected in series or parallel operation mode according to the requirements, to achieve less volume of water and higher standards of water quality in series operation mode, and larger volume of water and lower emission standards in parallel operation mode, meeting the requirements of different water volume and water quality.

Owner:南京国能环保有限公司

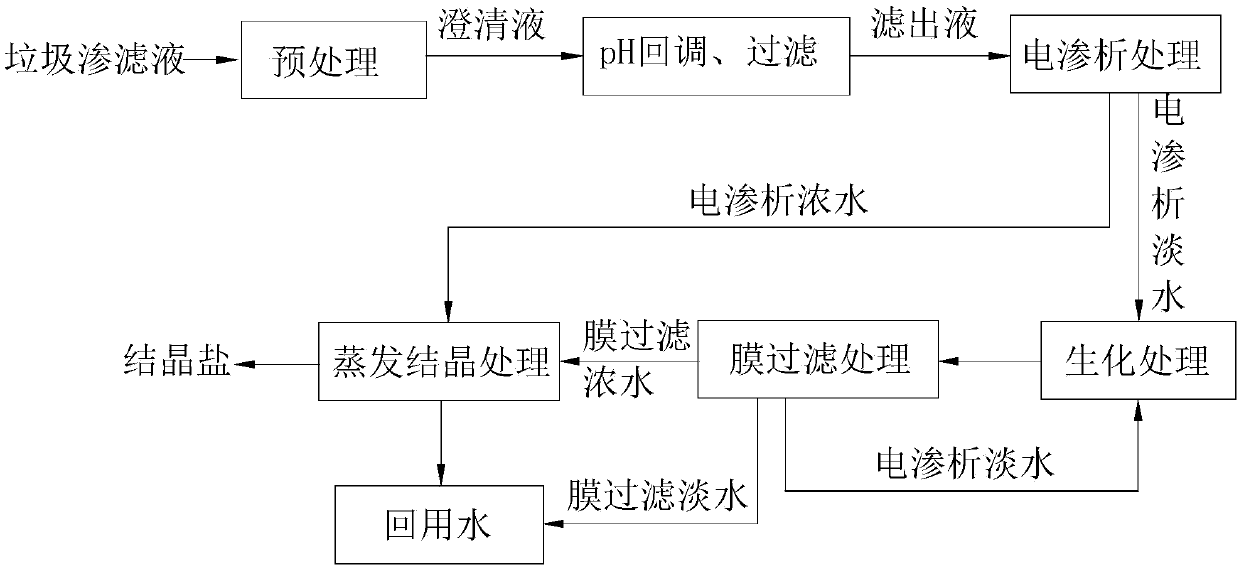

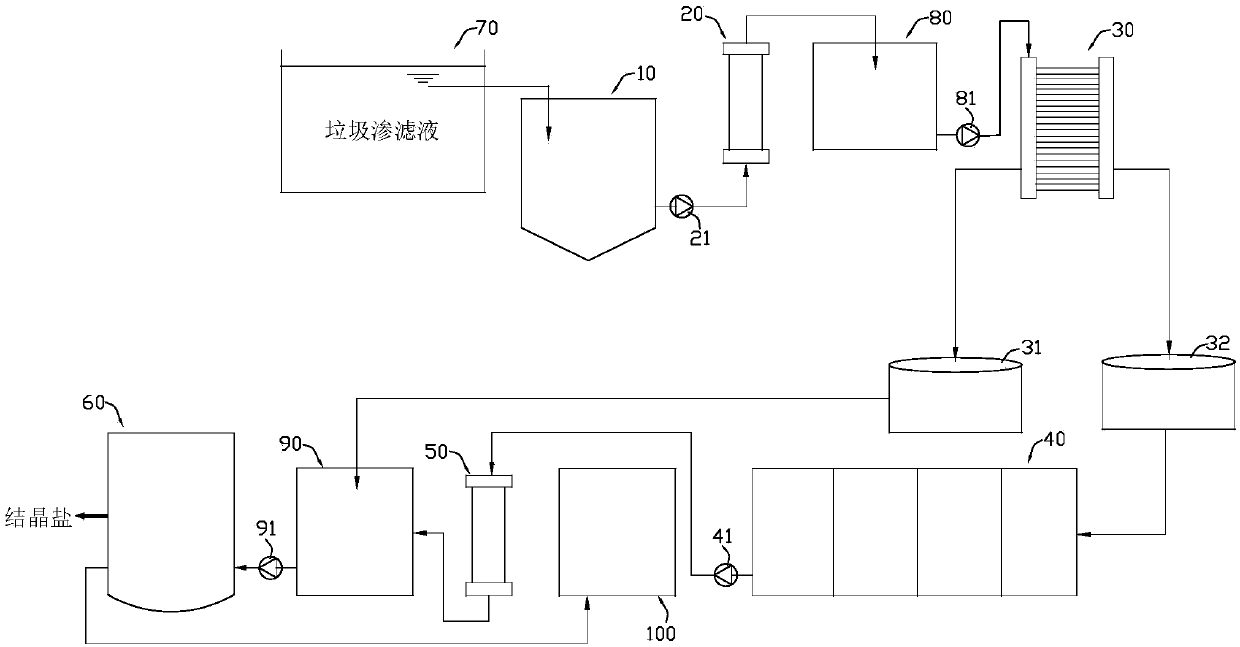

Landfill leachate treatment method and system

PendingCN107840537AReduce loadImprove stabilityWater treatment parameter controlWater contaminantsWater useSulfate radicals

The invention discloses a landfill leachate treatment method and system. The landfill leachate treatment method comprises the following steps: S1, pretreating landfill leachate to remove suspended solids, heavy metals, sulfate ions, calcium ions and magnesium ions so as to obtain clarified liquor; S2, performing pH regulation and filtration on the clarified liquor, and removing the residual suspended solids so as to obtain filtrate with SDI less than 3; S3, performing electrodialytic treatment on the filtrate so as to obtain electrodialytic concentrated water and electrodialytic fresh water; S4, performing biochemical and membrane filtration treatment on the electrodialytic fresh water so as to obtain membrane filtration concentrated water and membrane filtration produced water; and S5, performing evaporative crystallization treatment on the electrodialytic concentrated water and membrane filtration concentrated water, thereby obtaining crystalline salt and recycled water. According tothe method disclosed by the invention, the landfill leachate is subjected to treatments such as concentration and solid-liquid separation by virtue of a process combining pretreatment, filtration, electrodialysis, biochemical treatment and evaporative crystallization, so as to obtain the recyclable crystalline salt and the recycled water, zero wastewater emission and resource reutilization are realized, and the landfill leachate treatment method is environmental-friendly and has wide application prospects.

Owner:深圳能源资源综合开发有限公司

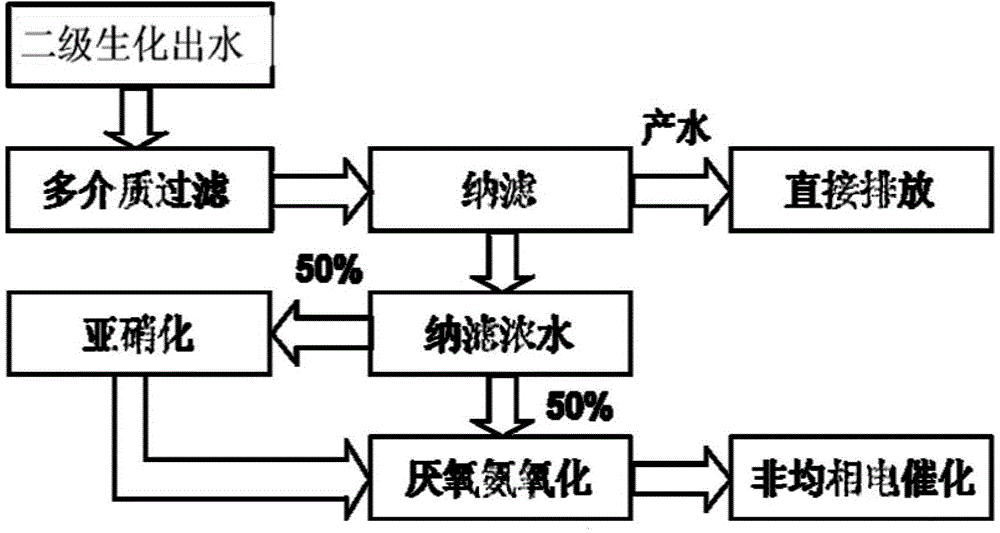

Acrylon wastewater deep treatment method based on dry method

InactiveCN104961298AEfficient removalImprove water qualityMultistage water/sewage treatmentNature of treatment waterSuspended organic matterFiltration

The invention belongs to the technical field of industrial wastewater treatment and particularly relates to an acrylon wastewater deep treatment method based on a dry method. The acrylon wastewater deep treatment method based on the dry method comprises the steps that acrylon wastewater to be treated is pretreated through multi-medium filtration, so that suspension organic matter is removed; then the acrylon wastewater enters a nanofiltration system, recalcitrant organic matter and ammonia nitrogen in the wastewater are separated and concentrated so that produced water can be directly discharged according to the standard; denitrification treatment continues to be conducted on concentrated water generated by the nanofiltration system through a nitrosification-anaerobic ammonia oxidation system, then water subjected to denitrification treatment enters a heterogeneous-phase electro-catalysis unit to be subjected to an oxidation reaction, so that recalcitrant organic matter in the concentrated water is removed, and nanofiltrated concentrated water is discharged according to the standard. According to the acrylon wastewater deep treatment method based on the dry method, pollutants in the acrylon wastewater can be effectively degraded and removed, and technical feasibility is provided for acrylon wastewater deep treatment based on the dry method.

Owner:SHENYANG RES INST OF CHEM IND +1

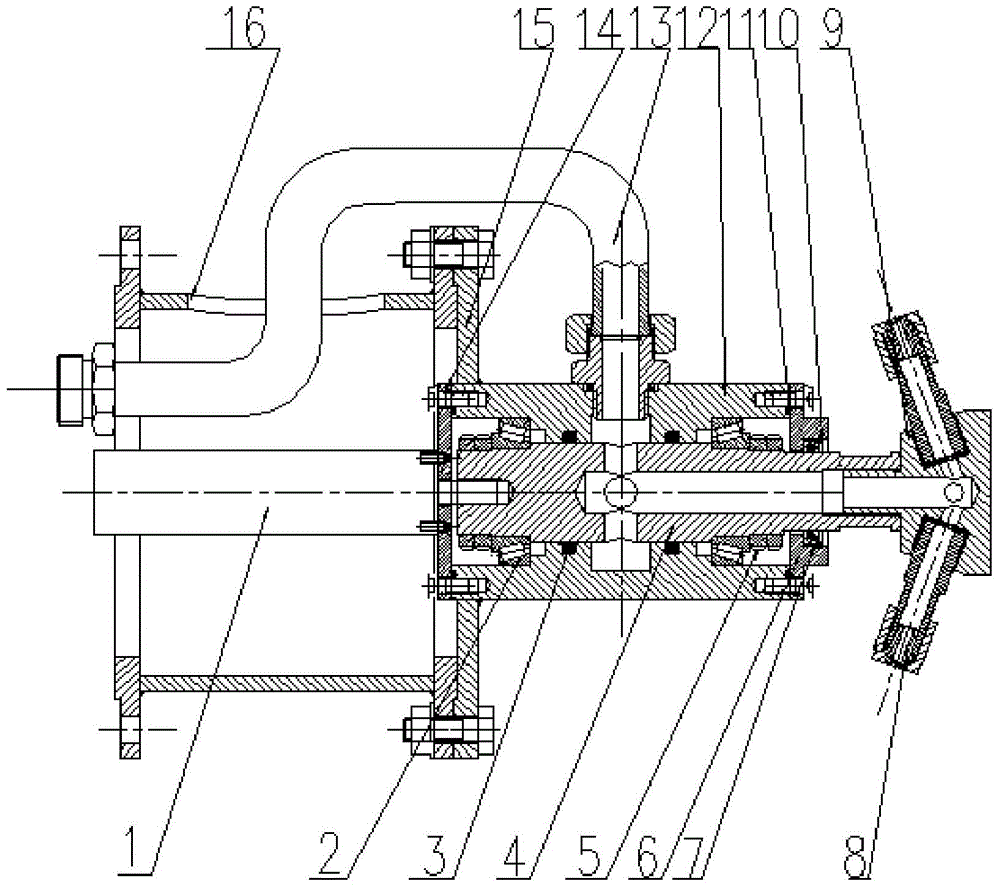

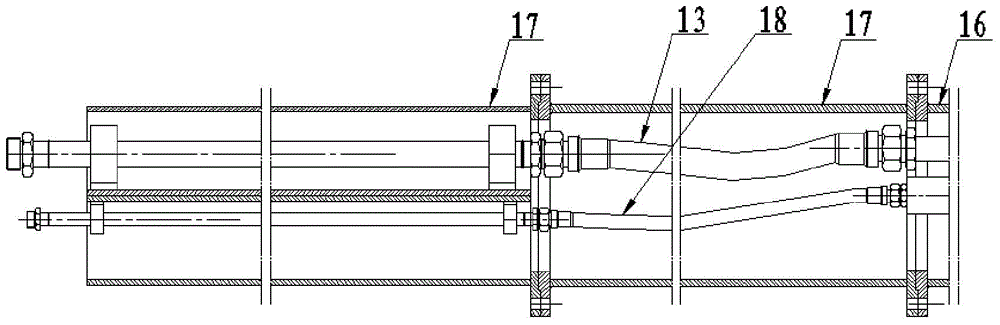

After-washing device of expanding machine

InactiveCN105032856AIncrease profitGood washing effectHollow article cleaningSpray nozzleWater delivery

The invention relates to the technical field of steel pipe expanding equipment, in particular to an after-washing device of an expanding machine. The after-washing device comprises a box body, a rotating shaft and a sprayer unit which are coaxially arranged. The box body is installed at the end of an after-washing cantilever of the expanding machine. One end of the rotating shaft is inserted in the box body and connected with a driving unit, and the other end of the rotating shaft is connected with the sprayer unit. The rotating shaft can rotate freely in the axial direction of the rotating shaft. The driving unit is used for driving the rotating shaft and the sprayer unit to rotate synchronously. The sprayer unit comprises a fixed piece and a plurality of nozzles which are evenly distributed on the periphery of the fixed piece. Water delivery channels which are communicated with the nozzles are formed in the rotating shaft and the fixed piece. A water injection cavity is formed in the box body, the water injection cavity is communicated with the water delivery channels, and the water injection cavity is communicated with a high-pressure water inlet pipe. By means of the after-washing device of the expanding machine, the problems that by the adoption of a fixed sprayer, residual oil stains exist on the inner wall of a washed steel pipe and the water utilization rate is low in the prior art are solved.

Owner:JIANGSU YULONG STEEL PIPE

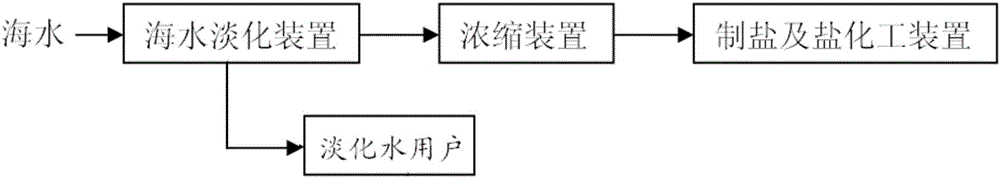

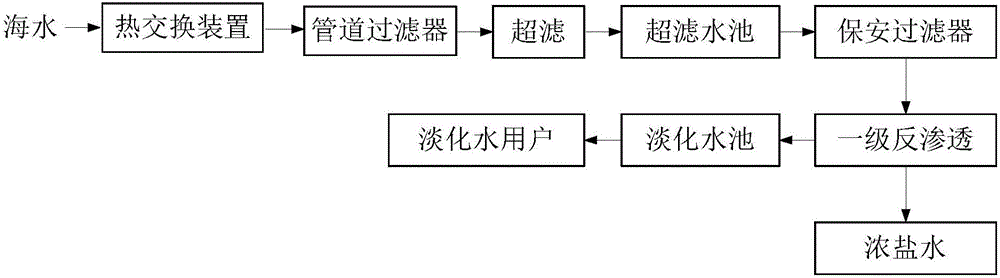

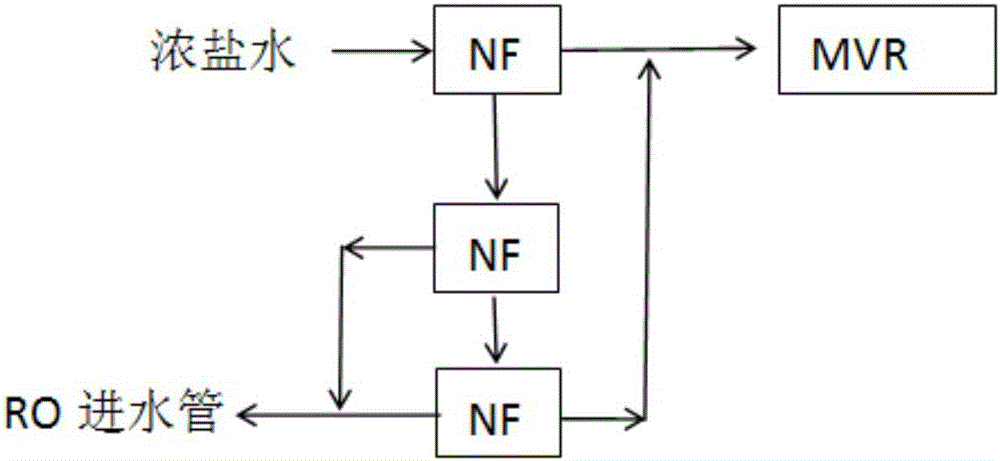

Integrated-membrane seawater desalination and strong brine comprehensive utilization system

InactiveCN106800351AIncrease profitLow running costSeawater treatmentMultistage water/sewage treatmentFiltrationSalt water

The invention discloses an integrated-membrane seawater desalination and strong brine comprehensive utilization system comprising a seawater desalination device and a concentration device which are connected through a pipeline; the seawater desalination device comprises a reverse osmosis pretreatment device, a primary reverse osmosis device and a desalination water tank which are connected through pipelines; the concentration device comprises a primary nanofiltration device, a secondary nanofiltration device and an MVR crystallizer; a water outlet of strong brine of the primary reverse osmosis device is connected with a water inlet of the primary nanofiltration device; a water outlet of concentrated water of the primary nanofiltration device is connected with a water inlet of the MVR crystallizer; a water outlet of filtered water of the primary nanofiltration device is connected with a water inlet of the secondary nanofiltration device; a water outlet of filtered water of the secondary nanofiltration device is connected with a water inlet of the primary reverse osmosis device; a water outlet of concentrated water of the secondary nanofiltration device is connected with the water inlet of the MVR crystallizer. The system can realize zero discharge and extraction of chemical products, synthetically applies energy consumption during filtration, and reduces the comprehensive operation cost.

Owner:恩那社工程有限公司

High-concentration pickle wastewater treatment process

InactiveCN110590074ASolve conflictsReduce the amount of treated waterWater treatment parameter controlSludge treatmentHigh concentrationElectrolysis

The invention discloses a high-concentration pickle wastewater treatment process. The process comprises the following steps: (1) adjusting the pH value of the pretreated pickle wastewater to be alkali, then obtaining salt solution and COD fresh water through electrodialysis separation, and carrying out biochemical treatment on the COD fresh water; (2) carrying out MVR evaporation crystallization on that salt solution, respectively collecting the mother liquor, the condensate and the crystalline salt; then electrolyzing the mother liquor; (3) subjecting the electrolyzed mother liquor in the step (2) to MVR evaporation crystallization again. According to the invention, COD and sodium chloride salt are separated by electrodialysis on the premise of not increasing water quantity; biochemical treatment of high concentration COD in fresh water is performed; MVR evaporation treatment on sodium chloride salt in concentrated water is performed; the problem of treatment contradiction between high COD and high salt content is solved.

Owner:四川恒泰环境技术有限责任公司

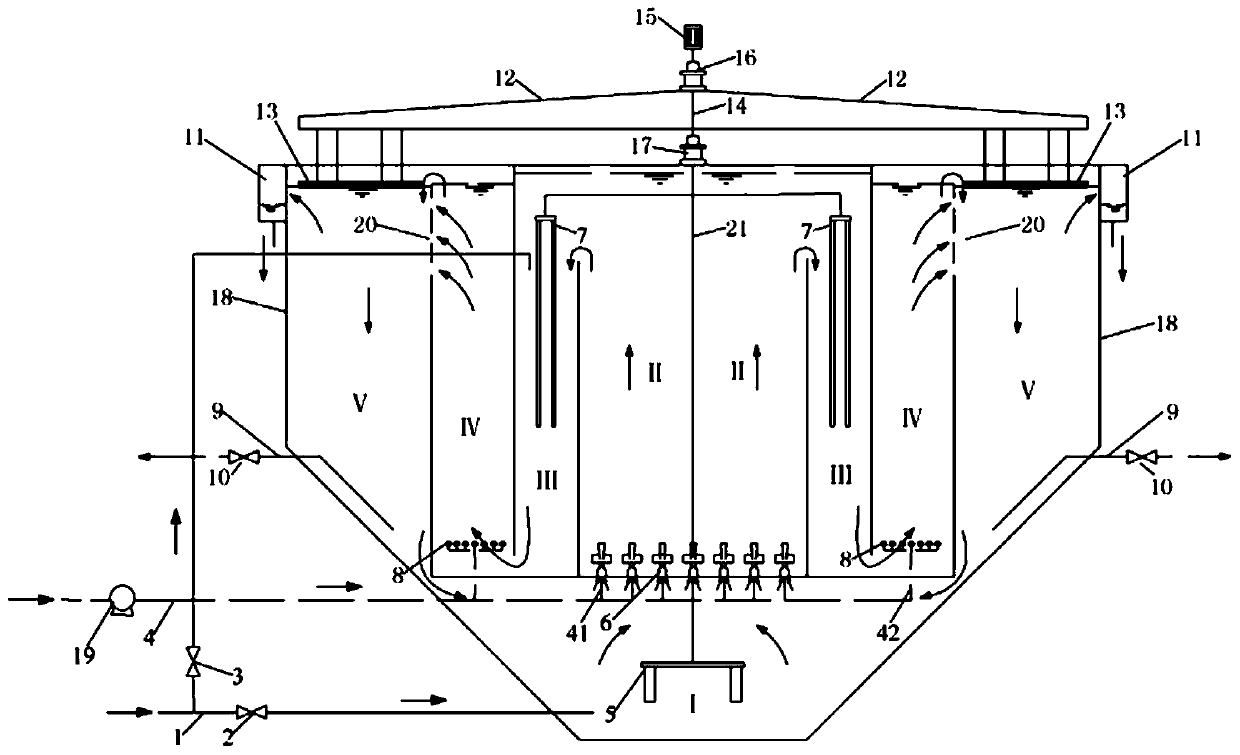

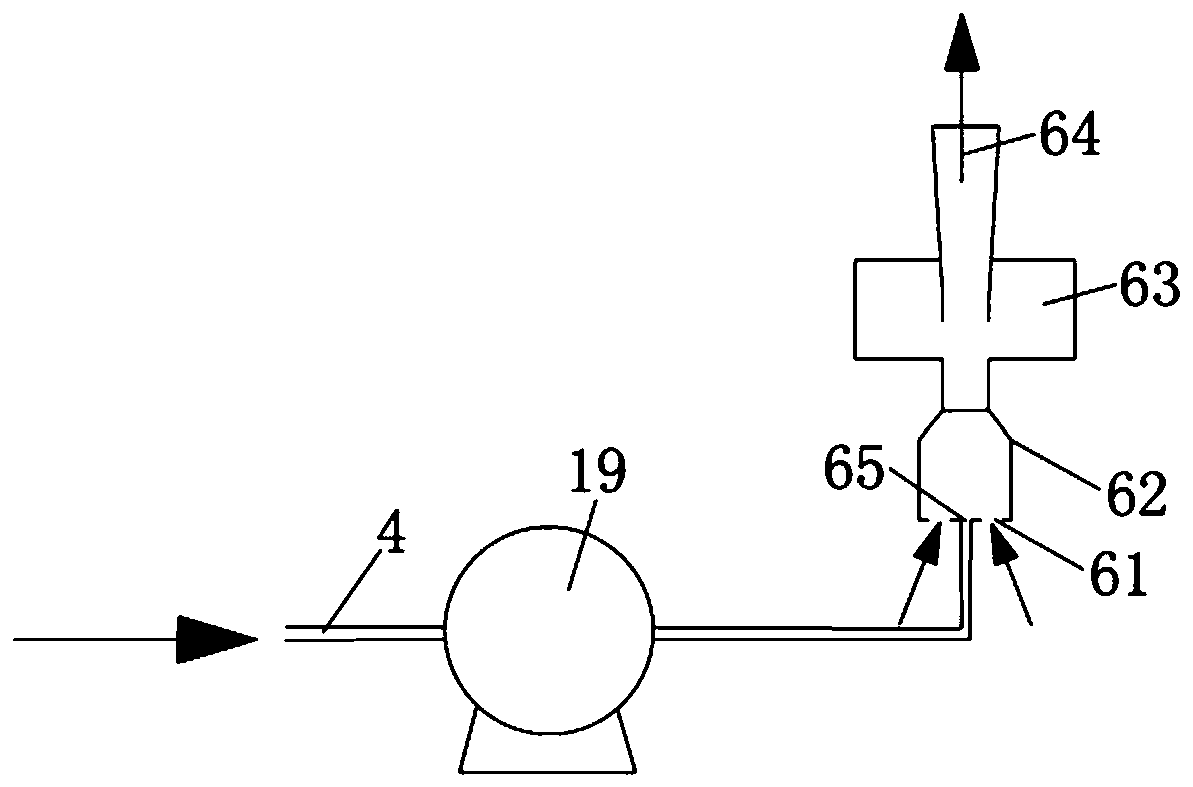

Anoxic oxic (AO)<2> and sediment integrated multistage circulating reactor

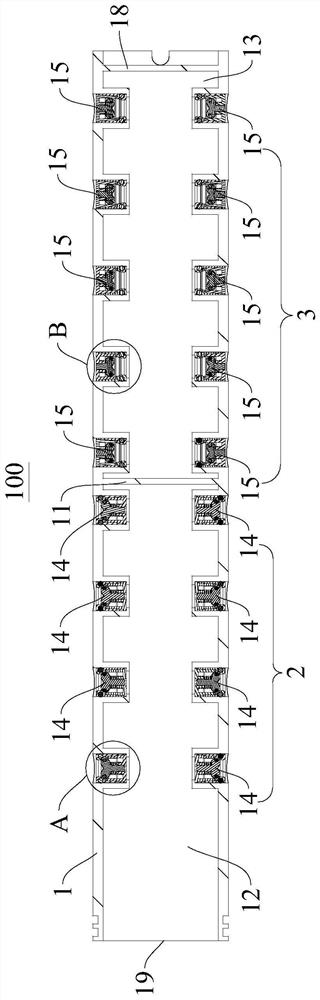

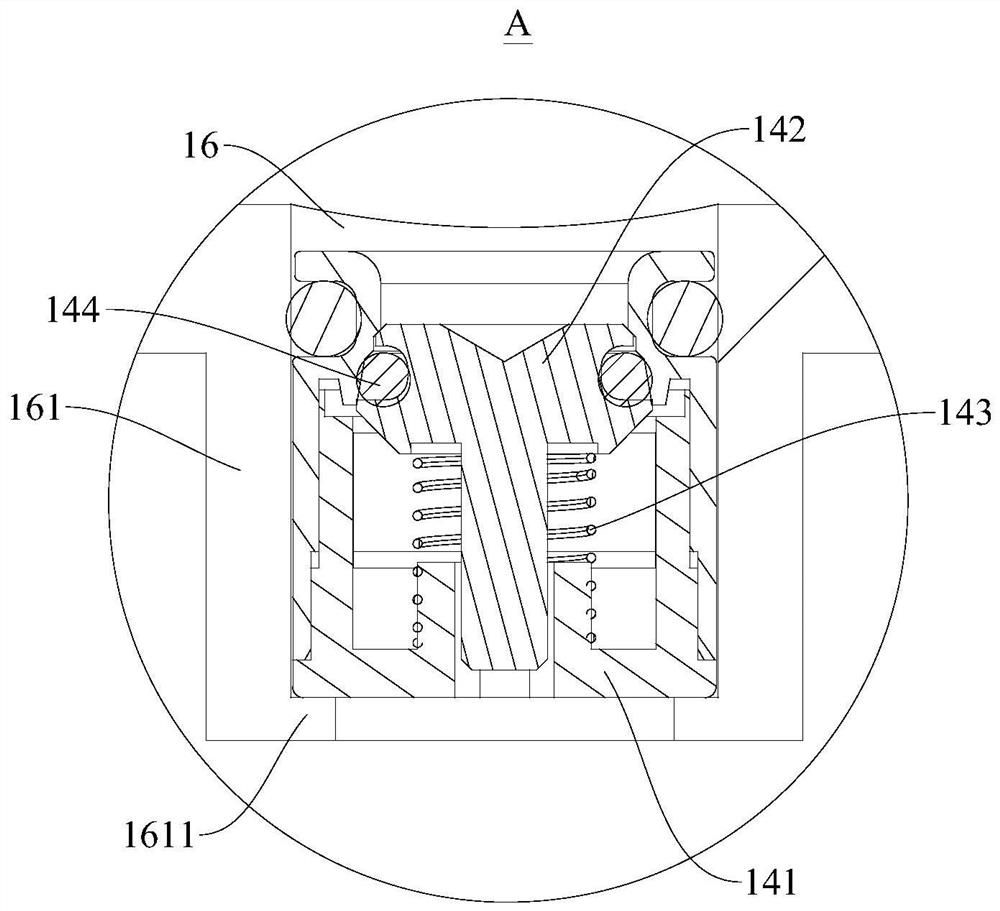

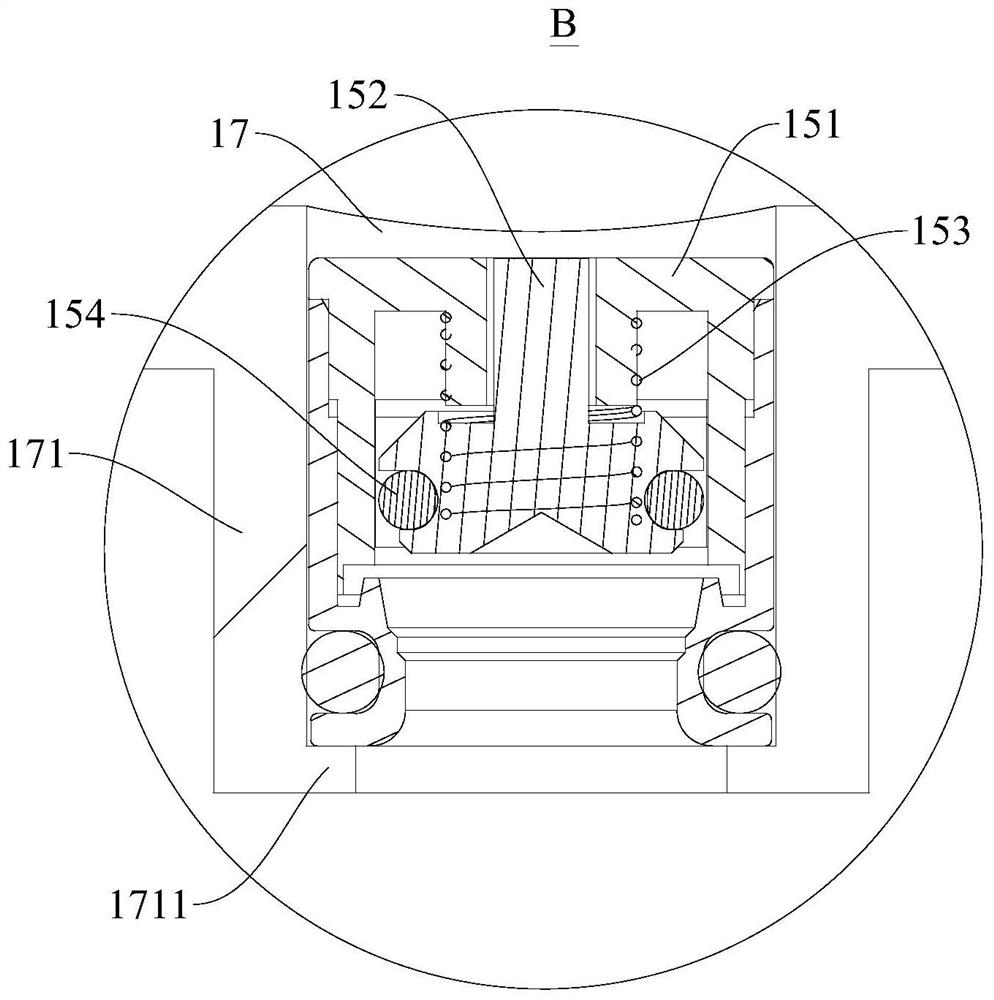

PendingCN110526397AReduce refluxSolve the series of multi-level AOSpecific water treatment objectivesWater contaminantsSludgeSmall footprint

The invention relates to the technical field of sewage treatment equipment, in particular to an anoxic oxic (AO)<2> and sediment integrated multistage circulating reactor. The (AO)<2> and sediment integrated multistage circulating reactor comprises a shell, a sewage inlet pipe and a lifting device; an anoxic area, a first oxic area, a facultative area, a second oxic area and a sediment area whichare connected cyclically are isolated in the shell through partition plates, the anoxic area is located on the lower middle part of the shell, the first oxic area, the facultative area, the second oxic area and the sediment area are sequentially arranged on the upper part of the shell from inside to outside, sewage sequentially flows in the first oxic area, the facultative area, the second oxic area, the sediment area and the anoxic area in an unpowered mode through the water level difference, clear water in the sediment area overflows from the outer side of the upper part of the sediment area, and parts of sludge in the sediment area is discharged from a sludge discharging pipe; the sewage inlet pipe provides the sewage to the anoxic area and the facultative area according to the proportion; and the lifting device is used for lifting the sewage in the anoxic area to the first oxic area. The (AO)<2> and sediment integrated multistage circulating reactor is small in floor space and small in investment.

Owner:ZHENGZHOU UNIV

Method for removing atrazine from drinking water

InactiveCN101445289ASimple and efficient operationReduce dosageWater/sewage treatment by sorptionActivated carbonChemistry

The invention discloses a method for removing atrazine from drinking water. The method is characterized in that tap water or source water is primarily filtered to remove the suspended substance in water; under the condition at the temperature of 1 to 40 DEG C, the tap water or the source water with insignificant amounts of the atrazin flows through an adsorption column filled with activated carbon fiber or modified activated carbon fiber at the flow rate of 30 to 400BV / h; the atrazin is absorbed on the activated carbon fiber or the modified activated carbon fiber and is removed from the water. The method has the advantages that the removal rate of the atrazin is close to 100% after the drinking water with insignificant amounts of the atrazin is treated in the method, and the concentration of the atrazin is far less than the concentration limit value of the atrazin in Sanitary Standard for Drinking Water (GB 5749-2006).

Owner:NANJING UNIV OF INFORMATION SCI & TECH

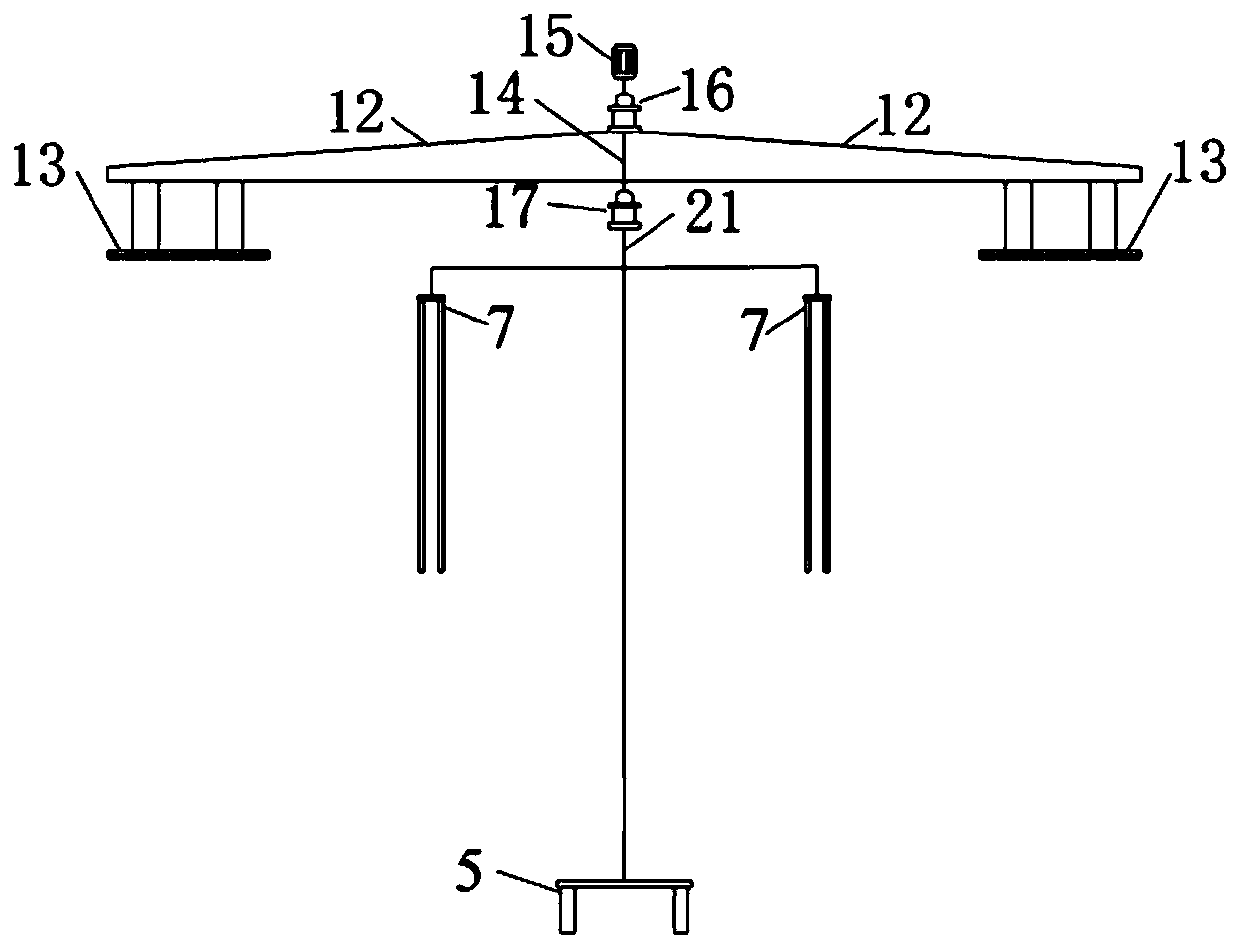

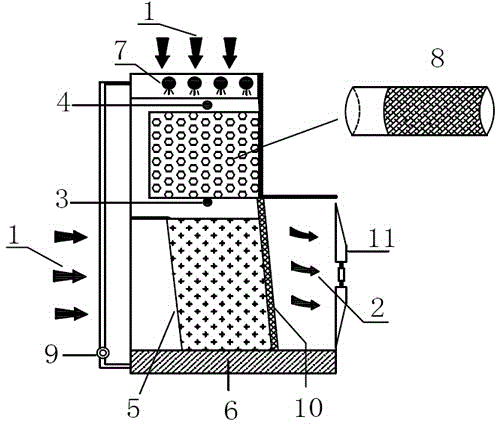

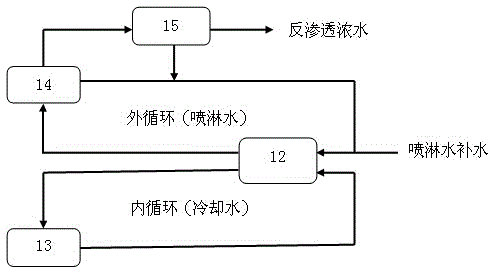

Closed cooling tower and closed circulating water system

InactiveCN105716442AGuaranteed uptimeImprove cooling effectTrickle coolersCooling towerReverse osmosis

The invention discloses a closed cooling tower and a closed circulating water system. The closed cooling tower comprises air inlet, a spray thrower, a heat exchange coil, a PVC heat exchange layer, a water collecting tank and an axial flow fan. The top and one side of a tower body are provided with the air inlets. The other side of the tower body is provided with an air outlet. The axial flow fan is installed at the air outlet. The heat exchange coil is arranged on the upper portion of the tower body. The spray thrower is arranged over the heat exchange coil. The PVC heat exchange layer is arranged under the heat exchange coil. The water collecting tank is arranged below the heat exchange layer and at the bottom of the tower body. The closed circulating water system adopting the closed cooling tower comprises an inner circulating part and an outer circulating part. The inner circulating part comprises the closed cooling tower and a heat exchanger. The outer circulating part comprises the closed cooling tower, the filter and a reverse osmosis device. According to the closed cooling tower and the closed circulating water system, the specific closed cooling tower and closed circulating water system are adopted, so that efficient operation of the circulating water system is ensured, the cooling ability is improved significantly, and water consumption and energy consumption are reduced more obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-cost concentration reduction and resourceful treatment process for high-salinity wastewater

PendingCN111675406AIncrease profitReduce the amount of treated waterWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFlue gasWastewater

The invention discloses a low-cost concentration reduction and resourceful treatment process for high-salinity wastewater, and solves the problems that in the prior art, the current environmental protection requirement cannot be met, the investment and operation cost is high, and resourceful utilization of a treated product cannot be realized. The process adopts a low-temperature flue gas / hot airheating concentration reduction system, a softening turbidity removal pretreatment system, a nanofiltration salt separation system and a bipolar membrane electrodialysis resourceful treatment system.Through the coupling synergistic effect of multiple systems, a new process is provided for treatment of high-salinity wastewater, the design is reasonable, the national environmental protection requirement is met, the operation cost is low, and the treatment product can be recycled.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

A method for the integrated removal of nitrate nitrogen in water by ion exchange and denitrification

ActiveCN105036495BAchieve removalAvoid it happening againWater contaminantsMultistage water/sewage treatmentIndustrial waste waterIon exchange

The invention discloses a method for removing nitrate nitrogen in water through ion exchange and denitrification integration to solve the problem that nitrate nitrogen pollution exists in water or waste water at present. The method includes the steps that enrichment of the nitrate nitrogen in the water or waste water is achieved through high-selectivity nitrate ion exchange resin; the ion exchange resin enriched with the nitrate nitrogen is regenerated and recycled under certain conditions directly through the action of biological denitrification; finally, the nitrate nitrogen in the water or the waste water can be effectively removed through the continuous technology. The method can be used for removing nitrate nitrogen in underground water, surface water, municipal sewage, industrial waste water and various kinds of water, and is particularly applicable to natural water body, sewage bio-chemical effluents and water bodies with few carbon sources capable of being used by organisms.

Owner:NANJING UNIV +1

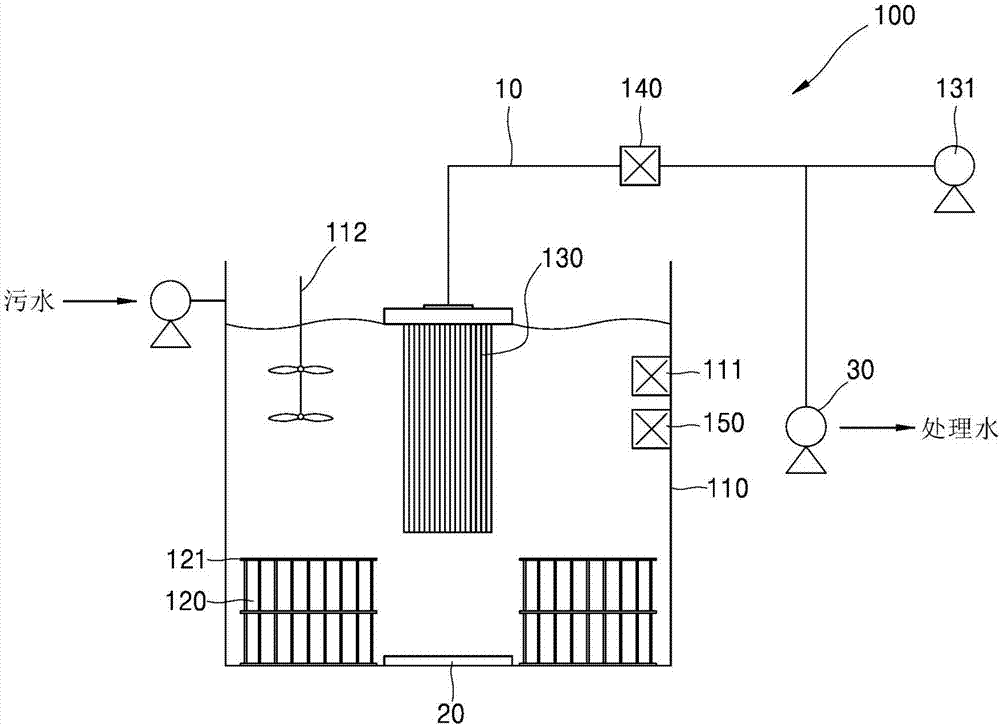

Advanced wastewater treatment apparatus using SBR system

InactiveCN107973400AImprove processing efficiencyOmit structureWater treatment parameter controlSemi-permeable membranesMembrane bioreactorOxygen

The invention relates to an advanced wastewater treatment device using the sequenching batch process including the wastewater inflow - microbial reaction - precipitate - evacuation step gets accomplished of the series of procedure. The advanced wastewater treatment device using the sequenching batch process comprises an SBR, ta fixed carrier, and a membrane bioreactor (MBR). In the SBR is the outside, it is provided with wastewater and the aerobic reaction, the aerobic reaction, and the anaerobic reaction are performed through the control unit in which the unattended operation is possible. Thefixed carrier is installed within SBR and multiple air gaps are formed and the microorganism is adhered to the air gap and exterior. The membrane bioreactor (MBR) is installed in the upper portion within SBR and the processing water is ejected to the outside after wastewater is solid from liquid separated to sludge and processing water.

Owner:国立韩国交通大学校产学协力团 +1

Method and apparatus for reducing cyanogen content of coking wastewater

InactiveCN106938873ALow running costLess investmentFatty/oily/floating substances removal devicesWater contaminantsWater volumeCoke oven

The invention relates to a method and an apparatus for reducing the cyanogen content of coking wastewater. The apparatus comprises a regenerating tower, a circulating ammonia pump, a raw material ammonia water pipeline, an alkali tank, a 42% alkali pump and a 2.5-5% alkali pump; the regenerating tower is connected with a desulphurization lean solution pump, the outlet of the desulphurization lean solution pump is connected with the circulating ammonia water pump, and the circulating ammonia water pump is connected with a coke oven; one end of the raw material ammonia water pipeline is connected with the raw material ammonia water pump, the other end of the raw material ammonia water pipeline is connected with the alkali washing section of a desulfurization tower, and the raw material ammonia water pipeline is connected with the 42% alkali pump; and the bottom of the alkali washing section of the desulfurization tower is connected with the alkali tank, and the alkali tank is respectively connected with an ammonia distiller and the alkali washing section of the desulfurization tower through the 2.5-5% alkali pump. Raw material ammonia water substitutes distilled ammonia wastewater and is mixed with a concentrated alkali, and the obtained mixture is sent to the alkali washing section of the desulfurization tower in order to remove hydrogen sulfide and hydrogen cyanide. The stability of the ammonia water volume of the alkali washing section is guaranteed; and the ammonia content of the raw material ammonia water is high, so the raw material ammonia water has a better desulphurization effect than the distilled ammonia wastewater.

Owner:ANGANG STEEL CO LTD

Air conditioner with water evaporator in condenser

InactiveCN1396417AImprove cooling effectPlay the role of auxiliary water coolingCondensate preventionWater sourceEngineering

An air conditioner with water evaporator in its condenser has a condenser and a water collecting box for evaporator. It features that the heat-radiating fins of the condenser have the rectangular or U (or V)-shaped holes for passing the strip evaporator through them. The evaporator has also water inlet tube. Its advantage is high refrigerating effect.

Owner:HAIER GRP CORP +1

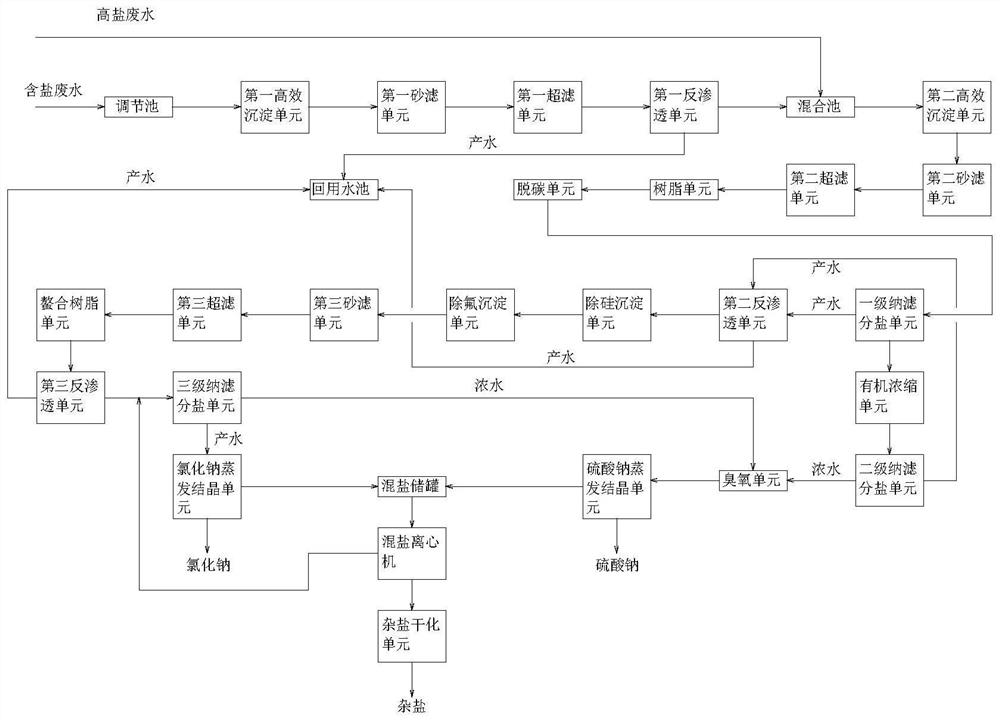

Coking wastewater advanced treatment system and treatment method thereof

PendingCN113582425ARelieve stressImplement hierarchical processingWater/sewage treatment by centrifugal separationWater contaminantsProcess engineeringPre treatment

The invention discloses a coking wastewater advanced treatment system and a treatment method thereof. The system comprises a first high-salinity wastewater conveying pipe, a first pretreatment system, a second high-salinity wastewater conveying pipe, a mixing pool, a second pretreatment system, a three-stage salt separation system and an evaporative crystallization system, the method comprises the following steps: (1) primary pretreatment; (2) secondary pretreatment; (3) third-stage salt separation; and (4) evaporative crystallization. According to the invention, stage treatment of high-concentration coking wastewater and low-concentration coking wastewater is realized, the water treatment pressure of a subsequent system is reduced, and safe and stable operation of the subsequent system can be ensured; the evaporation water quantity is greatly reduced, the energy consumption of evaporation and crystallization is effectively reduced, and the investment and operation cost of an evaporation and crystallization system is greatly reduced; the wastewater is subjected to salt separation by adopting a three-stage salt separation method, so that the yield of carnallite is greatly reduced, high-quality sodium sulfate crystal salt and sodium chloride crystal salt can be obtained, and the resource utilization rate is greatly improved.

Owner:内蒙古晶泰环境科技有限责任公司

Purifier for circulating water in heat exchange system

ActiveCN106315931AImprove processing precisionReduce trafficMultistage water/sewage treatmentFlocculationElectricity

Owner:SHANGHAI SHUANG JIN FLUID EQUIP CO LTD

Filter assembly and water purifying equipment with same

ActiveCN113307404ALow costReduce the amount of treated waterGeneral water supply conservationWater/sewage treatment by ion-exchangeTreatments waterFilter material

The invention discloses a filter assembly and water purification equipment with the filter assembly, the filter assembly comprises a central pipe and a reverse osmosis film, a first partition plate divides the interior of the central pipe into a liquid outlet cavity and a treatment cavity, the treatment cavity is internally provided with a filter material for reducing the TDS value, and the central pipe is provided with a first on-off device and a second on-off device. The first on-off device is configured to be in an open state when the pressure acting on the side, away from the center of the central pipe, of the first on-off device is larger than the closing pressure of the first on-off device, so that the exterior of the central pipe communicates with the liquid outlet cavity; the second on-off device is configured to be in a closed state to cut off communication between the outside of the central pipe and the processing cavity when the pressure acting on the side, away from the center of the central pipe, of the second on-off device is larger than the opening pressure of the second on-off device, so that the outside of the central pipe is prevented from being communicated with the treatment cavity; According to the filtering assembly, the situation that the TDS value of the first cup of water is too high when the water purifier is started can be effectively avoided. In addition, automatic switching between a treatment water path and a pure water path can be achieved.

Owner:SHUNDE APOLLO AIR CLEANER

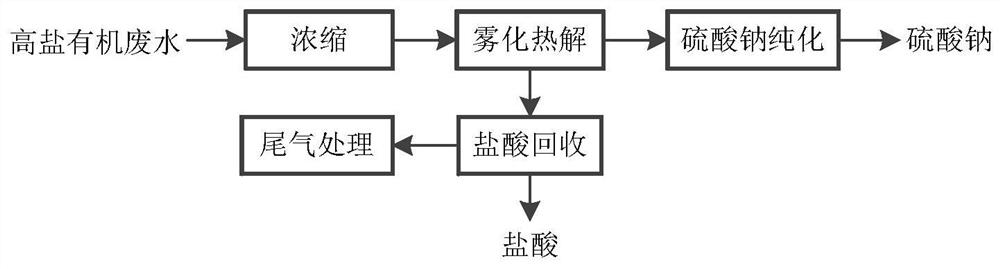

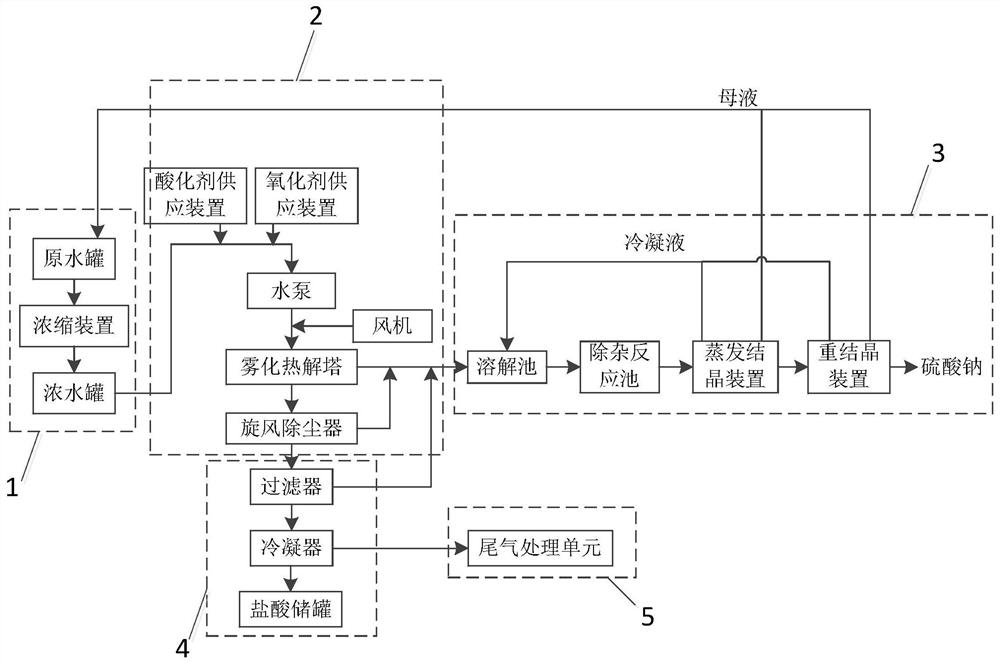

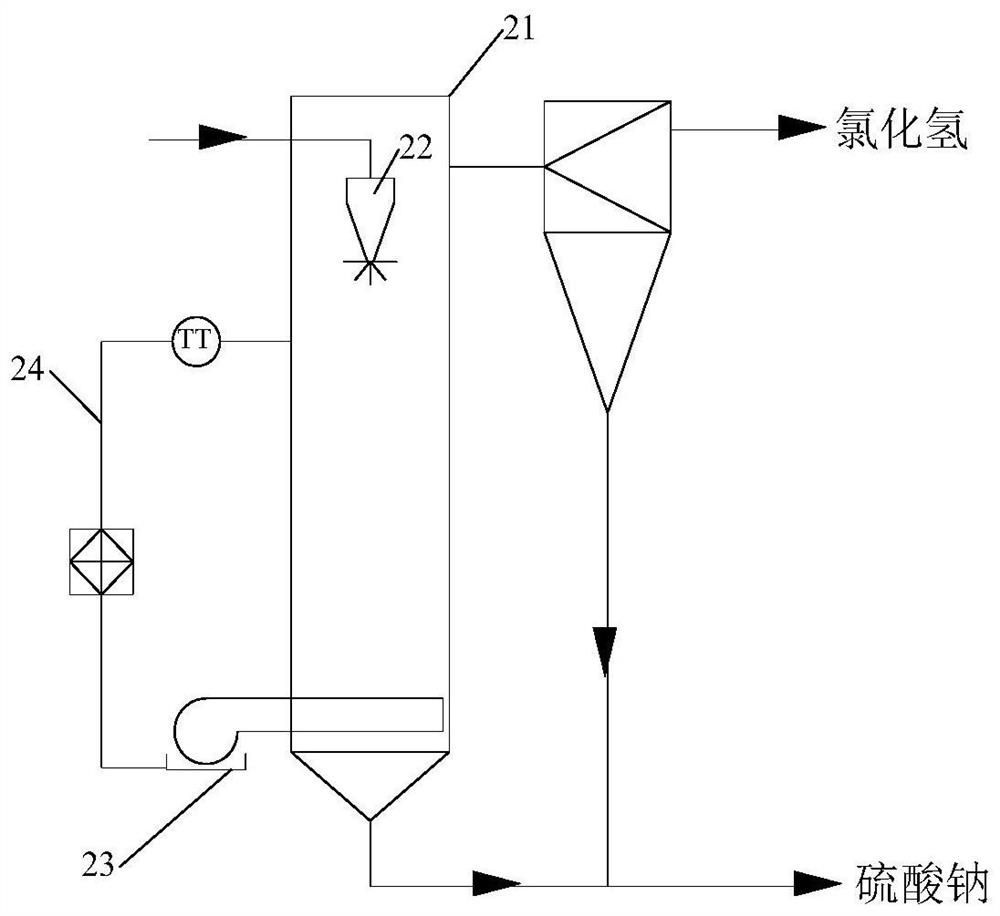

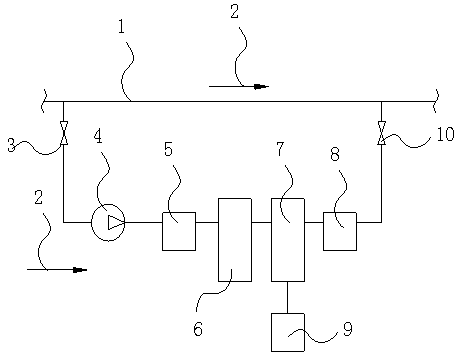

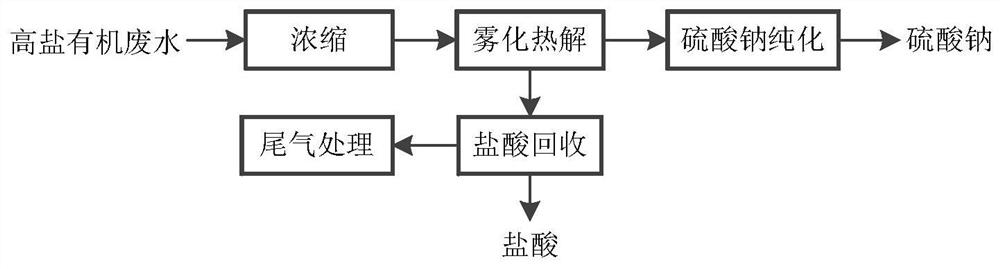

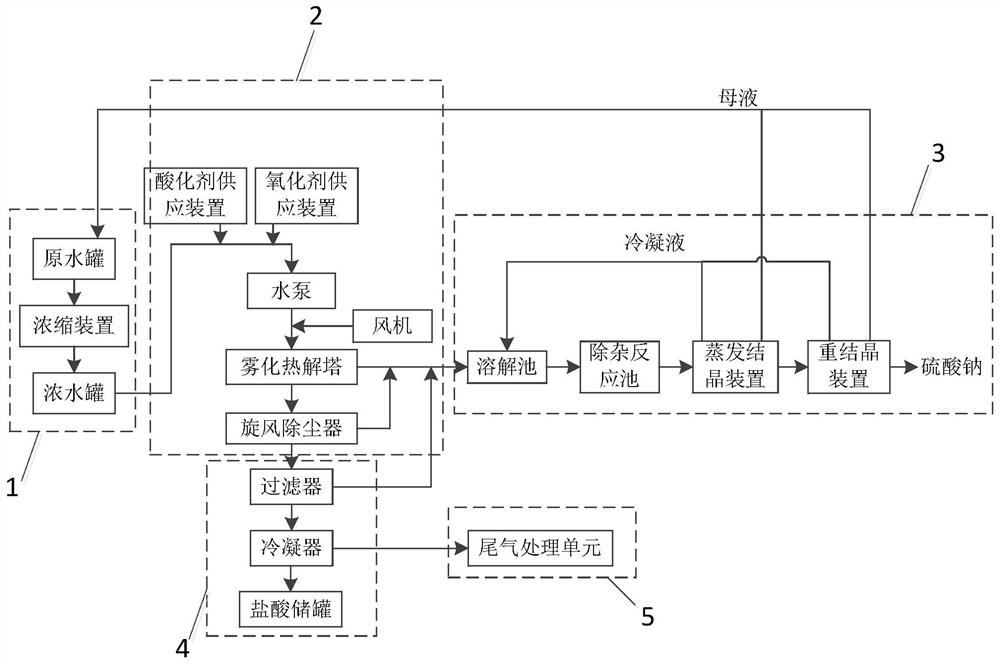

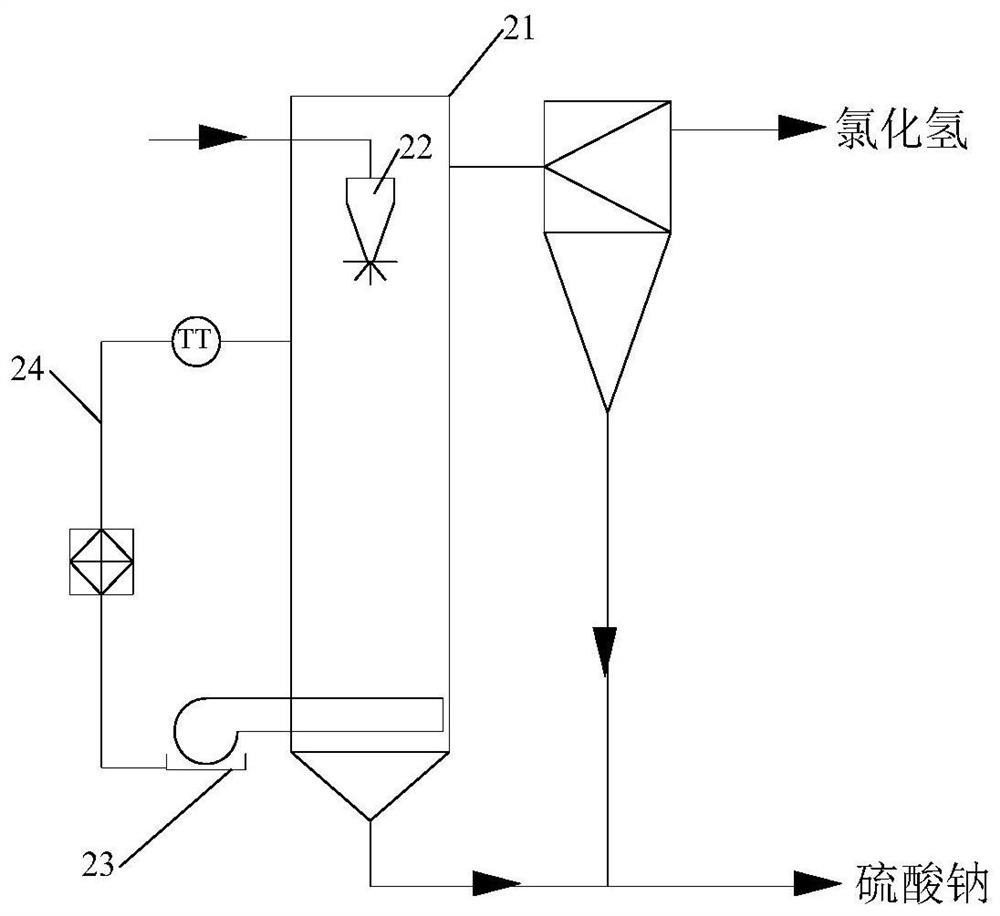

A system and method for resourceful treatment of high-salt organic wastewater

ActiveCN112225377BReduce consumptionIncrease concentrationChlorine/hydrogen-chloride purificationWater contaminantsOrganic matterHydrogen chloride

A system and method for resourceful treatment of high-salt organic wastewater, the system includes five units of raw water concentration, atomization pyrolysis, sodium sulfate purification, hydrochloric acid recovery and tail gas treatment. The raw water concentration unit concentrates the high-salt organic wastewater; the atomization pyrolysis unit adds an acidifying agent to the concentrated solution for acidification, and at the same time adds an oxidant, then atomizes and pyrolyzes the organic matter in the water to completely oxidize and remove, and separates to obtain hydrogen chloride gas and sodium sulfate. Mixed salt; the sodium sulfate purification unit dissolves, removes impurities, evaporates and crystallizes the separated sodium sulfate mixed salt, and the sodium sulfate is purified through recrystallization; the hydrochloric acid recovery unit filters and condenses the separated hydrogen chloride gas to recover hydrochloric acid; tail gas The processing unit deacidifies and purifies the remaining tail gas of the hydrochloric acid recovery unit. The system and method can realize high-efficiency removal of organic matter in high-salt wastewater, and recover hydrochloric acid and sodium sulfate crystalline salt at the same time; realize resourceful treatment of high-salt organic wastewater, and have good application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A purification device for circulating water in a heat exchange system

ActiveCN106315931BImprove processing precisionReduce trafficMultistage water/sewage treatmentElectro flocculationProcess engineering

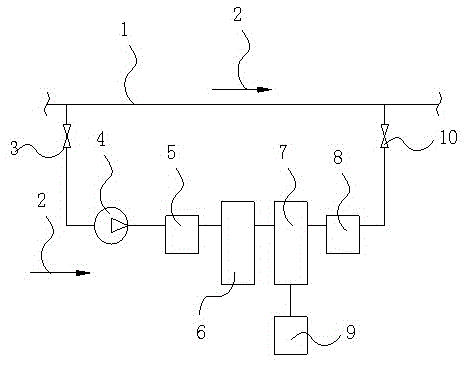

The invention discloses a purifier for circulating water in a heat exchange system; the purifier includes a heat exchange system circulating water header pipe, a split flow pump, an electron flocculator, a condenser, a centrifugal separator, a filth collector, and an electron scale-removal algae-removal device; both ends of the heat exchange system circulating water header pipe are connected with the heat exchange system, one end of the heat exchange system circulating water header pipe is also connected with an inlet of the split flow pump, and the other end of the heat exchange system circulating water header pipe is also connected with an outlet of the electron scale-removal algae-removal device; the split flow pump, the electron flocculator, the condenser, the centrifugal separator and the electron scale-removal algae-removal device are connected in order, and the centrifugal separator also is connected with the filth collector. The purifier adopts a way that a part of circulating water is led out and treated and the circulating water after treatment is sent back to the heat exchange system; the flow quantity of treatment is little, the centrifugal separator with higher treatment precision can be used, at the same time, the environmental-protection electric flocculation technique can be used, and disadvantages of adding chemical agents are solved.

Owner:SHANGHAI SHUANG JIN FLUID EQUIP CO LTD

System and method for resourceful treatment of high-salt organic wastewater

ActiveCN112225377AAchieve removalEfficient removalChlorine/hydrogen-chloride purificationWater contaminantsRaw waterProcess engineering

The invention discloses a system and a method for resourceful treatment of high-salt organic wastewater. The system comprises five units, namely a raw water concentration unit, an atomization pyrolysis unit, a sodium sulfate purification unit, a hydrochloric acid recovery unit and a tail gas treatment unit. The raw water concentration unit is used for concentrating the high-salt organic wastewater; the atomization pyrolysis unit is used for adding an acidifying agent into the concentrated solution for acidifying, adding an oxidizing agent at the same time, thoroughly oxidizing and removing organic matters in water through atomization pyrolysis, and separating to obtain hydrogen chloride gas and sodium sulfate mixed salt; the sodium sulfate purification unit is used for dissolving the separated sodium sulfate mixed salt, removing impurities, evaporating and crystallizing, and purifying sodium sulfate through recrystallization; the hydrochloric acid recovery unit is used for filtering and condensing the separated hydrogen chloride gas and recovering hydrochloric acid; and the tail gas treatment unit is used for deacidifying and purifying residual tail gas of the hydrochloric acid recovery unit. According to the system and the method, organic matters in the high-salinity wastewater can be efficiently removed, and hydrochloric acid and sodium sulfate crystalline salt can be recycled; the resourceful treatment of the high-salt organic wastewater is realized, and the method has a relatively good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com