Landfill leachate treatment method and system

A technology for landfill leachate and a treatment method, which is applied in the field of wastewater treatment, can solve the problems of long-term stable operation of wastewater treatment system, increased operating costs of subsequent processes, and ineffective treatment of biochemical systems, so as to achieve resource reuse and reduce overall operation. Cost and effect of reducing salt processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

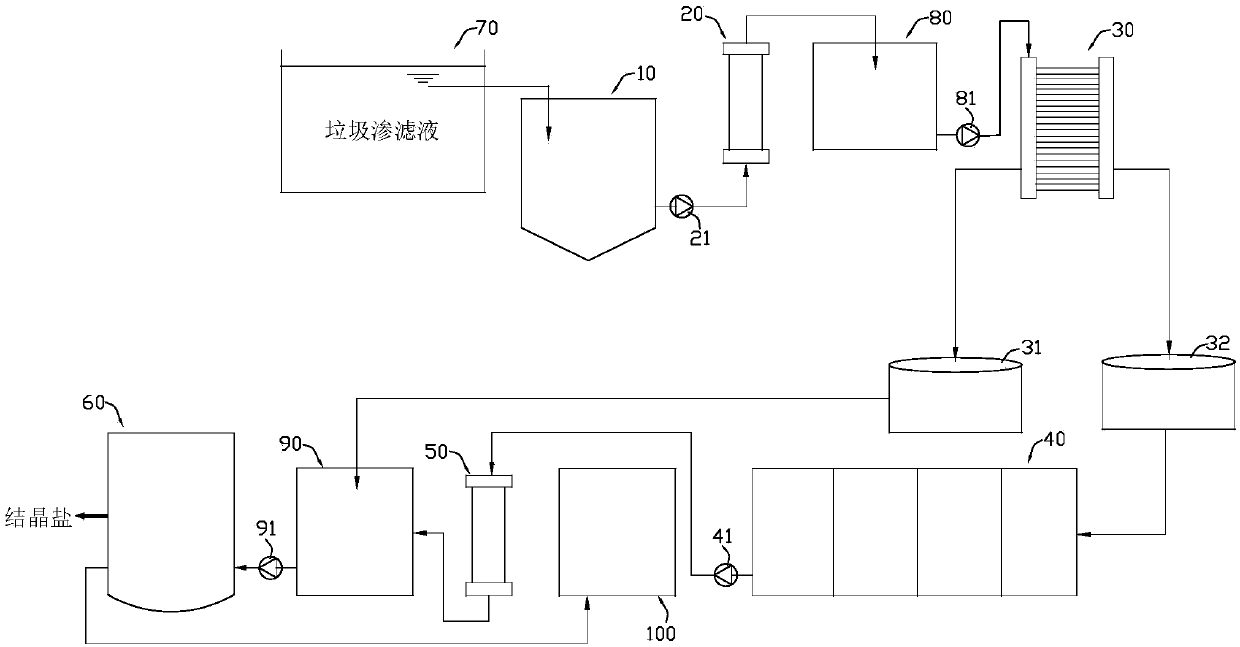

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

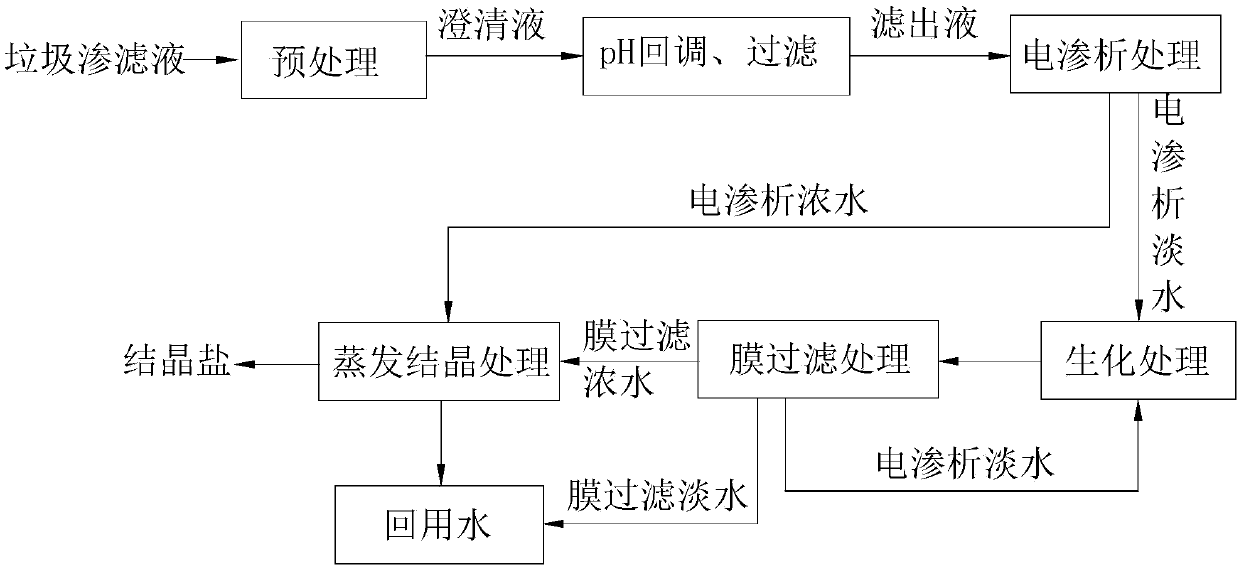

[0037] combine figure 1 , the landfill leachate treatment method of an embodiment of the present invention may comprise the following steps:

[0038] S1. Perform pretreatment on the landfill leachate to remove suspended solids, heavy metals, sulfate ions, calcium ions and magnesium ions to obtain clarified liquid.

[0039] Among them, landfill leachate is high-salt landfill leachate. Pretreatment mainly removes suspended solids, heavy metals, sulfate ions, calcium ions and magnesium ions through pH adjustment and flocculation precipitation.

[0040] Specifically, this preprocessing may include:

[0041] S1.1. Add sodium hydroxide to the landfill leachate, stir continuously, and adjust the pH of the landfill leachate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com