Method for comprehensive treatment of chemical strong brine

A technology for comprehensive treatment of concentrated brine, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc. The effect of economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

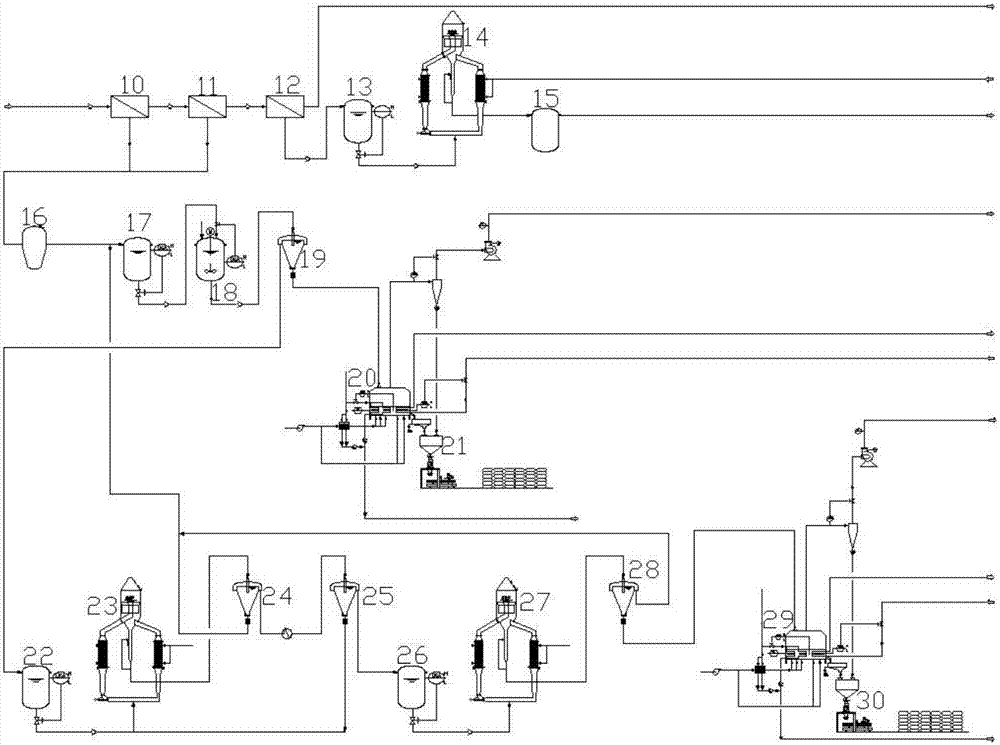

Image

Examples

Embodiment 1

[0043] 1) Membrane separation: pass the concentrated brine through the primary nanofiltration membrane and the secondary nanofiltration membrane to separate sodium sulfate and sodium chloride. The sodium produced water is further concentrated through the reverse osmosis membrane, the produced water is reused in the plant area, and the concentrated solution enters the concentrated brine storage tank;

[0044] 2) Evaporation and concentration of liquid salt: the sodium chloride concentrate in the concentrated brine storage tank is passed into the circulation pipe in the sodium chloride evaporation concentration device, and the feed liquid is pumped into the heating chamber by the circulation pump for heating. The upper limit of the saturated steam temperature is 158°C, and the upper limit of the pressure of the heating chamber is 0.6MPa. The heated feed liquid is evaporated and concentrated in the evaporation chamber. The sodium salt slurry is discharged from the salt leg into t...

Embodiment 2

[0051] 1) Membrane separation: pass the concentrated brine through the primary nanofiltration membrane and the secondary nanofiltration membrane to separate sodium sulfate and sodium chloride. The sodium produced water is further concentrated through the reverse osmosis membrane, the produced water is reused in the plant area, and the concentrated solution enters the concentrated brine storage tank;

[0052] 3) baking soda is made: the sodium sulfate concentrated water produced in step 1) is crystallized by cooling in a crystallization tower, adding mass ratio of sodium sulfate concentrated water and water of 1:1.5 in the crystallization tower in the crystallization process, carries out crystallization by cooling, Stir and crystallize for 30 minutes, then stand for crystallization for 20 minutes, and finally, stir and crystallize for 70 minutes to obtain sodium sulfate salt slurry. After the sodium sulfate salt slurry is washed with saturated sodium sulfate, it is stored in a c...

Embodiment 3

[0055] 1) Membrane separation: pass the concentrated brine through the primary nanofiltration membrane and the secondary nanofiltration membrane to separate sodium sulfate and sodium chloride. The sodium produced water is further concentrated through the reverse osmosis membrane, the produced water is reused in the plant area, and the concentrated solution enters the concentrated brine storage tank;

[0056]3) baking soda is made: the sodium sulfate concentrated water produced in step 1) is cooled and crystallized in a crystallization tower, and in the crystallization process, it is 1:0.5 sodium sulfate concentrated water and water to add mass ratio in the crystallization tower, carry out cooling crystallization, Stir and crystallize for 40 minutes, then stand for crystallization for 30 minutes, and finally, stir and crystallize for 80 minutes to obtain sodium sulfate salt slurry. After the sodium sulfate salt slurry is washed with saturated sodium sulfate, it is stored in a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com