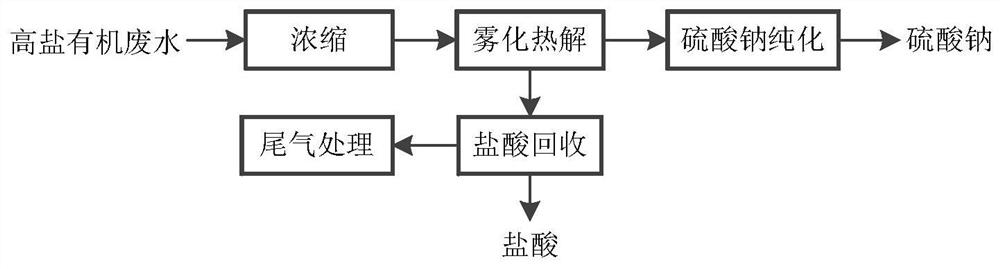

System and method for resourceful treatment of high-salt organic wastewater

A technology for recycling organic wastewater, applied in water/sewage treatment, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve problems such as the inability to realize high-efficiency treatment of high-salt organic wastewater and recycling of waste salt, and achieve Environmentally friendly No, achieve removal, efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

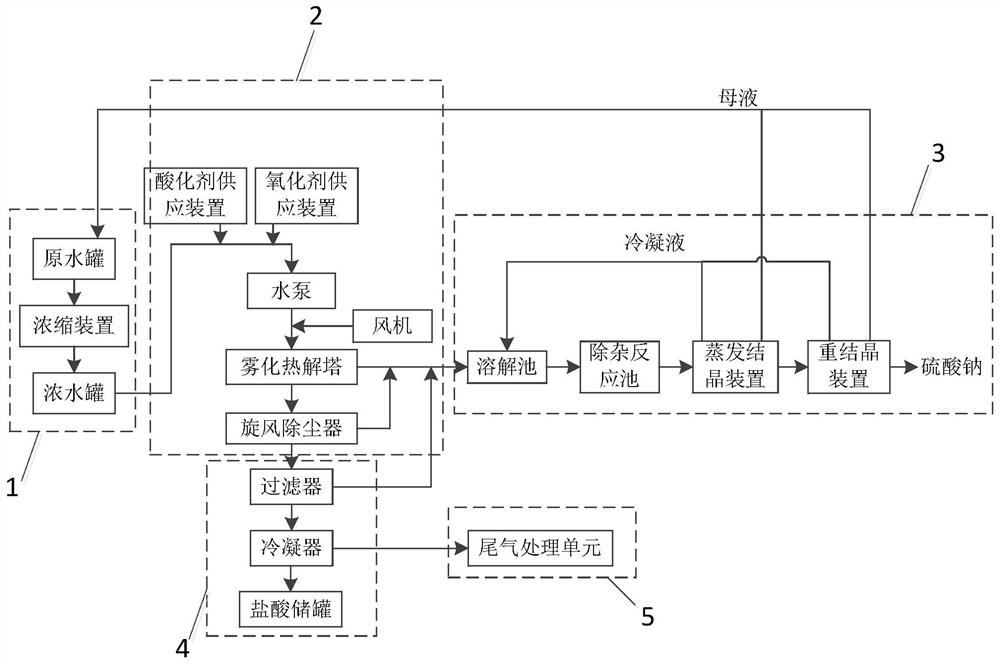

[0071] This embodiment provides a system for the resourceful treatment of high-salt organic wastewater. The schematic diagram of the system for the resourceful treatment of high-salt organic wastewater is as follows figure 2 As shown, it includes a raw water concentration unit 1, an atomization pyrolysis unit 2 and a sodium sulfate purification unit 3 connected sequentially through pipelines; the gas outlet of the atomization pyrolysis unit is sequentially connected to the hydrochloric acid recovery unit 4 and tail gas treatment through pipelines Unit 5;

[0072] The raw water concentration unit 1 is used to concentrate and treat high-salt organic wastewater; the raw water concentration unit 1 includes a raw water tank, a concentration device and a concentrated water tank connected in sequence through pipelines; the concentration device includes a pressure-driven membrane concentration device, Any one or a combination of at least two of electrically driven membrane concentrat...

Embodiment 2

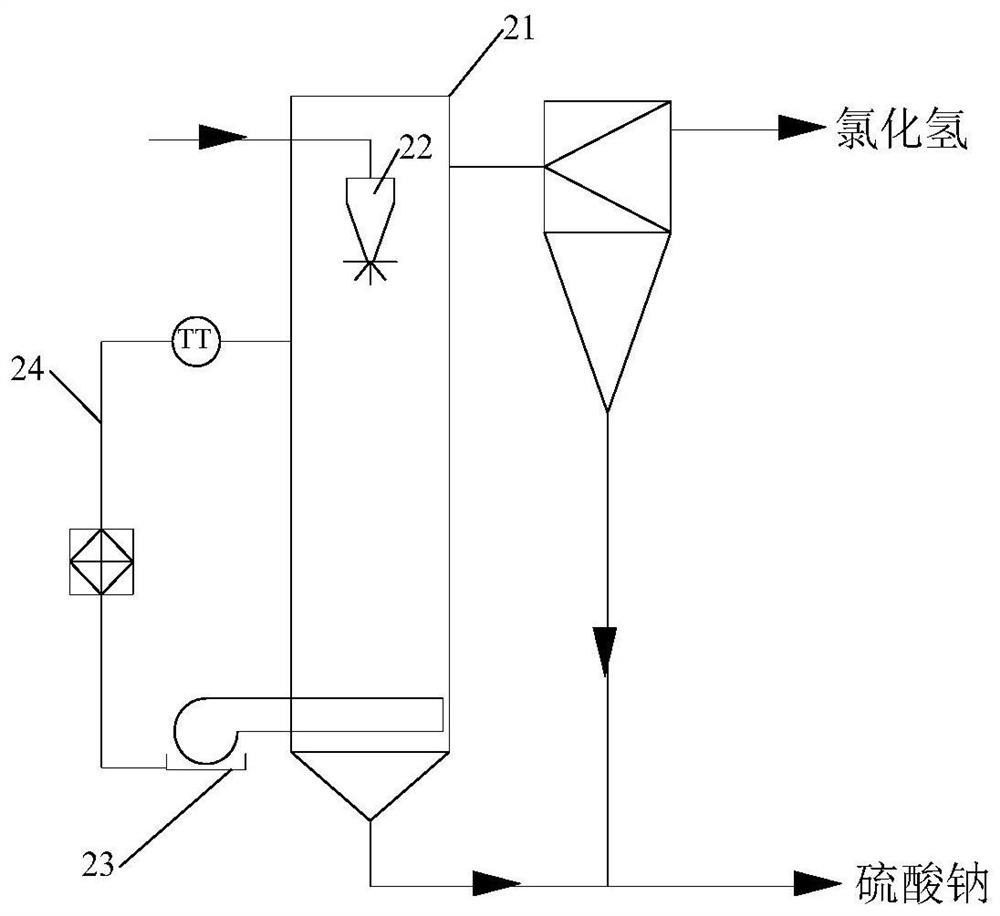

[0078] This embodiment provides a system for the resourceful treatment of high-salt organic wastewater. Compared with Example 1, the schematic structural diagram of the atomization pyrolysis tower in the system for the resourceful treatment of high-salt organic wastewater is as follows Figure 4 As shown, except that the concentrated liquid sprayed by the atomizing device 22 is in contact with the hot air provided by the burner 23, the rest is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com