Patents

Literature

95results about How to "Meet anti-corrosion requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anticorrosive waterproof nano industrial coating and its preparing method

InactiveCN1709994ASignificant heavy-duty anti-corrosion performanceSignificant coating acid resistanceCoatingsUltravioletSolvent

The invention discloses a kind of new industry dope. It comprises of two kinds of materials of following weight shares: Component A 95 - 105 and Component B 2 - 8 shares; thereinto, Component A is made from such materials as membrane forming object, pigment, filling agent, auxiliary agent, compound nanometer dispersing agent and solvent; Component B is made from nanometer Sb2O3 and mixed organic solvent carriers. The dope of the invention has following advantages: at room temperature, it has prominent heavy anticorrosion performance, and has excellent performances of acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it also has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:王继征

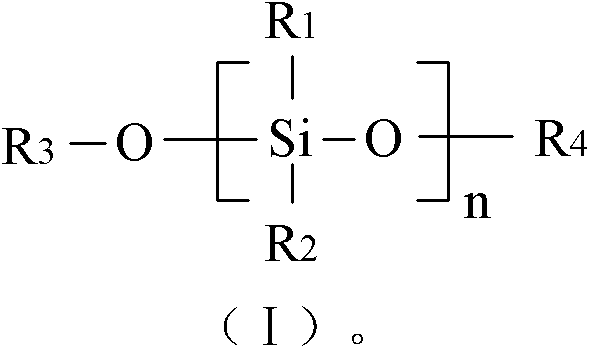

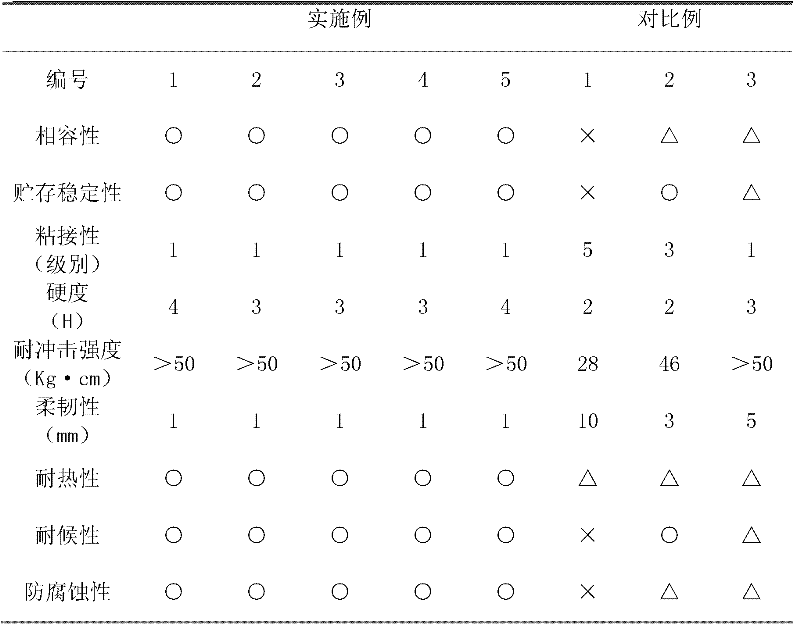

Epoxy-polysiloxane resin for paint and preparation method thereof

InactiveCN102352043AGood compatibilityGood storage stabilityEpoxy resin coatingsChemistryHeat resistance

The invention relates to epoxy-polysiloxane resin for paint and a preparation method thereof. The epoxy-polysiloxane resin for paint is characterized by being prepared from A hydrogenated bisphenol epoxy resin, active polysiloxane and organic tin catalysts, wherein the A hydrogenated bisphenol epoxy resin accounts for 20 to 80 mass percent, the active polysiloxane accounts for 20 to 80 mass percent, and the organic tin catalysts accounts for 0.5 to 5 percent of the total mass of the A hydrogenated bisphenol epoxy resin and the active polysiloxane. The epoxy-polysiloxane resin for paint prepared by the method has the characteristics of good compatibility and good storage stability. When the epoxy-polysiloxane resin for paint is applied to preparing epoxy-polysiloxane resin paint compositions, cured coating layers have excellent bonding performance, flexibility, weather resisting performance and anti-corrosion performance.

Owner:WUHAN UNIV OF TECH

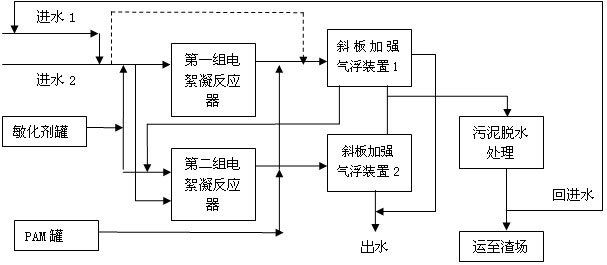

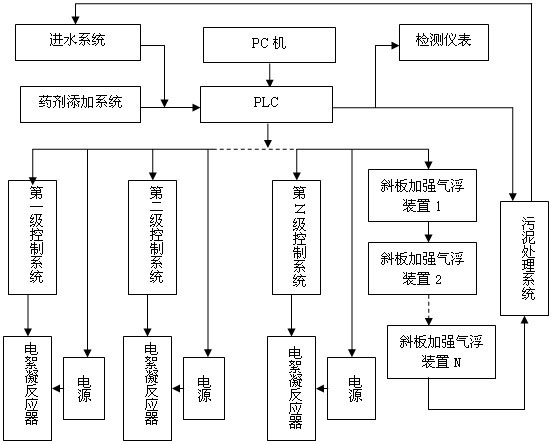

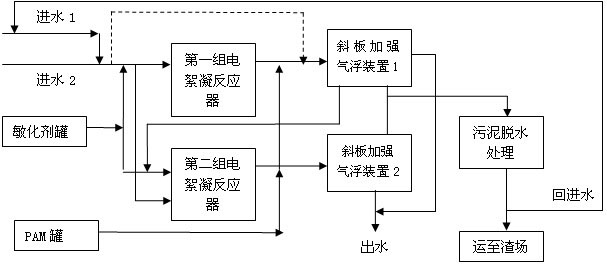

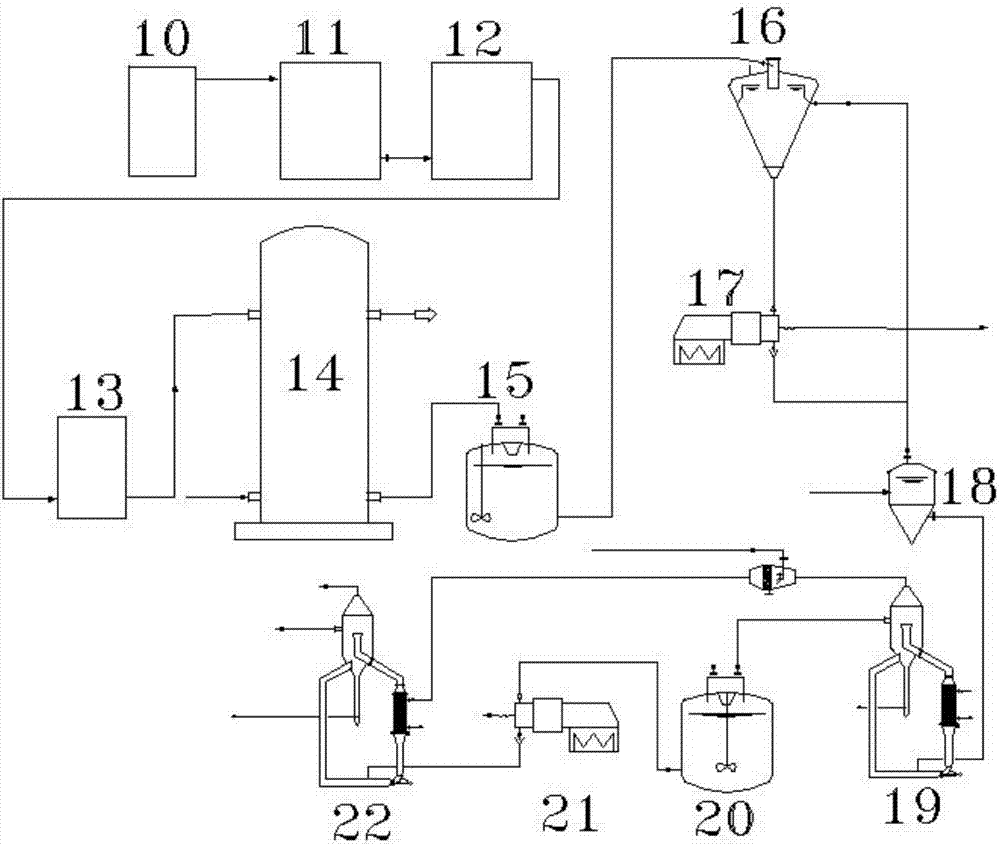

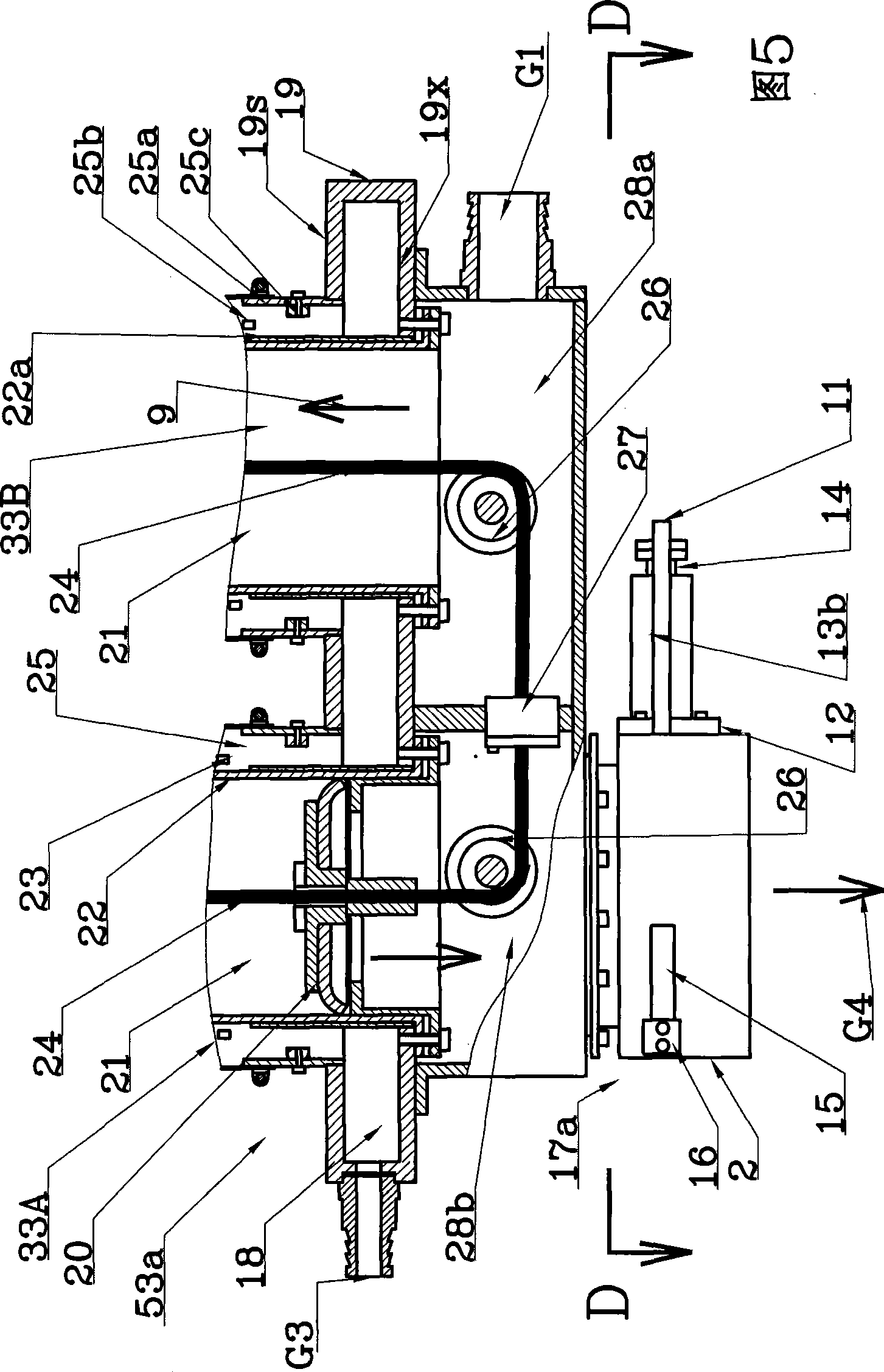

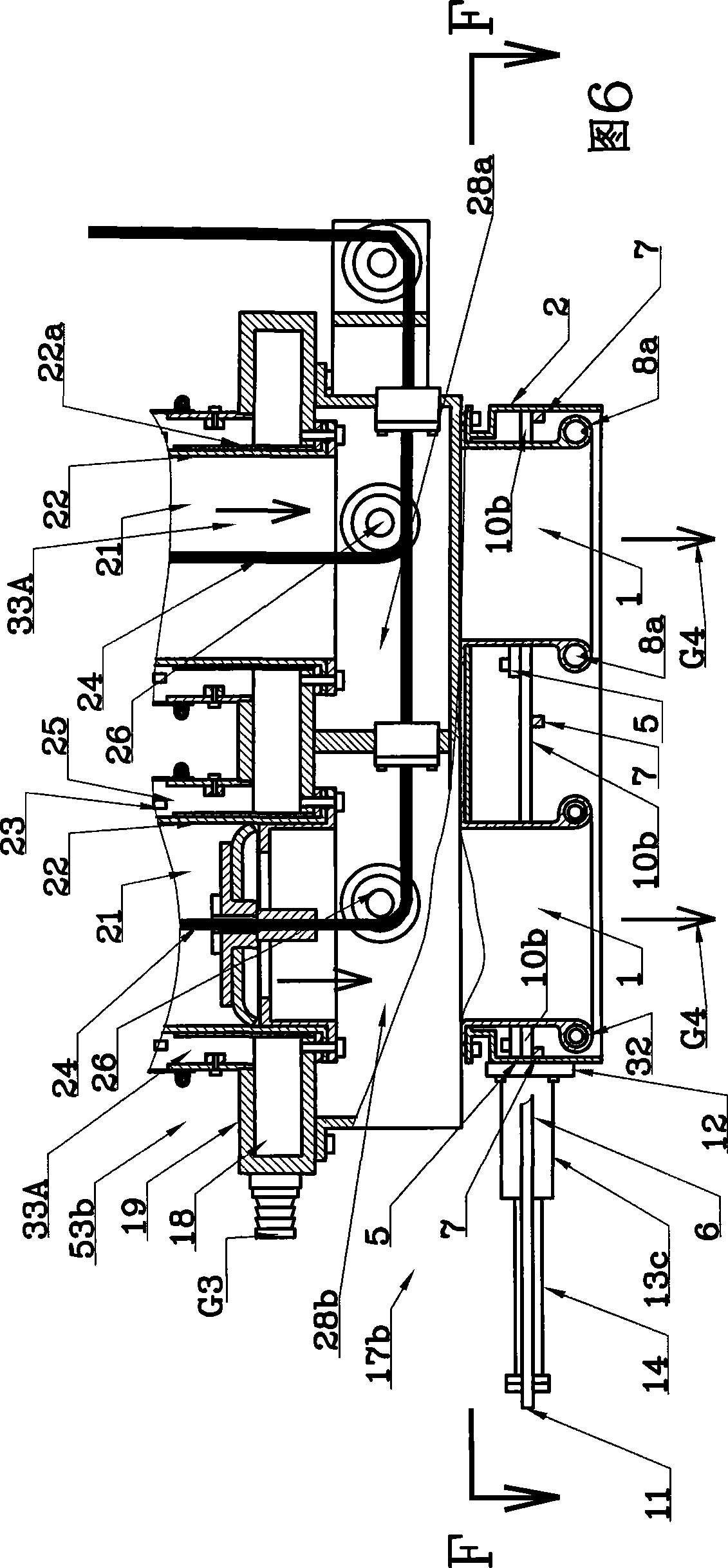

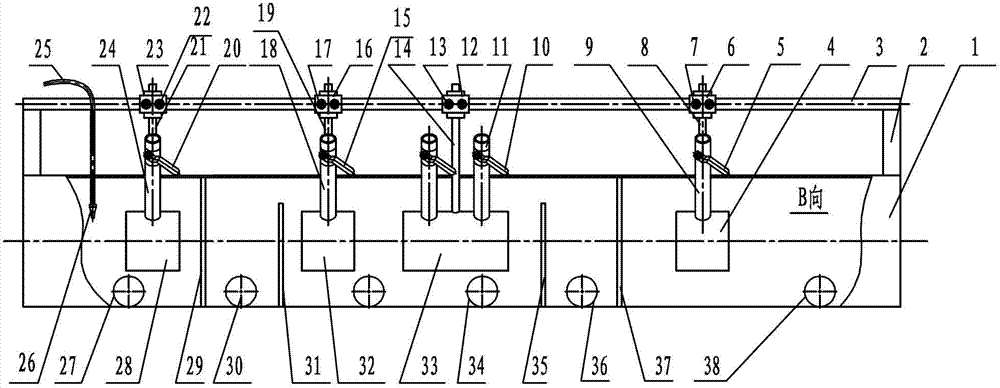

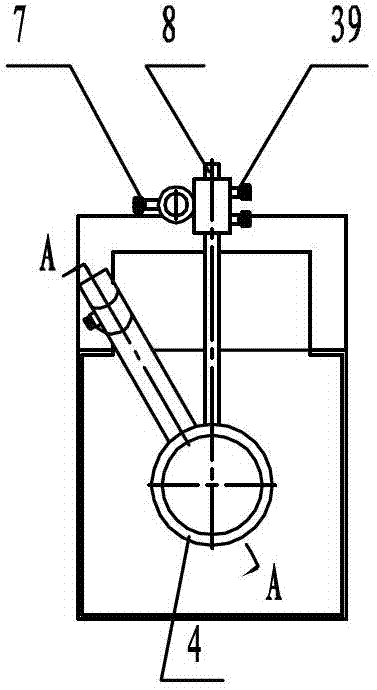

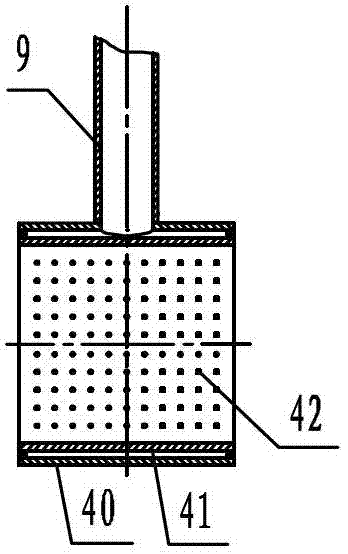

Electric flocculation method and device for recovering and processing desulfurized wastewater

ActiveCN101817575AEliminate passivationImprove electrolysis current efficiencyWater/sewage treatmentWaste water treatment from gaseous effluentsPollutantDewatered sludge

The invention discloses electric flocculation method and device for recovering and processing desulfurized wastewater. The electric flocculation method for recovering and processing desulfurized wastewater comprises the following steps of: collecting desulfurized wastewater to enter an electric flocculation reactor, then, carrying out solid-liquid separation, recovering the separated clear effluent water in a clinker-flushing system of an electric power plant or directly discharging the separated clear effluent water, conveying the sludge to dewater in a mud-processing system, and returning the effluent water of the mud-processing system to a water intake system. Compared with the prior art, the electric flocculation technology is adopted to substitute a complicated chemical method for recovering and processing the desulfurized wastewater, can effectively remove pollutants in the wastewater, reaches a heavy metal processing rate up to 95-99 percent, a chlorine-processing rate over 80 percent and removal rates of ammonian, and the like over 90 percent, greatly shortens the processing time, improves the processing efficiency and saves the investment cost. Moreover, the electric flocculation processing device has small size, extremely small floor occupation, good environmental-protection performance and low cost without additional flocculating agents.

Owner:华电水务工程有限公司

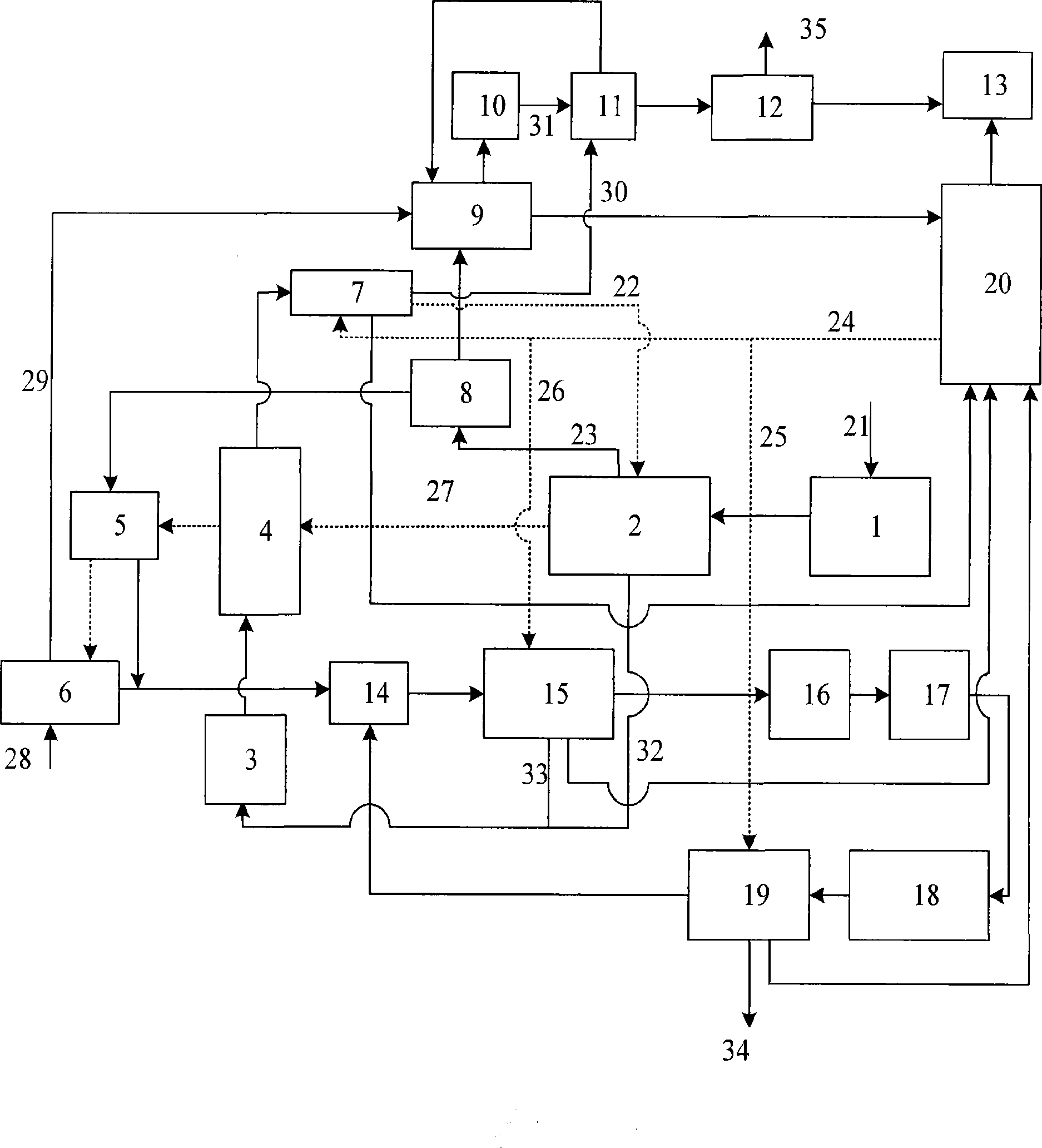

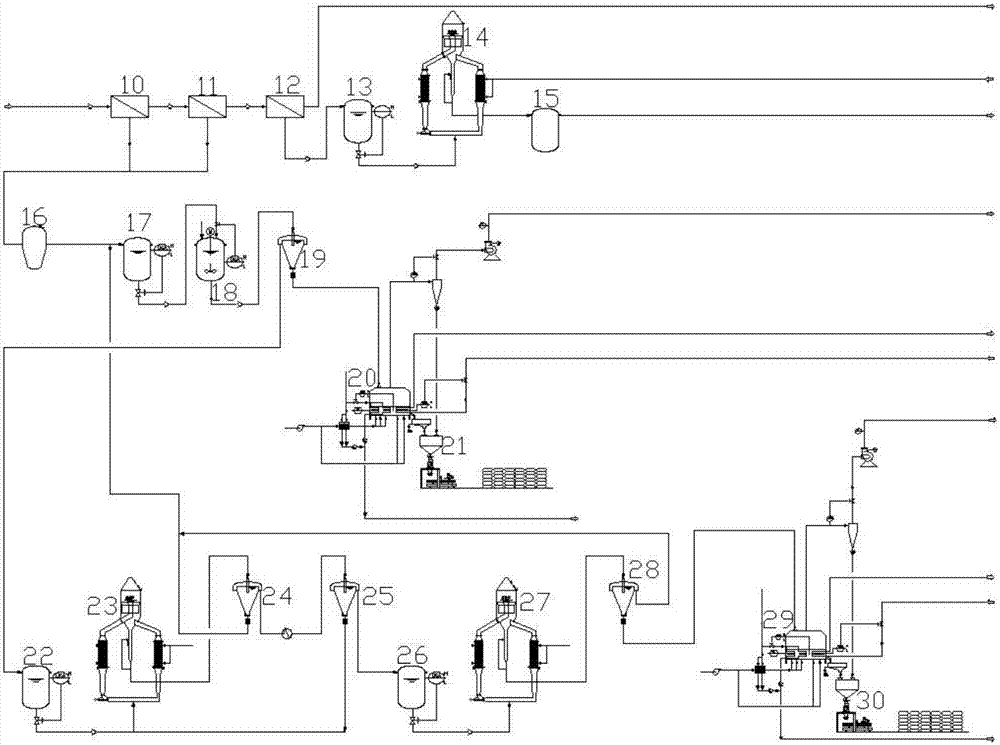

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

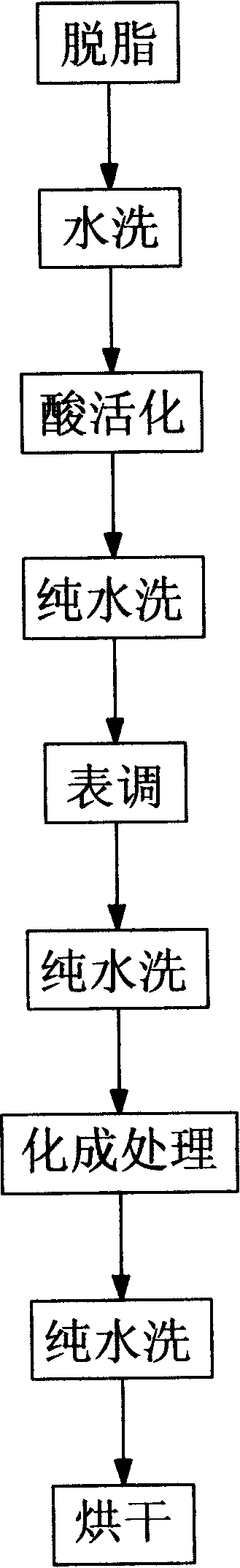

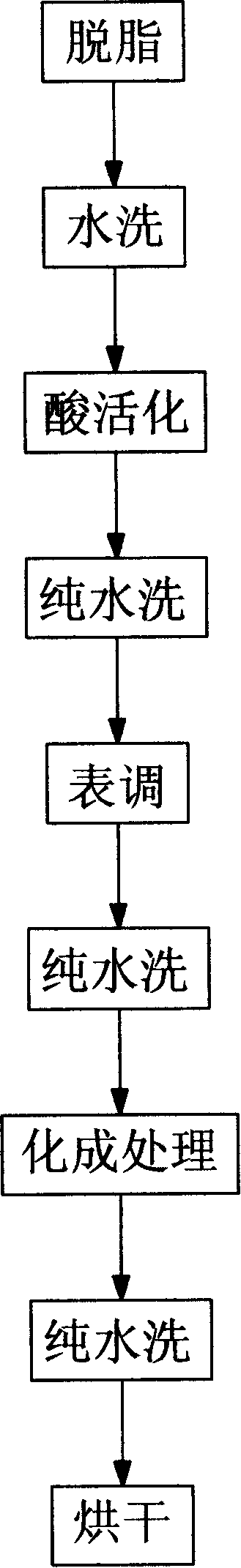

Magnesium alloy surface calcium series phosphorization solution and formation processing technique thereof

InactiveCN101191207AReduce pollutionImprove corrosion resistanceMetallic material coating processesPhosphoric acidWorking temperature

The invention provides a Ca-system phosphating solution for magnesium alloy surfaces which takes the water as the solvent. Each liter of the solution comprises: calcium biphosphate of 5 to 80 g, phosphoric acid of 2 to 15 ml, nitrate of 2 to 15 g and polyphosphate of 0.1 to 5 g. For the process using the Ca-system phosphating solution to make surface treatment to the magnesium alloy, the process flow is degreasing, bath, acid activation, pure bath, surface conditioning, pure bath, conversion treatment, pure bath and drying; wherein, the concrete procedures of the conversion treatment in the process flow are that: the magnesium alloy workpiece made a pre-treatment is dipped into the Ca-system phosphating solution for treatment, the working temperature of the workpiece is between 20 and 35 DEG C, the conversion treatment time is between 20 seconds to 5 minutes. With the Ca-system phosphating solution for magnesium alloy surfaces of the invention and the conversion process thereof, the obtained membrane has good corrosion resistance, can meet the requirement of environmental protection; the conversion treatment can be made under room temperature without need to be heated, and has small energy consumption.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

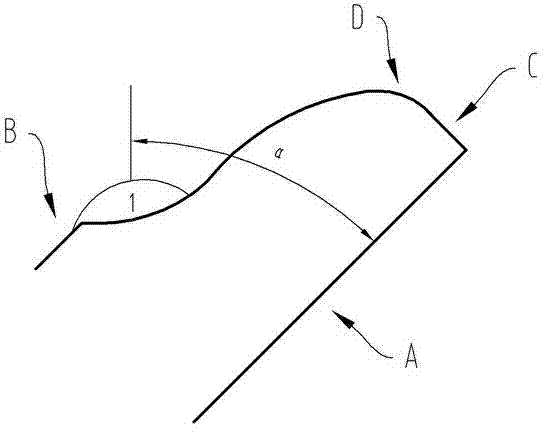

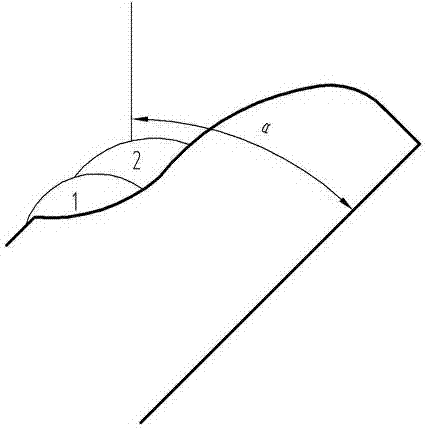

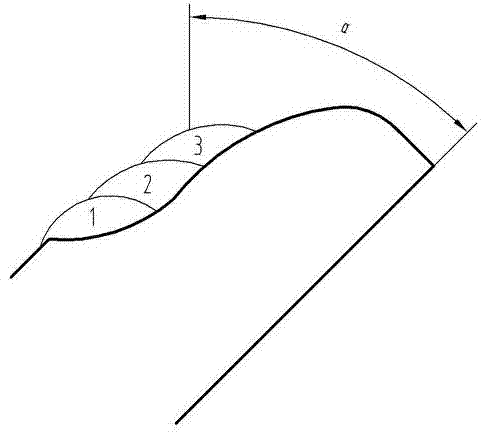

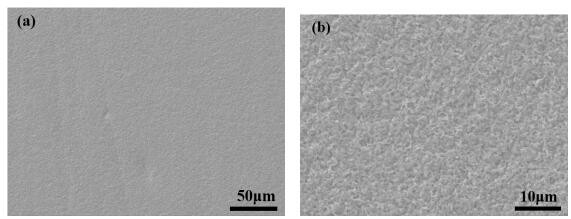

Water-erosion preventing method for turbine blade by laser cladding

ActiveCN103668188AControl deformationExtended service lifeMetallic material coating processesLaser beam welding apparatusStellite alloyAerospace engineering

The invention provides a water-erosion preventing method for a turbine blade by laser cladding. By adoption of the water-erosion preventing method, the laser cladding quality can be effectively ensured, the deformation of the laser-cladded blade can be reduced, and the requirement of different parts of the blade for the water erosion resistance can be ensured, so that the service life of the blade is prolonged. The water-erosion preventing method is characterized by comprising the following steps of: firstly carrying out roughening treatment on the surface of a blade cladding groove, then clamping the blade to a laser cladding machine tool, adopting a preheater to preheat the cladded areas of the blade, feeding powder by a side-shaft powder feeding head, and using a CO2 laser to clad stellite alloy powder in the blade cladding groove along the direction from the root of the turbine blade to the top of the turbine blade according to a mode of multilayered and multi-pass lapped cladding.

Owner:WUXI TURBINE BLADE

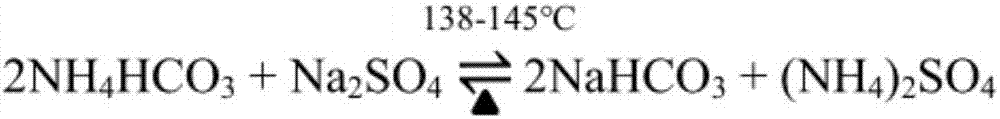

Method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine

ActiveCN106865571ASolve processing problemsAchieve recyclingAlkali metal carbonatesAmmonia compoundsSodium bicarbonateProcess engineering

Belonging to the technical field of solid waste miscellaneous salt recycling treatment, the invention discloses a method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine. According to the method, evaporated and concentrated chemical strong brine is subjected to hardness removal to obtain a delicate mirabilite solution, and then ammonia-soda process reaction is carried out to obtain sodium bicarbonate and ammonium sulfate products. The method provided by the invention solves the difficult treatment problem of chemical strong brine, realizes recycling of miscellaneous salt in strong brine, and meets the sustainable development requirements. At the same time, compared with the salt method for preparation of sodium bicarbonate, the method provided by the invention reduces the anti-corrosion requirement of equipment, saves the project investment for preparation of sodium bicarbonate, has the byproduct ammonium sulfate with a value higher than ammonium chloride, and has obvious advantages in economic benefits.

Owner:科莱环保(北京)有限公司

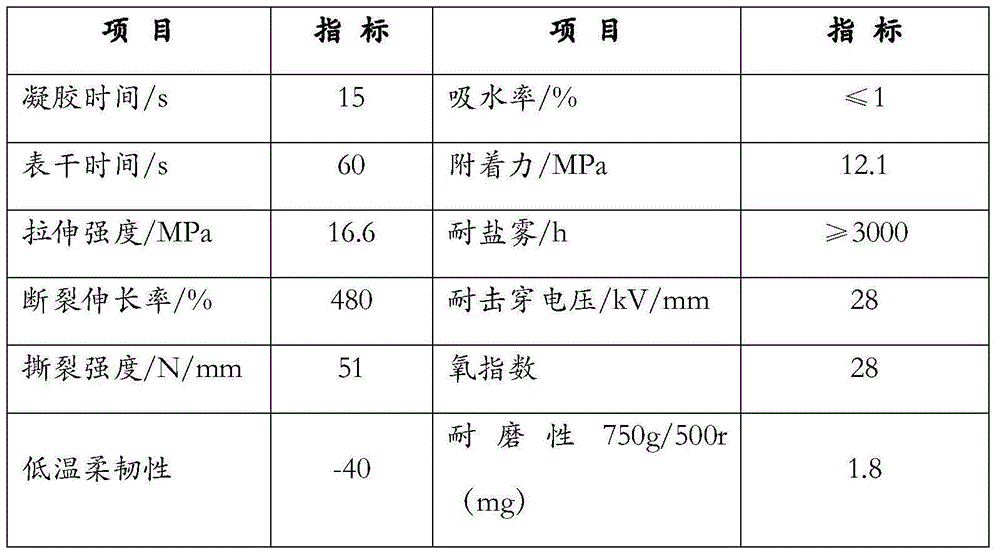

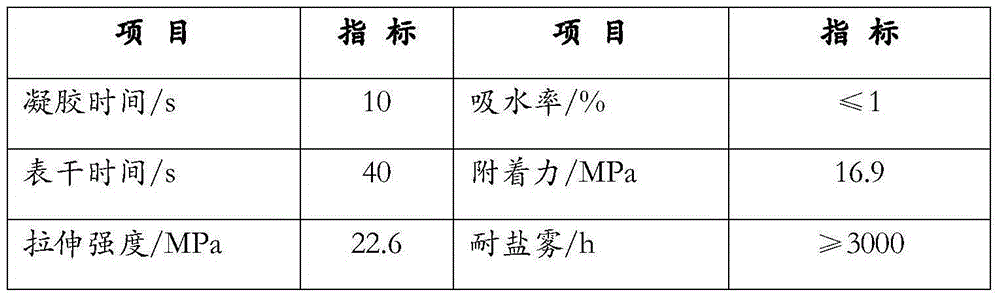

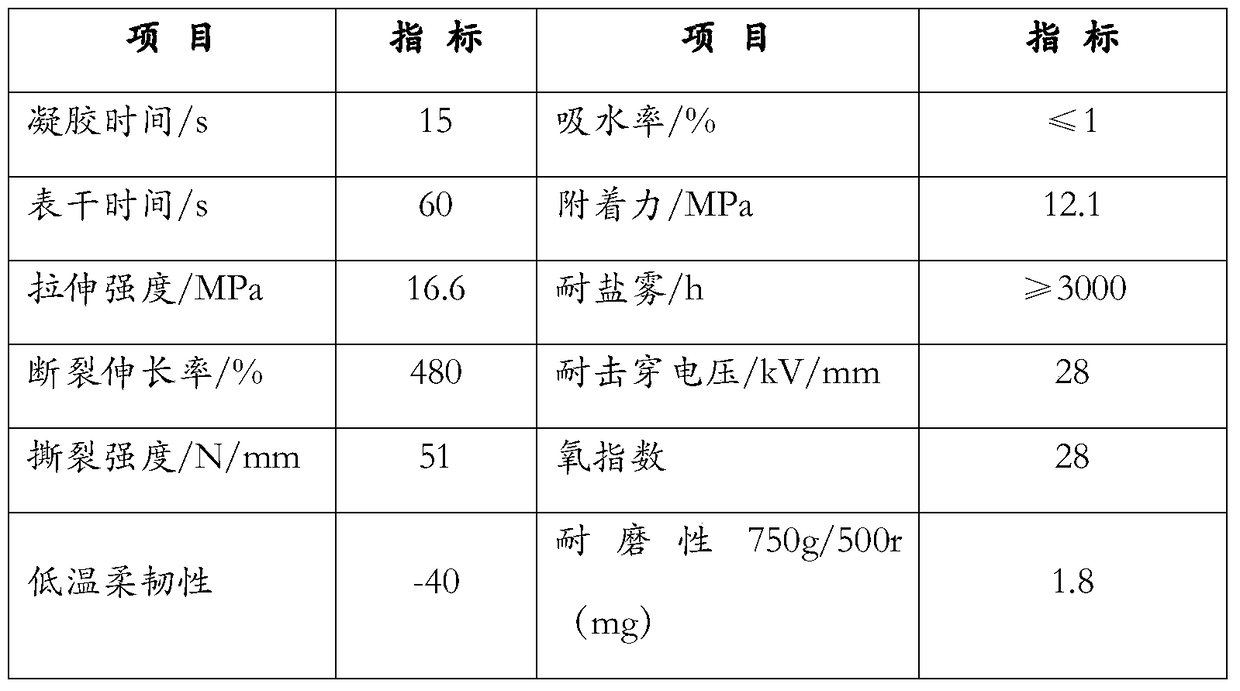

Spray polyurea elastomer and preparation method thereof

ActiveCN105038546AImprove corrosion resistanceMeet anti-corrosion requirementsPolyurea/polyurethane coatingsElastomerPolyol

The invention discloses a spray polyurea elastomer and a preparation method thereof. The spray polyurea elastomer comprises a component A and a component B, wherein the volume ratio of the component A to the component B is 1: 1; the component A is isocyanate prepolymer compounded through the reaction of polyether polyol, fluorine-containing polyol, and isocyanate, and the -NCO content is 12%-20%; the component B comprises the followings in parts by weight: 30-50 parts of amine-terminated polyether, 30-45 parts of a chain extender, 0.5-1.0 part of fumed silica, 0.1-0.5 part of a dispersing agent, 0.5-1.0 part of a defoaming agent and 1.0-5.0 parts of color paste. The polyurea elastomer provided by the invention is excellent in weather resistance, resistance to chemical reagents and fire resistance and good in abrasion resistance.

Owner:QINGDAO AIR NEW MATERIALS

Method for comprehensive treatment of chemical strong brine

InactiveCN106865859AReduce the amount of treated waterReduce energy consumptionWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentSodium bicarbonateEconomic benefits

Belonging to the technical field of resource recycling, the invention discloses a method for comprehensive treatment of chemical strong brine. According to the method, chemical strong brine is separated by a nanofiltration membrane to obtain a sodium chloride solution and a sulfuric acid solution, the sulfuric acid solution is then subjected to nitrate freezing purification in a cold way, then the product reacts with ammonia water and carbon dioxide gas to prepare sodium bicarbonate and ammonium sulfate products. The method provided by the invention solves the problem of difficult treatment of chemical strong brine, realizes recycling of miscellaneous salts in strong brine, and satisfies the requirements of sustainable development. At the same time, compared with salt method for preparation of sodium bicarbonate, the method can reduce the anticorrosion requirement of equipment and save the project investment for preparation of sodium bicarbonate, the byproduct ammonium sulfate has a value higher than ammonium chloride, thus having obvious advantages in economic benefit.

Owner:科莱环保(北京)有限公司

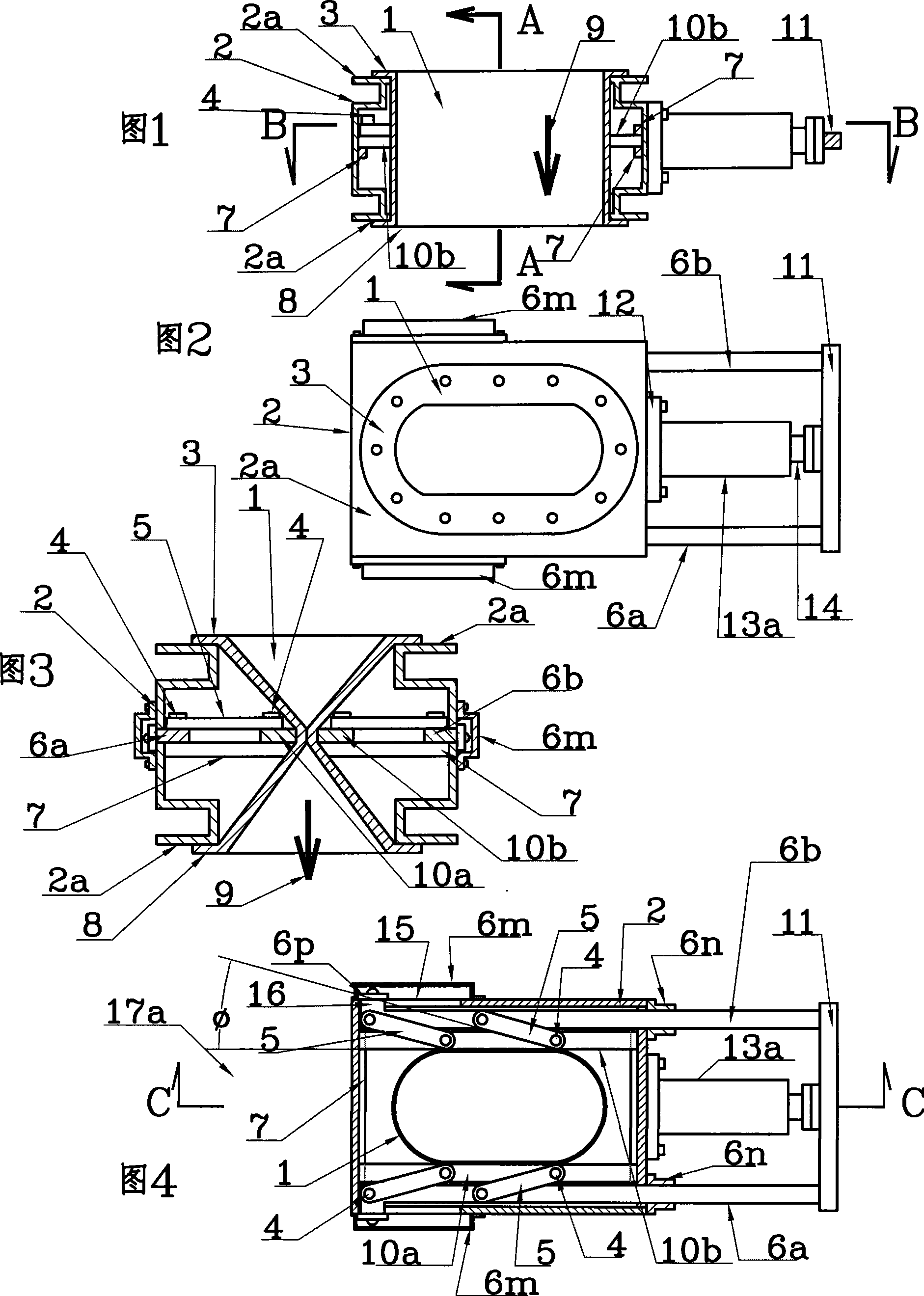

Flexible tube type cut-off valve capable of being used in flexible tube solid-liquid processing device

InactiveCN101413595AMeet anti-corrosion requirementsReduce manufacturing costDiaphragm valvesEngine diaphragmsPolyesterFiber

The invention provides a flexible pipe-typed stop valve which applies force on the flexible pipe chamber by a holder-typed connecting rod mechanism, thus staving the pipe wall and blocking the internal flow passage of the flexible pipe chamber, thereby achieving the object of stopping the fluid. The stop valve has no possibility of leakage or corrosion as the stop valve has no gaps besides a flange connected with the pipeline and the mechanical part used for cutting off the fluid (holder-typed connecting rod mechanism) is shielded at the external side by the flexible pipe chamber. The requirement of automatic reciprocating opening and closing of the valve can be met by driving the holder-typed connecting rod mechanism by a reciprocating execution mechanism. The stop valve is especially suitable for flexible pipe solid / liquid disposal device which adopts various film components; when the stop valve is combined with the technical proposal of the original film component, the structure is simplified further, the service life is prolonged further, and the price quality of the flexible pipe solid / liquid disposal device is greatly improved; particularly, the flexible pipe chamber adopts filter medium material such as micro-porous material using non-woven cloth or polyester fiber, therefore, the flexible pipe chamber can be also used as a filter element when in use.

Owner:张民良

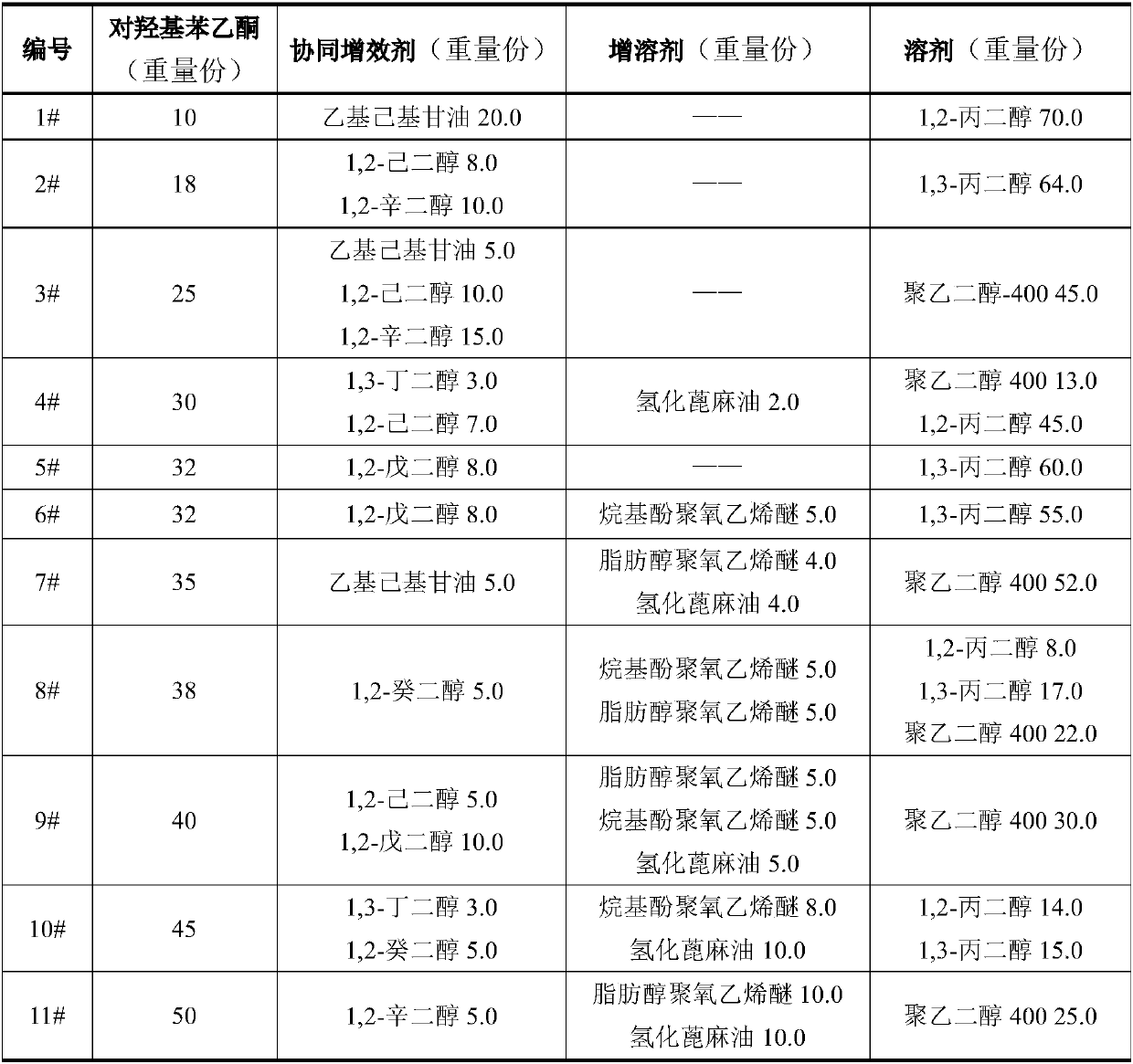

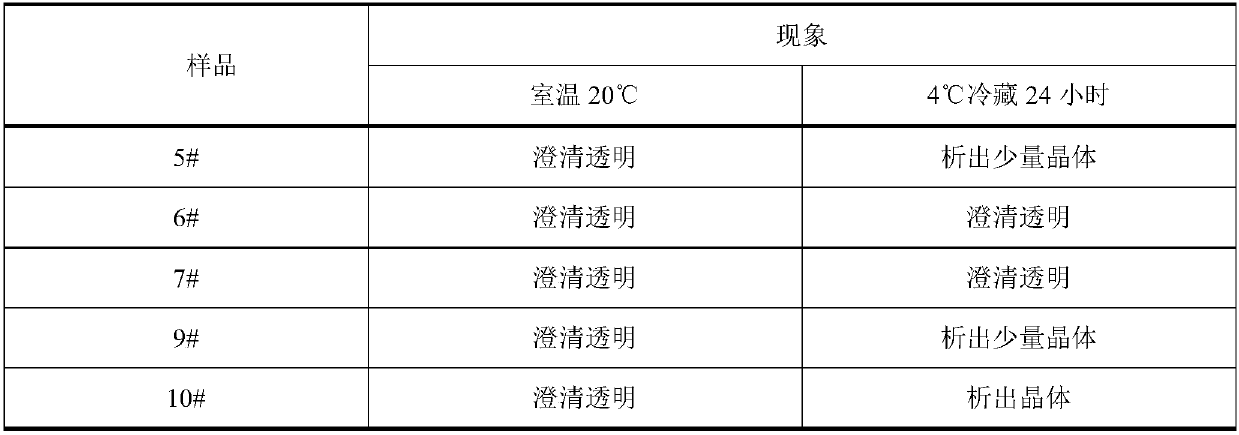

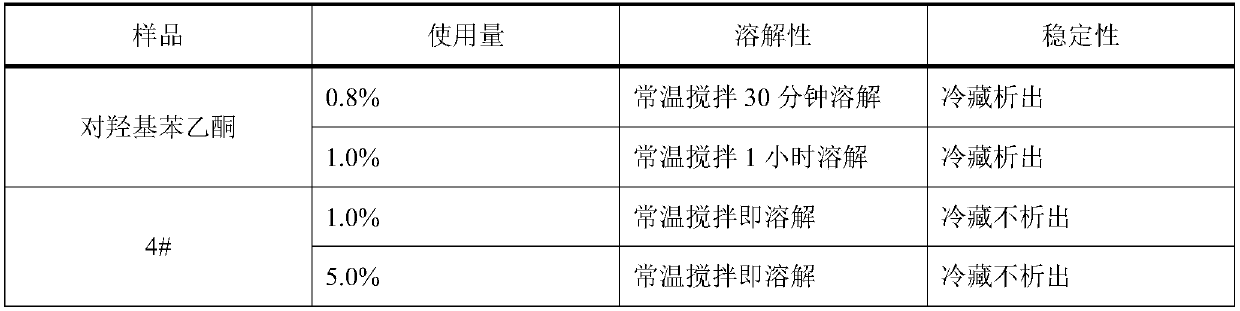

Complex composition containing p-hydroxyacetophenone as well as preparation method and application thereof

ActiveCN107624758AImprove solubilityImprove stabilityCosmetic preparationsBiocideSolventInhibitory effect

The invention discloses a complex composition containing p-hydroxyacetophenone as well as a preparation method and an application thereof. The complex composition comprises the following components inparts by weight: 10-50 parts of p-hydroxyacetophenone, 5-30 parts of a synergic additive, 0-20 parts of a solubilizer and 25-70 parts of a solvent. The complex composition disclosed by the inventionhas an excellent inhibiting effect on bacteria, molds and saccharomycetes. The product is wide in applicability and low in cost, the dissolubility and stability of the p-hydroxyacetophenone in the solvent are improved due to use of the solubilizer, and the synergic additive can assist in improving the antibacterial effect of the formula, so that the corrosion prevention requirements of household chemicals are met.

Owner:BEIJING SUNPU BIOCHEM TECH

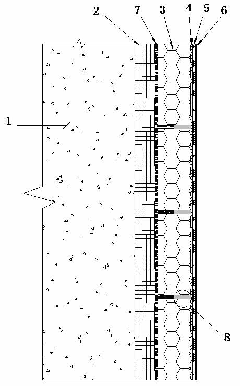

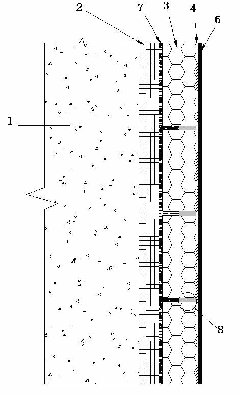

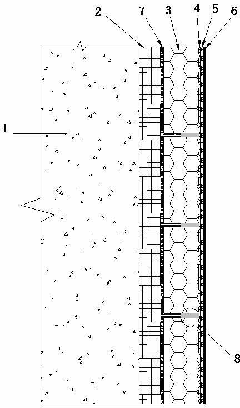

Method for making anticorrosive glass reinforced plastic layer of chimney

InactiveCN102192518AMeet anti-corrosion requirementsImprove integrityChimneysHeat resistanceFlue gas

The invention provides a method for making an anticorrosive glass reinforced plastic layer of a chimney. According to the method, the glass reinforced plastic layer of poly fluorine organic lining anticorrosive material is made after a base coating is coated on a basal body of the chimney. By the method, the inner wall of the chimney can be completely isolated with flue gas; the glass reinforced plastic of the poly fluorine lining anticorrosive material has good integrity, so construction blind spots are not caused; and the glass reinforced plastic of the poly fluorine lining anticorrosive material (VP3-2) has excellent properties such as acid resistance, abrasion resistance, heat resistance, strong adhesive force and the like, so the anticorrosive requirement of the chimney can be fully met.

Owner:重庆大众防腐股份有限公司

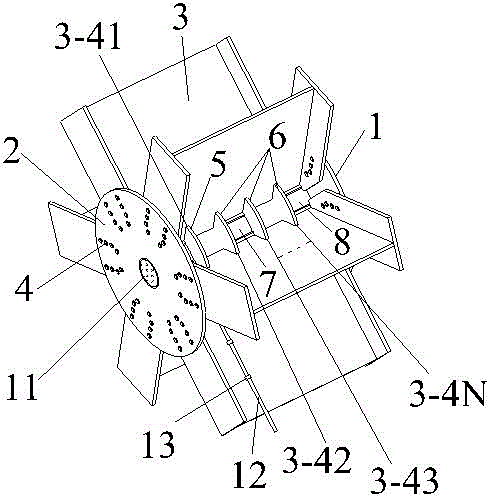

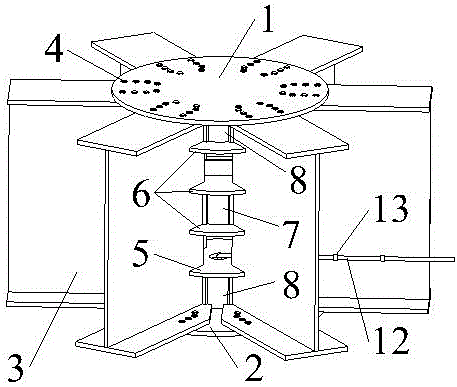

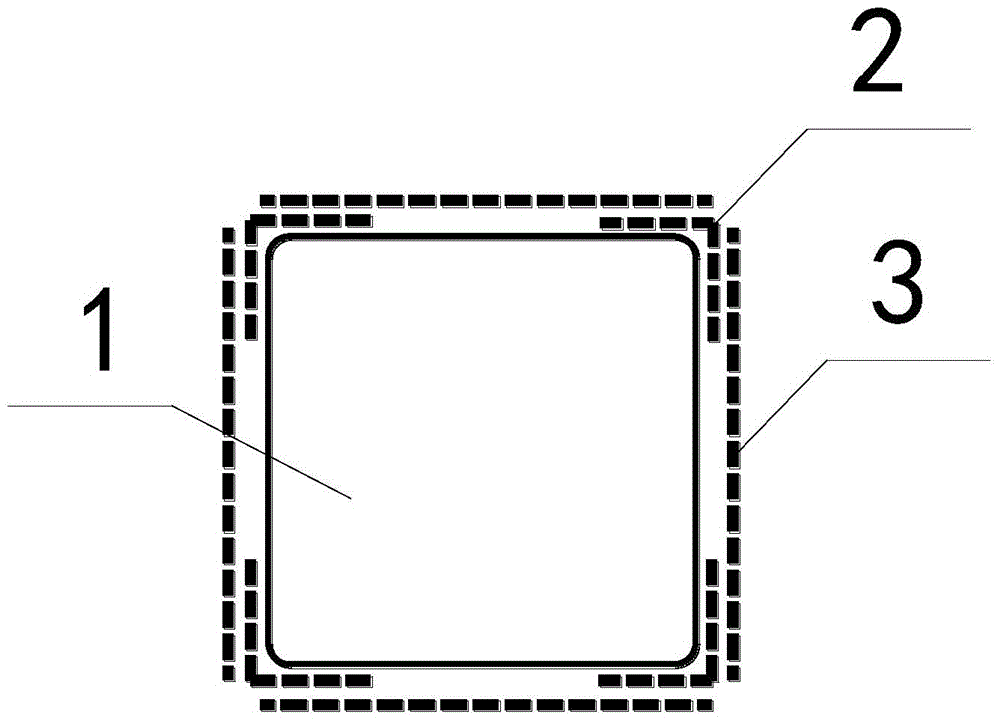

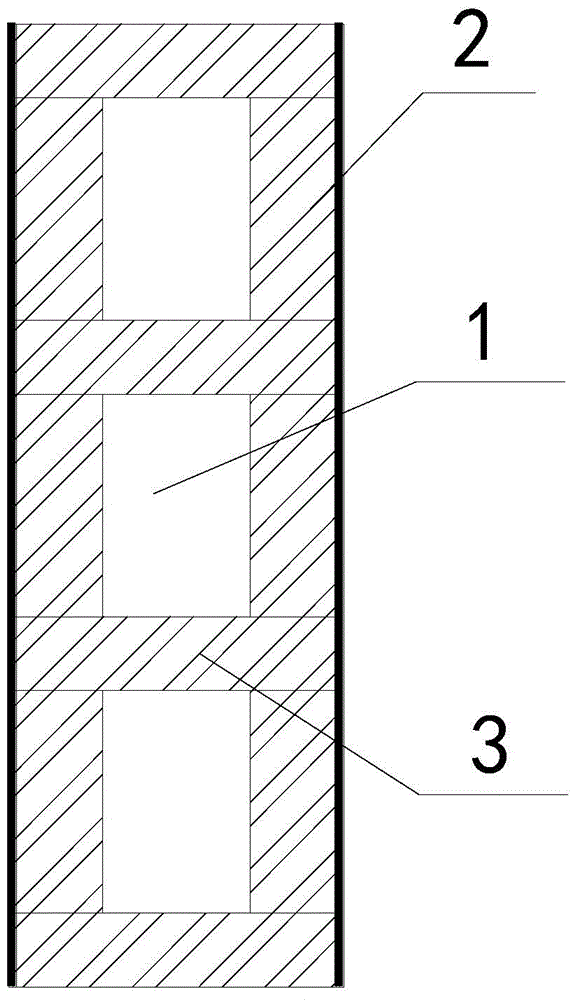

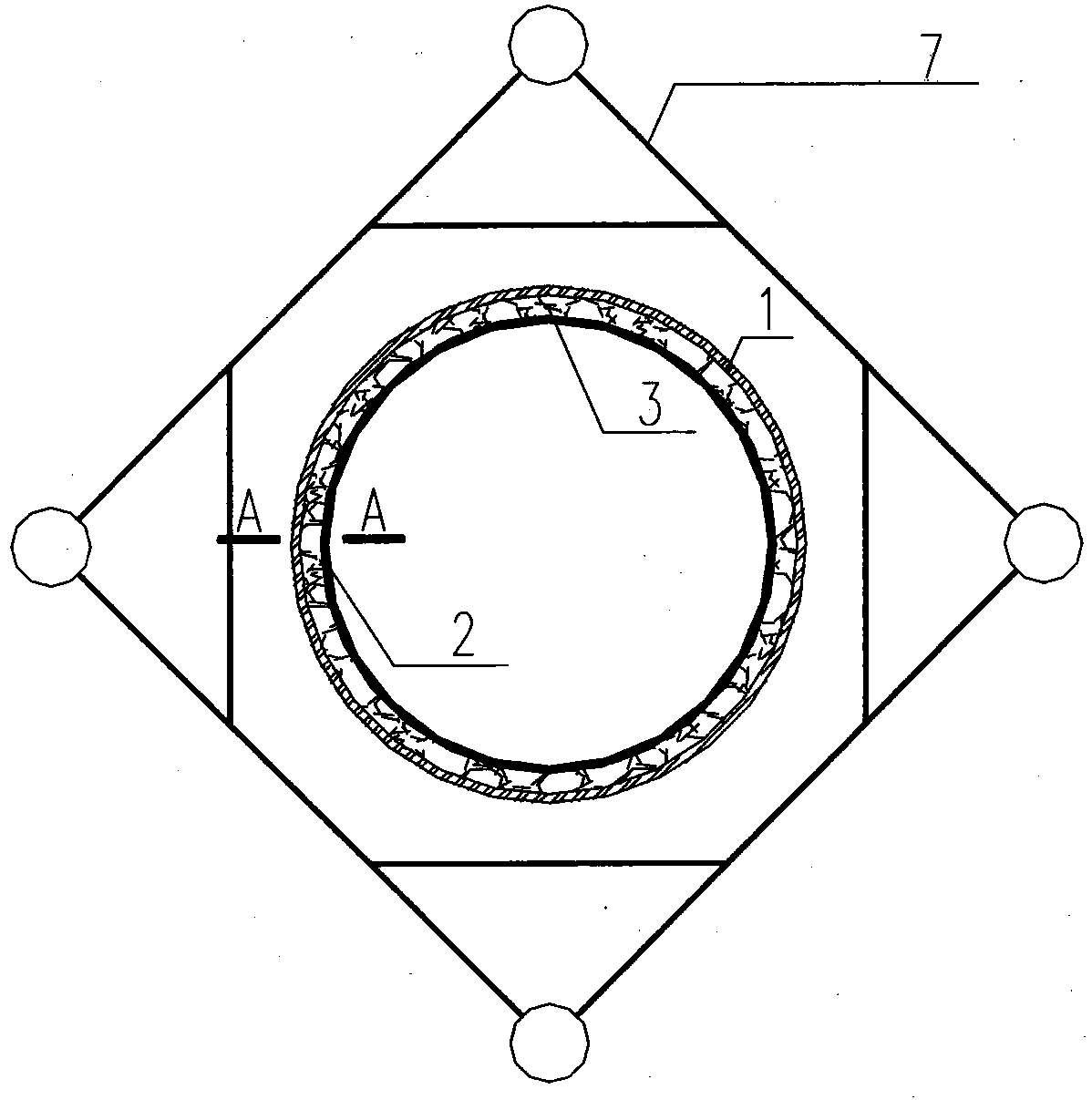

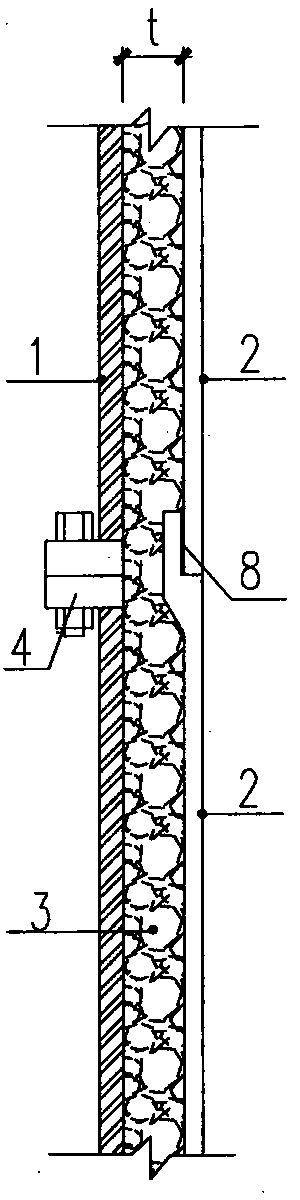

Reinforced plate type fire control joint structure for space structure

The invention relates to a reinforced plate type fire control joint structure for a space structure. Six I-shaped section beams are fixed between an upper joint plate and a lower joint plate. A chuck I is arranged in a female clamping groove at the first layer. A cylinder reinforcement ring II or a prism reinforcement ring II is arranged between the chuck I and the lower joint plate. A pipeline is fixed to one of the I-shaped section beams, and a sprayer head is arranged in an equipment hole II and connected with the pipeline; or, at least one chuck II is arranged in female clamping grooves at all layers between the female clamping groove at the second layer and the female clamping groove at the Nth layer. If one chuck II is adjacent to another chuck II, one cylinder reinforcement ring I or prism reinforcement ring I can be arranged. If the chucks II are adjacent to the upper joint plate, one cylinder reinforcement ring II or prism reinforcement ring II can be arranged. Precasting and connecting of sub-parts are simple, detailed design can be conducted in combination with the stress conditions to improve the bending moment and shearing force transmission capacity, space is reserved for passing of pipes through a non-closed web zone, and due to use of a built-in spraying facility, the service building occasions of an aluminum alloy net shell structure are widened.

Owner:HARBIN INST OF TECH

Zinc-aluminum-magnesium rare earth corrosion-resistant coating

InactiveCN102534305AImprove the effect of cathodic protectionReduce porosityMolten spray coatingRare earthZinc

The invention discloses a zinc-aluminum-magnesium rare earth corrosion-resistant coating, which contains the following components in percentage by weight: 5-23 percent of Al, 0.05-0.1 percent of Mg, 0.05-1 percent of rare earth metal RE and the balance of Zn. In the zinc-aluminum-magnesium rare earth corrosion-resistant coating, the rare earth metal RE is at least one of La and Ce. The zinc-aluminum-magnesium rare earth corrosion-resistant coating in accordance with the invention has wide application range, and meets the steel and iron corrosion resistance requirements under different environments; and brine corrosion resistance performance is over 2 times that of a pure zinc layer.

Owner:STATE GRID CORP OF CHINA +1

Heavy anti-corrosion clinkery epoxy powder coating

InactiveCN101857763AGood lookingMeet anti-corrosion requirementsAnti-corrosive paintsPowdery paintsEpoxyToughness

The invention relates to a heavy anti-corrosion clinkery epoxy powder coating, which comprises the following components in part by weight: 100 parts of epoxy resin, 20 to 30 parts of curing agent, 2 to 5 parts of flatting agent and 40 to 70 parts of filler. The heavy anti-corrosion clinkery epoxy powder coating is mainly applied in the field of pipeline corrosion prevention and has the advantages of high toughness, high impact resistance, simple preparation process and suitability for mass production.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

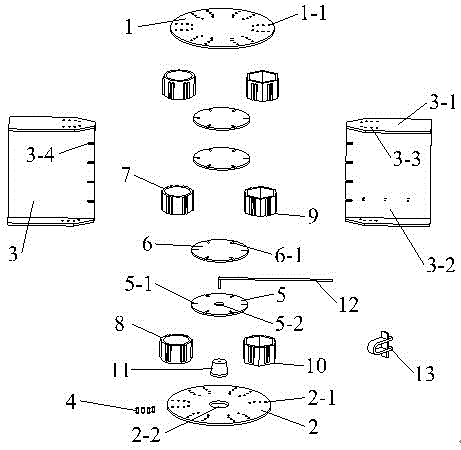

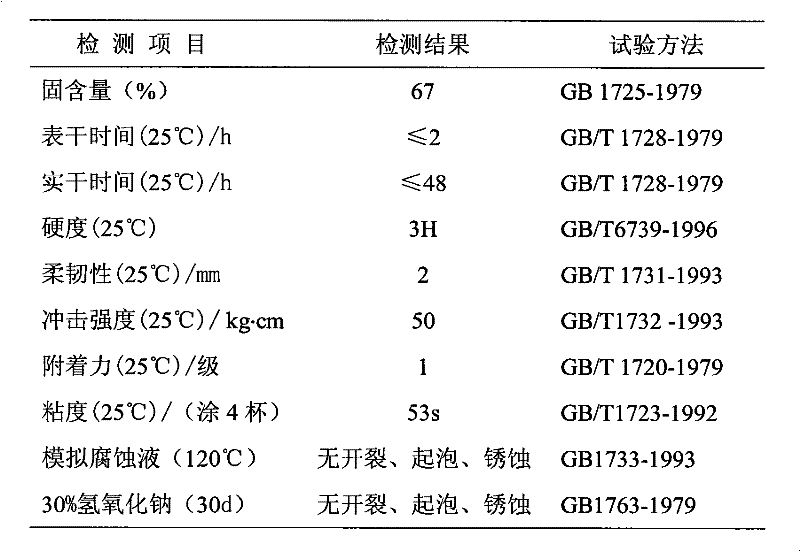

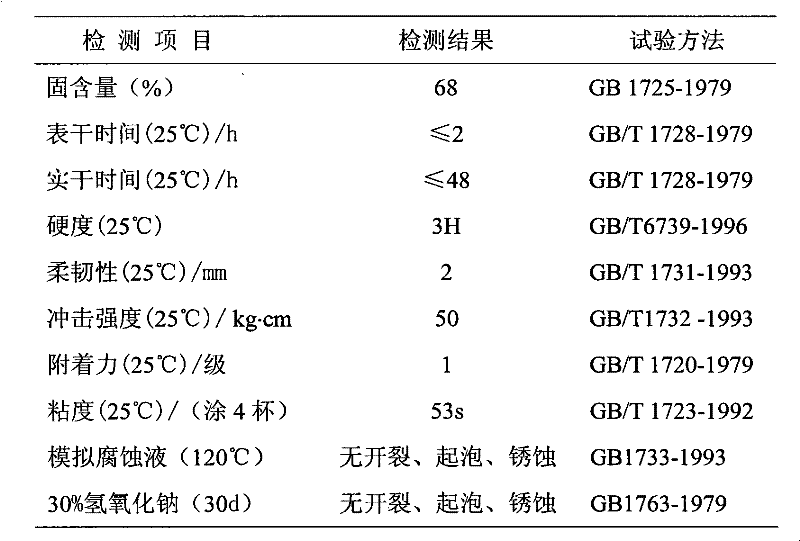

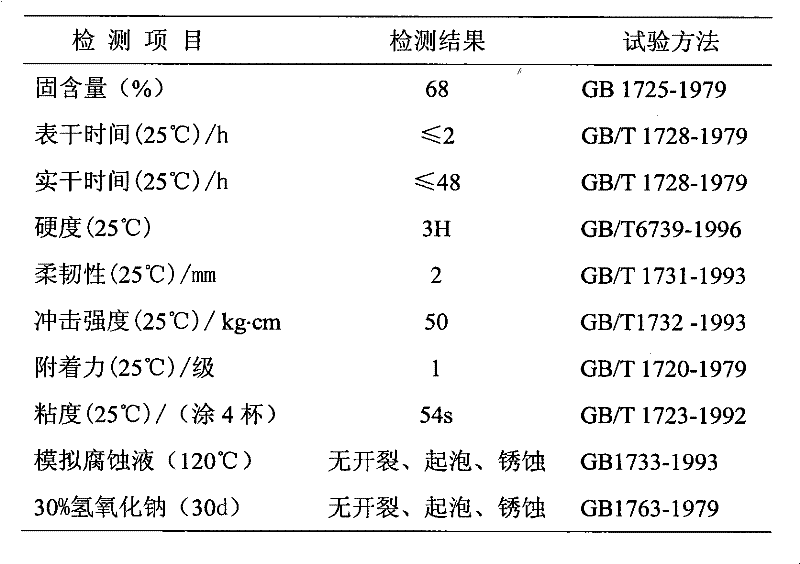

A kind of anti-corrosion coating for high temperature condensate recovery device

InactiveCN102260458AImprove mechanical propertiesAccelerated corrosionAnti-corrosive paintsEpoxyTalc

The invention provides a preparation method of an anticorrosion coating for a high-temperature condensate recovery device. The modified epoxy silicone resin is prepared by adding various pigments, fillers and additives at room temperature, and mixing it with a curing agent after fully stirring. It can be applied to hot water delivery pipes, and the inner wall of heat exchanger pipes is anti-corrosion. After the coating is tested periodically in condensed water at about 120°C, it shows good physical and mechanical properties and chemical corrosion resistance. The coating of the present invention comprises A and B components, and A component is made up of epoxy modified silicone resin, micaceous iron oxide ash, mica, talcum powder, zirconium dioxide, dispersant, defoamer, and B component is solidified In terms of coating mass percentage: epoxy modified silicone resin 30% to 50%, mica iron oxide ash 20% to 30%, mica 5% to 15%, talcum powder 2% to 8%, zirconium dioxide 5% to 10%, defoamer 0.1% to 0.4%, dispersant 0.2% to 0.5%, curing agent 3% to 10%.

Owner:BEIJING UNIV OF CHEM TECH

Chromium-free zinc-aluminum anticorrosive paint with phosphomolybdic acid hydrate as passivating agent

PendingCN109778159AMeet anti-corrosion requirementsImprove anti-corrosion performanceAnti-corrosive paintsMetallic material coating processesPhosphomolybdic acidChromium free

The invention discloses a water-borne chromium-free zinc-aluminum anticorrosive paint with phosphomolybdic acid hydrate as a passivating agent. The water-borne chromium-free zinc-aluminum anticorrosive paint with the phosphomolybdic acid hydrate as the passivating agent includes the following components, by mass, 250-310 parts of zinc powder, 10-30 parts of aluminum powder, 3-10 parts of the phosphomolybdic acid hydrate, 110-150 parts of polyethylene glycol, 70-140 parts of a silane coupling agent, 3-8 parts of 2-ethoxyethyl acetate, 1-18 parts of a surfactant, 1-6 parts of a defoaming agent,10-60 parts of tetraisopropyl titanate, 10-18 parts of boric acid and 380-480 parts of deionized water. The polyethylene glycol and the silane coupling agent being 35-50% of the total amount of formula, the 2-ethoxyethyl acetate, the surfactant and the defoaming agent are stirred to be made into an A component; the deionized water, the phosphomolybdic acid hydrate and the silane coupling agent inthe weight ratio and being 50-65% of the total amount of the formula, the tetraisopropyl titanate and the boric acid are stirred to be made into a B component; before use, the A component and the B component are mixed and stirred uniformly according to the weight ratio of 1:1-1.4, and the finished paint is prepared. The thermal stability of the prepared product of the water-borne chromium-free zinc-aluminum anticorrosive paint with the phosphomolybdic acid hydrate as the passivating agent is improved, and a coating after coating conforms to the comprehensive performance requirements of a thincoating, high adhesive strength, good anticorrosive performance and the like required by an automobile fastener.

Owner:沈阳市航达科技有限责任公司

Processing process for fresh-keeping fruit can

InactiveCN102485007AGuaranteed nutritional valueGood colorFruits/vegetable preservation by heatingPreservativeCitric acid

The invention relates to the field of can processing processes, and concretely relates to a processing process for a fresh-keeping fruit can. The processing process comprises the following steps: 1, raw material processing: cleaning a peeled fruit, and cutting the fruit into blocks; 2, thermal processing: blanching the well cut fruit with a proper shape in 80-110DEG C water for 5-10min, rapidly pulling out the fruit, and cooling the fruit in cold water; 3, preparing a liquid: fully dissolving 5-50 parts of a seasoning agent, 0.02-0.05 parts of an antiseptic and 0.2 parts of citric acid in 100 parts of water to form the seasoning liquid; 4, canning: canning the thermal processed fruit and the well seasoned seasoning liquid, and vacuum-sealing; and 5, disinfecting: disinfecting the vacuum-sealed can at 100DEG C for 20min, and rapidly cooling. According to the fruit can prepared with the process, the original brittleness and the original mouthfeel of the fruit are maintained, so compared with original processes, the process of the invention is improved

Owner:大连渴望科技发展有限公司

Method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes

ActiveCN102817038AGuaranteed StrengthSolve the mechanical propertiesFurnace typesHeat treatment furnacesInduction hardeningRebar

The invention relates to a method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes. The method includes the following steps of: subjecting a thread steel bar to multistage induction quenching heating, controlling the temperature of a quenching preheating zone at 700-850DEG C and the temperature of a quenching heat preservation zone at 820-950DEG C, and keeping the speed of quenching heating at 0.2-0.5m / min, then carrying out a quenching treatment, performing cooling at a cooling speed of 50-100DEG C / s, controlling the temperature of the thread steel bar released out of a spray ring cooling device at 60-100DEG C, then performing multistage induction tempering heating at a proceeding speed of 0.2-0.5m / min, controlling the tempering temperature at 500-650DEG C, delivering the tempered threaded steel bar to a surface coating zone to conduct heating blackening antiseptic treatment, implementing online packaging, and finally conducting offline storage. The technological method realizes on-line quenching and tempering, and heating blackening production of high-strength threaded steel bars, and has the characteristics of small deformation of workpieces, high production efficiency, energy saving, environmental protection, and less pollution, etc.

Owner:LIUZHOU OVM MASCH CO LTD

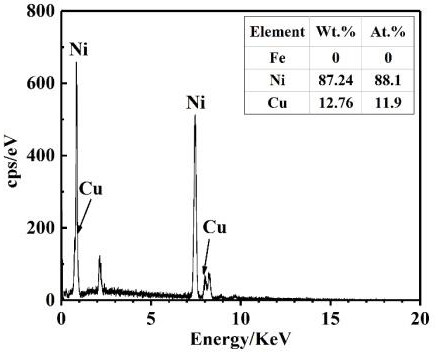

Method for preparing nickel-copper alloy plating layer on surface of carbon steel

The invention discloses a method for preparing a nickel-copper alloy plating layer on the surface of carbon steel. The method specifically comprises the following steps: (1) pretreatment, wherein a carbon steel workpiece is pretreated to obtain a carbon steel base material for later use; (2) preparation of an electroplating solution, wherein nickel sulfate, copper sulfate, trisodium citrate, boric acid, an additive and a brightener are dissolved in deionized water to prepare the electroplating solution for later use, and the concentrations of nickel sulfate, copper sulfate, trisodium citrate, boric acid, the additive and the brightener in the electroplating solution are 170-200 g / L, 5-20 g / L, 60-100 g / L, 10-25 g / L, 0.05-1 g / L and 0.1-1 g / L respectively; and (3) preparation of the nickel-copper alloy plating layer, wherein the carbon steel base material is immersed into the electroplating solution, the carbon steel base material serves as a cathode, one of monel alloy, pure nickel, graphite and pure copper serves as an anode, and electroplating deposition is conducted on the carbon steel base material to form the nickel-copper alloy plating layer. The nickel-copper alloy plating layer prepared through the method not only can effectively solve the problem of corrosion of a fluorine-making electrolytic cell made of carbon steel, but also has good thermal conductivity and strong binding force with the carbon steel base material.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Magnesium alloy surface chromium-free formation solution and processing technique thereof

InactiveCN101191206AMeet anti-corrosion requirementsReduce pollutionMetallic material coating processesChromium freeWorking temperature

The invention provides a non-chromium conversion solution for magnesium alloy surfaces which takes the water as the solvent. Each liter of the solution comprises: water-soluble cerium salt of 1 to 15g, nitrate of 2 to 12g and ammonium sulfate of 2 to 12g. For the process using the non-chromium formation solution to make surface treatment to the magnesium alloy, the process flow is as follows: degreasing, bath, acid activation, pure bath, surface conditioning, pure bath, conversion treatment, pure bath and drying; wherein, the concrete procedures of the conversion treatment in the process flow are that: the magnesium alloy workpiece made a pre-treatment is dipped into the non-chromium conversion solution for treatment, the working temperature of the workpiece is between 20 and 85 DEG C, the conversion treatment time is between 20 seconds to 5 minutes. With the non-chromium conversion solution for magnesium alloy surfaces of the invention and the conversion process thereof, the obtained membrane has good corrosion resistance, can meet the requirement of environmental protection, has low raw material cost, is simple and easy to obtain, has the formula without heavy metal ions and phosphor elements as well as simple waste water treatment.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Preparation method of wear-resistant toughened anticorrosive adhesive

InactiveCN104845569AImprove adhesionImprove wear resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesViscous liquidEpoxy

The invention discloses a preparation method of a wear-resistant toughened anticorrosive adhesive. The anticorrosive adhesive is a light grey viscous liquid, and is prepared from an epoxy resin (or polyurethane), vulcanized rubber, acetone (or xylene), a phenolic resin (or fatty acid diethylenetriamine), polyisobutylene, polymerized rosin, an antioxidant 1010 and mica iron oxide (alpha-Fe2O3) according to certain proportion. The novel anticorrosive adhesive has the advantages of high vertical attachment peel strength, water resistance, heat resistance, impact resistance, corrosion resistance and simple construction technique, can be cured to form a film at normal temperature, is suitable for corrosion resistance of steam condenser copper pipe ends and seepage prevention of copper pipe expanded openings, and can also be used for corrosion resistance and seepage prevention of similar equipment.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

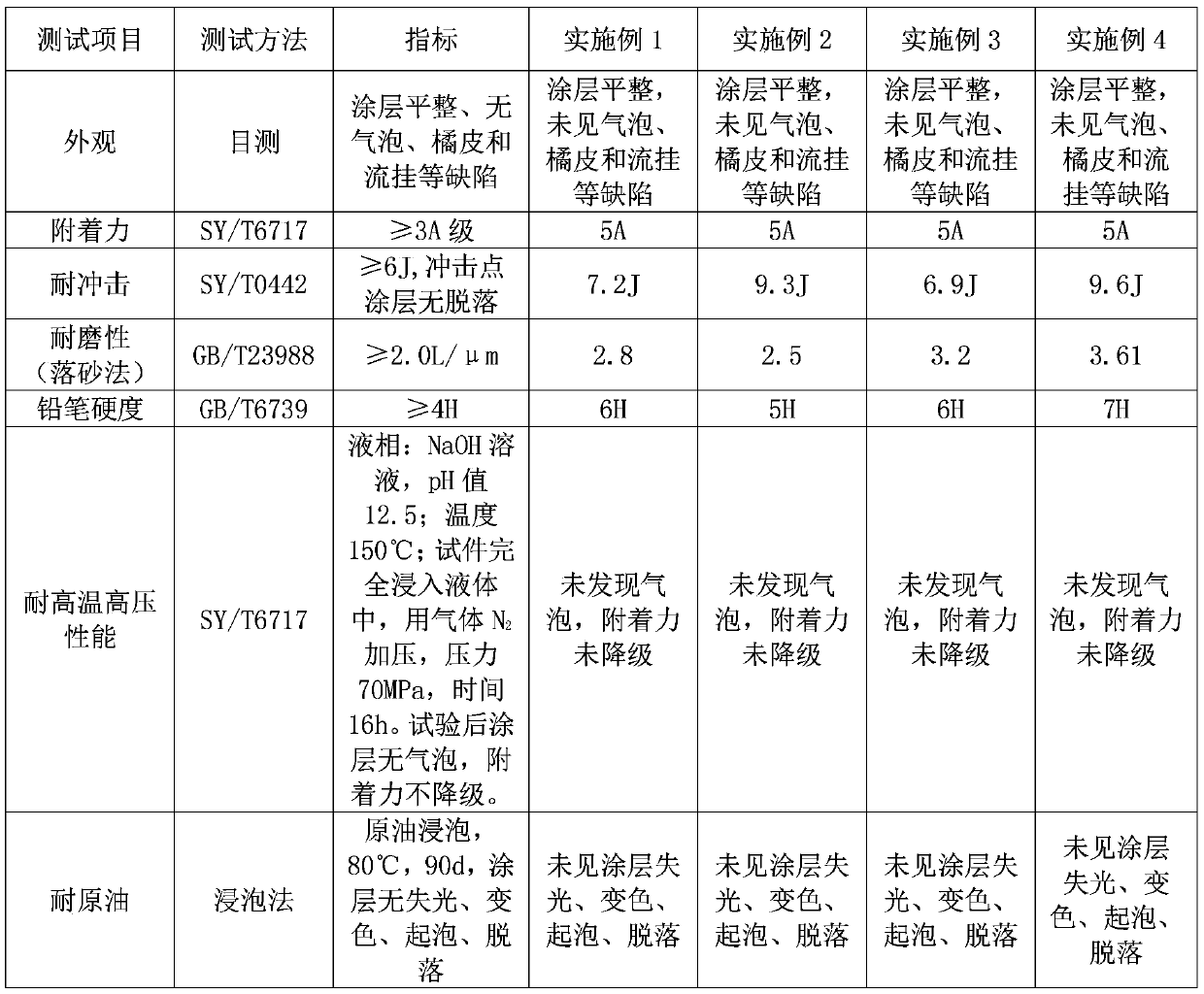

Corrosion-resistant and high-temperature-resistant anticorrosive powder coating in steel pipeline for oil field water injection well

ActiveCN110283517AImprove water resistanceImprove heat resistanceFireproof paintsPowdery paintsPliabilitySteel pipeline

The invention provides a corrosion-resistant and high-temperature-resistant anticorrosive powder coating in a steel pipeline for an oil field water injection well. The coating is prepared from the following components in parts by weight: 35-60 parts of bisphenol A epoxy resin, 20-35 parts of alicyclic epoxy resin, 20-35 parts of a curing agent, 10-20 parts of feldspar powder, 5-10 parts of barium sulfate, 10-30 parts of mica powder, 20-50 parts of a high-temperature-resistant and corrosion-resistant material, 0.8-3 parts of an acrylate copolymer leveling agent, 0.5-3 parts of a curing accelerator, 0.5-2 parts of an antifoaming agent, and 1-3 parts of a wetting agent. The coating is prepared by adopting non-toxic and harmless raw materials. Main film-forming materials are prepared by adopting the bisphenol A epoxy resin to be matched with the alicyclic epoxy resin; a certain flexibility is achieved while excellent water resistance, heat resistance, and corrosion resistance are achieved.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

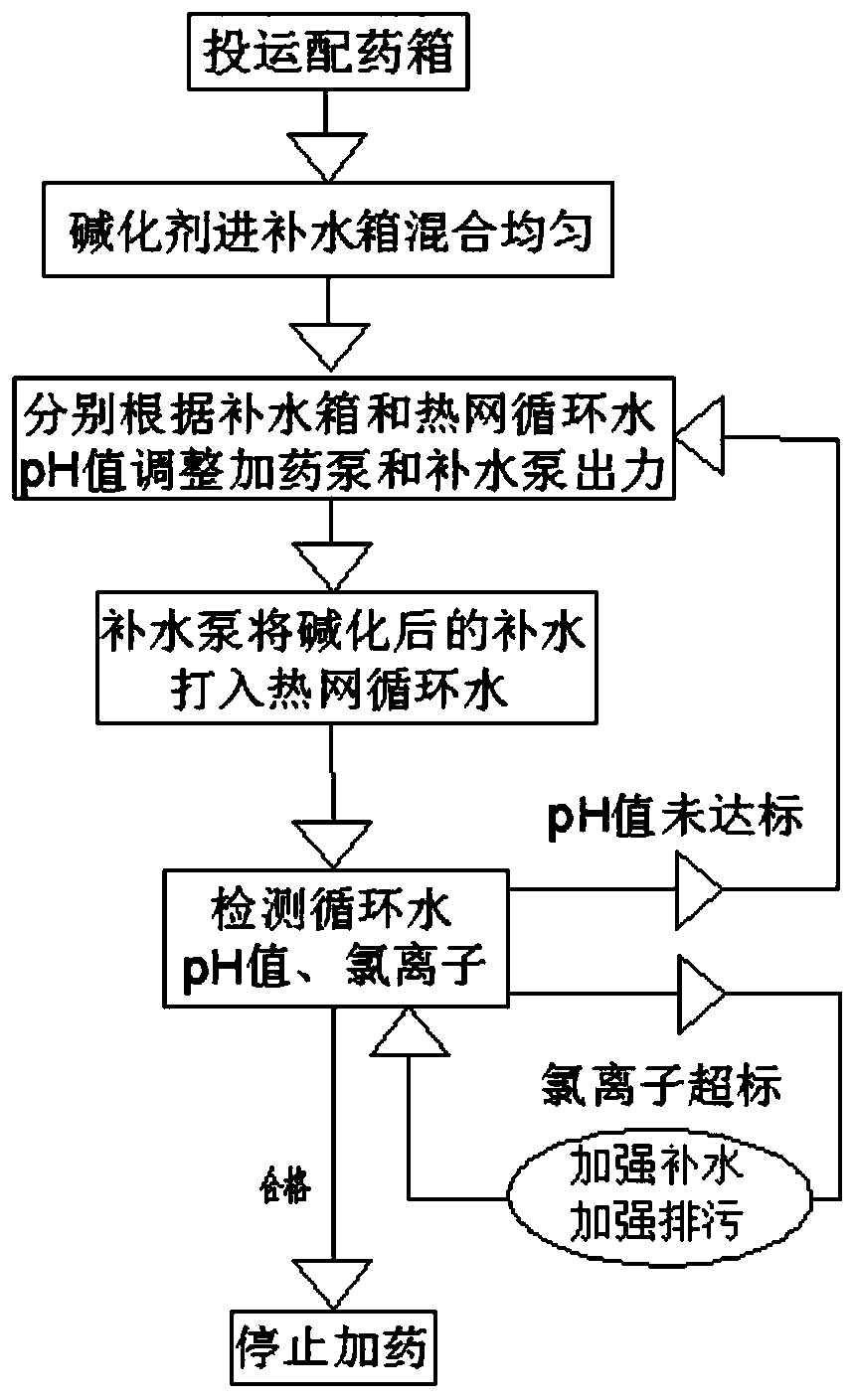

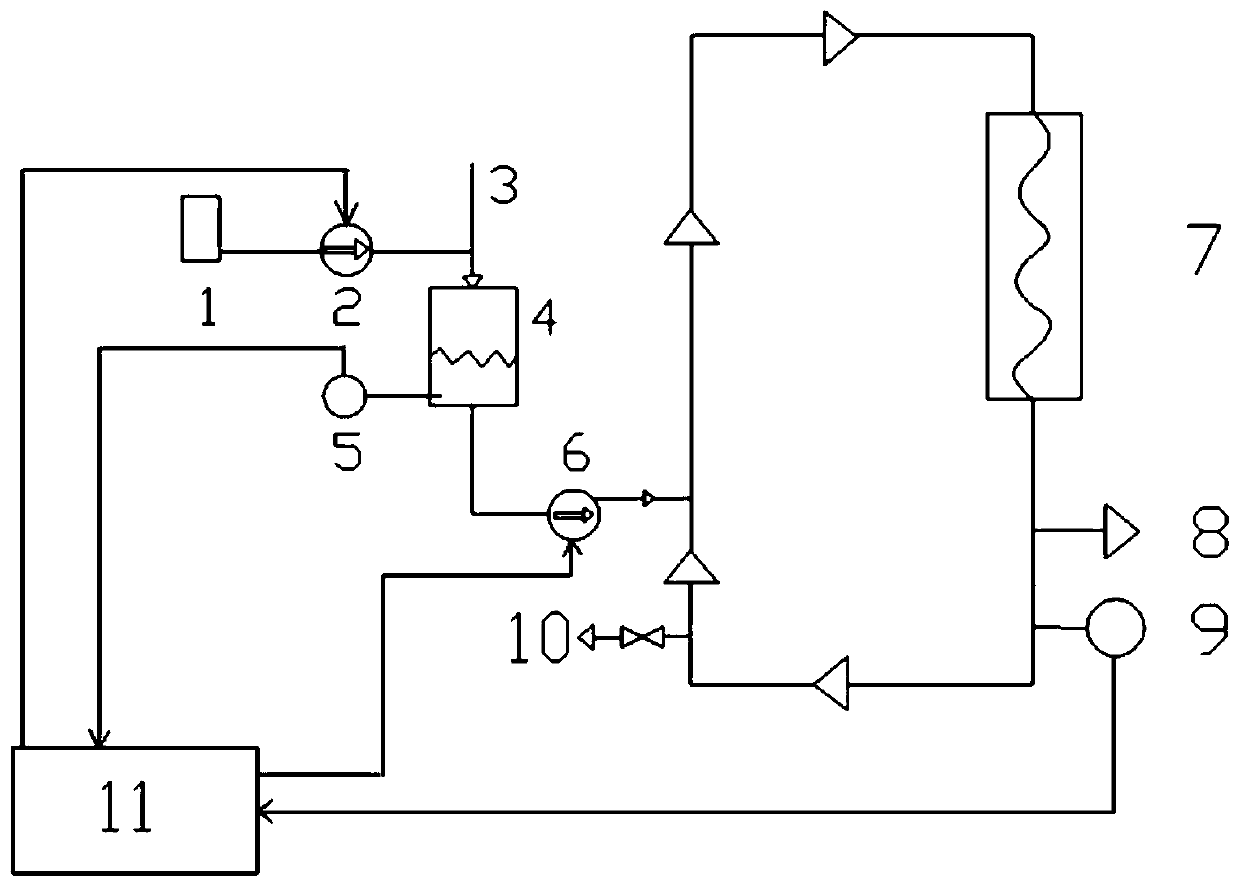

Monitoring and controlling method and device for corrosion resistance of heat supply network circulating water system

The invention provides a monitoring and controlling method and device for corrosion resistance of a heat supply network circulating water system. The device comprises an agent adding system, a detection system and a controller. The agent adding system comprises an agent preparing box and an agent adding pump which are sequentially connected. The agent adding pump is a frequency variable speed regulating pump, and the output end of the agent adding pump is connected to a heat supply network circulating water replenishing pipeline. An alkalizer solution is contained in the agent preparing box. The detection system comprises a water replenishing box online pH meter and a heat supply network circulating water online pH meter. The replenishing box online pH meter is arranged on a water replenishing box of the heat supply network circulating water system. The input end of the water replenishing box is connected with the heat supply network circulating water replenishing pipeline, and the output end of the water replenishing box is connected to a circulating water way pipeline of the heat supply network circulating water system through a heat supply network circulating water replenishingpump. The heat supply network circulating water online pH meter is arranged on the circulating water way pipeline of the heat supply network circulating water system. The input end of the controller is connected with the output ends of the water replenishing box online pH meter and the heat supply network circulating water online pH meter, and the output end of the controller is connected with theagent adding pump and the heat supply network circulating water replenishing pump.

Owner:XIAN THERMAL POWER RES INST CO LTD

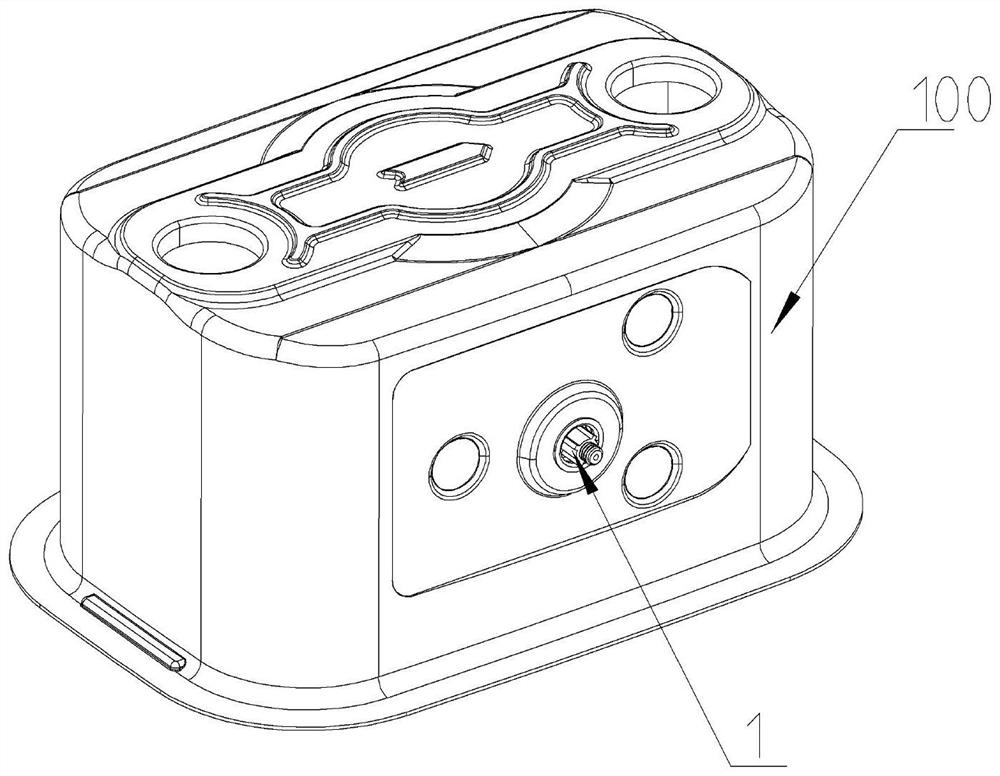

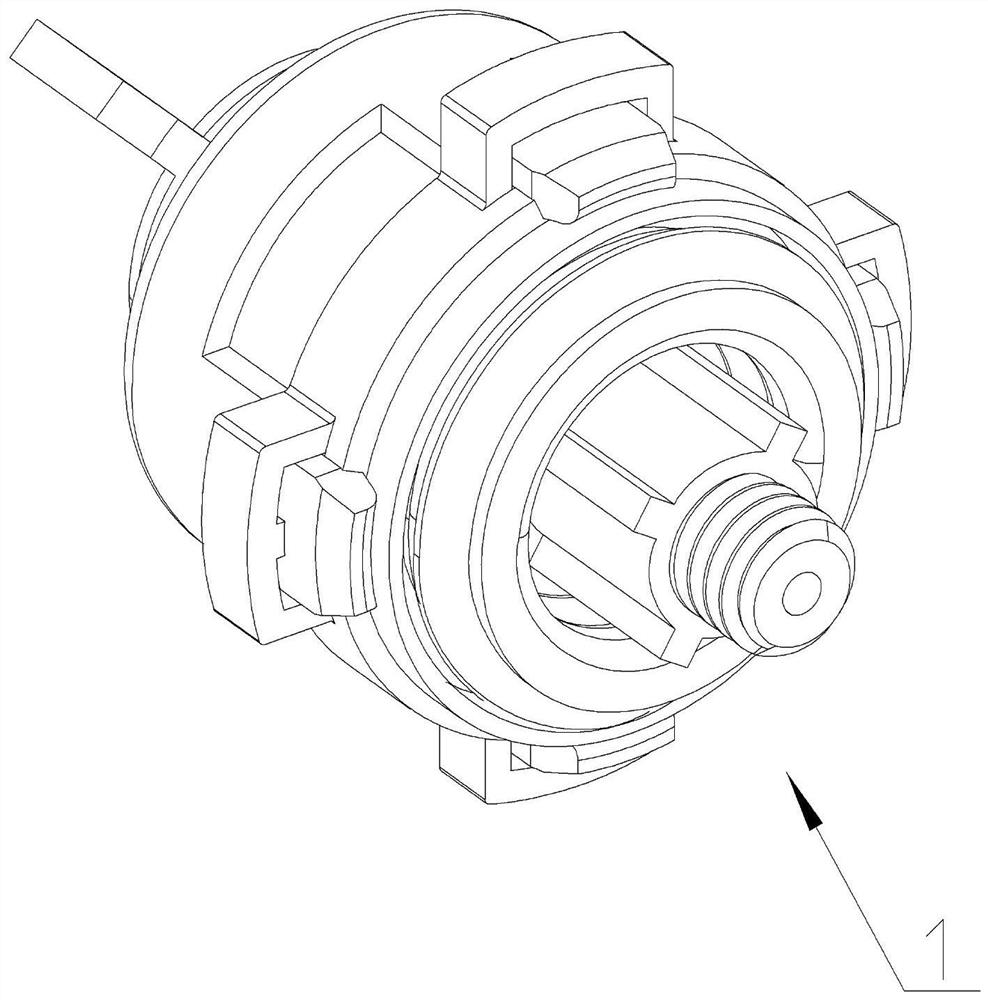

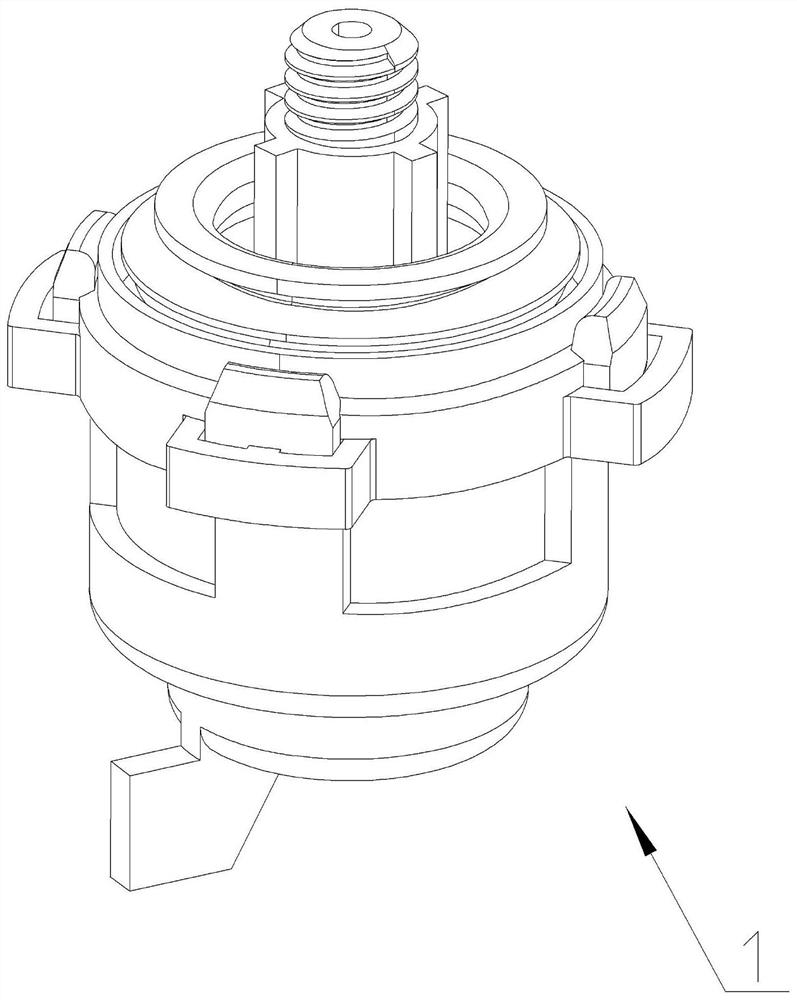

Small magnetic transmission structure of diaphragm gas meter

PendingCN113932871AReduce the size of the magnetic transmissionLow costVolume meteringNeodymium iron boronMagnetic tension force

The invention relates to the field of gas meters, and particularly discloses a small magnetic transmission structure of a diaphragm gas meter. The small magnetic transmission structure comprises a sealing gasket, a shaft sleeve, an outer magnetic set and an inner magnetic set, the inner magnetic set is located on the inner side of the shaft sleeve, the outer magnetic set is located on the outer side of the shaft sleeve, the outer magnetic set comprises a first outer magnetic sleeve, a second outer magnetic sleeve and an outer magnet, the outer magnet is an annular cylinder, and the first outer magnetic sleeve and the second outer magnetic sleeve are respectively clamped at two ends of the outer magnet; the inner magnetic set comprises a first inner magnetic sleeve, a second inner magnetic sleeve and an inner magnet, the inner magnet is also an annular cylinder, and the first inner magnetic sleeve and the second inner magnetic sleeve are clamped to the two ends of the inner magnet respectively; and the outer magnet is made of a ferrite material, and the inner magnet is made of a neodymium iron boron material with stronger magnetic force. The magnetic transmission structure with the inner magnet made of the neodymium iron boron and the outer magnet still made of the ferrite material is adopted, the torque required by magnetic transmission and the transmission space requirement of the small diaphragm gas meter can be met, the ferrite material is reserved in the outer magnet, and the material cost of the outer magnet can be reduced by reducing the size of the outer magnet.

Owner:QIANWEI KROMSCHRODER METERS CHONGQING

Method for reinforcing rectangular wood column by pasting angle steel

InactiveCN104141393AImprove bearing capacityImprove ductilityStrutsBuilding repairsCorrosionBearing capacity

A method for reinforcing a rectangular wood column by pasting angle steel comprises the steps of wood column processing, angle steel pasting and steel batten plate welding. The angle steel is pasted to the angle portion of the wood column, a steel batten plate is welded in the height direction, the bearing force and the ductility of the wood column can be effectively improved, and meanwhile the requirements for reinforcing and repairing for corrosion resisting and durability are met.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

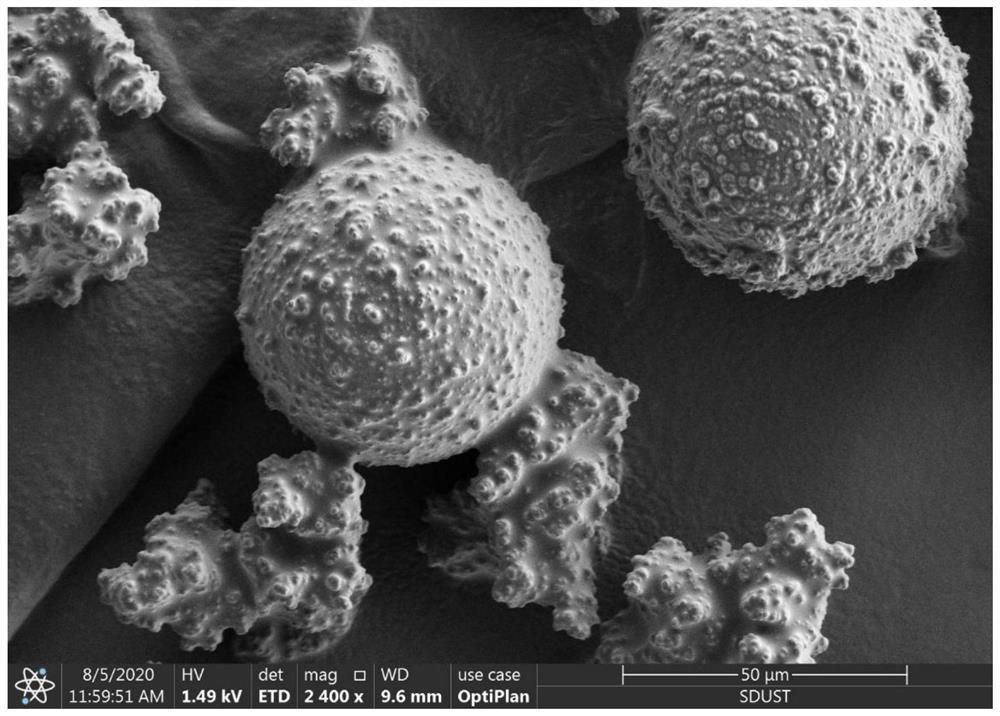

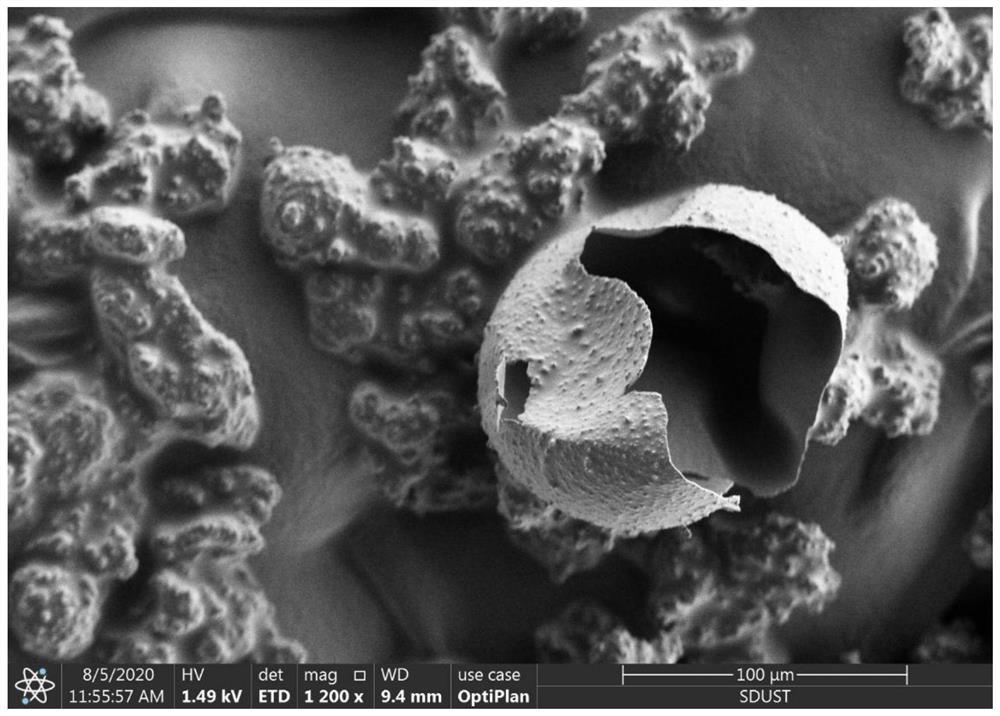

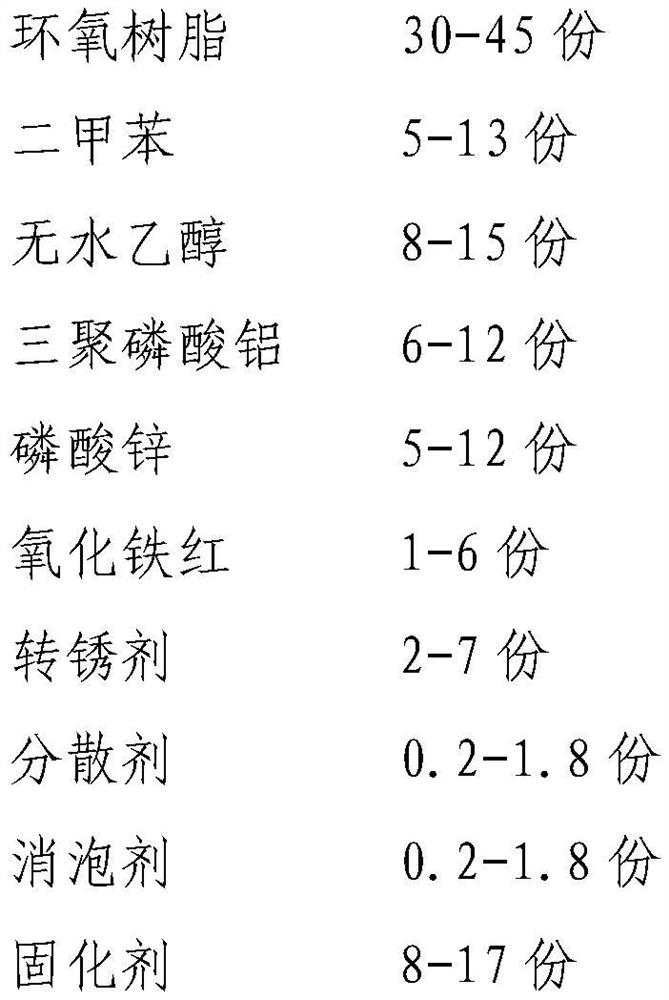

Self-repairing conversion permeation type antirust coating based on rusty matrix and preparation method thereof

InactiveCN111995929AExtended service lifeMeet anti-corrosion requirementsAnti-corrosive paintsMicroballoon preparationChemistryCoating

The invention discloses a self-repairing conversion penetration type antirust coating based on a rusty matrix and a preparation method thereof. The self-repairing conversion penetration type antirustcoating is composed of an antirust primer and self-repairing microcapsules. The coating has permeation and self-repairing effects, eleostearic acid contained in the tung oil in the capsule core of theself-repairing microcapsule can also play a role in converting a rust layer, and therefore the purpose of self-repairing of the antirust coating is further achieved on the basis of inheriting the advantages of permeation type and conversion type antirust coating for a rusty matrix.

Owner:SHANDONG UNIV OF SCI & TECH

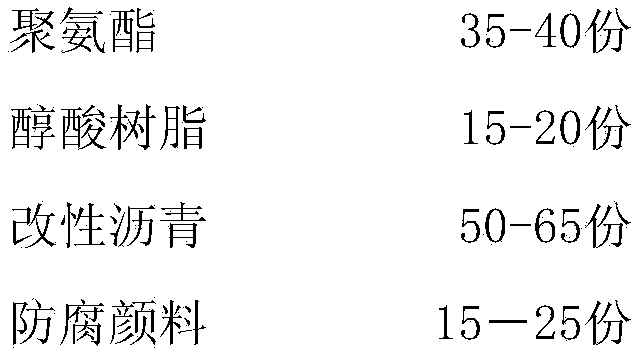

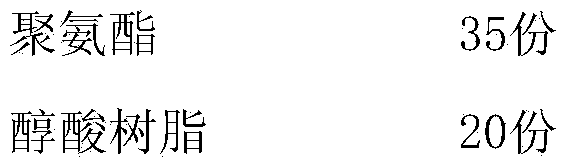

Efficient polyurethane asphalt anticorrosive coating

InactiveCN103436172AMeet the anti-corrosion requirements of the baseMeet anti-corrosion requirementsAnti-corrosive paintsPolyurea/polyurethane coatingsAdhesion forcePolyolefin

The invention provides an efficient polyurethane asphalt anticorrosive coating which is prepared from polyurethane, alkyd resin, modified asphalt, anticorrosive pigment and gallotannic acid in parts by weight. According to the invention, the idea of adding polyolefins modified asphalt into a polyurethane coating system to improve the surface elasticity of a coating film of the coating, high-and-low-temperature resistant transforming ability and the like is innovatively proposed, the preservation time of a product is as long as to be up to or even more than 5 years, meanwhile, composited zinc sulfate with a good anticorrosive property is taken as the anticorrosive pigment, the composited zinc sulfate takes part in transforming the slight corrosion, so that the tolerance of the coating on a base material and the adhesion force of the paint film are increased, furthermore, the gallotannic acid capable of reacting with a base material steel is added, so that the labor intensity is reduced, the rust adhered to the surface is removed, and the adhesion force of the paint film is increased.

Owner:TIANCHANG JULONG TRAVEL PAINT

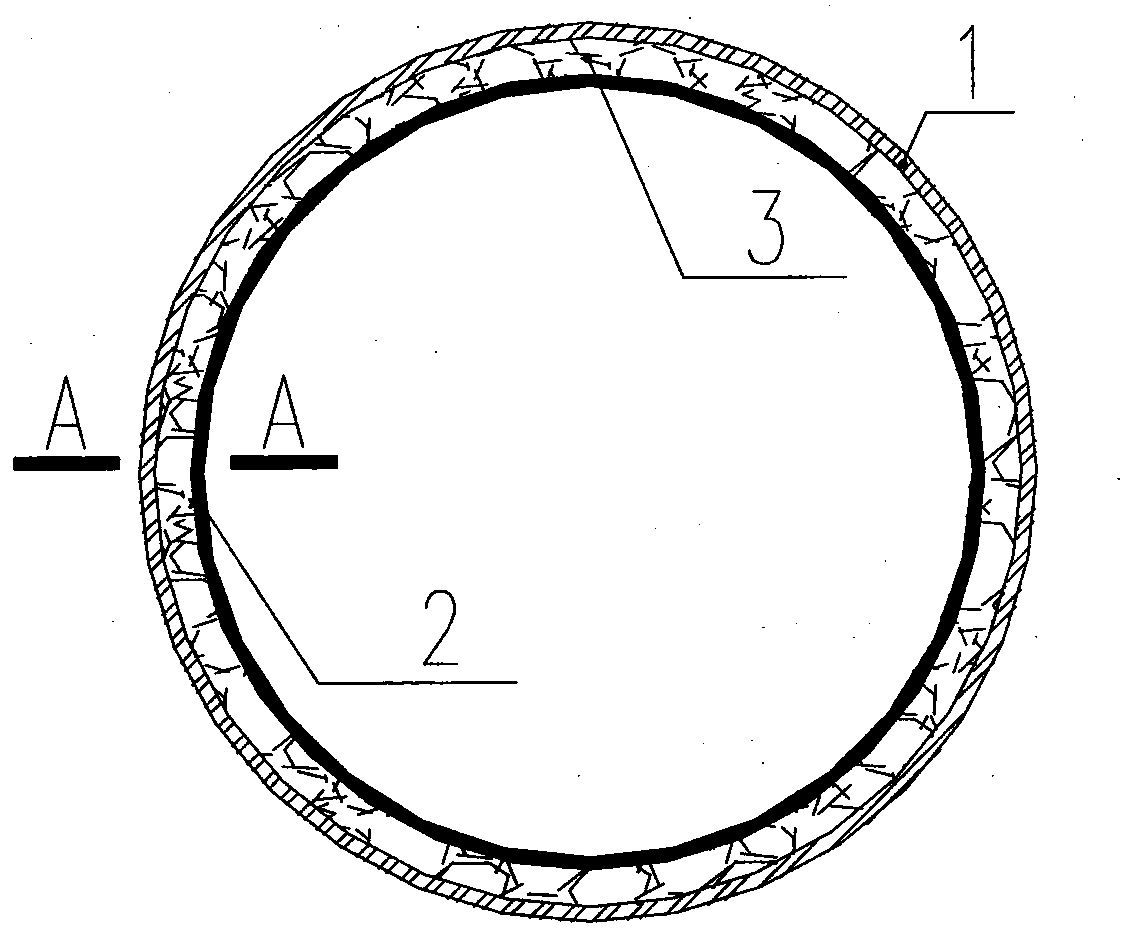

Steel-fiberglass composite smoke discharging facility

The invention discloses a steel-fiberglass composite smoke discharging facility. The steel-fiberglass composite smoke discharging facility is characterized in that the steel-fiberglass composite smokedischarging facility comprises a steel outer cylinder and a fiberglass inner cylinder which are different in diameter, the fiberglass inner cylinder is arranged in the steel outer cylinder matched with the fiberglass inner cylinder, and a bearing ring is arranged on the steel outer cylinder; and the bottom of the fiberglass inner cylinder is arranged on the bearing ring, and the steel outer cylinder and the fiberglass inner cylinder are connected in a composite mode through a polymer foaming material. According to the steel-fiberglass composite smoke discharging facility, the structure is simple, joint stress can be achieved, the structure strength requirement is met, and meanwhile the anti-corrosion requirement is met; good heat-preservation performance is achieved, and a heat-preservation layer does not need to be additionally arranged; and the steel-fiberglass composite smoke discharging facility is specially suitable for transformation of an existing steel inner cylinder chimney,the anti-corrosion purpose is achieved by utilizing the existing structure under the premise that the existing steel inner cylinder is not dismounted, thus the engineering manufacturing cost can be greatly reduced, and economic benefits are remarkable.

Owner:上海必立结构设计事务所有限公司

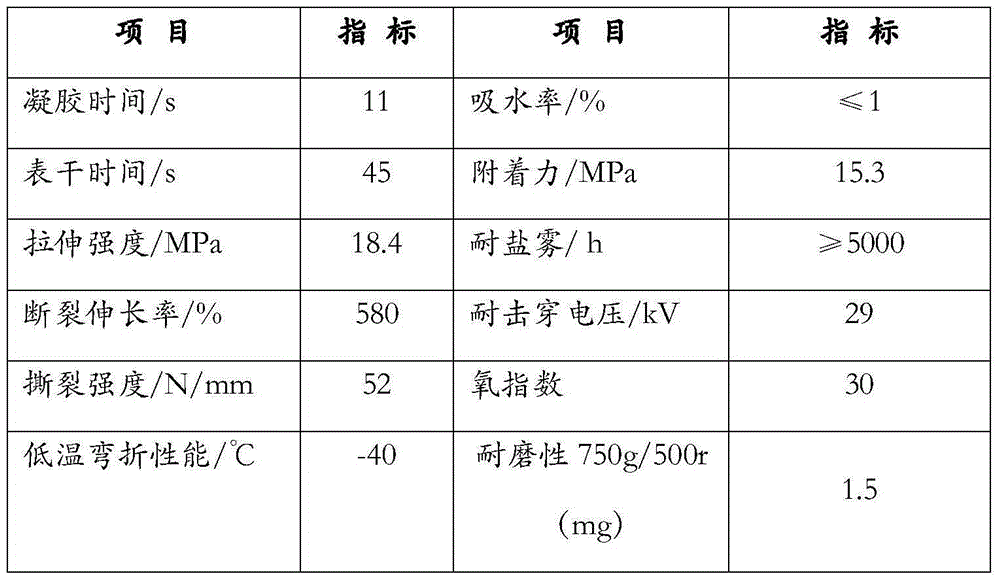

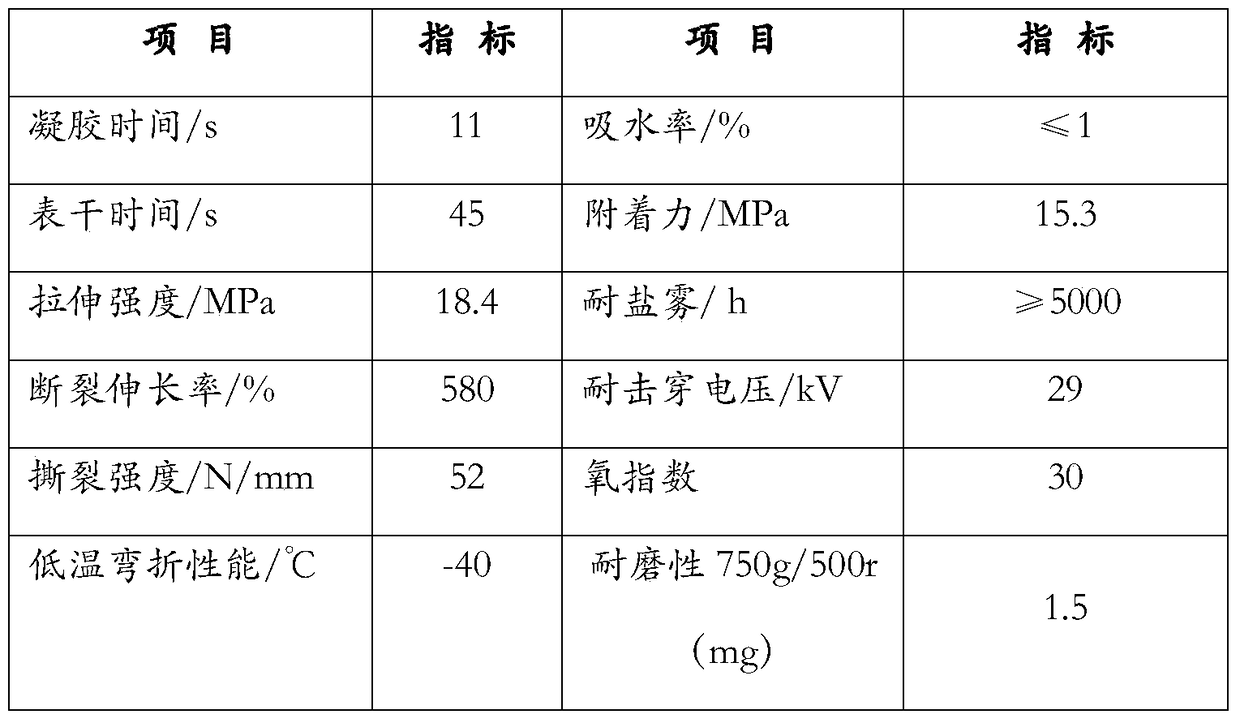

A kind of spray polyurea elastomer and preparation method thereof

ActiveCN105038546BImprove corrosion resistanceMeet anti-corrosion requirementsPolyurea/polyurethane coatingsElastomerPolyol

The invention discloses a spray polyurea elastomer and a preparation method thereof. The spray polyurea elastomer comprises a component A and a component B, wherein the volume ratio of the component A to the component B is 1: 1; the component A is isocyanate prepolymer compounded through the reaction of polyether polyol, fluorine-containing polyol, and isocyanate, and the -NCO content is 12%-20%; the component B comprises the followings in parts by weight: 30-50 parts of amine-terminated polyether, 30-45 parts of a chain extender, 0.5-1.0 part of fumed silica, 0.1-0.5 part of a dispersing agent, 0.5-1.0 part of a defoaming agent and 1.0-5.0 parts of color paste. The polyurea elastomer provided by the invention is excellent in weather resistance, resistance to chemical reagents and fire resistance and good in abrasion resistance.

Owner:QINGDAO AIR NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com