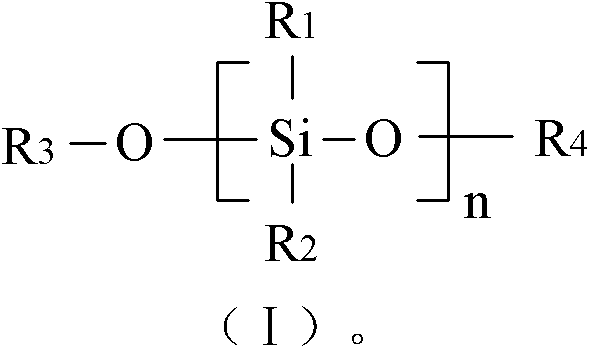

Epoxy-polysiloxane resin for paint and preparation method thereof

A technology of polysiloxane resin and polysiloxane, which is applied in the direction of epoxy resin coating, coating, etc., can solve the problems of poor compatibility, large difference in solubility parameters, unstable product performance, etc., and achieve compatibility Good, good storage stability, excellent storage stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

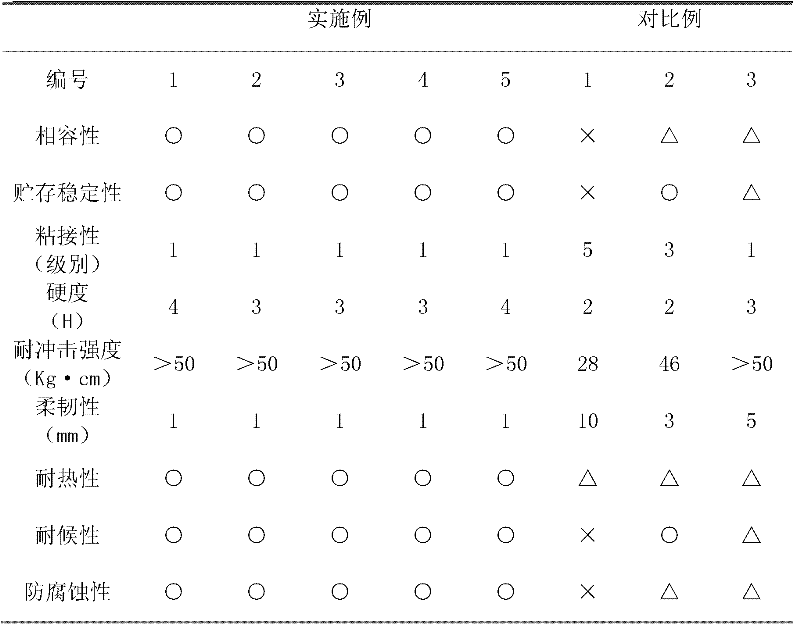

Examples

Embodiment 1

[0026] A kind of preparation method of epoxy-polysiloxane resin for coating, it comprises the steps:

[0027] 40g hydrogenated bisphenol A epoxy resin JET-300 (epoxy equivalent 230g / eq, Jiangshan Jianghuan Chemical Industry Co., Ltd.) and 160g methoxyl-containing polysiloxane DC-3074 (molecular weight 1400, U.S. Dow Corning Corporation) Placed in a three-necked flask, under N 2 Stir under protection and heat up to 80°C, then add 10g of dibutyltin dilaurate dropwise, continue to heat up to 140°C, stir at constant temperature for 4 hours, and after cooling, an epoxy-polymer for coatings with good compatibility and excellent storage stability can be obtained. Silicone resin. The experimental results are shown in Table 1.

[0028] The epoxy-polysiloxane resin for coating is applied to prepare epoxy-polysiloxane coating composition. Preparation of epoxy-polysiloxane coating composition: Component A: Add 100 g of the above-mentioned epoxy-polysiloxane resin, 15 g of banana water,...

Embodiment 2

[0030] A kind of preparation method of epoxy-polysiloxane resin for coating, it comprises the steps:

[0031] 160g of hydrogenated bisphenol A epoxy resin ST-3000 (epoxy equivalent 240g / eq, Dongdu Kasei, Japan) and 40g of methoxy-containing polysiloxane DC-3074 (molecular weight 1400) were placed in a three-necked flask. N 2Stir under protection and heat up to 80°C, then add 1g of dibutyltin dilaurate dropwise, continue to heat up to 140°C, stir at constant temperature for 4 hours, and after cooling, an epoxy-polymer for coatings with good compatibility and excellent storage stability can be obtained. Silicone resin. The experimental results are shown in Table 1.

[0032] The epoxy-polysiloxane resin for coating is applied to prepare epoxy-polysiloxane coating composition. Preparation of epoxy-polysiloxane coating composition: Component A: Add 100 g of the above-mentioned epoxy-polysiloxane resin, 25 g of banana water, and 2 g of leveling agent (Levelol 835) to a beaker in ...

Embodiment 3

[0034] A kind of preparation method of epoxy-polysiloxane resin for coating, it comprises the steps:

[0035] Put 100g ST-3000H (hydrogenated bisphenol A epoxy resin, epoxy equivalent 205g / eq, Japan Toto Kasei) and 100g DC-3037 (methoxyl-containing polysiloxane, molecular weight 1000, American Dow Corning) in three ports flask, in N 2 Stir under protection and heat up to 80°C, then add 5g of stannous octoate dropwise, continue to heat up to 140°C, stir at a constant temperature for 4 hours, and obtain an epoxy-polysiloxane for coatings with good compatibility and excellent storage stability after cooling alkane resin. The experimental results are shown in Table 1.

[0036] The epoxy-polysiloxane resin for coating is applied to prepare epoxy-polysiloxane coating composition. Preparation of epoxy-polysiloxane coating composition: Component A: Add 100 g of the above-mentioned epoxy-polysiloxane resin, 20 g of banana water, and 1 g of leveling agent (Levelol 835) to a beaker in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com