Flexible tube type cut-off valve capable of being used in flexible tube solid-liquid processing device

A technology for liquid treatment and globe valves, which is applied in the field of globe valves and flexible tubular globe valves, and can solve problems affecting filtration, pressing, heating and drying speed, valve stem leakage, and lax closure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

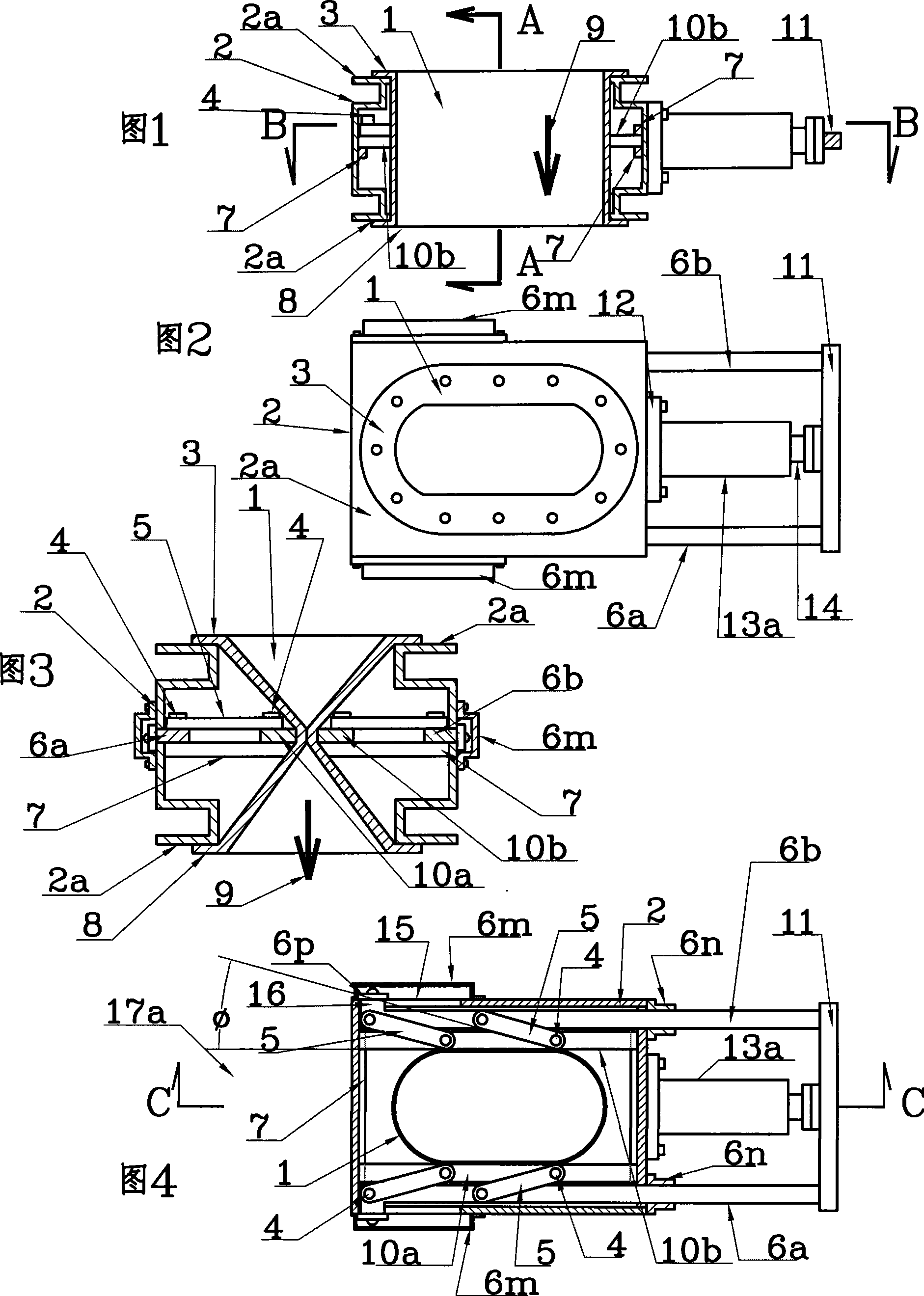

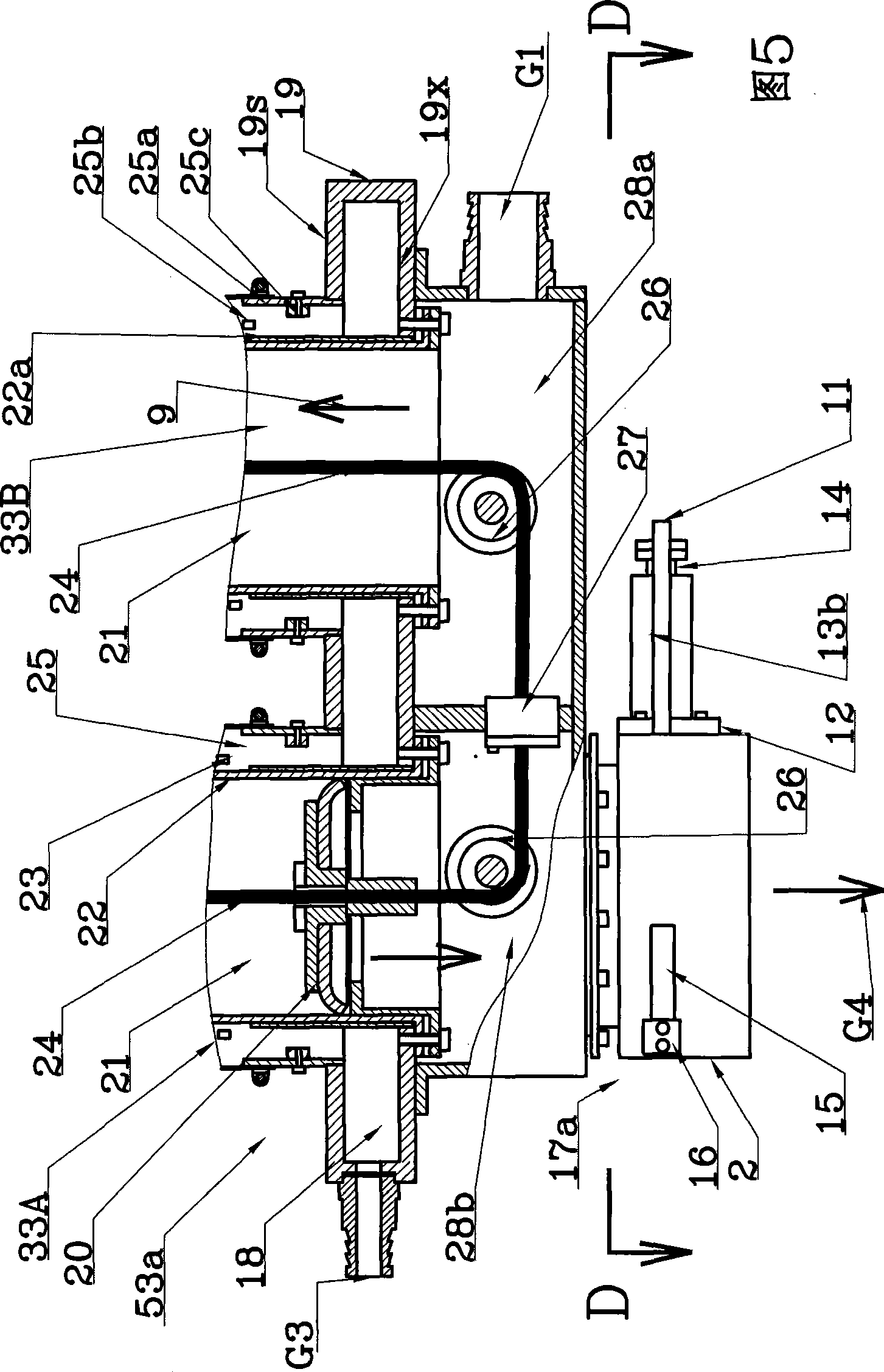

[0042] The flexible tubular stop valve in this embodiment can be used in a common pipeline system. Figures 1, 2 and 4 show the open state of the flexible tubular stop valve, and Figure 3 shows the closed state. The flexible tubular globe valve includes a valve housing 2, a reciprocating actuator 13, a wafer connecting rod mechanism and a flexible pipe chamber 1; the valve housing 2 is a rectangular valve mechanism cavity connected by rigid wall plates in the flow direction 9 of the filter slurry. A flexible tube chamber 1 is provided in the valve housing 2. The flexible tube chamber 1 is a pipe made of flexible material. The pipe axis of the flexible tube chamber is consistent with the axis through which the filter slurry flows in the cavity of the valve mechanism. The flexible tube chamber 1 The upper and lower ends of the valve are respectively provided with flanges 3 and 8, the flanges are pressed on a rigid ring frame, which is a closed flange 2a formed by the upper and lower ...

Embodiment 6

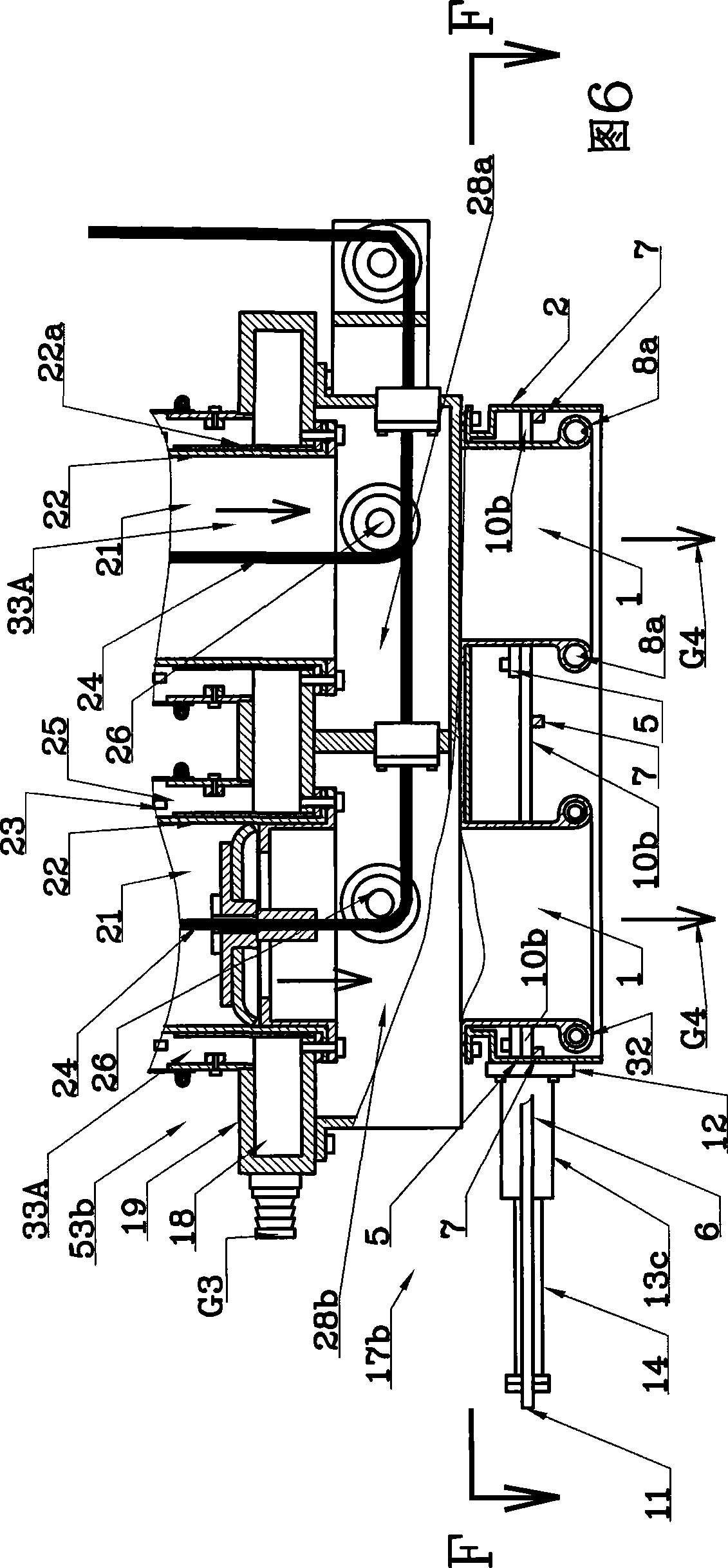

[0054] In Figure 15, there is shown Embodiment 6 of the membrane module of the present invention. The main difference between this embodiment and Embodiment 2 lies in the fact that the flexible pipe-type globe valve is installed side by side in series by using flange 2a and cable traction mechanism 32. Membrane module 53d (see the embodiment of Figure 7 in the application number 200710149861.6 in the "Flexible tube side-by-side series high-speed, high-pressure pressing and drying solid-liquid treatment device") of the membrane module 53d (see the connection channel 28b of the outlet of the lower flange chamber 19 of the membrane unit 33A) On the lower flange. The guide shaft 69 of the cable traction mechanism 32 is as short as possible, and the traction cable 24 in the membrane unit 33A is guided by two intermediate pulleys 26 and connected to the traction guide pulley 67a.

Embodiment 7

[0055] In FIG. 16, there is shown the embodiment 7 of the membrane module of the present invention. The difference between this embodiment and the embodiment 6 is mainly that: a membrane unit 33A of the filter residue of the membrane modules 53e connected in series adopts a flexible tube type The 17f scheme of the lower flange chamber of the shut-off valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com