Method for reinforcing rectangular wood column by pasting angle steel

A technology of wood column and angle steel, which is applied to the field of reinforced rectangular wood column by sticking angle steel, can solve the problems of uncertainty and randomness of repair results, and achieve the effect of improving bearing capacity and ductility, and meeting the requirements of anti-corrosion and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Take two square wooden columns made of Douglas fir, both with a side length of 200mm and a height of 650mm. One as an unreinforced comparison specimen;

[0023] The other is reinforced and repaired with the patented solution of the present invention: the angle steel is an equilateral angle steel with a specification of 50mm×3mm, the length, height and thickness of the steel panels are 200mm, 50mm and 3mm respectively, and the distance along the height direction is 400mm.

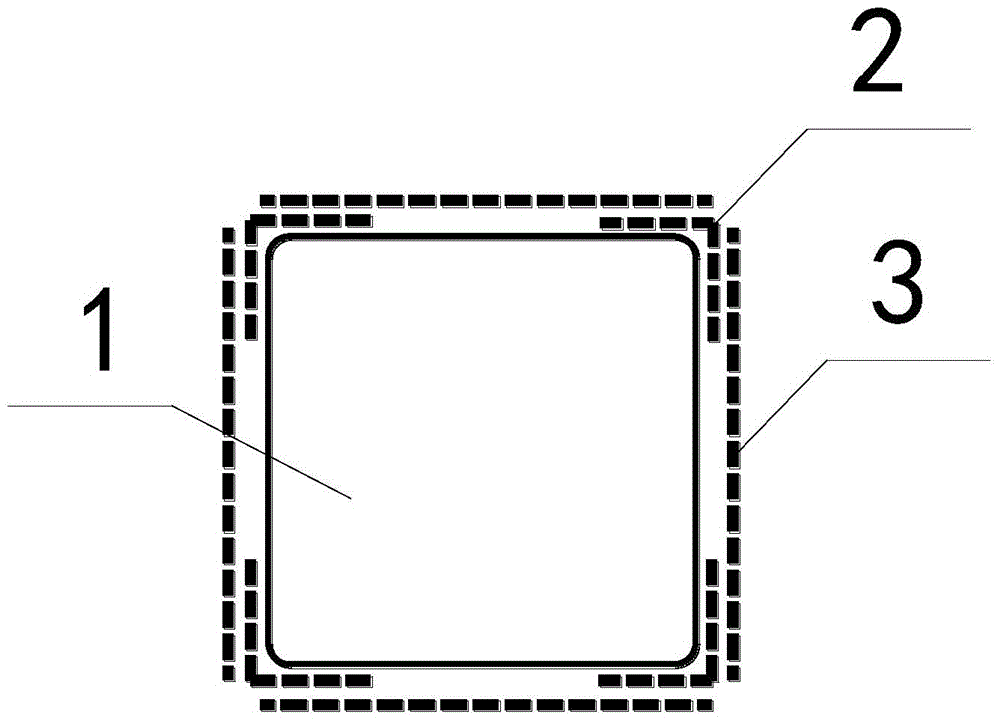

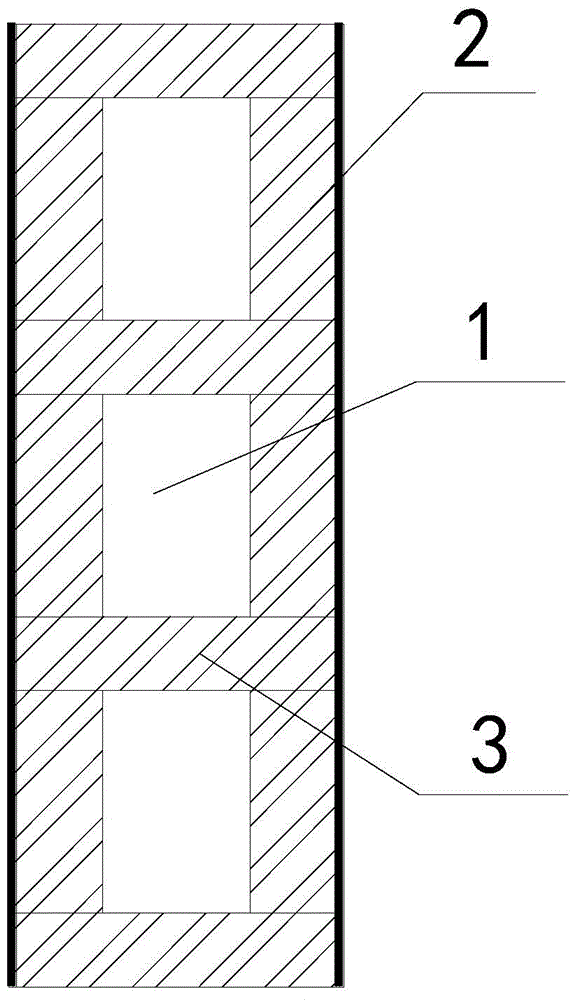

[0024] as attached figure 1 and 2 Shown, the concrete steps that carry out reinforcement by the present invention are:

[0025] (1) Treatment of wooden column 1: chamfer the four column corners along the full height of the column body, and carry out flatness treatment on wooden column 1, and the flatness is 0-1.5mm; the chamfering radius of wooden column 1 is the same as that of the selected angle steel 2 Corresponding to the inner angle, the error is not greater than ± 2mm.

[0026] (2) Paste ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com