Patents

Literature

70results about How to "Meet durability requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

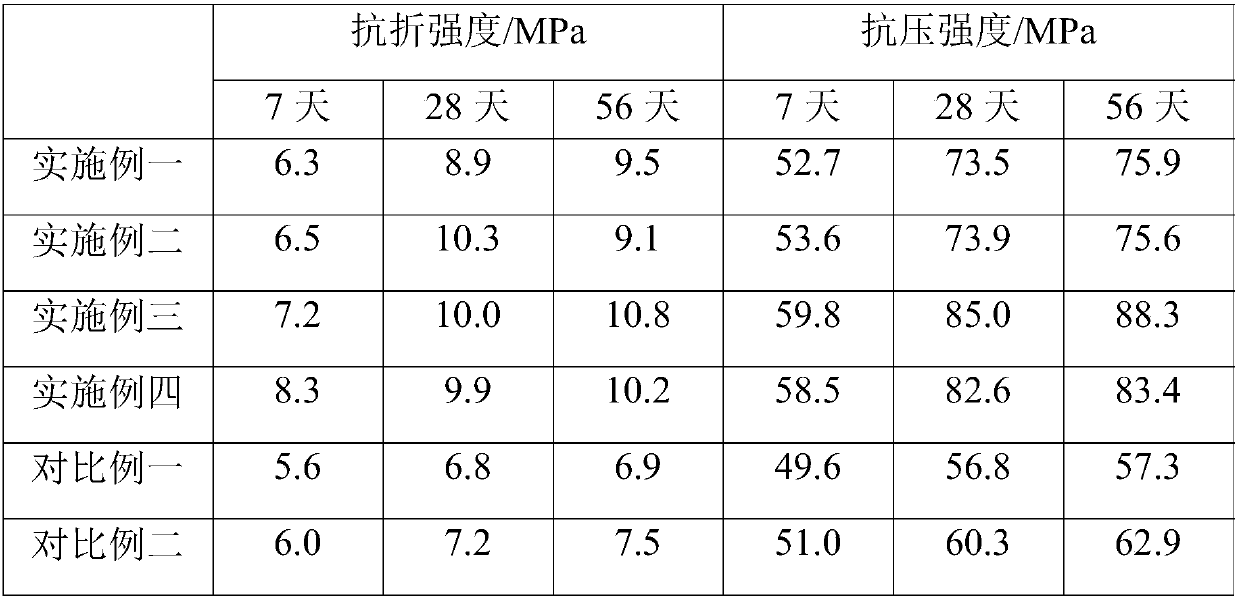

High-strength recycled concrete as well as preparation method and application thereof

InactiveCN112851250AReduce manufacturing costImprove greennessSolid waste managementAggregate (composite)Slag

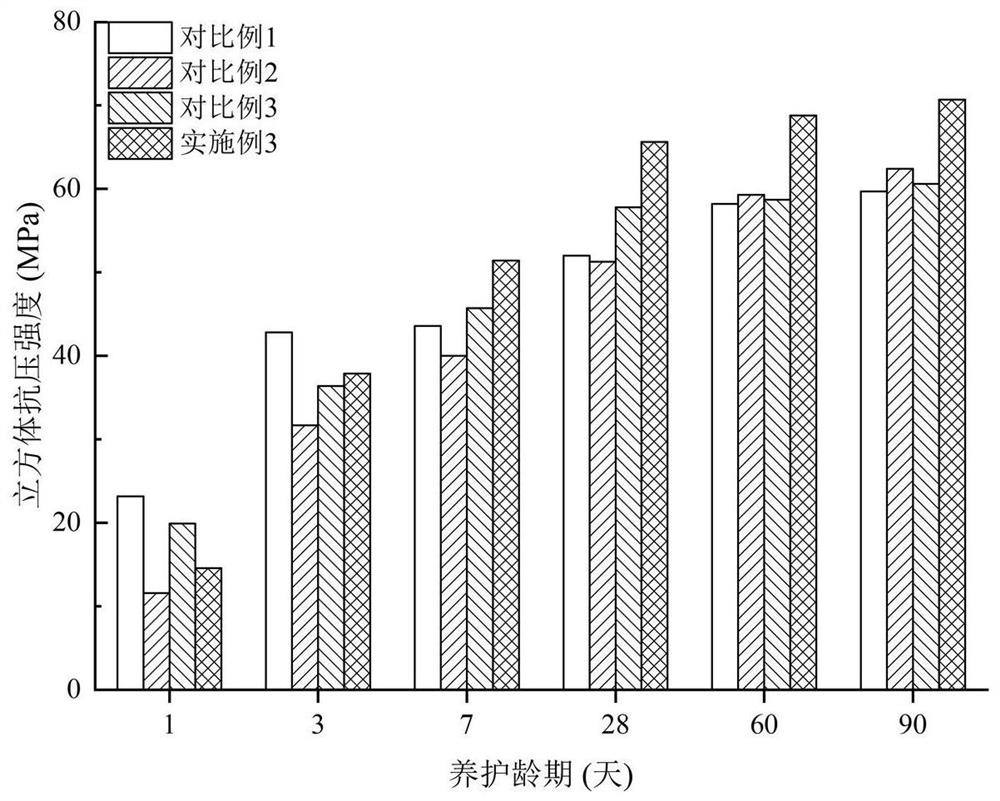

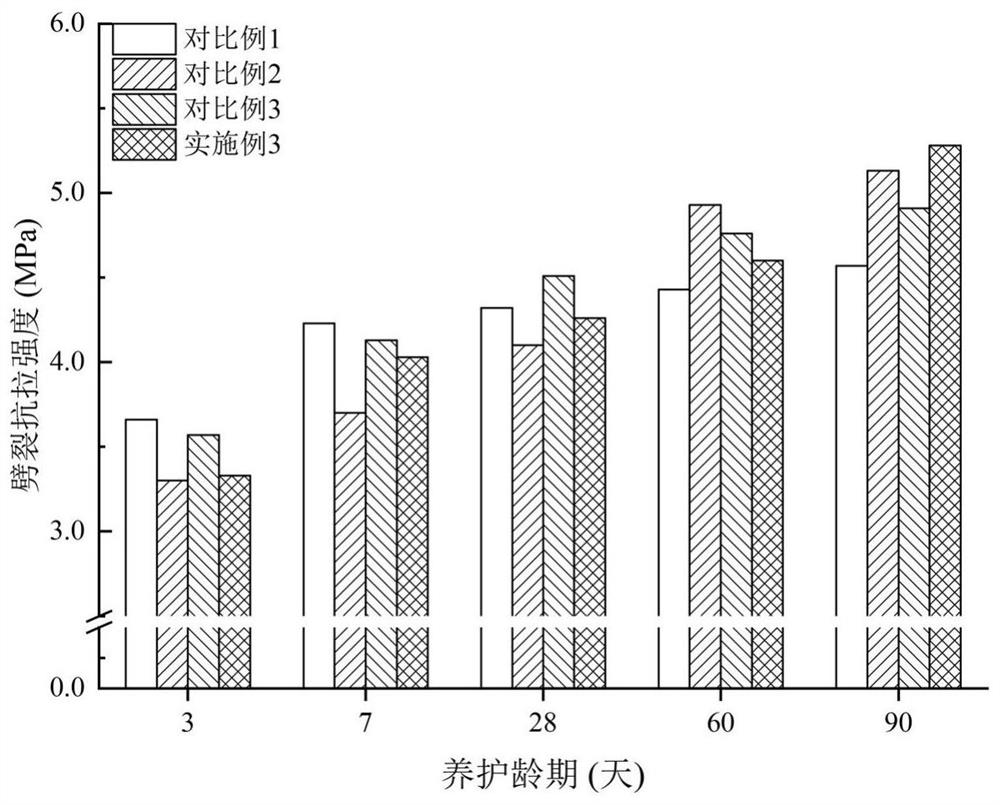

The invention relates to the technical field of building materials, in particular to high-strength recycled concrete and a preparation method and application thereof, and the high-strength recycled concrete is prepared from the following raw materials in parts by weight: 290 to 443 parts of cement; 20 to 70 parts of fly ash; 20 to 70 parts of slag; 20 to 70 parts of silica fume; 20 to 70 parts of metakaolin; 650 to 750 parts of fine aggregate; 550 to 600 parts of natural coarse aggregate; 450 to 510 parts of recycled coarse aggregate; 4.0 to 7.0 parts of a water reducing agent; and 140 to 160 parts of water. The high-strength recycled concrete is designed and prepared on the basis of the service environment and load-bearing requirements of a recycled concrete structure, and mineral admixtures comprise coal ash, slag, silica fume and metakaolin. According to the preparation method, a pre-wetting-double slurry wrapping method is adopted, the recycled aggregate is subjected to pre-wetting, slurry wrapping and repeated stirring treatment, the internal microstructure of the concrete is enhanced, and the mechanical property of the recycled concrete and the durability of the recycled concrete in a composite salt erosion environment are improved.

Owner:XIAN TECHNOLOGICAL UNIV

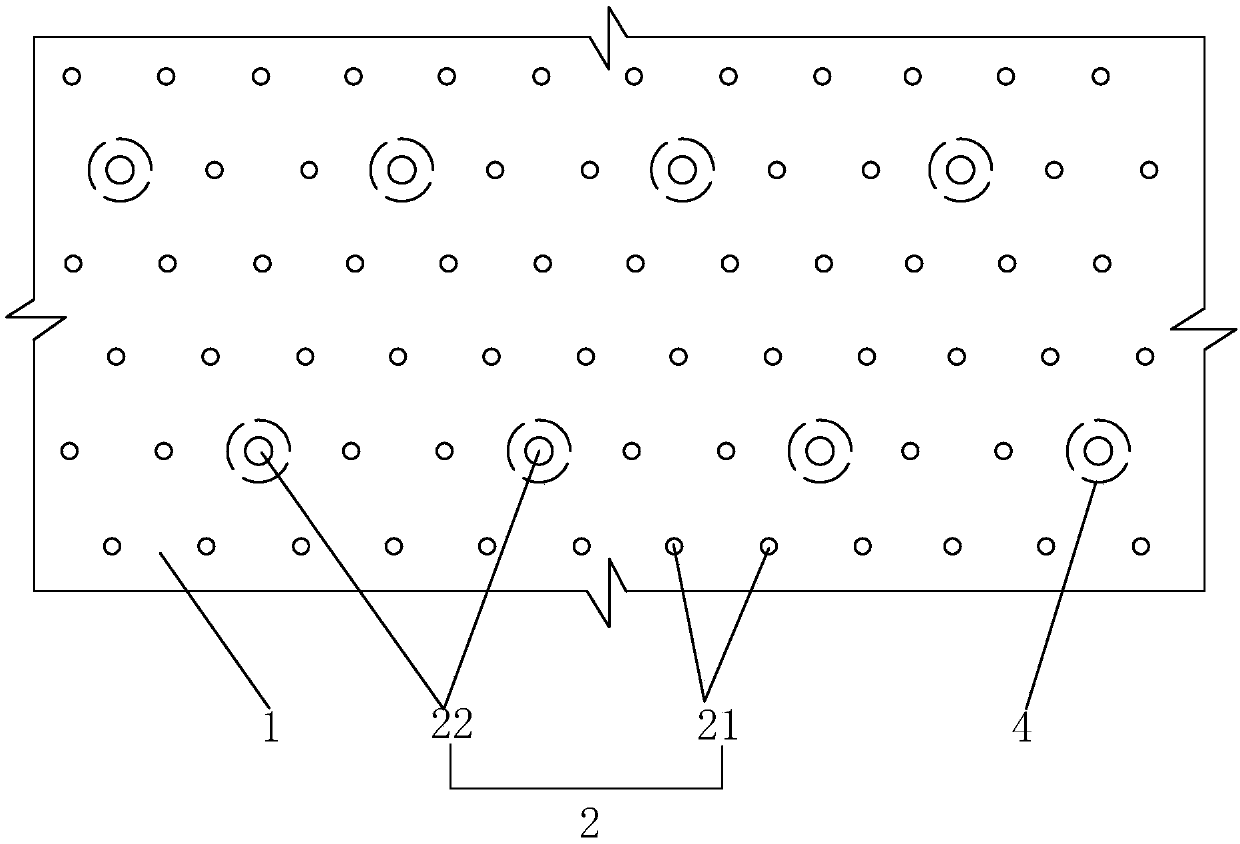

Construction method of bamboo wood reinforcement bidirectional enhanced part-cut and part-fill weak roadbed

The invention discloses a construction method of a bamboo wood reinforcement bidirectional enhanced part-cut and part-fill weak roadbed, comprising the following steps of: (1) machining a bamboo wood; processing a bamboo sheet; and manufacturing a bamboo rib cage, a bamboo rib grid and a bamboo rib U-shaped anchor nail; (2) flattening a field and setting out a pile position; (3) utilizing a vibration shock method of a vibration immersed tube method to construct to form a bamboo rib cage crushed stone pile and paving a crushed stone cushion layer on a pile top; and (4) digging a step; paving, connecting and anchoring the bamboo rib grid; and backfilling a soil material and rolling and leveling. The construction method is characterized in that the bamboo rib cage can effectively improve the bearing capability and the stability of the crushed stone pile; the bamboo rib grid can reinforce the connection between a filling region and a digging region, the differential deposition is reduced, and sliding and instability of sliding along a filling and digging connecting face is prevented; and the construction method has the beneficial effects that a bamboo rib is used as a reinforcement material so that a construction industry is developed towards a low-carbon, energy-saving, environment-friendly and sustainable development direction, and saves the investment under the condition of meeting the requirements of roadbed bearing capability and deformation stability.

Owner:HUNAN UNIV

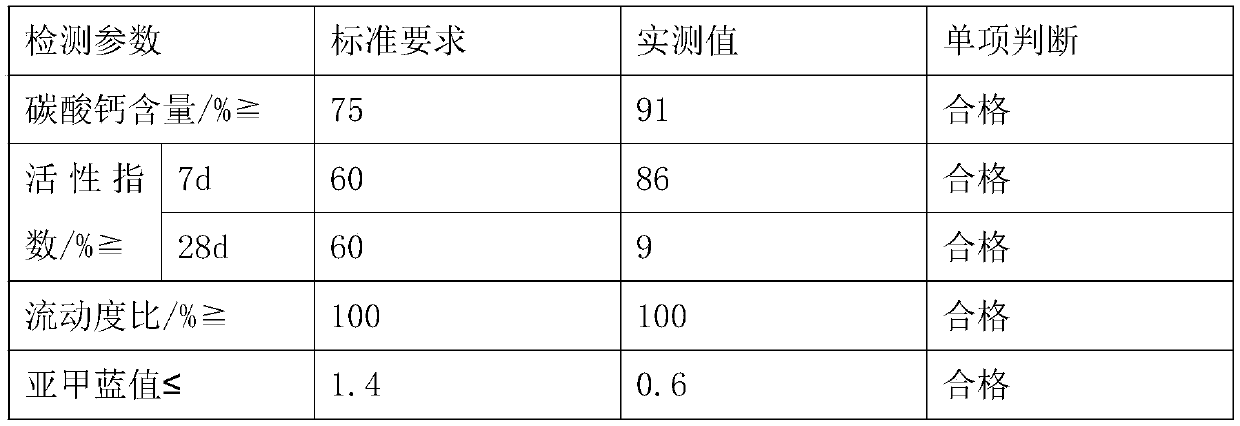

Marine fair-faced concrete containing limestone powder and preparation method of concrete

The invention discloses marine fair-faced concrete containing limestone powder. The marine fair-faced concrete is prepared from components as follows: a concrete additive, a mixed cementing material, aggregate and water, wherein the mixed cementing material is prepared from cement and a concrete admixture; the concrete admixture is prepared from the limestone powder and granulated blast-furnace slag powder, the added limestone powder accounts for 5%-20% of the total mass of the concrete, and the added granulated blast-furnace slag powder accounts for 15%-40% of the total mass of the concrete; the consumption of the cementing material is 320-450 kg / m<3>, and the ratio of water to the cementing material is 0.30-0.42. According to the fair-faced concrete, fly ash is replaced with the limestone powder, the problem of raw material shortage due to adoption of fly ash is solved, defects of the fair-faced concrete adopting the fly ash are also avoided, the homogeneity and the workability of the concrete are improved simultaneously, the concrete bleeding risk is reduced, the requirement for durability is met, the appearance quality of the concrete structure is stable, and the requirement for the appearance quality of the fair-faced concrete is met.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

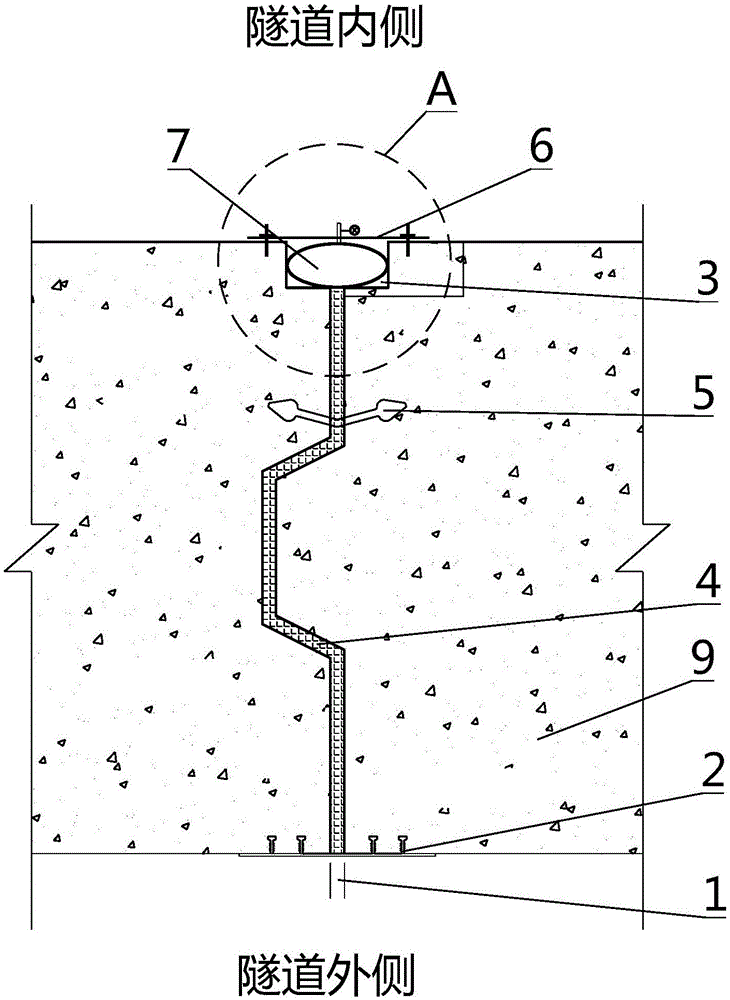

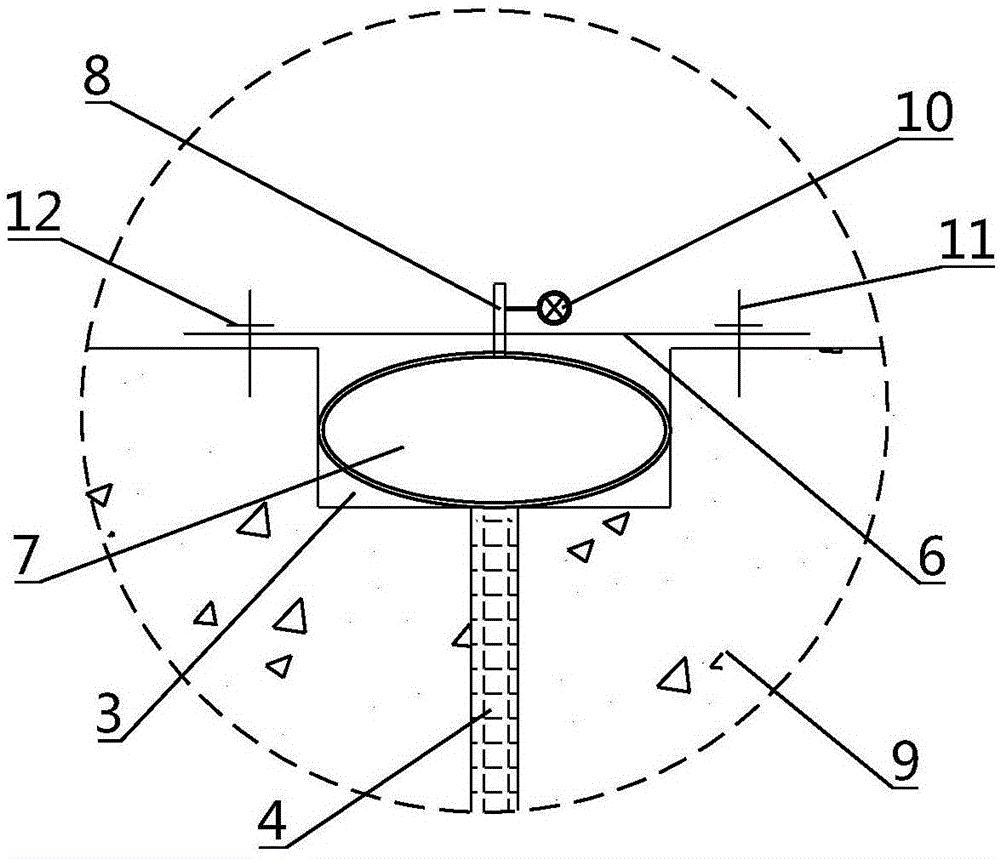

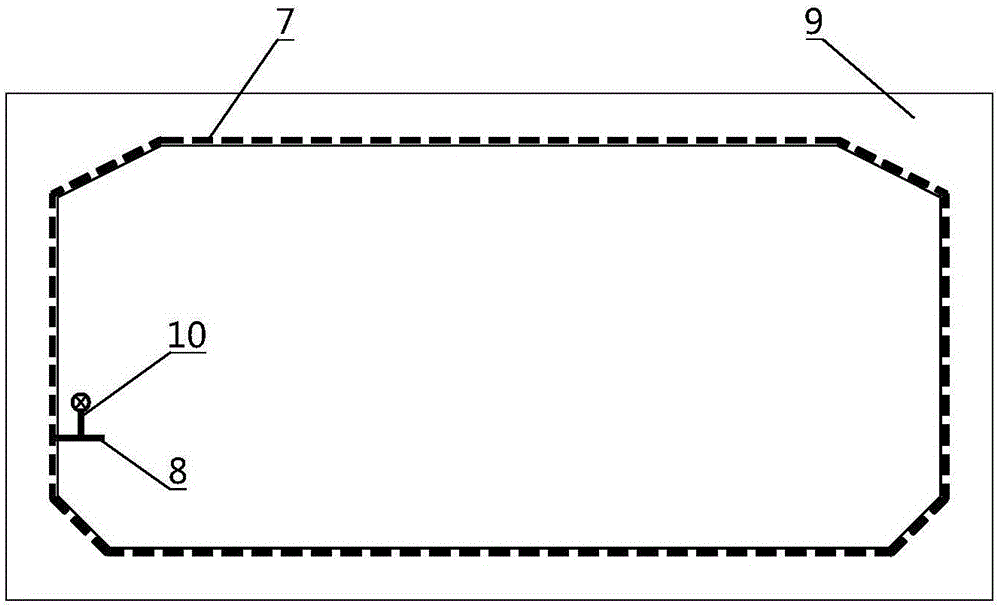

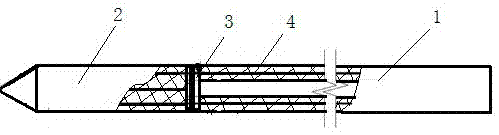

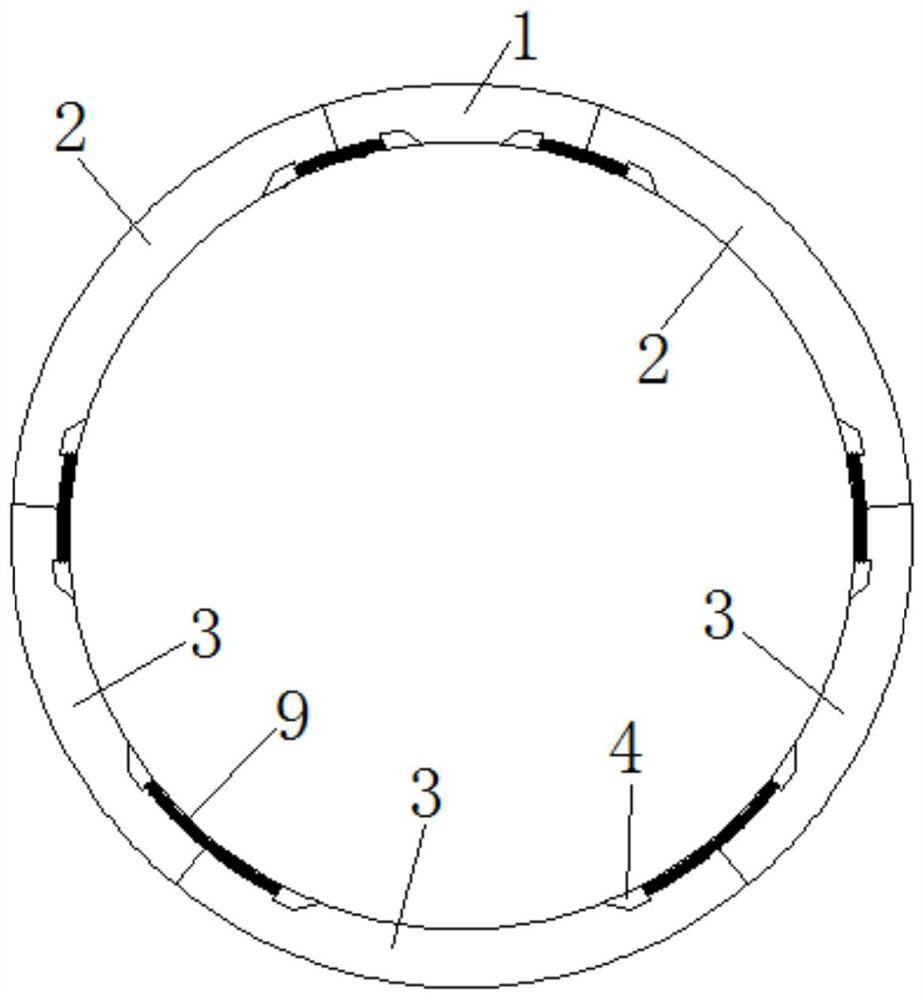

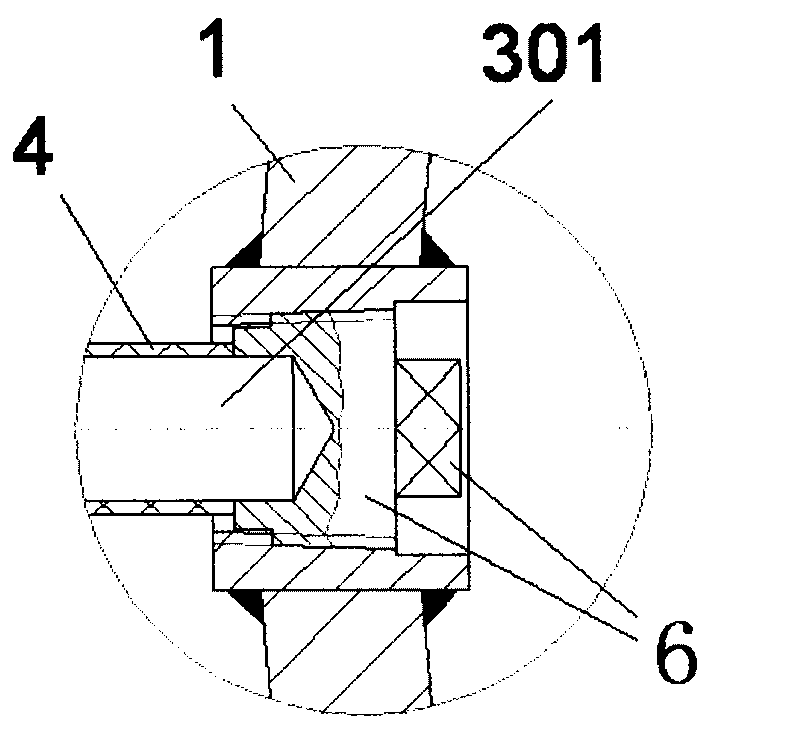

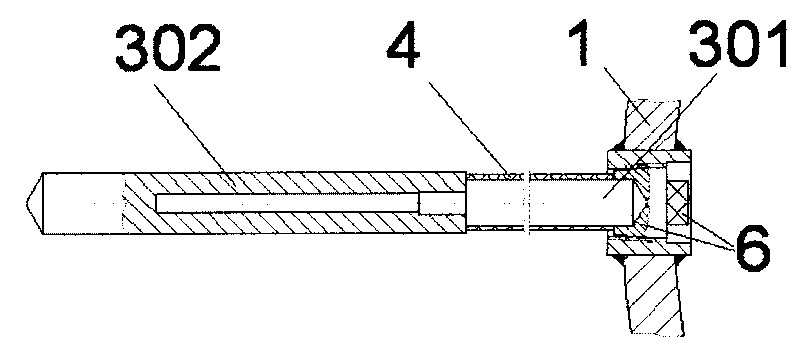

Air bag type sealing structure for deformation joint of open trench tunnel

ActiveCN105064412AMeet durability requirementsArtificial islandsProtective foundationFilling materialsInner wall zone

The invention discloses an air bag type sealing structure for a deformation joint of an open trench tunnel. A groove along the whole circle of the inner wall of the tunnel in the circumferential direction is formed in the position, with the deformation joint, of the inner wall of the tunnel; the deformation joint is filled with filling materials; the open end of the groove is provided with a baffle fixed to the inner wall of the tunnel, and an air bag type waterstop is arranged in the groove; and the air bag type waterstop is provided with an inflation valve penetrating out of the baffle. Because the back-loading type waterstop is adopted, the air bag type sealing structure is not limited by the conditions on a construction site, high-standard protection on the site is not needed, and meanwhile, the air bag type sealing structure for the deformation joint is also applicable to fault rectification of an existing tunnel; the air bag type waterstop can be replaced without influencing the use functions, and the request for durability is met; and a uniform air pressure monitoring system and an automatic inflation system can be built to form an intelligent waterproof system with an automatic maintenance function.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

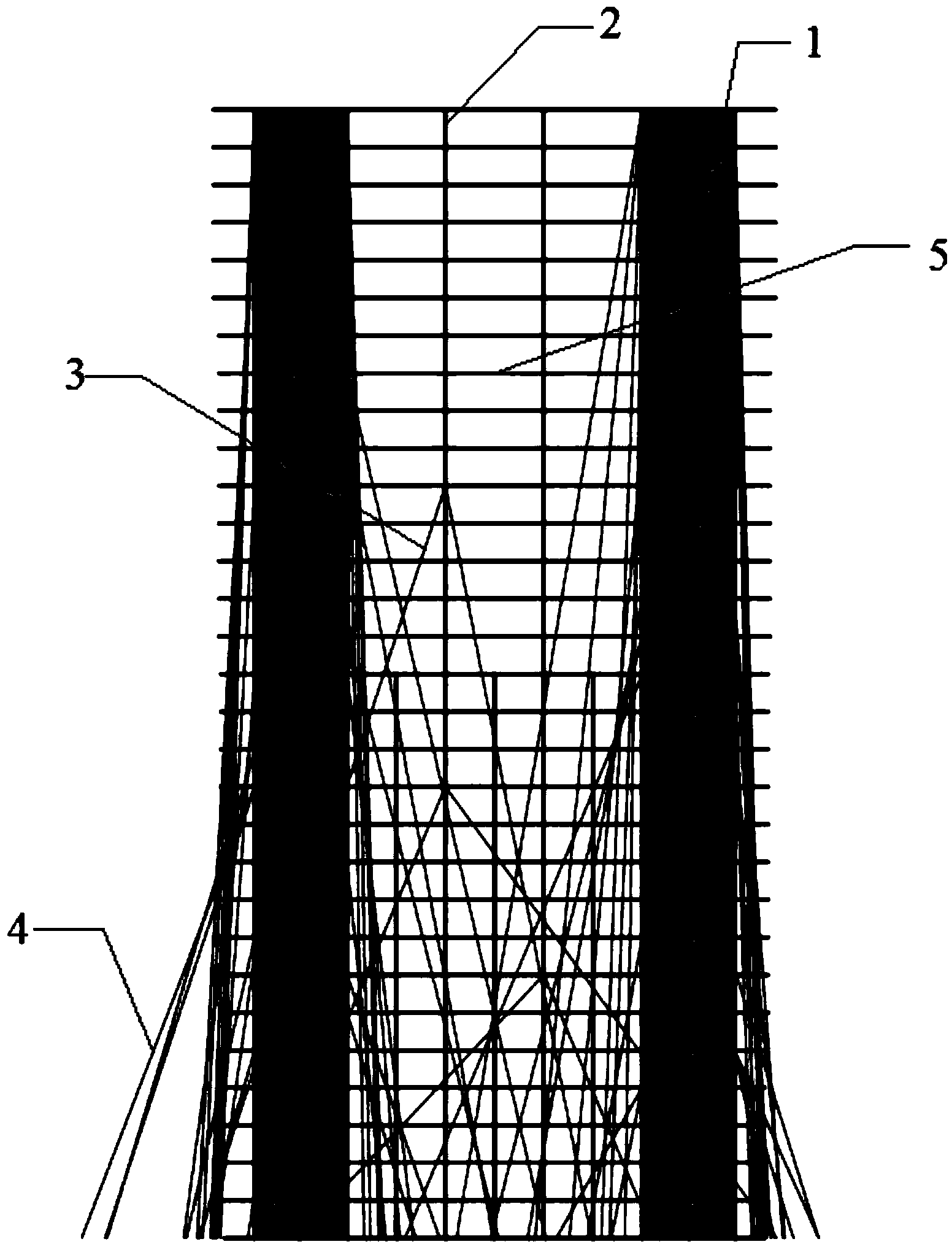

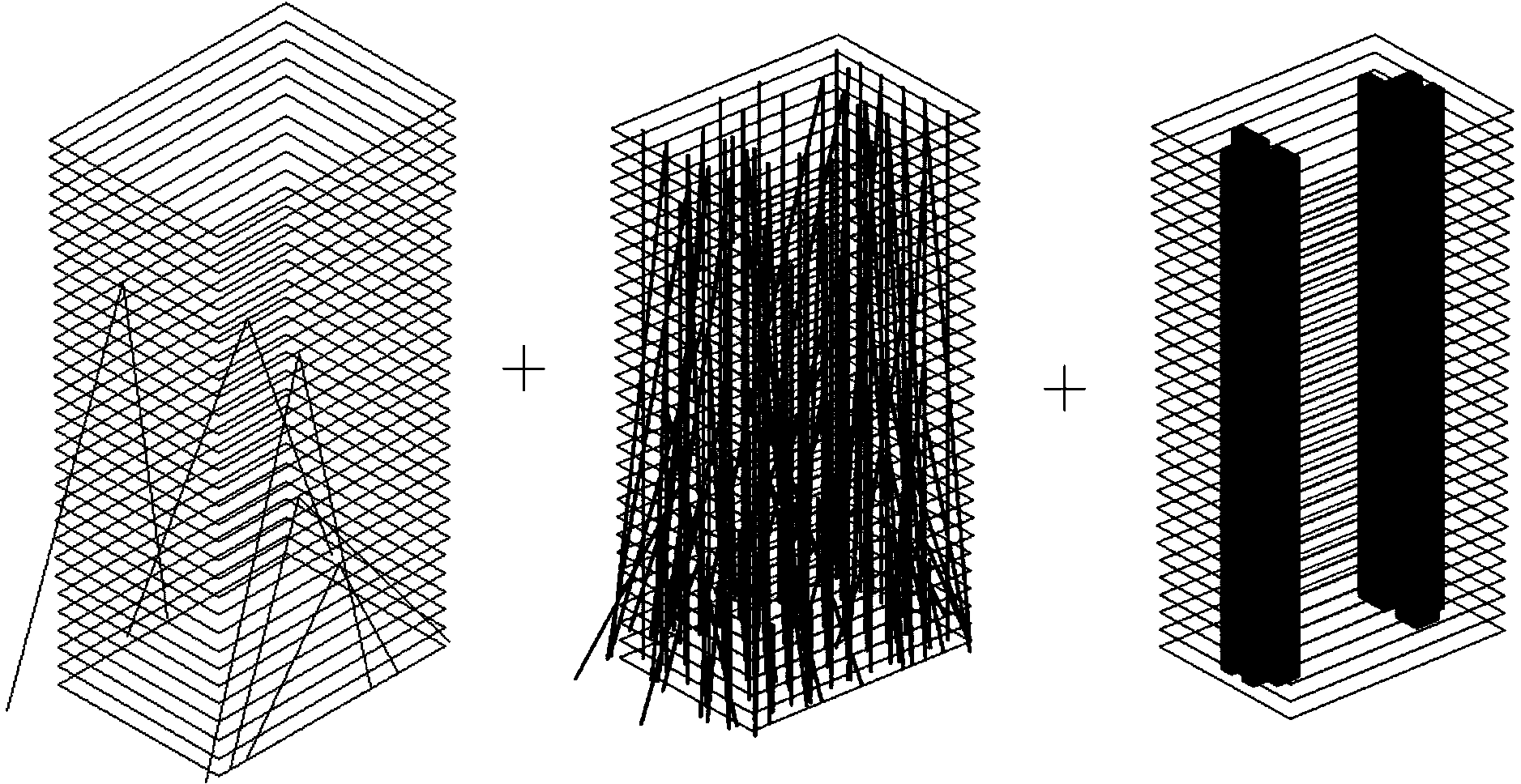

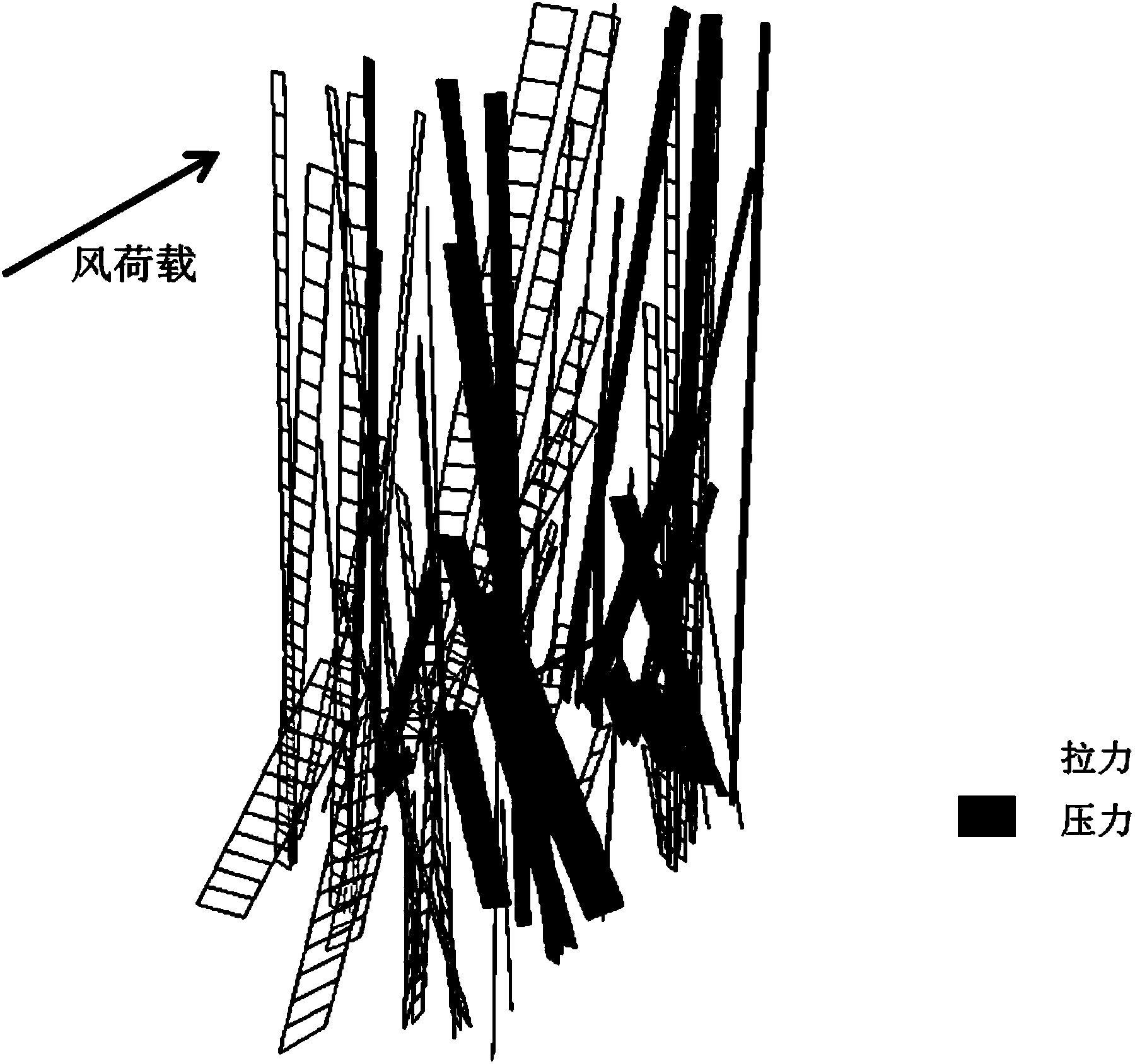

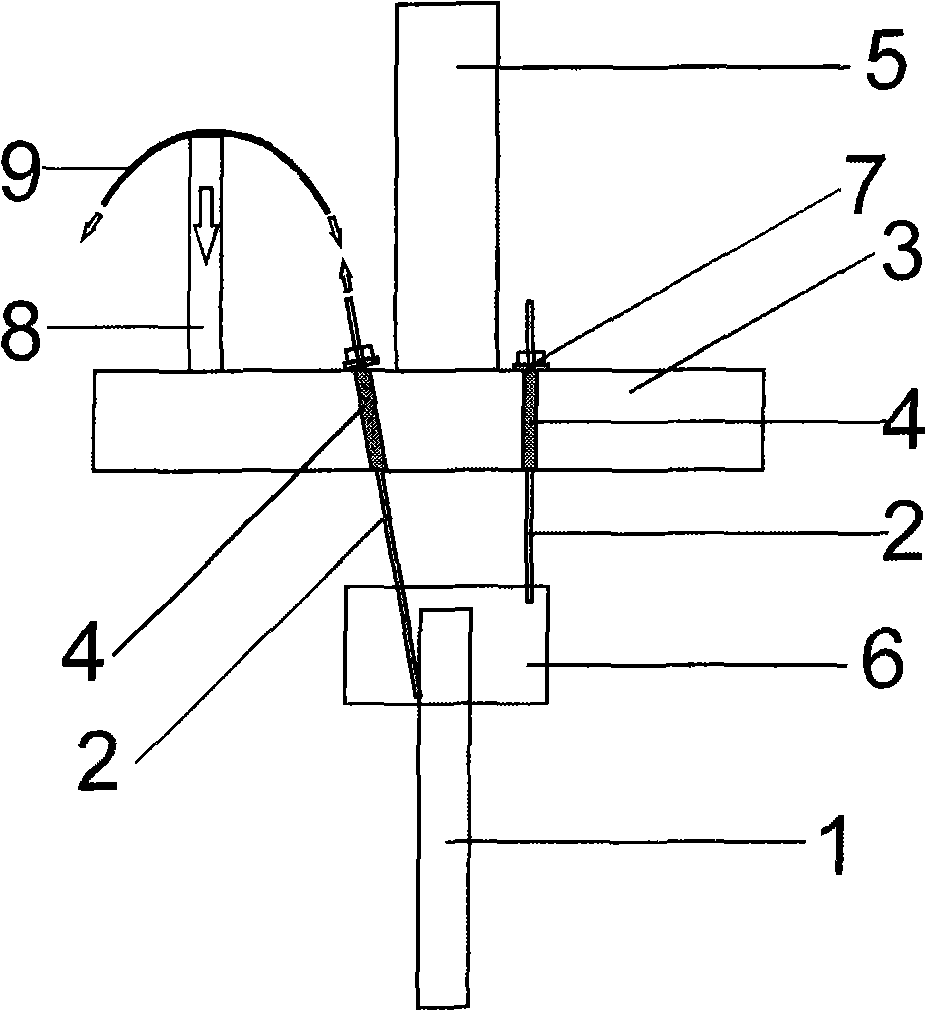

Frame-core tube structure with flexible inhaul cable

The invention relates to a frame-core tube structure with a flexible inhaul cable. The frame-core tube structure with the flexible inhaul cable comprises a core tube, frame pillars, a horizontal steel girder and a combination floor slab. The frame pillars are evenly arranged on the outer side of the core tube. After the horizontal steel girder is combined with the combination floor slab, the horizontal steel girder and the combination floor slab are arranged in an overall structure in the vertical direction in a layering mode. The frame-core tube structure with the flexible inhaul cable is characterized by further comprising multiple slant pillars and multiple flexible stay cables. The slant pillars are connected to the core tube and the flexible stay cables are connected to cross points between the core tube and the frame pillars or between the horizontal steel girder and the frame pillars. The slant pillars, the stay cables, the horizontal steel girder, the frame pillars and the core tube commonly form a stable structure system. Compared with the prior art, the frame-core tube structure with the flexible inhaul cable has the advantages that transmission of vertical loads and resistance to side direction loads can be transmitted harmonically, the building appearance requirement can be met, the design concept is achieved.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD +1

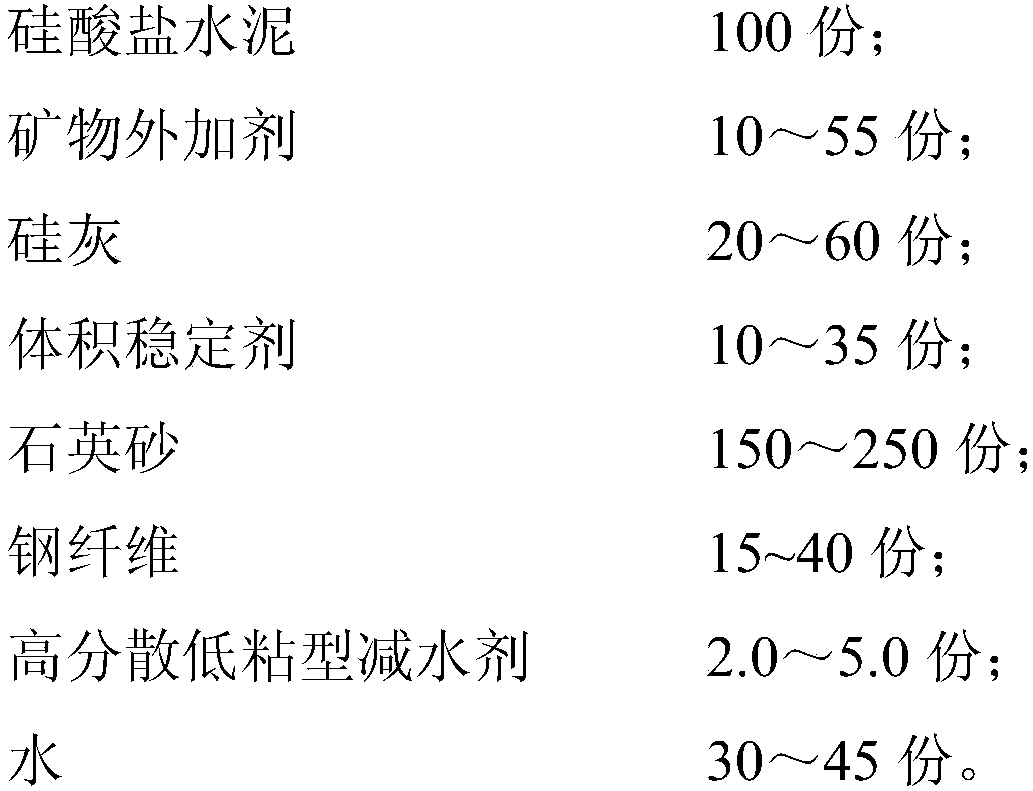

Microexpanded ultrahigh-performance concrete and preparation method

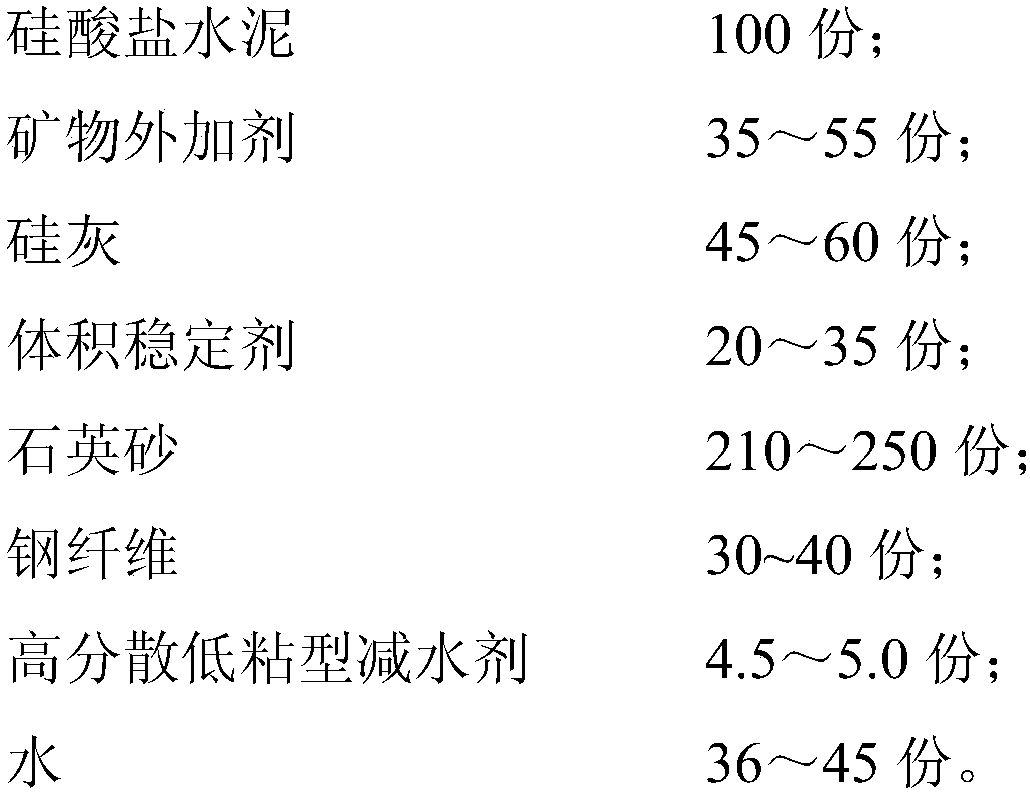

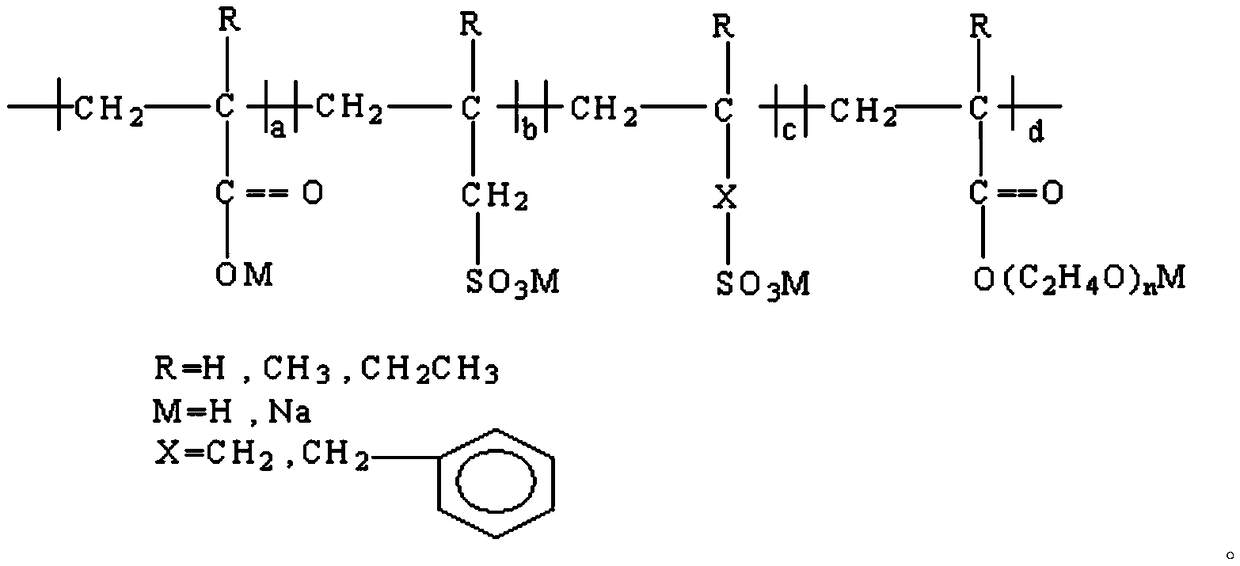

The invention discloses micro-expanded ultrahigh-performance concrete and a preparation method. The concrete is prepared from the following ingredients in parts by weight: 100 parts of Portland cement, 10 to 55 parts of mineral additives, 20 to 60 parts of silicon ash, 10 to 35 parts of volume stabilizers, 150 to 250 parts of quartz sand, 15 to 40 parts of steel fiber, 2.0 to 5.0 parts of high dispersion and low viscosity type water reducers and 30 to 45 parts of water. The micro-expanded ultrahigh-performance concrete replaces a negative bending moment region conventional mechanical tensioning prestress structure to form a non-prestress simple support rotation continuous system; the self-bearing force, interface bonding, micro-expanded expansion performance and durability requirements canbe met; the construction efficiency of the non-prestress simple support rotation continuous system bridge is effectively improved. The concrete has the ultrahigh pressure-resistant and tension-resistant intensity, ultrahigh durability, micro expansion performance, steam curing avoidance, bonding performance and reasonable economic performance; meanwhile, good construction performance is realized.

Owner:宁波市高等级公路建设指挥部 +1

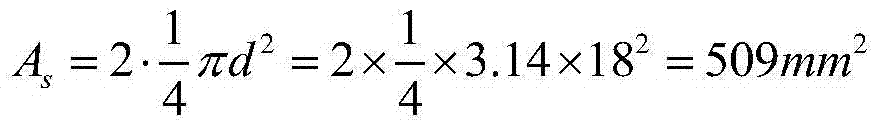

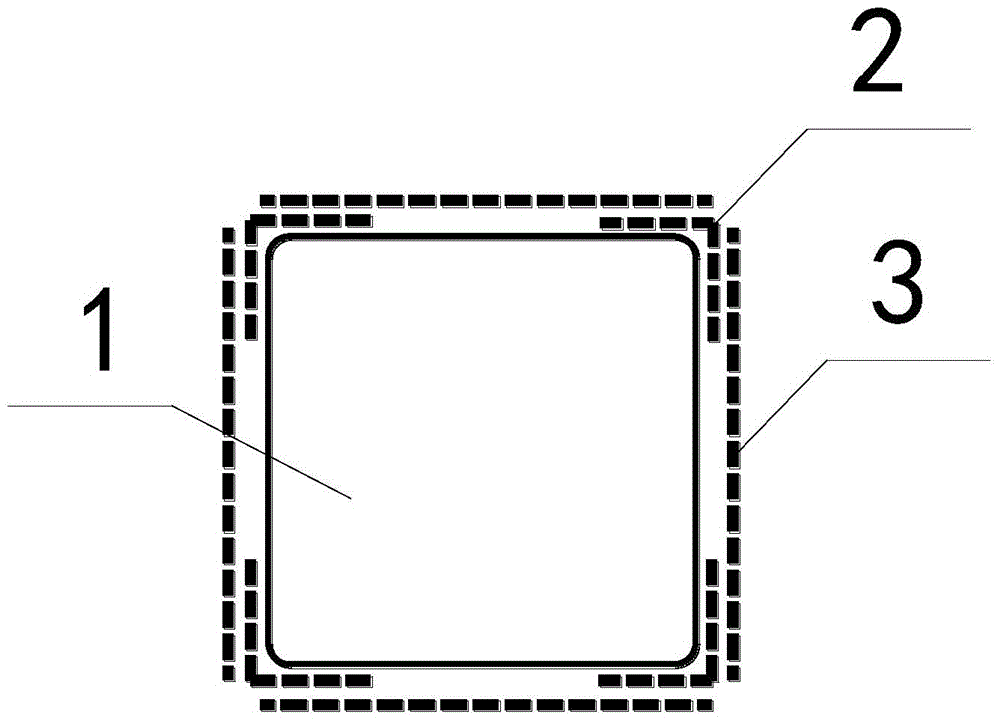

High-performance low-prestressed concrete hollow square pile

InactiveCN105442591AIncrease corrosion allowanceImprove bearing capacityCeramic shaping apparatusBulkheads/pilesFiberPre stress

The invention discloses a high-performance low-prestressed concrete hollow square pile. The high-performance low-prestressed concrete hollow square pile is characterized in that a pile body is composed of at least one unit pile; each unit pile is composed of concrete and parallel reinforcing steel bars tensioned with the prestress of 0.3-0.6 [sigma] in the concrete; the two ends of the reinforcing steel bars are connected with connection plates respectively; the adjacent unit piles are welded through the connection plates to form the pile body; the outer layers of the two connected connection plates are coated with fiber resin with the thickness not smaller than 1.5 mm; the fiber resin layers are wrapped with carbon fiber cloth capable of improving the antiseptic ability and tension resistance. The high-performance low-prestressed concrete hollow square pile has the advantages of being high in corrosion resistance, large in bearing force, low in production cost, high in durability and the like, the problem of the piling illusion is effectively solved, the integrity of the pile body is ensured during construction, the bearing force of the pile body is effectively improved, the weight is lower, cracks caused by mutual collision in the production and transportation process can be avoided, and the phenomena of pile breakage, pile body concrete falling and the like are also not prone to occurring in the site construction.

Owner:WEIHAI QIDE NEW BUILDING MATERIALS

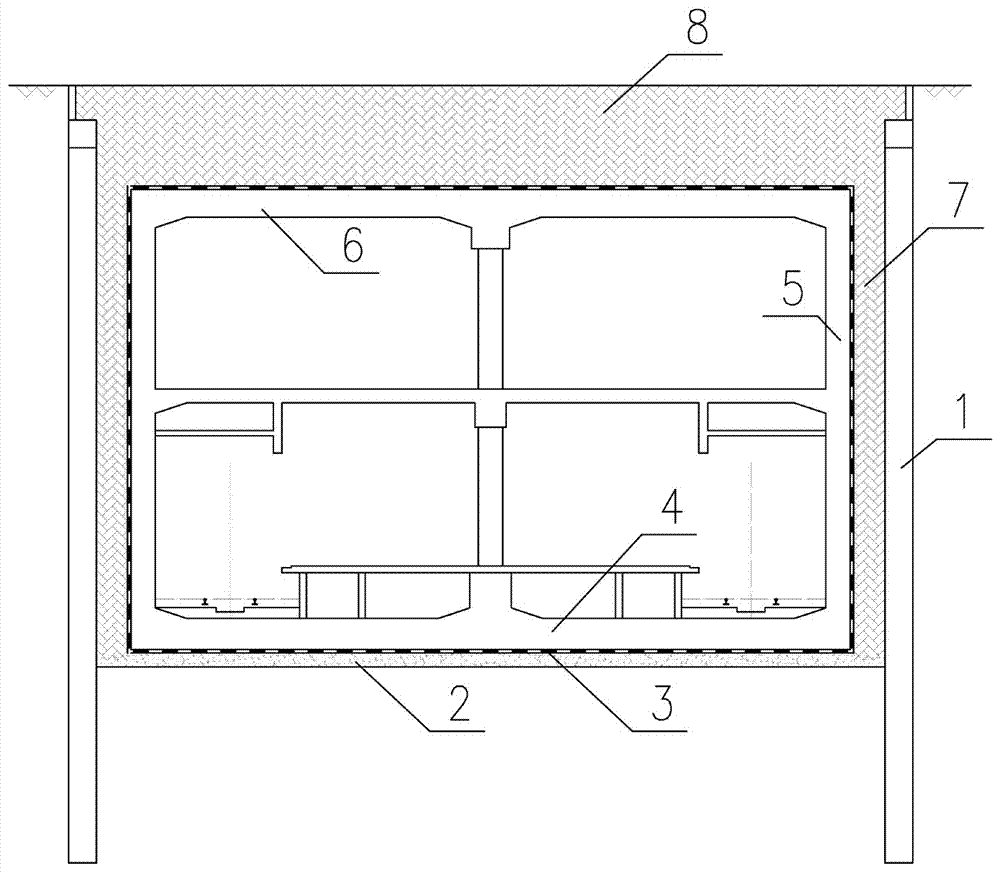

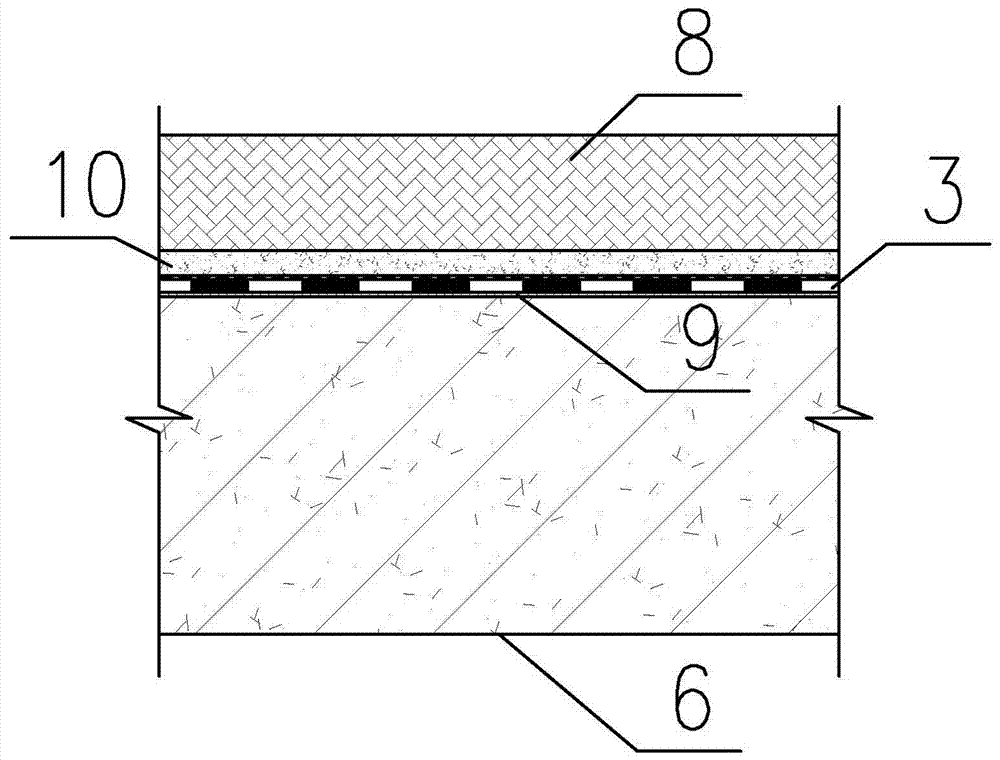

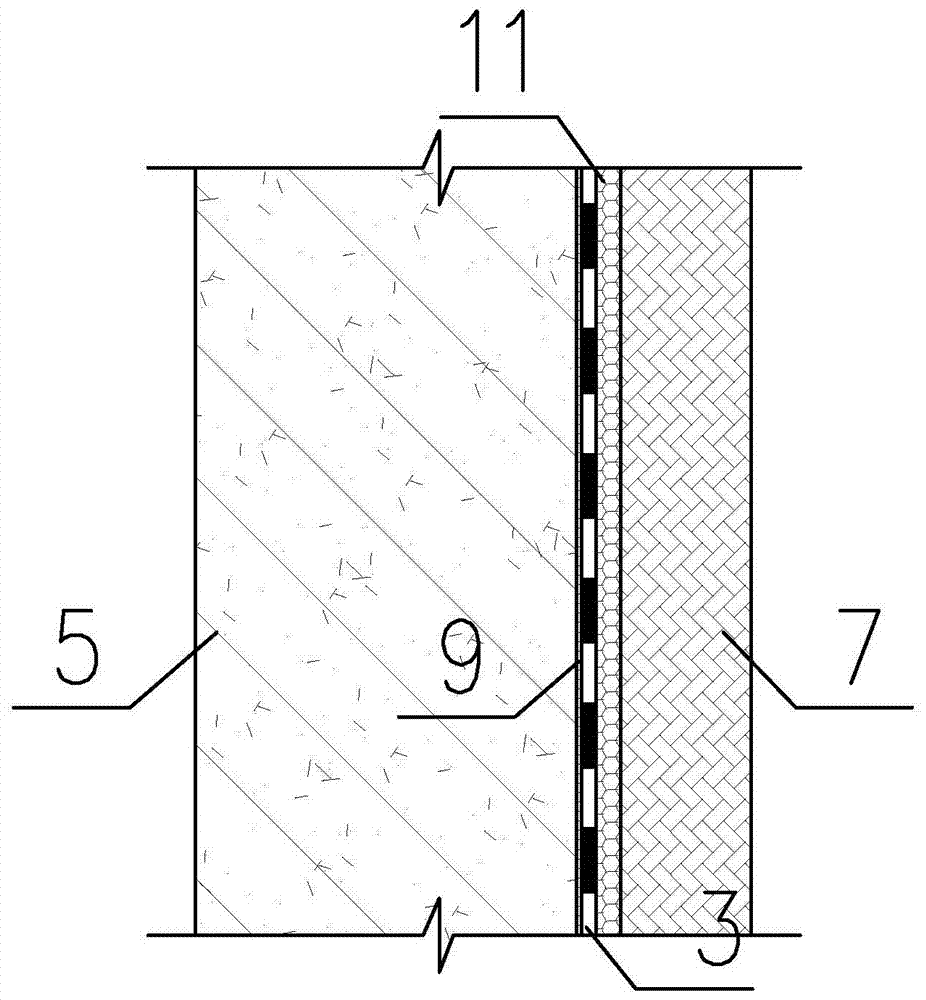

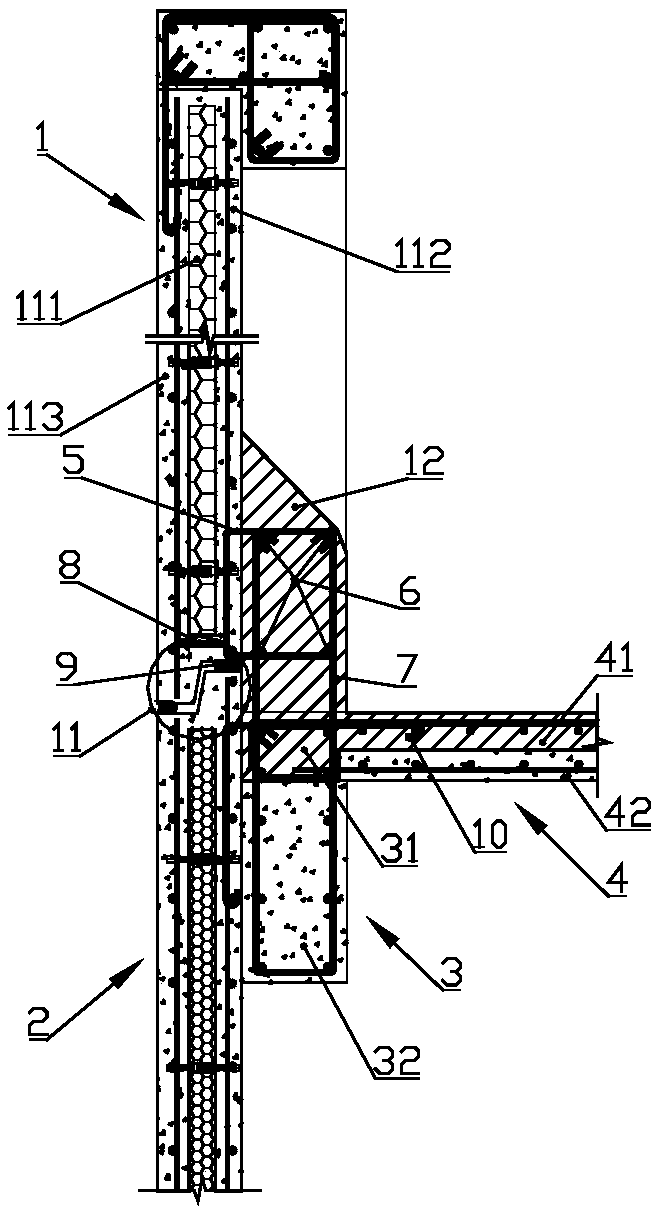

Comprehensive protective system for open-cut subway station under strongly corrosive environment and construction method for comprehensive protective system

PendingCN107059924AImprove corrosion resistanceMeet durability requirementsArtificial islandsUnderwater structuresHigh performance concreteEnvironmental geology

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Drilling rig derrick state online detection system and method

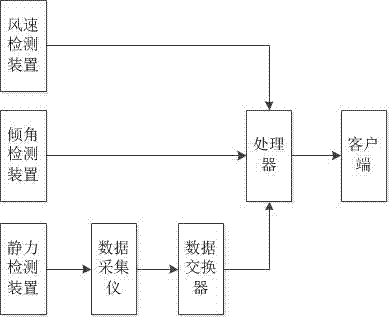

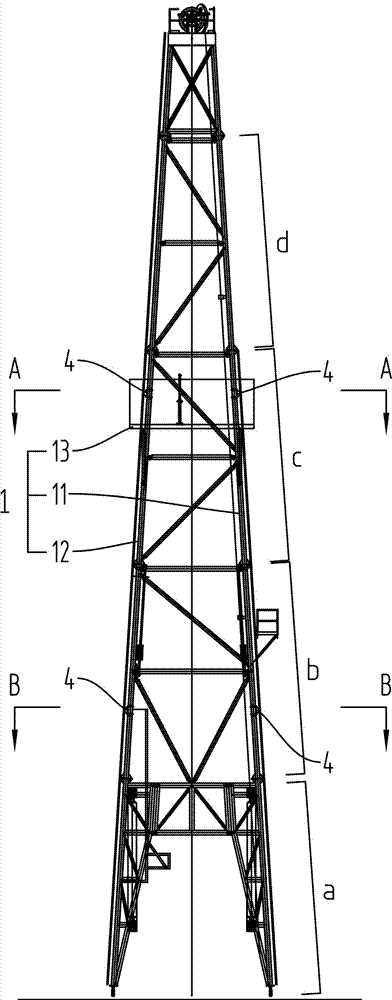

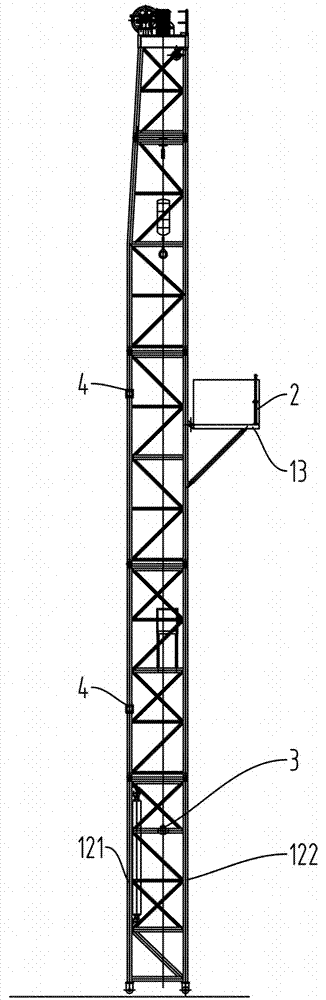

PendingCN106950054AStable and reliable real-time performanceStable and reliable analysisMachine part testingStructural monitoringReal-time data

The invention relates to the technical field of drilling rig derrick detection, and especially relates to a drilling rig derrick state online detection system. The system comprises a wind speed and direction detection device, a tilt angle detection device, a static force detection device, a data exchanger, a processor and a client side. The wind speed and direction detection device, the tilt angle detection device and the data exchanger transmit real-time data to the processor, the processor performs storage, analysis and other operation on the real-time data, and the client side calls the data from the processor to perform corresponding operation. The invention further discloses a drilling rig derrick state online detection method. The invention established the drilling rig derrick state full-life-cycle online monitoring system and method integrating structure monitoring, remote transmission and remote diagnosis into one body.

Owner:汉正检测技术有限公司

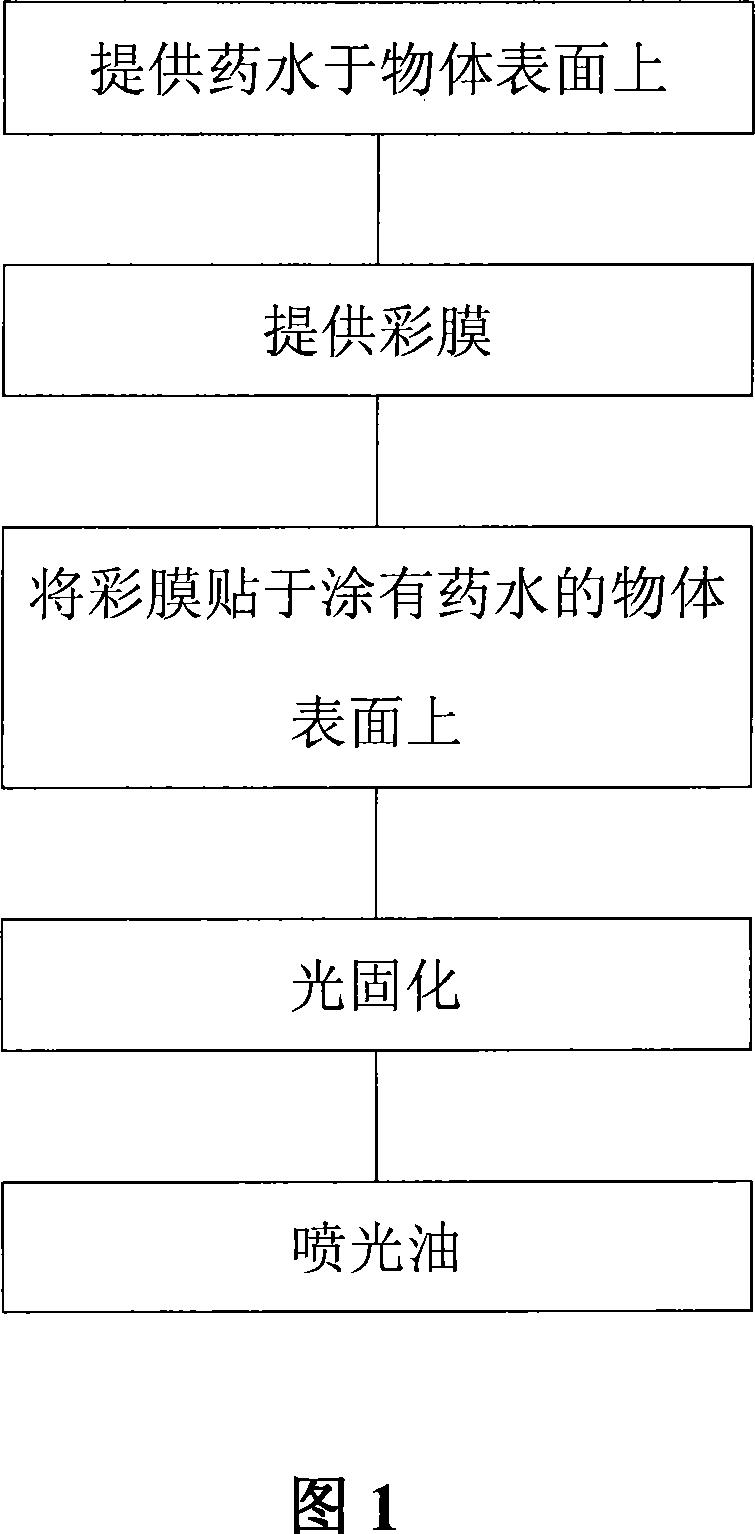

Manufacturing method for picture on surface of object

InactiveCN101045409ALong lasting colorHigh hardnessDecorative surface effectsPattern printingCyclohexanoneDiluent

A method for adhering a pattern on the surface of object includes such steps as coating on the surface of object with a liquid chemical prepared from cyclohexanone, electric vash oil and diluent, sticking a color film, optical solidifying, and spraying brightening oil.

Owner:刘伟平

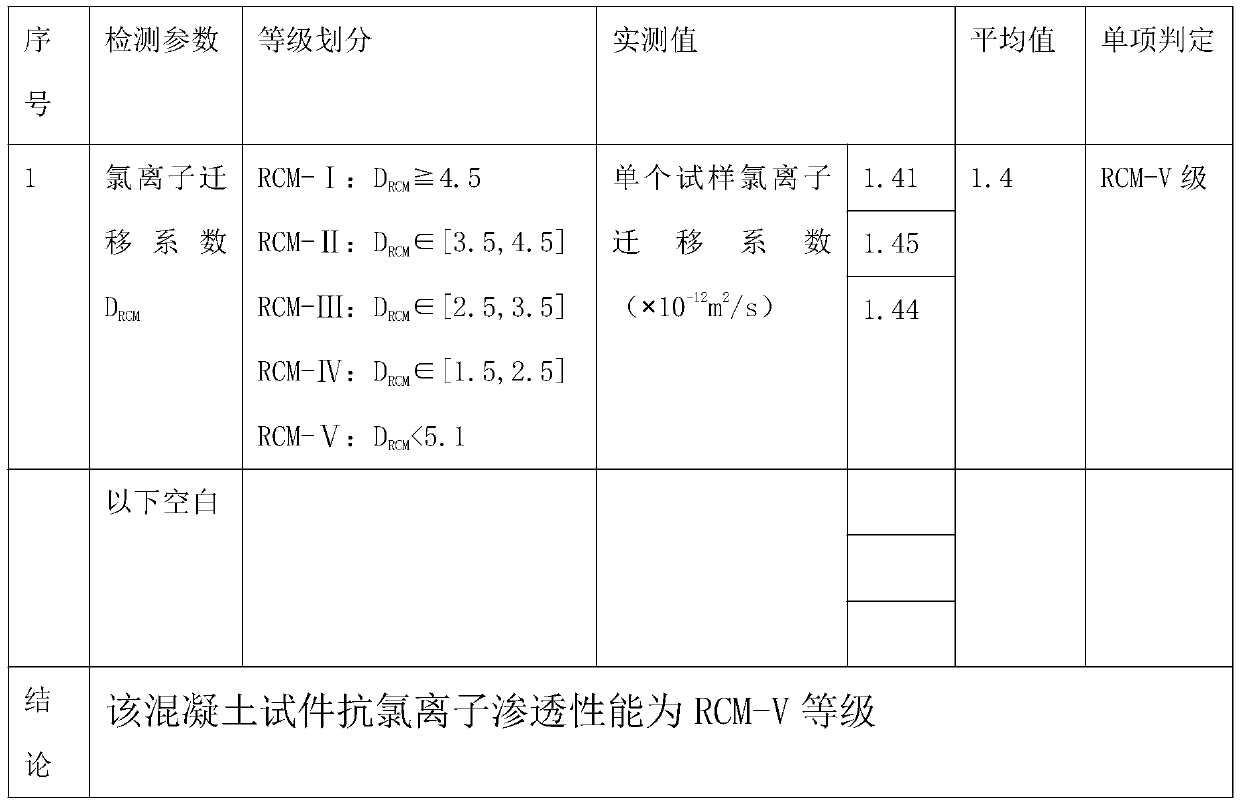

Corrosion resistant cast-in-place pile concrete in high and cold soft ground regions

The invention provides corrosion resistant cast-in-place pile concrete in high and cold soft ground regions. The concrete is characterized by being prepared from Portland cement, a mineral admixture of fly ash accounting for 15-20% of Portland cement by weight and ground slag accounting for 25-30% of Portland cement by weight, a water reducing agent which has water-binder ratio less than 0.4 and accounts for 1% of Portland cement by weight, and air entraining agents accounting for 3 / 10000 of Portland cement by weight by a traditional process. The prepared concrete has strength grade of C30 or C40, air content of (2.5+ / -0.5)%, total alkali content not more than 3.0kg / m<3>, impermeability grade not less than P10, freezing resistance not less than F50, sulfate corrosion resistance coefficient not less than 0.75 and 28d diffusion coefficient of chloride ion (D<RCM>) not more than 6X10<-12>M<2> / s. The compactness of the concrete can be effectively improved, permeation of ions with corrosivity can be prevented, the freezing resistance of the concrete can be improved, and the requirement for durability can be met, thus the concrete cast-in-place pile foundation with the strength grade of (C30, C40) is applied to high and cold soft ground regions with corrosive media such as SO4<2-> and Cl<->.

Owner:NORTHEAST ELECTRIC POWER DESIGN INST CO LTD OF CHINA POWER ENG CONSULTING GRP +2

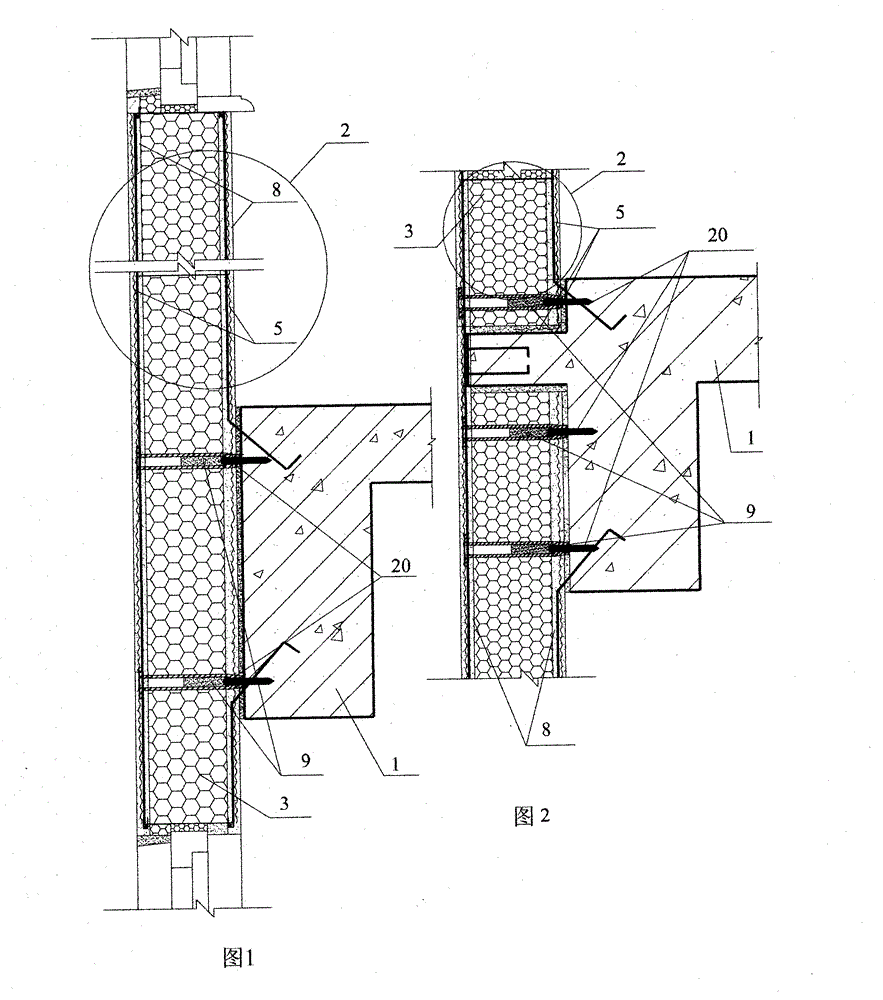

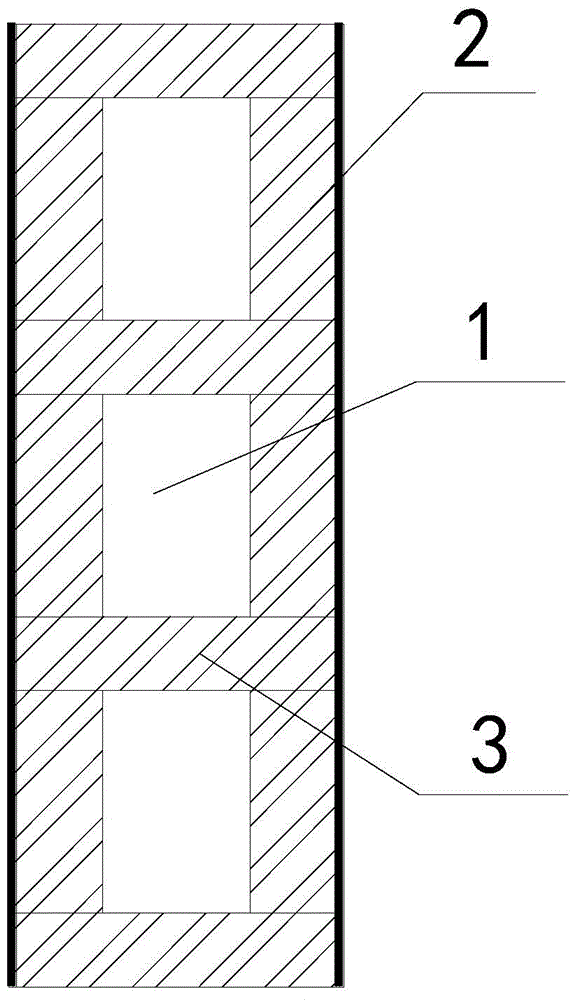

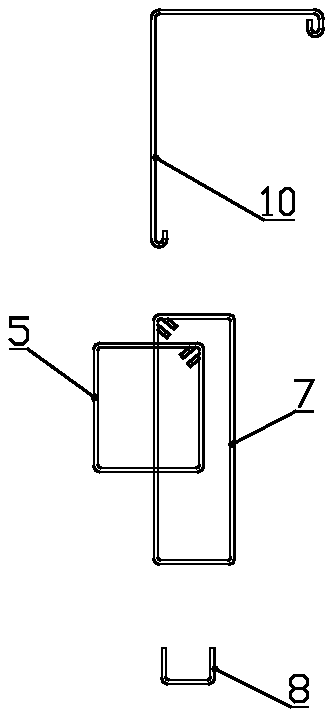

Structure with prefabricated composite insulation board mounted by anchor bolts

InactiveCN104005481AMeet durability requirementsGood fire resistance and good performanceHeat proofingBuilding insulationsEngineeringFire resistance

The invention discloses a structure with a prefabricated composite insulation board mounted by anchor bolts, relates to a structure with a prefabricated composite insulation board mounted by anchor bolts in a building, and aims at the problems that steel anchor bolts of a current prefabricated composite insulation board mounted by the anchor bolts are easy to corrode while passing through an insulating layer made of non-alkaline material and thus increasing in heat transfer and the steel is poor in fire resistance. The structure comprises that, the prefabricated composite insulation board and a building major structure are fixed together by the anchor bolts, fire-proof materials are arranged within a protective layer within a certain range of the outer ends of anchor bolts and / or within a certain range of the surfaces of the anchor bolts, and thus the structure with the prefabricated composite insulation board mounted by the anchor bolts is formed. The anchor bolts for mounting the prefabricated composite insulation board is good in fireproof performance and durability.

Owner:吴淑环

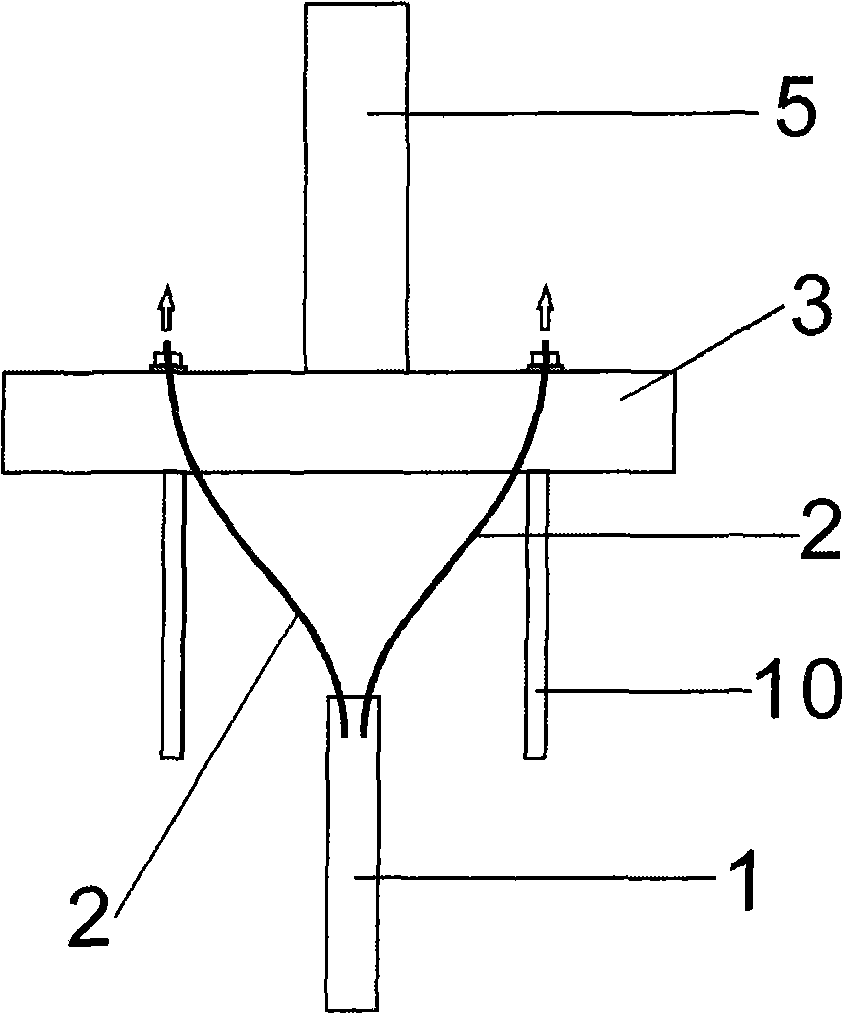

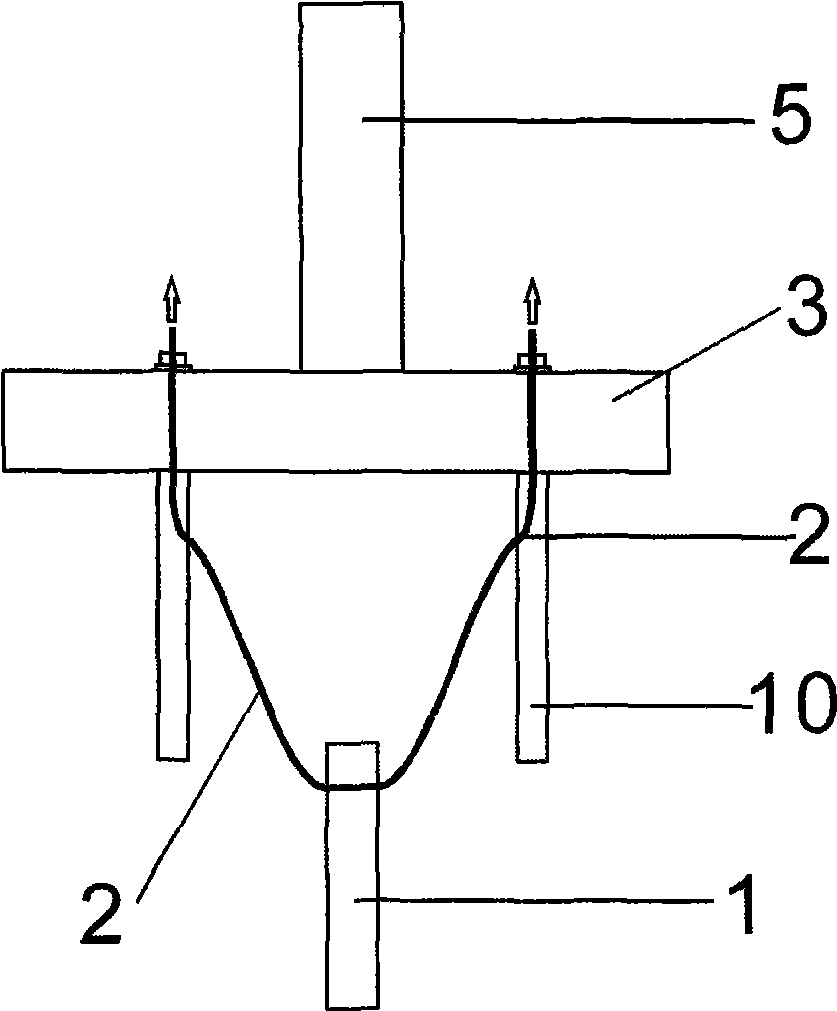

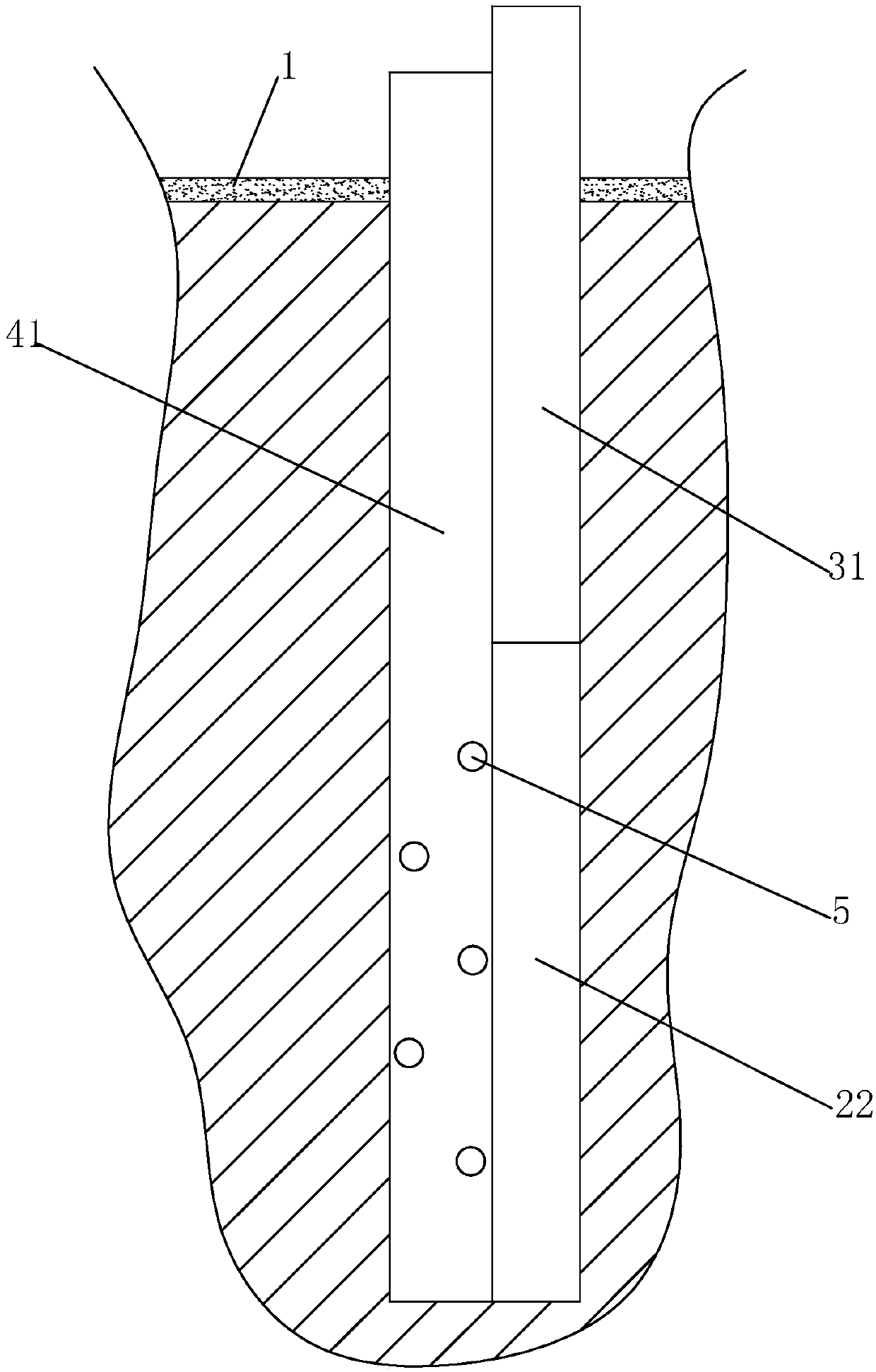

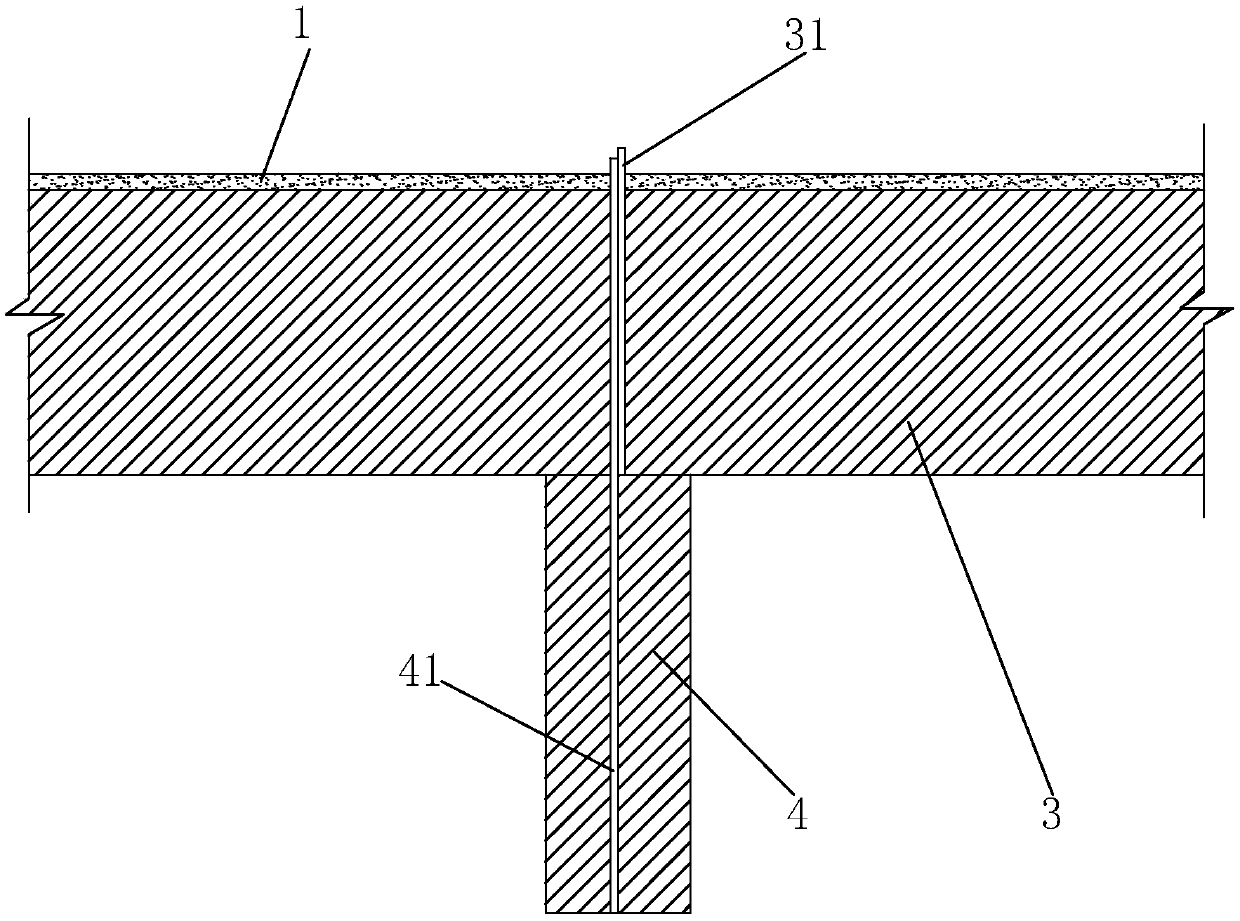

Method for changing applied force state of pile

InactiveCN101509260ATo achieve the purpose of regulating settlementMeet durability requirementsBulkheads/pilesPull forceEngineering

The invention discloses a method for changing the strained condition of a pile, wherein, a part connected with the pile and extending thereout is arranged at the outer flank of a pile shaft, a perforative hole is arranged in a cushion cap (foundation mat), the part extending out of the pile passes through the hole for fixing, or is fixed after set stretching-drawing or compressing operational procedure; load is passed to the pile through the part extending out of the pile so as to change the load passing route and the strained condition of the pile, therefore, the method can achieve the purpose of adjusting sedimentation by affecting the settlement in peripheral region of the pile, and can enable the pile without direct contact with the pile bolck and the cushion cap (foundation mat) to bear pulling force.

Owner:薛江炜

High-density frozen-penetration-resistant marine concrete and preparation method thereof

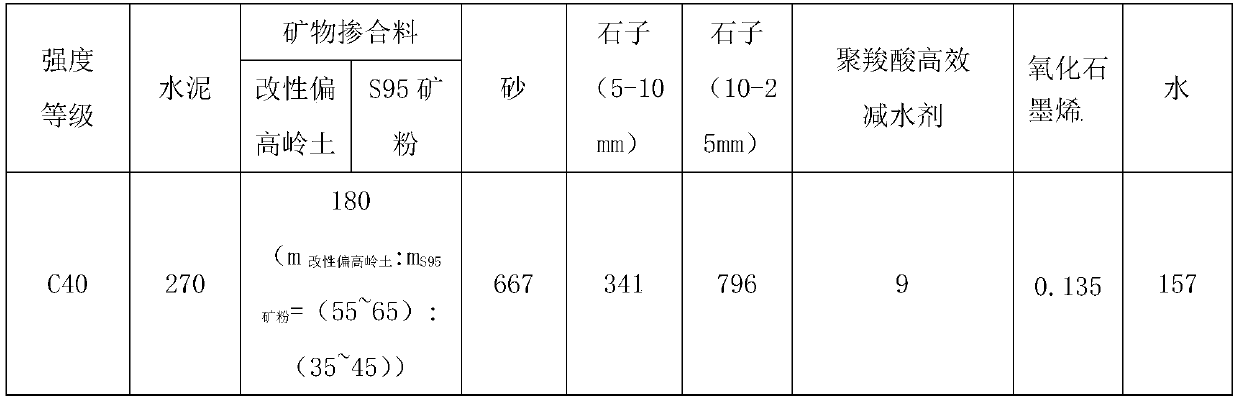

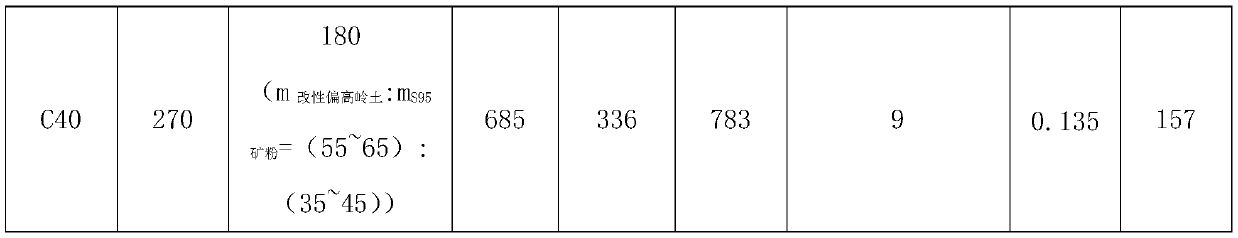

The invention belongs to the technical field of marine engineering high performance, and particularly relates to a high-density frozen-penetration-resistant marine concrete and a preparation method thereof. The high-density frozen-penetration-resistant marine concrete is composed of cement, a mineral admixture, sand, pebble, an additive, graphene oxide and water, and specifically, 270-280kg / m<3> of cement, 180-190kg / m<3> of the mineral admixture, 685-711kg / m<3> of sand, 1074-1119kg / m<3> of pebble, 9-9.4kg / m<3> of the additive, 0.135-0.141kg / m<3> of graphene oxide and 157-164 kg / m<3> of water.According to the invention, the binding capacity of calcined metakaolin and chloride ions is utilized; the influence of calcined metakaolin on the workability of a cement-based material is reduced through silica fume, so that a gelling system achieves the tightest stacking effect, meanwhile, the density of the gelling system is further improved by utilizing graphene oxide, and then the workabilityand the anti-freezing effect of concrete are improved by regulating and controlling the additive and the sand rate.

Owner:中建西部建设新疆有限公司 +1

Method for reinforcing rectangular wood column by pasting angle steel

InactiveCN104141393AImprove bearing capacityImprove ductilityStrutsBuilding repairsCorrosionBearing capacity

A method for reinforcing a rectangular wood column by pasting angle steel comprises the steps of wood column processing, angle steel pasting and steel batten plate welding. The angle steel is pasted to the angle portion of the wood column, a steel batten plate is welded in the height direction, the bearing force and the ductility of the wood column can be effectively improved, and meanwhile the requirements for reinforcing and repairing for corrosion resisting and durability are met.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

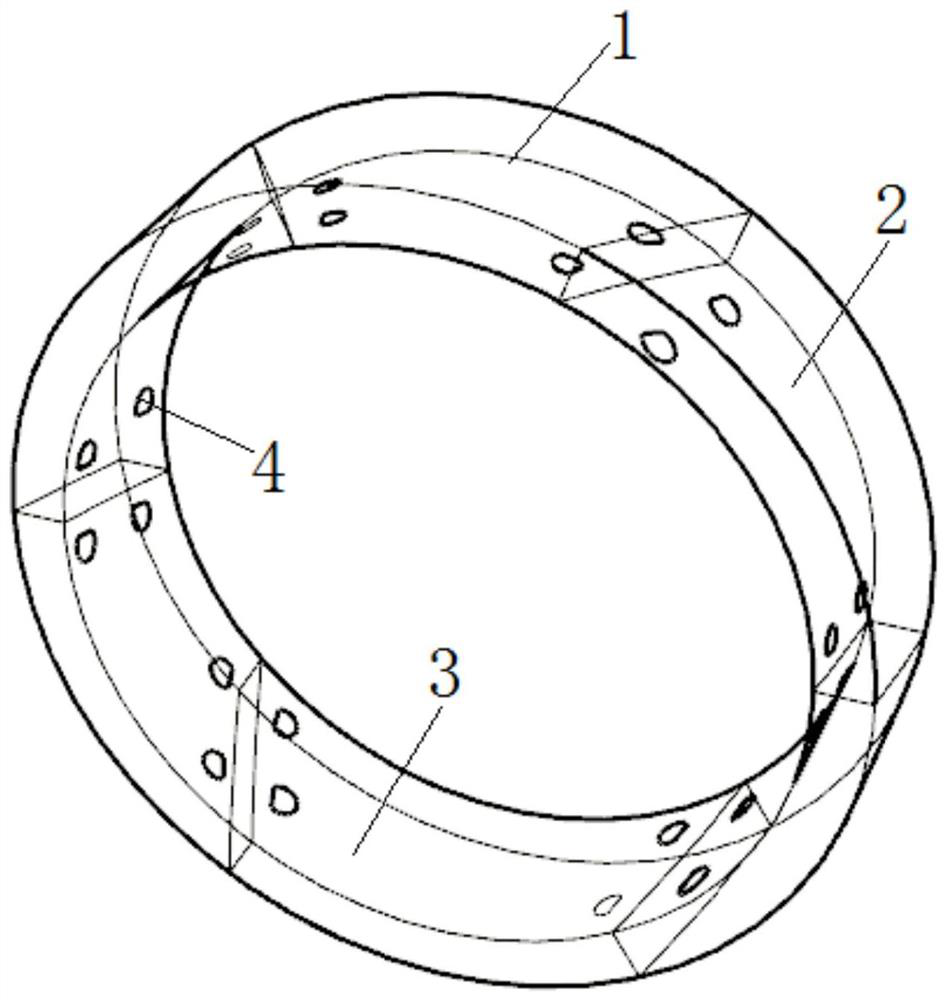

Special-shaped shield segment structure penetrating through loess ground cracks and construction method thereof

PendingCN113006822AAvoid damageEnsure safetyUnderground chambersTunnel liningMechanical engineeringParallelogram

The invention discloses a special-shaped shield segment structure penetrating through loess ground cracks and a construction method thereof. The special-shaped shield segment structure comprises a plurality of ring segments which are sequentially spliced along the axis of a tunnel; each ring segment is sequentially spliced into a ring by adopting splicing segments, and comprises a top sealing block, a plurality of adjacent blocks and a plurality of standard blocks; the plurality of standard blocks are sequentially spliced to form a lower half ring structure, the top sealing block is located at the top of the ring segment, and the two sides of the top sealing block are spliced and fixed with the lower half ring structure through the adjacent blocks; and the top sealing block and the standard blocks are wedge-shaped arc-shaped blocks, the adjacent blocks are parallelogram arc-shaped blocks, and the joints between the adjacent splicing segments are orthogonal to the loess ground cracks. The splicing segments are in a wedge-shaped arc-shaped block and parallelogram arc-shaped block combination form, and the joints between the adjacent splicing segments are kept orthogonal to the loess ground cracks, so that the damage to the tunnel structure when the ground cracks are vertically dislocated is effectively reduced, the safety of the tunnel structure is ensured, and the special-shaped shield segment structure has relatively high adaptability to the area penetrating through the ground cracks.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Anti-corrosive treatment method of welded junction part of construction process pipe of heavy caliber push pipe

ActiveCN101696759AFast constructionImprove the protective effectPretreated surfacesCoatingsArchitectural engineeringSolvent free

The invention relates to an anti-corrosive treatment method of a welded junction part of a construction process pipe of a heavy caliber push pipe. The pipe is arranged by applying an open type excavation construction or push pipe construction process; the process pipe is a section push-pipe construction pipe, all sections are fixed together by adopting a welding mode; an anode loss protection device (3) fixedly connected to the outer wall of the pipe is arranged outside the pipe, and a protection coating is arranged outside the whole pipe. The method is characterized by being particularly applied to the coating rapid junction repairing operation at the welded junction part of the outer wall of the pipe by using the solvent-free liquid epoxy coating so as to rapidly form an integral protection coating outside the pipe, wherein the performance of the solvent-free liquid epoxy coating meets the relevant requirements. The anti-corrosive treatment method of the welded junction part of the construction process pipe of the heavy caliber push pipe has the advantages of high construction speed, good protection effect, long service life and the like, and has huge predictable economic value and social value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

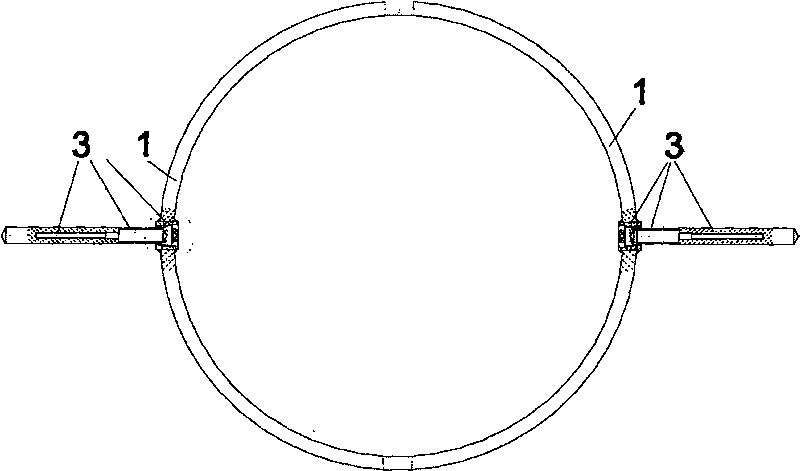

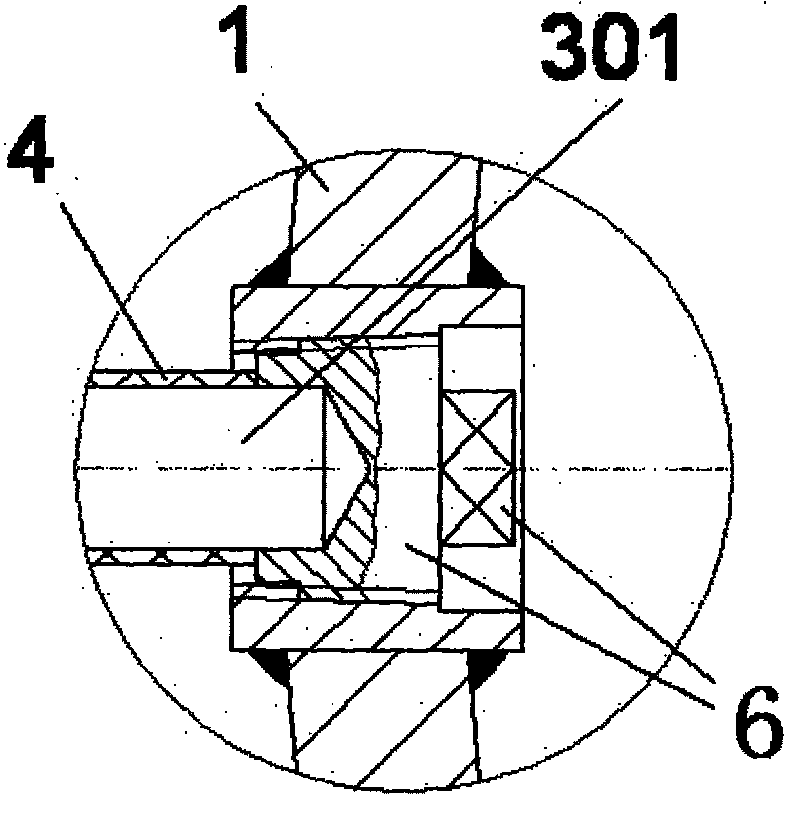

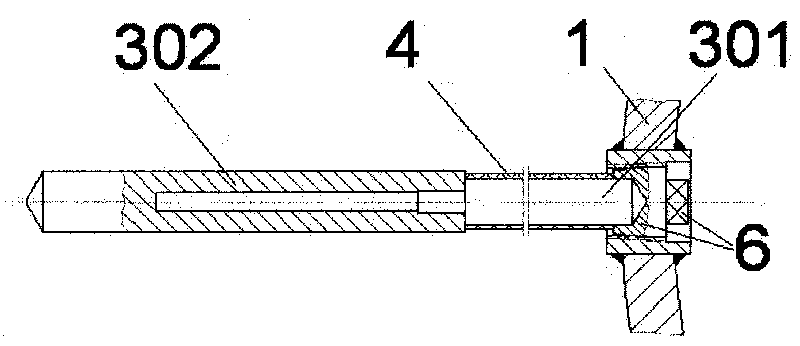

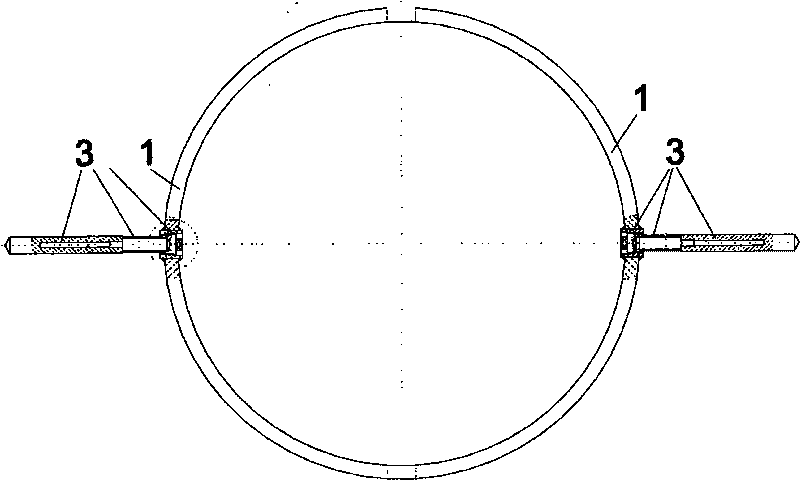

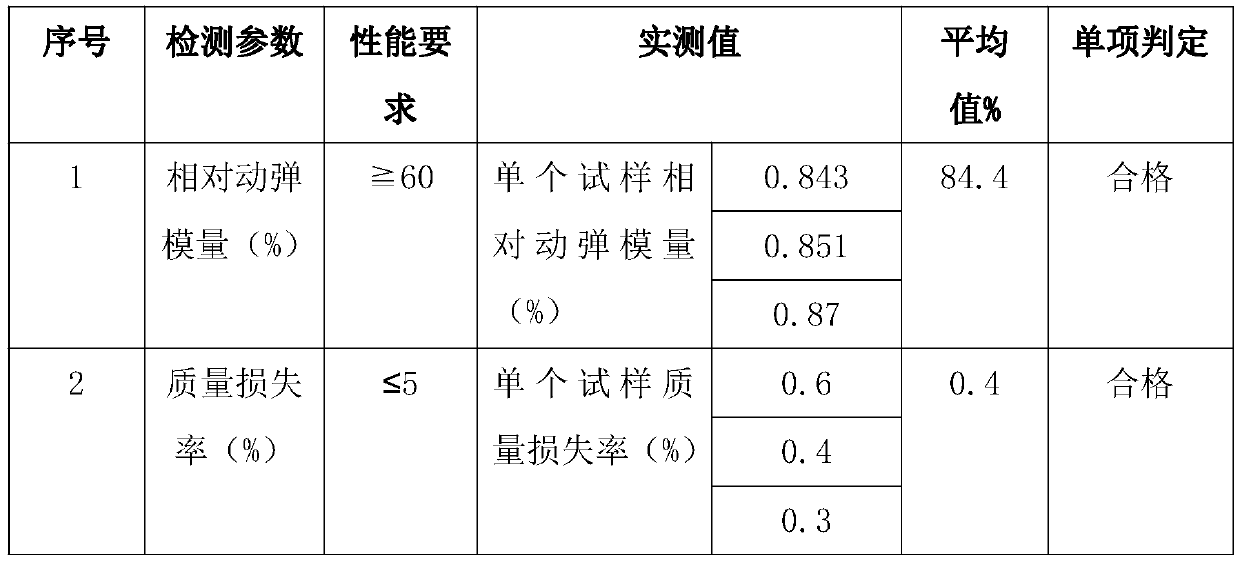

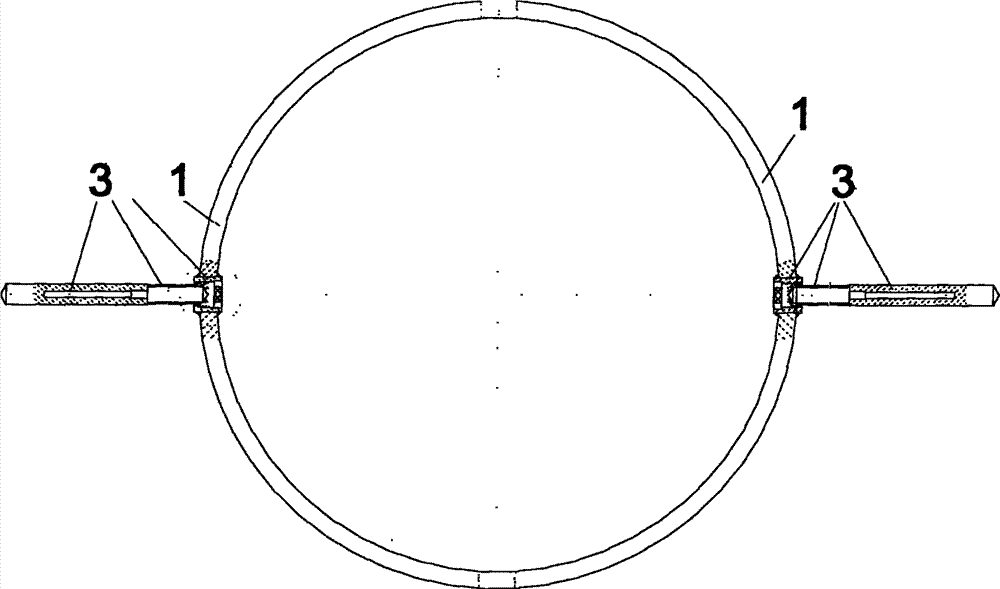

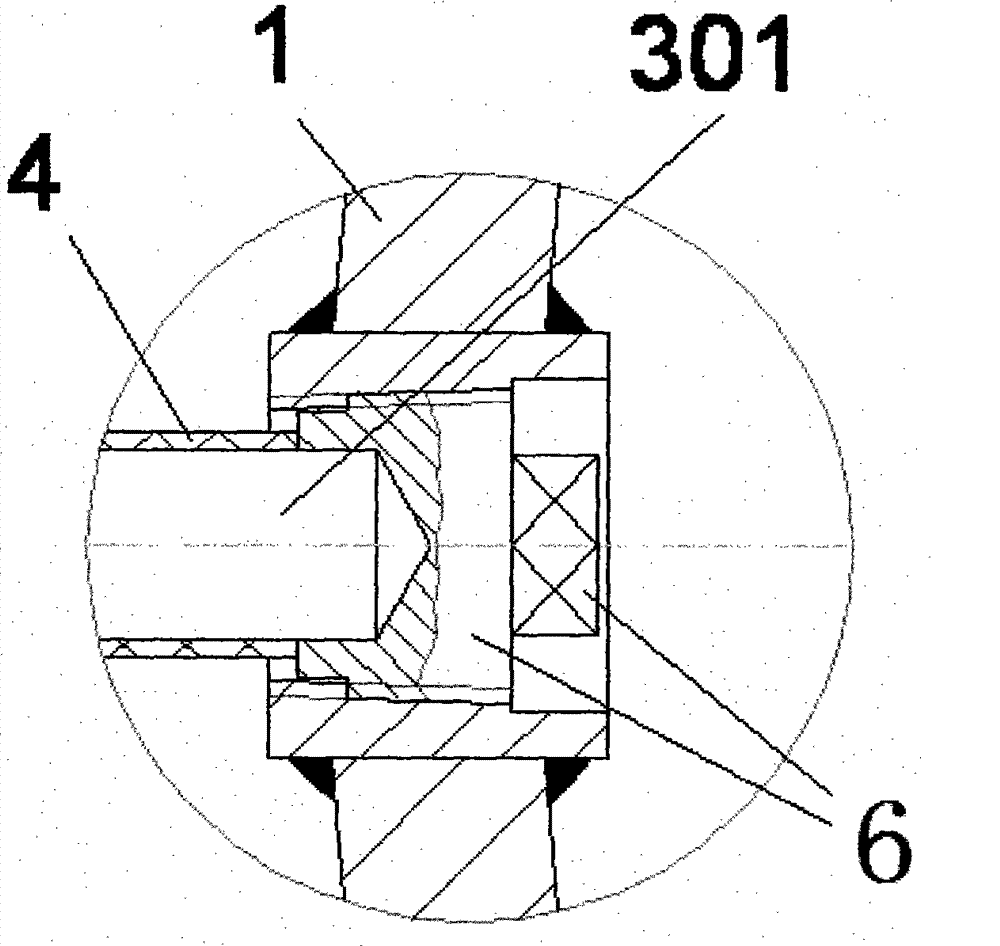

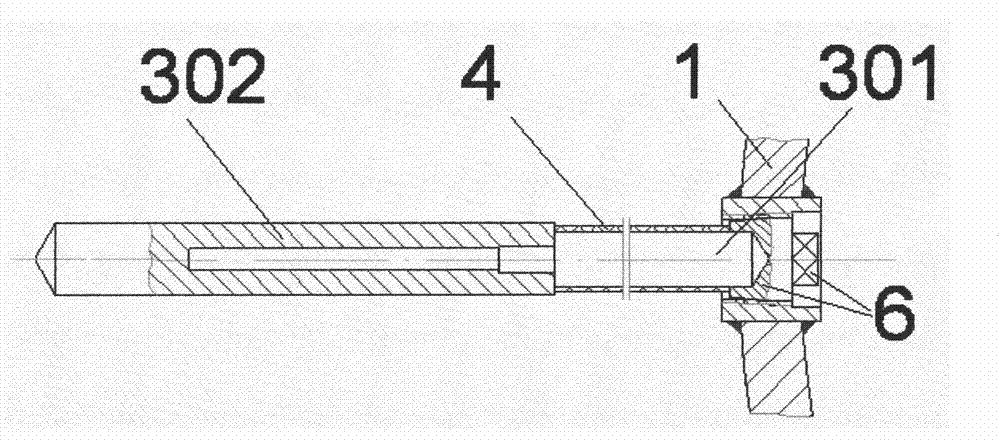

Pipeline outer wall anti-corrosion cathode protection device and construction installation method of filling material thereof

InactiveCN101760747AImprove the protective effectSolve the technical problems of corrosion controlPipe laying and repairCorrosion preventionFilling materialsArchitectural engineering

The invention relates to a pipeline outer wall anti-corrosion cathode protection device and a construction installation method of a filling material thereof; the method is characterized in that: after joint coating is welded and coated among all pipeline joints, the installation method of the anode loss protection device for pipeline outer wall corrosion control is as follows: firstly, pasty sacrificial anode filling material is injected in a mounting hole; and then the anode loss protection device (3) is arranged from inside of the pipeline to outside of the pipeline; then a stopper (6) is used fix a support steel rod on the pipeline (1). The invention can ensure the endurance of the pipeline pushing construction, greatly saves the installation workload and installation cost, can achieve long-acting protection through one-time construction, meets durability requirements of large-scale engineering construction and have great predictable economic and social values in the engineering application.

Owner:上海青草沙投资建设发展有限公司 +1

Concrete for high-durability construction

The invention discloses concrete for high-durability construction. The concrete is prepared from the following raw materials in parts by mass: 155-400 parts of cement, 110-60 parts of limestone powder, 20-80 parts of mineral powder, 780-735 parts of water sand, 1160-1150 parts of pebbles or 0 part of pebbles, 1010-980 parts of gravels or 0 part of gravels, and 160-155 parts of water. The specificsurface area of the limestone powder is 550-650m<2> / kg. According to the invention, the limestone powder with a certain specific surface area is adopted to improve the durability of the concrete, so that the frost resistance and chloride ion permeability resistance of the concrete are well improved, and the concrete with high durability is further formed.

Owner:冀东海德堡(泾阳)水泥有限公司

Anti-corrosive treatment method of welded junction part of construction process pipe of heavy caliber push pipe

InactiveCN101696759BFast constructionImprove the protective effectPretreated surfacesCoatingsArchitectural engineeringSolvent free

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Colorful high-strength anti-skid waterproof building material used for bridge and/or speedway and preparation method of colorful high-strength anti-skid waterproof building material

The invention relates to a colorful high-strength anti-skid waterproof building material used for a bridge and / or a speedway and a preparation method of the colorful high-strength anti-skid waterproofbuilding material. The building material comprises the following raw materials in parts by weight: 5-20 parts of epoxy resin, 5-30 parts of metakaolin, 10-30 parts of quartz sand, 5-30 parts of diatomite, 1-3 parts of an emulsifying agent, 10-15 parts of titanium dioxide, 5-20 parts of aluminous soil, 5-10 parts of fluff pulp, 0.5-10 parts of water glass, 1-10 parts of magnesium oxide, 1-3 partsof sodium lignin sulfonate, 30-80 parts of white cement, 0.5-2 parts of molecular sieves, 1-5 parts of boric acid and 50-100 parts of water. The building material has the waterproof, anti-skid, abrasion-proof and corrosion-resistant functions, is environmentally friendly and does not contain a volatile solvent; in addition, the building material is excellent in durability, long in service life, stable at high temperature and anti-crack at low temperature and can resist the erosion of various natural conditions, so that the using quality of a road surface is improved; the building material cannot only be used as a waterproof material of a bridge deck, but also be used for a colorful anti-skid road surface.

Owner:王鹏辉

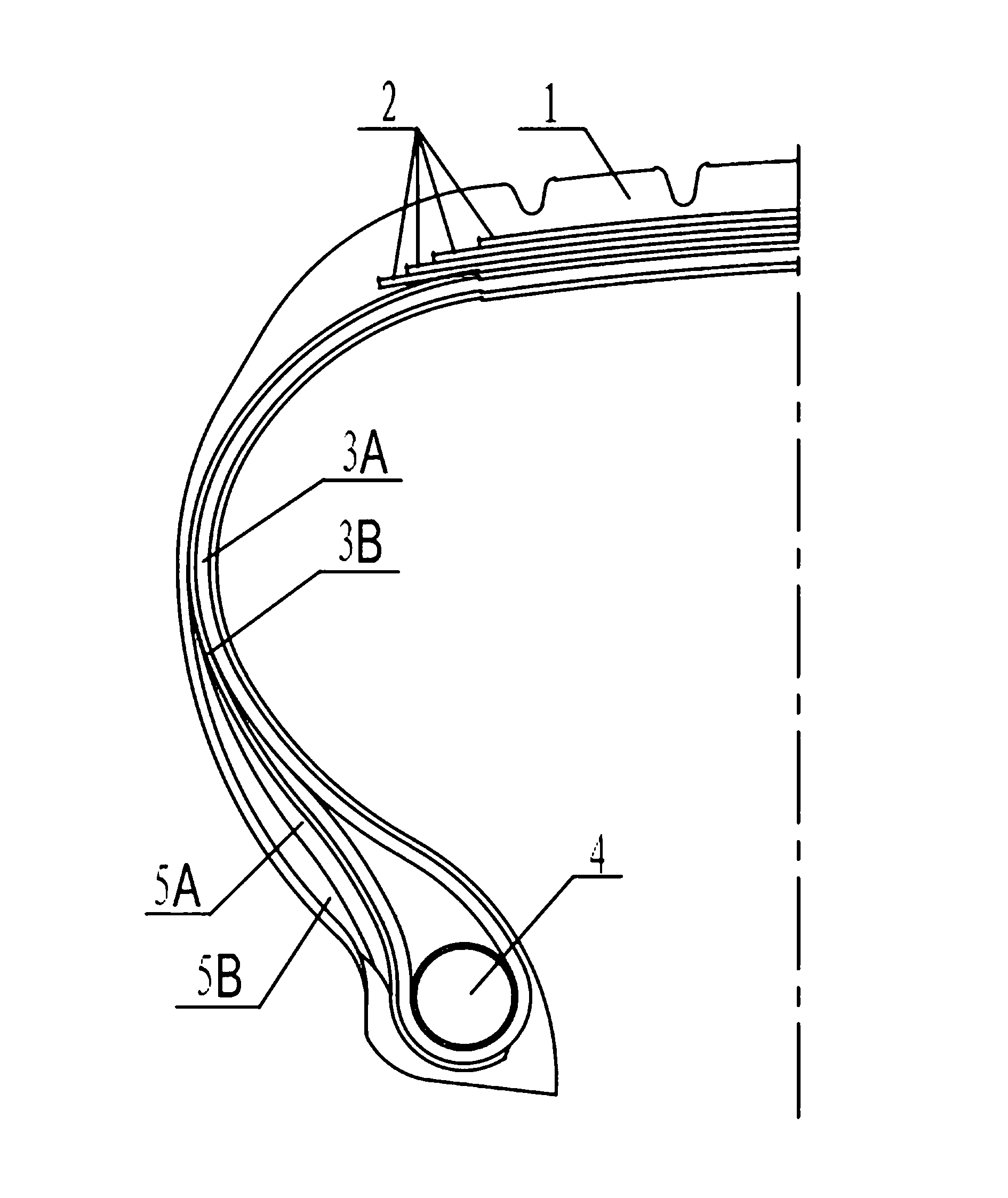

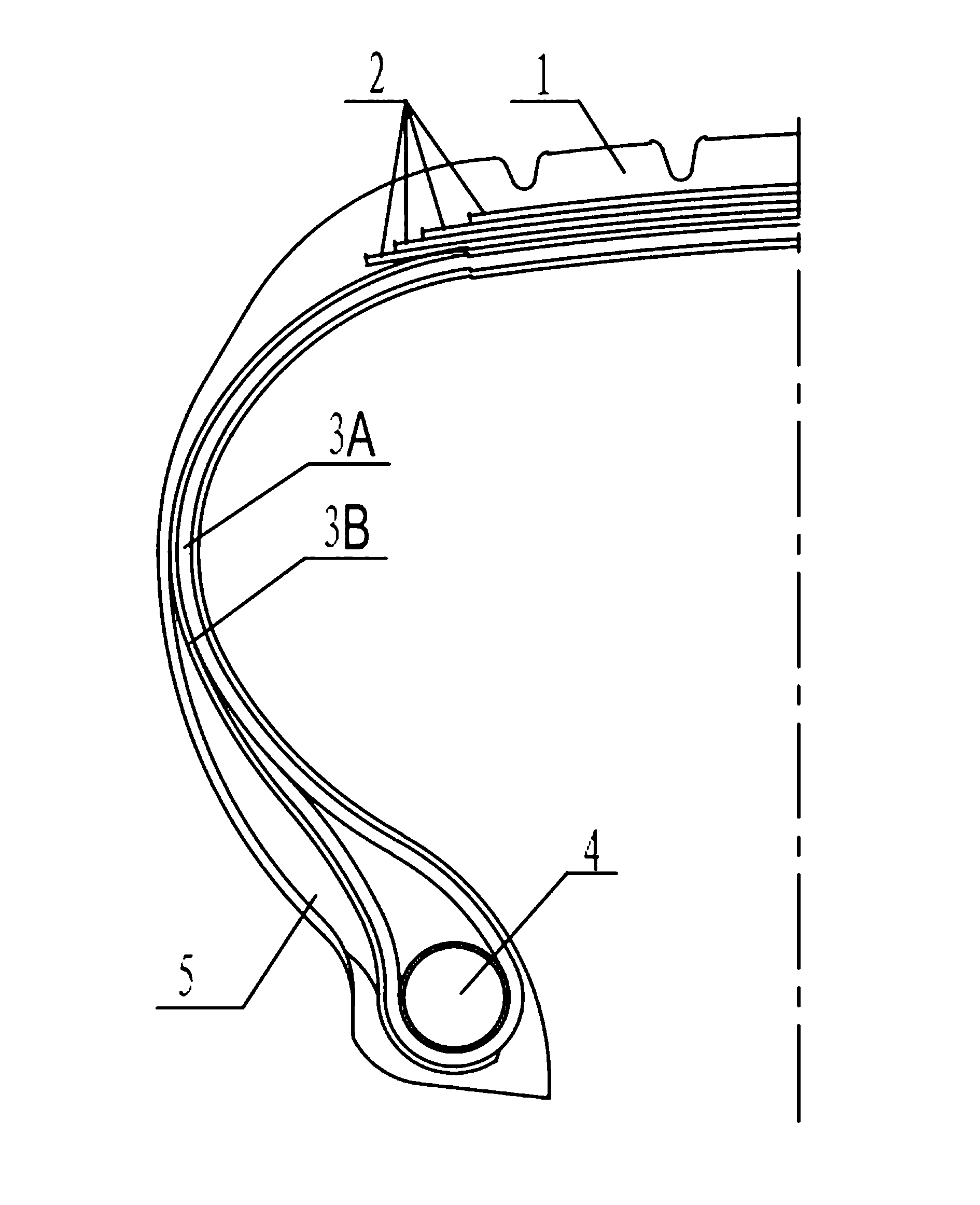

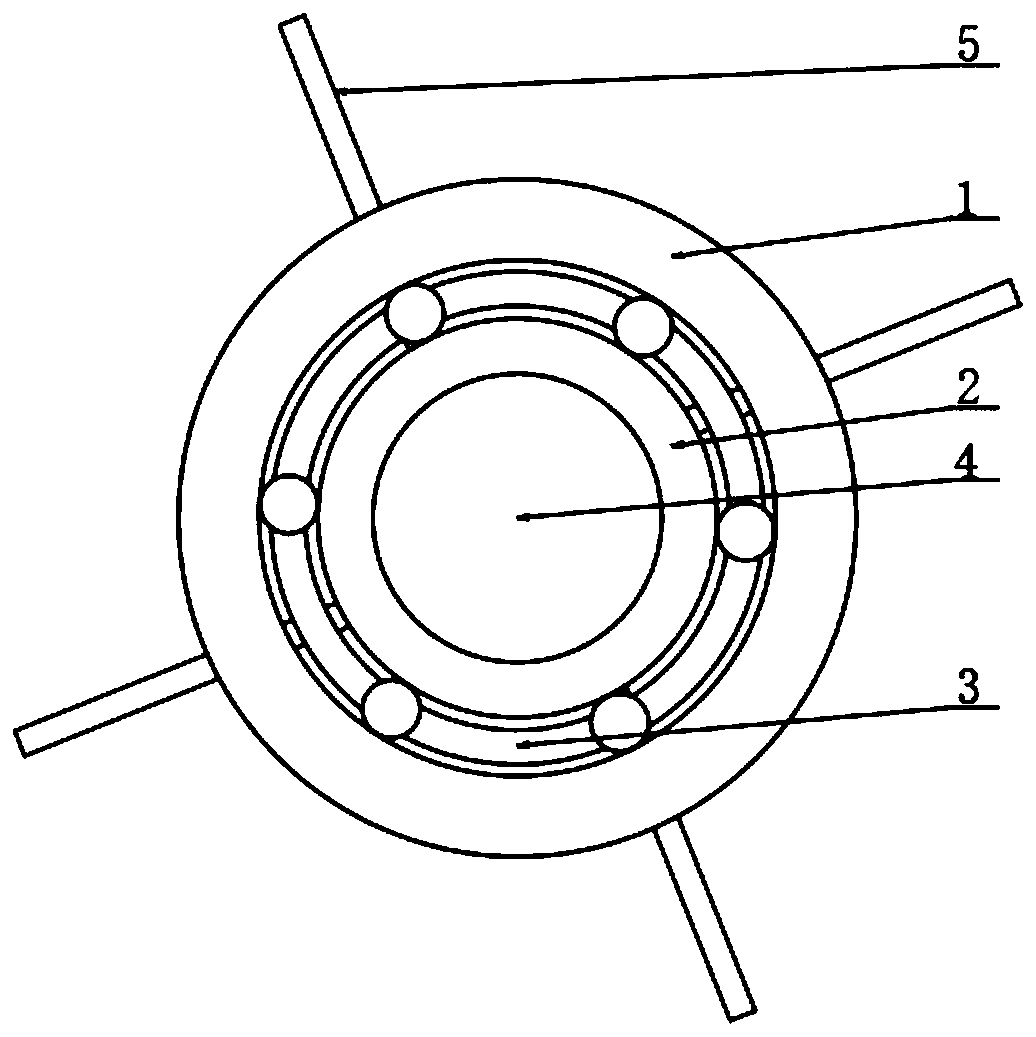

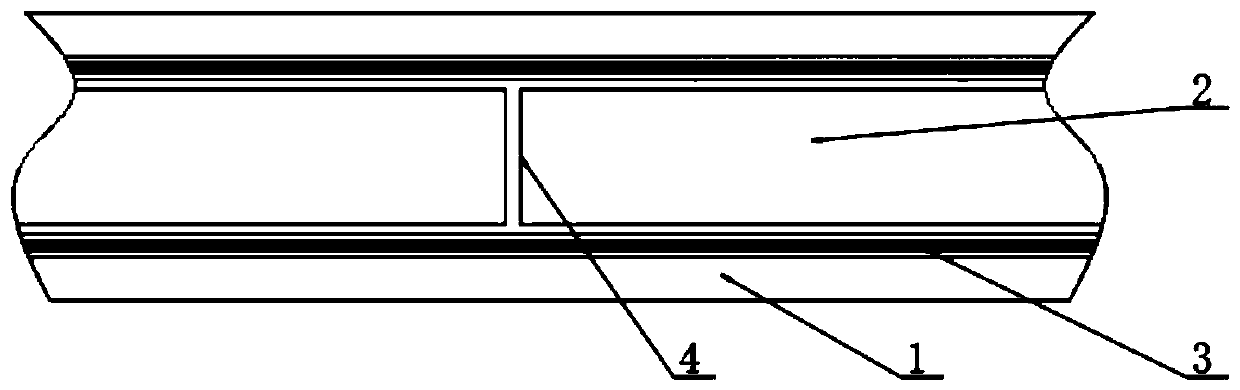

Meridian aircraft tire capable of reducing interface stress, strain and themogenesis and improving bead durability

ActiveCN103010460AIncreased durabilityReduce shear stressPneumatic tyre reinforcementsWheel arrangementsAutomotive engineering

The invention discloses a meridian aircraft tire capable of reducing interface stress, strain and themogenesis and improving bead durability. The tire is characterized in that two layers of stress buffer rubbers with different rigidities and thicknesses are arranged at a bead part between the outer side of a carcass ply and sidewall rubbers. The improved meridian aircraft tire can reduce interface stress, strain and themogenesis between the carcass at the bead part and the rubbers at the outer side, and can improve the bead durability under the rigorous conditions; According to tests, the bead durability is improved by more than 80%; and the dynamic performance of the tire can meet the requirements of airworthiness standard (GJB683A).

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

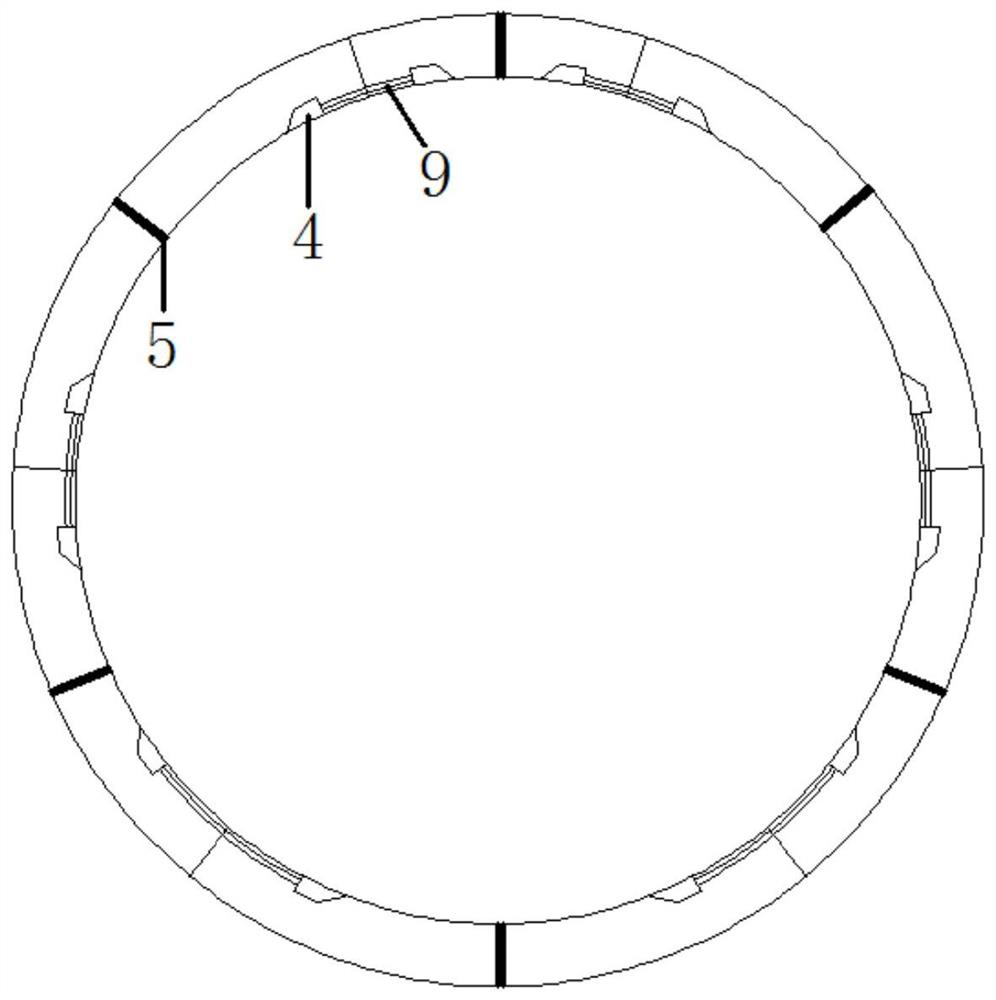

Partial solid prestressed pile produced through centrifuge method, and production process

InactiveCN110625780AImprove corrosion resistanceImprove work efficiencyMouldsShaping reinforcementsPre stressEngineering

The invention discloses a partial solid prestressed pile produced through a centrifuge method, and a production process, and belongs to the technical field of partial solid prestressed piles. The production process comprises the following steps of a, sorting; b, manufacturing concrete; c, manufacturing a cage frame; d, assembling a mold; e, filling the mold; f, carrying out a centrifugal molding method; g, standing; and h, demolding. An outer mold and an inner mold are adopted, and an obstruction plate is arranged in the inner mold at the same time; in the concrete feeding process, the concrete is fed into one side of an inner cavity of the inner mold, so that one half of a molded prestressed pile is solid, the other half of the molded prestress pile is hollow, the working efficiency is improved, and the molding quality is ensured; and meanwhile, the centrifugal molding method is further adopted, the concrete between the outer mold and the inner mold before centrifugal molding and theconcrete filled in one side of the inner cavity of the inner mold are filled densely, and the concrete is gathered toward a pile corner part under the effect of a centrifugal force, so that the denseness is improved, the overall strength is high, the service life is long, the quickness in demoulding is realized, and the production time is greatly reduced.

Owner:江苏瀚龙建材科技有限公司

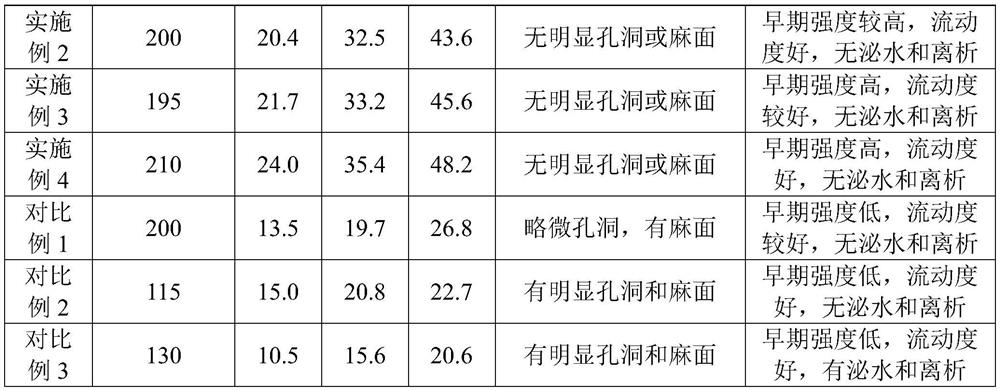

Slurry mineral admixture suitable for special-shaped member concrete, and preparation method thereof

The invention discloses a slurry mineral admixture suitable for special-shaped component concrete, and a preparation method thereof, and relates to the field of building materials. 150-180 parts of steel slag, 160-200 parts of slag, 150-180 parts of water and 5-9 parts of a functional additive are put into a mill with the ball ratio of 10-20 parts of powder with the particle size of 0.6-1.0 mm, 80-120 parts of powder with the particle size of 1.0-1.7 mm and 140-160 parts of powder with the particle size of 1.7-2.5 mm, and are ground for 40-60 min to obtain the slurry mineral admixture. When being applied to a component concrete material, the slurry mineral admixture has high working performance, effectively reduces the defects of holes, pitted surfaces and the like, has the 1 d compressivestrength of 20 MPa or above, meets the mold stripping strength requirement, has the 28 d compressive strength meeting the C40 concrete requirement, and can meet the performance requirements of special-shaped members. According to the technical scheme, green development of building materials can be promoted, meanwhile, progress of the fabricated building technology is promoted, and remarkable social and environmental significance is achieved.

Owner:HUBEI UNIV OF TECH

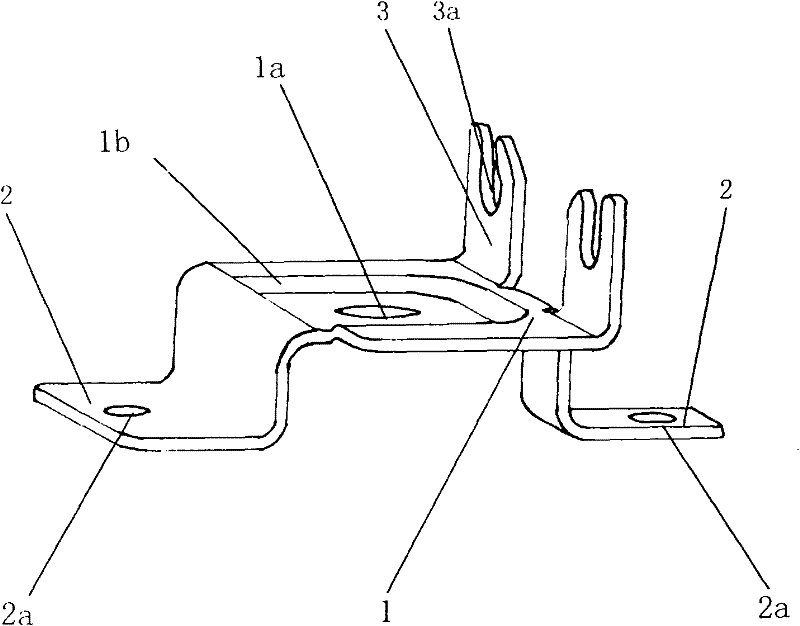

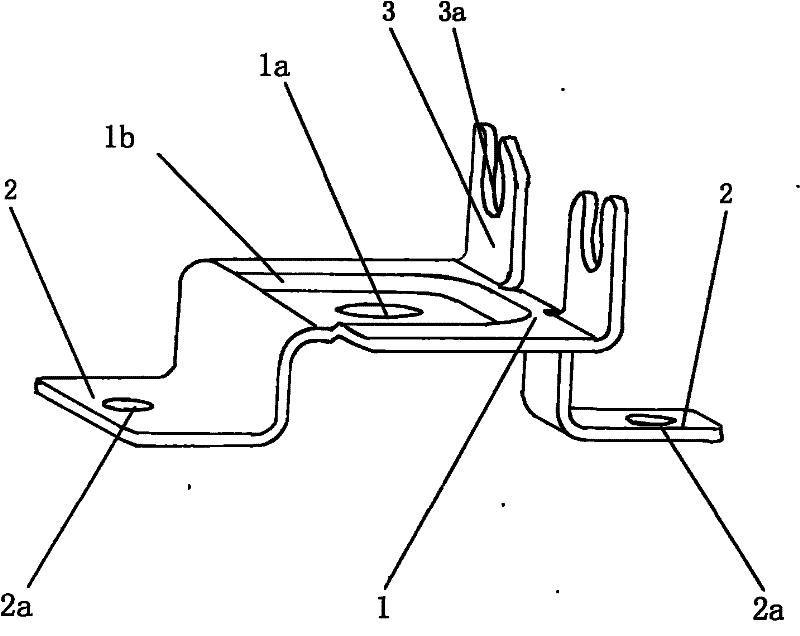

Automobile ABS mounting bracket

ActiveCN101665100BContour size accuracy requirements are not highSimple structureVehicle componentsSupport surfaceEngineering

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Prefabricated laminated parapet wall connection structure

PendingCN109339222AImprove waterproof performanceMeet security requirementsBuilding insulationsFloor slabWall plate

The invention discloses a prefabricated laminated parapet wall connection structure. The prefabricated laminated parapet wall connection structure is used for connection of a parapet wall, an externally-hung wall panel, a laminated beam and a laminated floor. The parapet wall comprises a parapet wall prefabricated portion and a cast-in-place fan kan located on the inner side of the parapet wall prefabricated portion, the bottom end of the parapet wall prefabricated portion is connected to the top end of the externally-hung wall panel through a groove, and the cast-in-place fan kan is subjectedto integrated cast-in-place forming with a cast-in-place portion of the laminated beam and a cast-in-place layer of the laminated floor. The prefabricated laminated parapet wall connection structureenhances the application of parapet wall joints in a fabricated building, improves the waterproof effect of the parapet wall, strengthens the connection strength between the parapet wall and a roof structural layer, improves the safety and integrity of the parapet wall, and can better meet the safety and durability requirements of the fabricated building.

Owner:BROAD HOMES IND SHANGHAI CO LTD

Uneven settlement reinforcing leveling repairing method for existing building floors

PendingCN110258676APrecise control of the lifting processGuaranteed lifting effectBuilding repairsSoil preservationBearing capacityBuilding construction

The invention discloses an uneven settlement reinforcing leveling repairing method for existing building floors, and belongs to the technical field of civil engineering construction. The uneven settlement reinforcing leveling repairing method for the existing building floors comprises the following steps that grouting is carried out to form a composite foundation reinforcing platform, specifically, grouting is carried out at the bottom of the floor to form the composite foundation reinforcing platform so as to raise and level the floor; grouting is carried out to form a plurality of composite pile foundations, specifically, grouting is carried out at the bottom of the composite foundation reinforcing platform to form the composite pile foundations so as to support the composite foundation reinforcing platform and the upper load. The uneven settlement reinforcing leveling repairing method for the existing building floors has the characteristics of capability of improving foundation bearing capacity and improving overall foundation stability and durability, lifting and leveling repairing, no interference, economy and short construction period.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

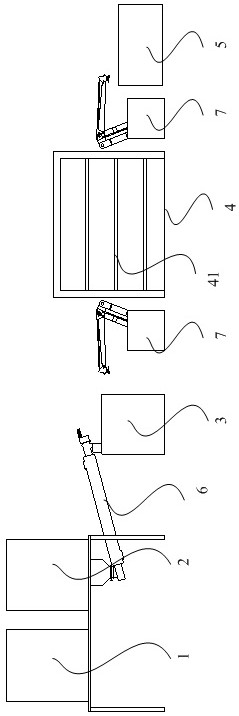

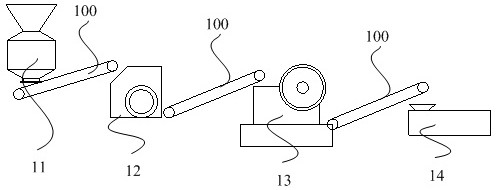

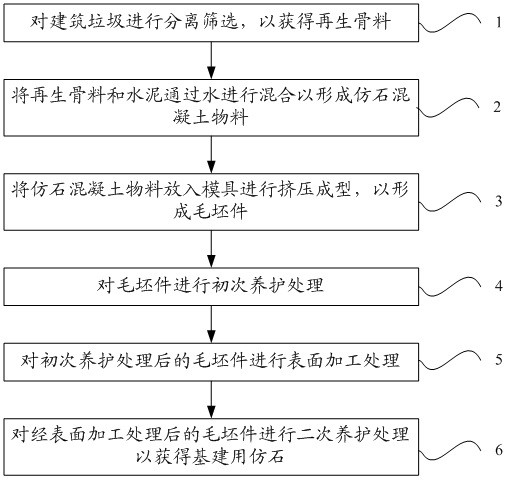

Processing method of imitation stone for capital construction and imitation stone for capital construction

ActiveCN111807774AImprove aestheticsImprove strength propertiesSolid waste managementArchitectural engineeringStructural engineering

The invention discloses a processing method for imitation stone for capital construction and the imitation stone for capital construction, wherein the processing method for the imitation stone for capital construction comprises the steps: step 1, separating and screening construction waste to obtain aggregate; step 2, mixing the aggregate, a cementing material and gravel through water to form a stone-like concrete material; step 3, adding the stone-like concrete material into a mold, and carrying out compression to form a blank piece; step 4, carrying out water retention and maintenance treatment on the blank; step 5, carrying out surface processing treatment on the blank subjected to the water retention and maintenance treatment; and step 6, carrying out spraying maintenance treatment onthe blank subjected to surface processing treatment so as to obtain the imitation stone for capital construction. The appearance of the imitation stone for capital construction is closer to that of real stone so as to improve attractiveness, meanwhile, the comprehensive strength performance of the imitation stone for capital construction is improved so as to improve durability and use reliability,and the purpose of environment-friendly production of the imitation stone for capital construction is achieved.

Owner:QINGDAO MUNICIPAL GRP CONCRETE IND ENG CO LTD

Concrete additive and preparation method and application thereof

InactiveCN109553327AImprove mechanical propertiesReduce dosageHydration reactionUltimate tensile strength

The invention relates to a concrete additive and a preparation method and application thereof. Raw materials of the concrete additive includes one or more of a water-reducing component, an expansion component, a retarding component, an early strength component, an air entraining component, an antifreeze component and a waterproof component, wherein the water-reducing component is used for reducingthe water consumption of a mixture, the expansion component is used for making concrete expand slightly, and the retarding component is used for delaying a hydration reaction of binding materials; the early strength component is used for accelerating the early strength of the concrete, the air entraining component is used for improving the freezing resistance and / or durability of the concrete, and the antifreeze component is used for improving the freezing resistance of the concrete; and the waterproof component is used for reducing the water permeability of the concrete. After the additive is applied to the concrete, the mechanical properties of the concrete can be improved significantly, and the dosage is reduced significantly; and the additive is suitable for preparation of concrete for high-speed rails, subways, highways, offshore, ports and other high-performance concrete, and is suitable for preparation of high-fluidity self-compacting concrete and other concrete.

Owner:浙江东洲混凝土有限公司

Railway traffic cross-sea segment concrete

The invention discloses railway traffic cross-sea segment concrete, of which the strength is C55P12, electric flux 56-day age (C) is less than 1000 and chloride ion diffusion coefficient 90-day age is not more than 2*10<-12> m<2> / s; alkali content is controlled to be not more than 2.1 kg / m<3>, the content of SO3 in the concrete is less than 4% of a cementing material, the content of chloride ions in unit volume of the concrete is less than 0.1%, water-binder ratio of the concrete is 0.32 and the addition quantity of an admixture is 45%. The concrete particularly includes the following raw materials: 142-143 kg / m<3> of water, 247-249 kg / m<3> of cement, 90-115 kg / m<3> of fly ash, 90-115 kg / m<3> of ore slag powder, 1160-1163 kg / m<3> of impact-crushed stone, 645-655 kg / m<3> of river sand, and 4.5-4.9 kg / m<3> of a polycarboxylate water reducer. A pipe segment produced from the railway traffic cross-sea segment concrete can adapt a serious corrosive environment in a cross-sea zone, and can reach durability demand of 100 years.

Owner:厦门智欣建材集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com